Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2031results about How to "High specific capacitance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-element composite nano-material, preparation method thereof and application thereof

ActiveCN103117175AComponents are easy to controlImprove stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceHigh energy

The invention provides a multi-element composite nano-material for a super capacitor, and a preparation method of the nano-material. The nano-material comprises a carbon material, metal oxide and conducting polymer, and components of the nano-material can be two or more than two materials. By the aid of the characteristics such as fine electrical conductivity, long cycle life and high specific surface area of the carbon material, high pseudo-capacitance of the metal oxide and low internal resistance, low cost and high operating voltage of the conducting polymer, different types of electrode materials generate synergistic effects, advantages are mutually combined, shortcomings are mutually weakened, the energy storage characteristics of an electric double-layer capacitor and a pseudo-capacitor are simultaneously made full use of, a composite electrode material with high power density, fine circulating stability and higher energy density is prepared, and the multi-element composite nano-material is excellent in comprehensive performance when used for an electrode of the super capacitor, has the advantages of simple preparation process, short cycle, low cost and the like, and is suitable for large-scale industrial production.

Owner:中科(马鞍山)新材料科创园有限公司

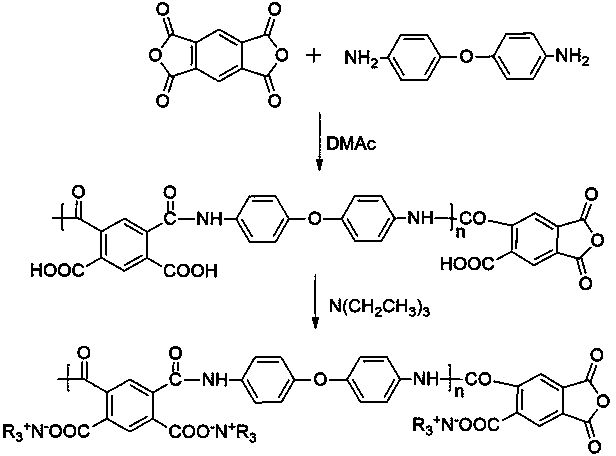

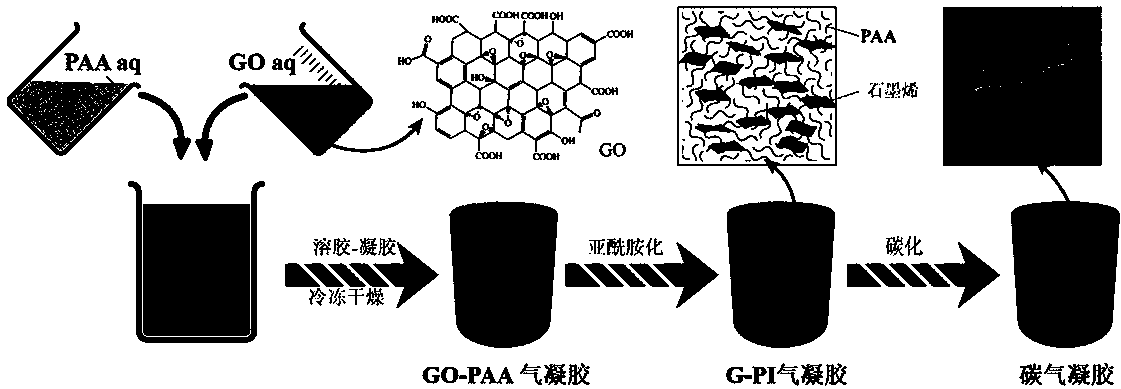

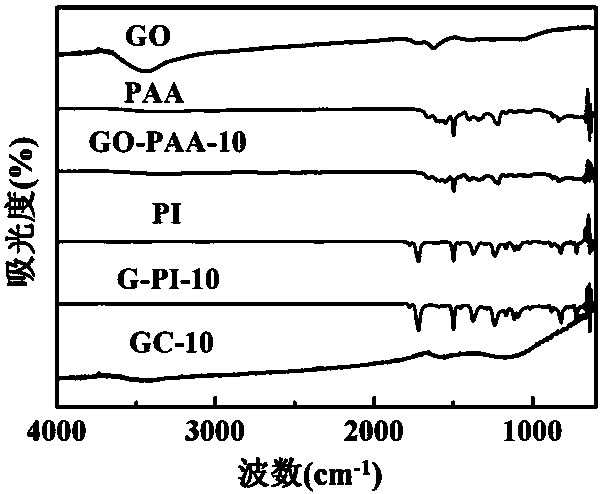

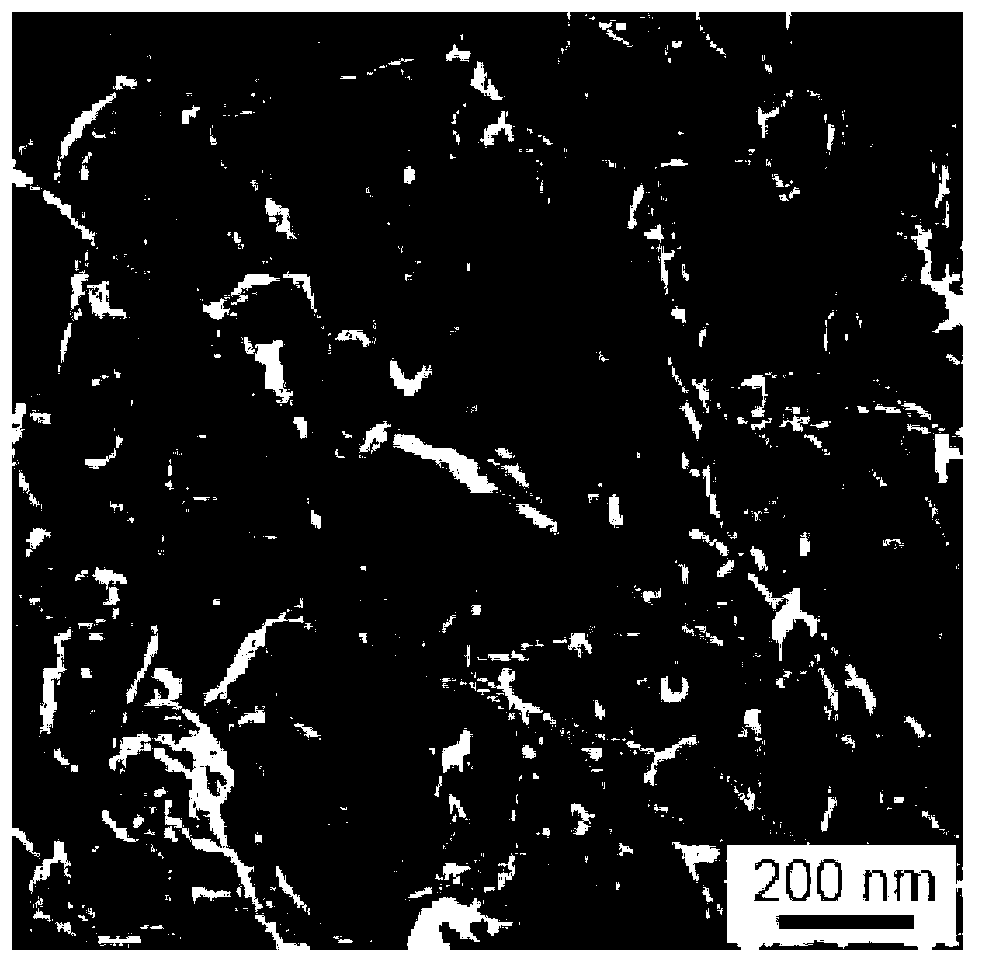

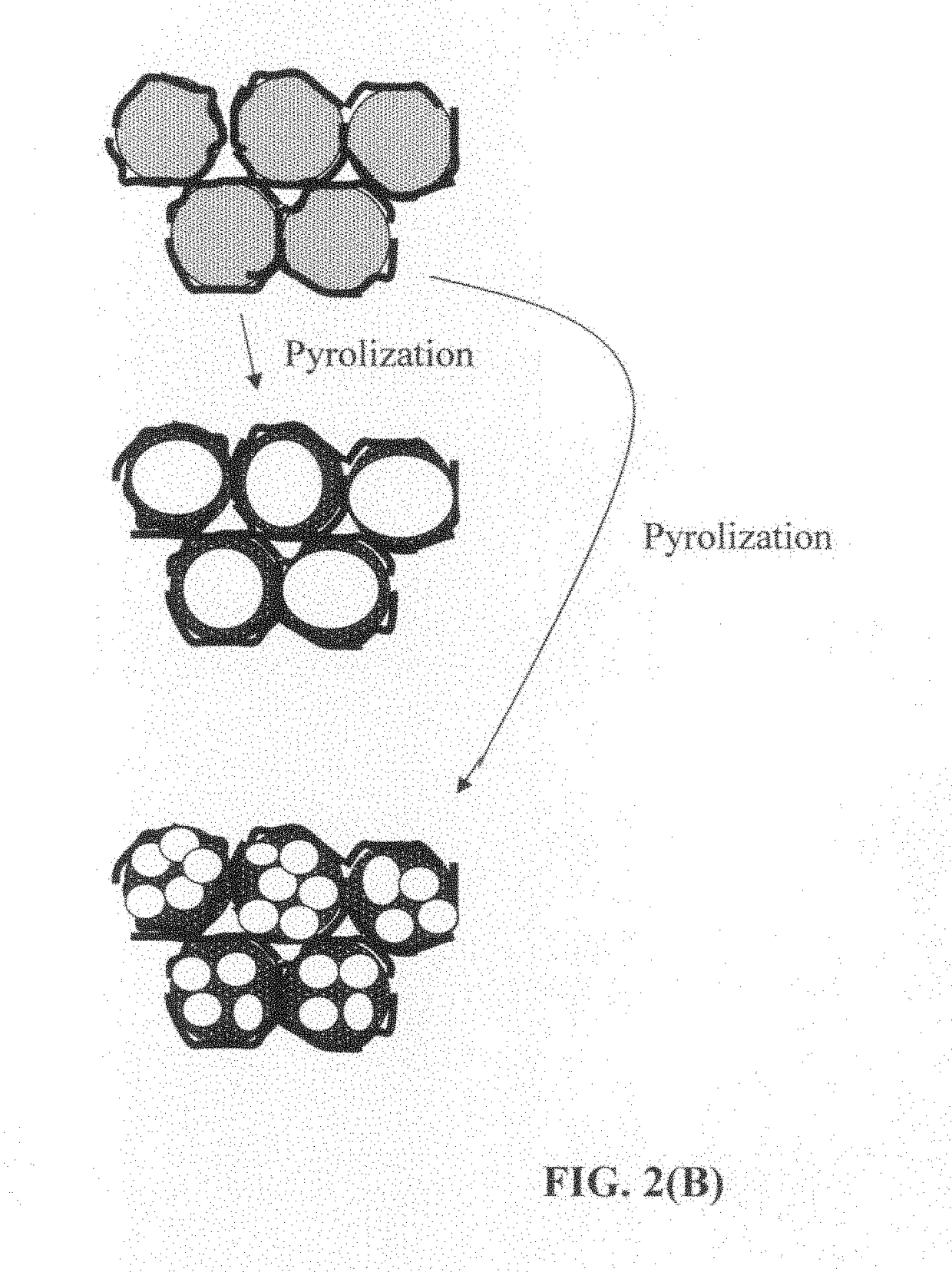

Preparation method of graphene/polyimide-based carbon aerogel

InactiveCN104355302AEasy to makeThe preparation process is environmentally friendlyFreeze-dryingNew energy

