Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

231results about How to "Shorten the installation period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

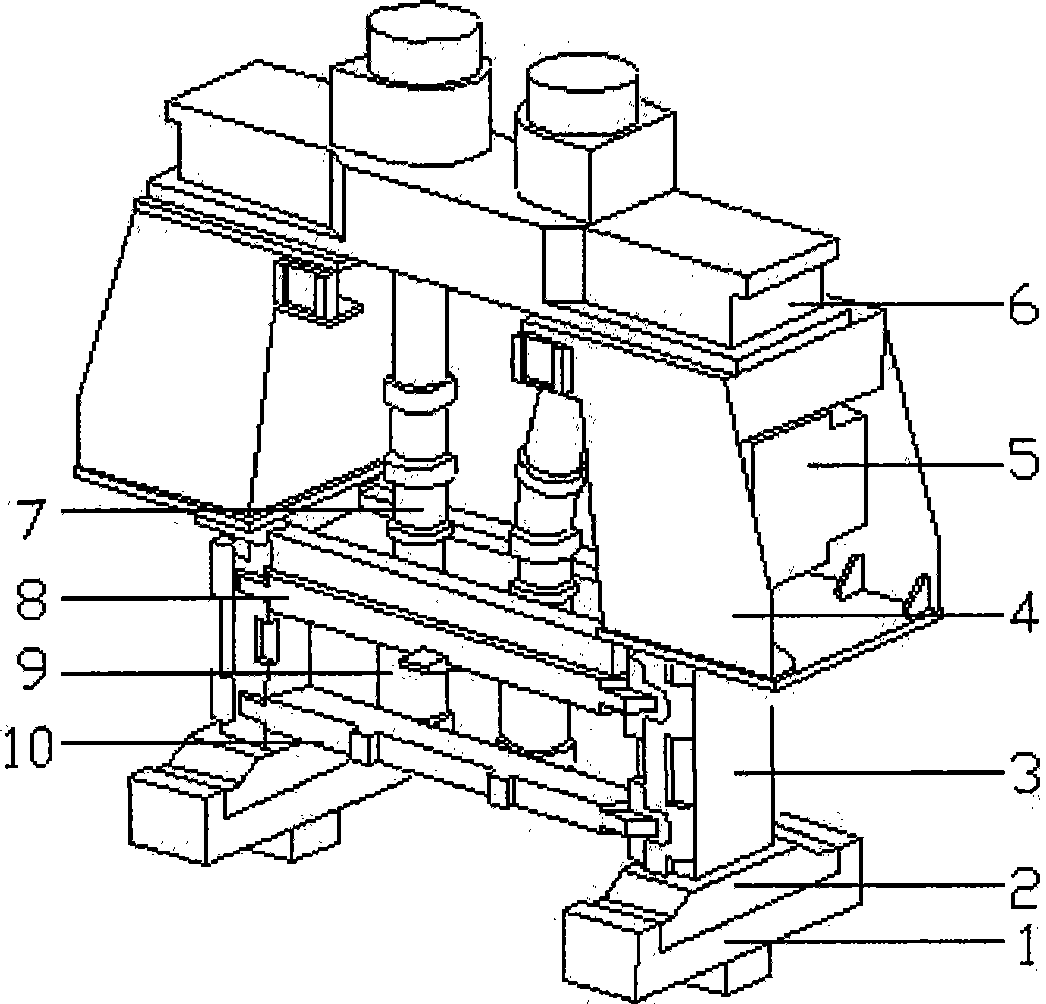

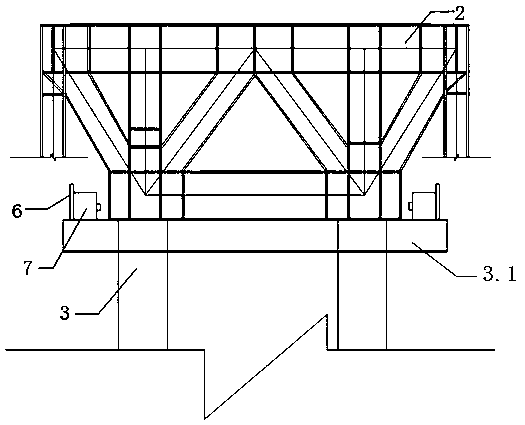

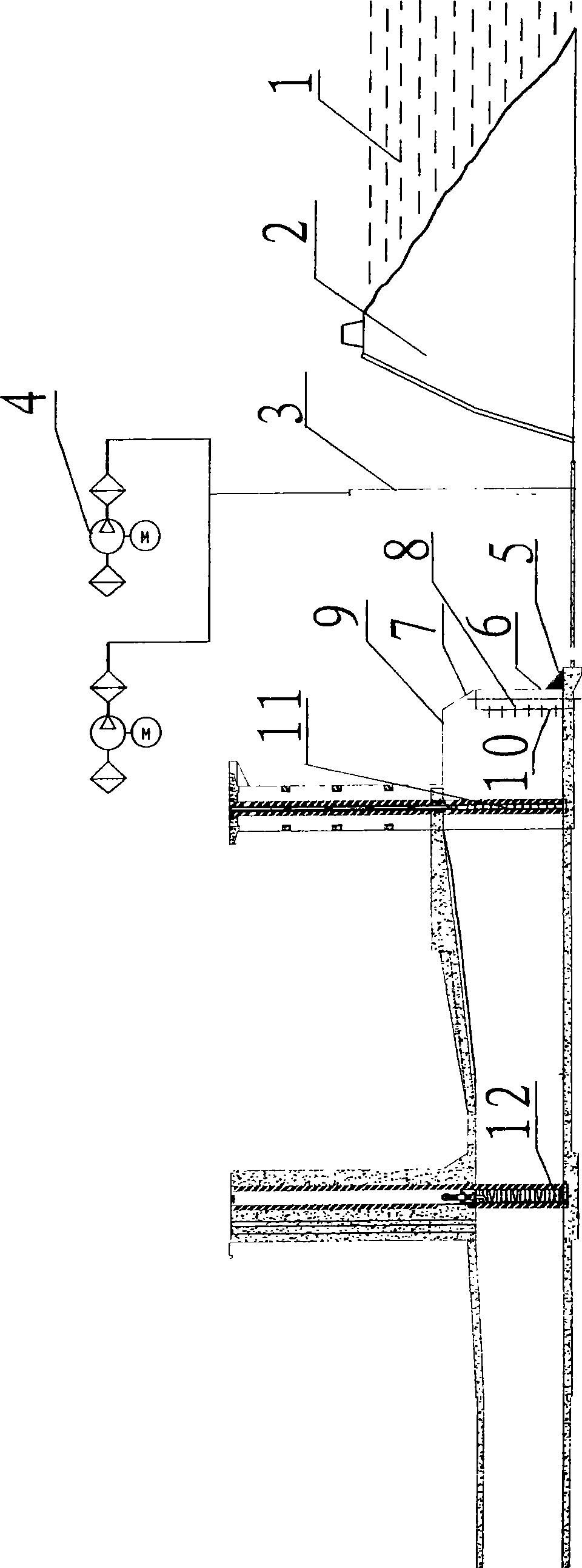

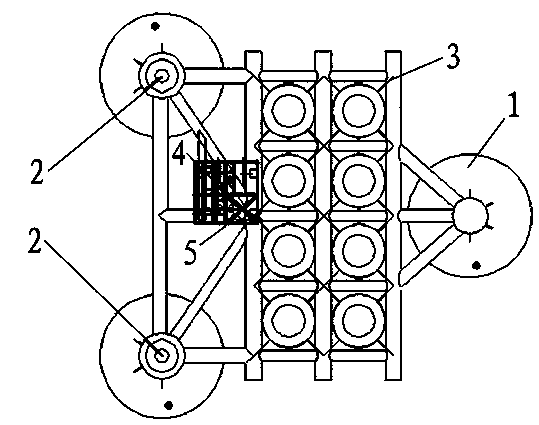

On-line assembling entirety on-position assembling method of edge mill

ActiveCN101391267ADelay in construction investmentReduce installation costsMetal rolling stand detailsMetal rolling arrangementsEngineeringBuilding design

The invention relates to a method for the integral falling installation of on-line assembly of a vertical miller, belonging to the technical field of installation of large-sale equipment. The installing steps comprise the installation and transverse alignment of the soleplate of the vertical miller, the arrangement of an assembling and falling device, the assembly of an upper beam and a lower beam of a stander outlet, the slippage of a stander torii, the assembly and fixation of an upper beam and a lower beam of a stander inlet; the integral falling installation position of the stander and the installation of a rolling mill transmission device. The invention has the advantages that a special lifting device is not needed to be manufactured; the architecture design of workshops is not needed; the constructing investment is not increased; a field for building a precision assembly platform is not needed to be reserved in a main workshop; the time for the vertical miller equipment to enter the arena is not limited, so the installation cost can be greatly reduced, the labor intensity is lightened, and the time limit for the installation is shortened; and the invention is applied to the projects of installation and repairing of vertical millers attached to hot plate or band roughing mills.

Owner:BEIJING SHOUGANG CONSTR GROUP +1

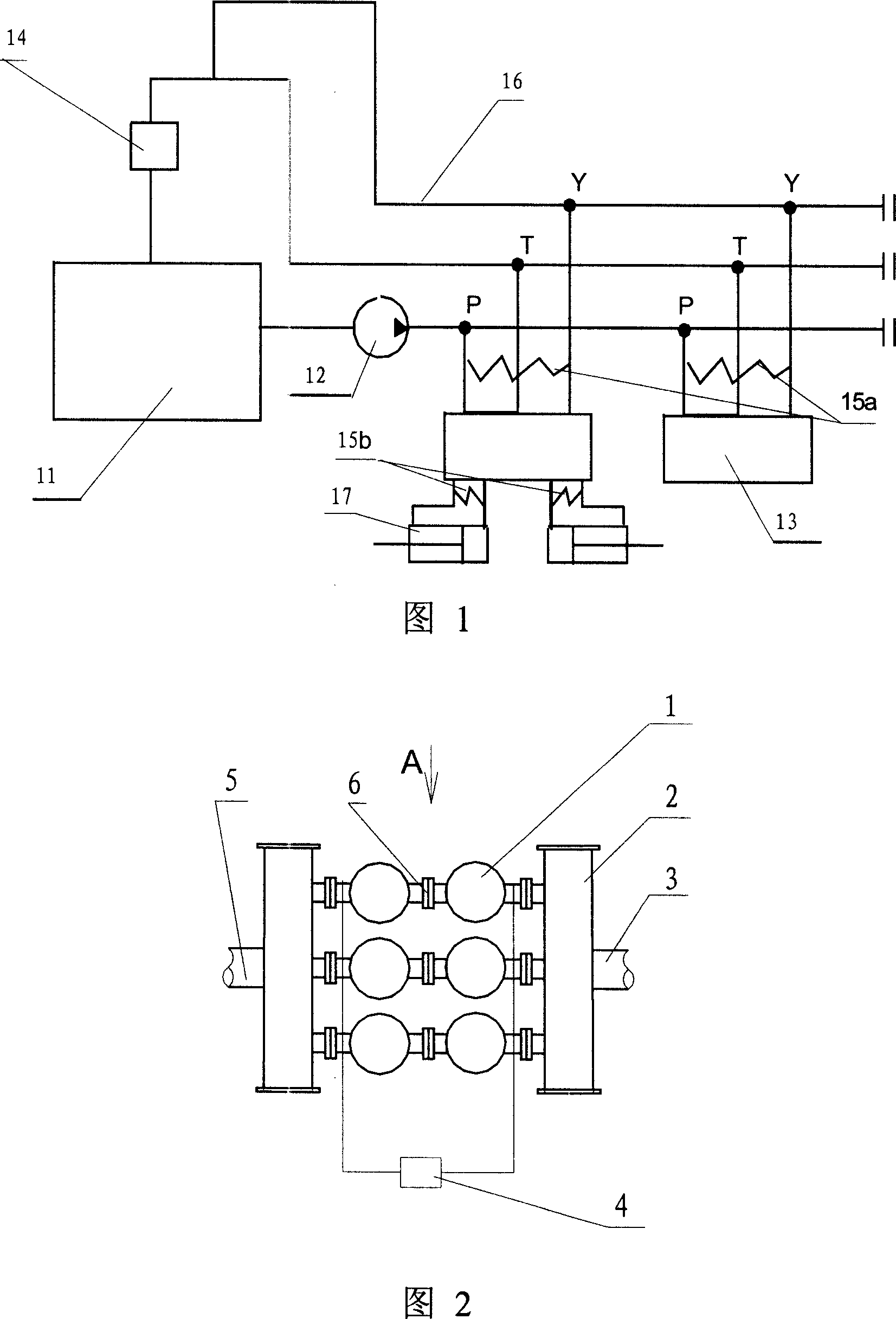

Flushing and installing methods by using online raw liquor press pump under piping once

The invention relates to a hydraulic device and pipeline installing method that mainly includes hydraulic system oil box, hydraulic pump, oil pipeline, and valve frame and oil cylinder. The hydraulic system first piping and online flushing method also includes a hydraulic pump protecting device. It includes the following steps: oil pipeline preprocess, installing and connecting; setting flushing circuit and flushing; after according to request, removing temporary circuit, reset oil pipeline, taking entire pressure testing and adjusting to operate. The invention avoids environment pollution, prevents human injuring, and saves resources, manpower and material.

Owner:SHANGHAI BAOYE GRP CORP

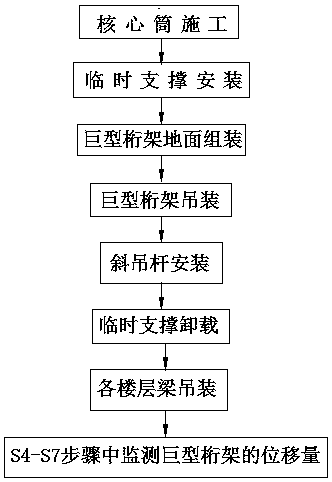

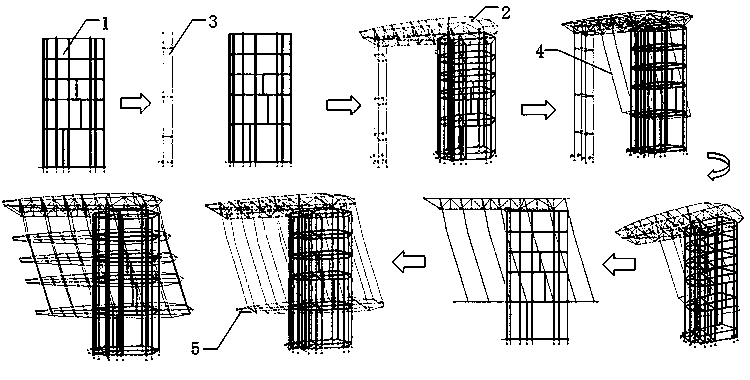

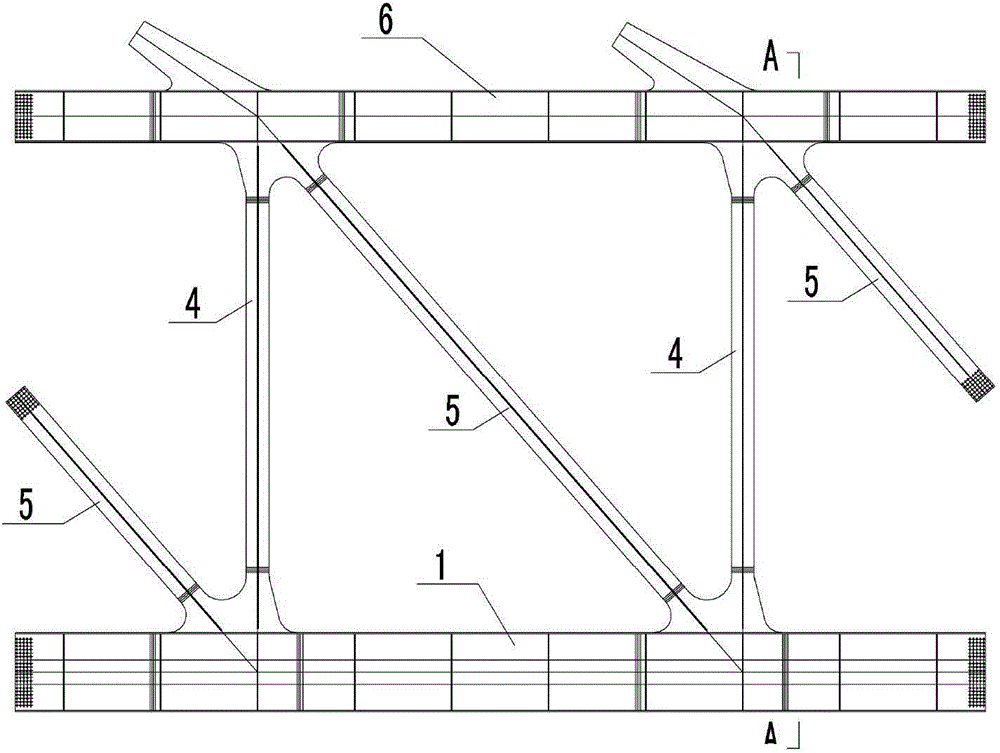

Installation method of special-shaped and curved-surface suspension type steel structure system

ActiveCN111364615AGuarantee welding qualityMeet penetration quality requirementsExtraordinary structuresBuilding material handlingFalseworkArchitectural engineering

The invention belongs to the technical field of steel structure construction, and particularly relates to an installation method of a special-shaped and curved-surface suspension type steel structuresystem. The problems are solved that the construction precision of a traditional installation method is difficult to guarantee, the construction period is long, a large amount of cost needs to be invested in scaffold and inclined suspender layer-by-layer hoisting, and many high-altitude hidden dangers exist. The special-shaped and curved-surface suspension type steel structure system comprises a core cylinder, a giant truss, a temporary support, an inclined suspender and beams of all floors. The installation method comprises the following steps that S1, the core cylinder is constructed; S2, the temporary support is installed; S3, the giant truss is assembled on the ground; S4, the giant truss is hoisted; S5, the inclined suspender is installed; S6, the temporary support is unloaded; S7, the beams of all the floors are hoisted; and S8, the displacement of the giant truss is monitored in the steps of S4-S7. According to the installation method, the construction precision is guaranteed, the installation efficiency is high, the installation construction period is shortened, and the operation safety risk is reduced. The erection and hoisting cost of a scaffold is saved, the high-altitude butting joints are reduced, the near-edge protection cost is reduced, and therefore the construction cost is reduced.

Owner:CHINA SHANXI SIJIAN GRP

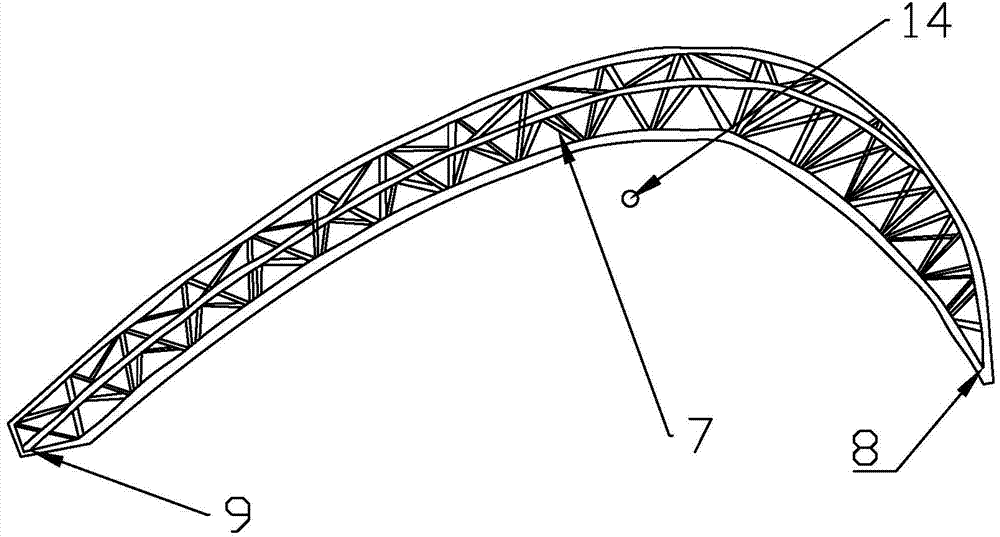

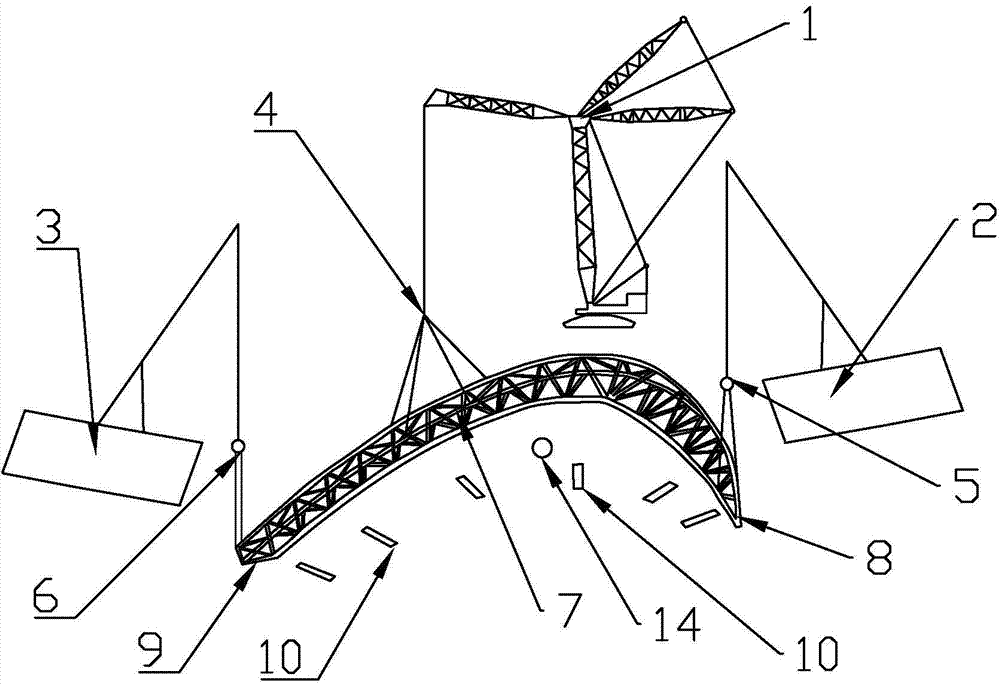

Construction method for three-crane lifting installation used for bow-shaped space truss

ActiveCN104746883ASave hoisting costsReduce split dockingBuilding material handlingButt jointGravity center

The invention discloses a construction method for three-crane lifting installation used for a bow-shaped space truss. The construction method includes the following steps of conducting simulation to determine the gravity center of the bow-shaped space truss, arranging three lifting points and three cranes, conducting separation through the three cranes, conducting carrying and correcting work after separation is completed, hoisting the bow-shaped space truss on a platform, and fixing the bow-shaped space truss to the platform. The construction method is simple, easy to achieve, high in installation efficiency, scientific, convenient and capable of saving the labor cost and greatly reducing hoisting expenses. By separating, carrying, correcting and hoisting the whole bow-shaped space truss, sectional butt joint and correction of the truss are reduced, aloft welding does not need to be conducted between sectional trusses, and therefore the installation quality and the welding quality are improved, the truss installation construction period is shortened, and truss hoisting expenses are saved.

