Pipe trench high-voltage cable concrete support installing and fixing structure and construction method thereof

A technology for high-voltage cables and fixed structures, which is applied in the installation of cables, cable installation devices, electrical components, etc., can solve the problems of the inability to guarantee the extension length of the concrete support, the length of the elevation angle, the long construction time, the large workload, etc. The effect of the offset of the bracket, the improvement of the construction efficiency and the convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

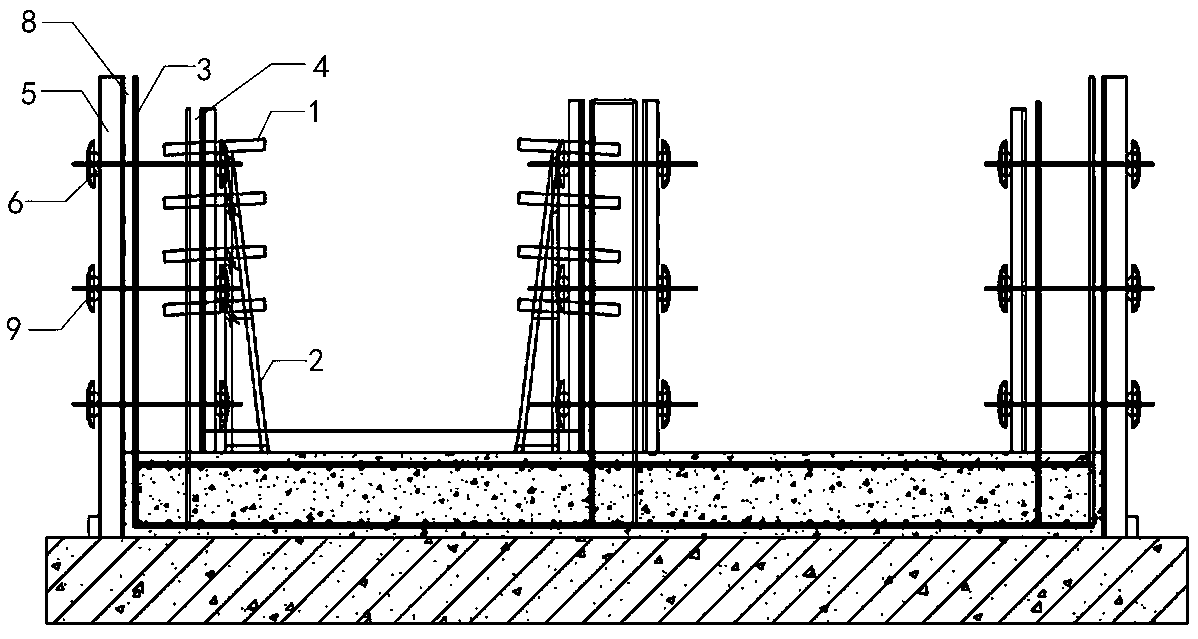

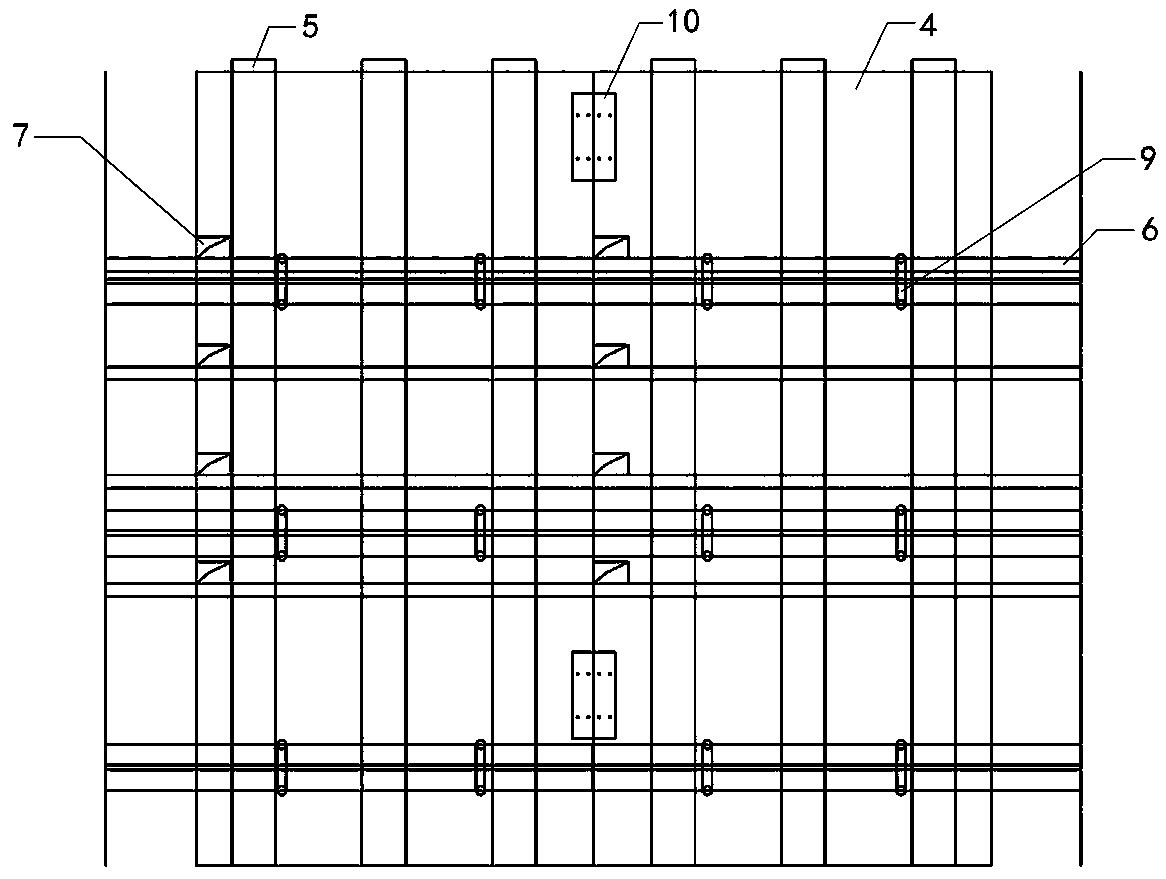

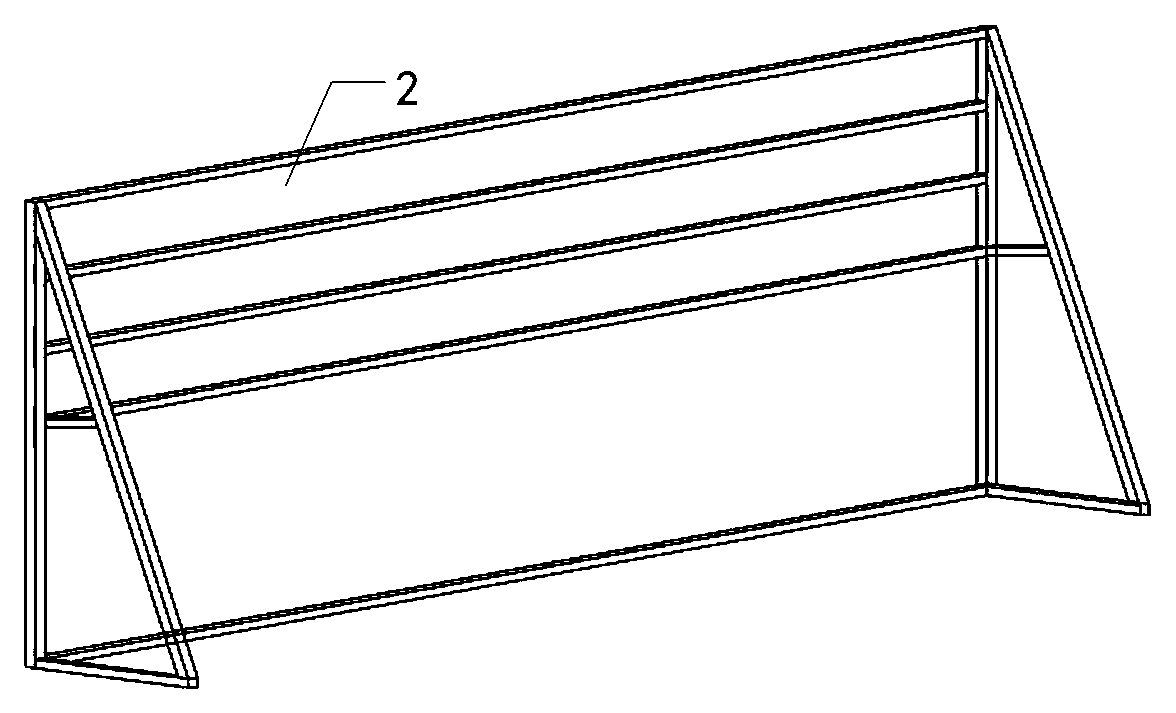

[0037] Examples see figure 1 and figure 2 As shown, a pipe trench high-voltage cable concrete support installation and fixing structure and its construction method, the pipe trench high-voltage cable concrete support installation and fixation structure includes a pipe trench side wall, a concrete support 1 and a fixing frame 2, and one end of the concrete support 1 is pre-prepared Buried in the side wall of the pipe ditch, the other end is supported by a fixing frame 2 arranged on one side of the side wall of the pipe ditch; the concrete support 1 is inclined from the outside of the side wall of the pipe ditch to the inside of the side wall of the pipe ditch; Including the pre-embedded steel bars 3 in the wall, the opening formwork 4 arranged inside the pre-embedded steel bars 3 in the wall, the supporting formwork 8 provided outside the pre-embedded steel bars 3 in the wall, and the main keel 5 arranged vertically outside the formwork 4 , the secondary keel 6 arranged in pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com