Method for installing decorative sheet on substrate surface

An installation method and decorative panel technology are applied in the field of architectural decoration, which can solve the problems of time-consuming, labor-intensive, cost, and affect the appearance, and achieve the effects of soft and comfortable touch, simple and convenient installation, and noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

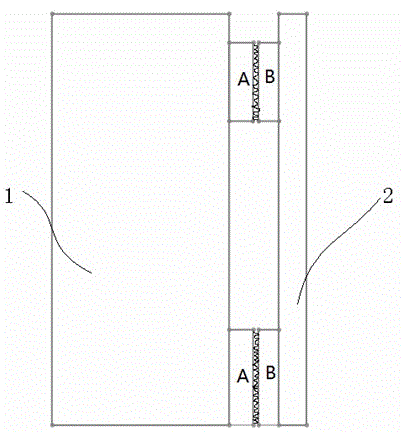

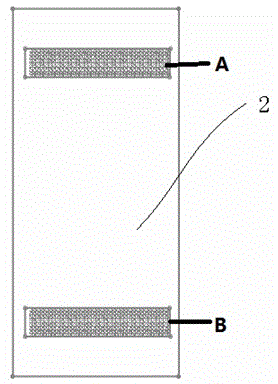

[0045] The base surface in this embodiment is a standing wall surface, including an inner wall surface and an outer wall surface, and the decorative board is a finished decorative wood board. In this embodiment, the A-surface and B-surface of the Velcro are respectively fixed on the wall or the decorative board and keep the corresponding positions, and then the decorative board is fixed on the wall to complete the connection and fixation of the two with the Velcro .

[0046] In this embodiment, the installation method for installing the decorative panel on the substrate surface specifically includes the following steps:

[0047] first step. Prepare to decorate the wooden board and Velcro. The Velcro here is divided into A-face and B-face, and a fixed-length ruler is prepared. The function of the ruler is to make the positions of the A-side and B-side of the Velcro correspond to each other, so that the fixation is more accurate. reliable.

[0048] The second step. Fix the s...

Embodiment 2

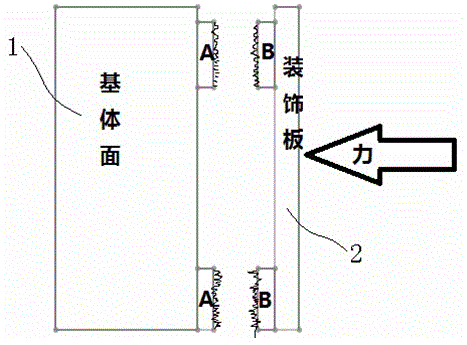

[0054] This embodiment is similar to Embodiment 1, the difference is that in Embodiment 1, the A surface and the B surface of the Velcro are fixed on the wall and the decorative board respectively, and then the A surface and the B surface are attached to the decorative wooden board by the Velcro. The surfaces fit together correspondingly. In this embodiment, the A surface body of the Velcro is first fixed on the body of wall, then the B surface body with the adhesive surface is connected with the A surface body correspondingly, and finally the decorative board is pasted on the wall, and the Velcro is used to fix the surface body on the wall. The bonding surface on the back of the B-face body is in contact with the decorative wood board, such as Figure 5 shown.

[0055] In this embodiment, the installation method for installing the decorative panel on the substrate surface specifically includes the following steps:

[0056] first step. Prepare decorative boards and magic st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com