Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1150results about How to "Not easy to collapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance foaming cement and preparation method thereof

The invention relates to high-performance foaming cement, which comprises cement slurry and foams, wherein the cement slurry is prepared from the following raw materials in parts by weight: 100 parts of cement, 10-30 parts of gypsum powder, 10-50 parts of active admixtures, 10-40 parts of mineral admixtures, 1-5 parts of re-dispersible gelatine powder, 0.5-1.5 parts of cellulose ether, 0.2-1.0 part of water reducing agent, 0.1-0.5 part of water repellent and 40-90 parts of water; and the foams are prepared from the following components in parts by weight: 1 part of foaming agent, 0.2-0.8 part of foam stabilizer and 30-50 parts of water. A preparation method of the high-performance foaming cement comprises the steps of: (1) preparing the cement slurry; (2) preparing the foams by using a foaming machine; and (3) mixing and uniformly stirring the cement slurry and the foams according to the weight ratio of 1:(0.1-1), and pouring and molding. The high-performance foaming cement disclosed by the invention has high closed porosity and small shrinkage value, and integrates the performances of heat insulation, sound insulation, water repellent, shock resistance, fire protection, durability, low carbon and environmental protection into a whole.

Owner:辽宁际洲环保节能建材有限公司

Composite reinforced wear-resistant part of metal-ceramic prefabricated member and manufacturing method of composite reinforced wear-resistant part

The invention discloses a composite reinforced wear-resistant part of a metal-ceramic prefabricated member and a manufacturing method of the composite reinforced wear-resistant part. The manufacturing method comprises the steps as follows: uniformly mixing ceramic particles with self-fluxing alloy powder to obtain a mixture; filling a mould cavity of a pressing machine with the mixture, pressing by pressure, forming and demoulding, and placing biscuits and gaskets into a drying box for drying; placing the dried biscuits and gaskets into a vacuum furnace for sintering, cooling and discharging to obtain the metal-ceramic composite prefabricated member; carrying out sand blasting on the prefabricated member, and spraying a layer of nickel-based self-fluxing alloy powder onto the surface of the prefabricated member; and placing the processed fabricated member onto the end surface of a cast cavity, and pouring metal liquid formed by smelting metal matrix materials into the bottom of the cast cavity to obtain the composite reinforced wear-resistant part of the metal-ceramic prefabricated member. According to the manufacturing method, the wear resistance and the impact resistance of the composite wear-resistant part are improved.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

