Self-compensating fastening type large-diameter fast joint

A fastening, large-diameter technology, which is applied in the direction of pipes/pipe joints/fittings, expansion compensation devices for pipelines, and connections that use fluid pressure for packing seals, etc., can solve high manufacturing costs, difficult molding, and practical Poor performance and other problems, to achieve the effect of shortening the installation period, convenient installation and positioning, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in further detail below in conjunction with accompanying drawing and embodiment thereof:

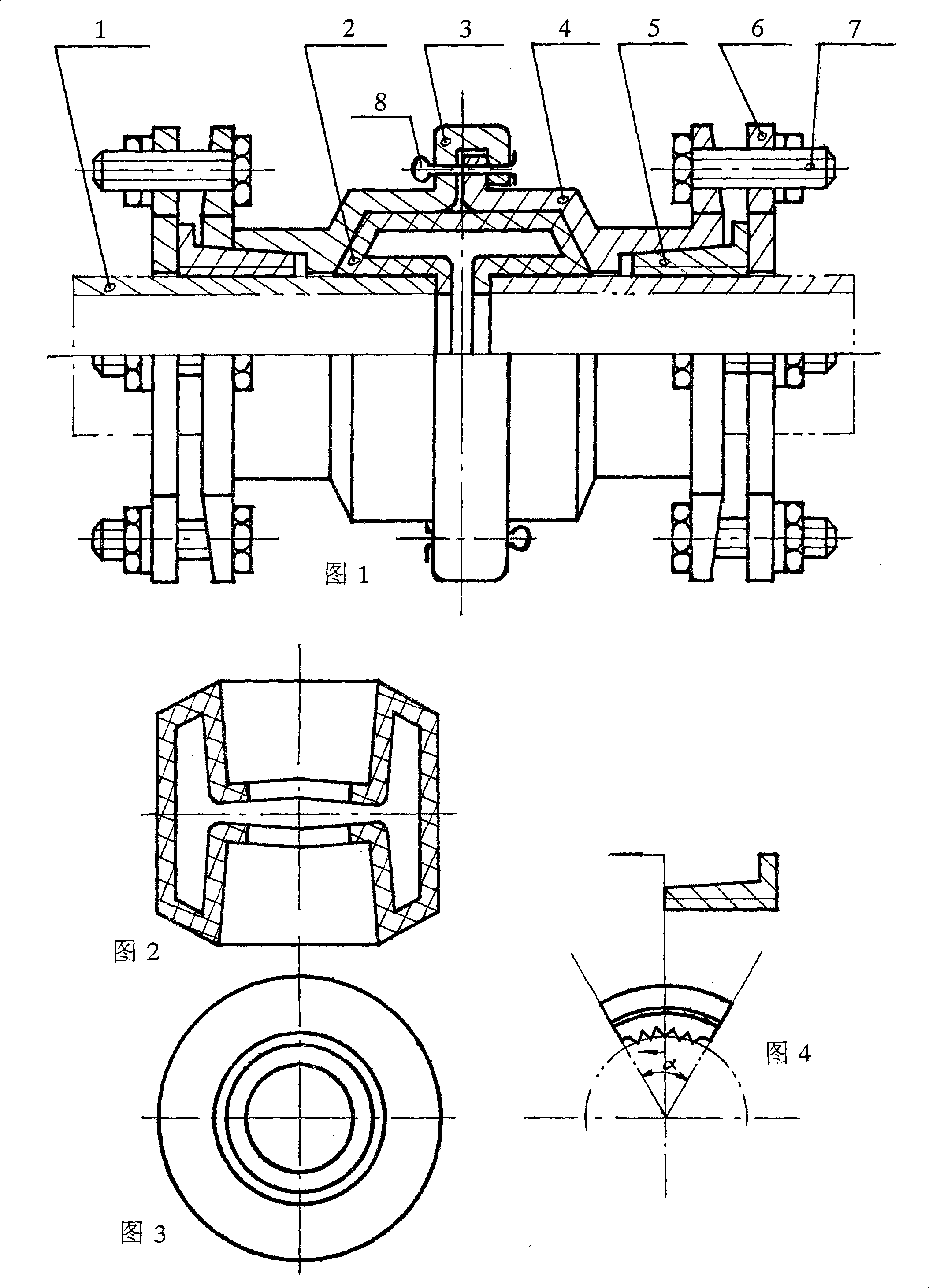

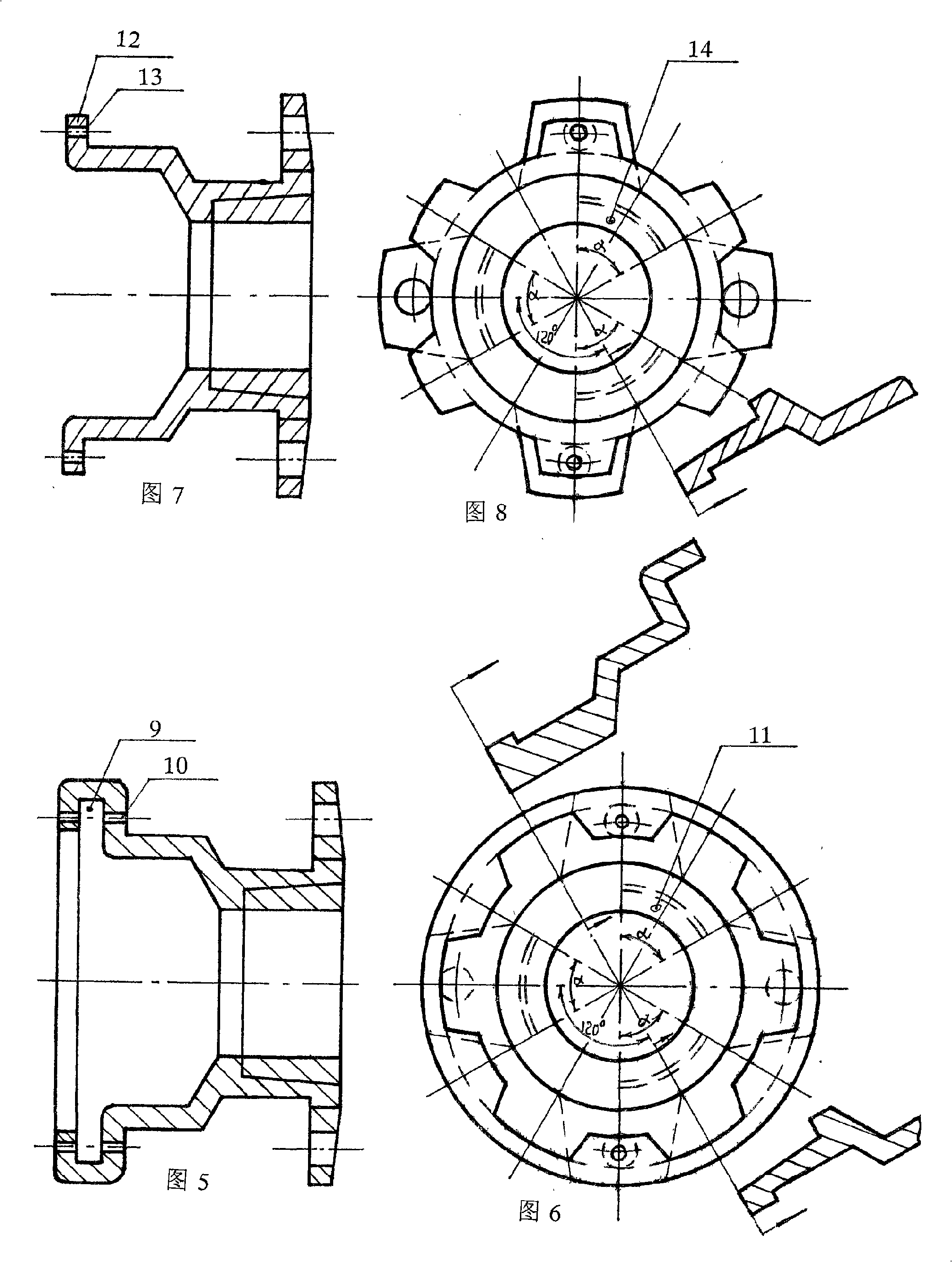

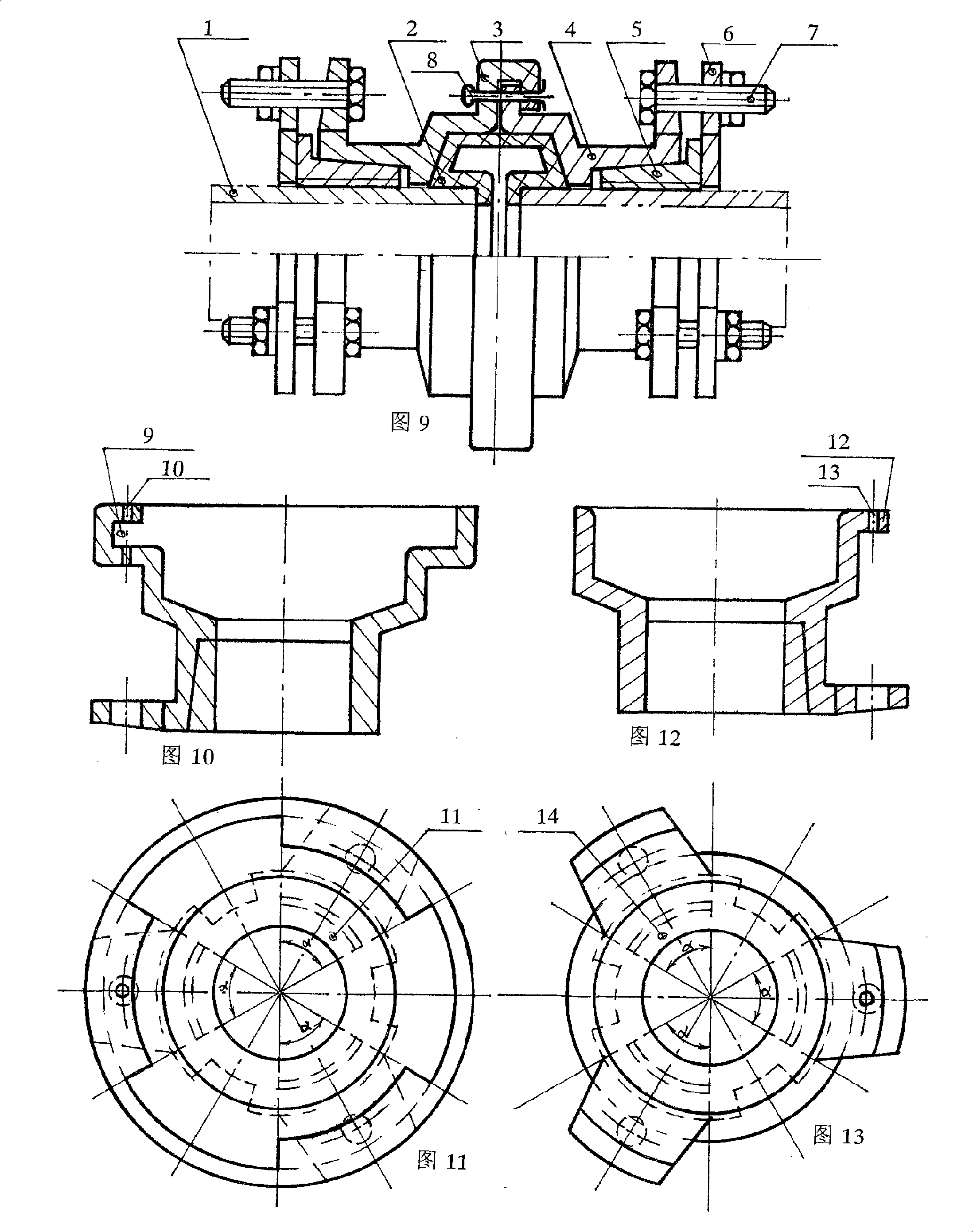

[0040] Figure 1 shows the overall structure of the self-compensating fastening type large-diameter quick connector of the present invention. It is characterized in that the rubber sealing sleeve 2 surrounds the outer circle of the pipe fitting 1, the T-shaped convex ring with an open inner cavity on the rubber sealing sleeve 2 is placed at the ports of the two pipe fittings, and the left and right sleeves 3 and 4 are respectively set on the two pipe fittings 1 and press against the outer surface of the rubber seal 2. The left cover 3 is provided with evenly distributed grooves 9 and is provided with evenly distributed projections 12 to engage with the outer edge of the right cover 4, just like a pot lid and a pot body buckling sealing structure of a pressure cooker. The left and right covers 3,4 are respectively shaped on connecting holes 10,13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com