Owner:浙江中南绿建科技集团有限公司

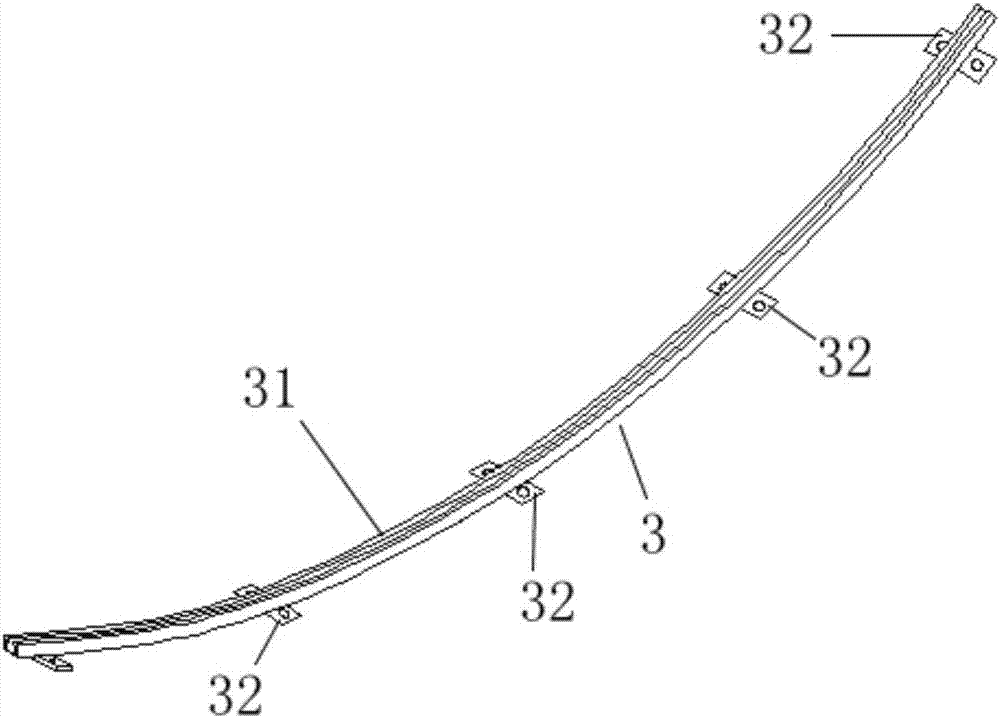

Installation method of ultra-large diameter pressure steel pipe on inclined shaft lower curved section

ActiveCN107588233ARealize secondary assembly weldingMeet the requirements of mechanized assembly of stiffening ringsPipe laying and repairWelding/cutting auxillary devicesWeldingCivil engineering

The invention discloses an installation method of an ultra-large diameter pressure steel pipe on the inclined shaft lower curved section. The method comprises the steps that the ultra-large diameter pressure steel pipe is assembled, steel pipe sections are transported in an adit, a formed steel pipe is positioned and installed on the inclined shaft lower curved section, the positioning and installing processes comprise the steps that a ground anchor and a traction steel cable are arranged on the inclined shaft upper horizontal section, the traction steel cable is connected with a traction climbing device and the ground anchor, and the traction climbing device is arranged at the lower end of the first section of the lower curved section pressure steel pipe; all single sections of the lowercurved section pressure steel pipe are subjected to assembly welding and climbing positioning fixation in sequence, and then the traction climbing device is removed to complete installation. Accordingly, traditional production line operation arrangement can be effectively simplified, hole assembly temporary facility arrangement is simplified, adit and main hole excavation sections are reduced, the pipe section assembly land area is reduced, land requirements for finished product stacking are canceled, pipe section secondary assembly welding once forming is achieved, the installation precisionis improved through mechanical assembly welding, hoisting and turning over are conducted without relying on an indigenous method, the safety risk is lowered, the installation construction period is shortened, the number of installation personnel is reduced, and the investment is saved.

Owner:SINOHYDRO BUREAU 7 CO LTD

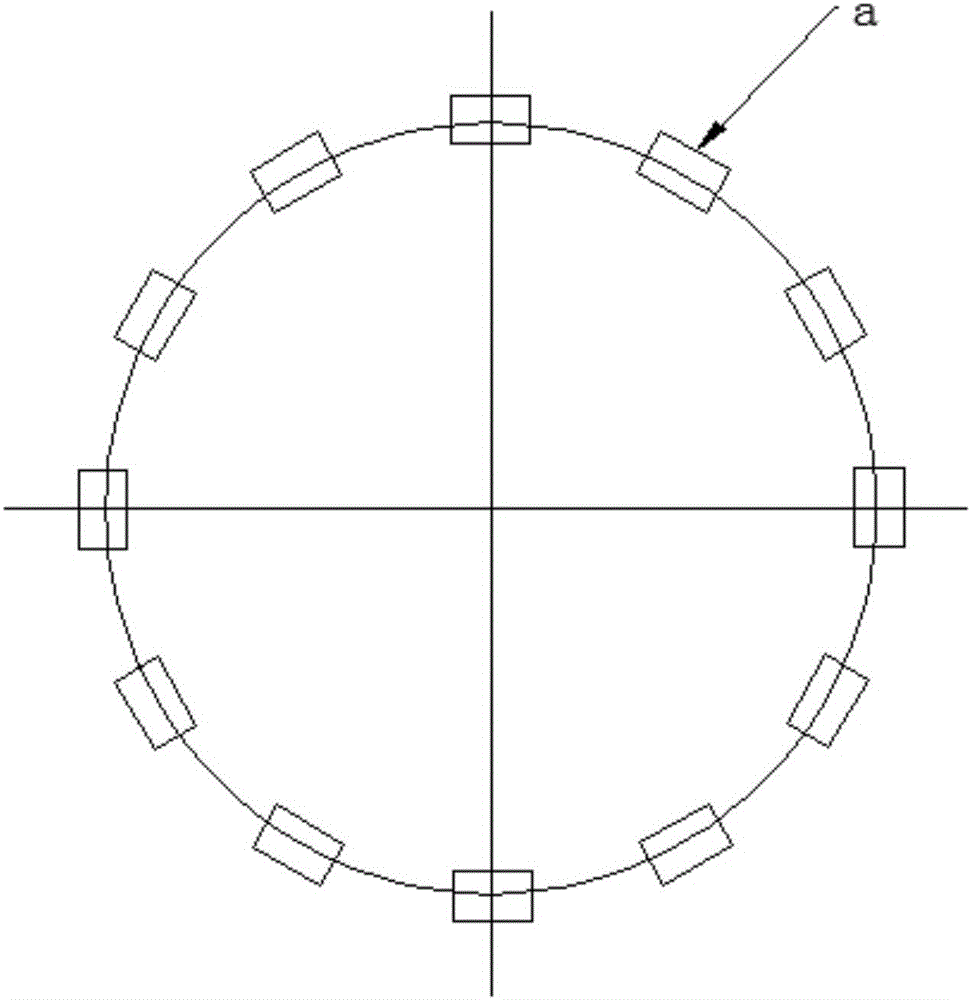

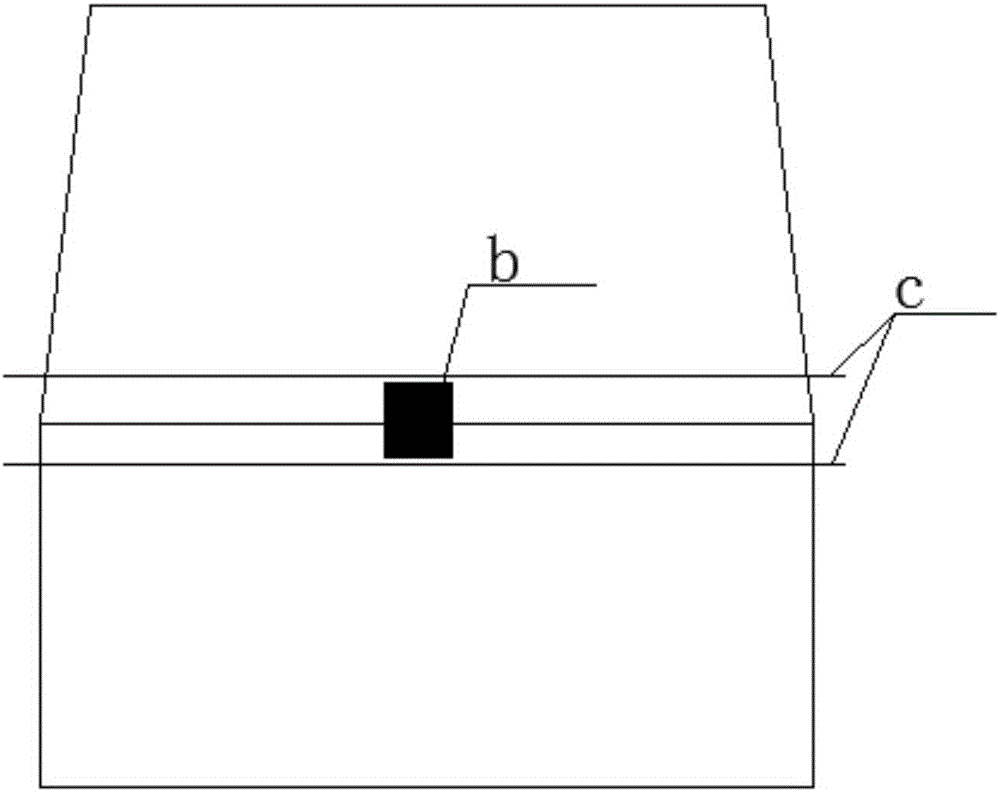

Pumped storage power plant tail water retained rock step blasting safety protection method

The invention discloses a pumped storage power plant tail water retained rock step blasting safety protection method, and relates to an underwater rock step blasting safety protection method. A bladder curtain and porous stoplog gates are constructed outside a rock step to be blasted; the bladder curtain consists of a plurality of steel pipes; two rows of holes are bored on each steel pipe; and each steel pipe is connected with an air pipe of an air compressor. The porous stoplog gates consist of a steel frame and bamboo rafts; I sections are arranged on both sides of the stoplog gate of eachhole; the two sides of each I section are fixed on round flow splitting support piers through steel plates and expansion bolts; each stoplog gate is in welded connection through channel steel, the I sections and angle bars; a layer of vertical bamboo gangway is spread on the water inlet surfaces of the stoplog gates; and simultaneously safety nets are arranged on the tops of flow splitting support piers on the top and both sides of a single hole stoplog gate. The method adopts the proposal of arranging the bladder curtain plus the steel frame, the bamboo rafts and the safety nets to replace aproposal of the stoplog gate, has scientific and reasonable design, protects a trash rack and a tail gate against the damage and the influence of the blasting, and brings about easy spoil removal, short manufacturing and installation time limits, and low manufacturing, installation and demolition cost.

Owner:STATE GRID CORP OF CHINA +2

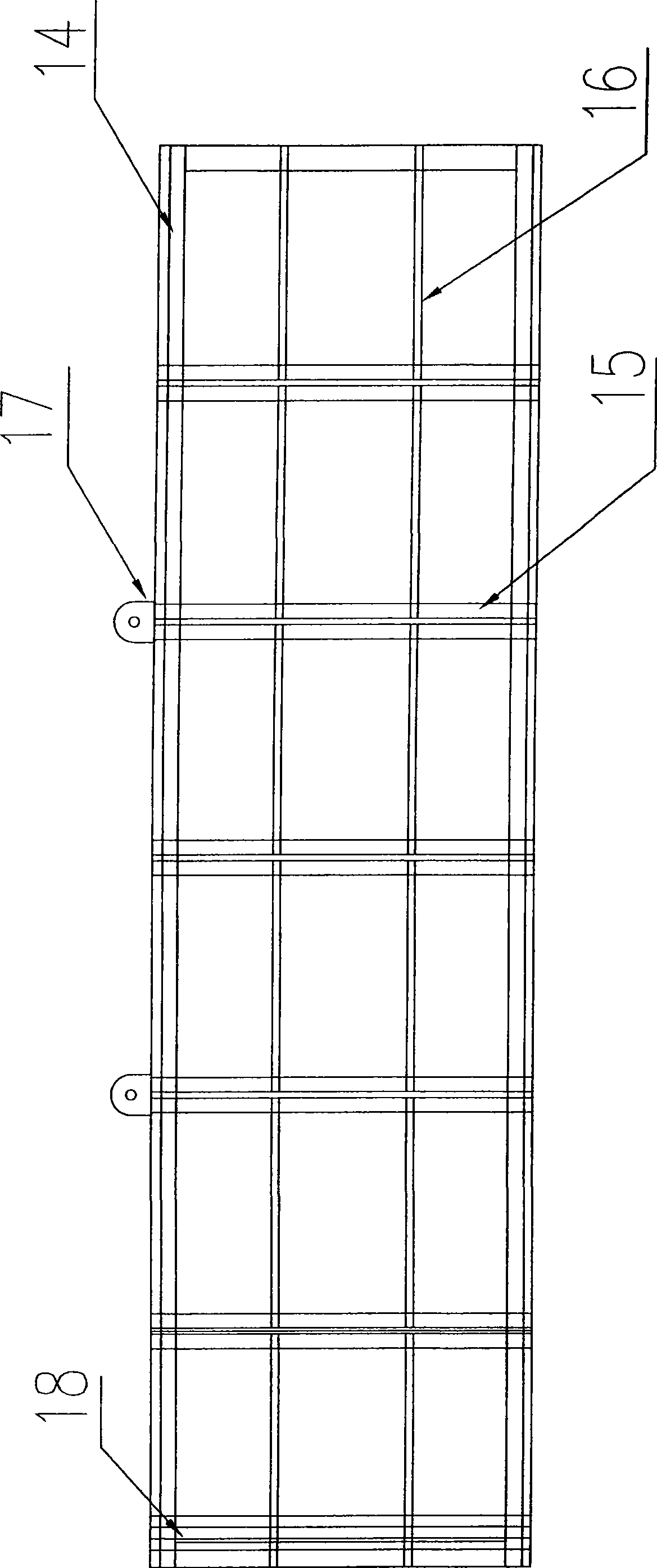

Elevator assembled by utilizing combination type derrick

InactiveCN102060222ASave the trouble of civil constructionFlexible assemblyElevatorsBuilding liftsEngineeringWork time

The invention discloses an elevator assembled by utilizing combination type derricks, relating to hoisting equipment. A hoistway wall of the elevator is formed by assembling more than two derricks, wherein each derrick comprises stand columns, a door beam, a front beam, a back beam, a left beam, a right beam, a cage guide rail and a counter-weight guide rail, wherein the four stand columns are distributed at four corners of the derrick, and connection seats are horizontally and fixedly arranged at the top end and the bottom end of each stand column and provided with connection holes; two ends of the door beam, the front beam, the back beam, the left beam and the right beam are transversely and respectively connected with the stand columns; and the cage guide rail and the counter-weight guide rail are respectively installed in the middle parts and the inner sides of the back ends of the left beam and the right beam. Because the derricks can be produced in a standardized way in a factory and assembled on site, the working time limit can be shortened, the cost can be lowered, the manufacturing cost can be reduced, and the installation efficiency and quality can be improved; and because the derricks are matched with an up-down door-opening and closing mechanism, the influence of the installed elevator on ventilation and daylighting of a household can be reduced. The elevator assembled by utilizing the combination type derricks is mainly used for places of low storey dwelling houses, in particular to the old style low storey dwelling houses of less than 9 storeys.

Owner:张向阳

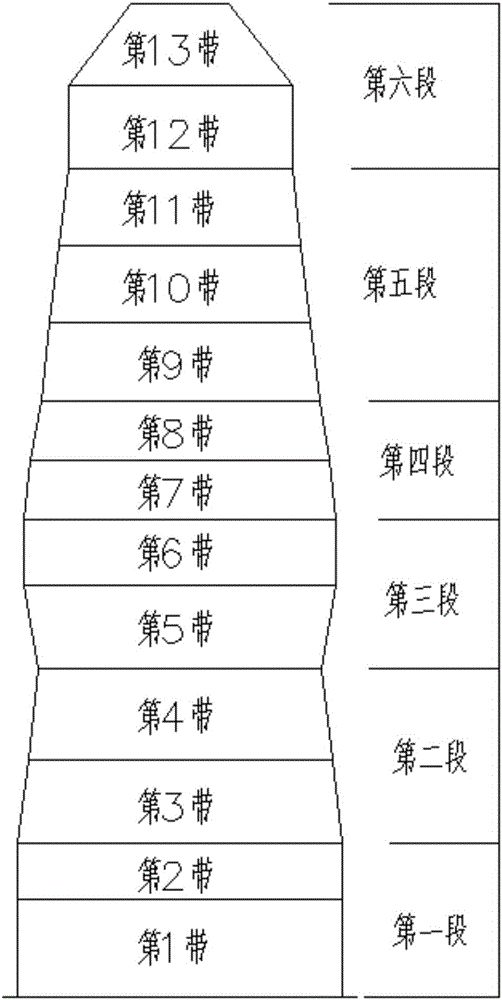

Blast furnace body preassembly technique

InactiveCN105969922AShorten the construction periodShorten the installation periodBlast furnace componentsBlast furnace detailsThroatEngineering

The invention discloses a pre-assembly process of a blast furnace body. A temporary pre-assembly platform is set up in a different place, and the furnace shells prepared by blanking coils are welded in groups of belts, and 13 belt furnace shells are grouped into six sections of furnace shells. Each section is assembled For butt welding, measure and set the center point and center line of the blast furnace on the temporary pre-assembled platform, then set up the furnace shell support on the temporary platform, and assemble the furnace shell. Iron gates are opened on the shell and riveted, and temporary brackets are installed on the furnace shell, and the hot air surrounding pipes are butt-welded; then the stave and throat steel bricks are pre-installed, and the pre-assembled sixth belt furnace shell is removed. The riser is then reinforced and welded. The process of the invention can assemble some small components together for overall hoisting, improve the installation efficiency, reduce the cost of the crane shift, reduce the cost for the construction unit, reduce the construction period, and put the blast furnace into production in advance, bringing considerable economic benefits to the enterprise. The application prospect Very broad.

