Forced circulation evaporation cooling device of hydraulic generator stator

A hydro-generator and generator stator technology, applied in cooling/ventilation devices, electromechanical devices, electric components, etc., can solve the problems of increasing the manufacturing cost of the unit and reducing the reliability, saving investment and operating costs, and reducing replacement. The effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

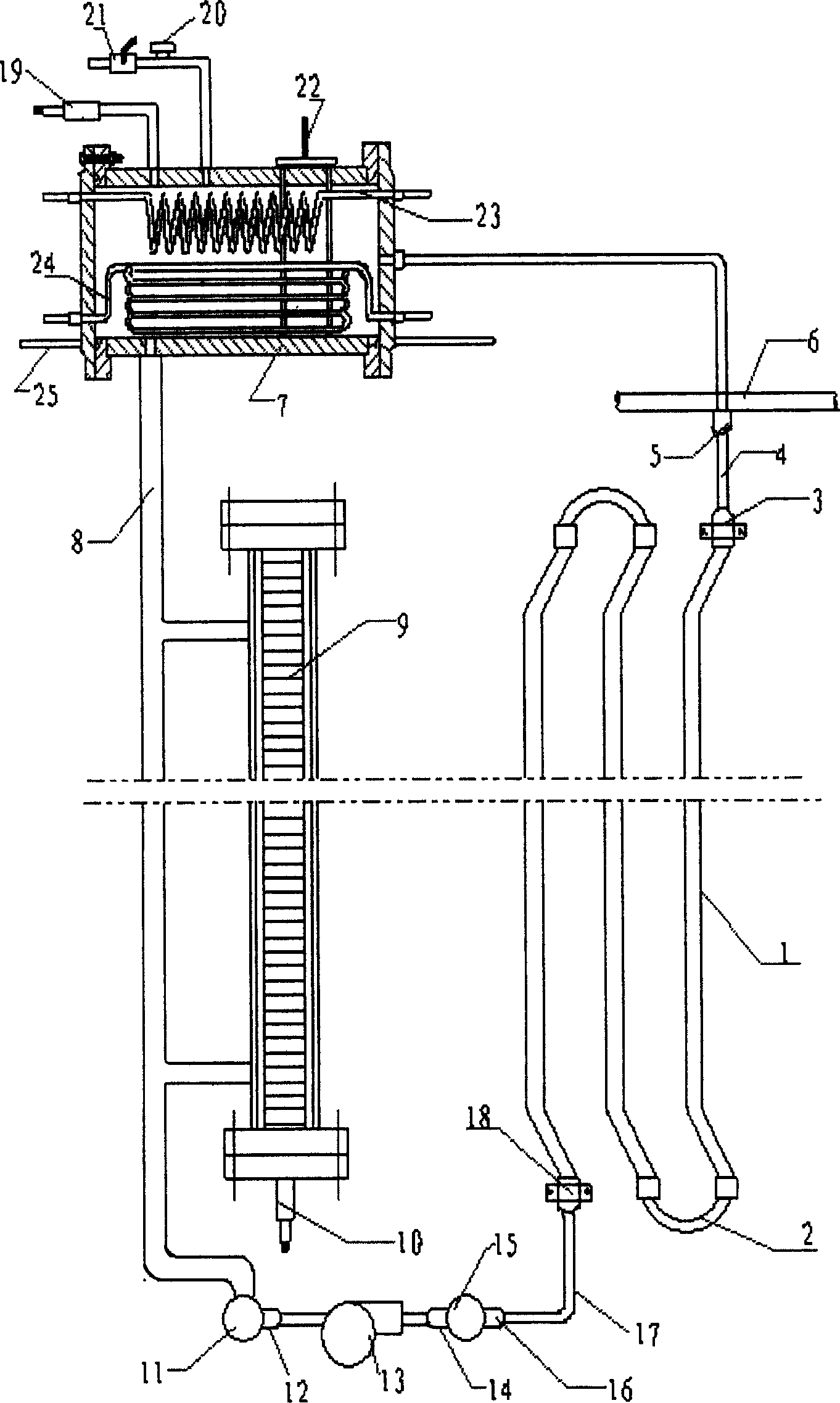

[0043] figure 1Shown is a forced circulation evaporative cooling device for the stator winding of a vertical hydroelectric generator. For the sake of brevity, a wire bar group in which three stator wire bars are connected in series is taken as an example for schematic illustration. The three stator bars are connected end-to-end through the parallel head cover 2 to form a serial stator bar group 1 . The upper end of the stator bar group 1 is connected with the upper insulating lead pipe 4 through the electro-hydraulic separation joint 3 . The electro-hydraulic separation joint is a fixed part that seals the insulating lead pipe and the stator bar. The upper insulating lead pipe 4 is connected with the gas collecting pipe 6 through the sealing joint 5 . The air collecting pipe 6 is connected with the cooling space of the condenser 7 again. The cooling space of the condenser 7 is connected with the liquid return pipe 8 . The liquid return pipe 8 is connected with the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com