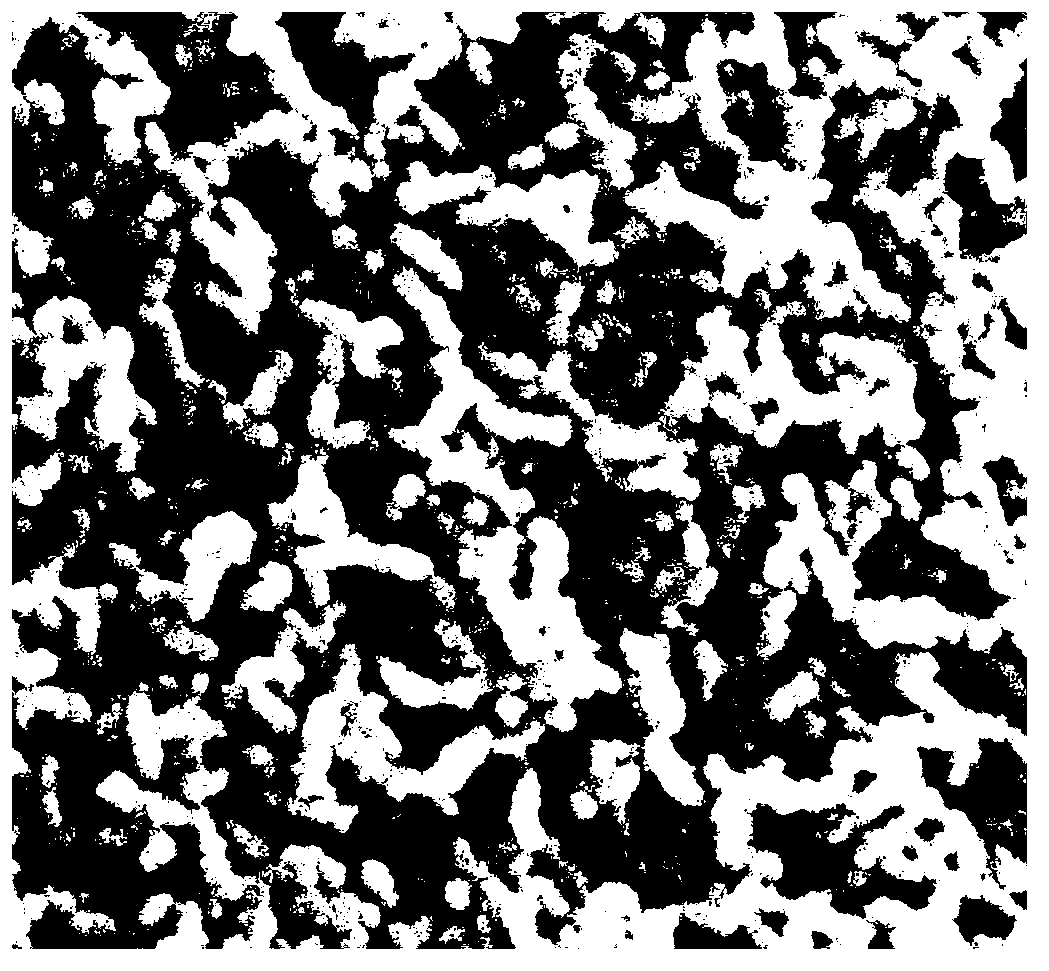

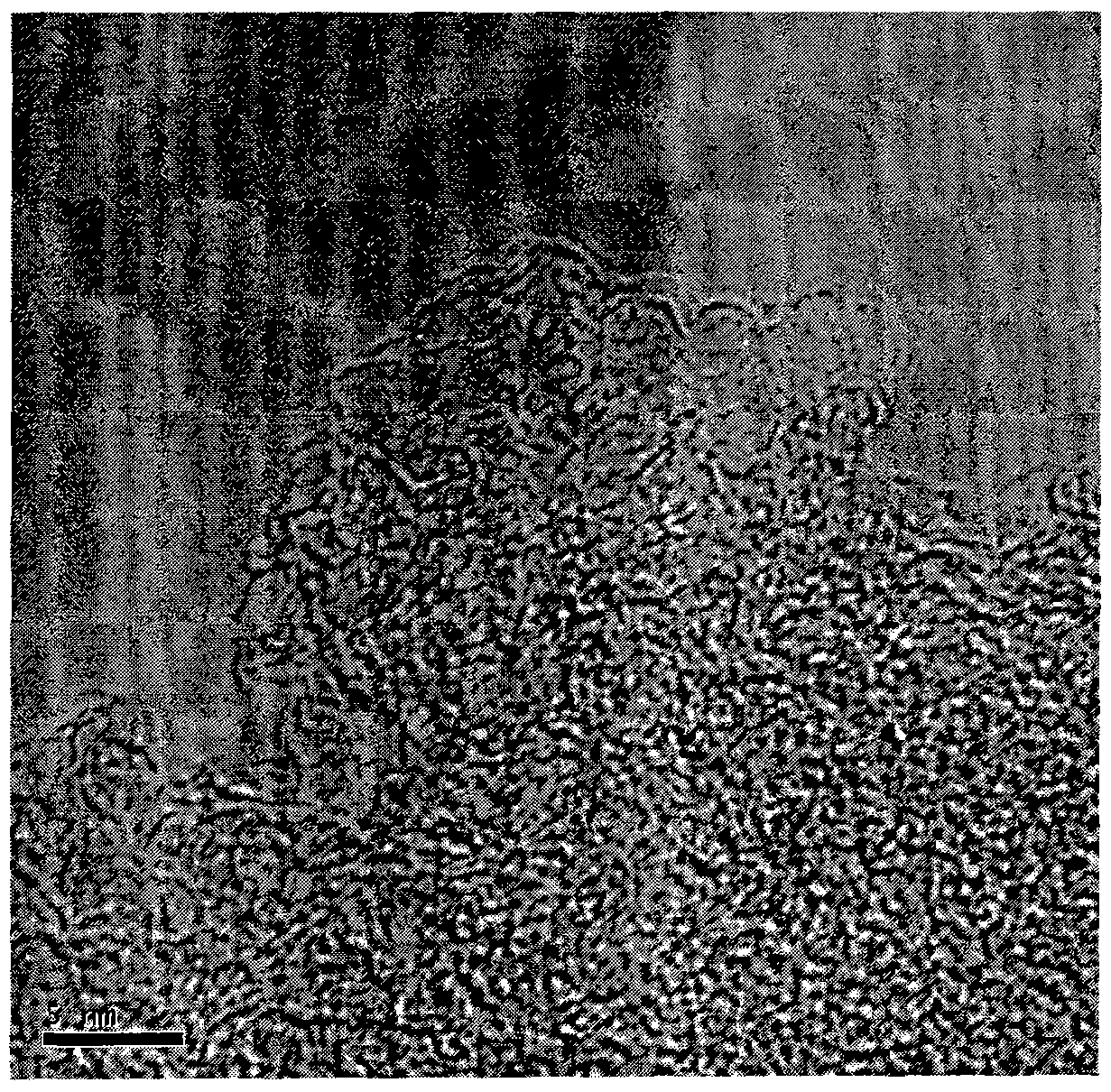

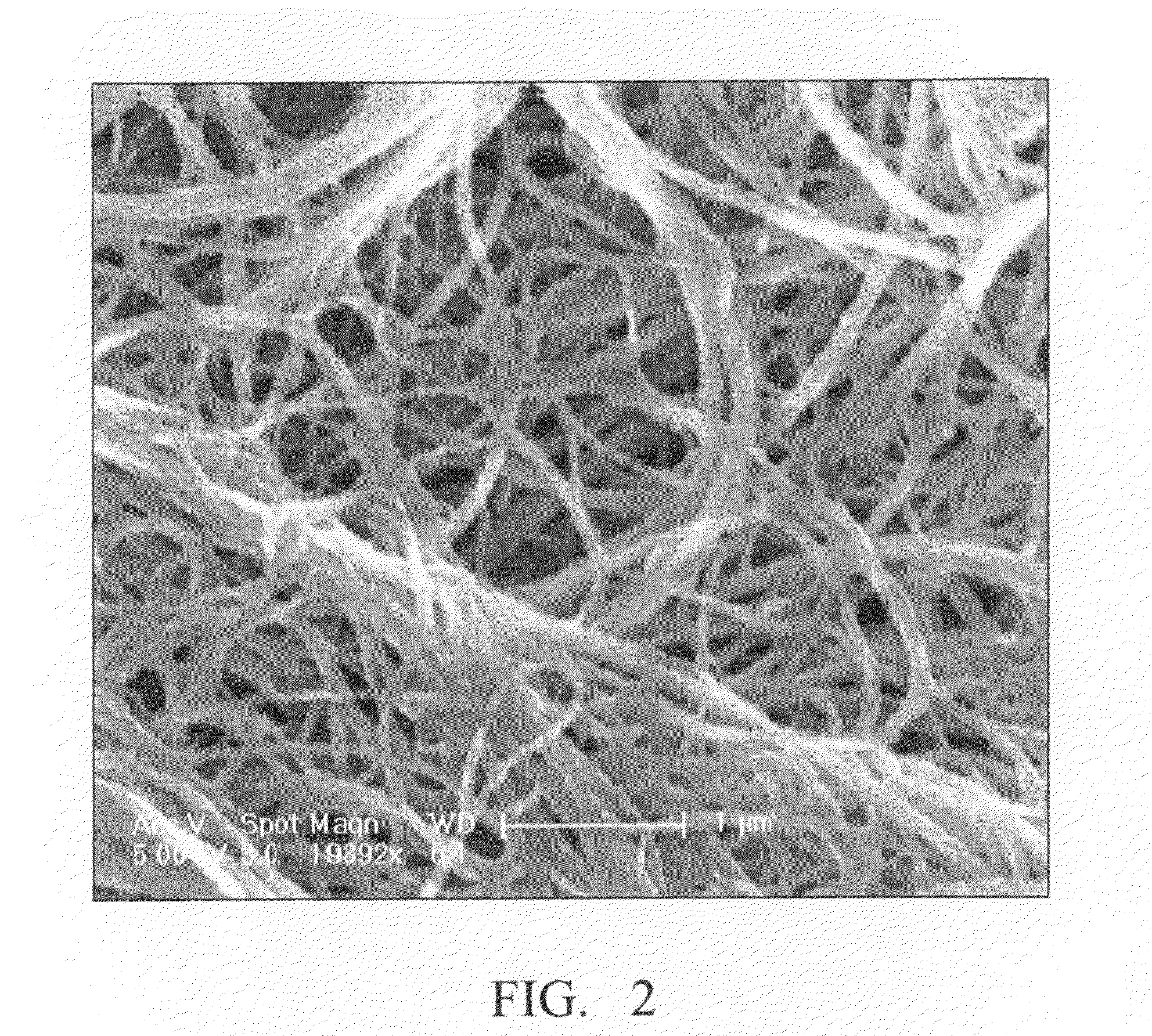

The invention belongs to the technical field of nanoporous material, namely carbon aerogel, and particularly relates to graphene oxide-crosslinked polyimide-based carbon aerogel and a preparation method thereof. The invention carbon aerogel is prepared by crosslinking polyamide acid aerogel by graphene oxide, and comprises the components of graphene oxide and one or more water-soluble polyimide precursor-polyamide acids. The preparation method comprises the following steps: mixing an aqueous graphene oxide solution with the water-soluble polyimide precursor-polyamide acid, and preparing graphene oxide / polyamide acid aerogel through sol-gel and freeze-drying processes; preparing the graphene / polyimide-based carbon aerogel through thermal imidization and high temperature carbonization. According to the preparation method, a toxic reagent formaldehyde is not used; the prepared carbon aerogel has a mesoporous, microporous and macroporous three-level three-dimensional network porous structure, high specific surface area, high conductivity and stable physical and chemical properties, and is an ideal electrode material for preparing a supercapacitor and other new energy devices and a high-performance adsorbent material.

Owner:FUDAN UNIV

Method for preparing electrodes of super capacitor based on nickel foam and products thereof

InactiveCN103258656AHigh specific capacitanceIncrease energy densityHybrid capacitor electrolytesHybrid capacitor electrodesCapacitanceNon symmetric

The invention discloses a method for preparing electrodes of a dissymmetric super capacitor based on nickel foam. The method comprises the steps: washing the nickel foam, soaking the nickel foam into a graphene oxide aqueous solution to obtain nickel foam in which graphene oxide deposits, serving the nickel foam in which the graphene oxide deposits as precursor materials, and respectively adopting a three-electrode method for preparaing a positive electrode and a negative electrode of the dissymmetric super capacitor, wherein the positive electrode is composed of composite materials of graphene, a carbon nanometer tube and the nickel foam, and the negative electrode is composed of composite materials of graphene, manganese dioxide and the nickel foam. The invention further discloses some other methods for preparing the electrodes of the super capacitor based on the similar principle, and products which correspond to the methods. By means of the methods and the products, respective high-ratio capacitance characteristics of the composite materials are fully played, and energy density of the super capacitor is improved. In addition, usage of various combined reagents can be avoided, and accordingly large-batch industrial production is conducted in a mode of convenient control, low cost and low energy consumption.