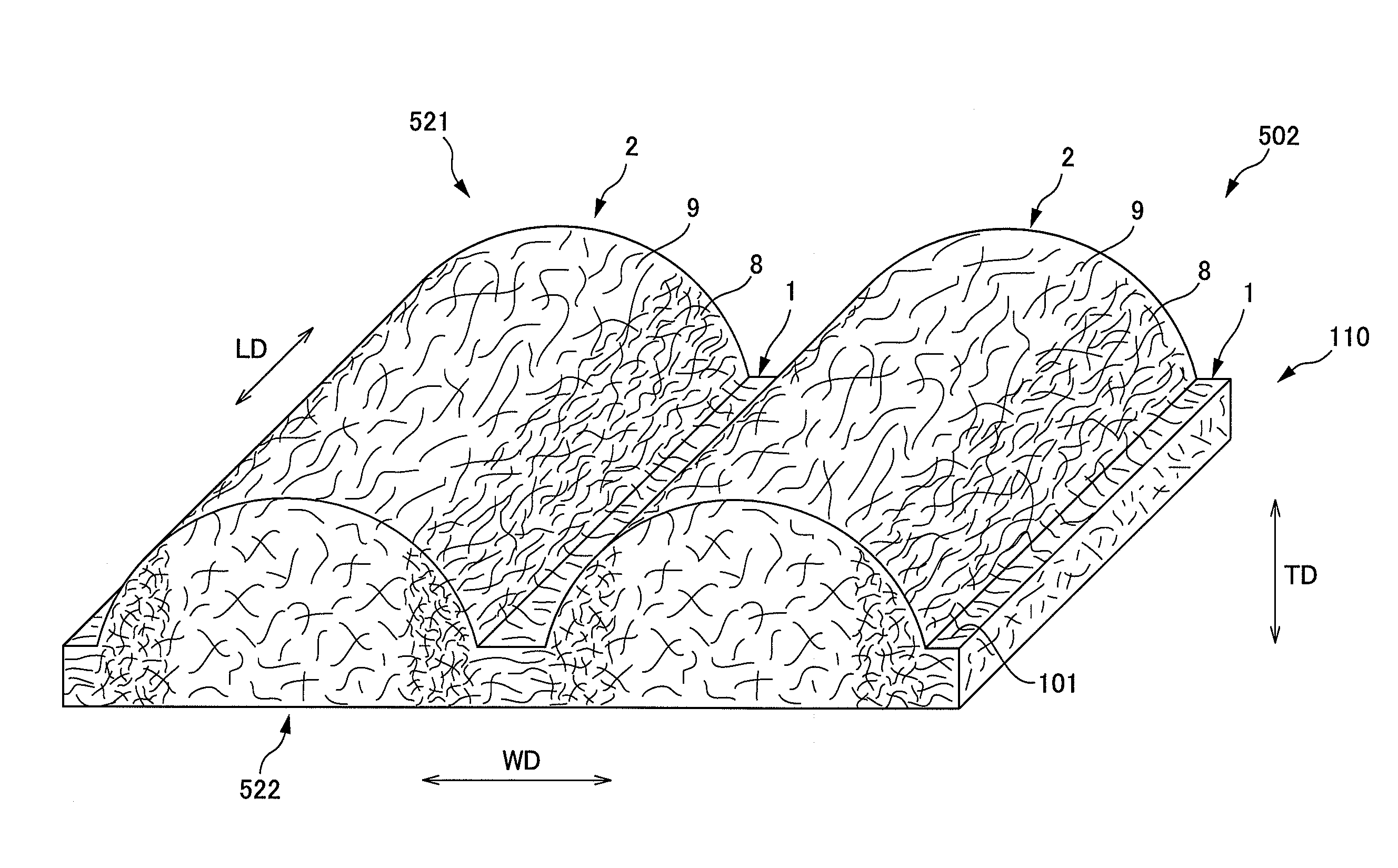

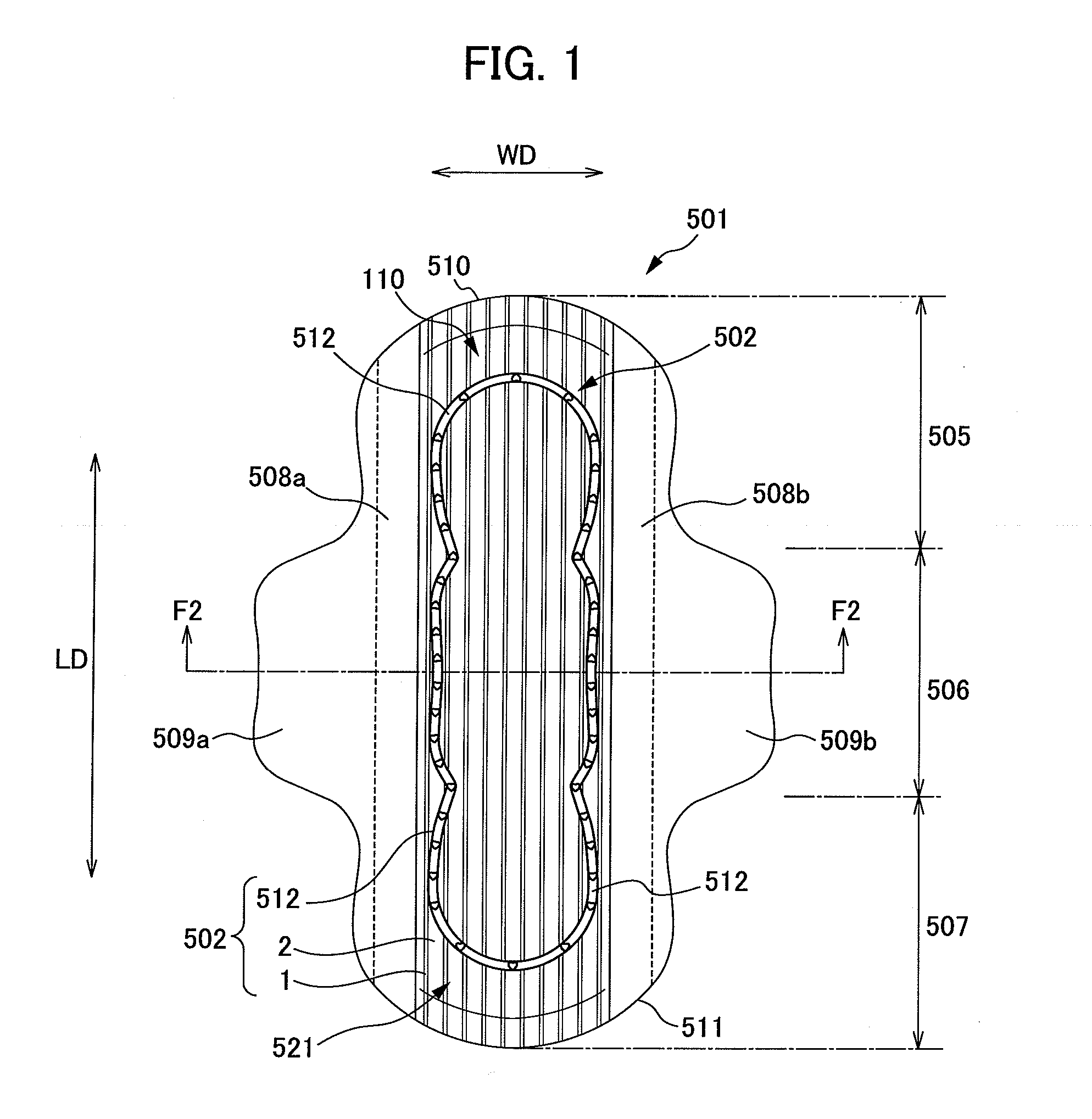

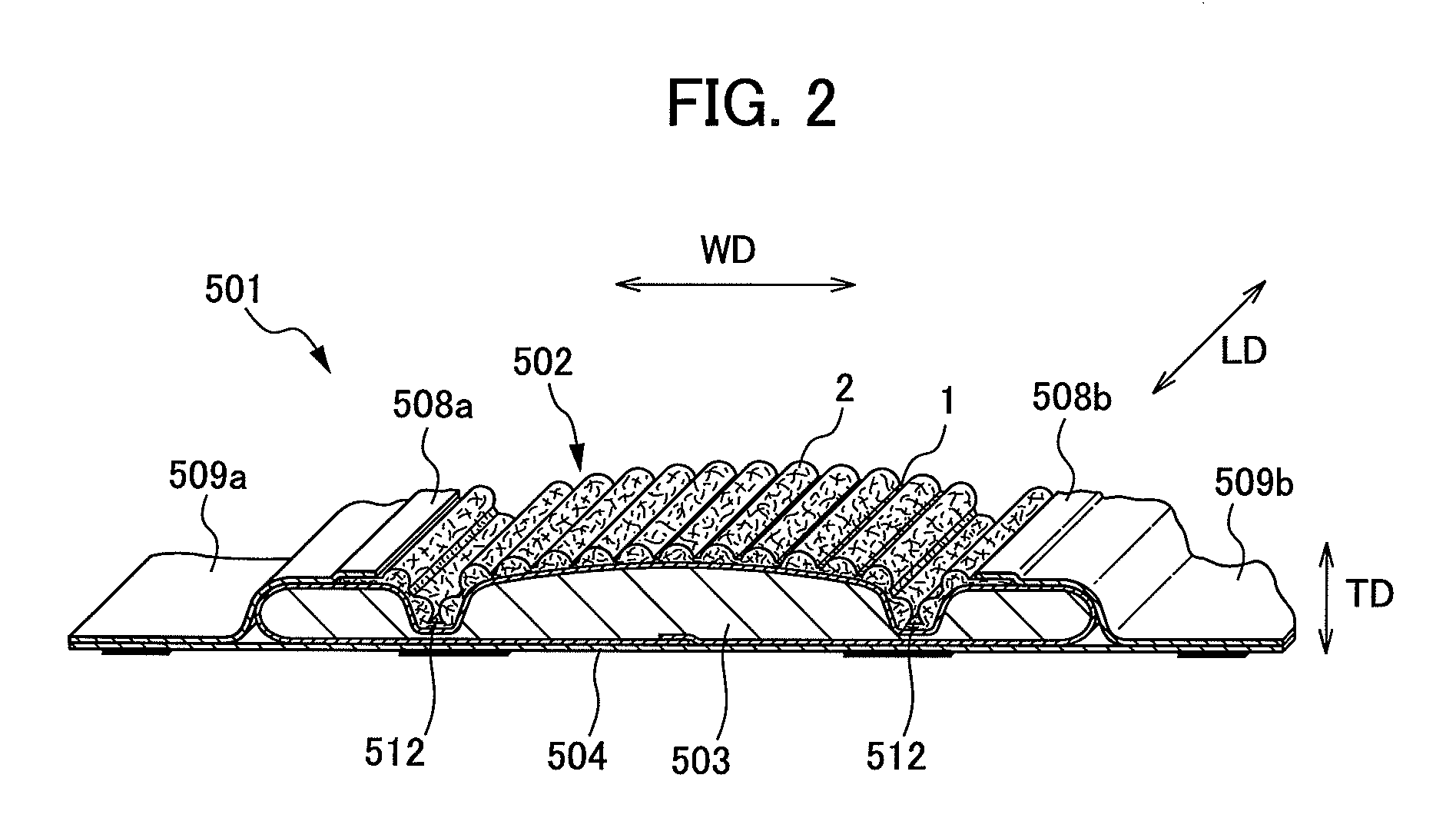

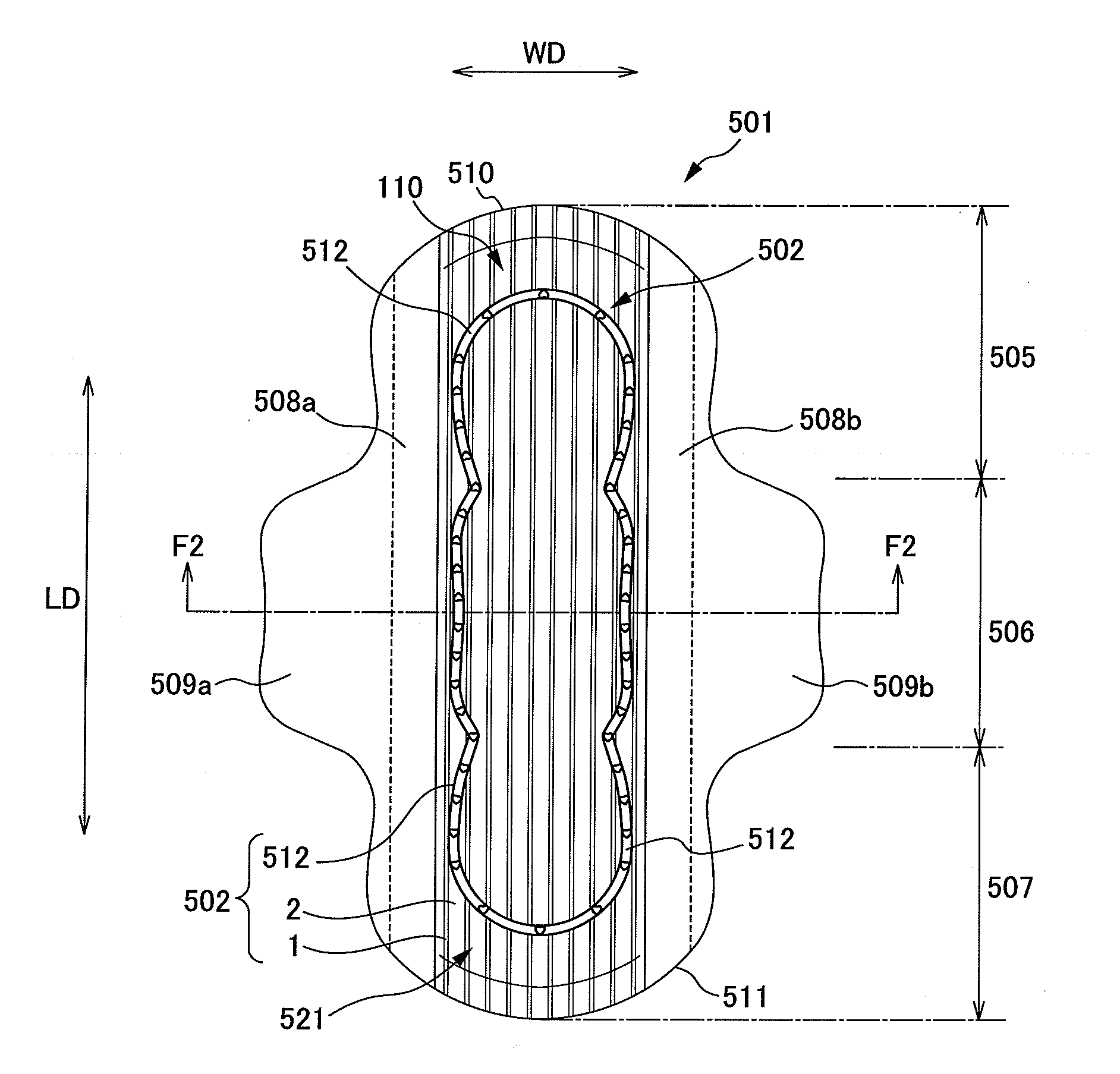

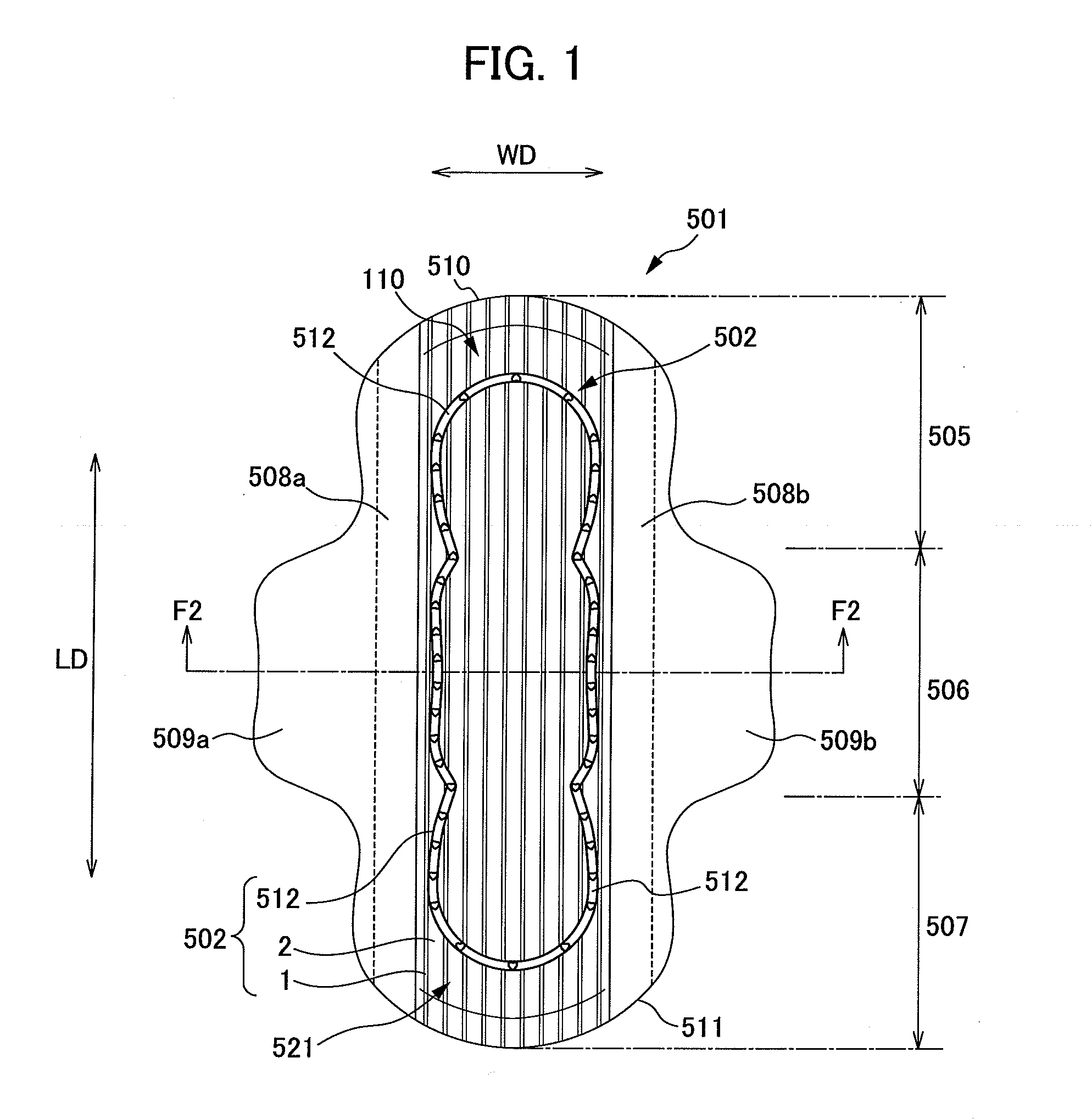

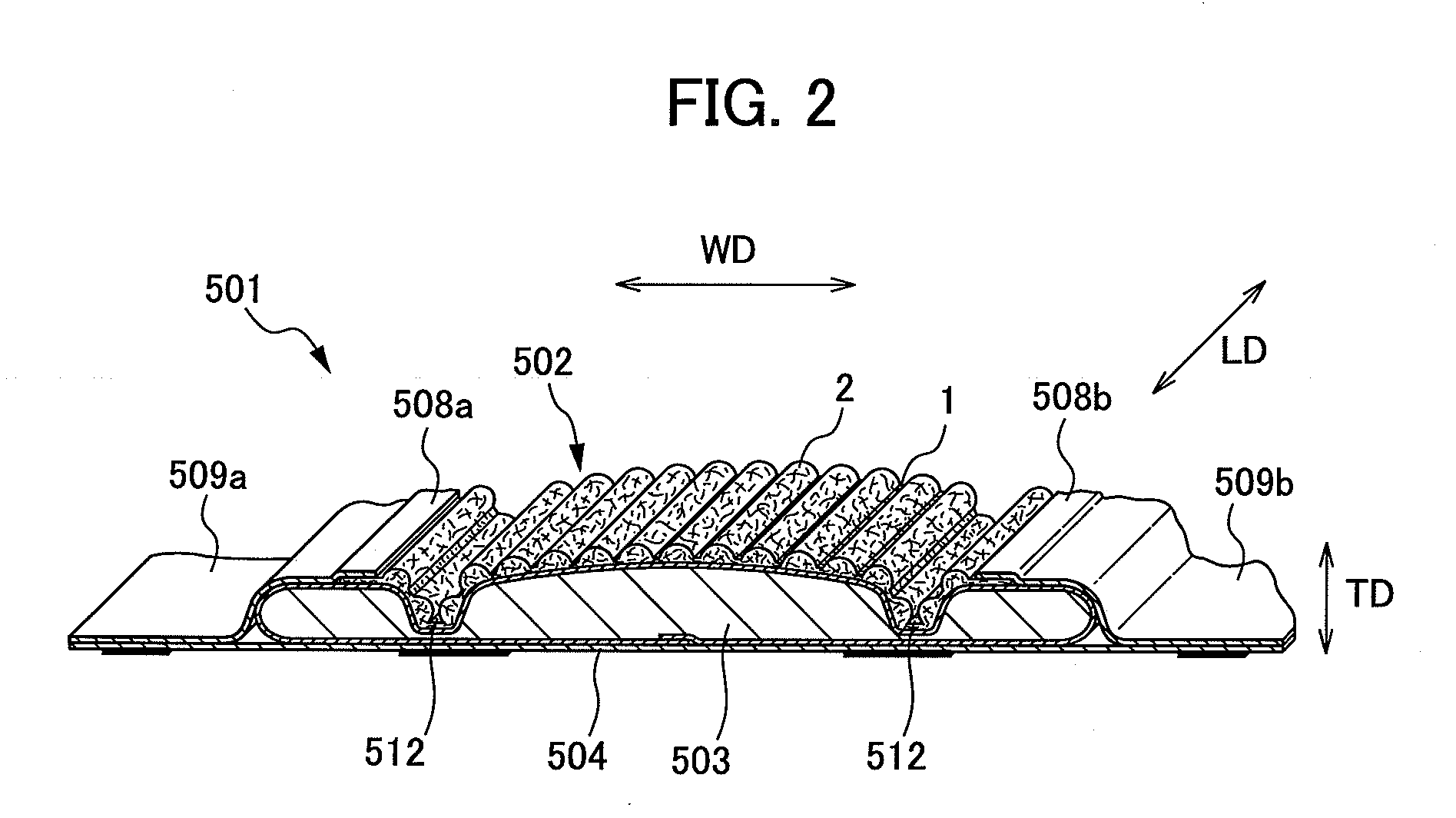

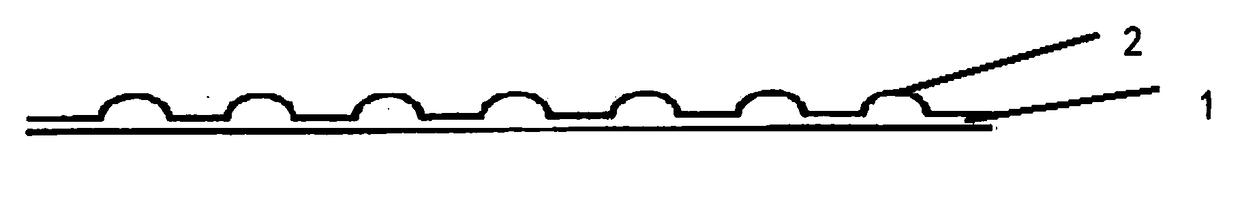

Absorbent article

ActiveUS8304600B2Not easy to collapseEasily passes liquidLayered productsBaby linensEngineeringNonwoven fabric

An absorbent article comprising nonwoven fabric having convex and concave surfaces, and that allows liquid such as excreta and the like to permeate quickly. A sanitary napkin has a plurality of raised ridge portions and groove portions in a top sheet member. The fiber density of the side edge portions of each of the plurality of raised ridge portions in the thickness direction of the nonwoven fabric is substantially uniform, and is higher than the average fiber density in the raised ridge portions. The fiber density of the central portion between both the side edge portions of each of the plurality of raised ridge portions is substantially uniform in the thickness direction of the nonwoven fabric, and is lower than the average fiber density in the raised ridge portions.

Owner:UNI CHARM CORP

Absorbent article

ActiveUS20080045915A1Improve permeabilityNot easy to collapseLayered productsBaby linensNonwoven fabricMechanical engineering

An absorbent article comprising nonwoven fabric having convex and concave surfaces, and that allows liquid such as excreta and the like to permeate quickly. A sanitary napkin has a plurality of raised ridge portions and groove portions in a top sheet member. The fiber density of the side edge portions of each of the plurality of raised ridge portions in the thickness direction of the nonwoven fabric is substantially uniform, and is higher than the average fiber density in the raised ridge portions. The fiber density of the central portion between both the side edge portions of each of the plurality of raised ridge portions is substantially uniform in the thickness direction of the nonwoven fabric, and is lower than the average fiber density in the raised ridge portions.

Owner:UNI CHARM CORP

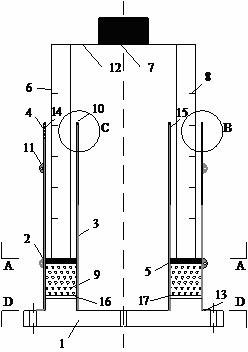

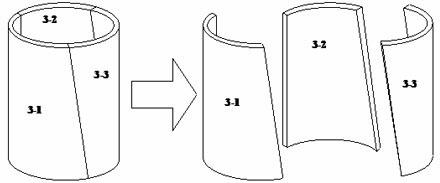

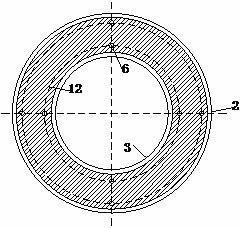

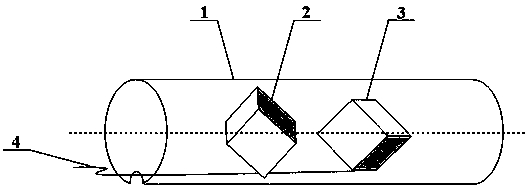

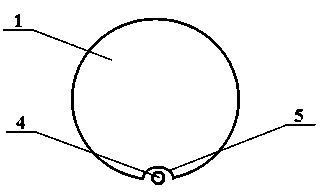

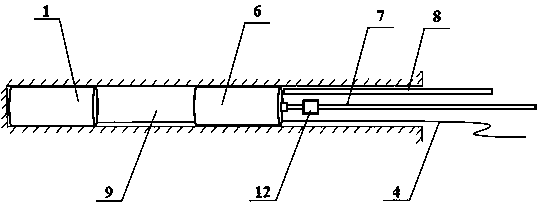

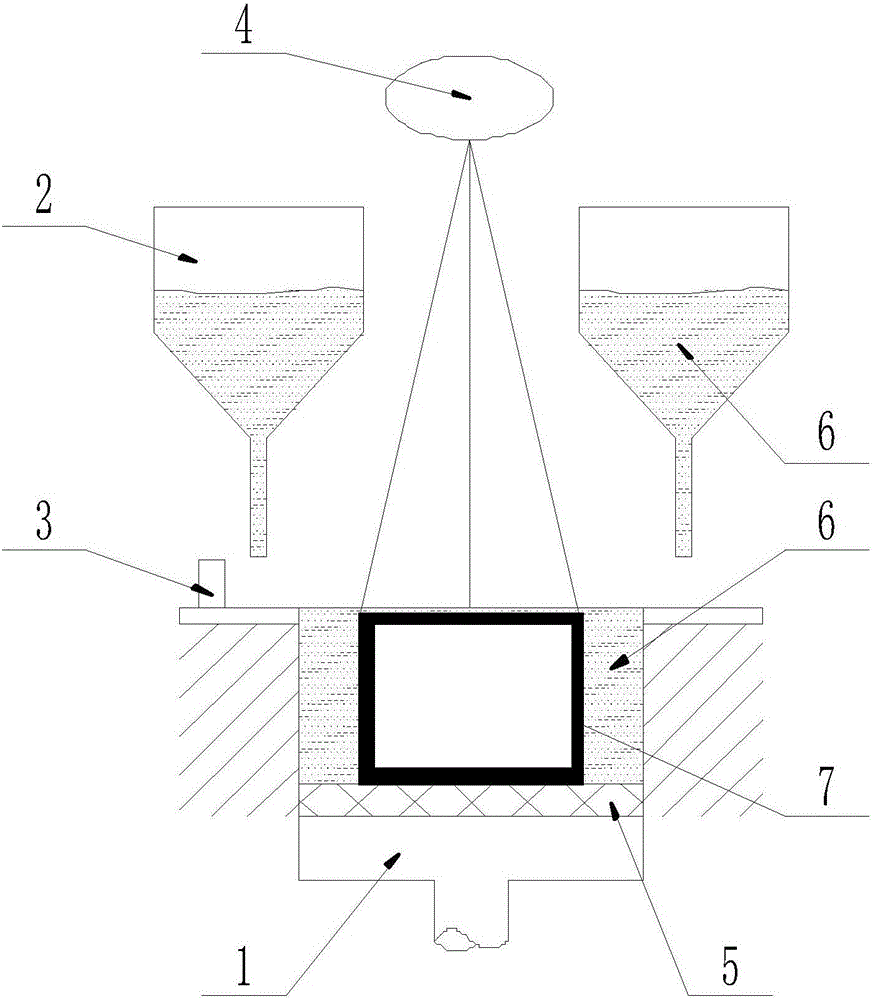

A large hollow cylinder sample maker for coarse-grained soil and its use method

ActiveCN102288461AAvoid uneven forceFlexible accessPreparing sample for investigationSoil scienceTest sample

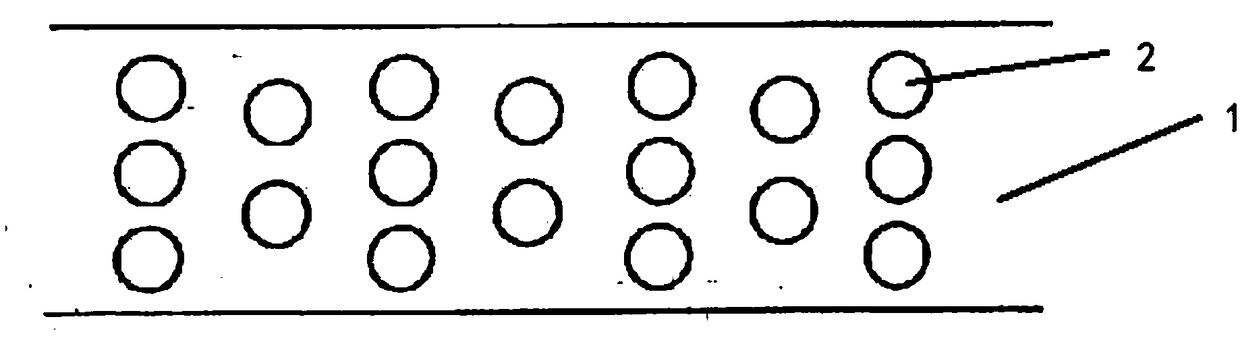

The invention discloses a large-sized hollow cylindrical sampler for coarse grained soil and a use method thereof. The sampler comprises an annular sleeve and a vibrating compacter, two parts in all, wherein the annular sleeve comprises an annular base (1), an annular outer sleeve (2), an annular inner sleeve (3) and an annular extension barrel (4); and the vibrating compacter comprises a vibrating motor (7), a circular iron plate (12), a dowel bar (6), a positioner (8) and an annular iron plate (5). While using the instrument, a soil sample (9) is paved at first and then put into the annulariron plate (5); next, the vibrating motor (7) is turned on; when the edge of the annular outer sleeve (2) is level with the positioner (8), the vibrating motor (7) stops vibration and the next layer of soil sample (9) is added; and then vibration compaction is performed until the soil samples reach a predetermined height. The sampler is simple to use, convenient for operation and control, and capable of preparing a highly compact and even test sample, so that the time and labour for preparing the test sample are saved.