Owner:XINXING DUCTILE IRON PIPES CO LTD

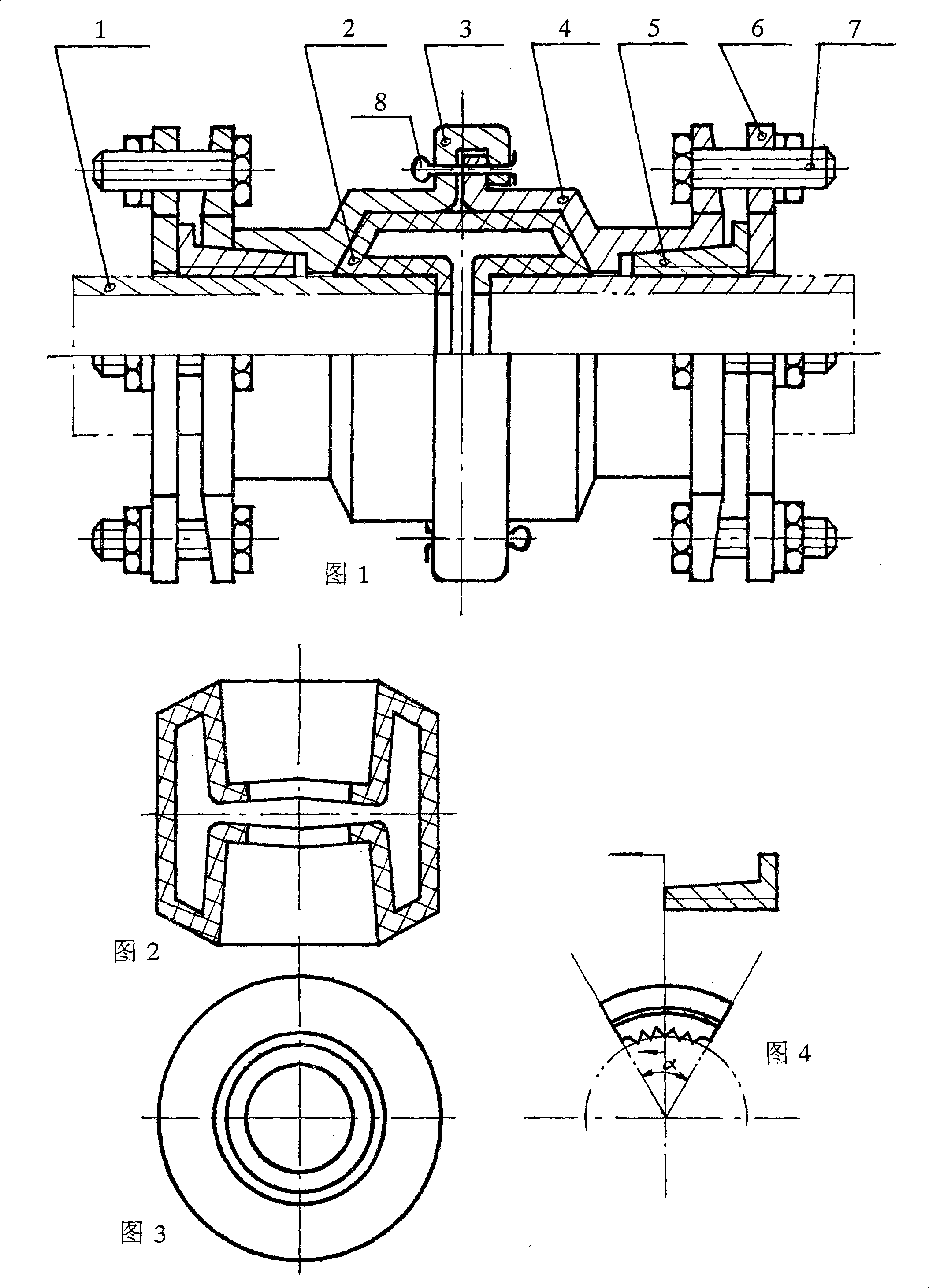

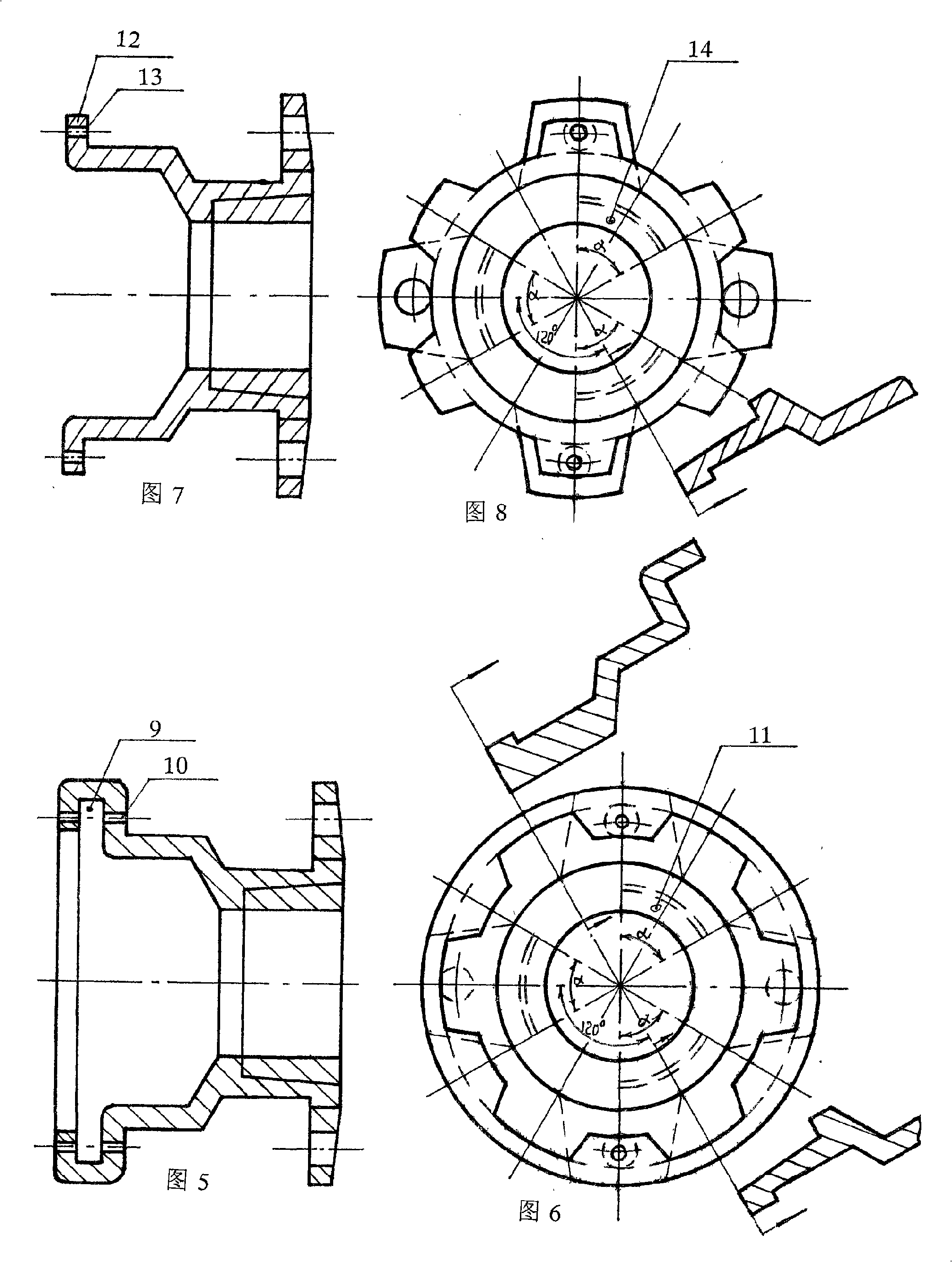

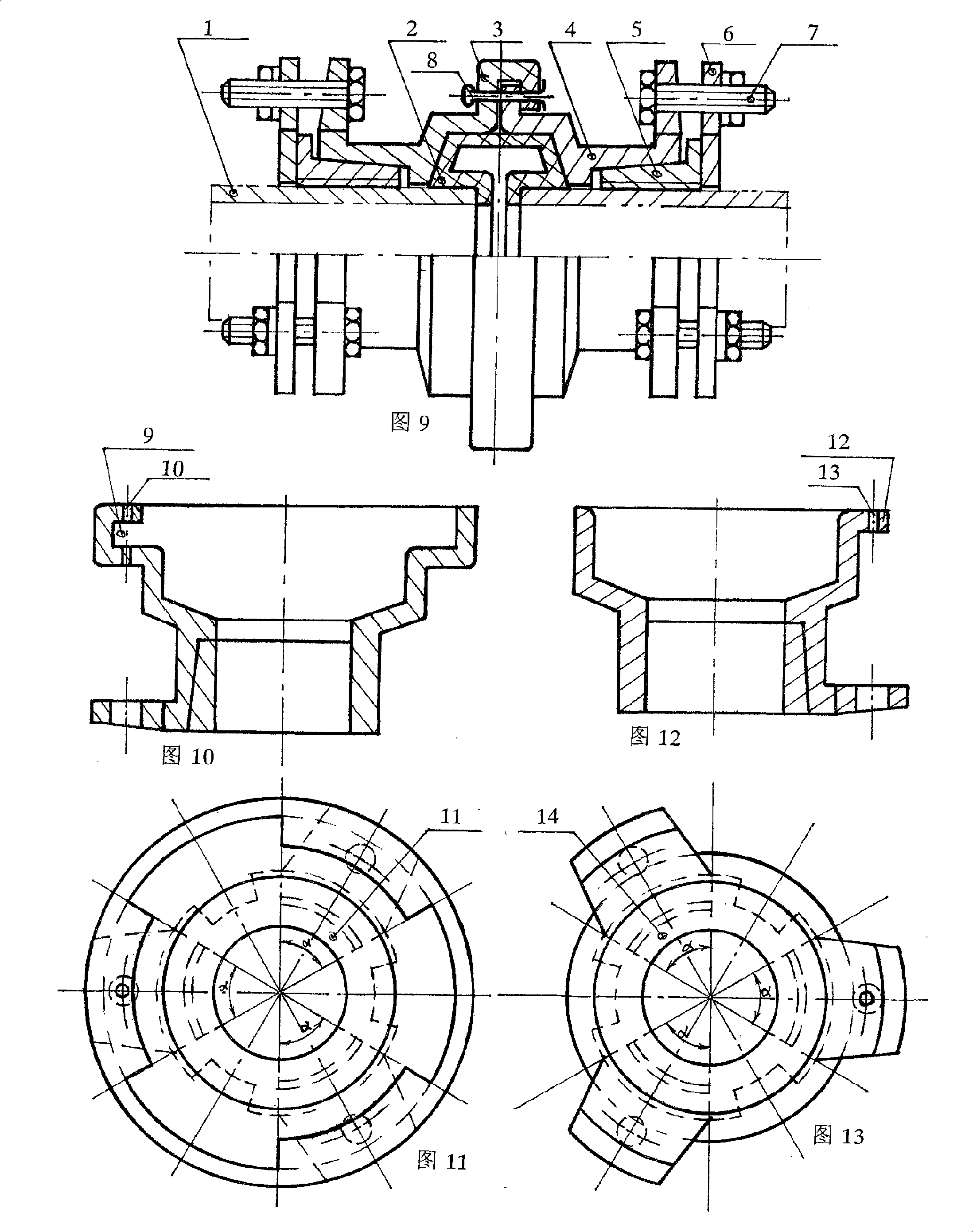

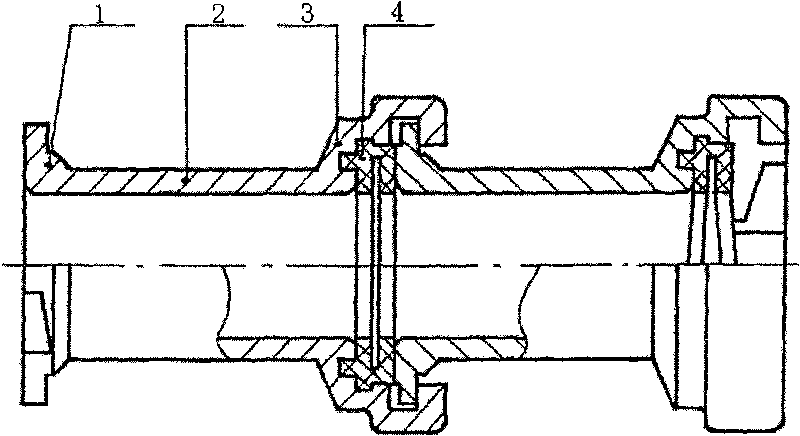

Self-compensating fastening type large-diameter fast joint

InactiveCN101344206AShorten the installation periodQuick connectionFluid pressure sealed jointsPipeline expansion-compensationPipe fittingOmni directional

The invention relates to a self-compensating fastening large-caliber fast adaptor which is used for butt jointing of two pipes and solves the defects of high cost and poor practicability in the prior art. The invention is characterized in that: the outer circumference of pipe fittings is encircled by a rubber sealing boot 2, a convex ring of which is arranged among the pipe fittings. Left and right sleeves 3 and 4 are respectively sheathed on the pipe fittings, and pressed on the outer surface of the rubber sealing boot 2. A trough 9 of the left sleeve 3 is meshed with a projection 12 of the right sleeve 4. A cotter pin 8 fixedly locks the left and right sleeves 3 and 4. A claw 5 is provided with a pointed teeth on the concave surface, arranged in dovetail inner cone troughs 11 and 14 in the left and right sleeves 3 and 4, pasted on the outer wall of the pipe fittings, can slide along the axial direction of the pipe fittings and concentrically contract to occlude and tighten the pipe fittings. The fast adaptor is high, middle and low pressure resistant. The self-compensating fastening omni-directional secure seal with firm soft syncretic is provided without welding or flange type, not being opened with trench type, and not being provided with a compensator additionally, thereby saving labor and time, especially under the condition of severe environment, the fast adaptor of the invention has the advantages of being convenient and fast, low cost, energy saving and environmental protection. The fast adaptor of the invention is used for connecting two pipes through which the fluid is to be conveyed.

Owner:王甲南

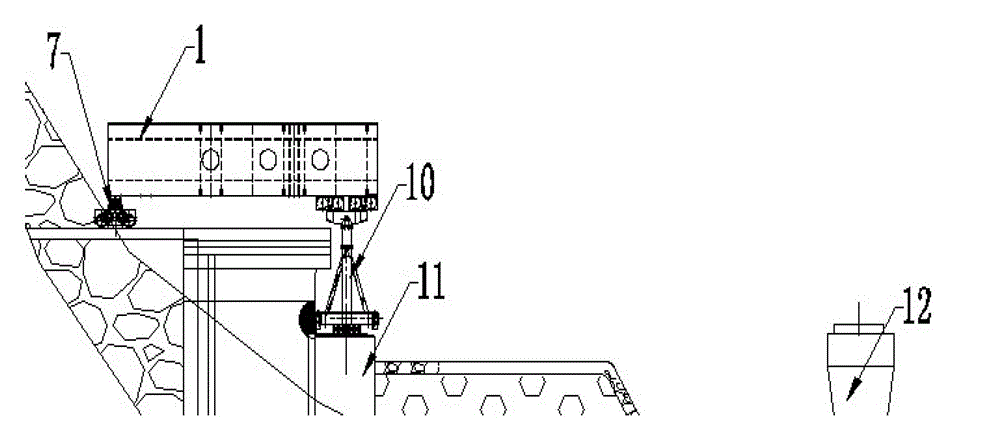

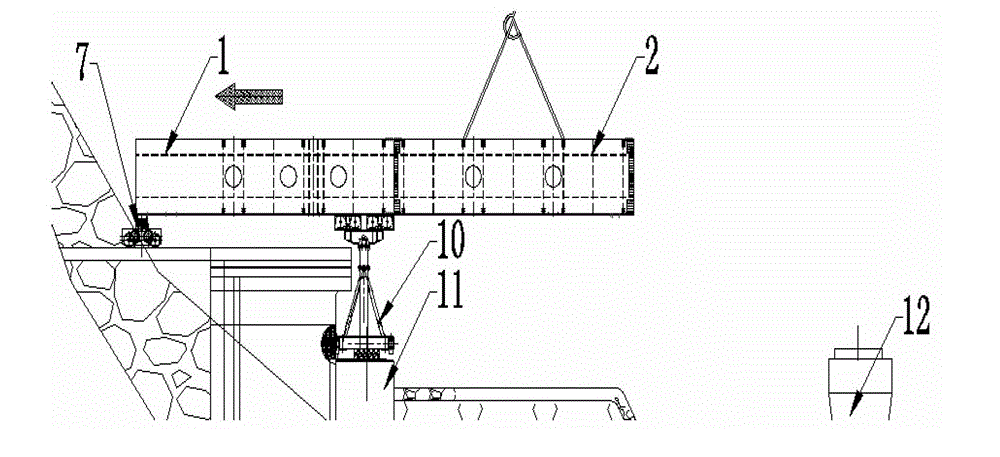

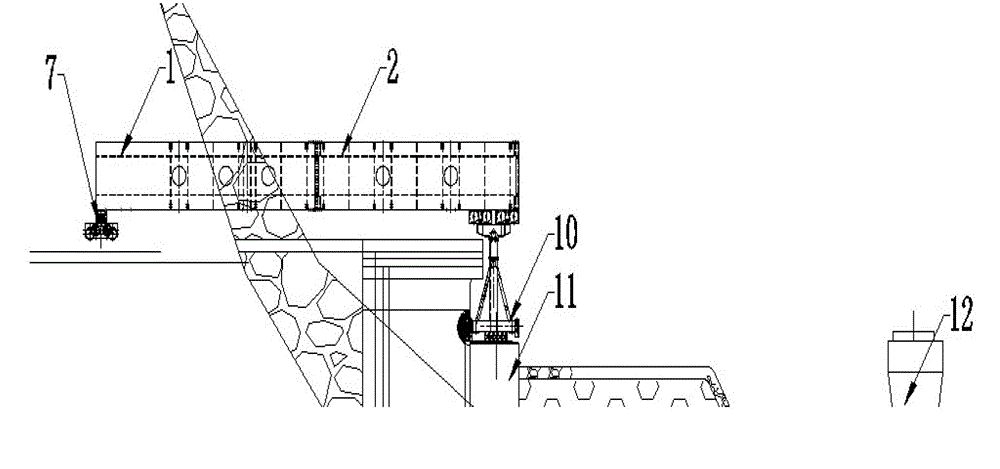

Assembly method of bridge-building machine at exit of tunnel connected with bridge

ActiveCN102979040ASave the amount of earthworkShorten the installation periodBridge erection/assemblyStructural engineeringArchitectural engineering

The invention discloses the field of bridge construction, and particularly relates to an assembly method of a bridge-building machine at an exit of a tunnel connected with a bridge. The assembly method of the bridge-building machine mainly comprises the following steps of: setting aside a working site; installing sliding devices at the bottoms of a second main beam and a third main beam; installing an electric running mechanism for a rear support leg of a first main beam of the bridge-building machine at the bottoms of an inverted arch of the tunnel, and installing a front support leg on a No. 0 platform; assembling the main beams and guide beams through a running motor in the electric running mechanism for the rear support leg, and returning into the tunnel; and moving the whole assembled structure of the main beams and the guide beams out of the tunnel through the running motor in the electric running mechanism for the rear support leg. By adopting the assembly method, large-scale backfilling, flattening and hardening are not needed for an assembly site, large quantities of earthwork and stonework engineering and shifts for operation of large-tonnage lifting devices can be saved, and the installation period can be greatly shortened.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

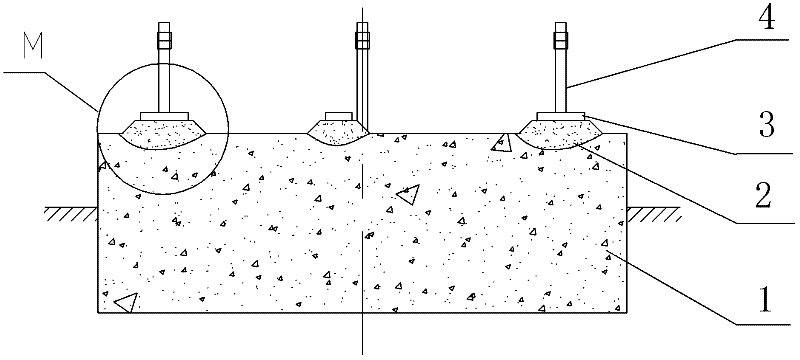

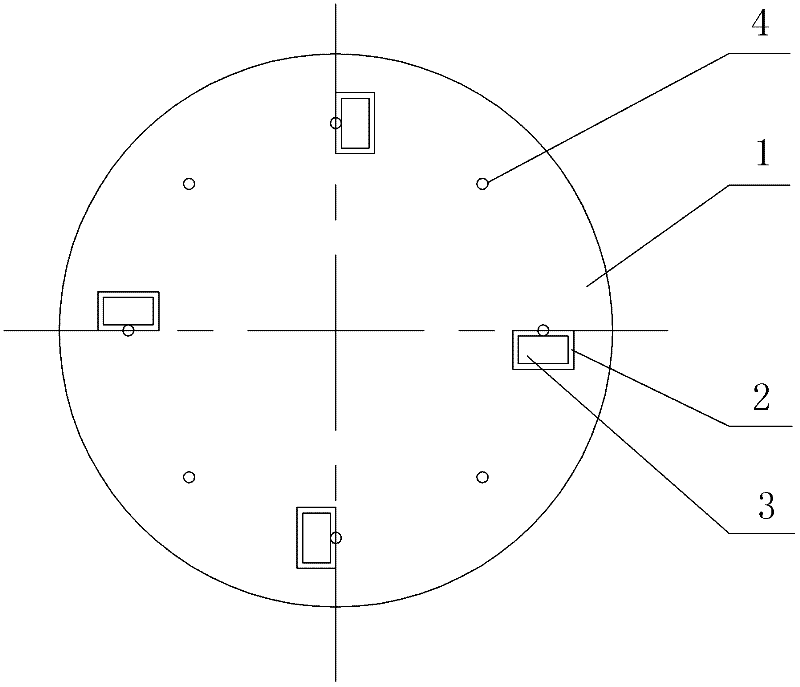

Method for mounting seat pulp cushion plates of petrochemical static equipment and foundation structure

The invention discloses a method for mounting seat pulp cushion plates of petrochemical static equipment and a foundation structure. The method includes that a plurality of concrete piers with cushion plates are manufactured on a concrete base, the minimum area of each single cushion plate is computed according to the sum of the weight of the equipment and pre-tightening force of anchor bolts, load added on the cushion plate and compressive strength of selective concrete, the concrete piers are trapezoidal tables, the seat pulp cushion plates are arranged on tops of the concrete piers, and surfaces of the cushion plates are positioned on the same horizontal plane. The equipment is seated on the cushion plates of the concrete piers by means of hoisting, and the various anchor bolts are fastened. A secondary grouting layer is formed by means of secondary grouting for a space between the bottom of the equipment and the concrete base. The trapezoidal table concrete piers which are positioned below a reinforcing plate of the equipment are arranged on the concrete base of the foundation structure, the cushion plates are disposed on the tops of the piers, and the surfaces of the cushion plates of the piers are positioned on the same horizontal plane. The secondary grouting layer is disposed between the bottom of the equipment and the concrete base. The method and the foundation structure have the advantages that wedge liners are omitted, materials are saved, the cushion plates of the concrete piers are integrally connected with the base, installation is carried out conveniently, installation quality is improved, and installation work period is shortened.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