Owner:HUAZHONG UNIV OF SCI & TECH

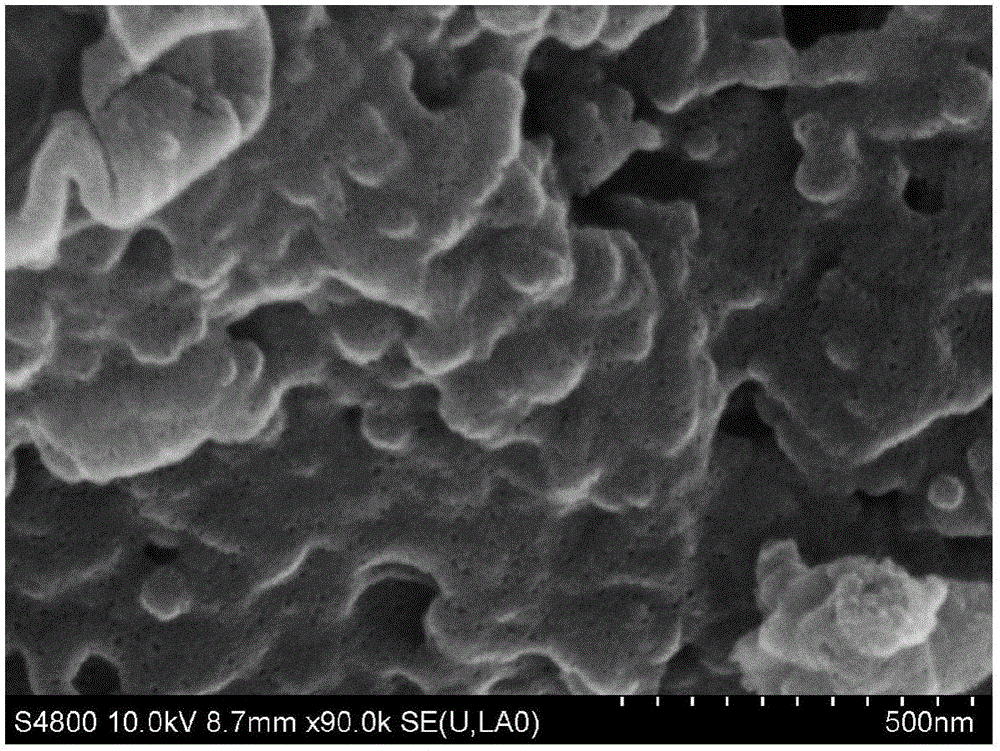

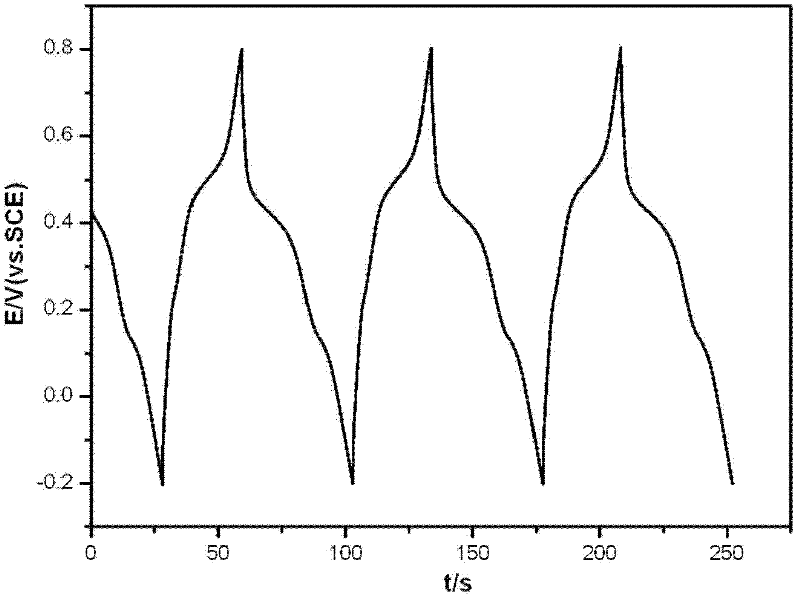

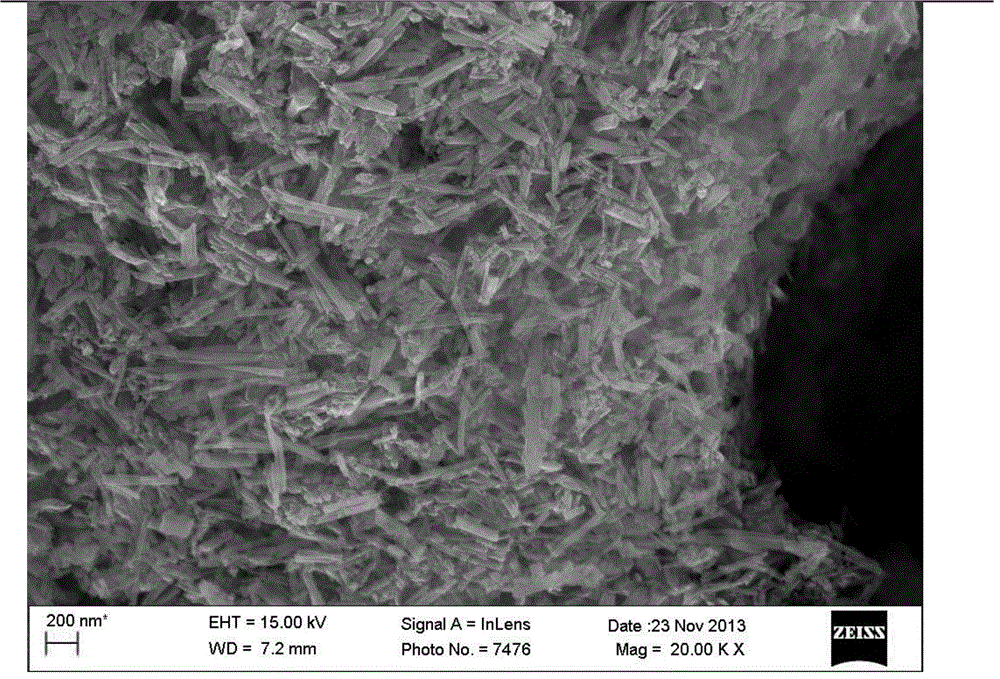

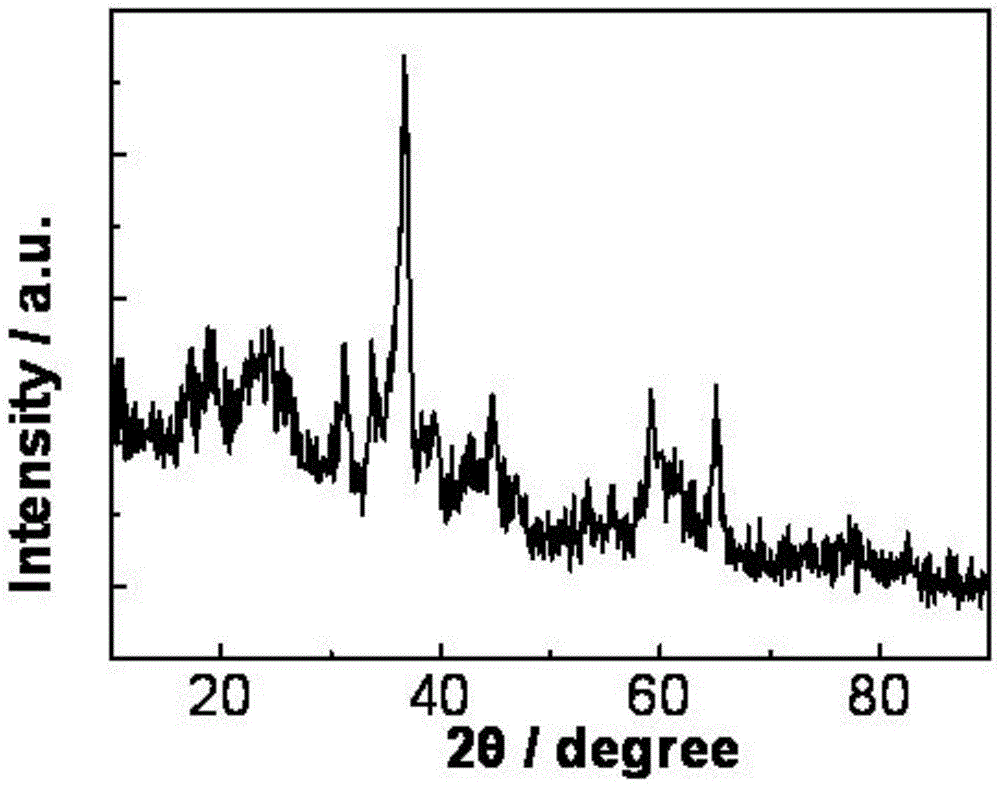

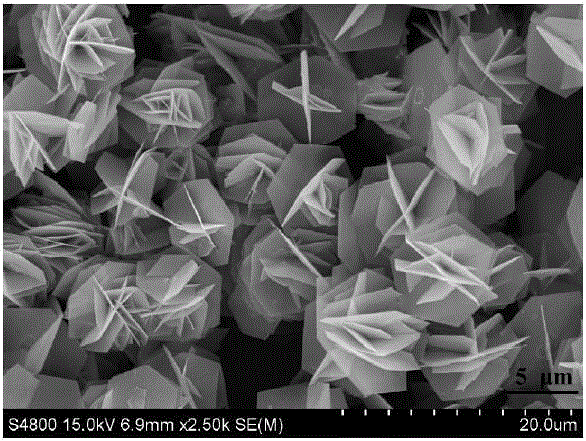

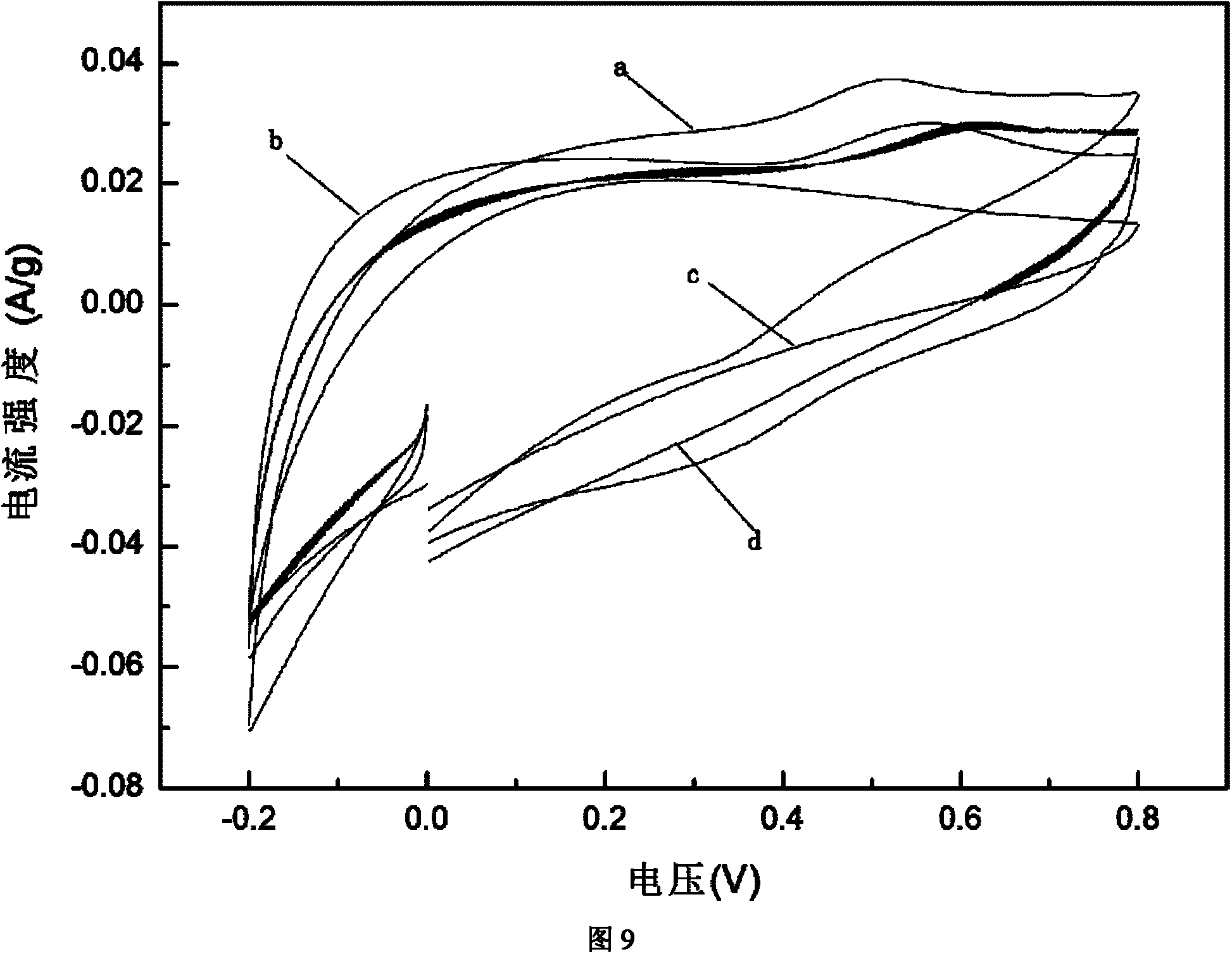

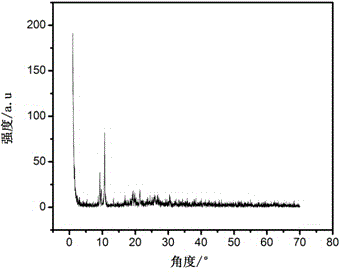

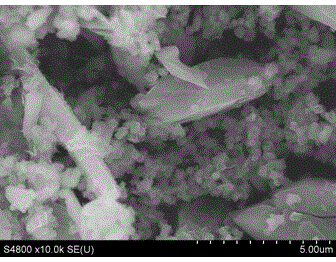

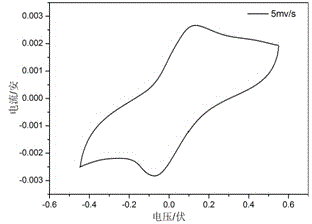

Preparation method of supercapacitor electrode material NiCo2O4

InactiveCN103107025AHigh specific capacitanceImprove electrochemical stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceReaction temperature

The invention relates to a preparation method of supercapacitor electrode material NiCo2O4. The preparation method comprises: (1) hexahydrated nickel nitrate Ni (NO3) 2 6H2O, hexahydrated cobalt nitrate Co (NO3) 2 6H2O and ureophil in a molar ratio of 1:2:1-10 are added to a mixed solution of ethanol and water, stirred and dissolved so as to obtain a mixed solution; and (2) a hydrothermal reaction is conducted to the mixed solution, the reaction temperature is from 90 DEG C and 200 DEG C, the reaction time is from 3h to 48 h, the mixed solution is cooled to the room temperature so as to obtain the NiCo2O4 by centrifuging, and then the NiCo2O4 is washed, dried and calcined so that the material NiCo2O4 is obtained. The materials obtained through the preparation method are high in specific capacitance and good in electrochemical stability and are excellent supercapacitor electrode materials. The preparation method has the advantages of being simple, green and environment-friendly and low in cost.