Owner:HOHAI UNIV

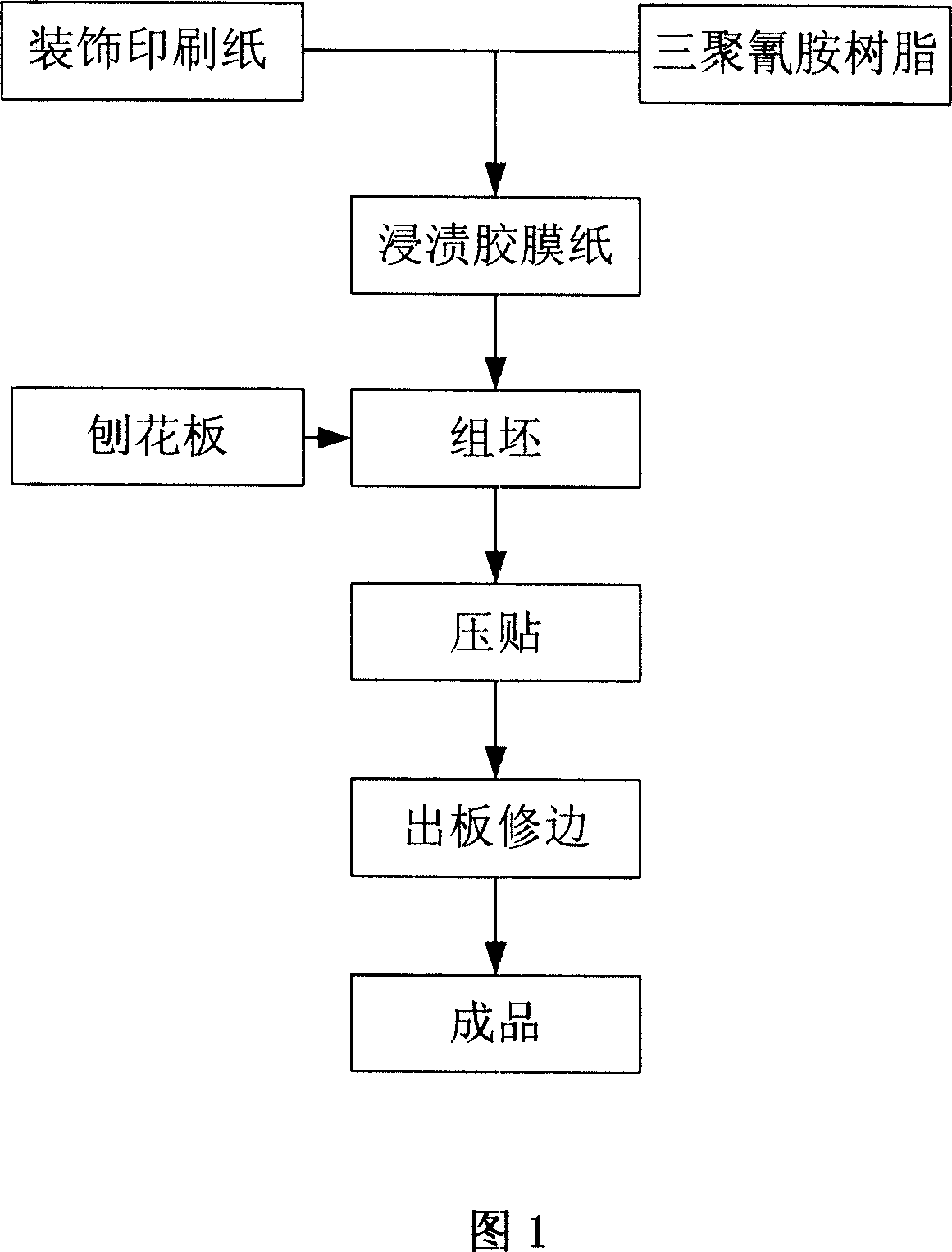

Bright mirror surface and facing artificial plate and manufacturing technique thereof

InactiveCN101011828AIncrease usageOvercoming the deficiency of low brightnessNon-macromolecular organic additionPaper/cardboardDiethylene glycolPulp and paper industry

A melamine impregnated bond paper and chipboard compressed bright surface wood based board is composed of 60-70 portions of water, 100 portions of melamine, 90-130 portions of formaldehyde, diethylene glycol monoethylether 10-15 portions, aminocaprolactam 3.5-5.5 portions and caustic soda 0.3-0.6 portions. Firstly, it wipes off the powder on the surface of the chipboard, aligning them with melamine impregnated bond paper covering the chipboard, increasing the temperature, sending the chipboard and the paper into the compressing machine, ensuring the aligning of the center line of the chipboard and that of the compressing machine, closing the compressing machine, sending out the board, trimming, and getting the bright artificial board. It is bright, with good luster saturation, fine wearing resistance, heat, burning, crack, light and corrosion features.

Owner:吴根水

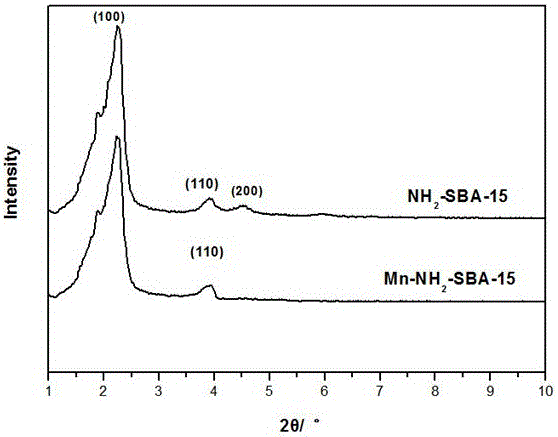

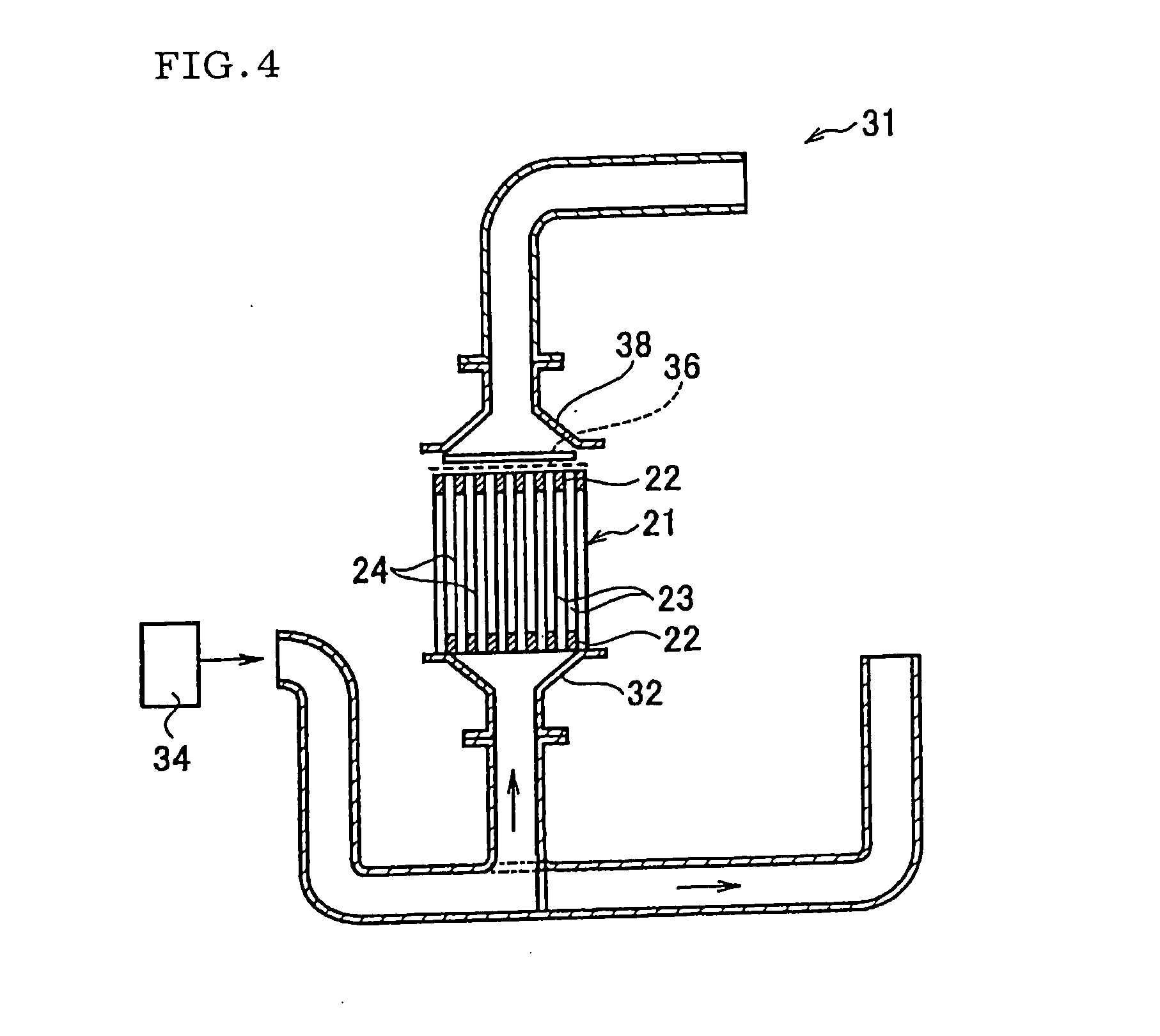

Organic-inorganic hybrid mesoporous catalyst for purifying VOCs (volatile organic compounds) and method for preparing organic-inorganic hybrid mesoporous catalyst

ActiveCN106215978ATo achieve the purpose of doping modificationImprove adsorption capacityGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsAlkaline earth metalLow temperature plasma

The invention discloses an organic-inorganic hybrid mesoporous catalyst for purifying VOCs (volatile organic compounds) and a method for preparing the organic-inorganic hybrid mesoporous catalyst. SBA-15 mesoporous molecular sieves are used as carriers of the organic-inorganic hybrid mesoporous catalyst, organic groups (phenyl groups, amino groups and sulfhydryl groups) and transition metal oxide (oxide of Mn, Fe and Co) are used as active components of the organic-inorganic hybrid mesoporous catalyst, and chloride of alkali metal or alkaline-earth metal is used as an auxiliary of the organic-inorganic hybrid mesoporous catalyst. The specific surface area of the organic-inorganic hybrid mesoporous catalyst ranges from 700 m<2> / g to 900 m<2> / g, and the average pore diameter of pore passages in the organic-inorganic hybrid mesoporous catalyst ranges from 8 nm to 15 nm. The method includes supporting the organic groups on the SBA-15 molecular sieves by the aid of an in-situ solvent thermal synthesis process; modifying the SBA-15 mesoporous molecular sieves by the transition metal oxide by the aid of an impregnation process to obtain the organic-inorganic hybrid mesoporous catalyst. The organic-inorganic hybrid mesoporous catalyst and the method have the advantages that the organic-inorganic hybrid mesoporous catalyst has large mesoporous pore diameters and the large specific surface area and is high in catalytic activity, catalytic active constituents are good in dispersibility, acid centers can be reinforced, and the method is simple and feasible and is low in cost; the VOCs can be converted into harmless carbon dioxide and water under synergy of the organic-inorganic hybrid mesoporous catalyst and low-temperature plasma technologies at the normal temperature, and the organic-inorganic hybrid mesoporous catalyst has few byproducts and is difficult to inactivate.

Owner:WUHAN UNIV

Detection method for soft rock multi-point ground stress by adopting sensing columns

InactiveCN103513016ARealize measurementGrouting solidification time is shortEarth material testingRelative displacementCoal

The invention discloses a detection method for soft rock multi-point ground stress by adopting sensing columns. According to the invention, the relative positions of a pair of three-dimensional pressure sensors are fixed by the sensing columns; one measuring point corresponds to one sensing column; in the sending process, relative movement between the two three-dimensional pressure sensors can be prevented; the diameter of each stress sensing column is only slightly smaller than that of a drill hole, so that only a small amount of grouting is required to enable the stress of the soft rock to be transferred to the sensors; the depth and the rotation angle of each sensor can be obtained accurately; the ground stress value at the testing point can be obtained accurately through numerical calculation of drill hole sectional mechanics, and the regional ground stress field can be obtained through inversion. The method can monitor the stress evolution process of multiple measuring points inside a surrounding rock, so that the research on ground stress of a coal mine and other deep soft rocks, as well as the stability of a surrounding rock, is facilitated.

Owner:WUHAN UNIV

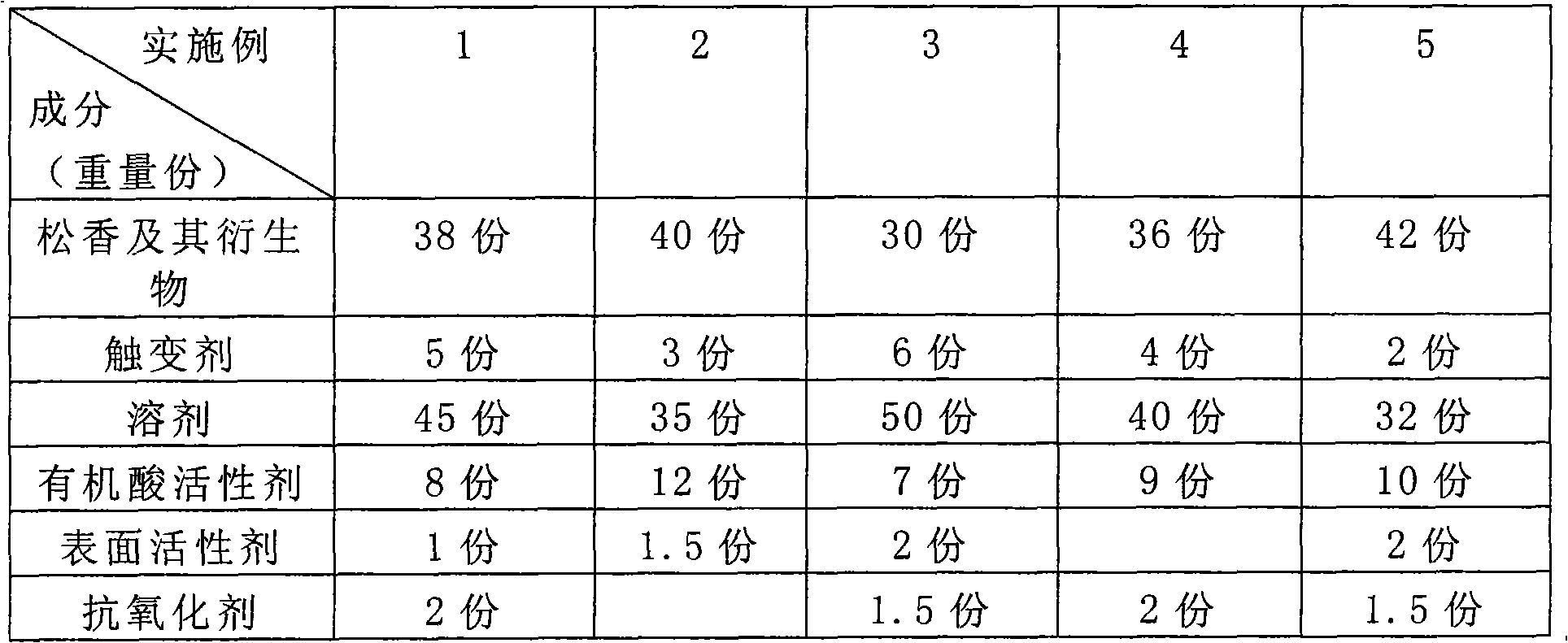

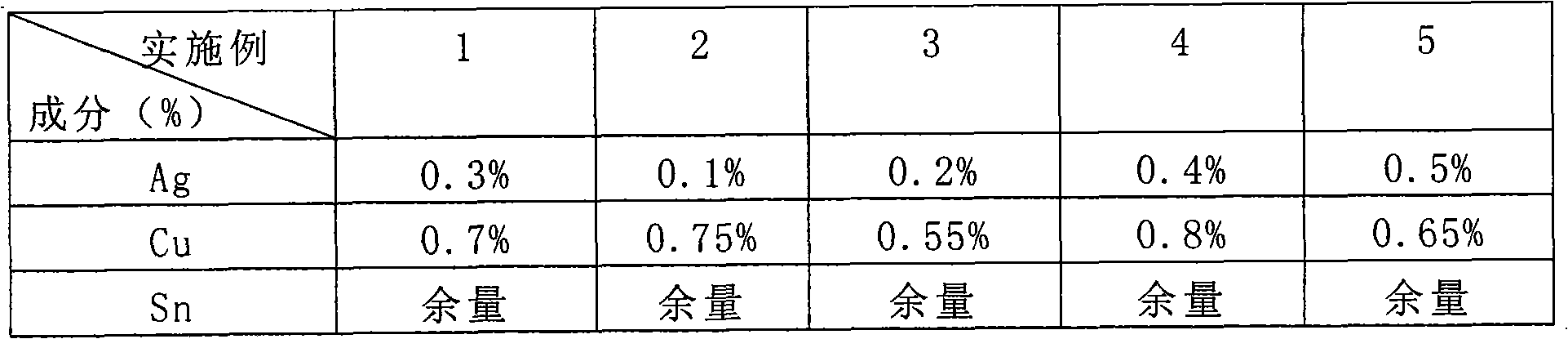

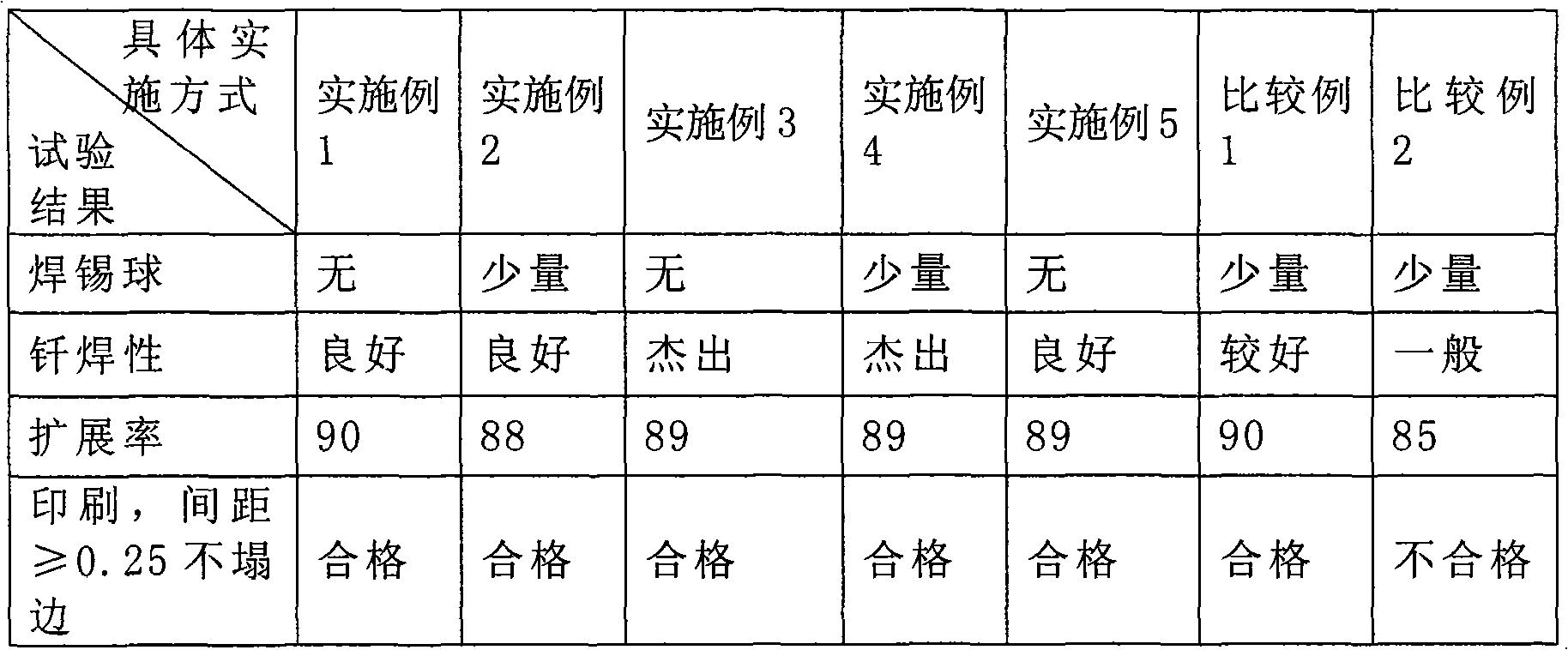

Low-silver halogen free soldering paste

InactiveCN101653876AGood printing performanceCompatibility is reasonableWelding/cutting media/materialsSoldering mediaSolderingHalogen free

The invention provides a low-silver halogen free soldering paste, which solves the problems that the existing soldering paste has high production cost and poorer soldering performance, and is not applicable to welding of components with precision spacing and the like. The low-silver halogen free soldering paste comprises the following components by weight percentage of 88 percent to 91 percent ofalloy welding powder and 9 percent to 12 percent of paste flux, wherein, the alloy welding powder comprises the following components by weight percentage of 0.1 percent to 0.9 percent of Ag, 0.1 percent to 0.8 percent of Cu and the balance Sn. The low-silver halogen free soldering paste has the advantages of low cost, good welding performance, no easy edge-collapse after printing and the like.