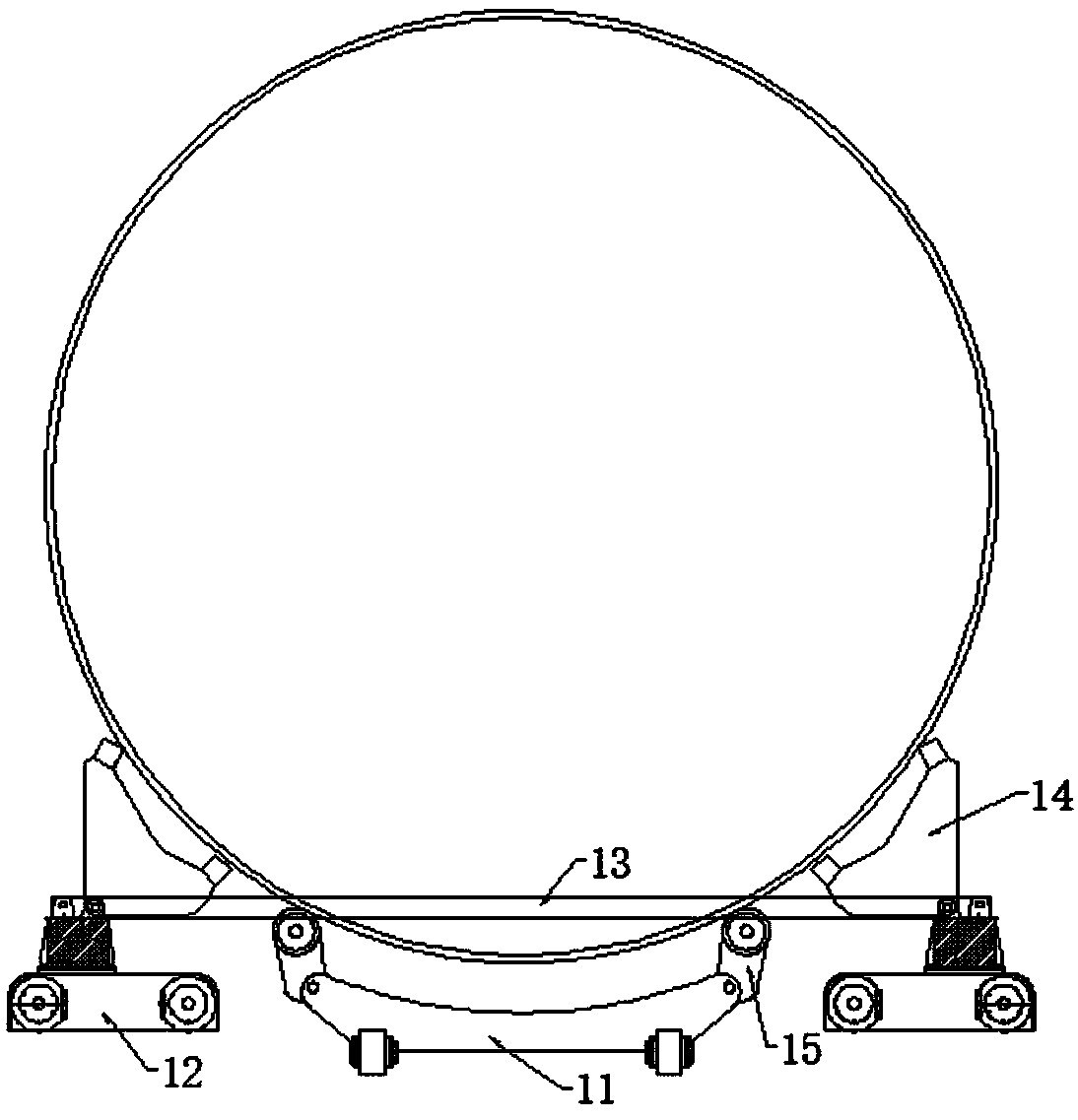

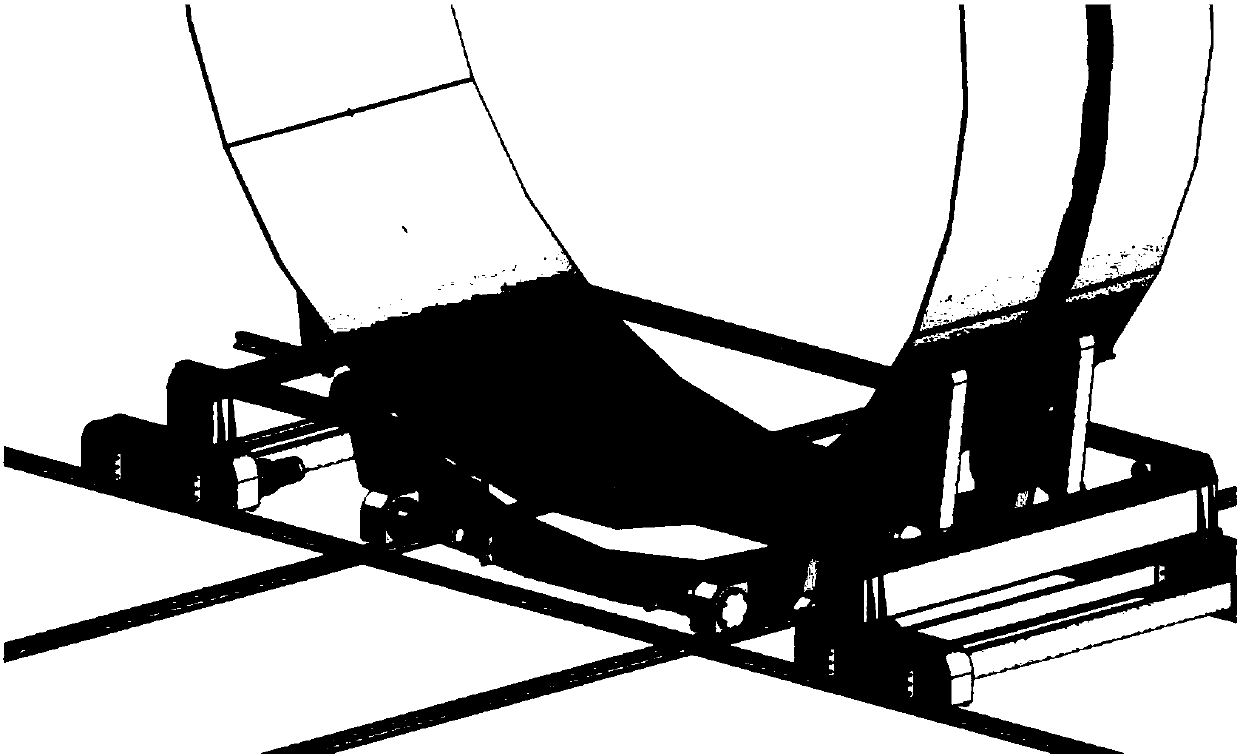

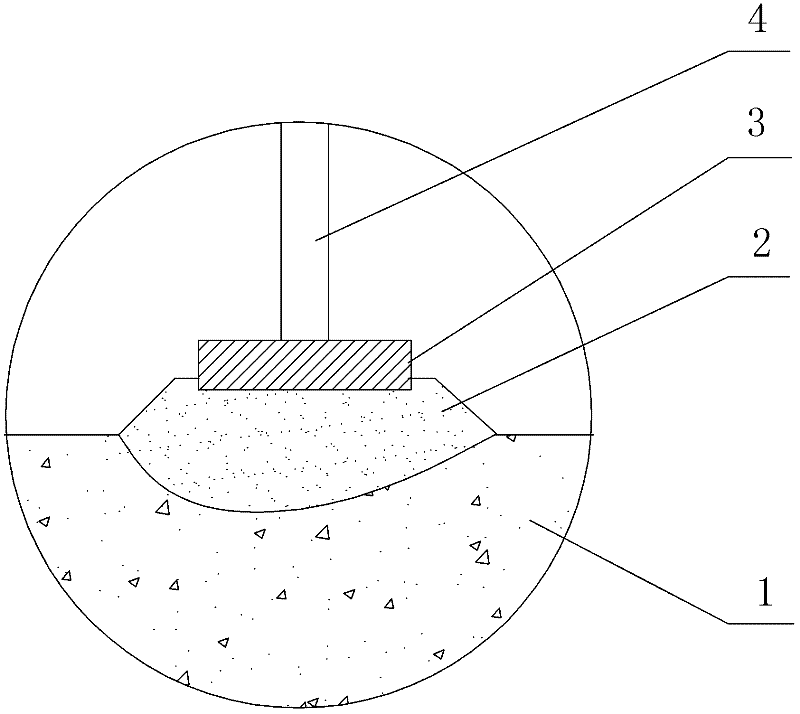

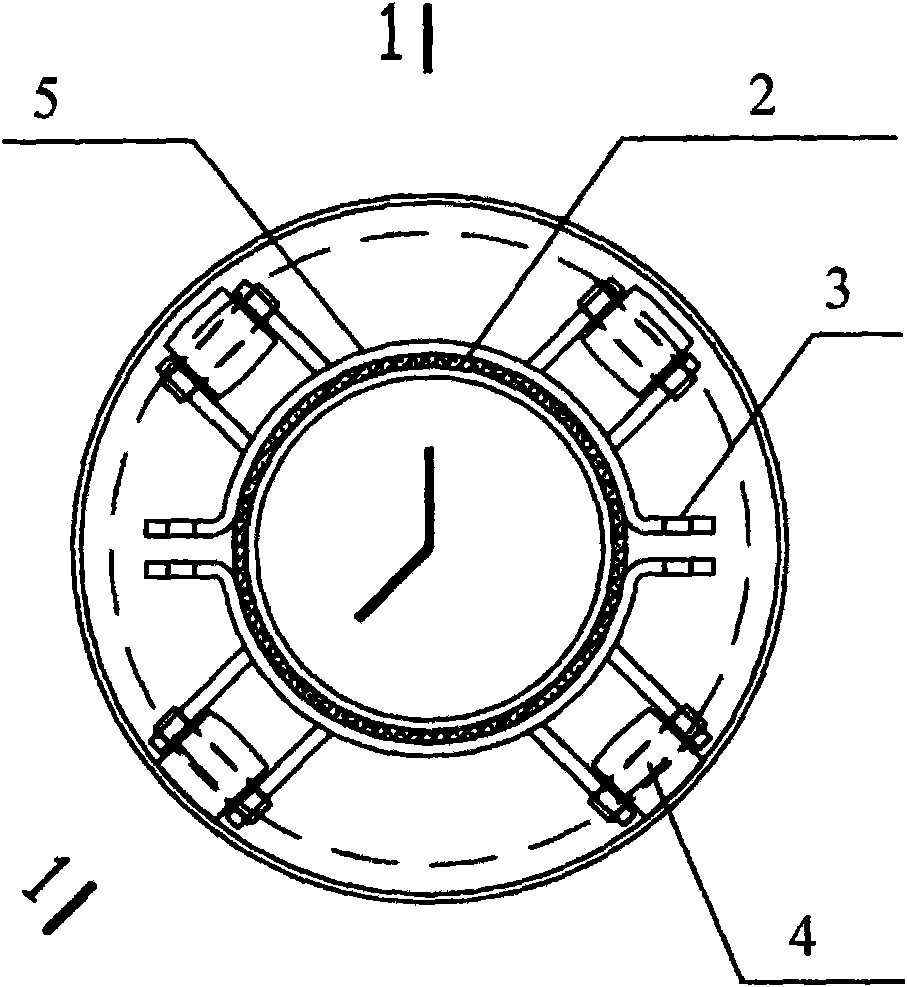

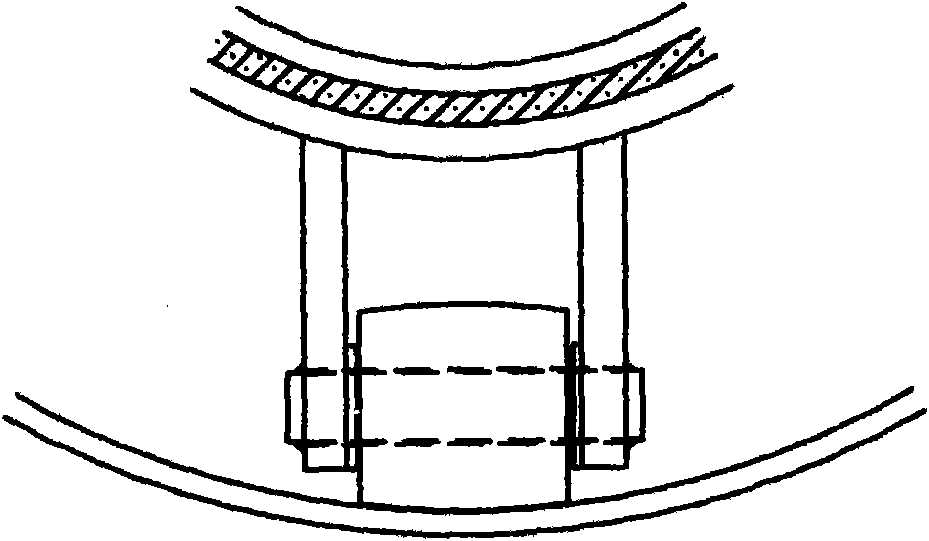

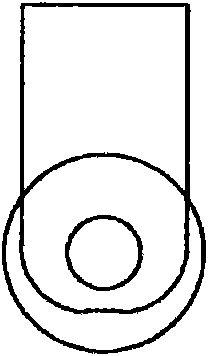

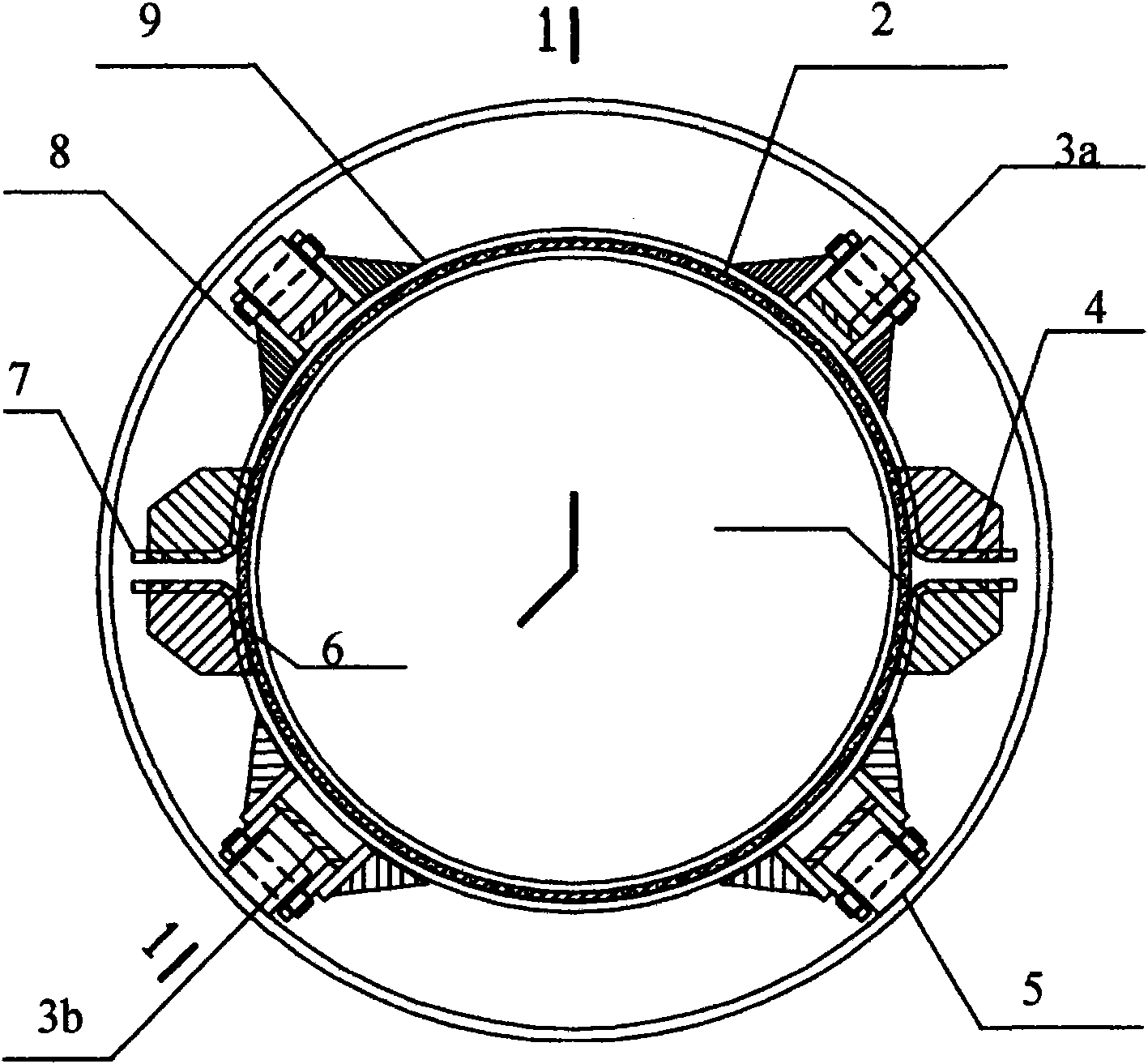

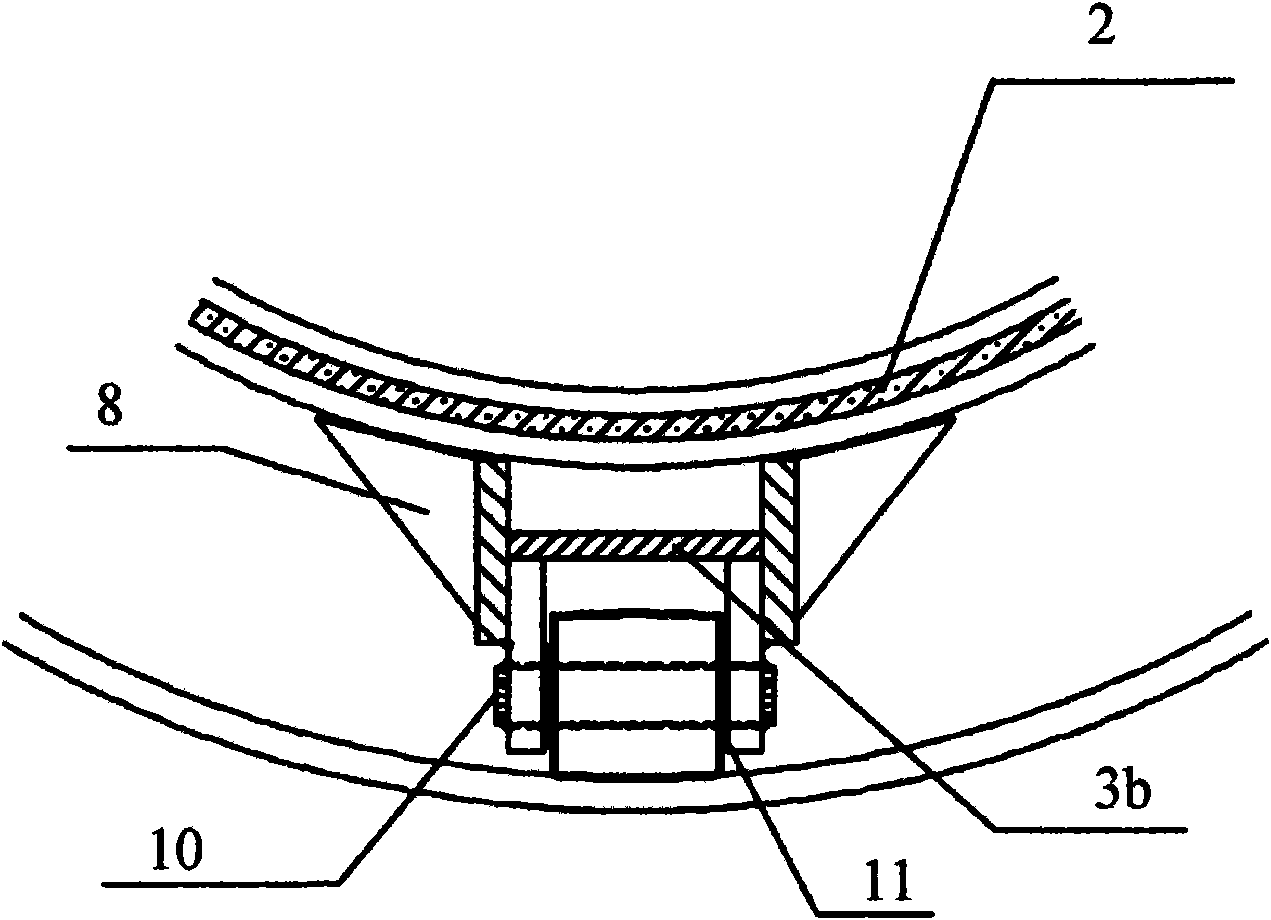

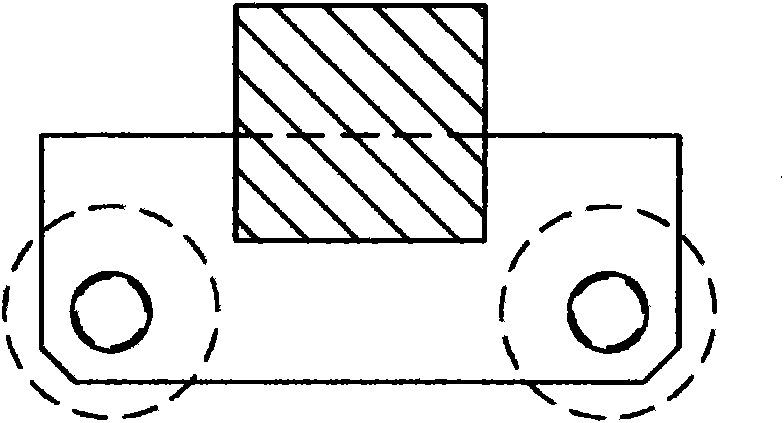

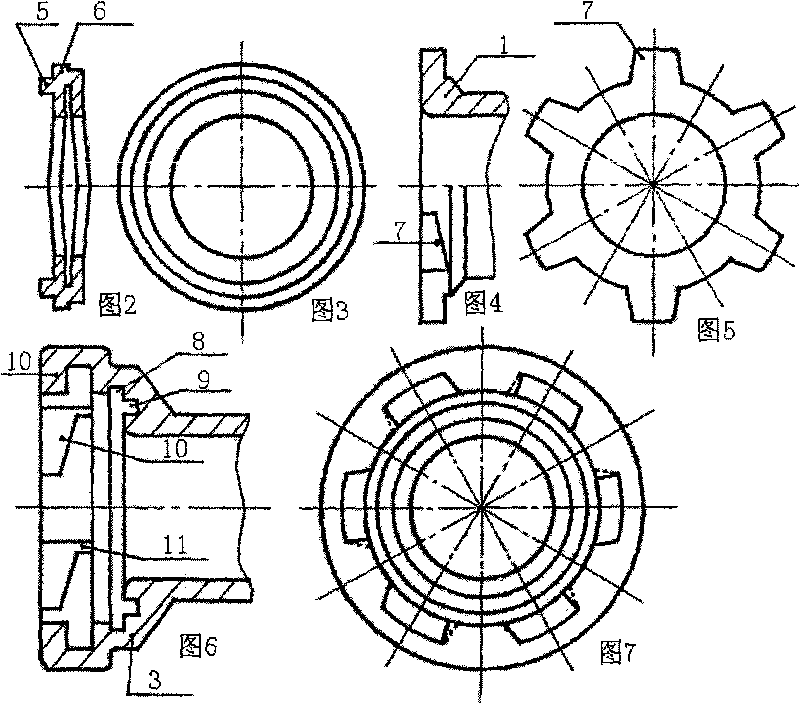

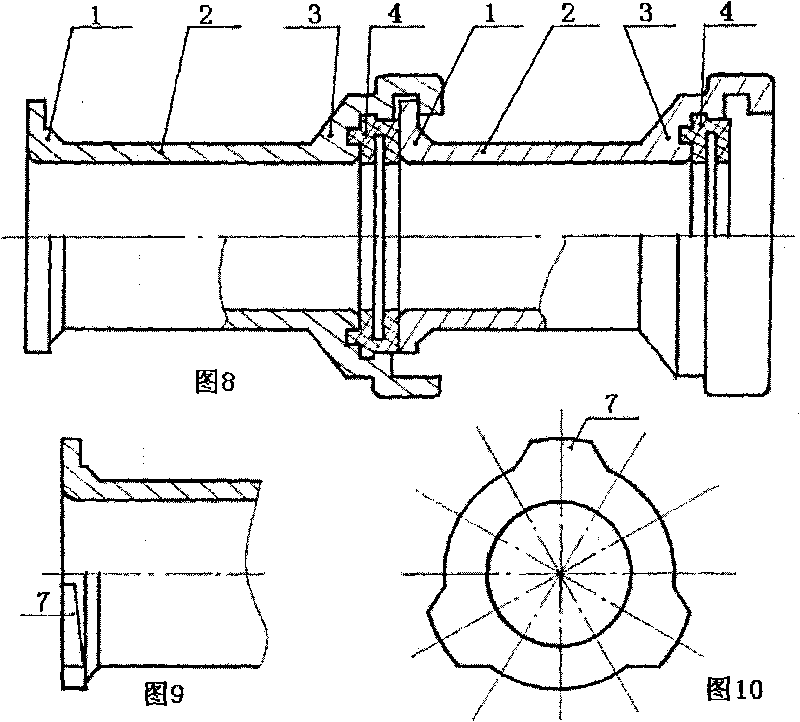

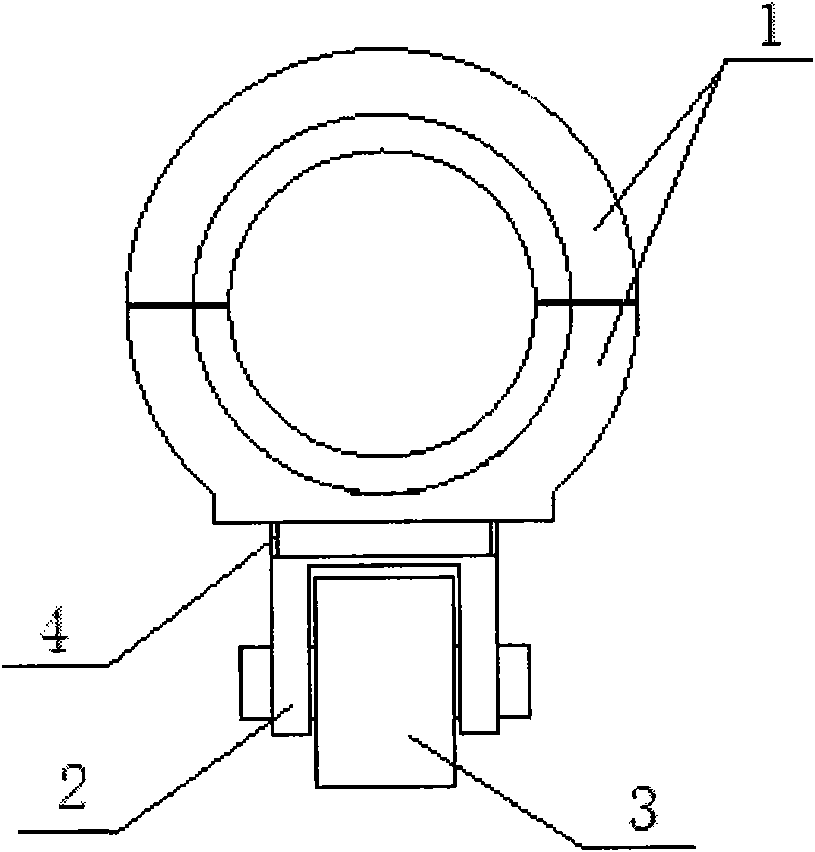

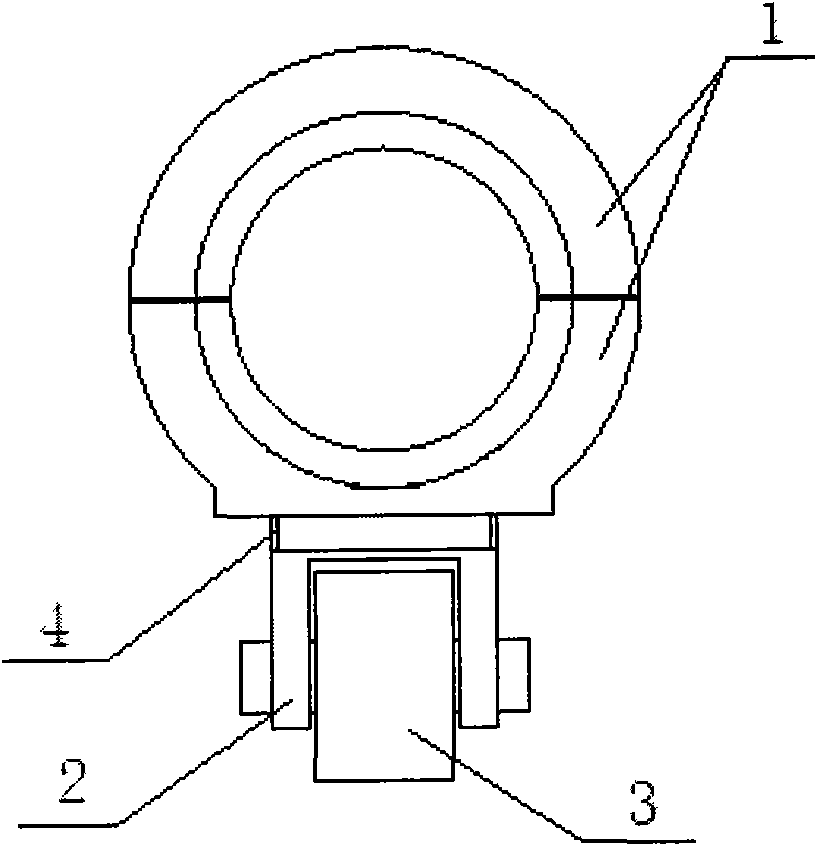

Steel-sleeve steel steam insulation pipe and rolling supporting mechanism thereof

InactiveCN101666419AReduce processImprove insulation effectPipe supportsThermal insulationRolling resistanceEngineering

The invention relates to a steel-sleeve steel steam insulation pipe and a rolling supporting mechanism thereof, wherein the nominal diameter of an inner sleeve steel pipe of the steel-sleeve steel steam insulation pipe is DN 250-DN 500. The rolling supporting mechanism comprises an upper steel hoop, a lower steel hoop, two upper idler wheels and two lower idler wheels, wherein the upper idler wheels and the lower idler wheels are respectively arranged on the upper steel hoop and on the lower steel hoop and distributed symmetrically; the end parts of the upper steel hoop and the lower steel hoop are clamped tightly by bolts; and when the axes of the inner sleeve steel pipe and an outer sleeve steel pipe are overlapped, the two lower idler wheels and the inner wall of the outer sleeve steelpipe are contacted in a rolling friction way, and fit-up gaps are left between the upper idler wheels and the inner wall of the outer sleeve steel pipe. The steel-sleeve steel steam insulation pipe comprises the inner sleeve steel pipe, the outer inner sleeve steel pipe, the rolling supporting mechanism, insulation material and heat-preservation material, wherein the external diameter of the heat-preservation layer is smaller than the internal diameter of the outer sleeve steel pipe and an air layer is formed between the heat-preservation layer and the sleeve steel pipe. The rolling supportingmechanism has small friction force, therefore, the stress of the rolling supporting mechanism and the inner sleeve steel pipe is reduced.