Owner:DONGHUA UNIV

Preparation method of transition metal oxide/carbon-based laminated composite material

InactiveCN104733712ALengthy process routeLong process routeHybrid capacitor electrodesCell electrodesNew energyConductive materials

The invention relates to a preparation method of a transition metal oxide / carbon-based laminated composite material. According to the preparation method, a conducting material such as metal carbide, metal nitride or metal carbonitride with a two-dimensional laminated structure is taken as a precursor, a gas containing oxygen elements is taken as an oxidant, and the two-dimensional conducting material is converted into the transition metal oxide / carbon-based laminated composite material by in-situ oxidation under the condition of controlling the oxidation temperature at 300-1000 DEG C and controlling the oxidation time at 1-300 min. The method disclosed by the invention has the advantages of simplicity and easiness in operation, controllable structure and morphology, controllable crystal form and electrochemical properties of metal oxides, and the like; the preparation method is environment-friendly, and nuisanceless, has no by-product, can be used for reducing the economic costs of traditional preparation methods, and can be popularized; and the transition metal oxide / carbon-based laminated composite material not only can be used as a key electrode material of a new energy storage device, but also can be used as a denitration catalyst, so that the material can be applied to the fields of environmental remediation, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH +1

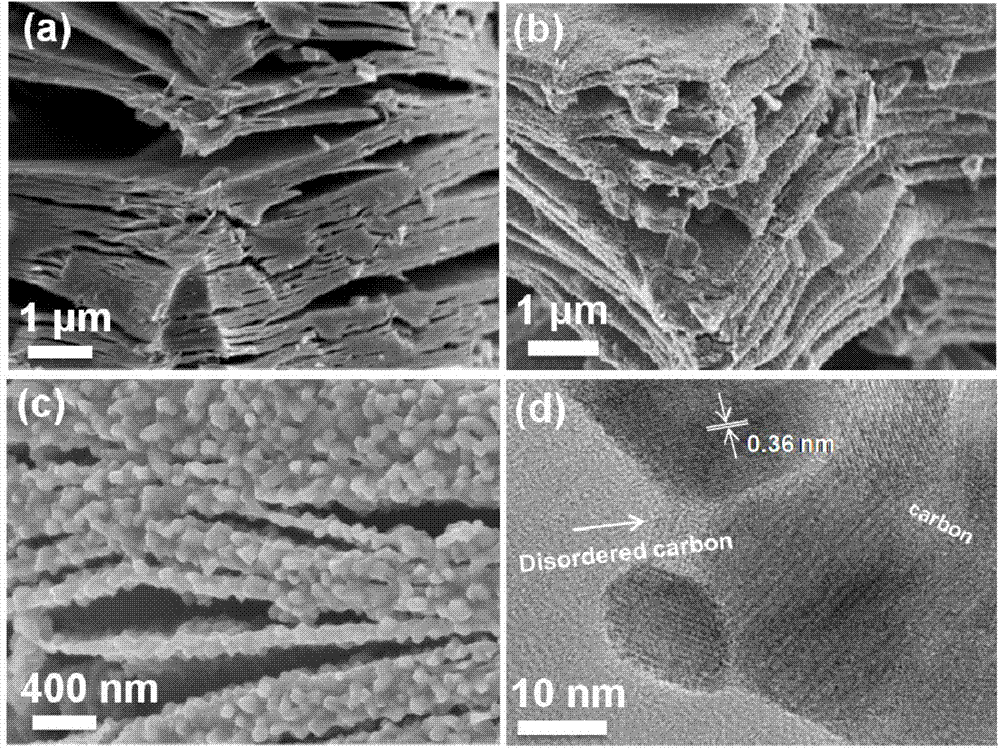

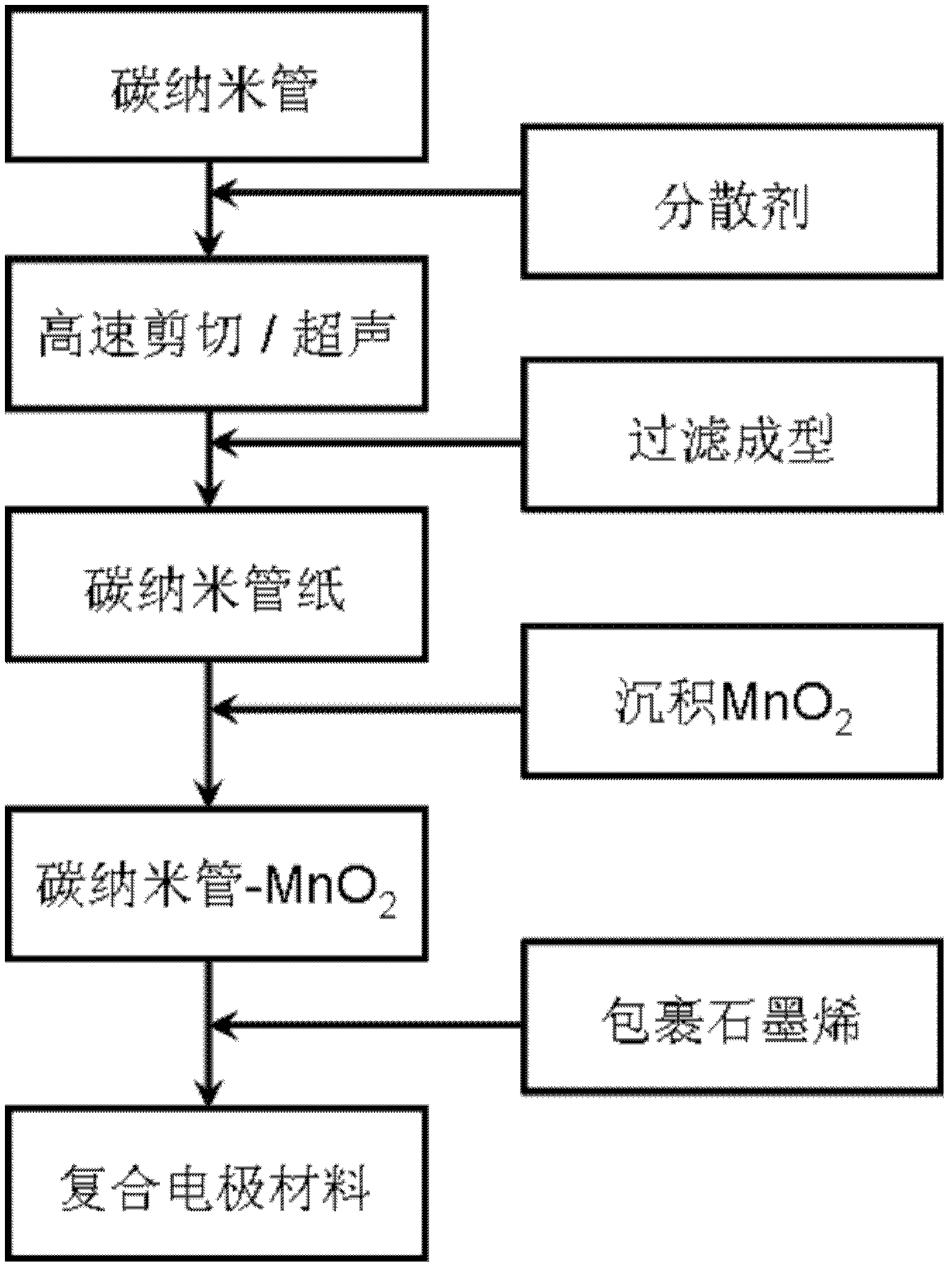

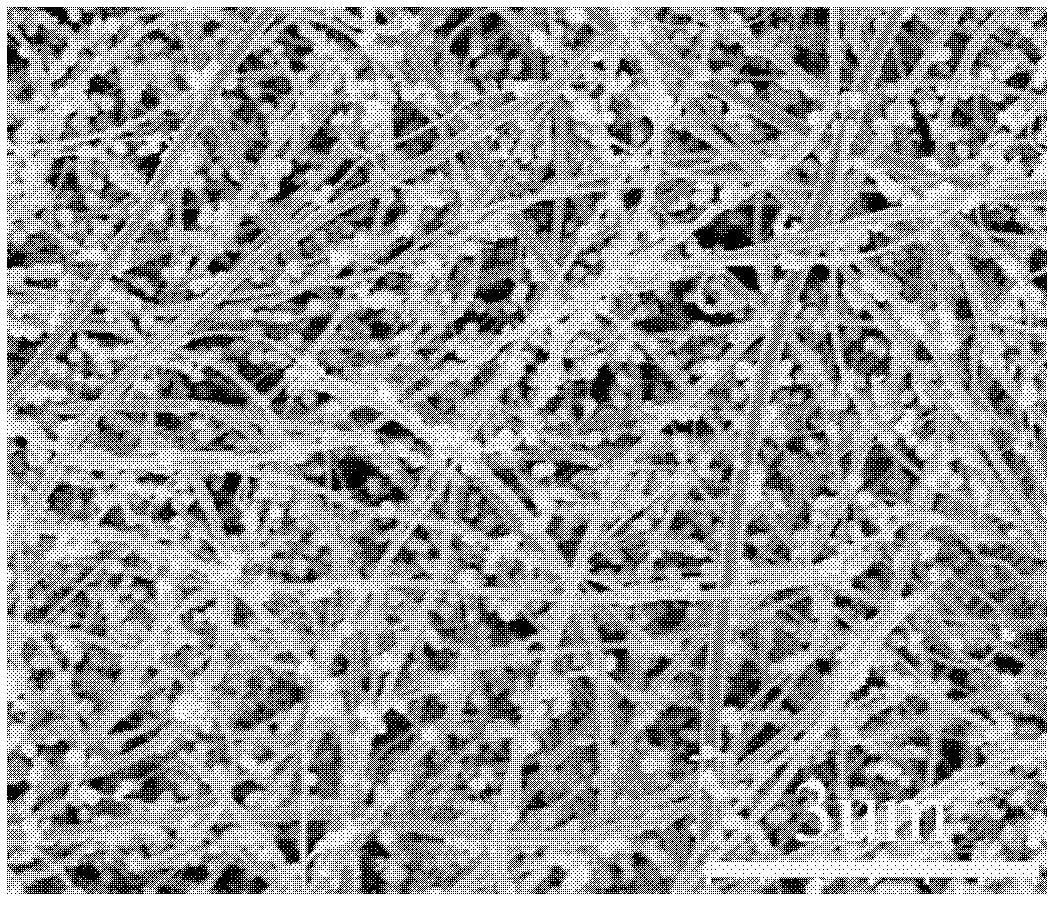

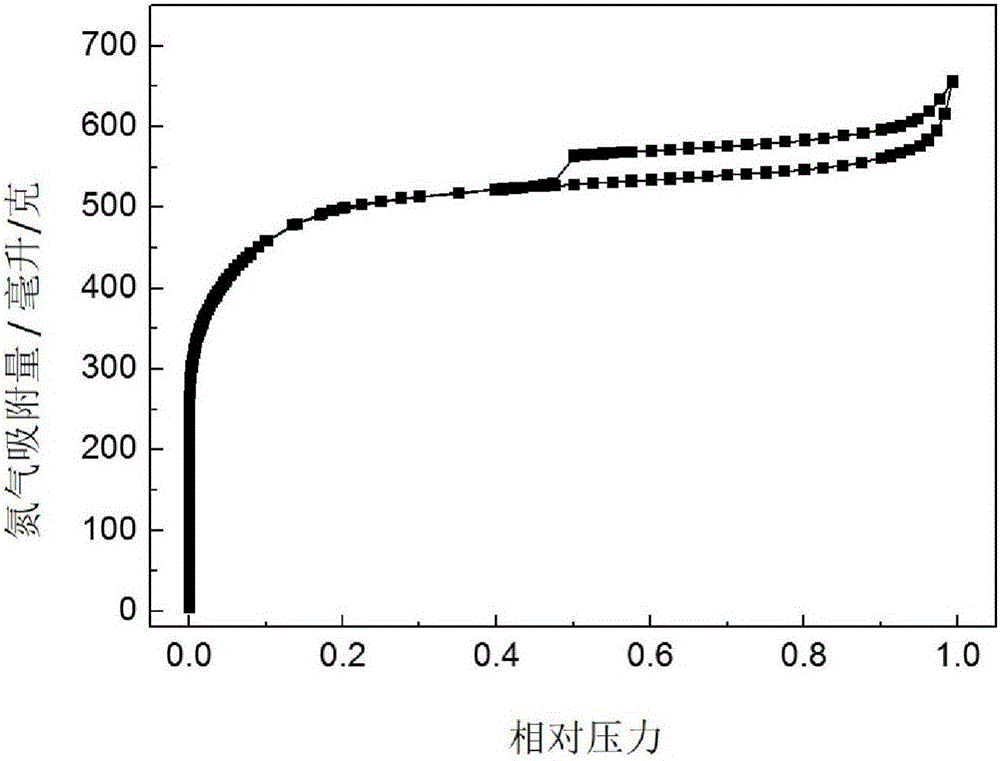

Composite nanometer carbon paper and preparation method thereof

ActiveCN102436934AGood Faraday capacitance characteristicsLarge specific surface areaElectrolytic capacitorsLayered productsNew energyCarbon nanotube

