Active chlorine dioxide disinfectant production method and apparatus

A chlorine dioxide and production method technology, applied in the direction of disinfectants, botany equipment and methods, biocides, etc., can solve the problems of unsatisfactory product quality and cost, difficulty in preparing high-concentration active disinfectants, and increased disinfection costs, etc. problems, to achieve the effect of reducing construction investment and workload, easy operation and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of production method of active chlorine dioxide disinfectant, comprises the steps:

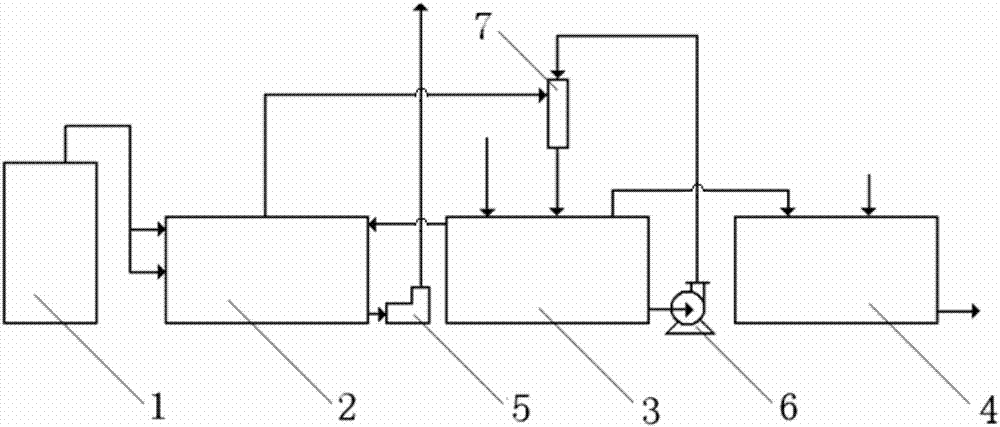

[0024] (1) The high-purity ClO prepared by the high-purity chlorine dioxide generator 2 The gas is pumped into the middle and upper part of the absorption tank under negative pressure for forced bubbling absorption to make high-concentration active ClO 2 Solution, the finished product is directly sent to the application site through the metering pump;

[0025] (2) The tail gas absorbed by the absorbing tank in step (1) is sucked by the circulating pump through the circulating liquid in the circulating tank, and sucked by the water ejector, and then the exhaust gas absorbed by the circulating tank is passed into the tail gas treatment tank, and the treated intermediate Regular discharge of liquid;

[0026] (3) In step (2), the circulation fluid in the circulation tank overflows into the absorption tank, and the circulation fluid in the circulation tank is supplemented by tap wat...

Embodiment 2

[0029] The difference with embodiment 1 is:

[0030]During normal operation, the high-purity chlorine dioxide generator generates negative pressure through the water ejector suction system, and its negative pressure value is controlled at 8KPa. The absorption tank is under the system negative pressure, and the negative pressure value is controlled at 12KPa. The pressure drop is controlled at 4KPa; the absorption tank absorbs ClO 2 The gas-liquid ratio of the gas is controlled at 1:22; the circulation tank is sucked by the water ejector, and the gas-liquid ratio of the absorbed tail gas is controlled at 4:1.

Embodiment 3

[0032] The high-purity chlorine dioxide generator operates normally under the negative pressure of the system, and the ClO produced 2 Gas, through the water ejector suction system to generate negative pressure, control the negative pressure value of the generator to 7KPa, the absorption tank absorbs ClO under the system negative pressure 2 Gas, the control negative pressure value is 10KPa, the control pressure drop is 3KPa, and the absorption tank absorbs ClO 2 The gas-liquid ratio of the gas is controlled at 1:8, and the active ClO after absorption 2 The disinfectant is directly sent to the application site by the metering pump; after absorption, the exhaust gas is sucked by the water ejector of the circulation tank, and the gas-liquid ratio of the water ejector is controlled to be 2:1.

[0033] Active ClO 2 The result of the test of the finished disinfectant is: ClO 2 Content 2021ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com