Deviation analysis and factory correction guiding method of large-scale complicated special-shaped steel component

A technology of special-shaped steel and steel components, which is applied in the field of building steel structures, can solve problems such as low measurement efficiency, double errors of instruments and labor, and cumulative errors of equipment, and achieve the effect of improving measurement efficiency and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

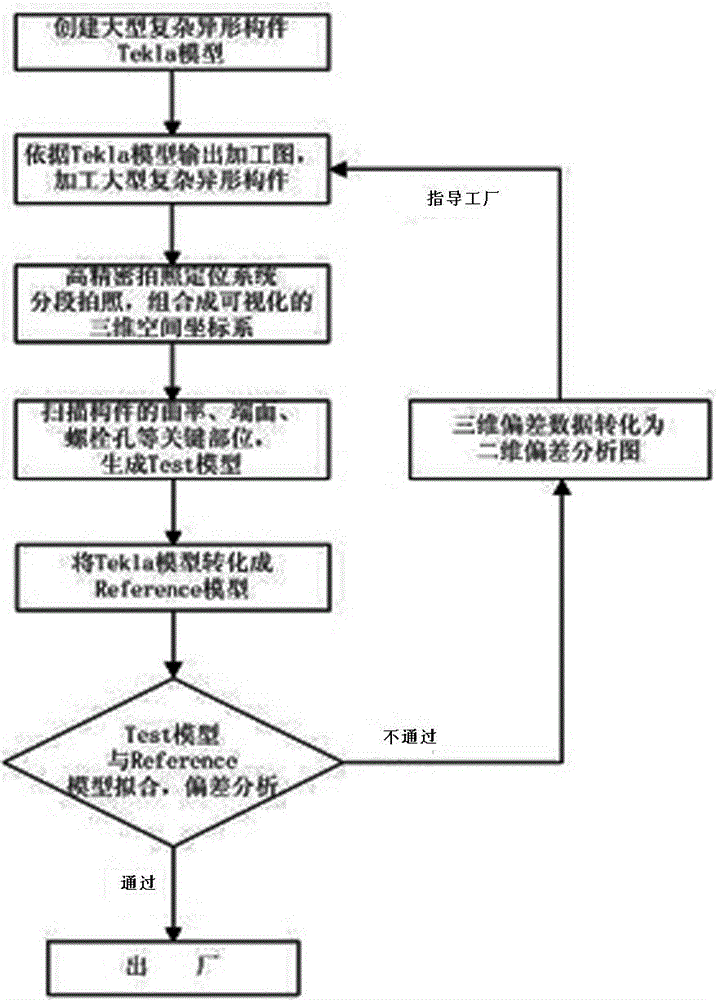

[0020] A method of deviation analysis and factory correction guidance for large and complex special-shaped steel components (steel components for short). Based on comprehensive technology (computer technology, reverse forming, virtual reality, three-dimensional scanning technology), the deviation analysis and Correction (e.g. figure 1 Shown), including the following steps:

[0021] Step 1: Create a Tekla model of large, complex and special-shaped steel components based on the structural construction drawings provided by the design institute;

[0022] The second step: according to the Tekla model output processing drawing, processing large complex special-shaped steel components;

[0023] The third step: use the high-precision camera positioning system to take pictures and locate the complex special-shaped steel components in the second step in stages (to reduce the cumulative error of the equipment), and form a visualized three-dimensional coordinate system of the steel components i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com