The invention discloses composite nanometer carbon paper and a preparation method thereof. The nanometer carbon paper uses carbon nanometer paper as a framework network, MnO2 metallic oxides are deposited on the surface, the outer layer is covered with grapheme, and the composite nanometer carbon paper belongs to a flexible composite film material. The preparation method of the composite nanometer carbon paper comprises the steps that carbon nanometer tubes are dispersed in a solvent, then, the suction filtering is carried out to obtain carbon nanometer tube paper, next, the carbon nanometer tube paper is used as a carrier for depositing the MnO2 metallic oxides on the surface, and finally, the grapheme is adhered on the product surface to obtain target products. The electrical conductivity, the heavy current charging and discharging capability, the specific capacitance and the cycle life of the composite nanometer carbon paper are respectively and obviously enhanced through being compared with those of the carbon nanometer tube-MnO2, the problems that in the existing super capacitor, the metallic oxides easily fall off from the surface of the carbon nanometer tubes, the electrical conductivity of the metallic oxides is poor, and the like are solved, the composite nanometer carbon paper also has the characteristics of light weight and flexibility of materials and high efficiency, simultaneously, the preparation process is simple, the operation is easy, the controllability is good, and in addition, the cost is low. The composite nanometer carbon paper and the preparation method have wide application prospects in fields of new energy sources, advanced chemical engineering, electronic devices, film preparation and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Preparation method of biomass-based nitrogenous porous carbon, porous carbon prepared by method and use thereof

ActiveCN106601490AWidely distributedAbundant resourcesHybrid capacitor electrodesCarbon preparation/purificationPorous carbonNitrogen doped

The invention discloses a preparation method of biomass-based nitrogenous porous carbon, the porous carbon prepared by the method and the use of the prepared nitrogenous porous carbon in a super capacitor. The preparation method comprises the steps of (1) drying a biomass material, and grinding the biomass material into fine powders, (2) evenly mixing the biomass material powders and water or a dilute acid solution, (3) placing the above mixture into a reactor for hydrothermal reaction, and (4) drying and grinding an obtained hydrothermal reaction product, and calcining the hydrothermal reaction product in a tube furnace to obtain a nitrogen-doped porous carbon material with a large surface area. According to the method of the invention, cheap and renewable plant is used as carbon and nitrogen precursors, and the porous nitrogen-doped carbon material is prepared through a hydrothermal method. The method has the advantages of simple preparation process, no need of an activator or template agent, low cost, environmental protection, and convenient operation, problems of strong corrosion, a high price of transition metal and environmental pollution caused by heavy metal are avoided, and the method is suitable for mass production.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

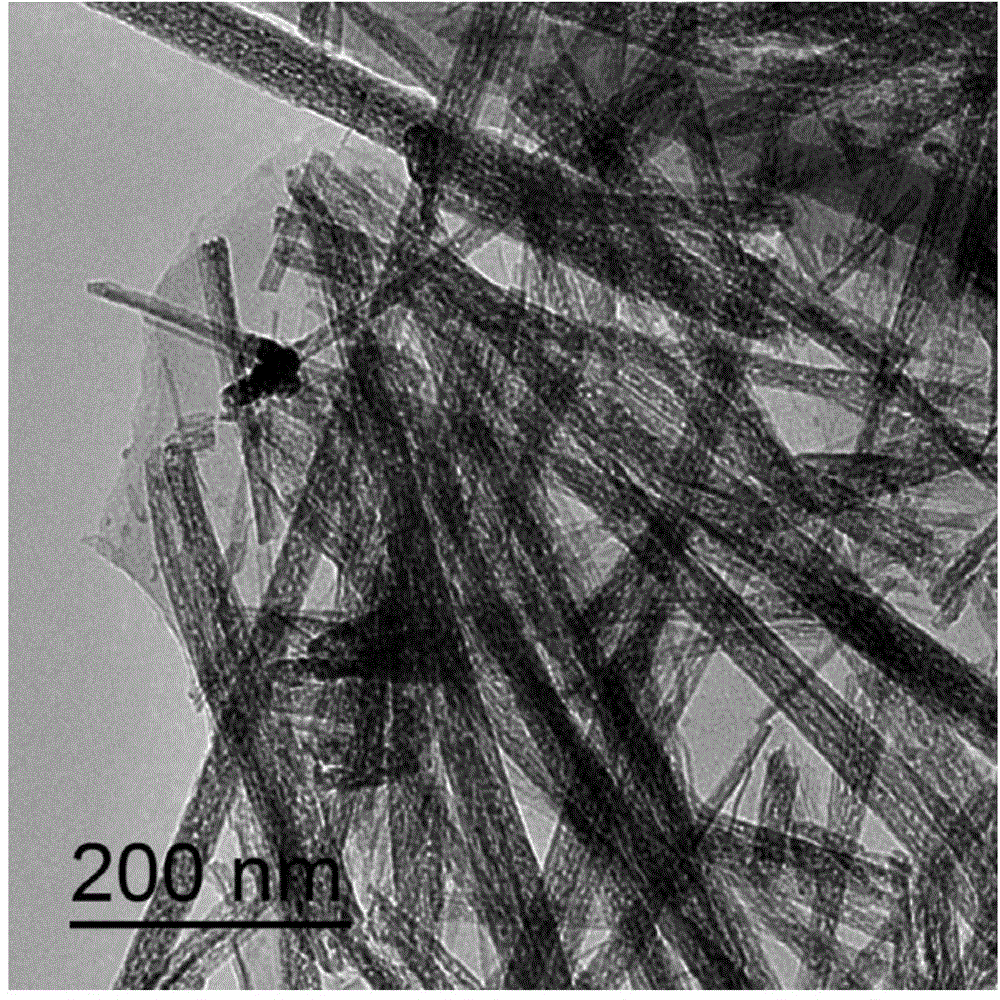

Method for manufacturing carbon nanotube-conducting polymer composite

ActiveUS20100051471A1Reduce contractionReduce expansionMaterial nanotechnologyNon-metal conductorsPolymer scienceConductive polymer

A method for manufacturing a conducting polymer composite with carbon nanotubes is described. A conducting polymer is compounded with the CNT film by in-situ electrochemical polymerization.

Owner:TSINGHUA UNIV +1

Method for preparing supercapacitor carbon aerogel by utilization of bagasse

ActiveCN103839699AImprove electrochemical performanceLow costHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceToxic industrial waste

The invention discloses a method for preparing supercapacitor carbon aerogel by the utilization of bagasse. The method includes the steps that the bagasse is used for preparing cellulose powder without xylogen and hemicellulose; the cellulose powder is used for preparing cellulose aerogel; the cellulose aerogel is carbonized to obtain carbon aerogel; the carbon aerogel is activated to obtain the supercapacitor carbon aerogel. According to the method, the industrial waste bagasse is used as raw materials, the requirements for sustainable development and environmental protection are met, and the cost of electrode materials is effectively lowered. The product prepared through the method is of a three-dimensional hierarchical pore structure; compared with a product obtained through a conventional method, the product prepared through the method is large in specific area and good in repeatability, and has higher specific capacitance and better cycling stability. The method is more suitable for preparing supercapacitor electrode materials and has wide development prospects.

Owner:SHANDONG UNIV

Poly(3,4-ethylenedioxythiophene)/sulfonated graphene composite hydrogel and preparation method thereof

InactiveCN102558772APorous Structure RegulationEasy to controlElectrolytic capacitorsCapacitanceIron salts

The invention relates to a method for preparing poly(3,4-ethylenedioxythiophene) / sulfonated graphene composite hydrogel with a porous structure through supramolecular self-assembly. The method comprises the following steps of: dissolving sodium polystyrene sulfonate and sulfonated graphene in water, stirring, performing ultrasonic dispersion to ensure that the sodium polystyrene sulfonate and thesulfonated graphene are dissolved, adding a 3,4-ethylenedioxythiophene monomer, uniformly stirring, adding polyvalent iron salt, standing at room temperature and reacting to obtain blocky poly(3,4-ethylenedioxythiophene) / sulfonated graphene composite hydrogel. The poly(3,4-ethylenedioxythiophene) / sulfonated graphene composite hydrogel with a controllable and porous structure is prepared by using the interaction and electrostatic action of a hydrogen bond and a pi-pi bond among the sulfonated graphene, the sodium polystyrene sulfonate and 3,4-ethylenedioxythiophene through supramolecular self-assembly. The prepared composite hydrogel has high electrical conductivity and mechanical strength, and high specific capacitance and cycle stability in electroactive electrolyte.

Owner:HOHAI UNIV

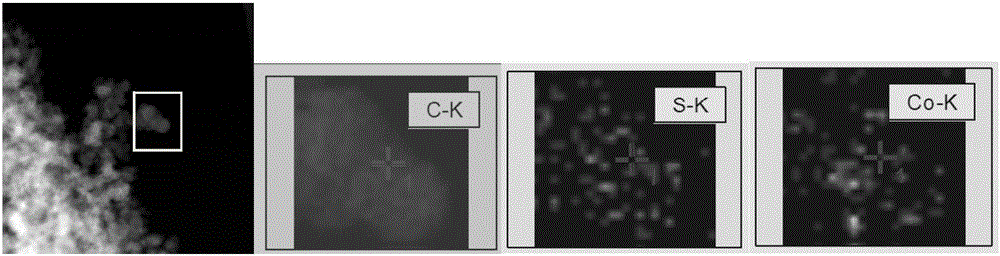

Graphene in-situ load needle-shaped Co3O4 composite electrode material and manufacturing method thereof

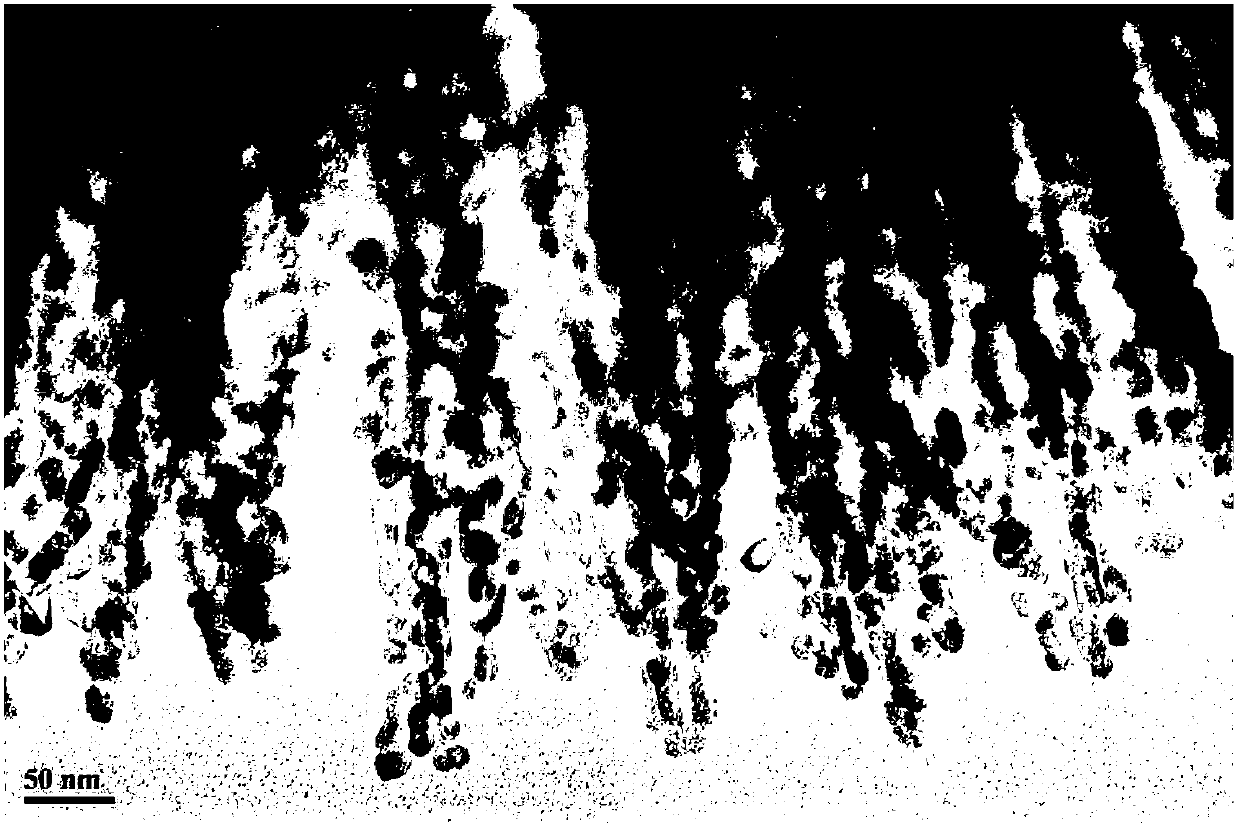

InactiveCN103985561AImprove conductivityOptimized areaHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNano structuring