Owner:刘毅 +1

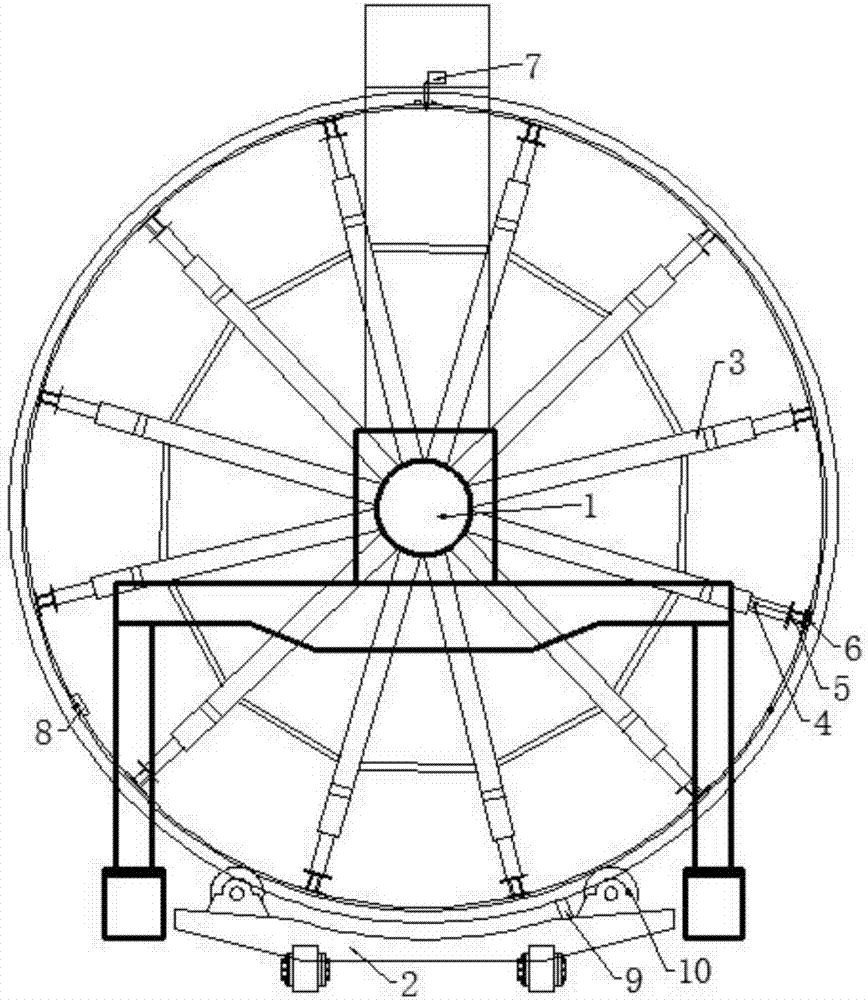

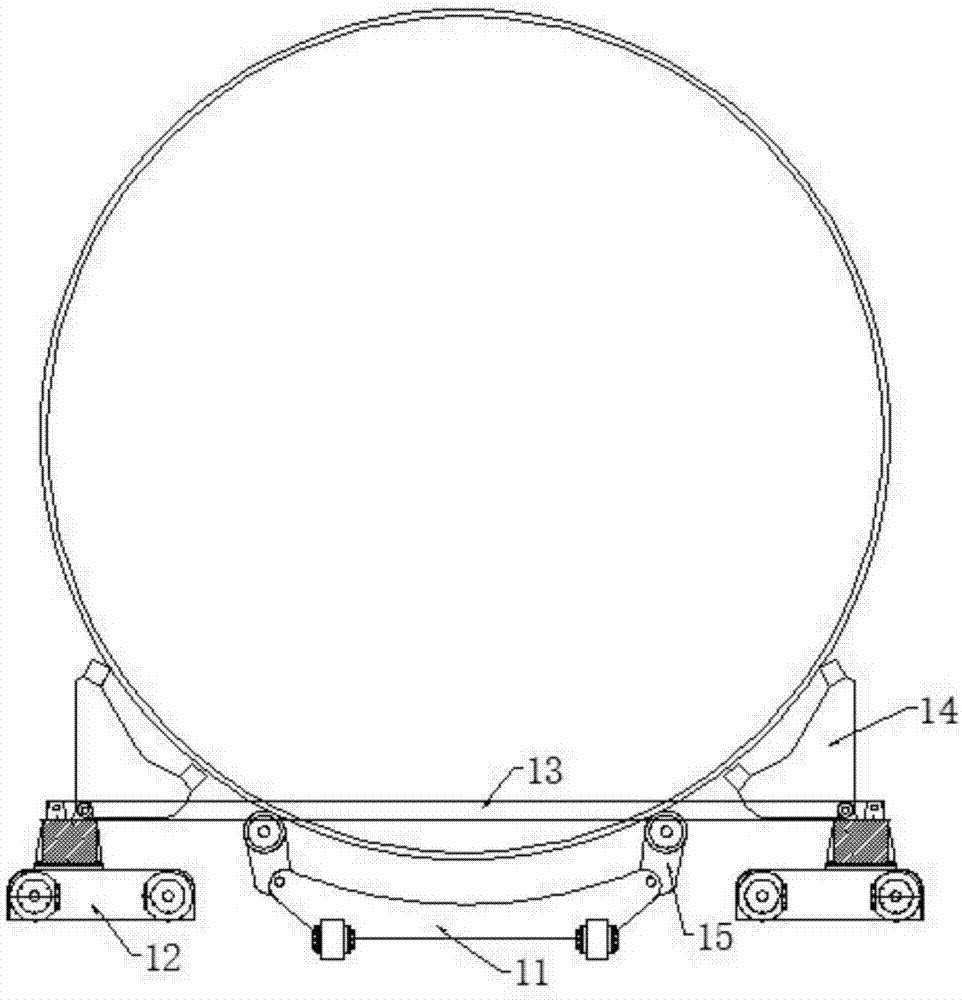

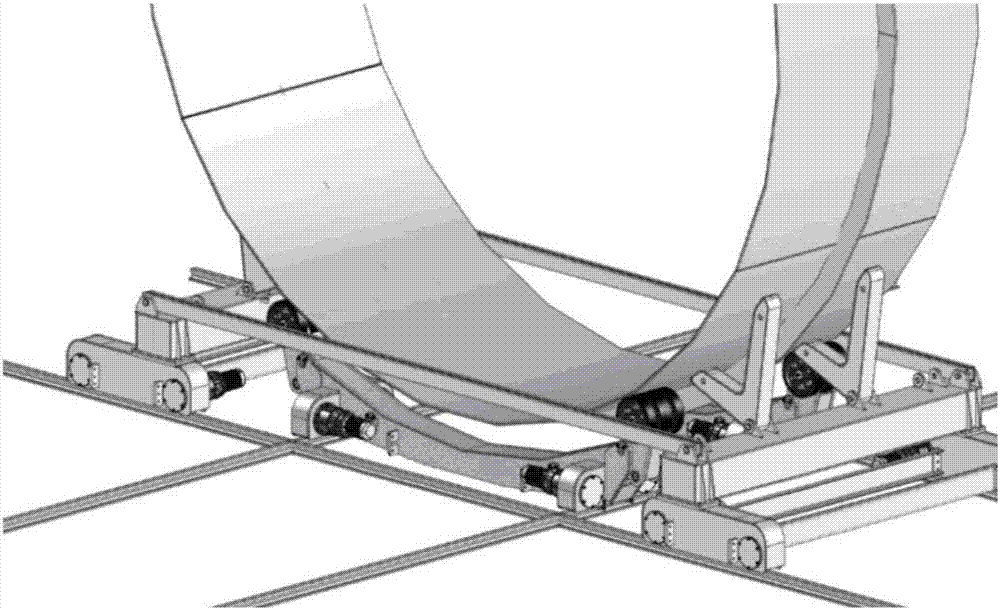

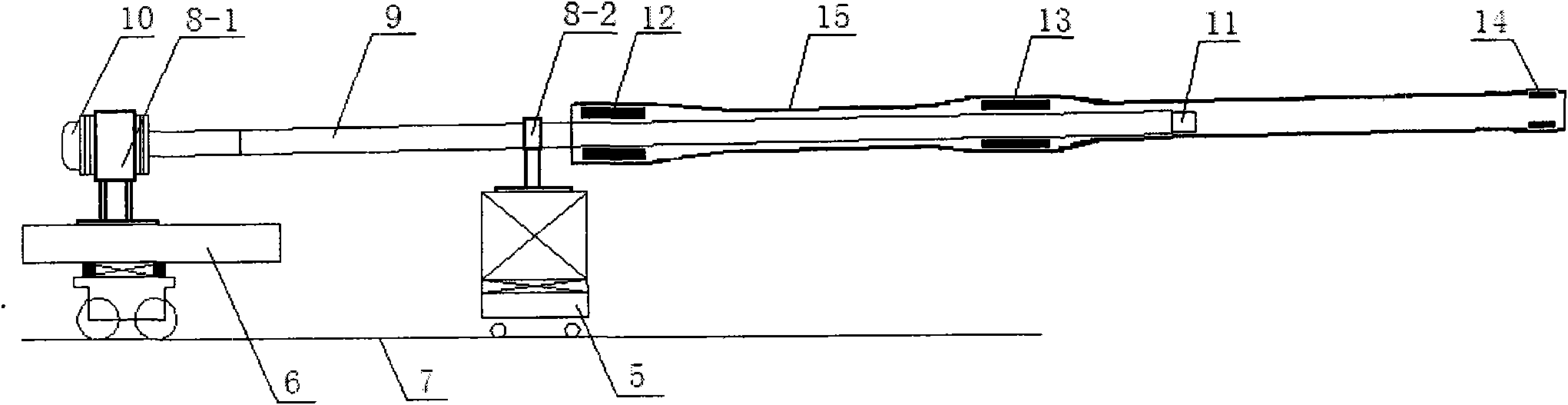

Ultra-large-diameter steel penstock installation method

InactiveCN107503333ARealize secondary assembly weldingMeet the requirements of mechanized assembly of stiffening ringsFinal product manufactureWater-power plantsProduction linePenstock

The invention discloses an ultra-large-diameter steel penstock installation construction technique. An installation method comprises the steps that ultra-large-diameter steel penstocks are coupled on site, specifically, tiles split into three flaps are rounded, single-section steel penstocks are assembled into multi-section steel penstock sets through assembling and welding, and stiffening rings are additionally welded to the multi-section steel penstock sets; the coupled steel penstock sections are transported in an adit, specifically, rails are prefabricated and paved in the adit, and the steel penstocks are transported to an installation station through a separable trolley; and the formed steel penstocks are positioned and installed, specifically, in the installation station, after steel penstock bodies are regulated to the installation height and fixed through a separable trolley jacking device, the trolley is removed, and integral installation of the multiple steel penstock sections is achieved. According to the ultra-large-diameter steel penstock installation construction technique, the operation layout of a traditional production line is effectively simplified, temporary assembling facilities inside the adit are simplified, the excavated sections of branched holes and the excavated sections of a main hole are decreased, the occupied area for steel penstock section assembling is decreased, and the requirements of a place where finished products can be stacked are eliminated; steel penstock sections are formed at a time during secondary assembling and welding, and the installation precision is improved through mechanical assembling and welding; and the installation construction technique does not rely on traditional lifting and turning modes any more, the safety risk is lowered, the installation construction period is shortened, the installation personnel number is decreased, and investment is reduced.

Owner:SINOHYDRO BUREAU 7 CO LTD

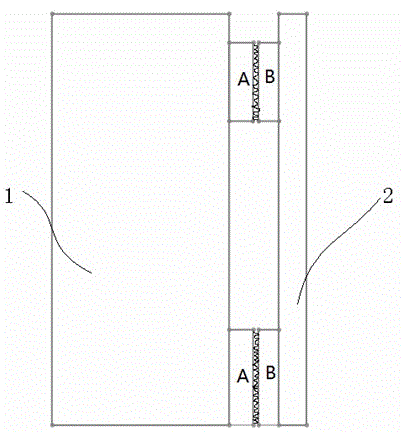

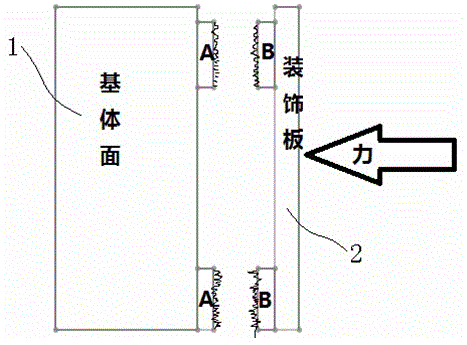

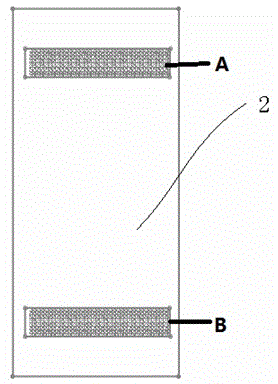

Method for installing decorative sheet on substrate surface

ActiveCN102979278AReduce installation costsEasy to installCovering/liningsEngineeringSubstrate surface

The invention relates to a method for installing a decorative sheet on a substrate surface. A single decorative sheet is installed on the substrate surface in a detachable pasting mode, and adjacent single decorative sheets are mutually spliced to form a complete decorative sheet. The front face of the decorative sheet is a decorative surface, and the back face of the decorative sheet is an installation surface. The installation surface is connected with a wall through a Velcro, and the Velcro comprises a surface body A and a surface body B which are cooperative. The surface body A of the Velcro is fixed on the installation surface of the decorative sheet, and the corresponding surface body B of the Velcro is fixed in the corresponding position of the substrate surface. The decorative sheet and the substrate surface are correspondingly pasted and fixed together through the mutually-fitted surface body A and the surface body B of the Velcro. The method provides a low-cost and convenient mode for the installation of decorative materials and innovatively replaces the current complex time-wasting and wasteful installation method.

Owner:苏州正乙丙纳米环保科技有限公司

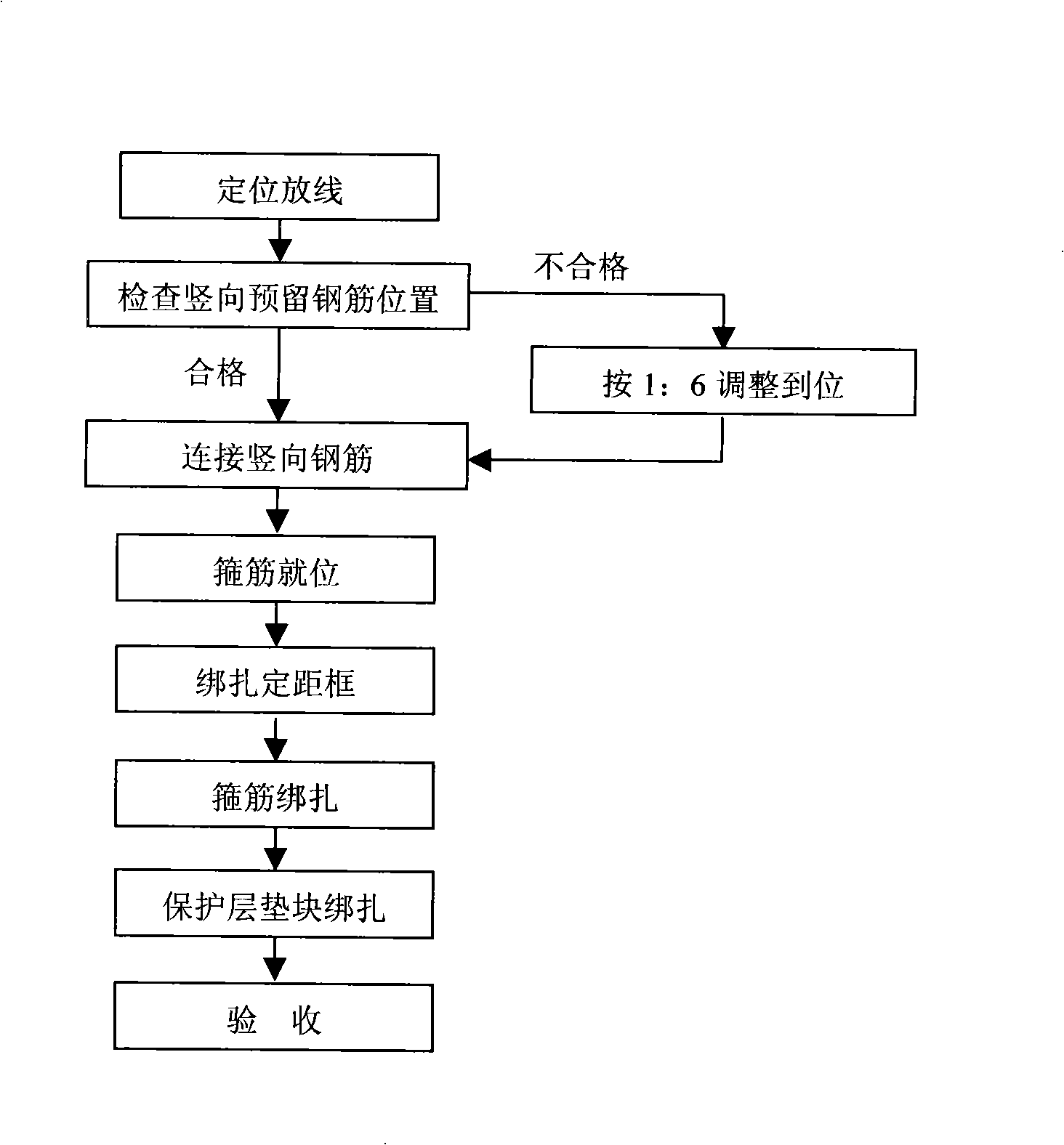

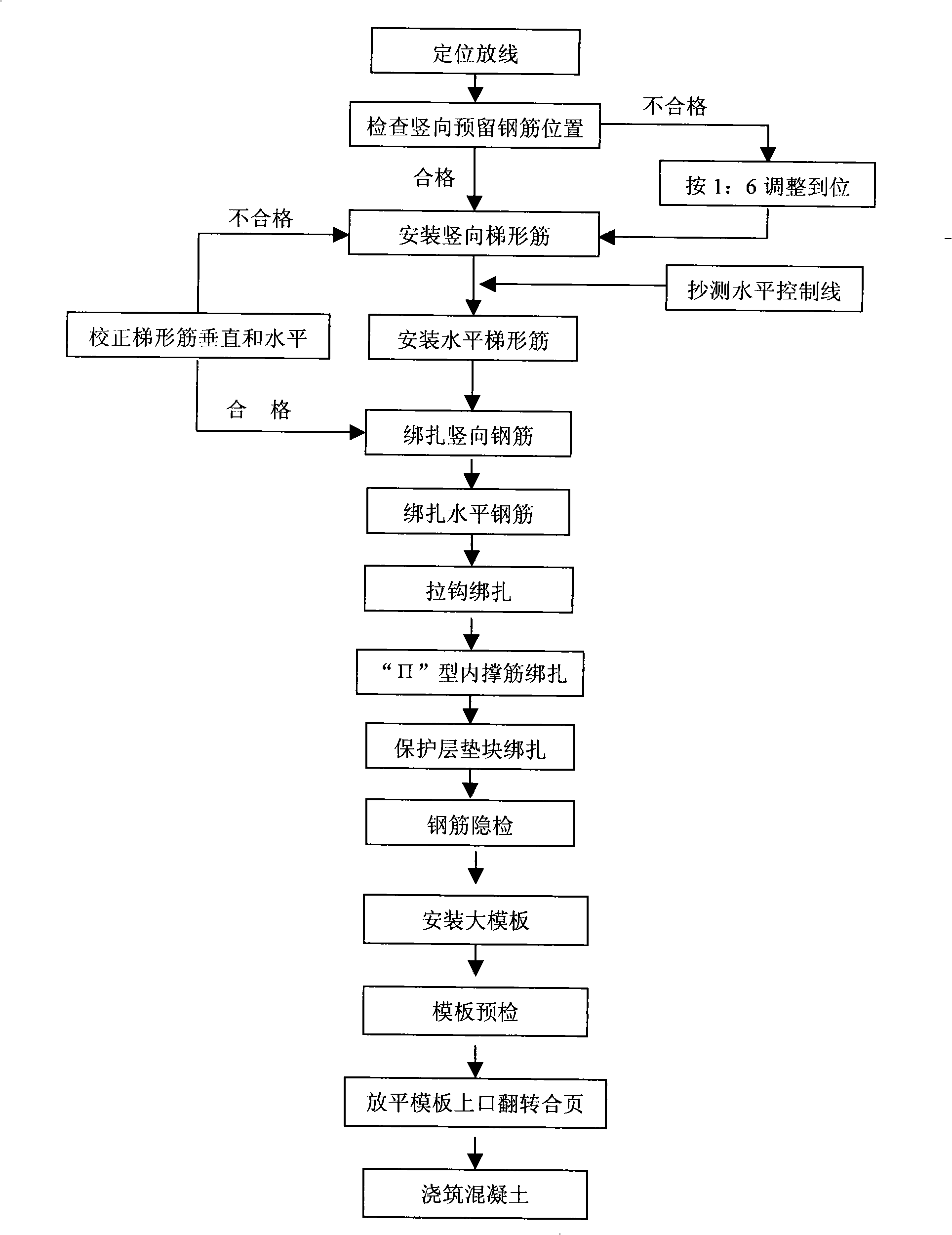

Method for binding high-layer shear force wall reinforcing steel bar

InactiveCN101353920AReduce the ratioImprove protectionBuilding reinforcementsReinforced concreteSteel bar

The invention discloses a steel bar bonding method of a shearing wall of a high-rise building, which relates to the technical filed of building engineering, in particular to the technical field of steel bar bonding in the construction of the shearing wall of the high-rise building. The method comprises ordinal steps of bonding a vertical ladder steel bar, bonding a horizontal ladder steel bar, bonding the vertical steel bars of a wall body and boding the horizontal steel bars of the wall body; the vertical ladder steel bar consists of two vertical steel bars and a plurality of horizontal steel bars; the horizontal ladder steel bar consists of two vertical steel bars and a plurality of horizontal steel bars; and the horizontal ladder steel bar is disassembled after concrete is poured. The method has easy operation and promotion, reduces the proportion of skillful workers, raises assembly speed, improves labor productivity, can effectively control the interval between the steel bars of walls and columns in reinforced concrete structure and the accuracy of the protective layer, and ensure the quality of assembly location of steel bar engineering.

Owner:JIANGSU JIANGDU CONSTR GRP

Process for heating sleeve shaft through magnetic induction by large ring component

InactiveCN103170796AShorten the installation periodShorten round-trip shipping timesMetal working apparatusThermodynamicsThermal deformation

The invention relates to a process for heating a sleeve through magnetic induction by a large ring component. Finish machining is conducted on the ring component until certain size of the ring component is reached before shrinkage fit. In order to avoid thermal consumption after heating and prevent the surface of a ring from being burned due to the fact of partial overheat, asbestos cloth is coated and surrounds the outer surface of the ring, induction coils are wound on the outer surface of the ring, the ring is lifted above a rotating shaft through a crane, and after the ring is heated, when the minimum size of the ring is detected to meet requirements of a drawing through a measuring bar, the ring is smoothly dropped, and the shrinkage fit is conducted on the ring. After the ring is cooled to room temperature, size difference of an outer ring of the ring before the shrinkage fit and after the shrinkage fit is not larger than 0.02 millimeter. After the shrinkage fit is finished for the first time, the ring does not need machining a large equipment for the second time again after the shrinkage fit, the lowest heating temperature is controlled through intermediate-frequency electromagnetic induction heating, and deformation of the ring is small after the shrinkage fit after the ring is heated. The process for heating the sleeve shaft through magnetic induction by the large ring component has the advantages of being simple in operation, simple in required equipment, low in manufacturing cost, short in working period and the like, can save a large amount of cost from secondary machining to large-equipment machining, and is very high in application value.

Owner:HARBIN ELECTRIC MASCH CO LTD

Steel-sleeve steel steam insulation pipe and rolling supporting mechanism thereof

The invention relates to a steel-sleeve steel steam insulation pipe and a rolling supporting mechanism thereof, wherein the nominal diameter of an inner sleeve steel pipe of the steel-sleeve steam insulation pipe is DN 600-DN 700. The rolling supporting mechanism comprises an upper steel hoop, a lower steel hoop, two upper idler wheels arranged on the upper steel hoop and distributed symmetrically, and four lower idler wheels arranged on the lower steel hoop and distributed symmetrically, wherein the four lower idler wheels are evenly divided into two groups; the end parts of the upper steel hoop and the lower steel hoop are connected by bolts; and when the axes of the inner sleeve steel pipe and an outer sleeve steel pipe are overlapped, the four lower idler wheels and the inner wall of the outer sleeve steel pipe are contacted in a rolling friction way, and gaps are left between the two upper idler wheels and the inner wall of the outer sleeve steel pipe. The steel-sleeve steel steaminsulation pipe comprises the rolling supporting mechanism and also comprises insulation material positioned between the rolling supporting mechanism and the inner sleeve steel pipe, heat-preservation material with the external diameter smaller than the internal diameter of the outer sleeve steel pipe, an air evaporation valve arranged on the outer sleeve steel pipe, and erosion resistant coatingsleeved outside the outer sleeve steel pipe. The rolling supporting mechanism has small friction force, therefore, the stress of the rolling supporting mechanism and the inner sleeve steel pipe is reduced.

