On-line assembling entirety on-position assembling method of edge mill

A technology of vertical rolling mill and installation method, which is applied in the direction of metal rolling frame, metal rolling mill stand, metal rolling, etc., can solve the impact of civil construction and equipment installation, does not consider equipment installation, and is unfavorable for the clean environment of rolling precision equipment Requirements and other issues to achieve the effect of shortening the installation period, saving installation costs, and reducing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

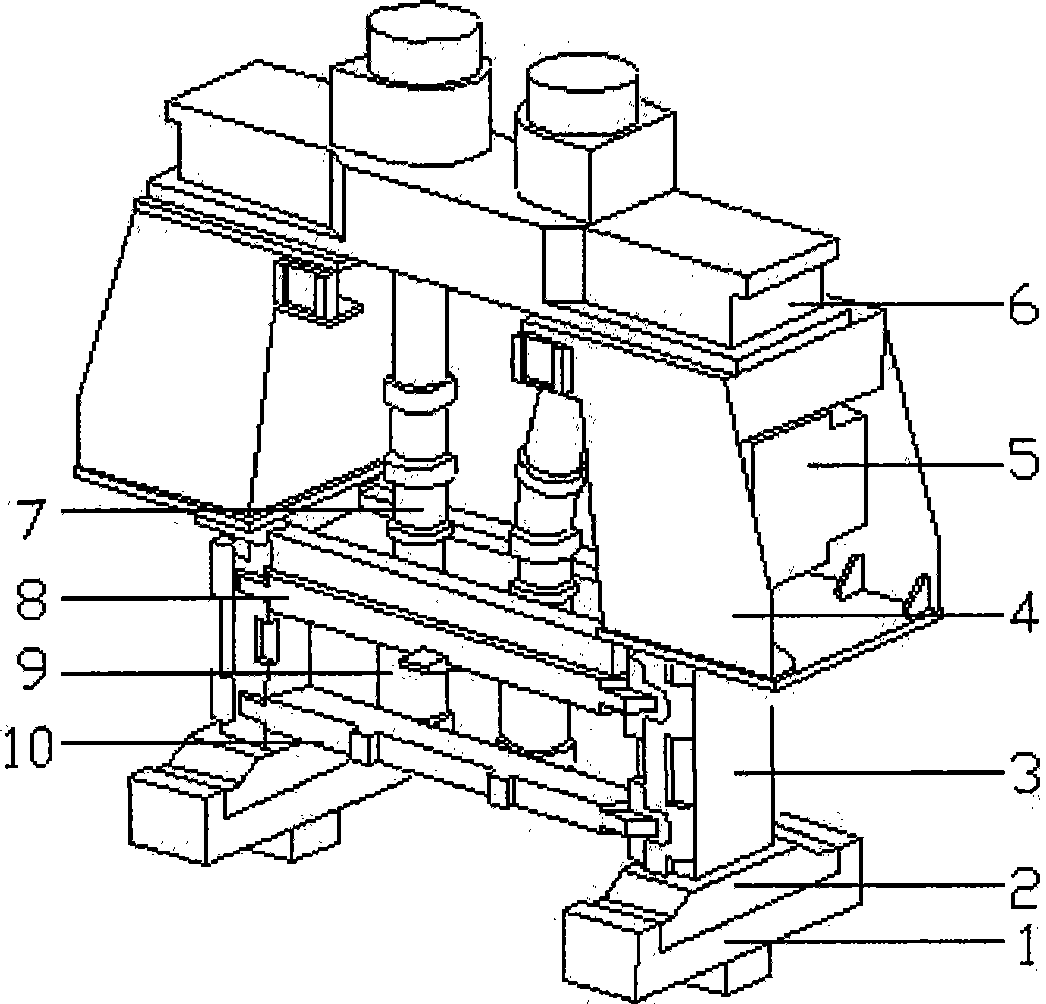

[0039] On-line assembly of the vertical roll mill and the installation method of the overall position, including assembly and setting of the position device, assembly of the upper and lower beams (hook beams) at the exit of the rack, sliding and fixing of the archway of the rack, assembly and fixing of the upper and lower beams at the entrance of the rack, and The overall lowering installation is in place, the installation of the rolling mill transmission device, etc. The assembly and positioning device includes a backing plate-jack system, a component position measuring device, and a hydraulic pushing device for sliding. This installation method is performed according to the following steps:

[0040] Step 1, installation and alignment of bottom plate 1 of vertical roll mill

[0041] a. The setting of the installation datum line and elevation datum point of the vertical rolling mill, the base plate 1 backing board seat slurry, and the erection of the installation center line;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com