The invention discloses a graphene in-situ load needle-shaped Co3O4 composite electrode material and a manufacturing method of the graphene in-situ load needle-shaped Co3O4 composite electrode material. Single-layer graphene with needle-shaped Co3O4 growing on the edge or two faces is adopted as a load frame of the composite electrode material, the plane size of a nanosheet layer is one micron to 50 microns, and the manufacturing method comprises the steps that graphite oxide is manufactured through a modified Hummers method, then ultrasonic treatment is carried out to obtain graphene oxide, a precursor of the composite electrode material is manufactured through the graphene oxide, and the precursor is annealed in inert atmosphere to obtain the composite electrode material. The manufacturing method of the composite electrode material is simple and environmentally friendly, according to the typical structure of the composite electrode material, the needle-shaped Co3O4 is combined with the surface or the side face of the graphene, a quasi two-dimensional nano structure is formed, the graphene sheet layer can be loaded with the needle-shaped Co3O4 in situ, the cycle life of the Co3O4 is prolonged, and the specific capacitance and other good electrochemical performance are improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

Stephanoporate carbon electrode material and preparation method thereof

InactiveCN101299397AFast deliveryExcellent electrochemical capacitance performanceHybrid capacitor electrodesElectrolytic capacitorsPorous carbonCarbonization

The invention relates to a porous carbon electrode materials and the preparation method, belonging to the electrochemistry and the novel energy source materials, wherein the porous carbon electrode materials adopt the template carbonization and the method combined with the CO2 post-processing using the meso-porous oxide silicon as the remplate, and the cane sugar, furfuryl alcohol, polyacrylonitrile and the like as the precursors, through the technology steps of the liquid phase impregnation, the high temperature carbonization and the template removal and the like, then combines high temperature process, obtaining the super capacitor porous carbon electrode materials. The porous carbon electrode materials prepared by the method has high surface area, large pore volume, adjustable pore structure and multilevel-microporous pore structure, wherein the pore channel is composed of a meso-porous of 2-5 nm and the microporous with the meso-porous wall of 0.1-2 nm, so the electrochemistry capacity of the prepared porous carbon electrode is marked increased, and the integral property of good.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

