Device used for shear wall elevation and levelness control and use method thereof

A technology of horizontal control and shear wall, applied in the processing of building materials, construction, building structure, etc., can solve the problems of extremely inconvenient impact of reserved inserts, labor-consuming and time-consuming manual operation, poor control effect, etc. The effect of shortening the installation period, improving construction efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred modes of the present invention will be described in further detail below in conjunction with the examples.

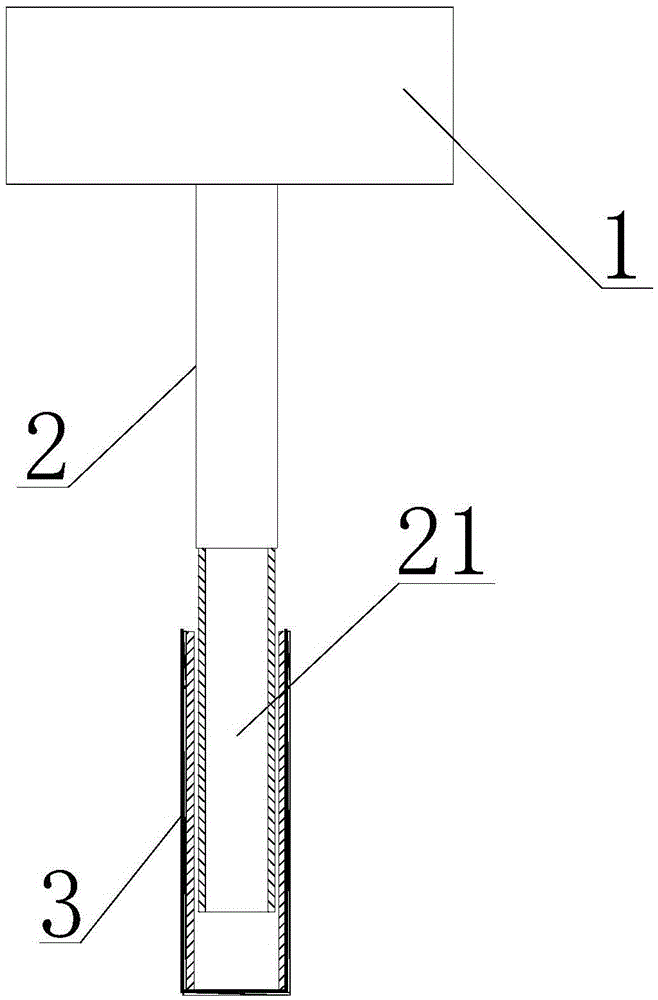

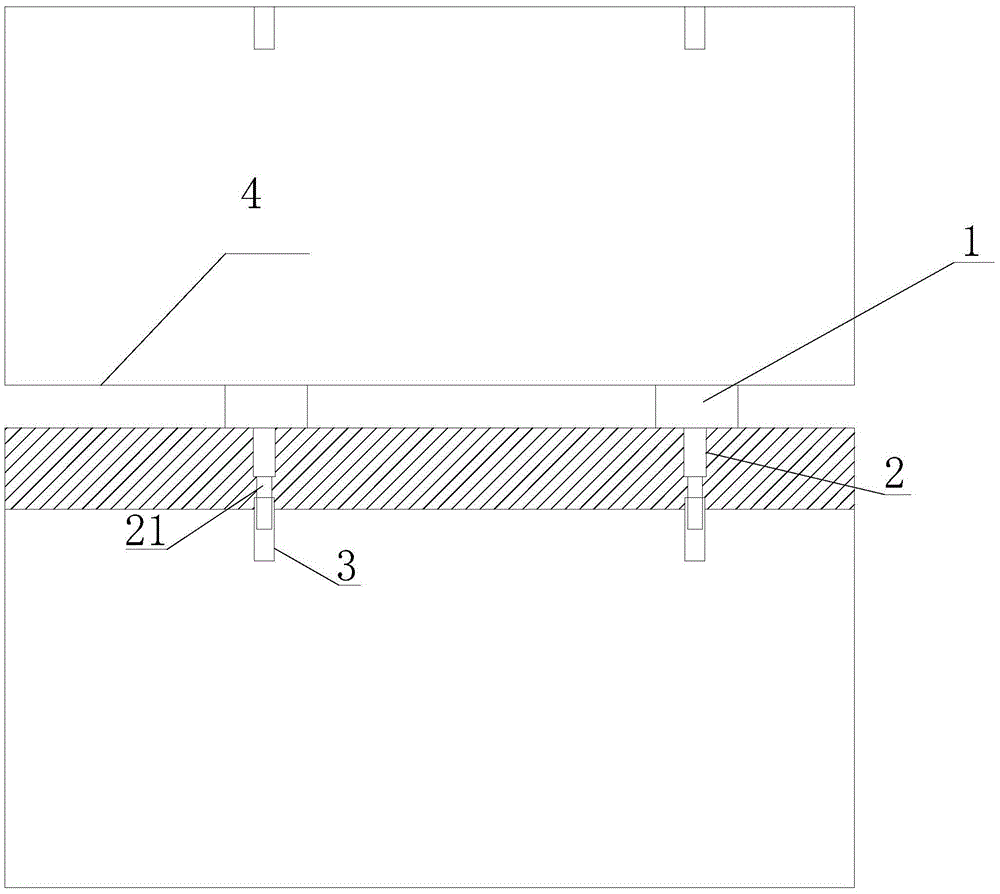

[0017] Such as figure 1 As shown, a device for controlling the elevation and level of a shear wall includes a horizontal control plate 1, which is a steel plate, and the end surface of one side of the horizontal control plate 1 is connected with a wall for supporting the upper shear wall 4 The fine-tuning support rod 2, the fine-tuning support rod 2 is round steel, the end of the fine-tuning support rod 2 away from the horizontal control board 1 is provided with a threaded part 21, the fine-tuning support rod 2 is movably connected with the fine-tuning support rod support 3, and the fine-tuning support rod support 3 is a round pipe provided with an internal thread matched with the threaded part 21.

[0018] In order to further optimize the technical solution, the thickness of the horizontal control panel 1 is equal to the distance from the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com