Owner:上海一远电子科技有限公司

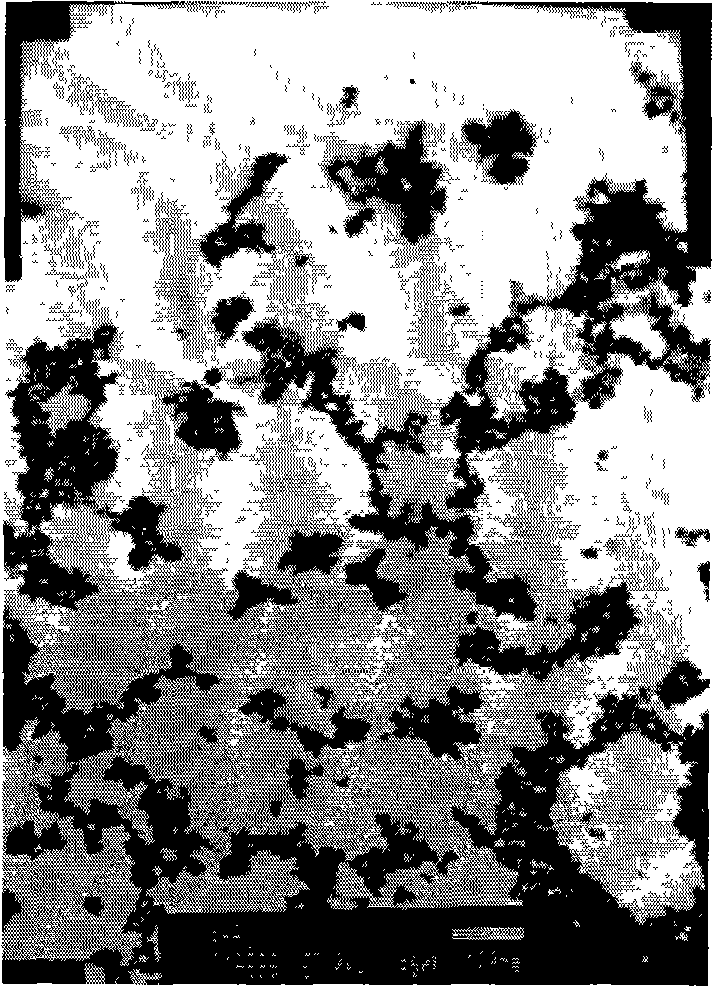

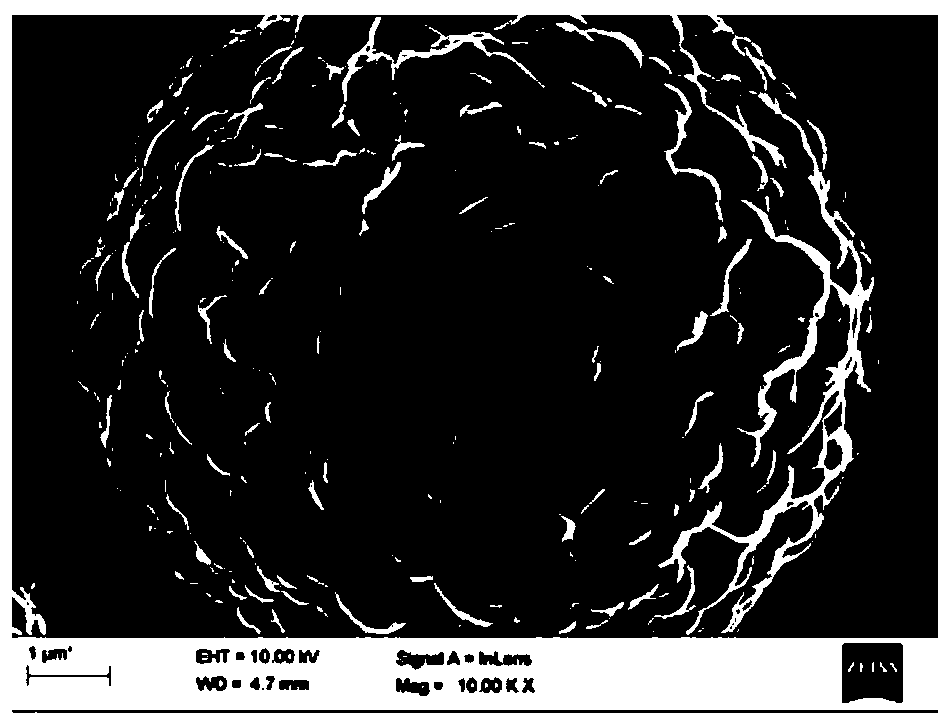

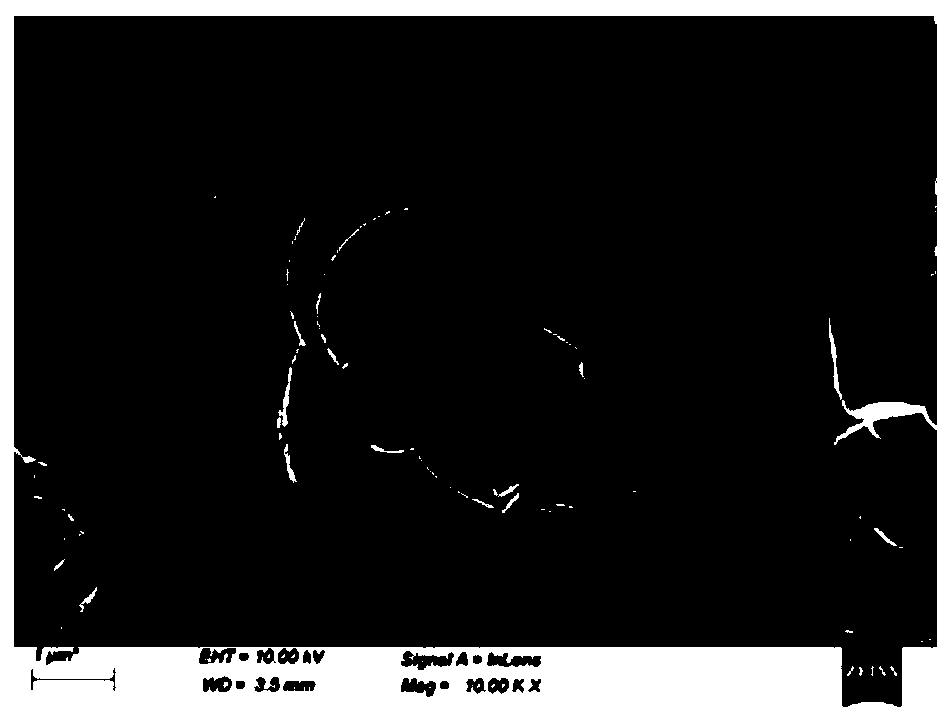

Hollow microsphere containing silicon magnetism and preparation method and use thereof

InactiveCN101337171ALow densityLarge specific surface areaMagnetic materialsMicroballoon preparationTumor targetingMicrosphere

The invention provides a hollow silicon magnetic microsphere, as well as the preparation method and the application thereof. The hollow silicon magnetic microspheres have the preparation method that a polystyrene / silicon dioxide composite microsphere is used as a core; Fe3O4 coats the periphery of the core through the layer-by-layer self-assembly method; then, a PS / SiO2 / Fe3o4 polymeric magnetic composite nanosphere is obtained, and polystyrene is removed through the high temperature sintering method, thereby forming a magnetic material with hollow structure; the inner layer of the hollow magnetic material is SiO2, and the stability is good, thereby the material is not easy to collapse at high temperature; furthermore, the specific surface area of the material can be improved, and the material is a monodisperse hollow magnetic microsphere material. The method has the advantages of low cost and good repetitiveness. The obtained product not only can be used as a magnetic targeting drug carrier material, but also can be used in the biological and the medical fields such as biosensors, immunologic diagnosis, drug delivery and tumor targeting therapy as well as DNA isolation, etc.

Owner:SHANGHAI HUAMING HI TECH GRP +1

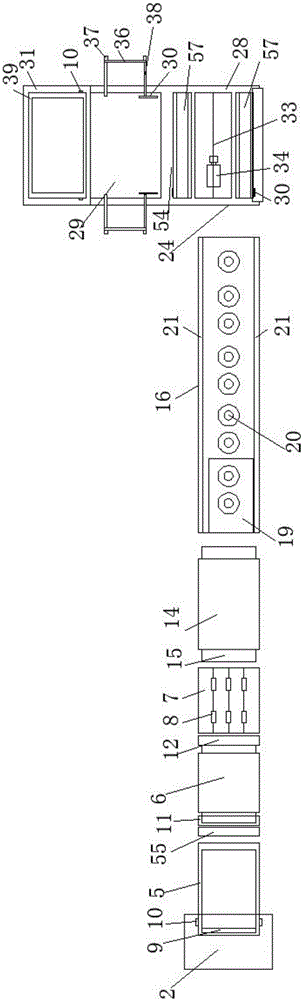

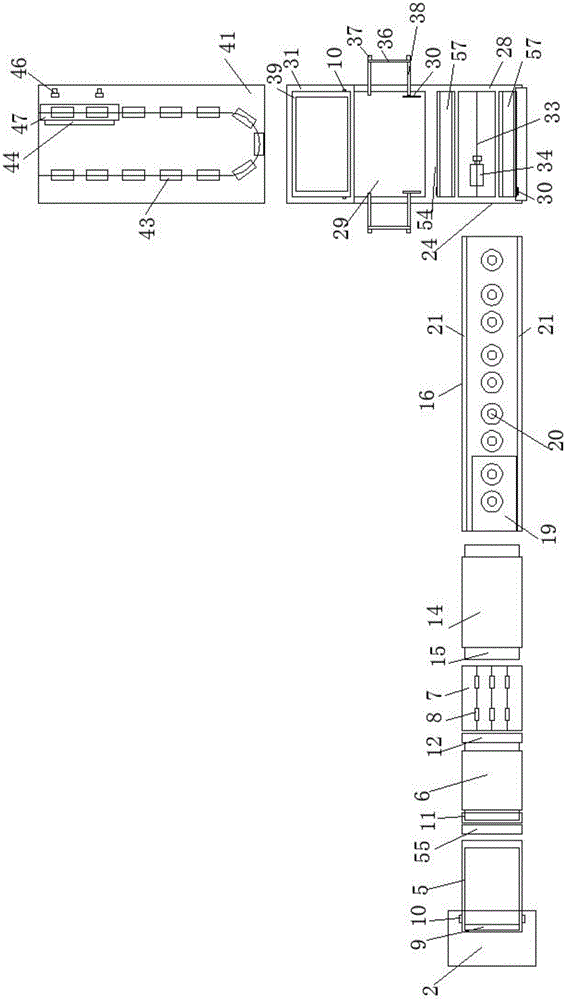

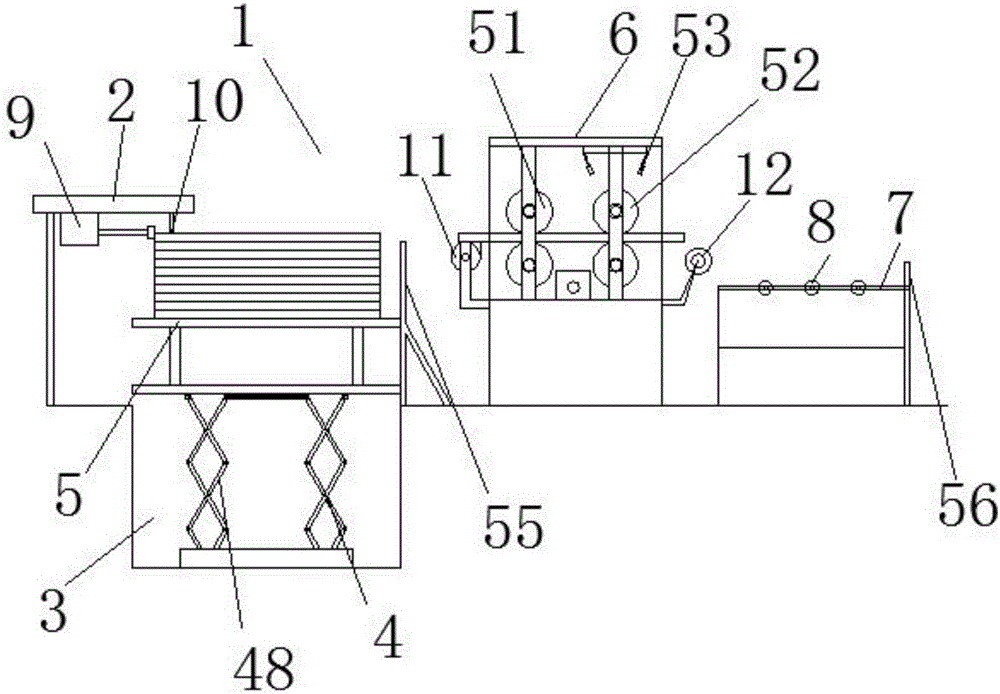

Novel processing production line and control method for plywood

ActiveCN106042084AReasonable structural designImprove processing productivityOther plywood/veneer working apparatusWood veneer joiningManufacturing engineeringHot pressing

The invention provides a novel processing production line and a control method for plywood, and relates to the technical field of plate processing equipment. The novel processing production line comprises a glue coating device, a hot pressing device, cooling equipment and a trimming device, wherein the glue coating device comprises a front end bracket, a first groove, a first lifting device, a first plate support frame, glue coating equipment and a receiving frame; rollers are arranged at the top of the receiving frame; the hot pressing device comprises a hot press and plate conveyor belts mounted on two sides of the hot press; the cooling equipment comprises a cooling chamber, rails, a material conveying trolley and a cooling device; and the trimming device comprises a bracket, a transversal sliding rail, a sliding seat, a push rod, a first support, a second support, four cutting machines, a second groove, a second lifting device and a second plate support frame. The novel processing production line is reasonable in structural design, and can greatly improve the production efficiency of the plywood.