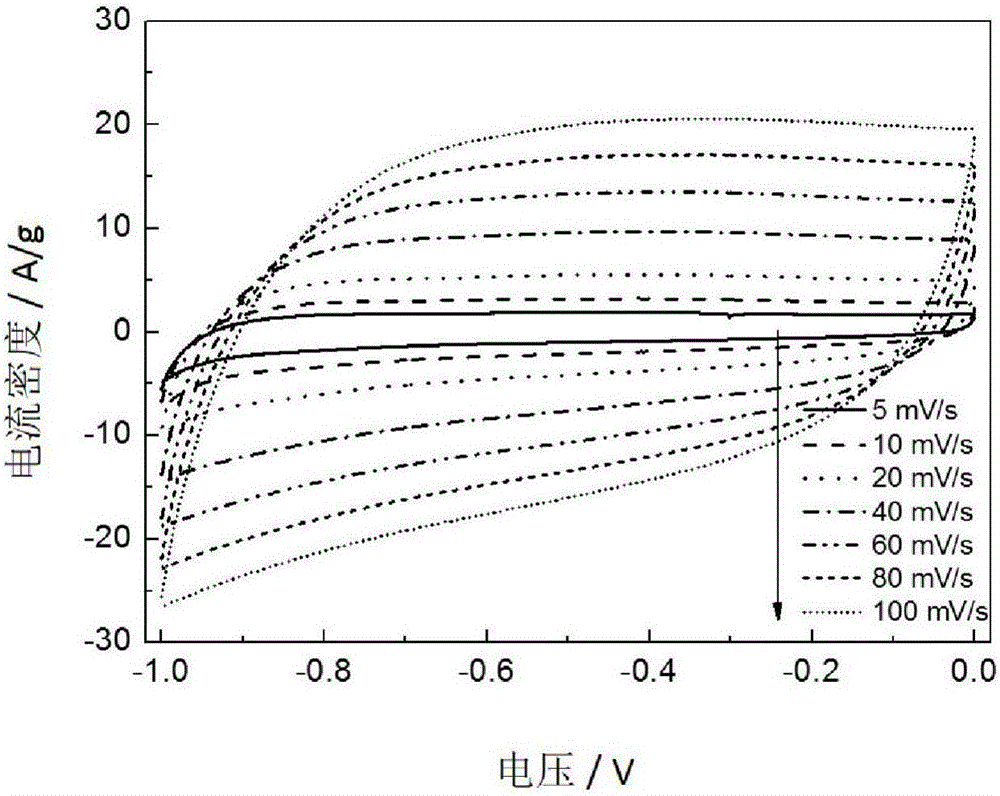

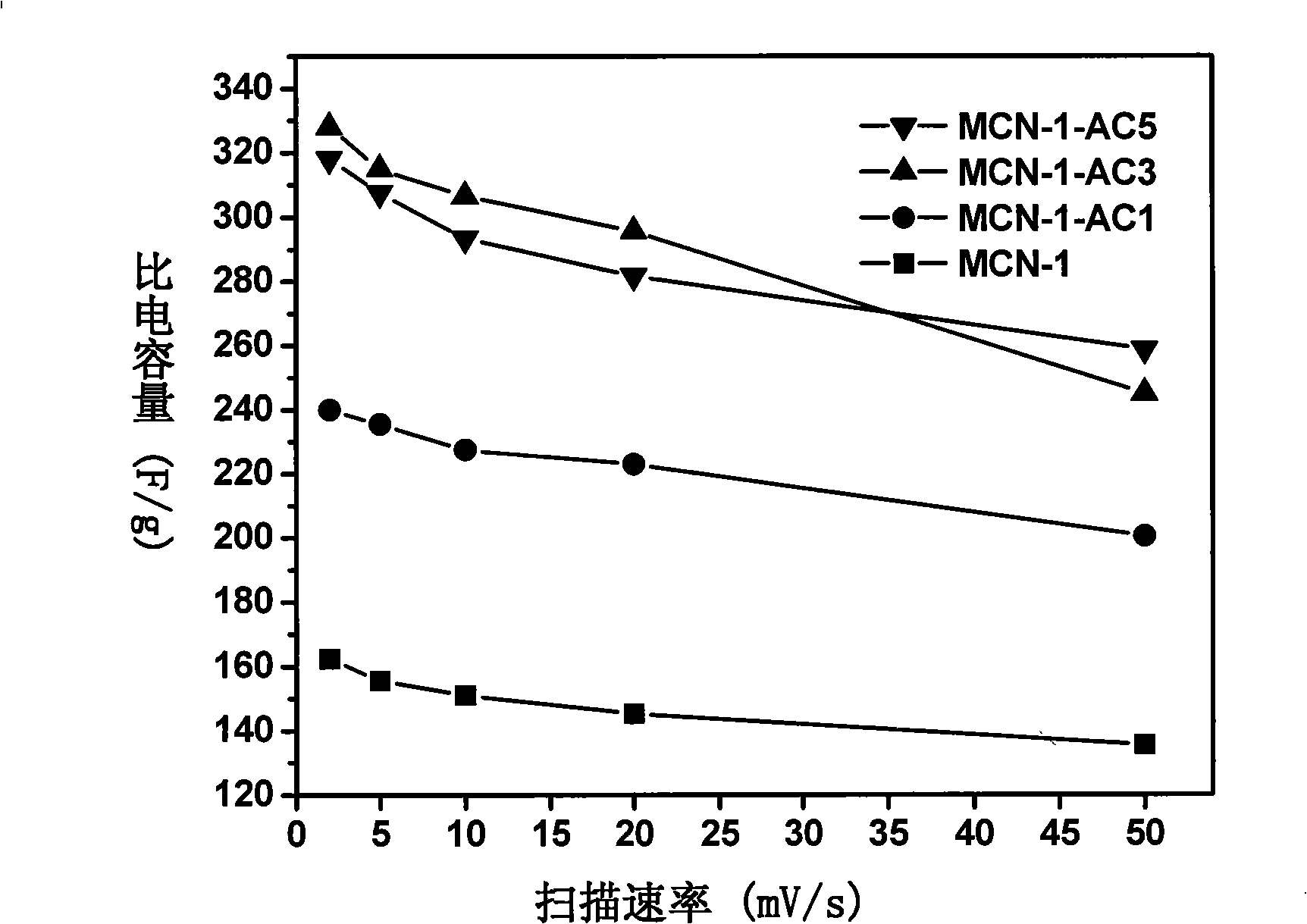

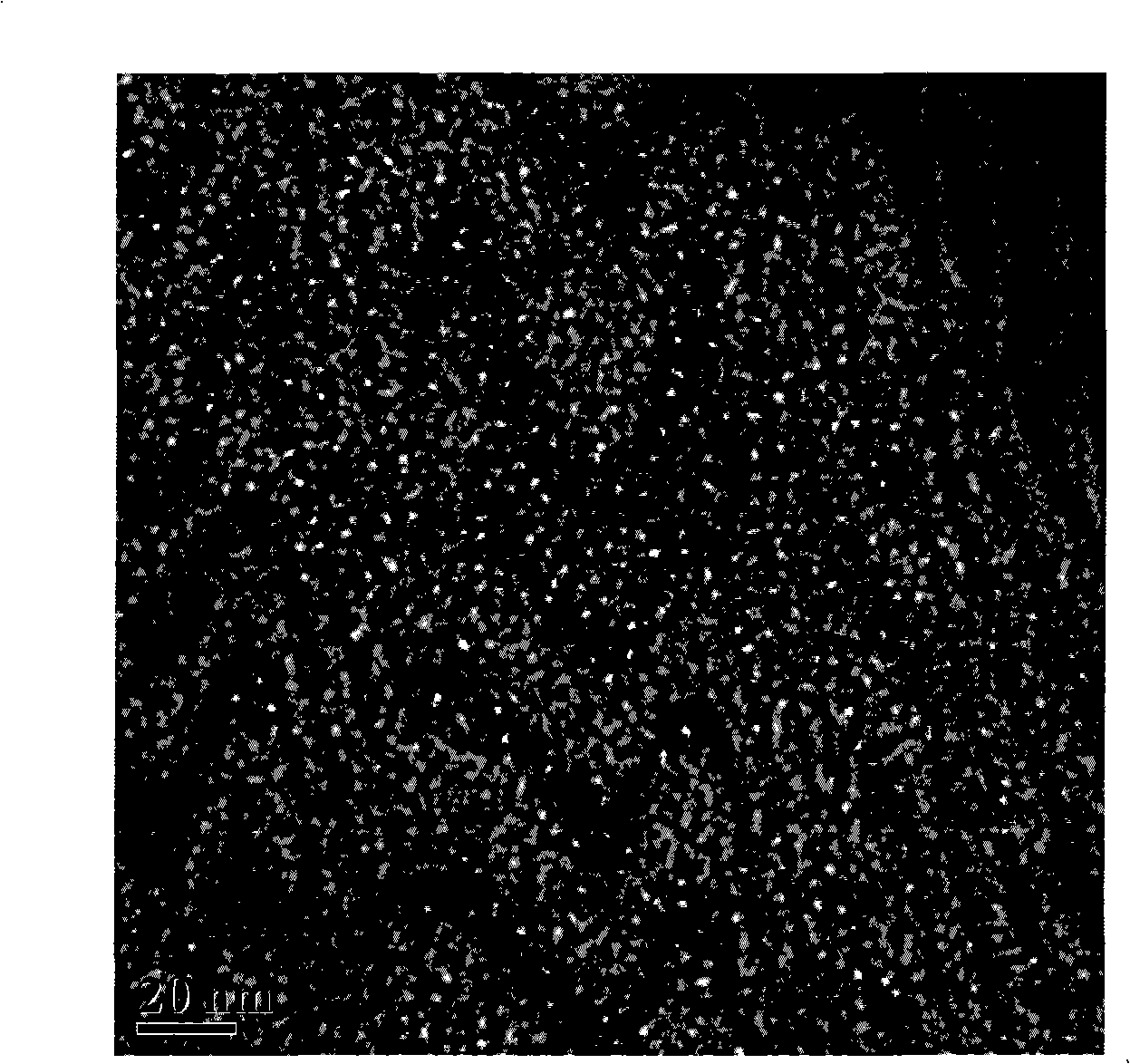

Method for preparing nitrogen-doped porous carbon material

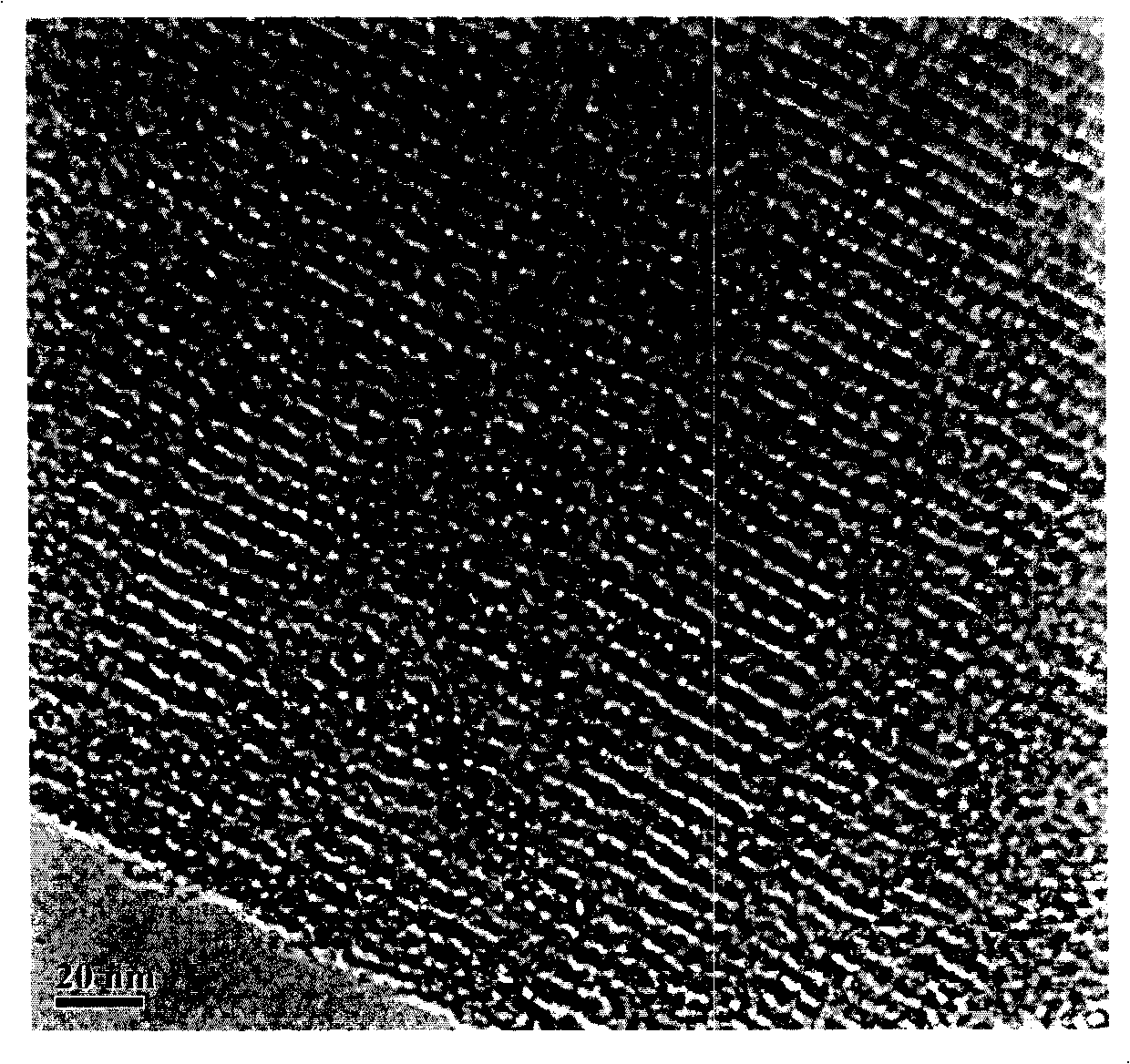

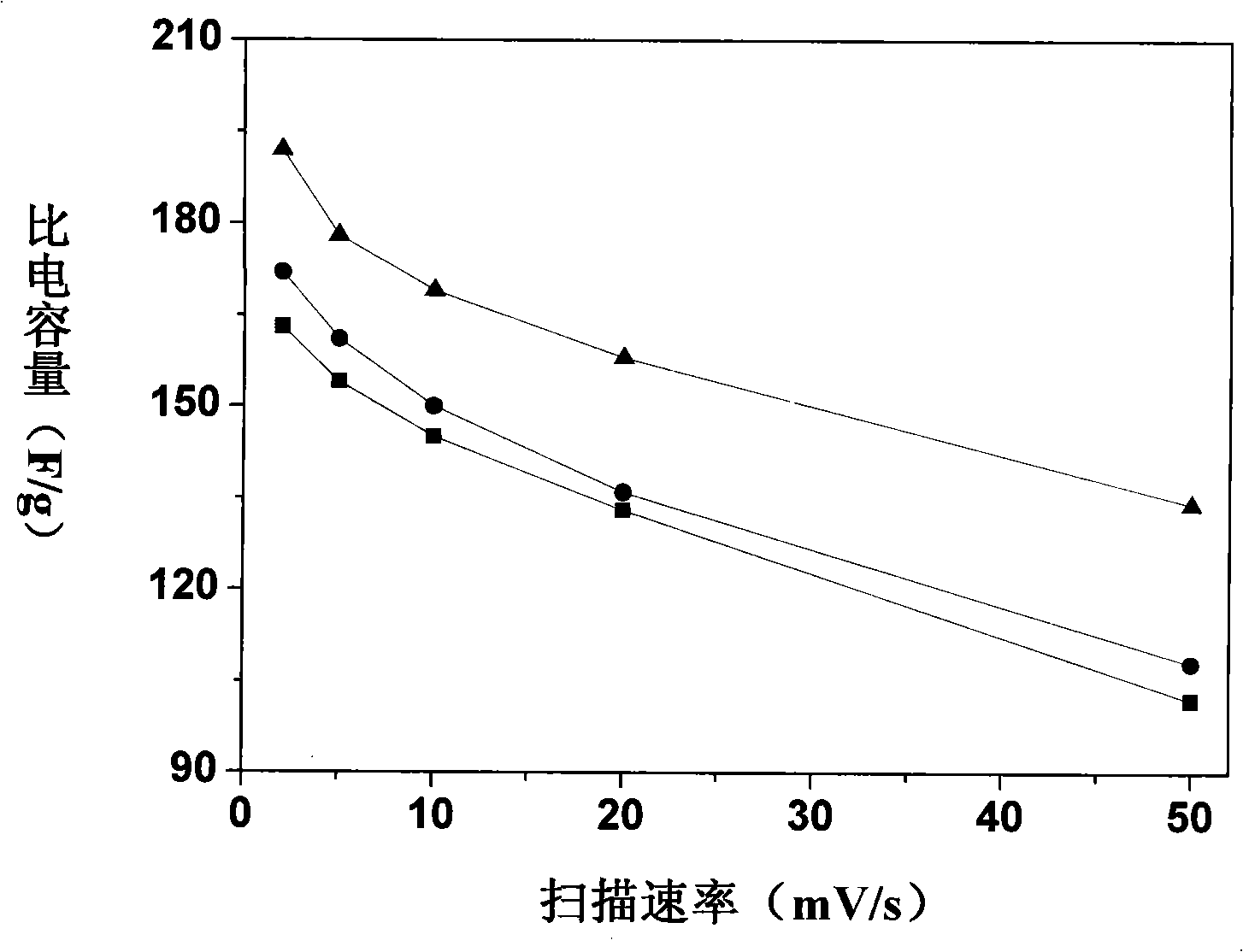

InactiveCN101306807AHigh specific surface areaLarge pore volumeDouble-layer capacitanceAqueous electrolyte

The invention relates to a method of preparing a nitrogen-doped porous carbon material, and belongs to the field of inorganic nanometer materials and electrochemistry. The inventive method comprises the steps of: preparing mesoporous carbon nitrogen compound with mesoporous silicon oxide powder and ethylene diamine as precursors, and activating with an activator potassium hydroxide at high temperature while controlling the mass ratio of the potassium hydroxide and the mesoporous carbon nitrogen material to obtain a nitrogenous material with high specific surface area and pore volume. The specific electric double layer capacitance of the inventive nitrogen-doped porous carbon material in alkaline aqueous electrolyte under potential scanning speed of 2mV / s is 328F / g and 318F / g, respectively, which are much higher than that of the reported porous carbon materials. The inventive nitrogen-doped porous carbon material has good application prospect as a high-power super capacitor active material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

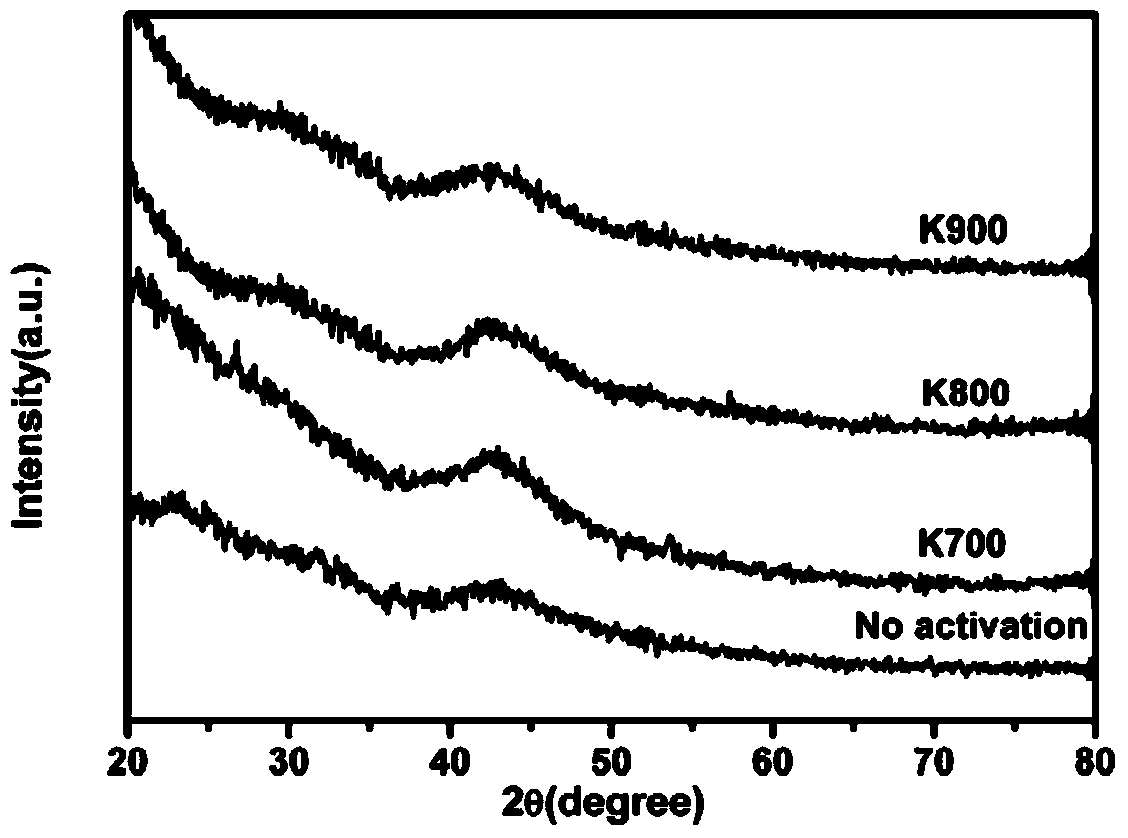

Active carbon for preparing carbon electrode of super capacitor and preparation method thereof