Owner:刘毅 +1

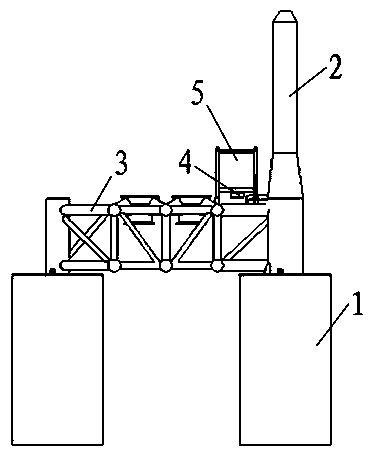

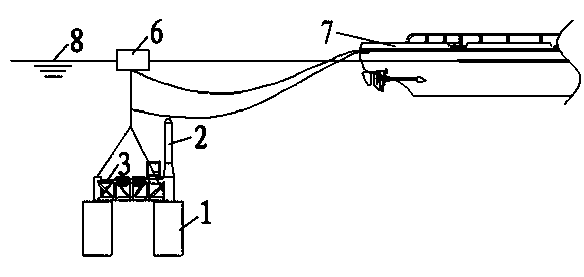

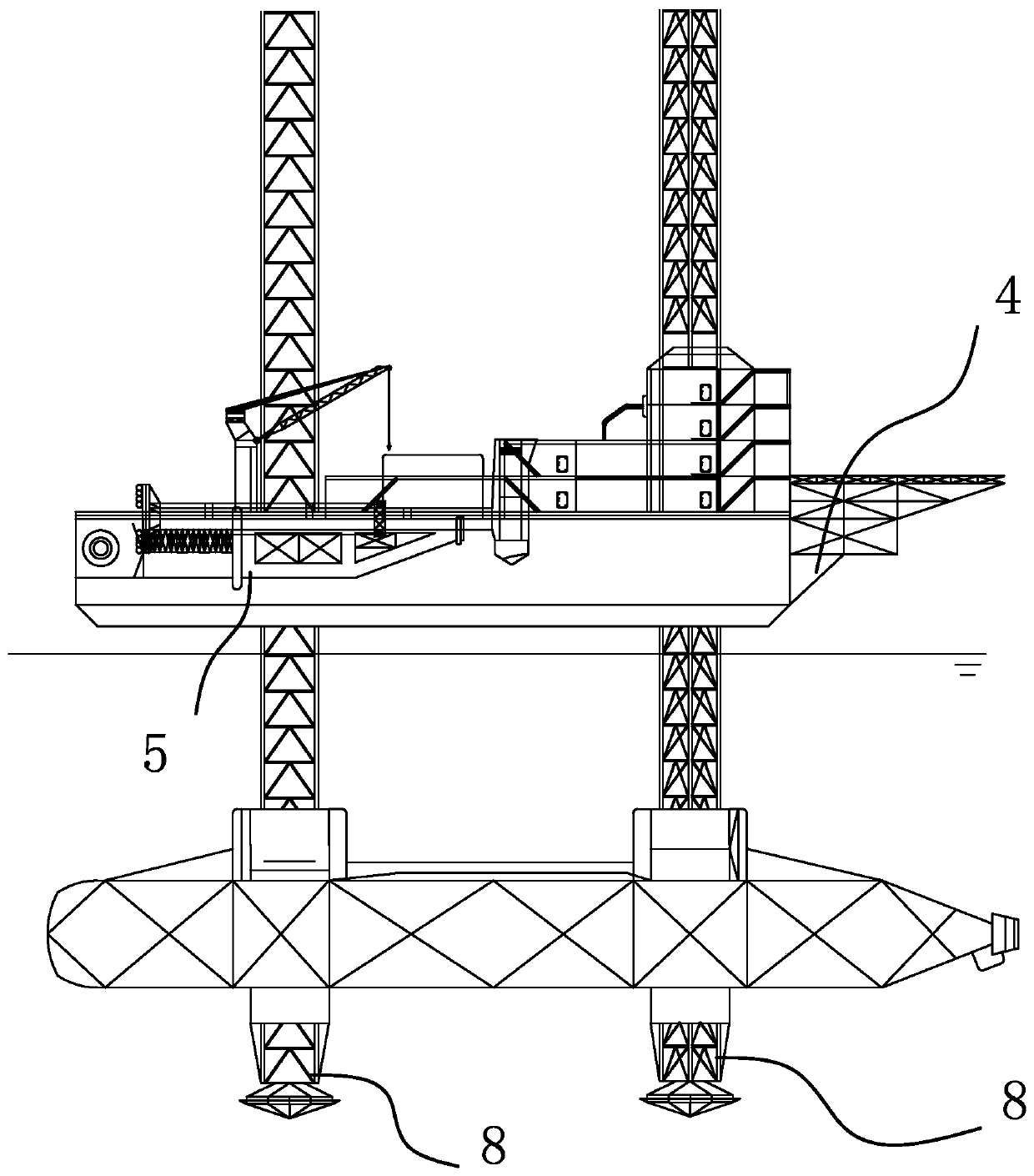

Self-installed ocean floor drilling template and installation method thereof

InactiveCN103556972ASimplified installation procedureShorten the installation periodBorehole/well accessoriesBulkheads/pilesBuoyOffshore drilling

The invention discloses a self-installed ocean floor drilling template and an installation method thereof. The self-installed ocean floor drilling template comprises a pile foundation, a guide post and a wellhead guide framework, the pile foundation is a suction pile, the suction pile and the guide post are connected into an integral structure through the wellhead guide framework, the integral structure can be conveniently leveled in the suction immersion process, and a pump opening is formed in the wellhead guide framework and used for installing a submersible pump for extracting water in the suction pile. The self-installed ocean floor drilling template has the advantages that the self-installed ocean floor drilling template can be assisted in underwater towing by a buoy and can be lowered in water by an inherent small lifting device on a ship after reaching an installation position, the template can be leveled in the negative pressure immersion process of the suction pile, piling operation and grouting operation are omitted, a special leveling device for leveling operation is omitted, installation procedures of an offshore drilling template are simplified, offshore installation period is shortened, and construction cost is reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Self-compensating direct quick-connection pipeline

A self-compensating direct quick-connection pipeline comprises a left head 1, a pipeline 2, a right head 3 and a rubber sealing ring 4, is used for the contra-aperture quick connection of pipelines, and solves the defects that the prior pipe connection technique has high cost and poor practicability, wherein the left head 1 is inserted into and spirally buckled with the inner cavity of the right head 3, the rubber sealing ring 4 is compressed and sealed therein. The pipe fittings and valves of the self-compensating direct quick-connection pipeline are resistant to high pressure, medium pressure and low pressure, do not pull screw thread, are not welded, are not in flange mode, channeling mode and electric heating melting mode, are not additionally added with a compensator, are capable of realizing direct contra-aperture quick connection of the pipelines in severe environment conditions, such as lofty mountains and steep hills, deserts, water of rivers, lakes and seas, narrow space, windy, rainy, high-temperature and chill weather, combustible and explosive places, provide self-compensating lockable rigid-flexible omnibearing safety sealing, save labor and time, and have low cost, high efficiency, energy conservation and environment protection. The invention provides the self-compensating direct quick-connection pipeline for conveying fluids.

Owner:王甲南

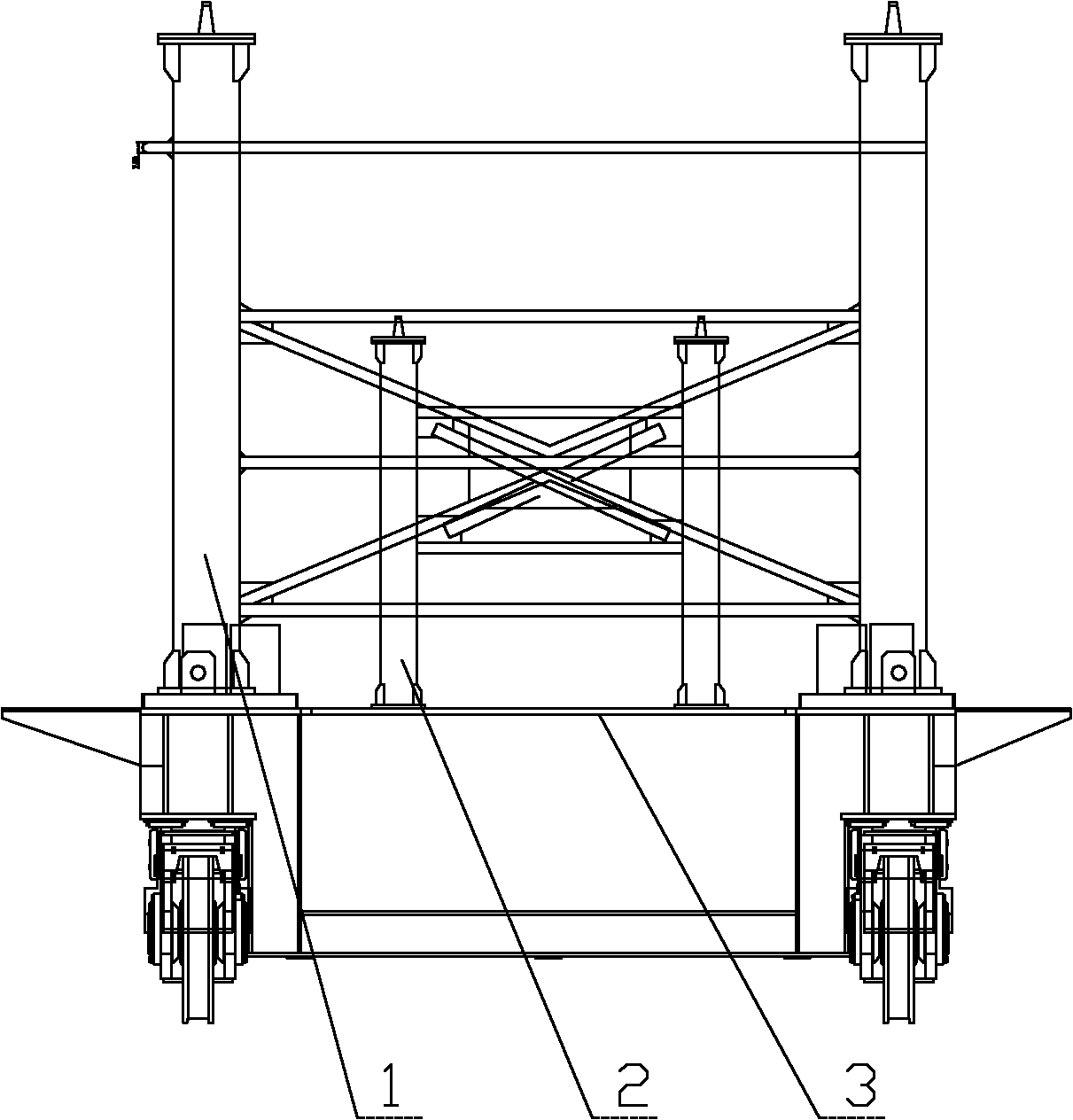

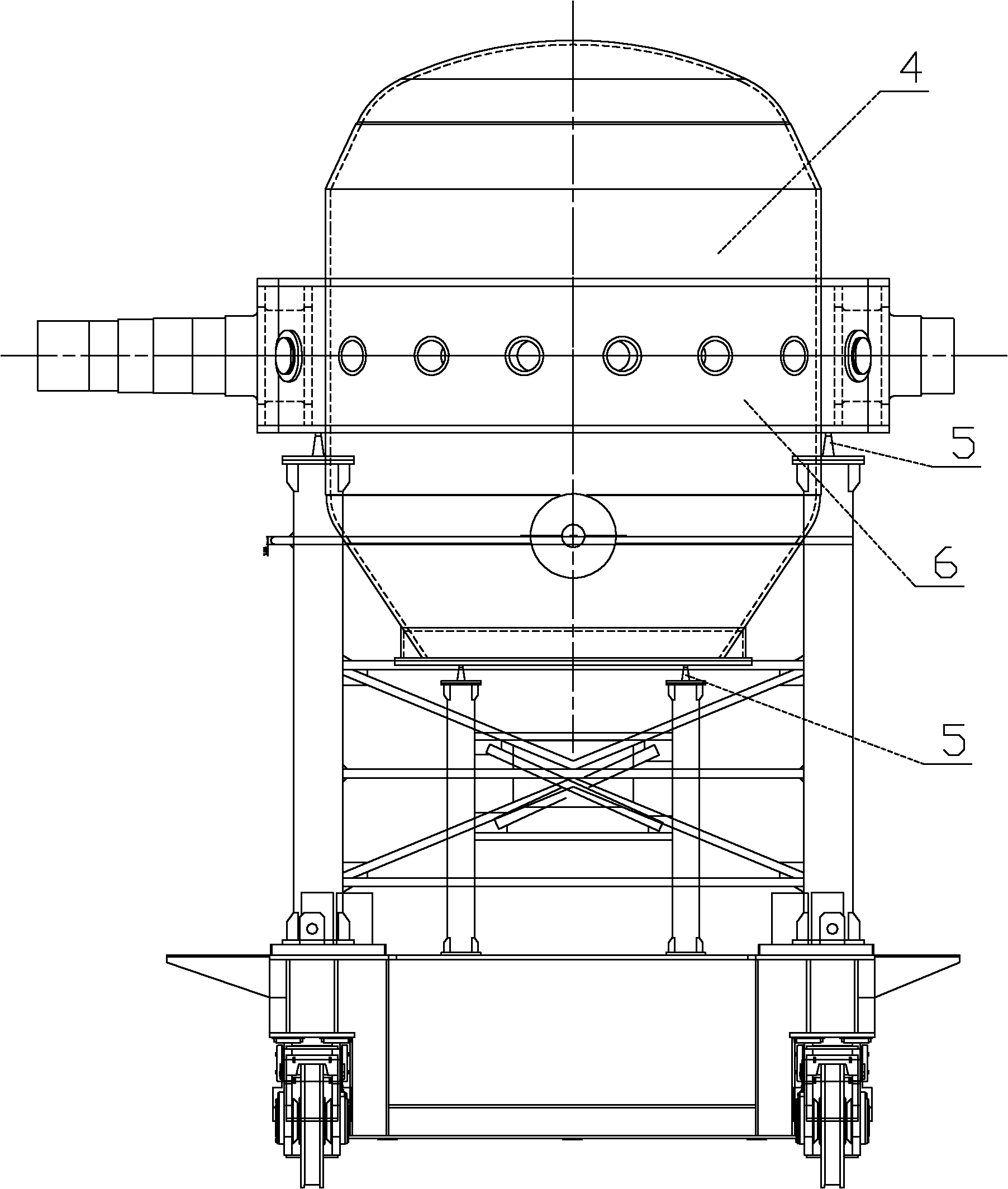

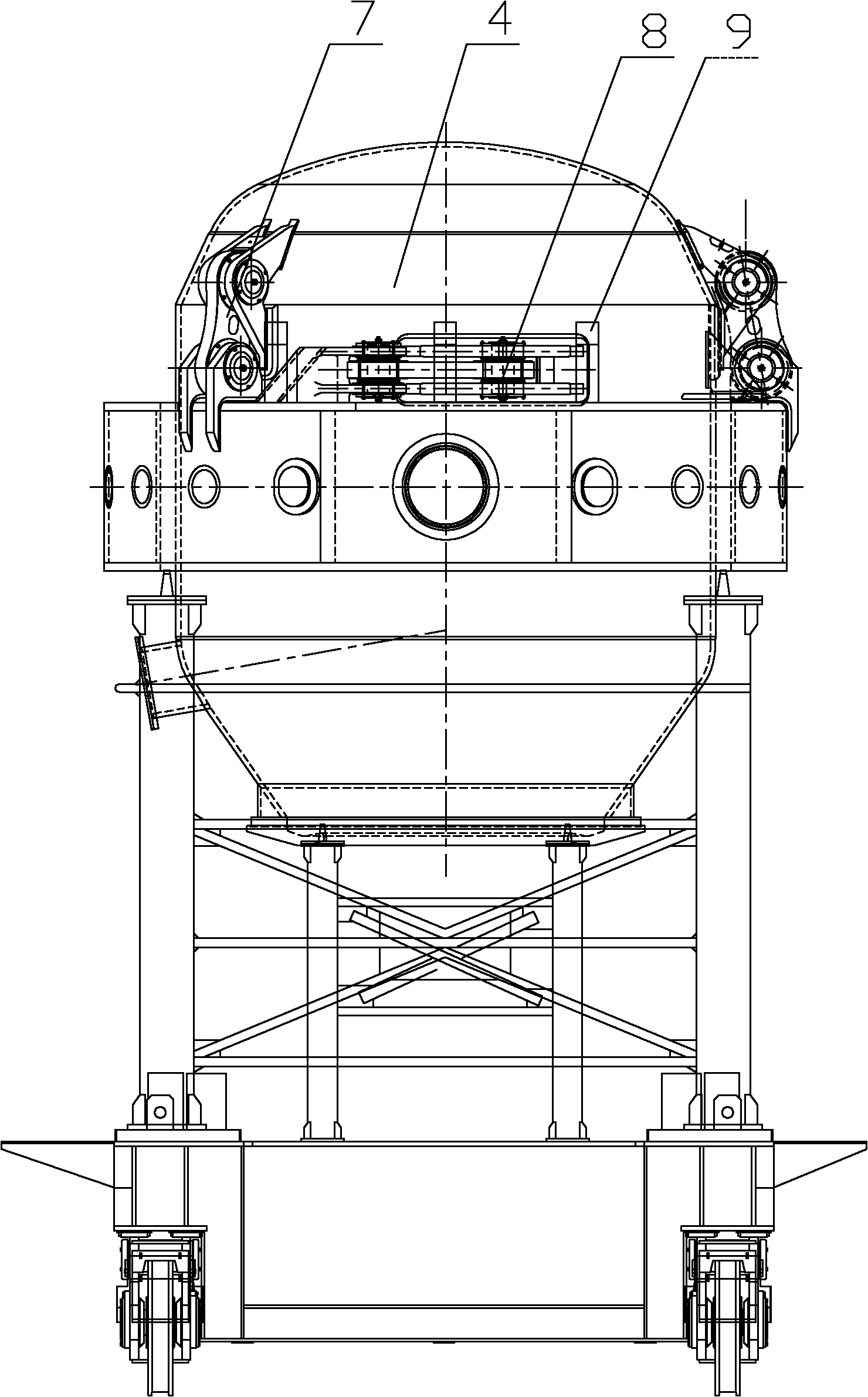

Integral hydraulic jacking inverted construction method of large converter

ActiveCN102010927AShorten the installation periodReduce construction costsManufacturing convertersTrunnionWelding

The invention discloses an integral hydraulic jacking inverted construction method of a large converter, comprising the following steps: 1) in an additive bay, fixedly installing a converter shell bracket and an integral bracket on a ladle car, and building an erecting stage on the integral bracket; 2) successively inverting and hoisting the welded converter shell and backing ring which are welded into a whole on the converter shell bracket and the integral bracket, respectively adjusting the positions of the converter shell and the backing ring by a hydraulic jack to cause the relative positions of the converter shell and the backing ring to satisfy a design requirement, and ensuring that a center elevation is bigger than a designed elevation; 3) installing and hanging; 4) moving the ladle car to transport the converter to the base of the converter, finishing installation of a trunnion bearing pedestal before transporting; and 5) lowering the backing ring to cause the bearing pedestal to land on the base, and fixing after adjusting. In the invention, the phenomenon that the additive bay of a converter workshop uses a large crane is avoided, a jack is adopted to adjust the positions of the backing ring and the converter shell, and construction is convenient. The converter is assembled in the mode that the backing ring and the converter shell are inverted, and hoisting and welding are easy to operate.

Owner:TIANJIN 20 CONSTR

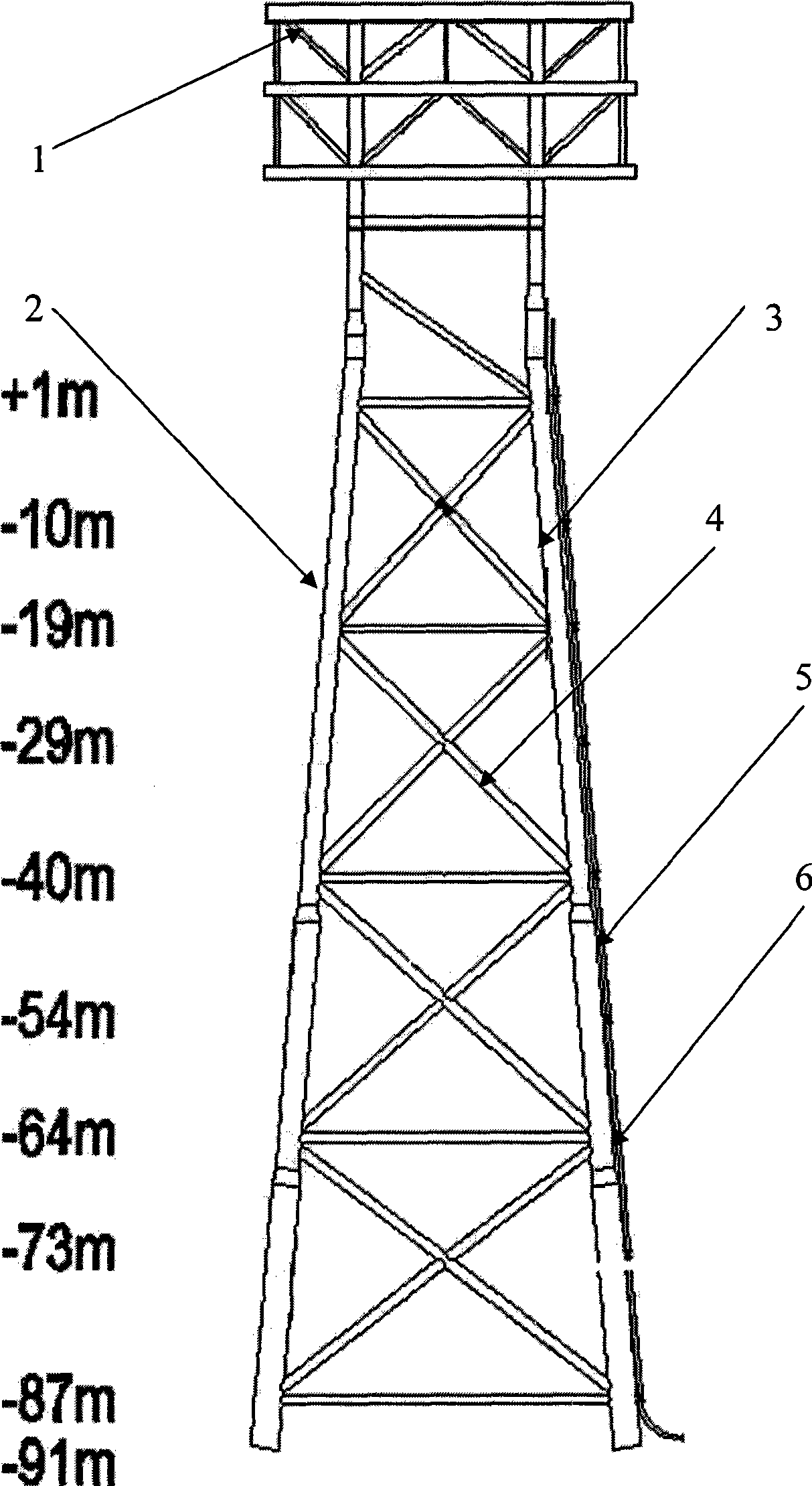

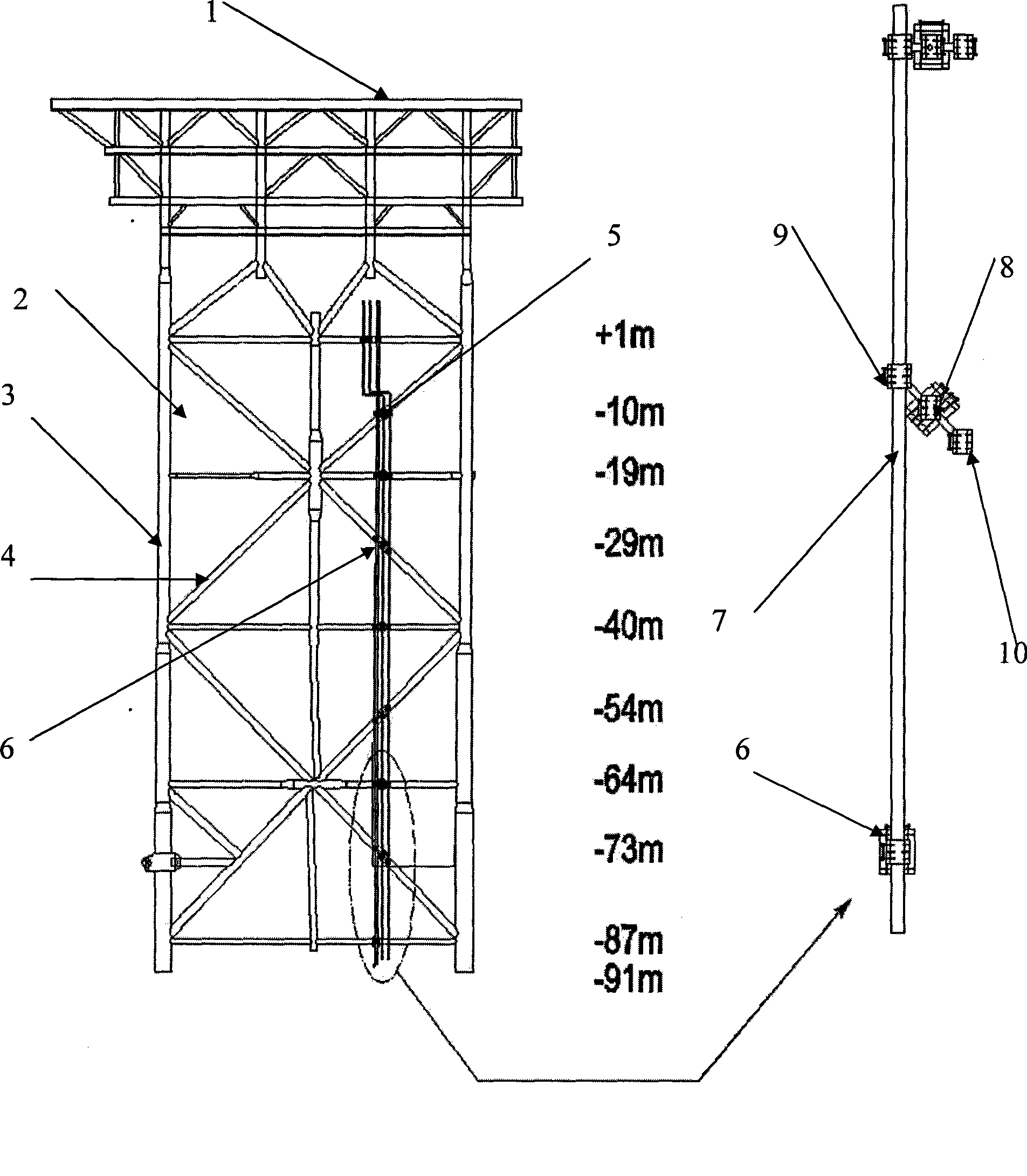

Installation method of riser clip on offshore jacket

InactiveCN101363218AImprove installation efficiencyEliminate coaxial adjustment workArtificial islandsUnderwater structuresLine tubingEngineering

The invention discloses an installation method of the vertical pipe clamp of a jacket, which comprises the following steps: marking, clamp installation, swinging, initial installation, continued installation and wiring, wherein, in the step of the marking, a diver sets an underwater mapping and installation location; in the step of the clamp installation, in accordance with the measured sizes, a plurality of small clamps are fixed on the pipe at intervals, lifting points are provided on the pipe and large clamps are opened; in the step of the swinging, the pipes are lifted to the installation location and the driver is responsible for the underwater command that a windlass straighten the location of the pipe on a platform; in the step of the initial installation, the large clamps are fixed on a lacing pipe from bottom to top, the small clamps are opened and the pipes are lifted to the platform; in the step of the continued installation, the clamps at the higher installation position are installed in sequence by circularly carrying out clamp installation, swinging and initial installation; and in the step of the wiring, the pipelines are arranged into the small clamps.