Owner:ANHUI DONGPING WOOD GRP

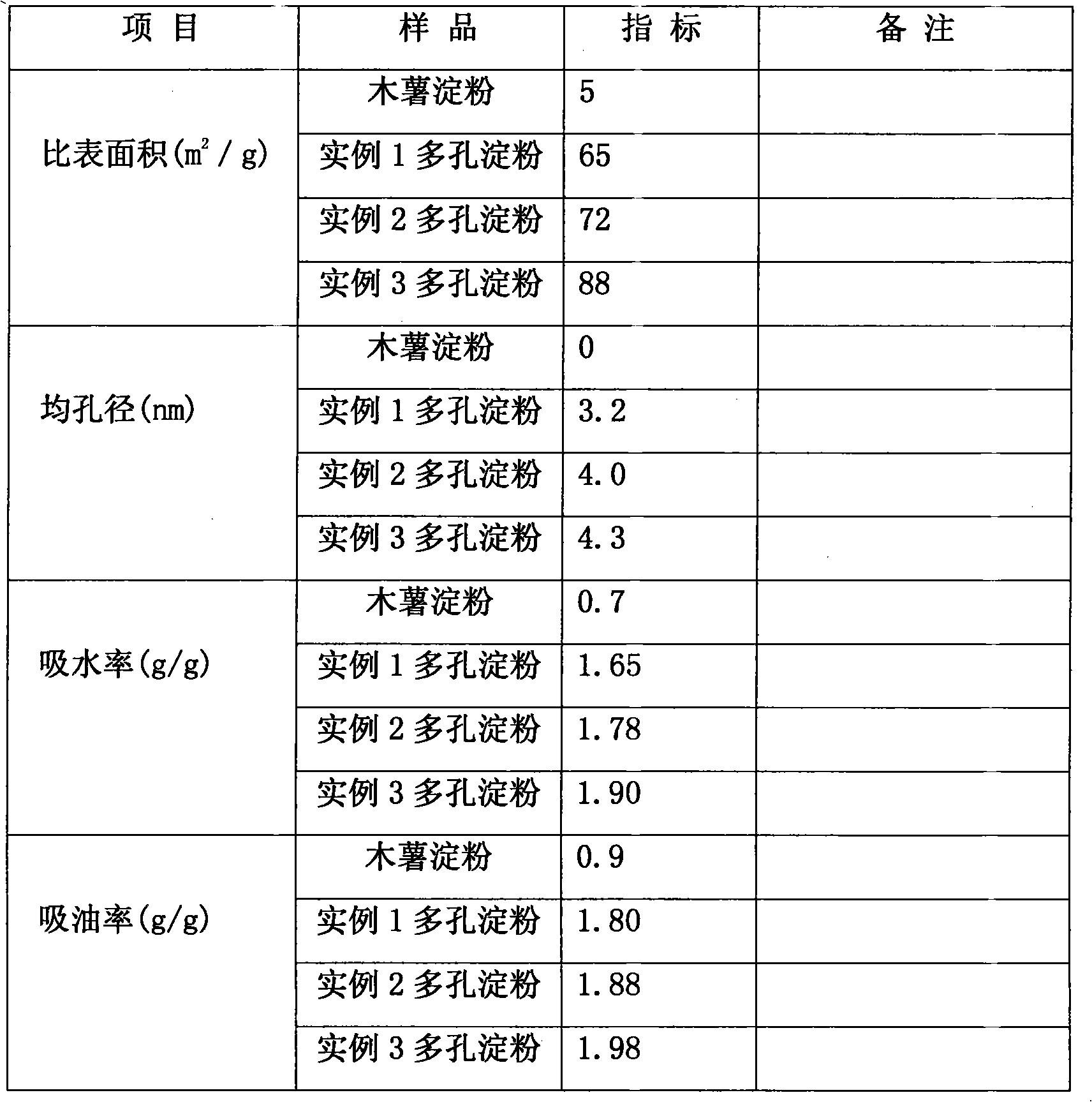

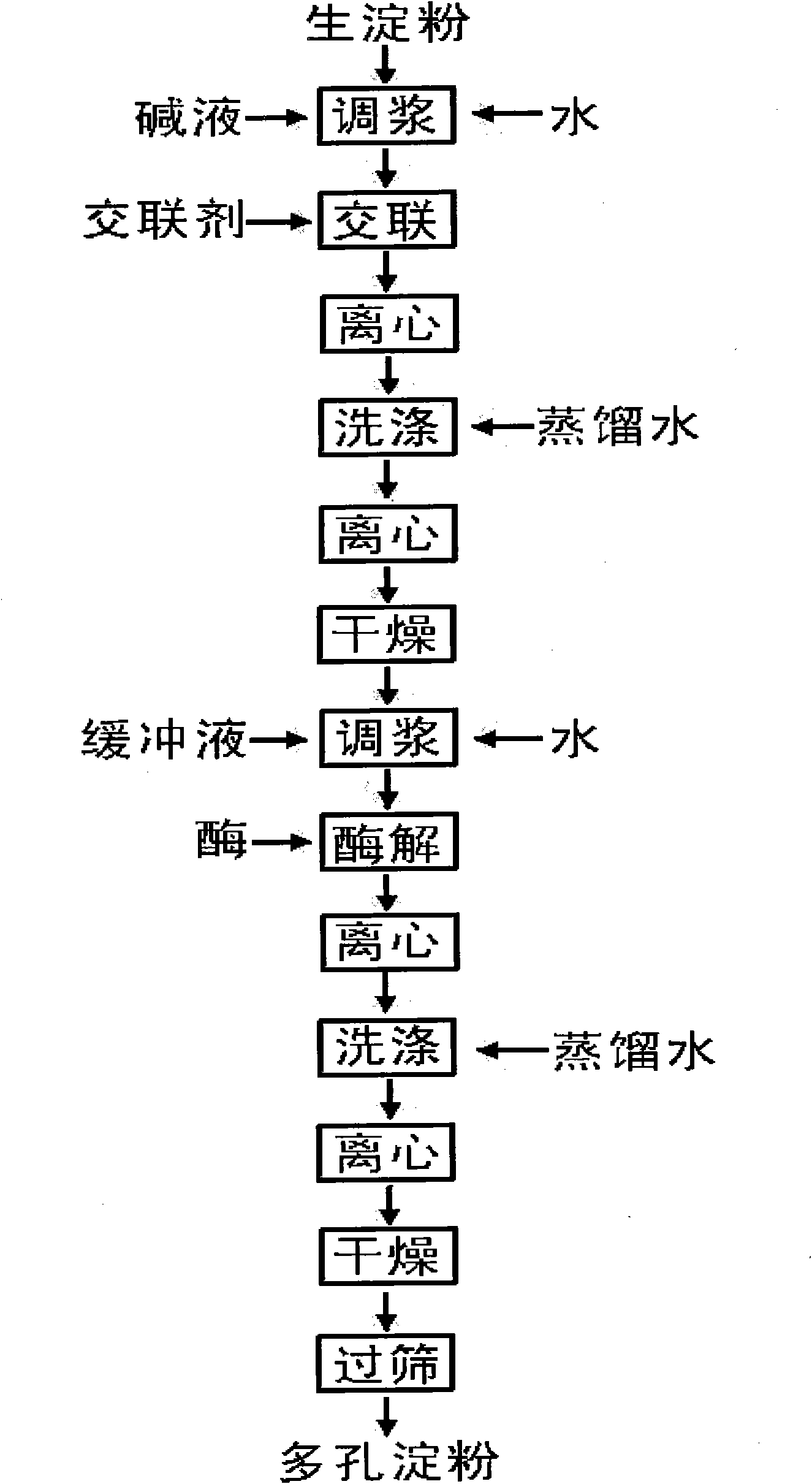

Method for preparing crosslinked porous cassavastarch

InactiveCN101979638AGood for cross-linking reactionIncrease the degree of cross-linkingFermentationMolecular networkChemistry

The invention discloses a method for preparing crosslinked porous cassavastarch, which is to regulate the concentration of cassavastarch suspension to a diluter range from 20 to 34.8 weight percent for facilitating cross-linking reaction, achieving high degree of crosslinking and ensuring the quality uniformity of the crosslinked starch and creating a favorable condition for subsequent enzymolysis. The prepared crosslinked porous cassavastarch has a compact molecular shell structure, is stable in structure, enzymolysis resistant, chemically stable, free from collapse, safe, nontoxic, biodegradable and widely applicable and allows the size of the aperture of the molecular network to be adjusted by processes. In the preparation method, the production process is simple, the raw material cassavastarch is rich, cheap and readily available, the production cost is low, the production scale can be adjusted flexibly and the adaptability is high. The method is applicable to common fine starch manufacturers, chemically modified starch manufactures and common food, medicine, industrial, farm chemical, pesticide manufacturers and other manufacturers.

Owner:南宁创新科技医药技术有限公司

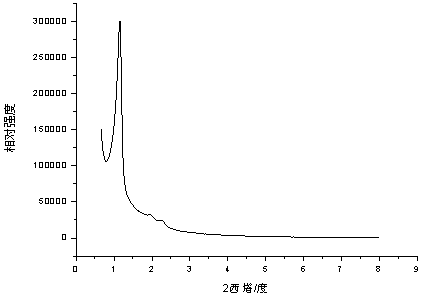

Ellipsoidal nitrogen-doped mesoporous carbon, and preparation method and applications thereof

InactiveCN103407986AHigh bulk densityHigh specific capacitanceHybrid capacitor electrodesCarbon preparation/purificationPhysical chemistrySupercapacitor

The invention discloses a preparation method of ellipsoidal nitrogen-doped mesoporous carbon. Ellipsoidal mesoporous silica is taken as a hard template, an organic high-molecular polymer is taken as a carbon source, a precursor containing nitrogen is taken as a nitrogen source, and ethanol is taken as a solvent. The preparation method comprises following steps: full immersing of the carbon source and the nitrogen source into the pores of ellipsoidal mesoporous silica is realized by stirring, and ellipsoidal mesoporous silica is dried after complete volatilization of ethanol so as to obtain nitrogen-doped ellipsoidal mesoporous carbon; in nitrogen atmosphere, nitrogen-doped ellipsoidal mesoporous carbon is heated to 600 DEG C at a heating rate of 1 DEG C / min, and is calcined for 2h, and then nitrogen-doped ellipsoidal mesoporous carbon is heated to 700 to 1000 DEG C at a heating rate of 2 DEG C / min, and is calcined for 2h so as to obtain an ellipsoidal mesoporous carbon / silica composite material; and then the ellipsoidal mesoporous carbon / silica composite material is stirred in an acid solution for 2h, and is centrifuged, washed and washed so as to obtain ellipsoidal nitrogen-doped mesoporous carbon. Stacking density of ellipsoidal nitrogen-doped mesoporous carbon is relatively high, and the mesoporous structure is orderly, so that ellipsoidal nitrogen-doped mesoporous carbon can be used as an electrode material for preparation of supercapacitors.

Owner:SHANGHAI INST OF TECH

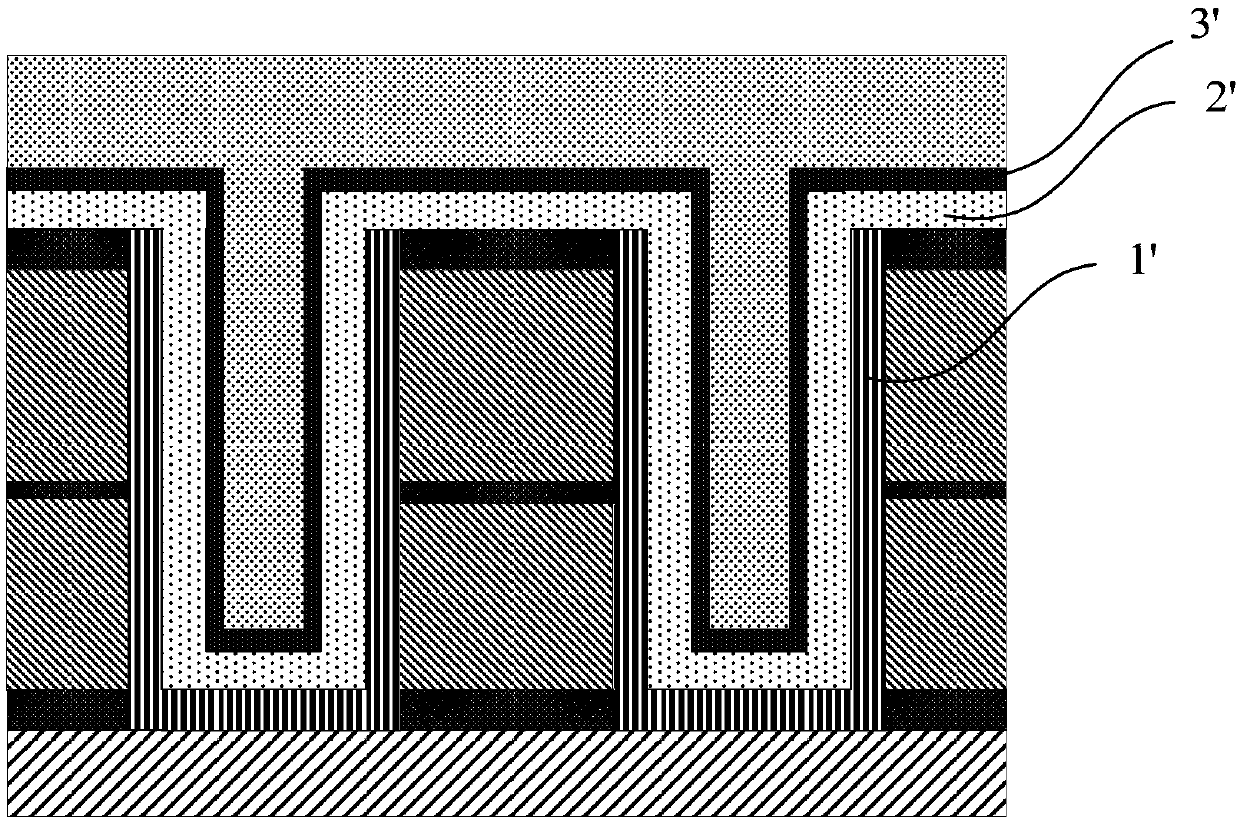

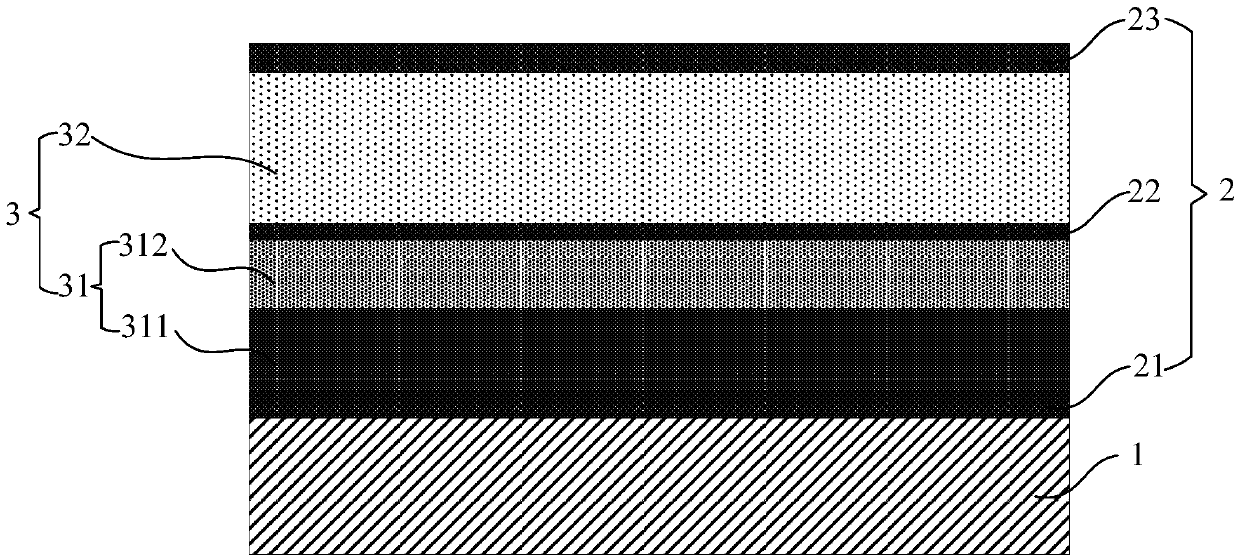

Double-sided capacitor structure and preparation method thereof

PendingCN108717936AHigh mechanical strengthGuaranteed CapacitanceTransistorSemiconductor/solid-state device detailsCapacitanceElectrical conductor

The invention provides a preparation method of a double-sided capacitor structure. The preparation method of the double-sided capacitor structure comprises the following steps: 1) providing a semiconductor substrate, and forming a stacked structure on the semiconductor substrate; 2) forming a graphical mask layer on the stacked structure, and etching a plurality of capacitance holes in the stackedstructure based on the graphical mask layer; 3) forming a lower electrode layer at the bottom and side walls of the capacitance holes; 4) forming a mask layer on the structure obtained by the step 3,and forming a mask opening on the stacked structure based on the mask layer, wherein the opening exposes 20% to 60% inner aperture area of the capacitance holes; and removing a sacrificial layer based on the mask opening; and 5) forming a capacitive dielectric layer on the inner and outer surfaces of the lower electrode layer, and forming an upper electrode layer on the outer surface of the capacitive dielectric layer. The invention adopts different opening modes to form the double-sided capacitor with denser density, stronger mechanical strength and guaranteed capacitance value through controlling the opening area of the capacitor and using a supporting layer etching gas source.

Owner:CHANGXIN MEMORY TECH INC

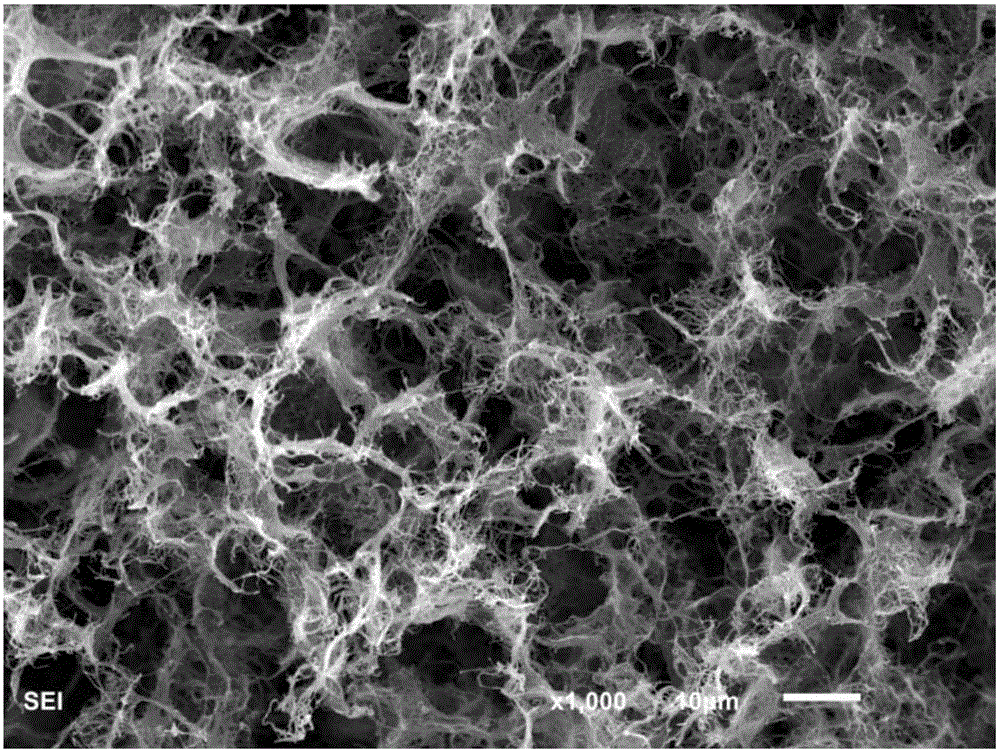

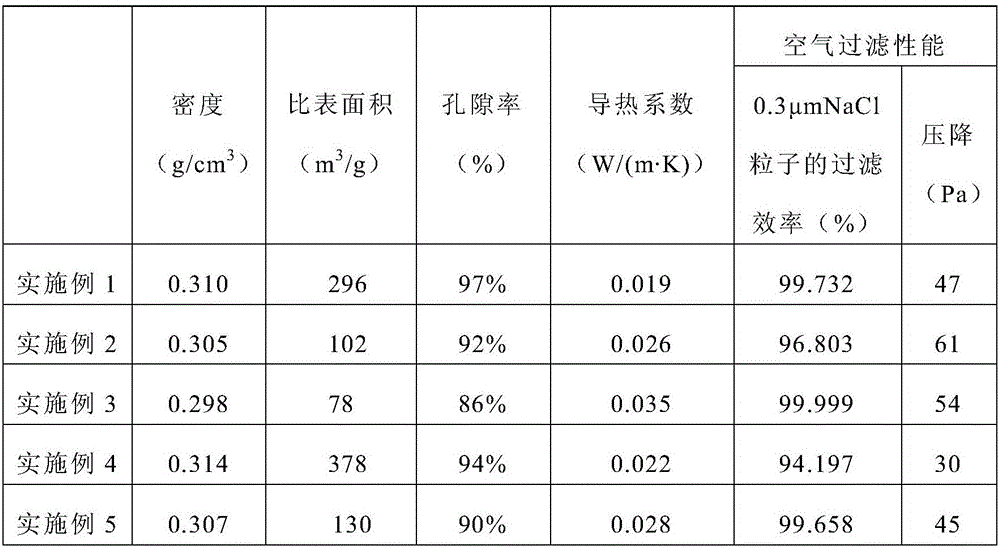

Polymeric nanofiber-based aerogel material and preparation method thereof

The invention discloses a polymeric nanofiber-based aerogel material and a preparation method thereof, and belongs to the fields of aerogel materials and preparation methods thereof. The preparation method comprises the steps that a thermoplastics polymer and cellulose acetate butyrate are subjected to melt blending, drawing, extracting and the like to prepare polymeric nanofibers, the polymeric nanofibers are added into water or a water solvent prepared from water and an organic solvent to generate polymeric nanofiber dispersion liquid, a cross-linking reaction is conducted to obtain cross-linked polymeric nanofiber suspension liquid, freeze drying is conducted on the cross-linked polymeric nanofiber suspension liquid, and then the polymeric nanofiber-based aerogel material is prepared. The polymeric nanofiber-based aerogel material prepared through the method has the advantages of being obvious in nanofiber porous structure, good in mechanical property and the like. The material prepared through the method can be applied to the fields of air filtration, thermal insulation, adsorption and the like directly or by being composited with other materials.

