Factory and mine salt rock road and construction method thereof

A salt rock, factory and mine technology, applied in the field of salt rock road construction in factories and mines, can solve the problems of high road construction cost, easy subsidence of roadbed, etc., and achieve the effect of reducing investment and cost, not easy to collapse, and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

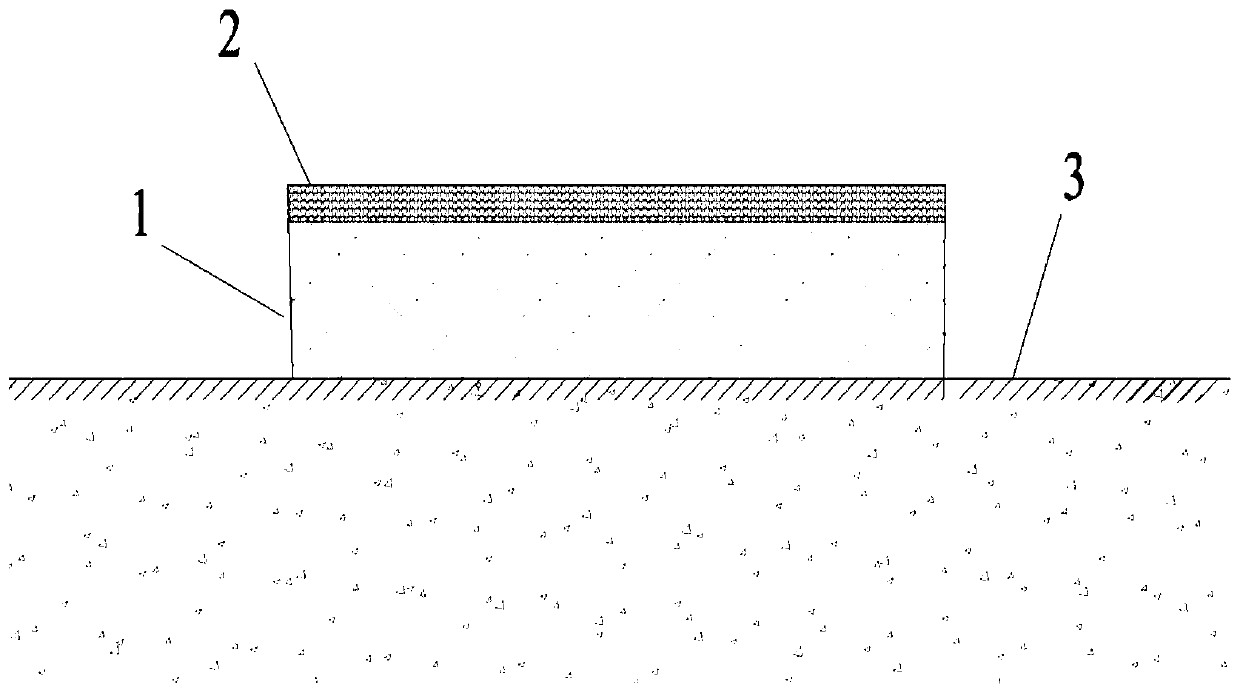

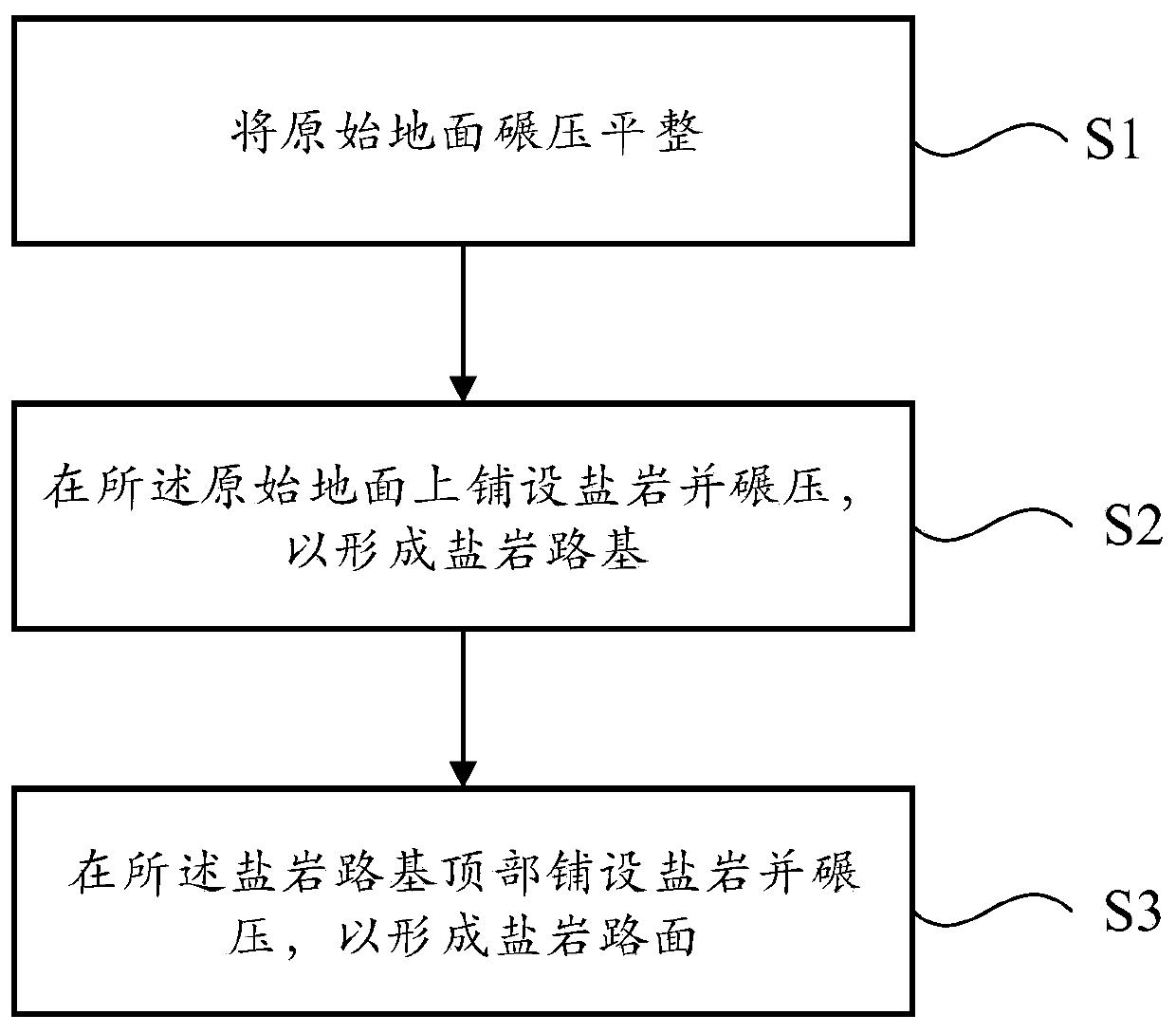

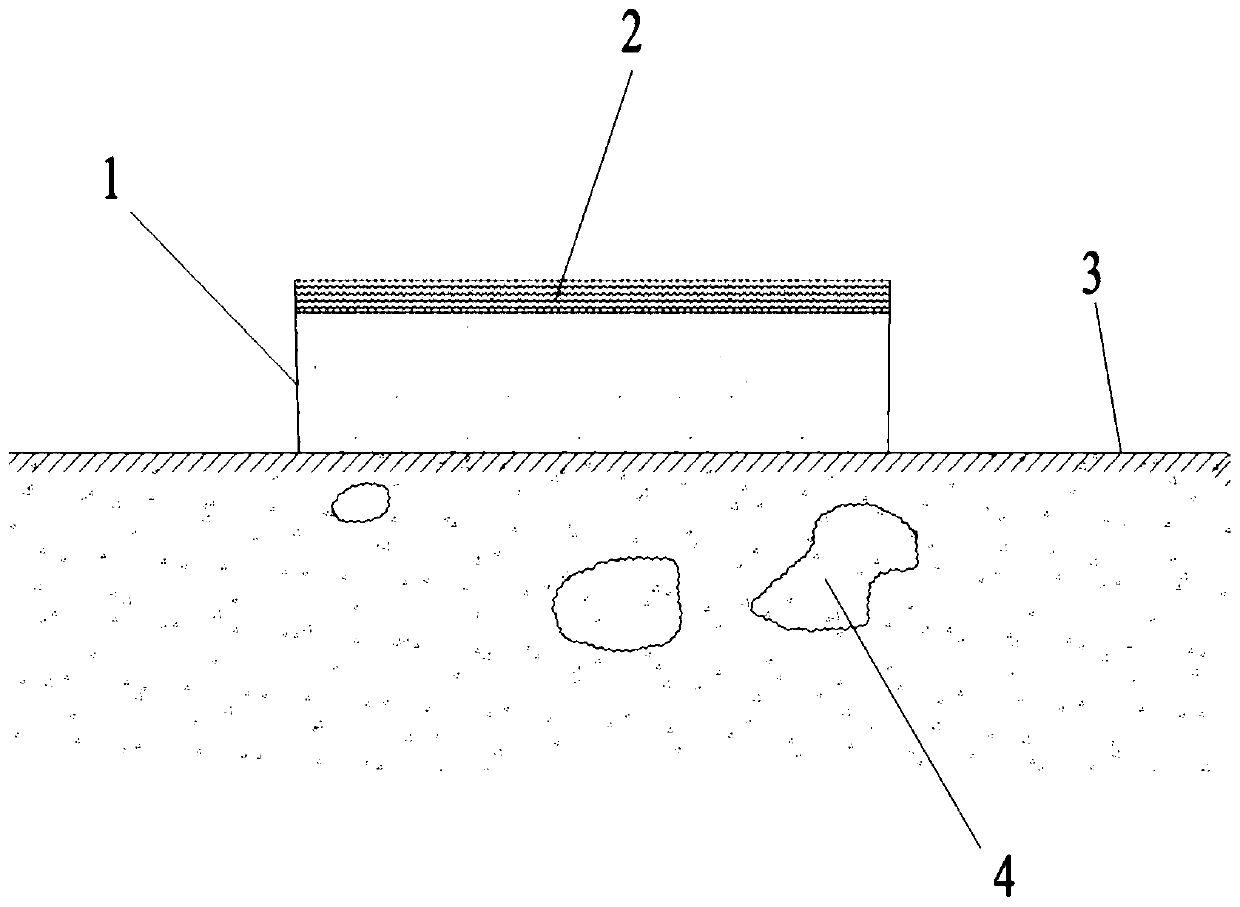

[0075] Embodiment 1: build a kind of as Figure 7 The specific construction method of the salt rock road in factories and mines shown is as follows: the original ground 3 is rolled and leveled, and the compaction coefficient of the original ground 3 is ≥ 92%; multi-layer salt rock is laid on the original ground 3, and each layer of salt rock is The thickness of loose laying is ≤50cm, and then rolling is carried out, and the compaction coefficient of the salt rock subgrade is ≥93%. After the salt rock rolling of each layer is completed, saturated brine is sprinkled for consolidation, and saturated brine is sprinkled at least 3 times until rolling The thickness reaches 80-100 cm to form the salt rock subgrade 1; loosely lay salt rock with a thickness of 30-50 cm on the top of the salt rock subgrade 1, and carry out rolling, and the rolling compaction coefficient is ≥ 93%, and then shaping and shaping After completion, sprinkle saturated brine for maintenance, sprinkle saturated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com