Owner:CHINA NAT OFFSHORE OIL CORP +3

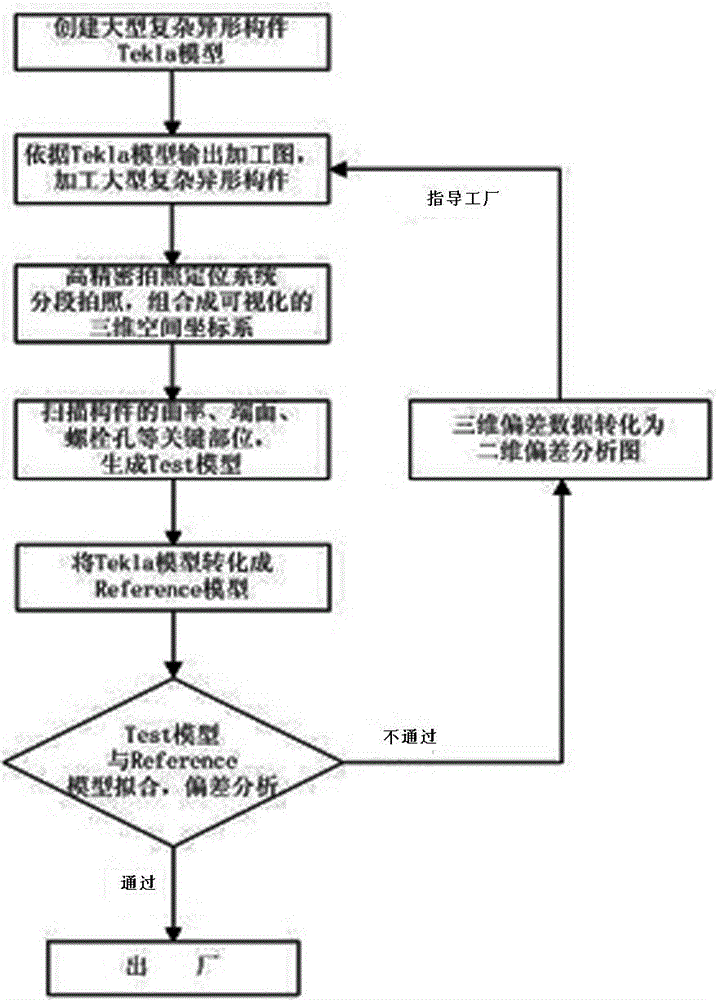

Deviation analysis and factory correction guiding method of large-scale complicated special-shaped steel component

InactiveCN106247931AImprove measurement efficiencyHigh measurement accuracyUsing optical meansThird partyComputers technology

The invention discloses a deviation analysis and factory correction guidance method for large complex special-shaped steel components, which analyzes and corrects the deviation of large complex special-shaped steel components based on comprehensive technologies (computer technology, reverse forming, virtual reality, and three-dimensional scanning technology). Including the following steps: create a steel member Tekla model; make steel members; make a 3D coordinate system for steel member visualization; reversely generate a 3D Test model; convert the Tekla model into a third-party Reference model; make a 3D deviation color difference map; and The deviation part is cut on any surface, and the two-dimensional view deviation analysis diagram is made; the deviation steel member is trimmed. The present invention digests the problems existing in on-site installation in the factory in advance, greatly improves the efficiency of on-site installation, shortens the installation period, and thereby improves the overall progress.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

Three-incompetent bed cutting hole large section construction and supporting method

ActiveCN105041323AShorten the installation periodReduce investmentTunnelsAnchoring boltsSupport materialsBuilding construction

The invention relates to a three-incompetent bed cutting hole large section construction and supporting method. The method sequentially comprises a step of cutting hole construction and supporting and a step of cutting hole large section secondary brush expansion construction and supporting. The cutting hole construction step comprises a step of large section primary construction and a step of cutting hole normal section construction. The three-incompetent bed cutting hole large section construction and supporting method has the advantages of shortening a working face installing construction period, reducing the project amount of cutting hole blasting brush expansion during the working face installing period, lowering workers' labor intensity and reducing investment of a supporting material.

Owner:LONGKOU MINING GRP

Method for installing tail shaft on 10,000DWT roll-on-roll-off ship as well as dedicated roller tool

InactiveCN101934464AEasy to installEasy to adjustMetal working apparatusMetal-working hand toolsPulp and paper industryScrew thread

The invention provides a method for installing a tail shaft on a 10,000DWT roll-on-roll-off ship as well as a dedicated roller tool. The method comprises the following steps: threading the tail shaft of the roll-on-roll-off ship in a tail shaft tube equipped with a front bearing, a middle bearing and a rear bearing in a safe and rapid manner. The dedicated roller tool comprises haff fasteners, a support and a roller, wherein one end of the support is mounted on one haff fastener via threads, and the roller is mounted at the other end thereof. By achieving the safe and rapid installation of the tail shaft on the 10,000DWT roll-on-roll-off ship, the invention can shorten the installation period; meanwhile, by using the dedicated roller tool, the invention can facilitate the installation and adjustment of the tail shaft and prevent the components in the tail shaft tube from being damaged.

Owner:CSC JINLING SHIPYARD

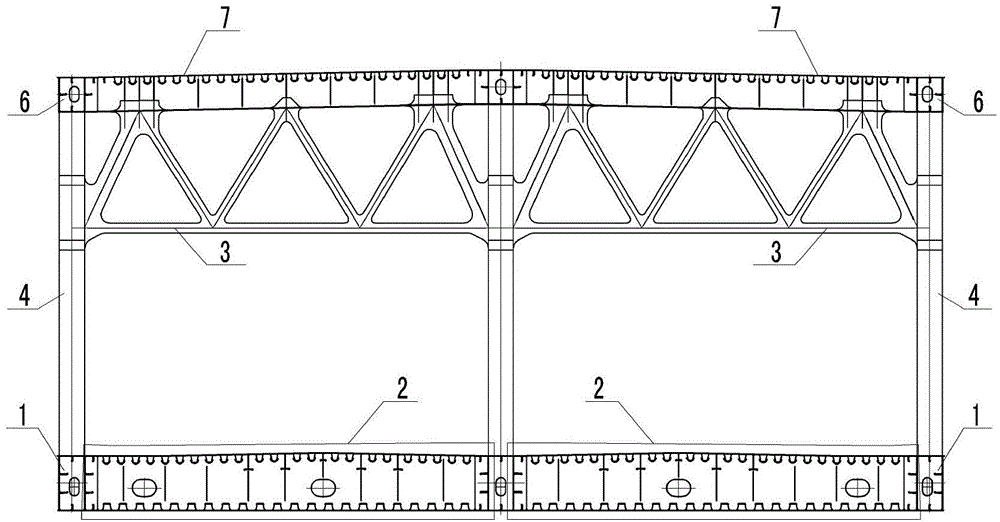

All-welded box girder combination section constructing method

ActiveCN104018427AIncreased durabilityReduce post-maintenance workloadBridge erection/assemblyBridge engineeringBox girder

The invention relates to an all-welded box girder combination section constructing method. The method comprises the specific steps that a girder is divided by making the distance length of two sections serve as one novel box girder combination section, plate units of sectional unit parts are manufactured, a girder lower chord is welded to a lower bridge surface steel box, a girder upper chord is welded to an upper bridge surface panel, a transverse bracing system is welded to a girder vertical rod, the girder vertical rod and an inclined rod are welded to the girder lower chord and the girder upper chord, and the novel box girder combination sections are formed; trial splicing is performed on adjacent novel box girder combination sections on a preset trial assembly platform, and anticorrosion coating is performed on the outer surface. All-welded box girder combinations are welded in place according to a construction order on a bridging construction site. According to the method, the girder is designed into the all-welded box girder combination sections, few hanging units are used, durability of the girder is improved, maintaining workloads during the later period are reduced, site construction is simplified, work efficiency is improved, and an installation period is shortened; the appearance is beautiful, and durability is good. The method has been successfully applied to the Shanghai-to-Nantong railway Yangtze river highway-railway dual-purpose great bridge engineering.

Owner:CHINA MAJOR BRIDGE ENERGINEERING +1

Device used for shear wall elevation and levelness control and use method thereof

ActiveCN105672676AControl elevationControl levelBuilding material handlingWorkloadUltimate tensile strength

The invention discloses a device used for shear wall elevation and levelness control and a use method thereof. The device comprises a levelness control plate, fine adjusting supporting rods are connected to the end face of one side of the levelness control plate, a threaded part is arranged at the end, far away from the levelness control plate, of each fine adjusting supporting rod, and the fine adjusting supporting rods are movably connected to fine adjusting supporting rod support bases. The method includes the steps that S1, when a prefabricated shear wall is produced and manufactured, the fine adjusting supporting rod support bases are pre-buried; S2, the fine adjusting supporting rods are screwed into the fine adjusting supporting rod support bases and adjusted, so that the height of the end face of the top of the levelness control plate is consistent with the height of control elevation of the bottom of a prefabricated wallboard on the upper layer; S3, after concrete reaches certain strength, it is only needed that the prefabricated shear wall wallboard on the upper layer is directly placed on the levelness control plate. The elevation and levelness of the wallboard are effectively controlled, the installation period of the prefabricated wallboard is shortened, labor cost is reduced, and meanwhile wet construction workloads of operators in a construction site are reduced.

Owner:CHINA MCC17 GRP

Device for fast mounting subway tunnel electromechanical equipment and pipelines

ActiveCN107218059AGuaranteed uptimeLow costMining devicesUnderground chambersSteel barMaterial Perforation

The invention relates to the technical field of tunnel construction, in particular to the mounting of subway tunnel electromechanical equipment and pipelines, and specifically discloses a device for fast mounting the subway tunnel electromechanical equipment and pipelines. The device comprises a tunnel segment, an embedded anchor bolt, a plurality of external anti-seismic slide grooves and a mounting support, wherein the embedded anchor bolt comprises a segment positioning device and an anchor bolt body, and each external anti-seismic slide groove comprises a C-shaped toothed slide groove body and at least two mounting bases. The device has the advantages that the embedded bolt is arranged in the tunnel segment to replace a traditional perforation and steel bar embedding process, dense perforation of a tunnel structure is not needed, tunnel structure zero damage is guaranteed, tunnel structure integrity is protected, the service life of the tunnel structure is prolonged greatly, and subway operation safety is guaranteed; damage to construction worker health is avoided; the device is simple in embedding construction, fast in mounting, capable of greatly reducing the mounting period of the electromechanical equipment and pipelines and capable of greatly lowering construction and maintenance costs.

Owner:康元轨道交通科技(福建)有限公司

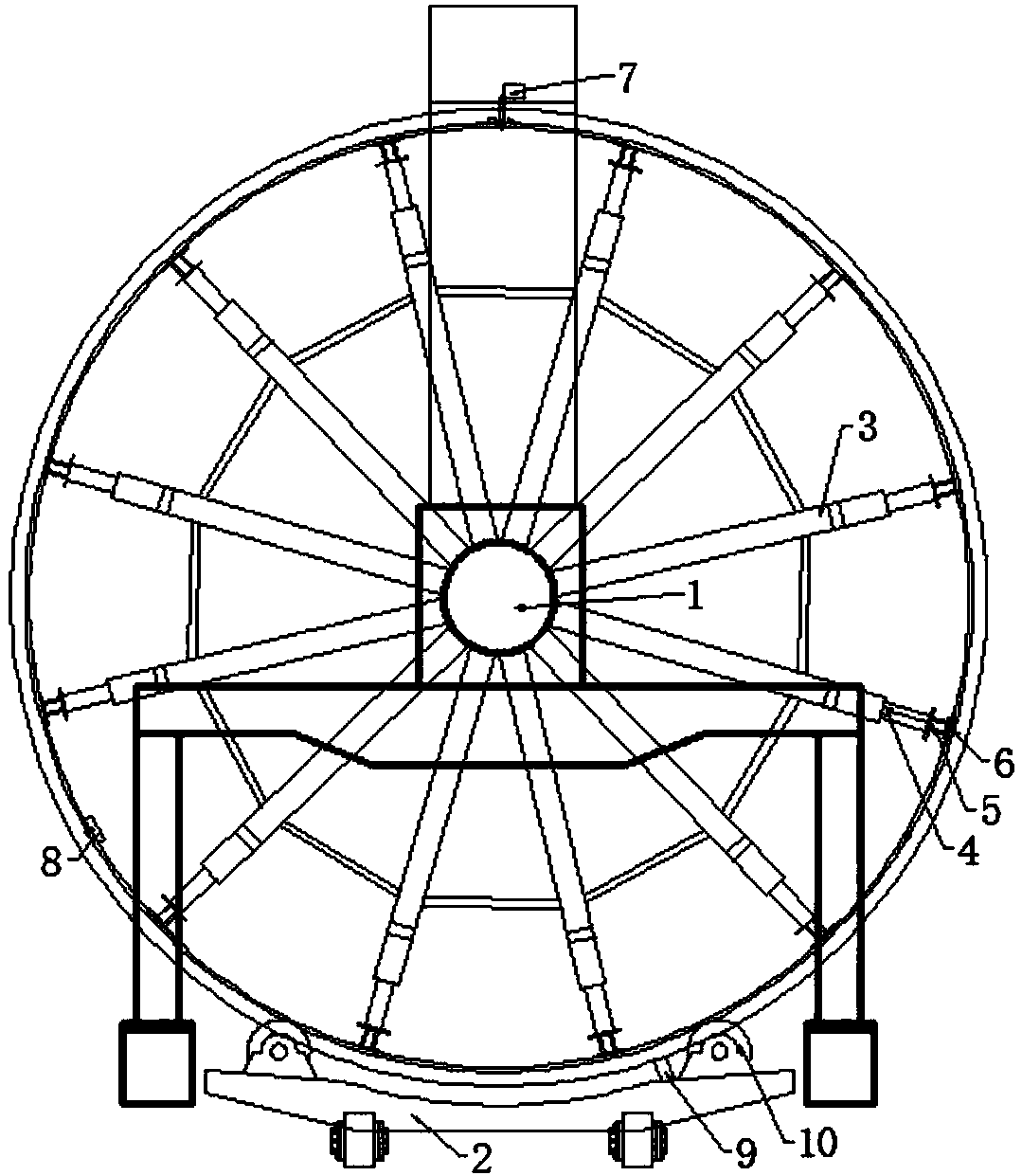

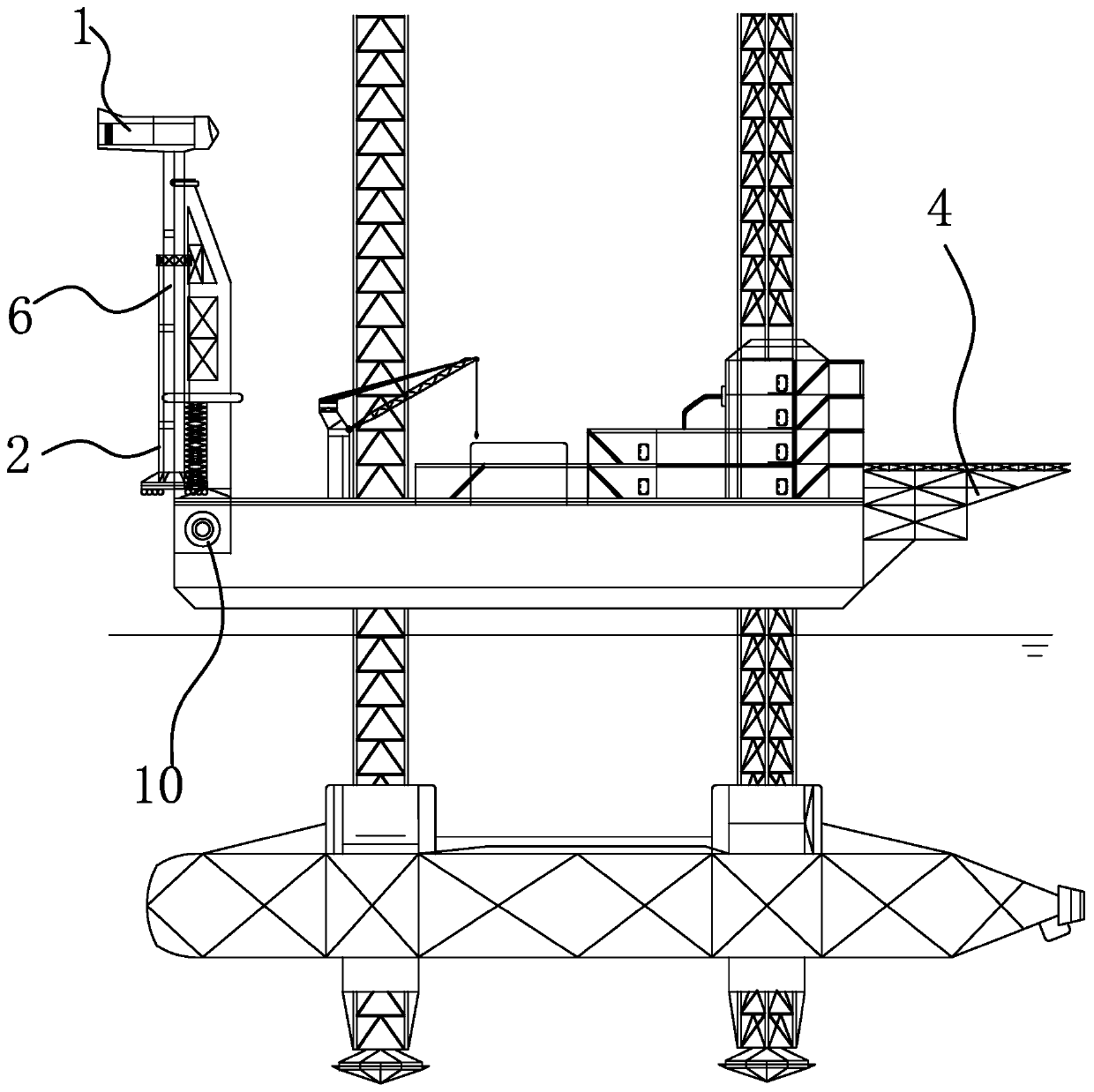

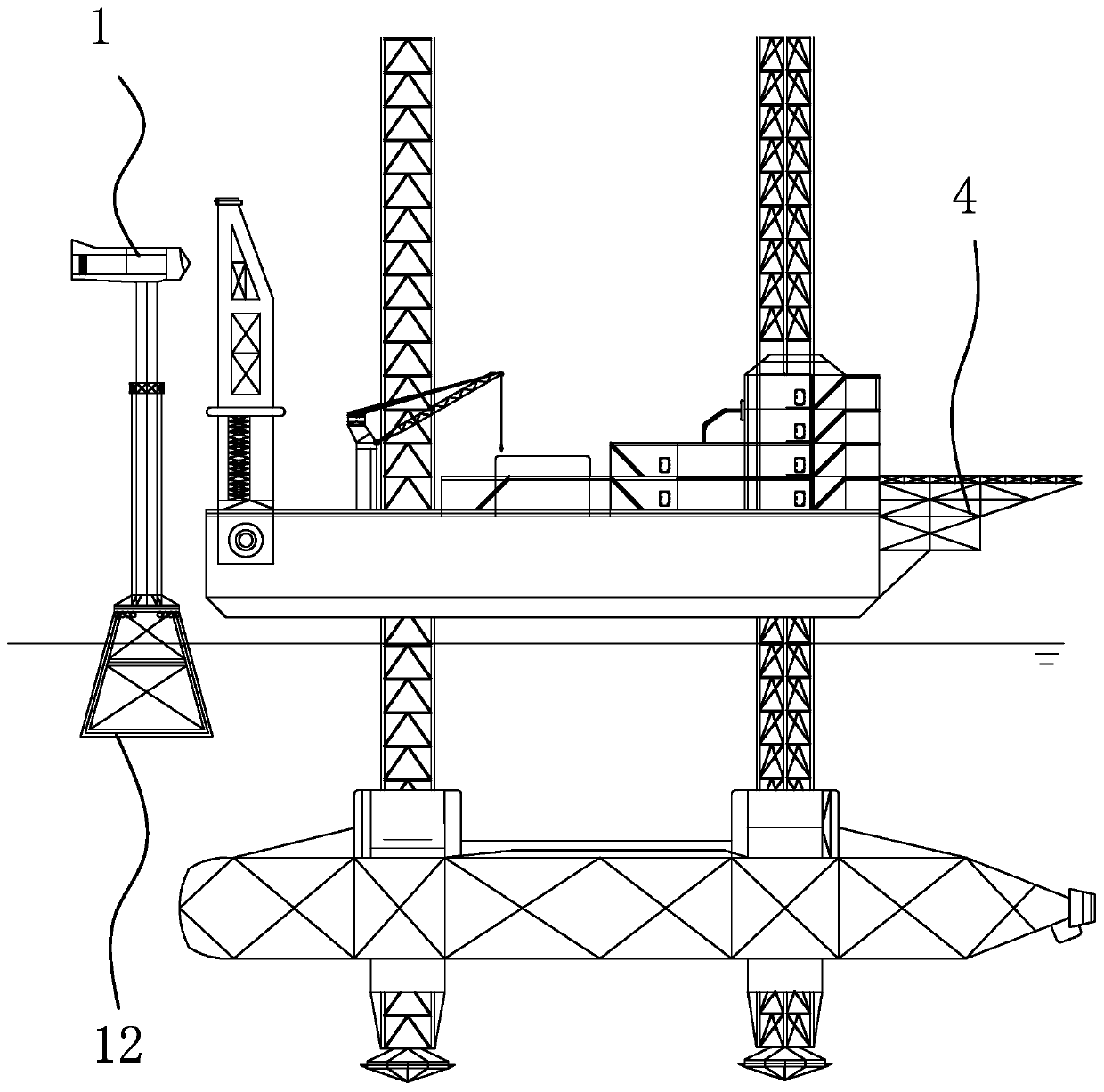

Offshore wind turbine installation method and installation system

ActiveCN109869279AAvoid shakingImprove docking accuracyWind motor assemblyWind energy generationNacelleButt joint

The invention belongs to the technical field of marine machinery, relates to an offshore wind turbine installation method and installation system and aims at solving the problems of large difficulty and the like during butt joint installation of a wind turbine in the prior art. A wind turbine comprises an engine room, a tower barrel and a blade. The installation system comprises a fan mounting ship; the fan mounting ship is provided with a rotating table which can swing between a horizontal position and a vertical position in a reciprocating manner; the rotating table is provided with a translation device capable of moving in the reciprocating manner in a horizontal direction; and the translation device is provided with a fastening device capable of fixing the engine room, the tower barreland the blade and a sliding rail capable of being aligned with a mounting base. For the offshore wind turbine installation method and installation system, when the tower barrel, the engine room and the blade are installed, the sliding rail is designed, so that shaking caused by a wind force during the installation process can be effectively avoided, the butt joint precision during installation iseffectively improved, the butt joint difficulty is lowered, the installation efficiency is improved, and the installation period is shortened.