Owner:武汉维晨科技有限公司

Preparation method of non-woven fabric for shoe linings

InactiveCN105019143AEasy extractionIncrease relative volatilityInsolesNon-woven fabricsActivated charcoal powderAfter treatment

The invention relates to the field of preparation of non-woven fabrics for shoe linings and discloses a preparation method of non-woven fabric for shoe linings. The preparation method comprises following steps of: (1) taking and adding natural perfume to water, adding sea-foam stone powder to a solution, allowing mixed liquor to stand and obtaining sea-foam stone powder loaded with natural perfume by centrifugal and drying treatment; (2) additionally taking activated charcoal powder, aluminum chloride, polyoxyethylene, carboxymethylcellulose, dispersants, silane coupling agents and sea-foam stone powder loaded with natural perfume in order to obtain a mixture; (3) fusing isotatic polypropylene slices and the mixture and performing spinning, drawing, web-forming and hot-rolling operation in order to obtain base cloth of the non-woven fabric; (4) utilizing finishing liquor to process one of surfaces of the base cloth of the non-woven fabric and performing roll-pressing operation on the base cloth after treatment; (5) drying the base cloth of the non-woven fabric subjected to roll-pressing operation and thus obtaining the non-woven fabric for shoe linings. The preparation method of non-woven fabric for shoes is good in deodorization function and breathability and high in hardness so that the shape of a vamp can be kept for a long time.

Owner:LANXI YIMING WEAVING

Preparation method of diamond segment

ActiveCN104399985AEasy to prepareImprove sharpnessTurbinesOther manufacturing equipments/toolsVolumetric Mass DensityHardness

The invention discloses a preparation method of a diamond segment. The preparation method comprises the following steps in sequence: a certain amount of prealloy powder or elemental metal powder, diamond and additives are weighed and mixed; the diamond segment is formed through pressing; the pressed diamond segment is sintered; and the sintered diamond segment is polished, wherein the sintering is high-temperature continuous sintering. The preparation method of the diamond segment is simple, wide in application range and low in processing cost, the sharpness of a product is good, the production efficiency is high, edge breakage is almost avoided, and automatic batch production can be realized. According to the diamond segment finishing high-temperature continuous sintering, the diamond can be firmly held by the prealloy powder or elemental metal powder matrix, so that the diamond segment has longer service life and higher sharpness, the relative density of the sintered diamond segment can be higher than 90%-98%, and the hardness can reach HRB 100-115.

Owner:广东新劲刚金刚石工具有限公司

Method for three-dimensionally cultivating white mushroom by wall soil-covered cultivation process

InactiveCN101810103AMeet the requirements for fruitingImprove land utilizationHorticultureRural areaEcological environment

Owner:镇江市食用菌研究所

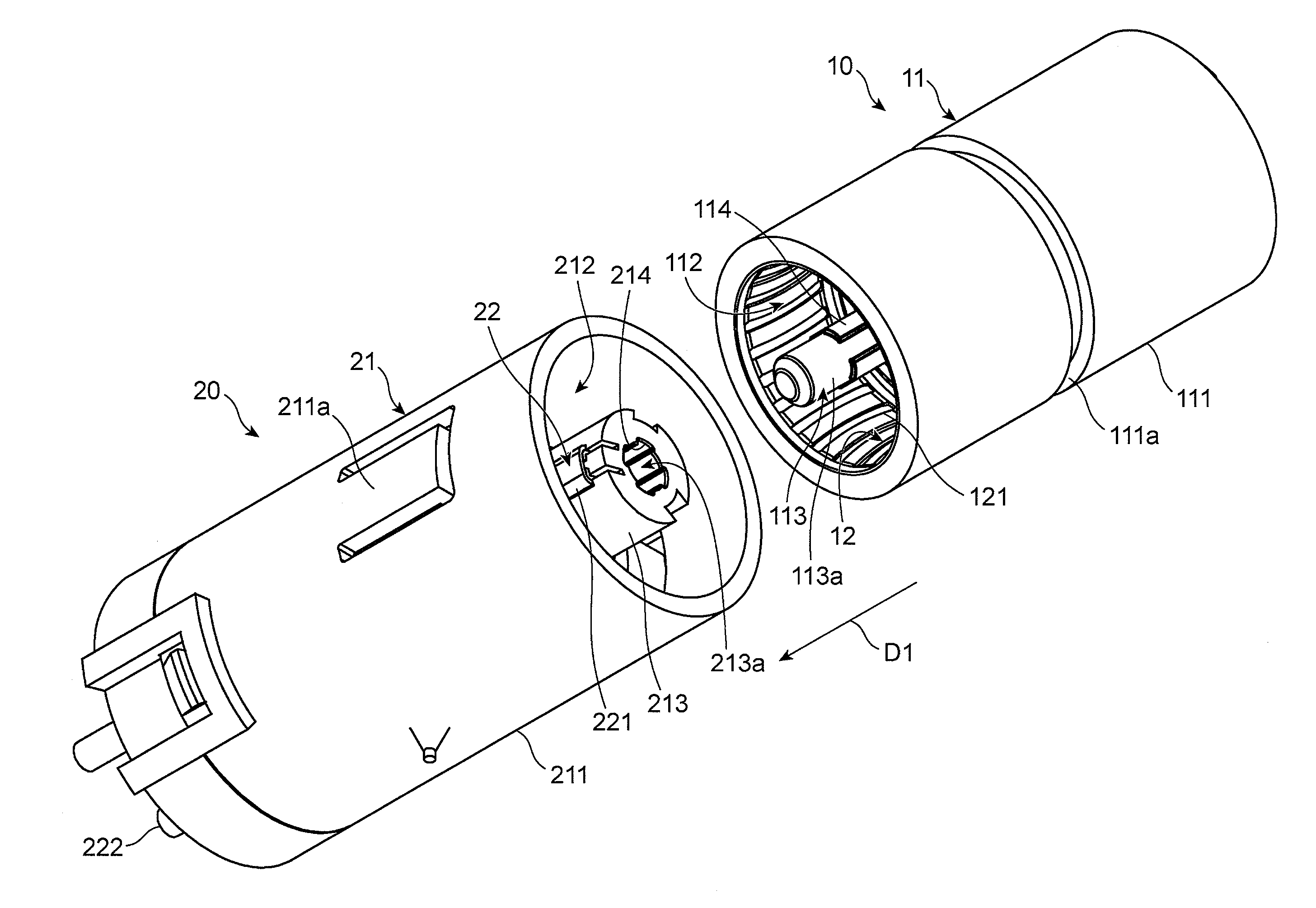

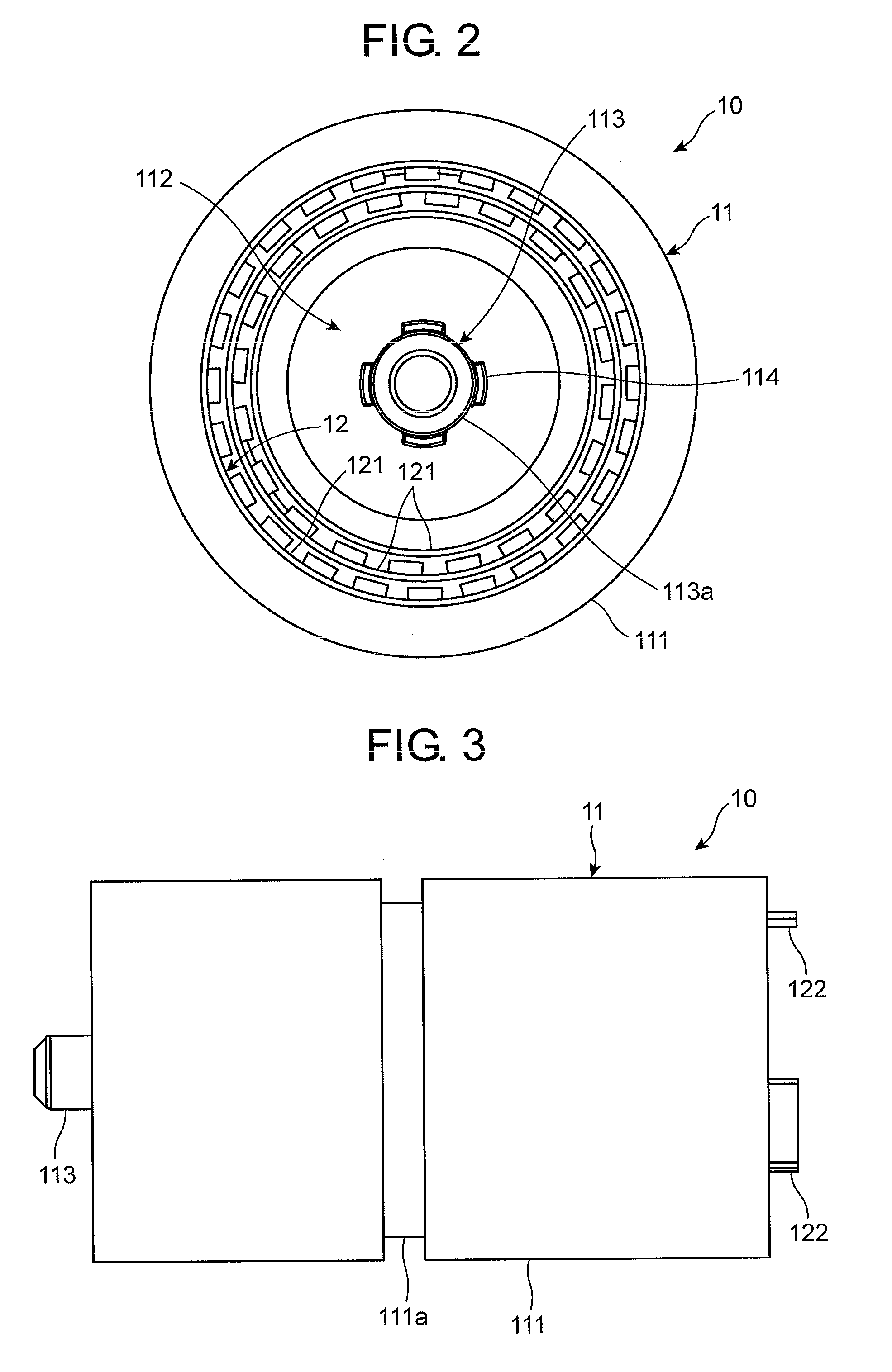

Electric connector

InactiveUS20150099391A1Proof stress is improvedImprove electrical connection reliabilityIncorrect coupling preventionTwo-part coupling devicesMechanical engineeringContact plane

An electric connector includes a first housing including a guide shaft and a second housing including a guide hole into which the guide shaft is inserted, the guide shaft including a main body, and a projection radially projecting from the main body, the guide hole being formed at an inner surface thereof with a groove into which the projection is fit, the projection and the groove being formed such that a first imaginary line intersects with a second imaginary line, the first imaginary line being defined by extending a contact plane at which the projection and the groove make contact with each other when the first housing rotates relative to the second housing, towards a center of the main body, the second imaginary line being defined as a line bisecting a top surface of the projection and extending towards a center of the main body.