Owner:ZHEJIANG OCEAN UNIV

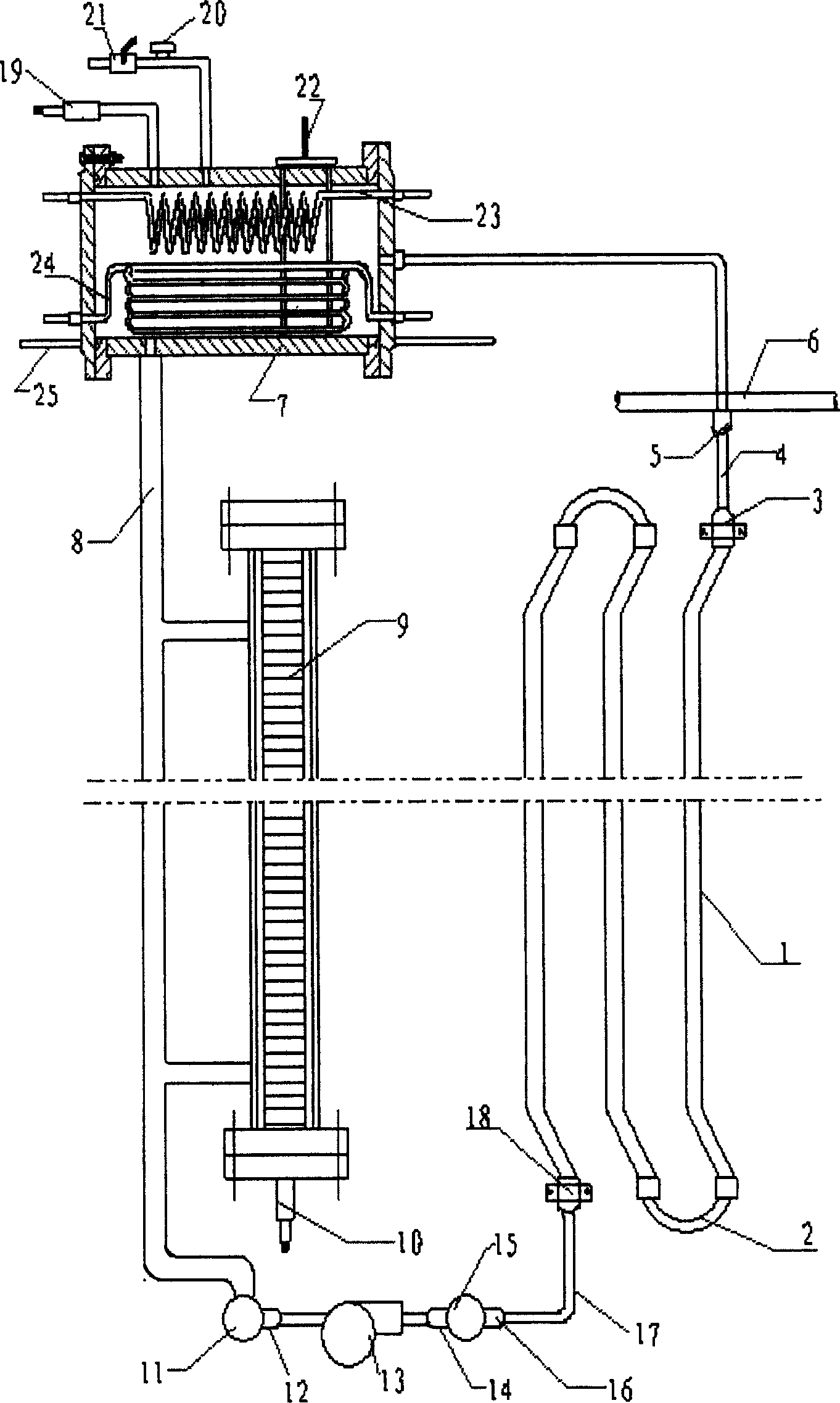

Forced circulation evaporation cooling device of hydraulic generator stator

InactiveCN1617426ARemarkable effectImprove insulation performanceCooling/ventillation arrangementSerial linePressure cycle

This invention relates to a cooling technology of motors providing a forcing circulation evaporation cooling device of a hydrogenrerator stator winding connection pipes connect the stator winding, a condenser, a pressure circulation pump and electro-hydraulic separation joints to an evcaporation cooling loop filled with evaporation cooling medium and a pressure circulation pump forcing the circulation of the evaporation cooling medium is also in the loop, every line-rod set consisting hollow heads and solid leads in the stator winding contains odd N serial line-rods, two leading out ends of the line rod set are connected with the up and down insulation lead pipes by the electro-hydaulic separation joints, several line-rod sets and a condenser constitute an independent evaporation cooling loop.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

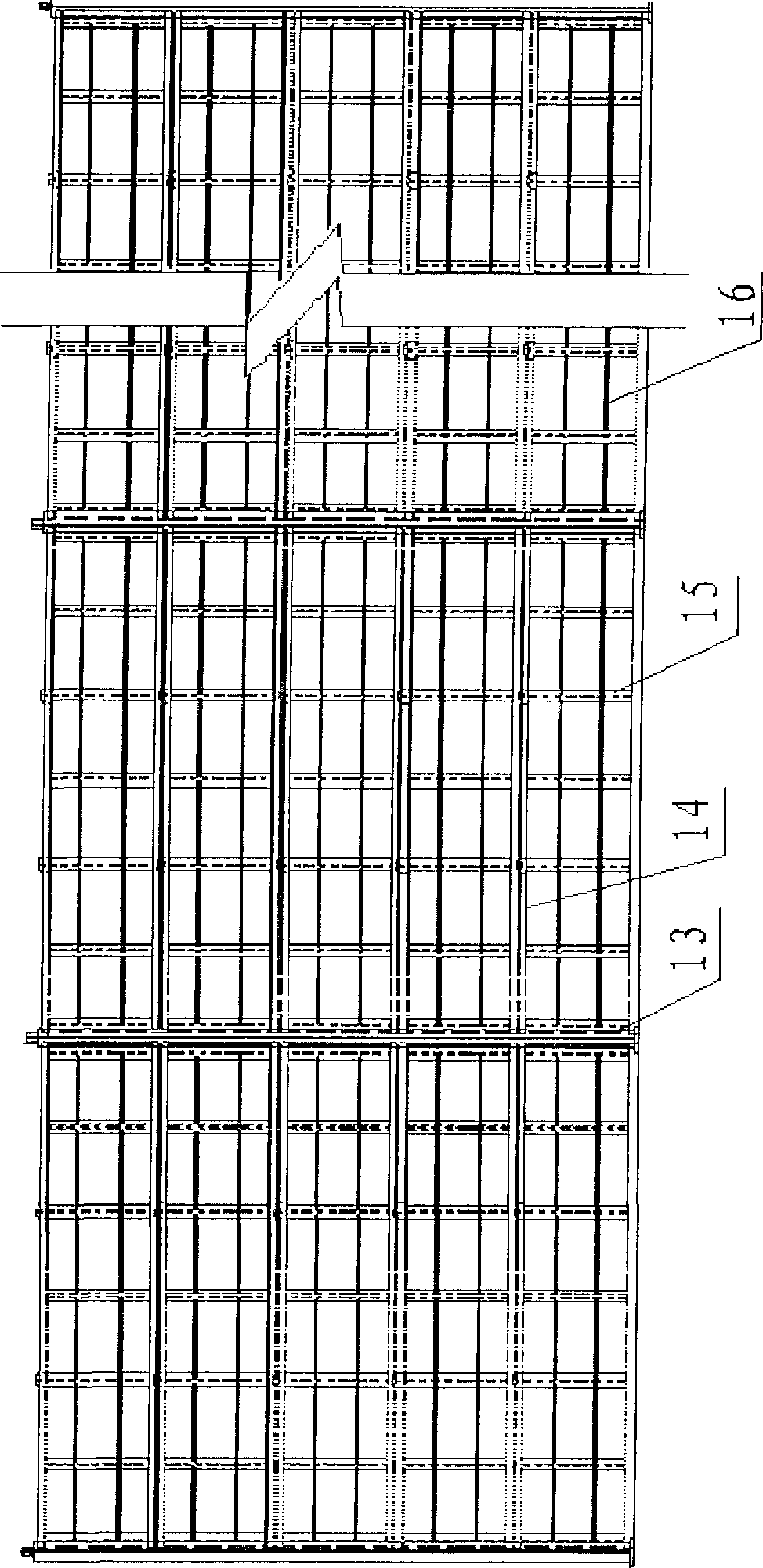

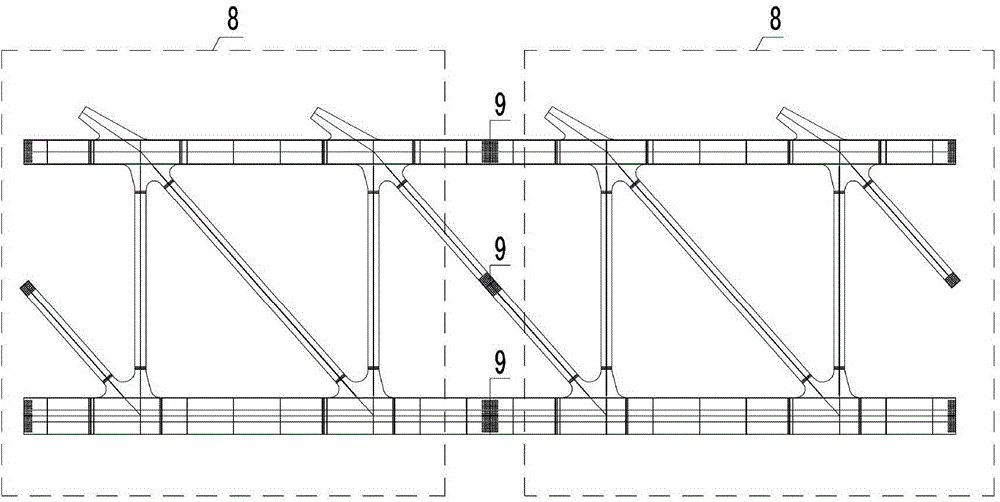

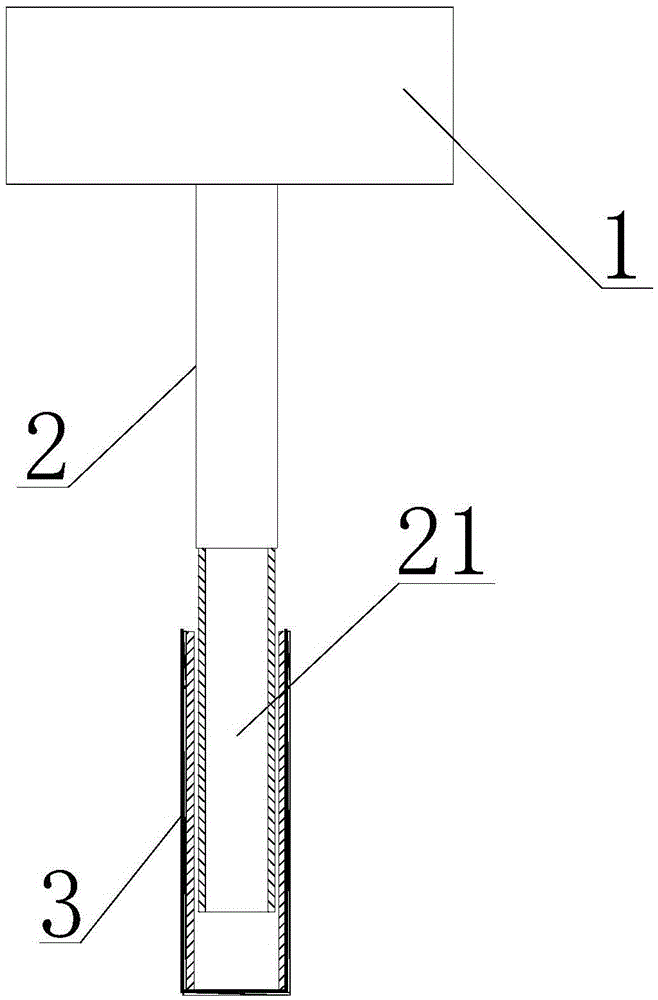

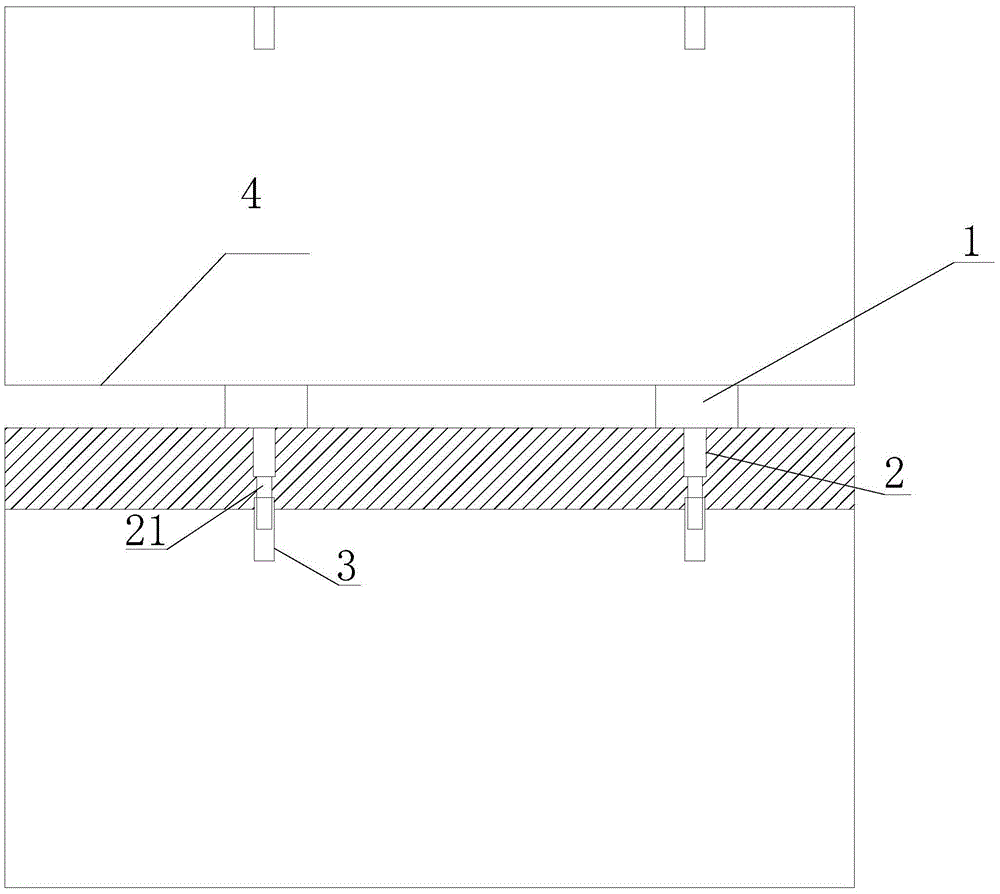

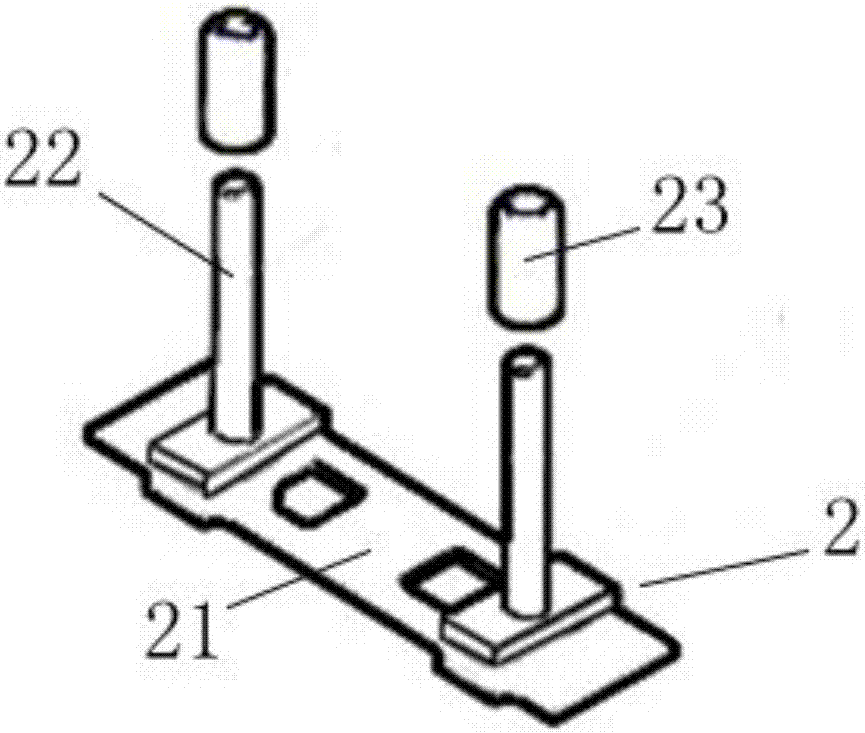

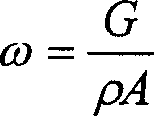

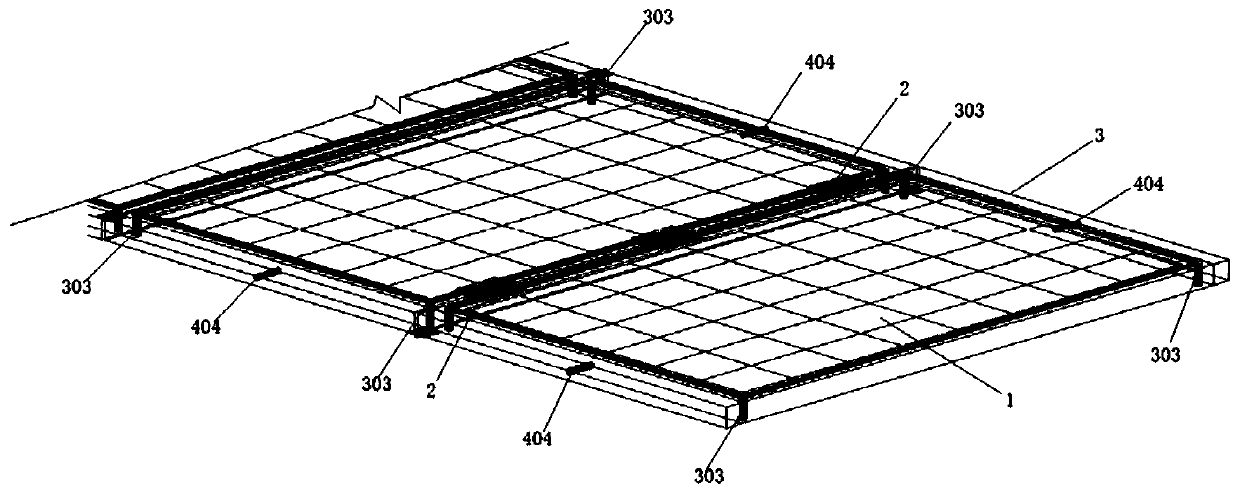

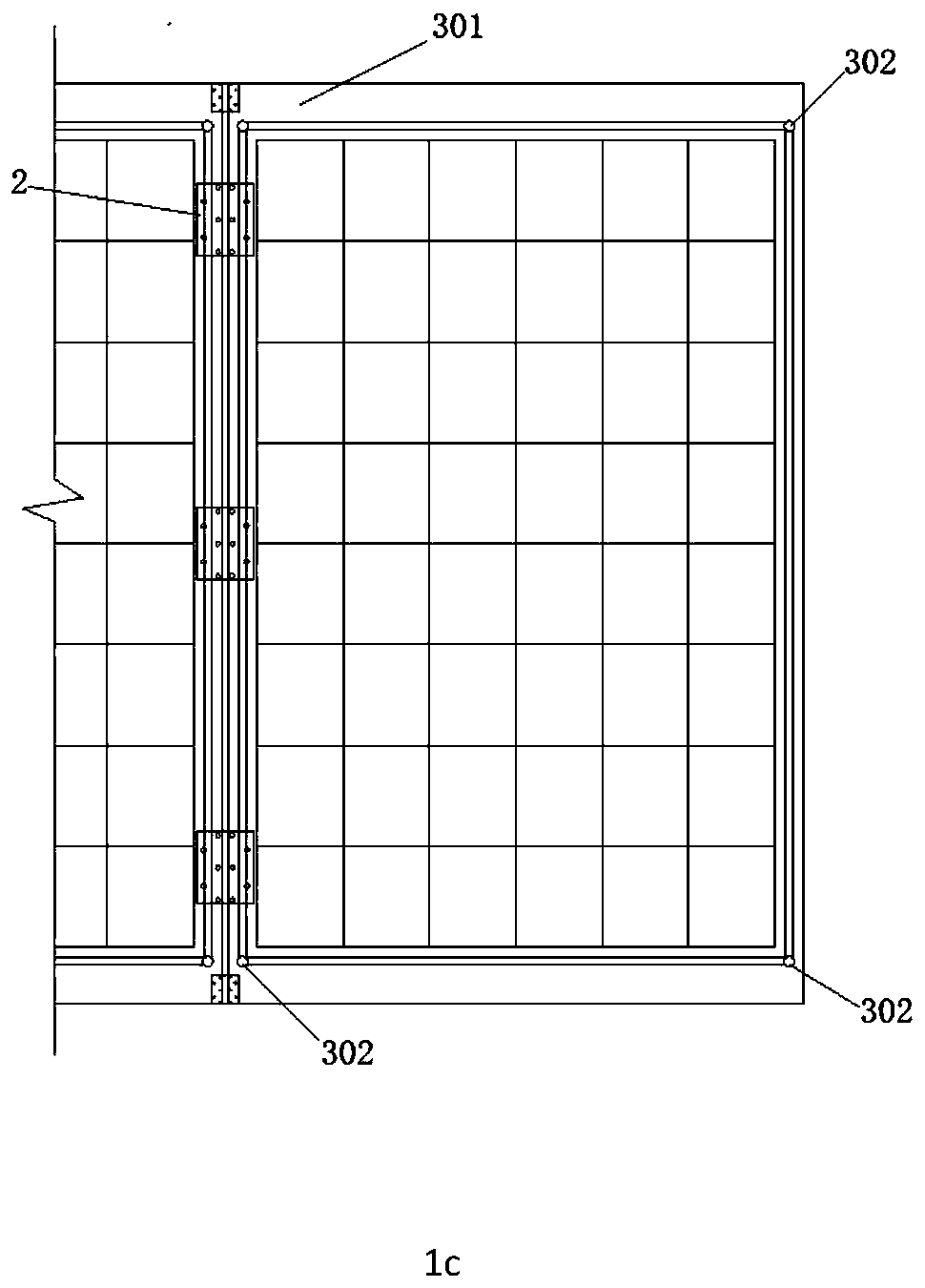

Rapidly-installed photovoltaic module integrated board and installation method

PendingCN110601653AImprove protectionReduce construction costsPhotovoltaic supportsPhotovoltaic energy generationCells panelEngineering

The invention provides a rapidly-installed photovoltaic module integrated board and an installation method. The rapidly-installed photovoltaic module integrated board comprises a plurality of photovoltaic modules, a foldable integrated board fixing frame and a positioning installation device. The foldable integrated board fixing frame comprises a fixing frame component and a positioning hinge. Thepositioning installation device comprises at least two groups of positioning brackets and a driving part; the driving part drives the positioning brackets to move; a linkage mechanism is formed between the positioning brackets and the foldable integrated board fixing frame; and unfolding and folding of the foldable integrated board fixing frame are controlled through the positioning brackets. A plurality of photovoltaic module single boards connected in series are connected through a foldable integrated board fixing frame to form an integrated unit, the structural shape of the integrated unitafter being unfolded is controlled through the positioning angle of the positioning hinge, and the integrated unit is folded to form the size of one photovoltaic module single board or form a plane structure or a curved surface structure after being unfolded. Thus, a photovoltaic cell panel is protected, the transportation and installation efficiency is improved, and the construction cost of a photovoltaic power station is reduced.

Owner:SHANGHAI JIAO TONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com