Owner:DAIICHI SEIKO CO LTD

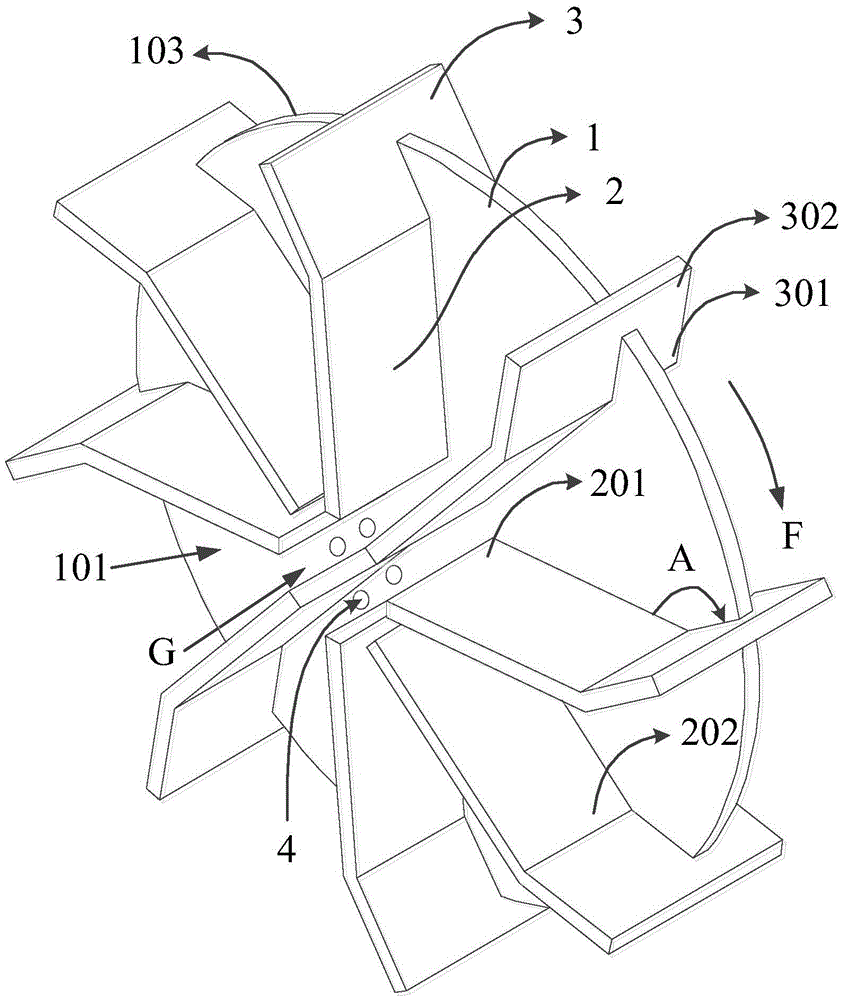

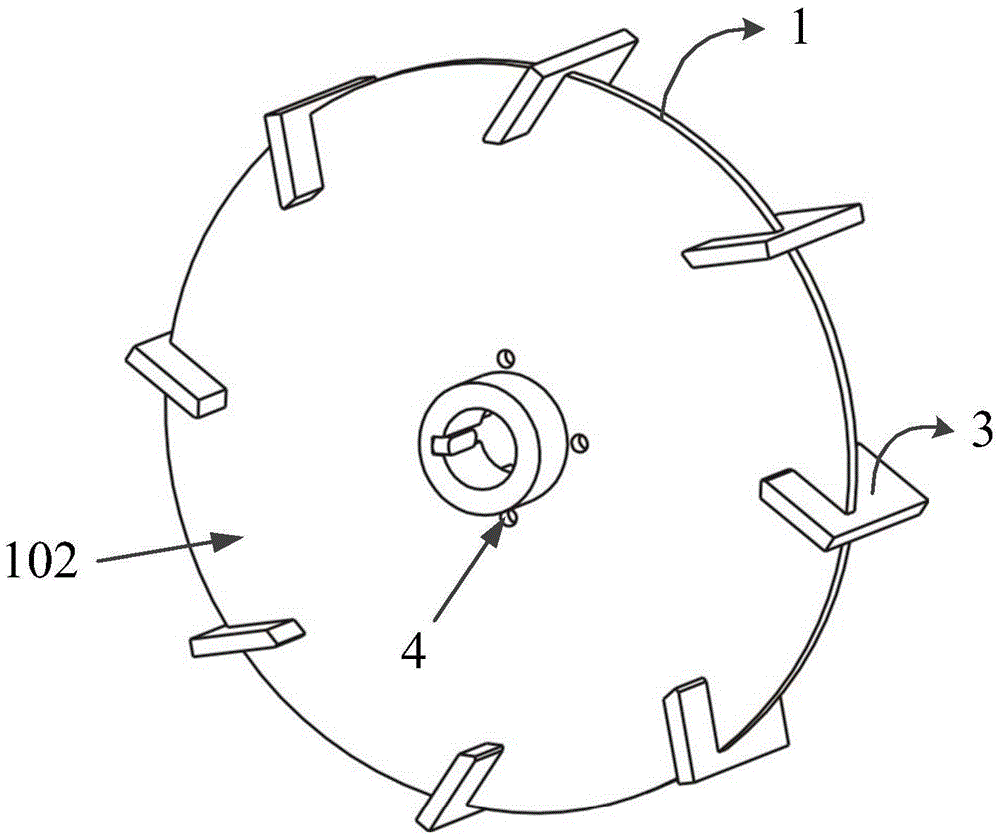

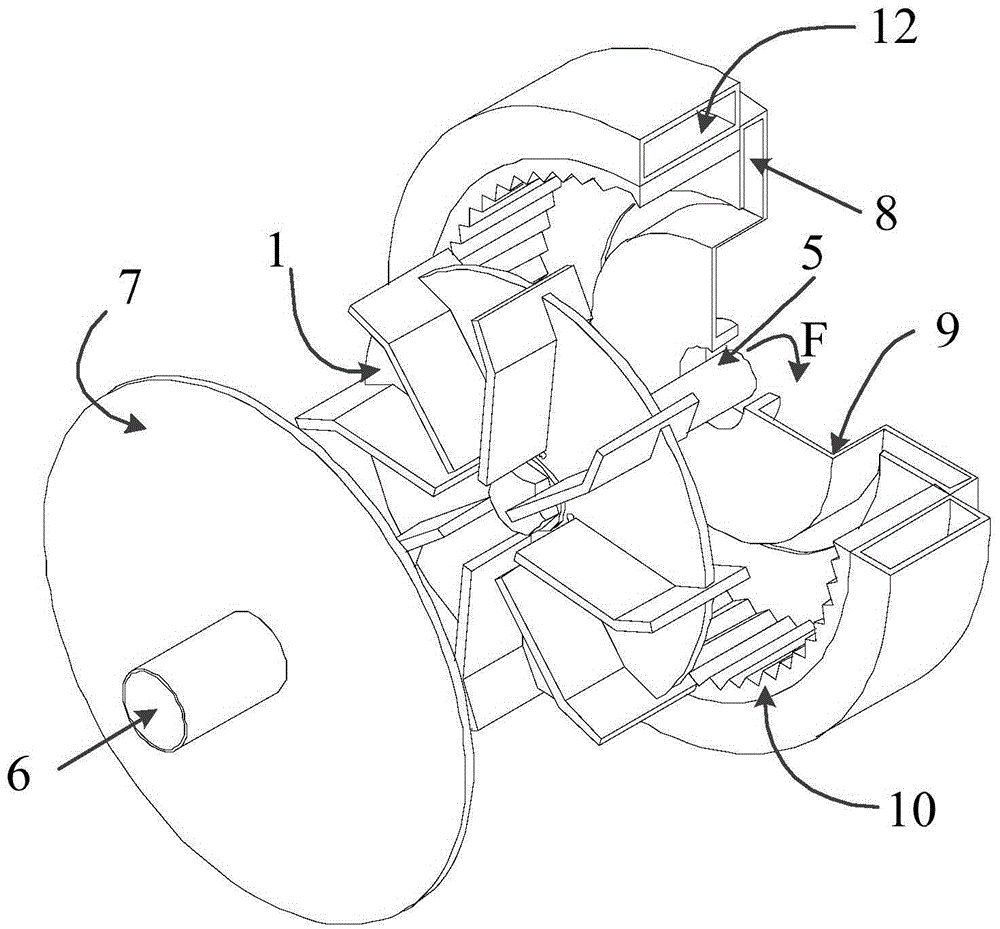

Impeller, superfine mill and superfine milling system

The invention provides an impeller, a superfine mill applying the impeller and a superfine milling system comprising the superfine mill. The impeller comprises a wheel disc, straight surface type blades and straight surface type impact plates, and an abrasion-resistant layer is adhered to the surface of each straight surface type blade. The straight surface type blades are multiple and uniformly arranged on the wheel disc in the radial direction. The tail end of each straight surface type blade is provided with one corresponding straight surface type impact plate in the extension direction of the center of the wheel disc to the outer diameter edge of the wheel disc, and a first included angle is formed between each straight surface type blade and the corresponding straight surface type impact plate. The tail ends of the straight surface type blades are located within the outer diameter edge of the wheel disc. The initiating end of each straight surface type impact plate is connected with the tail end of the corresponding straight surface type blade. The tail ends of the straight surface type impact plates exceed the outer diameter edge of the wheel disc. According to the impeller, the superfine mill applying the impeller and the superfine milling system comprising the superfine mill, high-hardness nonmetal or metal can be milled into superfine powder; in addition, abrasion of equipment parts is small, and the function of particle size classification is achieved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

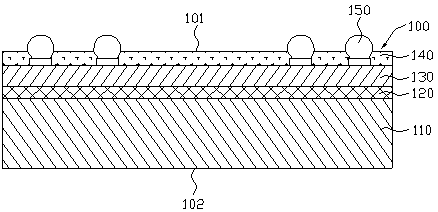

Wafer level scribing method for CIS (Cmos image sensor) product

InactiveCN103358032AAvoid breakingNot easy to collapseSemiconductor/solid-state device manufacturingLaser beam welding apparatusPhysicsCMOS

The invention relates to a wafer level scribing method for a CIS (Cmos image sensor) product, and belongs to the technical field of semiconductor packaging. The wafer level scribing method for the CIS product comprises the following processes: attaching a wafer (100) of the CIS product to a scribing film (400); cutting a structure except a glass layer (110) by a blade (200), and cutting the glass layer (110) by a laser (300); and performing splitting, film expansion and picking on the wafer (100) to form an independent single CIS product. The wafer level scribing method for the CIS product, provided by the invention, is high in scribing speed, good in scribing quality and low in production cost, and can be applied to a complicated product structure.

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING CO LTD

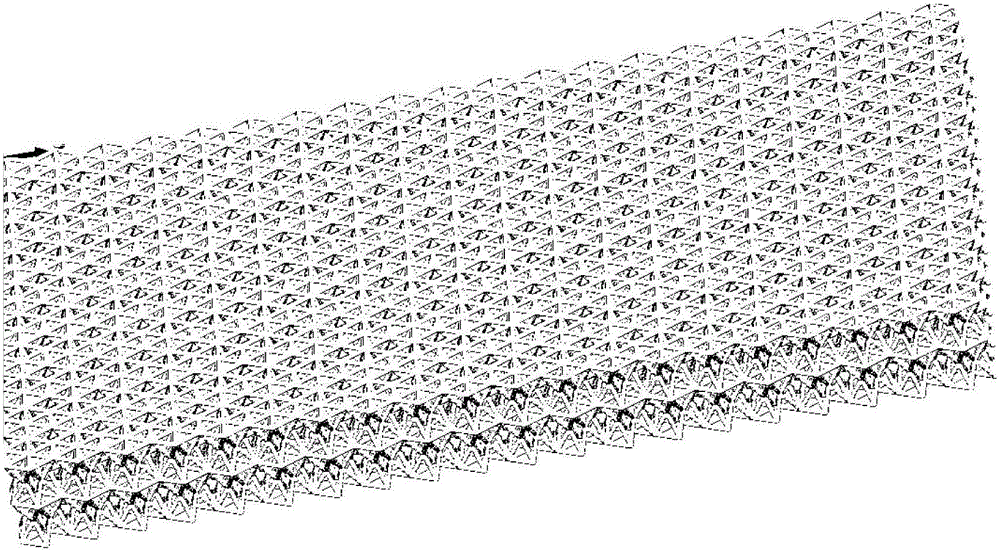

Laser selected area fusion forming method for weldless metal dot matrix component

InactiveCN105057666AUniform and complete structureAvoid Weld DefectsMetallic material coating processesDot matrixEntity model

The invention discloses a laser selected area fusion forming method for a weldless metal dot matrix component. The method includes the following steps that a three-dimensional entity model of the weldless metal dot matrix components is established; slicing treatment is conducted, and the cross section messages of all layers of slices are obtained; a scanning path is generated according to the cross section messages of all the layers; a base plate and metal powder are placed into laser selected area fusion forming equipment, and atmosphere protection is conducted on a forming cavity; a first entity slice layer is prepared; a forming cylinder descends by a layer thickness, the next entity slice layer is prepared, and in this way, the metal dot matrix component is formed by overlapping a plurality of layers ultimately; after preparing is completed, cooling is conducted for 30 minutes, unformed powder is removed, then the base plate is taken out, and the weldless metal dot matrix component is obtained through a wire-electrode cutting method. According to the method, the technology is simple and easy to control, operation is easy and reliable, the production period is short, production efficiency is high, and the repeatability is high. The weldless metal dot matrix structural component formed through the method is excellent in mechanical property, and not prone to deformation or collapse.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

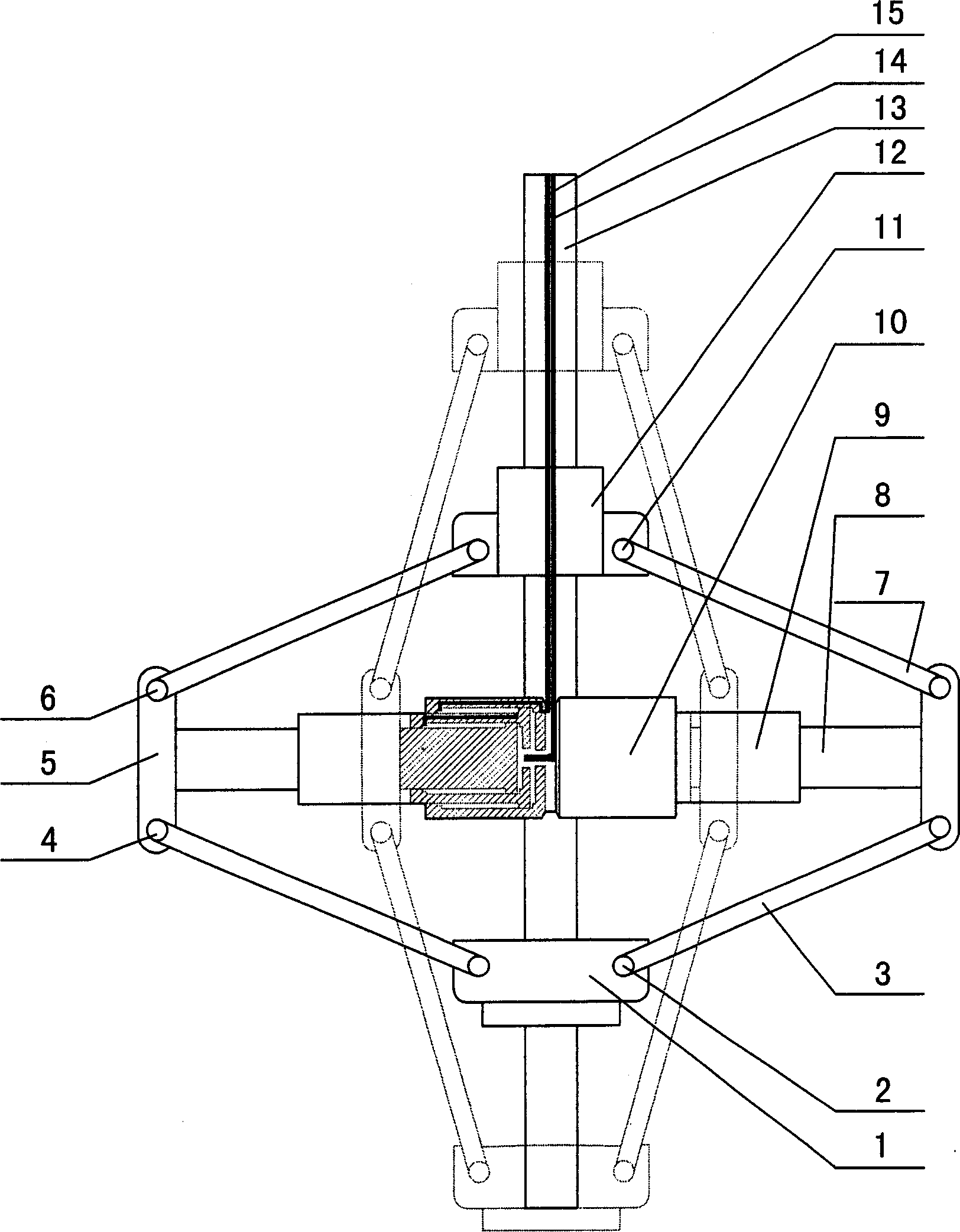

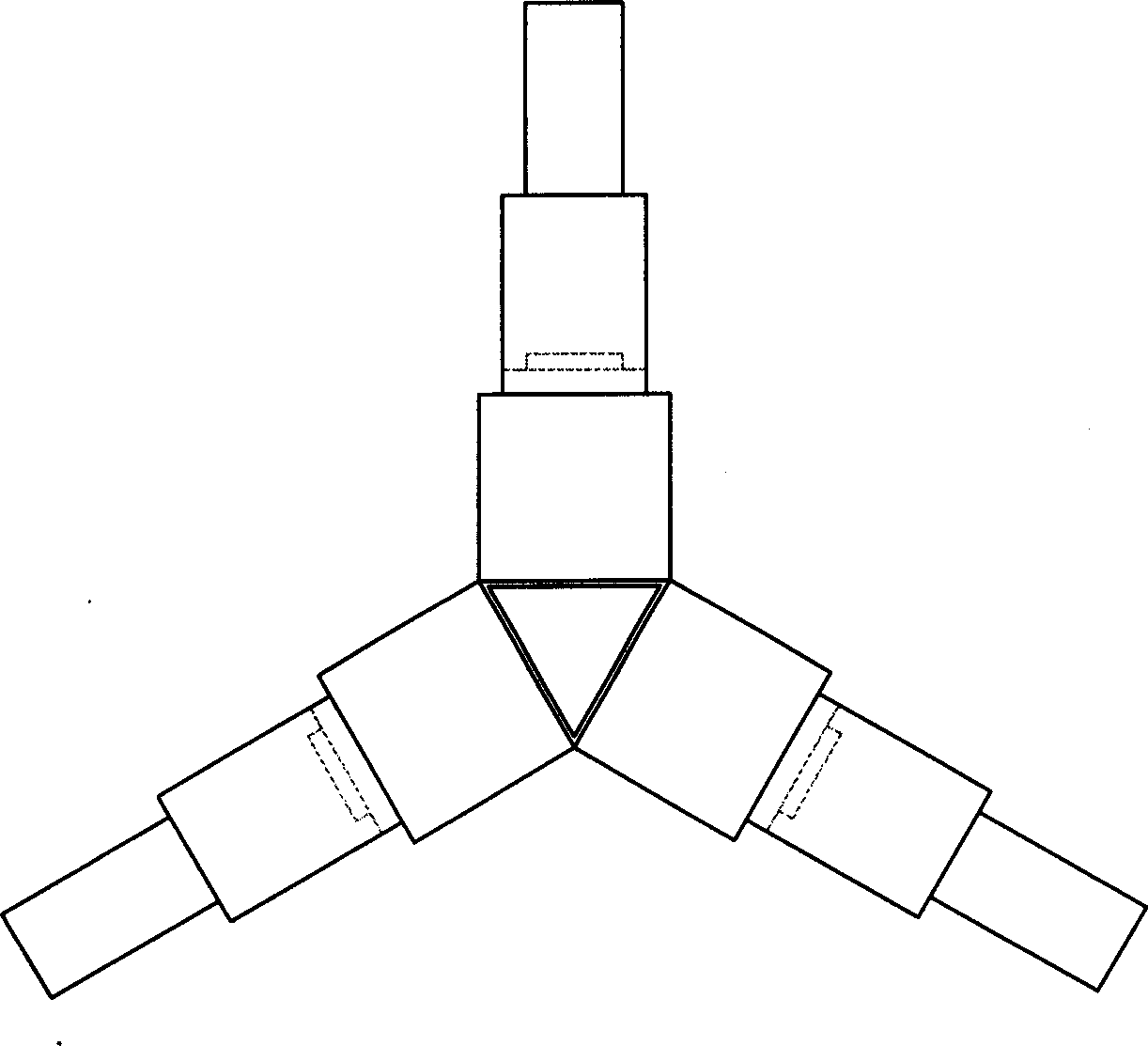

Gradient pushing and enlarging device

InactiveCN1800508AStrong shear resistanceSoil disturbance is smallBulkheads/pilesDrilling machines and methodsLow volumeHydraulic pressure

The invention relates to a gradient expansion device which is formed by expansion arm, cylinder, piston rod, axial pin, moving oil pipe, up-down connection disc, and connection rod group. Wherein, said cylinder is gradient hydraulic cylinder formed by big cylinder, middle cylinder and piston rod; the connection rod is connected to the gradient hydraulic cylinder; the big cylinder is connected to the middle cylinder; the middle cylinder is connected to the piston rod which is connected to the middle expansion arm; the middle expansion arm is connected to the upper and lower expansion arms via axial pins; the upper and lower expansion arms are individually connected to the upper and lower connection discs via axial pins; and the upper and lower connection discs are sheathed with connection rods. The invention uses direct horizontal expansion, with large expansion force, high speed, little disturb on soil, stable expanded chamber, high anti-cutting property, high efficiency, lower volume, lighter, and improved bearing ability, while it can solve the problem of using large-diameter multi-section expansion post to expand hole, to reduce the operation cost.

Owner:北京中阔地基基础技术有限公司

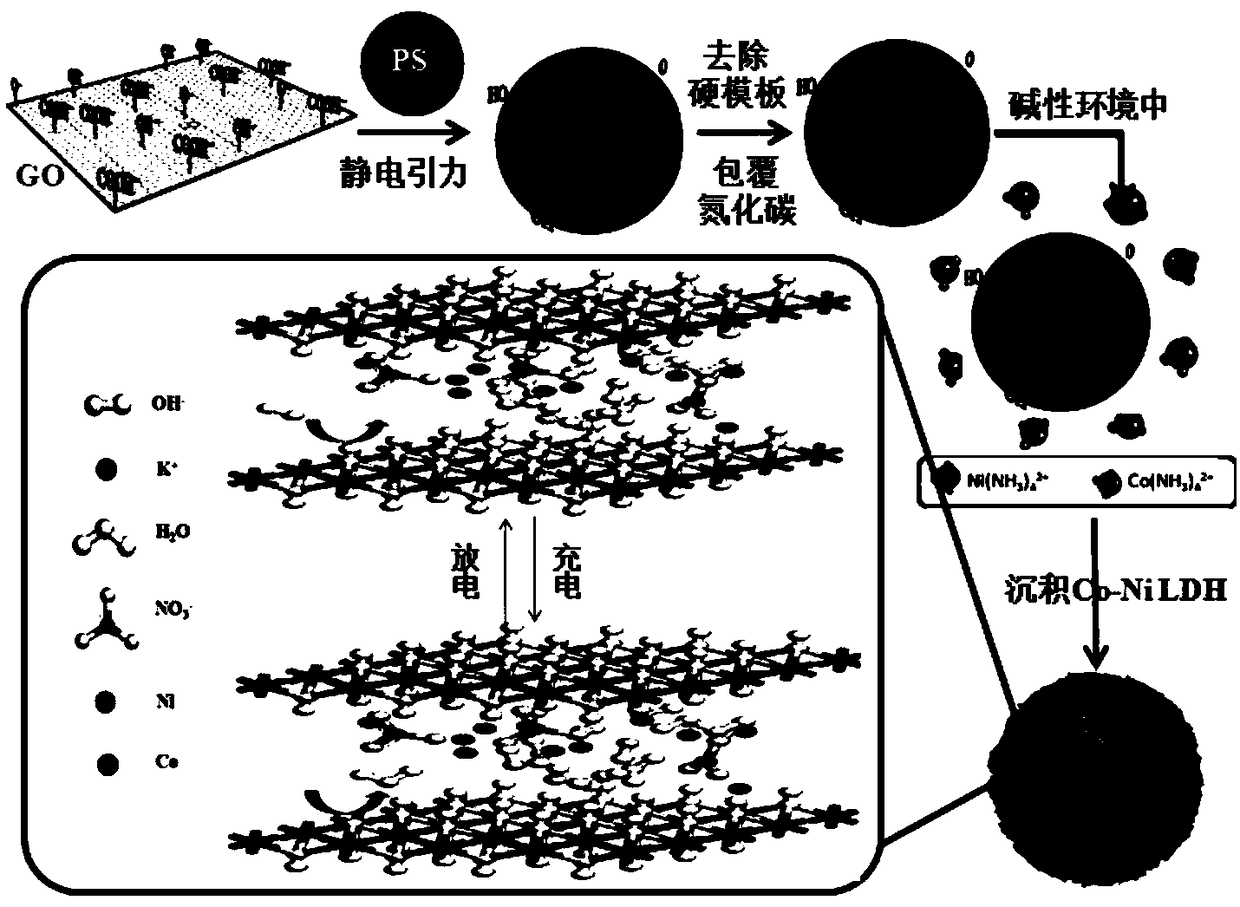

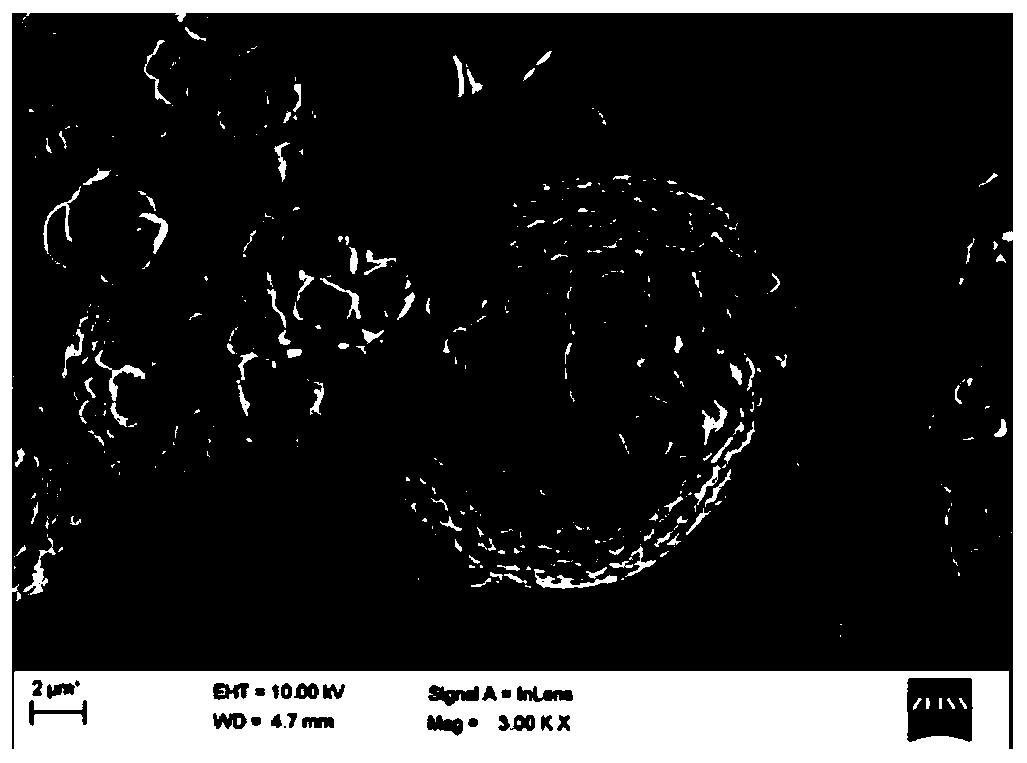

Cobalt-nickel-double-metal-hydroxide-nanosheet/carbon-nitride-coated nitrogen-doped hollow graphene sphere composite material and preparation method thereof and application

InactiveCN109300703AImprove stabilityAvoid deformationHybrid capacitor electrodesElectric capacityUnit structure

The invention discloses a cobalt-nickel-double-metal-hydroxide-nanosheet / carbon-nitride-coated nitrogen-doped hollow graphene sphere composite material and a preparation method thereof, and application as a supercapacitor electrode material. The composite material comprises a cobalt-nickel-double-metal-hydroxide-nanosheet / carbon-nitride-coated nitrogen-doped hollow graphene sphere has a 3D spherical appearance; and the specific surface area is 100 to 1000m<2> / g and the average pore diameter of 1 to 200mm. In addition, the preparation method includes the following steps: preparing a small polystyrene sphere; preparing a polyaniline-coated graphene sphere; preparing a carbon-nitride-coated nitrogen-doped hollow graphene sphere; and preparing a cobalt-nickel-double-metal-hydroxide-nanosheet / carbon-nitride-coated nitrogen-doped hollow graphene sphere composite material. Therefore, a problem of series agglomeration of the cobalt-nickel double-metal hydroxide unit structure during the traditional preparation technology process is solved effectively; and a novel method is provided for preparing an electrode material with advantages of large specific surface area, high flexibility, high electric capacity, and high stability.

Owner:ZHEJIANG SCI-TECH UNIV

Protuberant hot-melt road marking coating, and preparation method and construction method thereof

ActiveCN109021830AGood formabilityImprove deformation resistanceRosin coatingsTraffic signalsHot meltRosin

The invention discloses a protuberant hot-melt road marking coating, and a preparation method and a construction method thereof, and relates to the technical field of road marking construction. The protuberant hot-melt road marking coating is mainly prepared from the following raw materials by the weight percentage: 3-8% of petroleum resin, 3-8% of rosin resin, 2-6% of polyamide resin, 0.5-1.5% ofalkyd resin, 20-50% of a reflective material, 1-10% of a pigment, 0-1.5% of an anti-sedimentation agent, and the balance a filler. The defects of poor formability, poor cohesion, poor low temperatureresistance, easy cracking when being used in winter and poor deformation resistance at high temperature of a traditional road marking coating are alleviated. The formula of the protuberant hot-melt road marking coating improves the performance of the coating through the cooperative use of petroleum resin, rosin resin, polyamide resin and alkyd resin; pigments and fillers, the reflective materialand the optional anti-sedimentation agent are added for compounding, so the product has the advantages of good performance, improved high temperature anti-compressive performance, no cracking in winter and no collapse when being pressed in summer.

Owner:河北新思维创业空间服务有限公司 +1

Positive electrode material, positive electrode comprising same, and electrochemical device comprising positive electrode material

ActiveCN110416511AUnbreakableImprove structural stabilityPositive electrodesLi-accumulatorsUltrasound attenuationLithium

The invention relates to a positive electrode material, a positive electrode comprising the same, and an electrochemical device comprising the positive electrode material. The positive electrode material includes first particles, wherein the first particles include secondary particles composed of third particles, and the third particles are primary particles; the first particles have an average particle diameter of 5 [mu]m to 20 [mu]m, and the average particle size of the third particles is 200 nm to 700 nm; the first particles comprise first lithium-containing transition metal oxide. The positive electrode material also comprises second particles, wherein the second particles comprise fourth particles and / or secondary particles composed of the fourth particles; the fourth particles are primary particles, wherein the average particle size of the second particles is 3 [mu]m to 5 [mu]m, and the average particle size of the fourth particles is 800 nm to 5 [mu]m; and the second particles comprise second lithium-containing transition metal oxide. The electrochemical device comprising the positive electrode material is significantly improved in terms of energy density, capacity attenuation, and service life.

Owner:NINGDE AMPEREX TECH

Polyolefin resin foam and the process for producing the same

An object of the invention is to provide a polyolefin resin foam which is excellent in flexibility, cushioning property and processability, especially excellent in cutting processability. The present invention relates to a polyolefin resin foam obtained by foaming a polyolefin resin composition using carbon dioxide in a supercritical state, wherein the polyolefin resin composition contains at least: (1) a thermoplastic elastomer composition obtained by subjecting to a dynamically heat treatment a mixture of (A) a rubber, and (B) (B-1) an α-olefin crystalline thermoplastic resin and / or (B-2) an α-olefin amorphous thermoplastic resin, each having a melt tension of less than 3.0 cN at a temperature of 210° C. and at a take-up speed of 2.0 m / min, in the presence of (C) a crosslinking agent; (2) a polyolefin resin; and (3) a nucleant agent having an average particle diameter of from 0.1 μm to less than 2.0 μm. The polyolefin resin foam has a density, for example, of 0.2 g / cm2 or less.

Owner:JSR CORPORATIOON +1

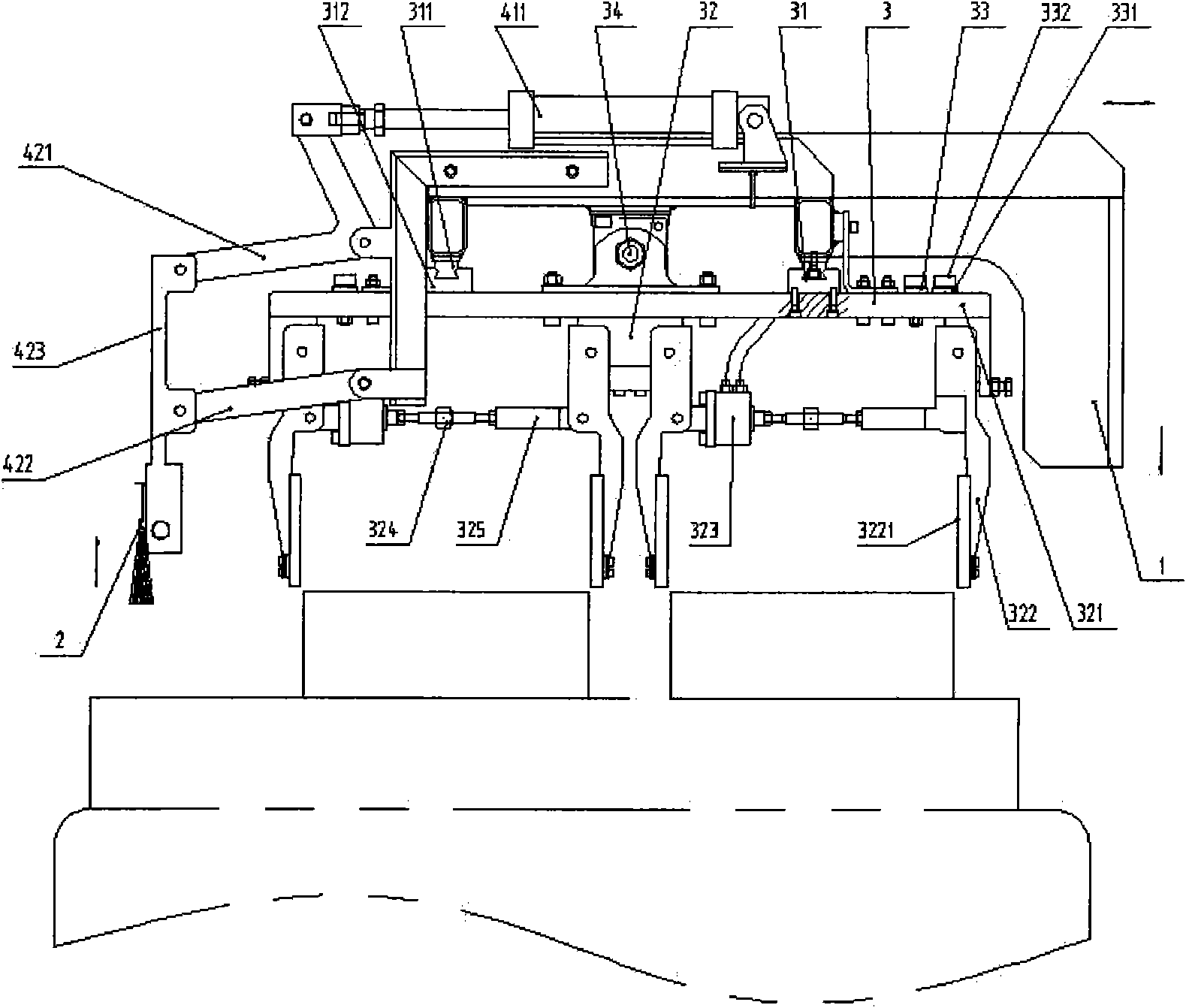

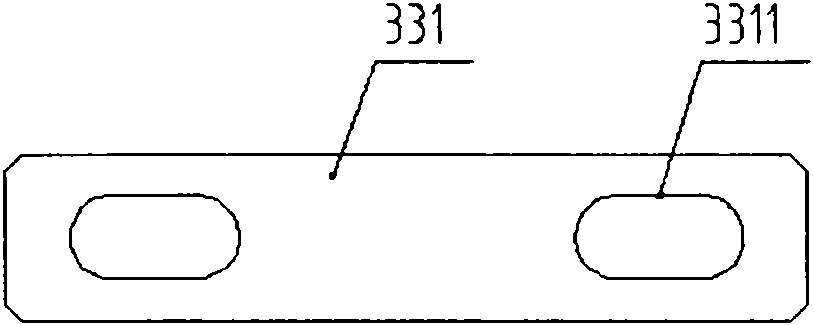

Manipulator of stacker crane

ActiveCN102069530ASimplify the structure of the manipulatorEasy to operateProgramme-controlled manipulatorDischarging arrangementBrickPalletizer

The invention discloses a manipulator of a stacker crane, which relates to the technical field of stacking machinery. The manipulator comprises a stand, a cleaning mechanism and a clamping mechanism, wherein the cleaning mechanism comprises a hairbrush and an air pipe; a tilting driving mechanism is hinged with a tilting mechanism; the tilting driving mechanism and the tilting mechanism are respectively hinged with the stand; and the cleaning mechanism and the tilting mechanism are fixedly connected. When the tilting mechanism is at the inferior limit position, the lower end face of the hairbrush is lower than the lower end face of the clamping mechanism; when the cleaning mechanism is at the superior limit position, the lower end face of the hairbrush is higher than the lower end face ofthe clamping mechanism. In the technical scheme, the manipulator has a simple structure and is convenient to operate and adjust; the hairbrush of the cleaning mechanism can be avoided entraining residual materials and the cleaning effect on the surfaces of unburned bricks is greatly improved. The stacking quality on the unburned bricks is improved and the unburned bricks are compact and are not easy to collapse after being stacked. The clamping mechanism can be used for adjusting the gap between the clamping face and the unburned bricks so that the manipulator has a medium clamping force, theunburned brick clamping effect is improved and the unburned bricks are ensured not to damage.

Owner:洛阳腾和达智能装备有限公司

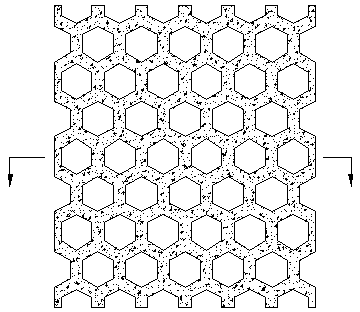

Method of producing honeycomb structure body

InactiveUS20060192324A1Avoid distractionHigh mechanical strengthDispersed particle filtrationCeramic shaping apparatusPorosityMetallurgy

There is provided a method for producing a honeycomb structure, including: a first step of mixing and kneading a ceramic raw material, an organic binder, a water-absorbing resin, and water to obtain clay, a second step of forming the clay into a honeycomb-structured shape and drying the clay to obtain a honeycomb dried body, and a third step of firing the honeycomb dried body to obtain a honeycomb structure having a porosity of 40% or more after firing. The method can suppress defects or deformation upon forming and improve a yield.

Owner:NGK INSULATORS LTD

Antibacterial 3D warp-knitted spacer fabric prepared from antibacterial polyester filaments

InactiveCN102031585ABroad-spectrum antibacterialImprove thermal stabilityWarp knittingMonocomponent polyesters artificial filamentPolyesterPolymer science

The invention relates to the field of polyester filament preparation, in particular to a 3D warp-knitted spacer fabric prepared from antibacterial polyester filaments, which is characterized by being prepared by the following steps of: adding 0.5 to 1 percent of nano-scale silver-loaded zirconium phosphate in the process of synthesizing polyethylene terephthalate to obtain nano-modified polyester; and directly performing a melt spinning process to obtain antibacterial polyethylene terephthalate filaments, and weaving the prepared filaments by using a double tricot machine. The 3D warp-knitted spacer fabric is mainly applied to 3D mattresses, infant mattresses, pillow inners, fillers of auto seat cushions, sofa and other high-grade soft furniture, medical protective articles, air conditioner filter systems and other fields, and the products have excellent properties such as nontoxicity, long-term self-cleaning property, low possibility of sinking, good air permeability and the like.

Owner:王飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com