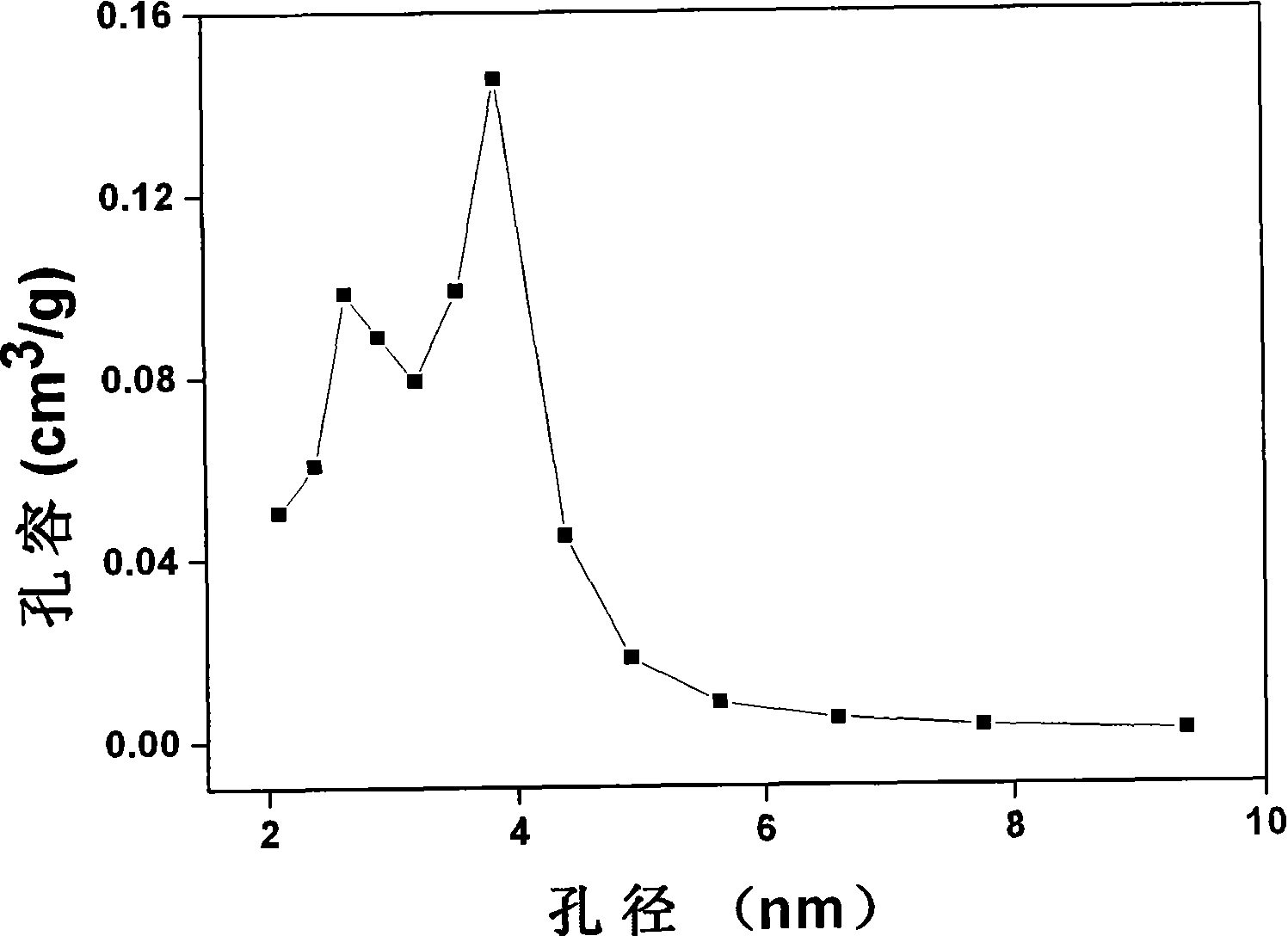

The invention discloses an active carbon for preparing a carbon electrode of a super capacitor and a preparation method thereof. The average particle size of active carbon particles is between 15 and 30 mu m, the specific surface area of the active carbon particles is between 3,000 and 3,400 m<2> / g and pore channels with pore diameters of between 2 and 5 nanometers account for 25 to 32 percent of all pore channels in the particles. The preparation method comprises the following steps of: mixing an amphipathic carbon material serving as a precursor and potassium hydroxide (KOH) and deionized water and stirring the mixture to obtain solution; drying the solution to obtain a solid mixture; and activating, washing, and drying the washed solid mixture to obtain the active carbon. The active carbon and the preparation method have the advantages that: the process for preparing the active carbon is simple; the amphipathic carbon material is soluble in water and is easy to be uniformly mixed with KOH, so not only the using amount of KOH is reduced but also the uniformity and high efficiency of an activating process are improved; and the prepared active carbon has a large specific surface area, high occupation ratio of the pore channels with particle sizes of between 2 and 5 nanometers in the particles, high specific capacity for manufacturing the electrode of the super capacitor and excellent heavy current performance.

Owner:成都佰思格科技有限公司

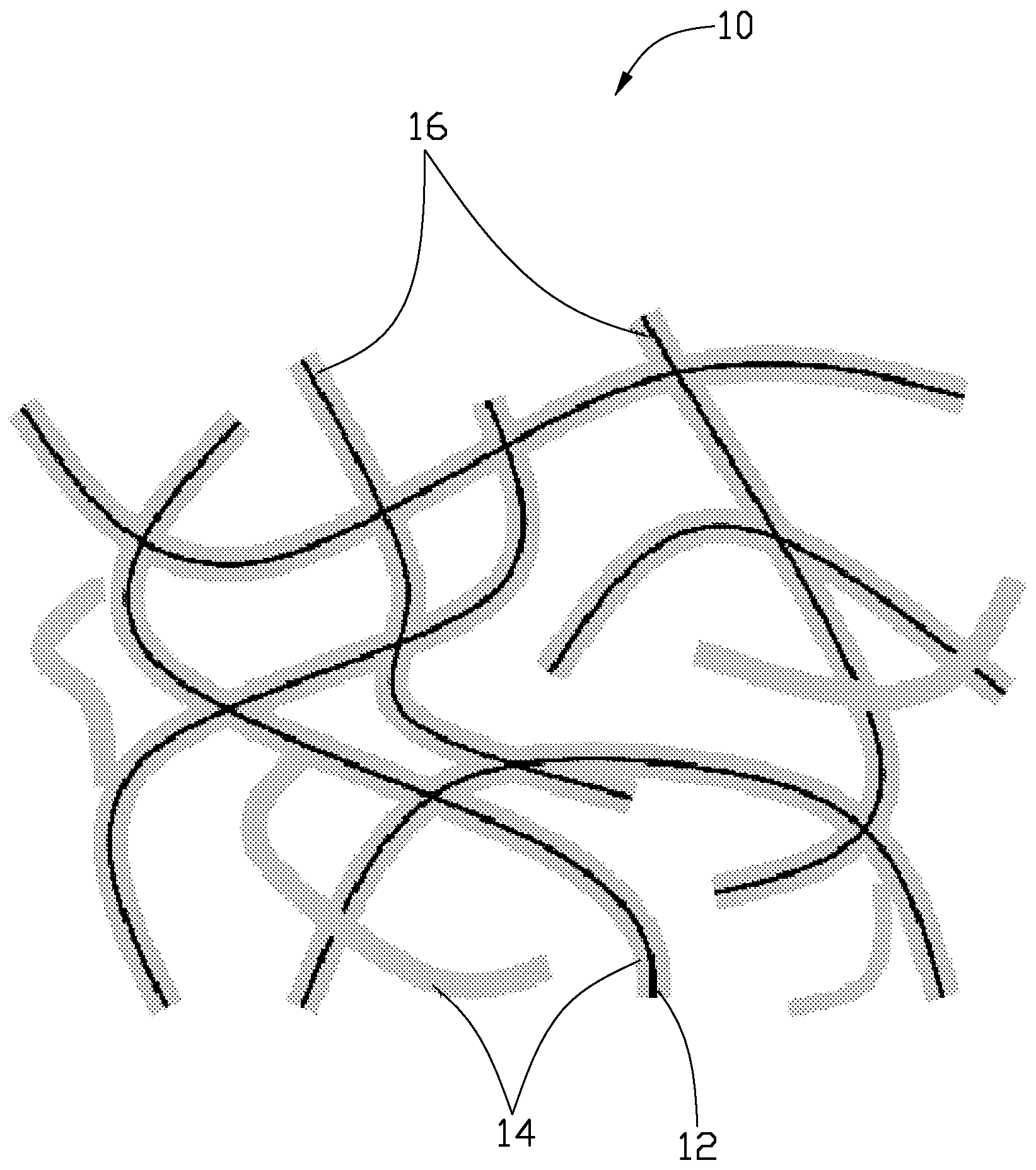

Carbon nanotube-conductive polymer composite

ActiveUS20100019209A1Reduce contractionReduce expansionMaterial nanotechnologyHybrid capacitor electrodesFiberPolymer science

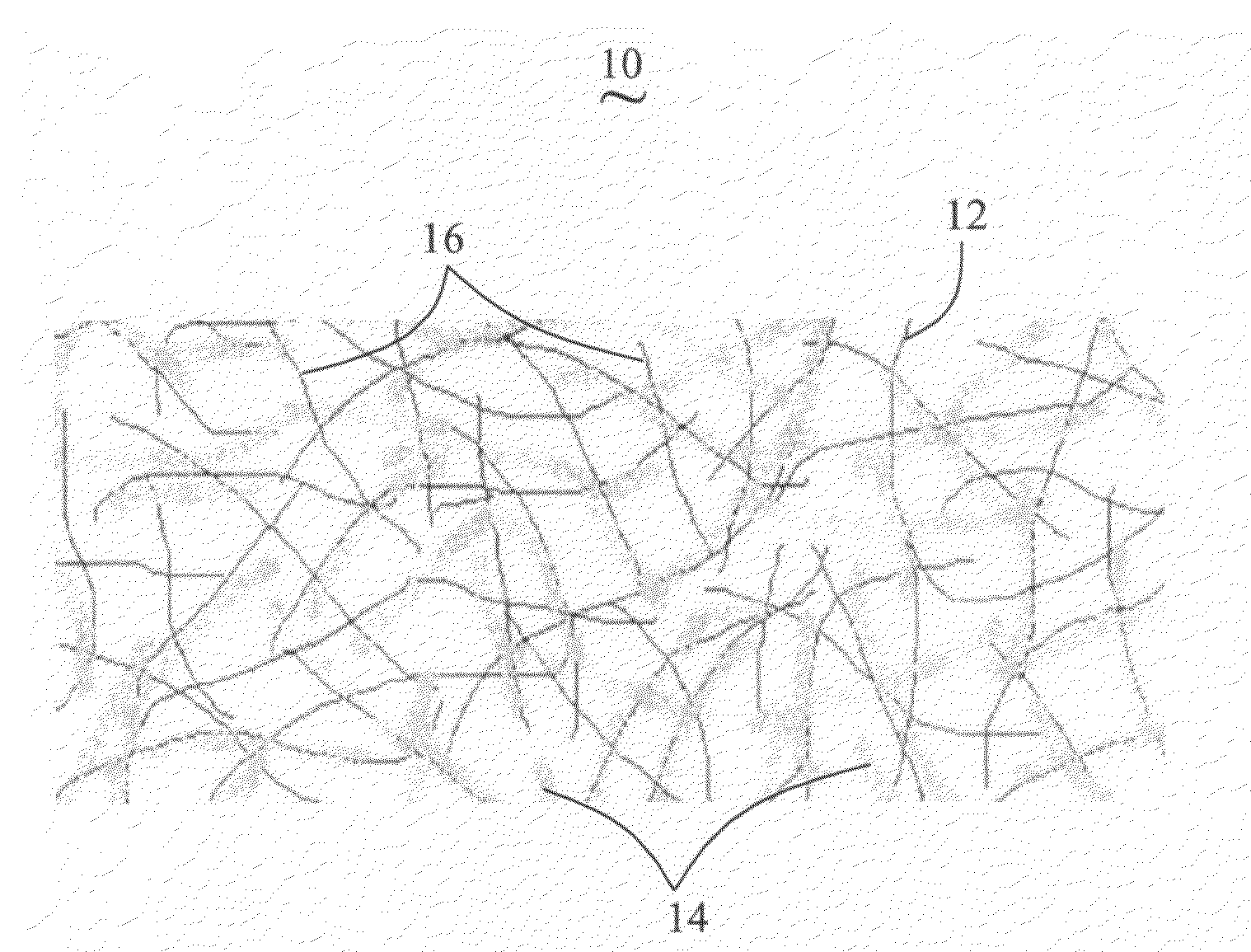

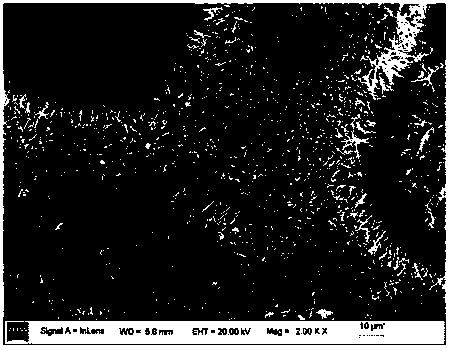

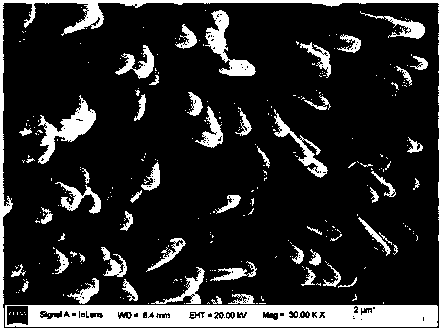

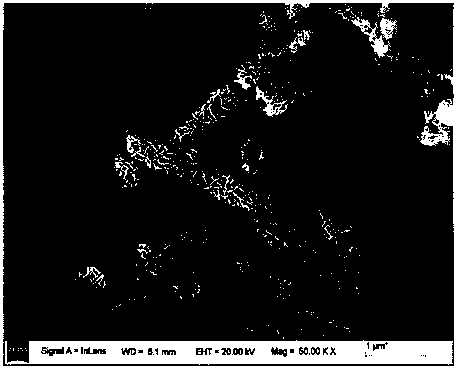

A carbon nanotube-conductive polymer composite includes a plurality of CNTs and conductive polymer fibers. The CNTs are connected with each other to form a network. The conductive polymer fibers adhere to surfaces of the CNTs and / or tube walls of the CNTs.

Owner:TSINGHUA UNIV +1

Electrode material in hollow tubular structure, and preparation method for electrode material

InactiveCN105513831AExcellent supercapacitor performanceIncrease loadHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceElectrochemical corrosion

The invention provides an electrode material in a hollow tubular structure, and the electrode material is in the hollow tubular structure which consists of a composite hydroxide / copper hydroxide / copper-contained metal substrate. The chemical formulation of the composite hydroxide is MxM'y(OH)2, wherein M is Ni2+ or Co2+, M' is Co2+, Al3+, or Fe3+. According to the invention, a method of solution dipping and constant potential deposition, and a copper hydroxide nanowire array grows on the copper-contained metal substrate in an in-situ manner. The composite hydroxide is deposited on a copper hydroxide nanorod in electrolyte containing mixed metal salt solution in a manner of electro-deposition through employing the method of constant potential deposition. Meanwhile, electrochemical corrosion enables the copper hydroxide nanorod to be dissolved in a process of electro-deposition, thereby obtaining the hollow tubular structure of the composite hydroxide / copper hydroxide / copper-contained metal substrate. The electrode material is good in super-capacitance performance, and can be used for a super-capacitor.

Owner:BEIJING UNIV OF CHEM TECH +1

Multilayer structure-based novel battery type supercapacitor with high power density and high energy density and preparation method

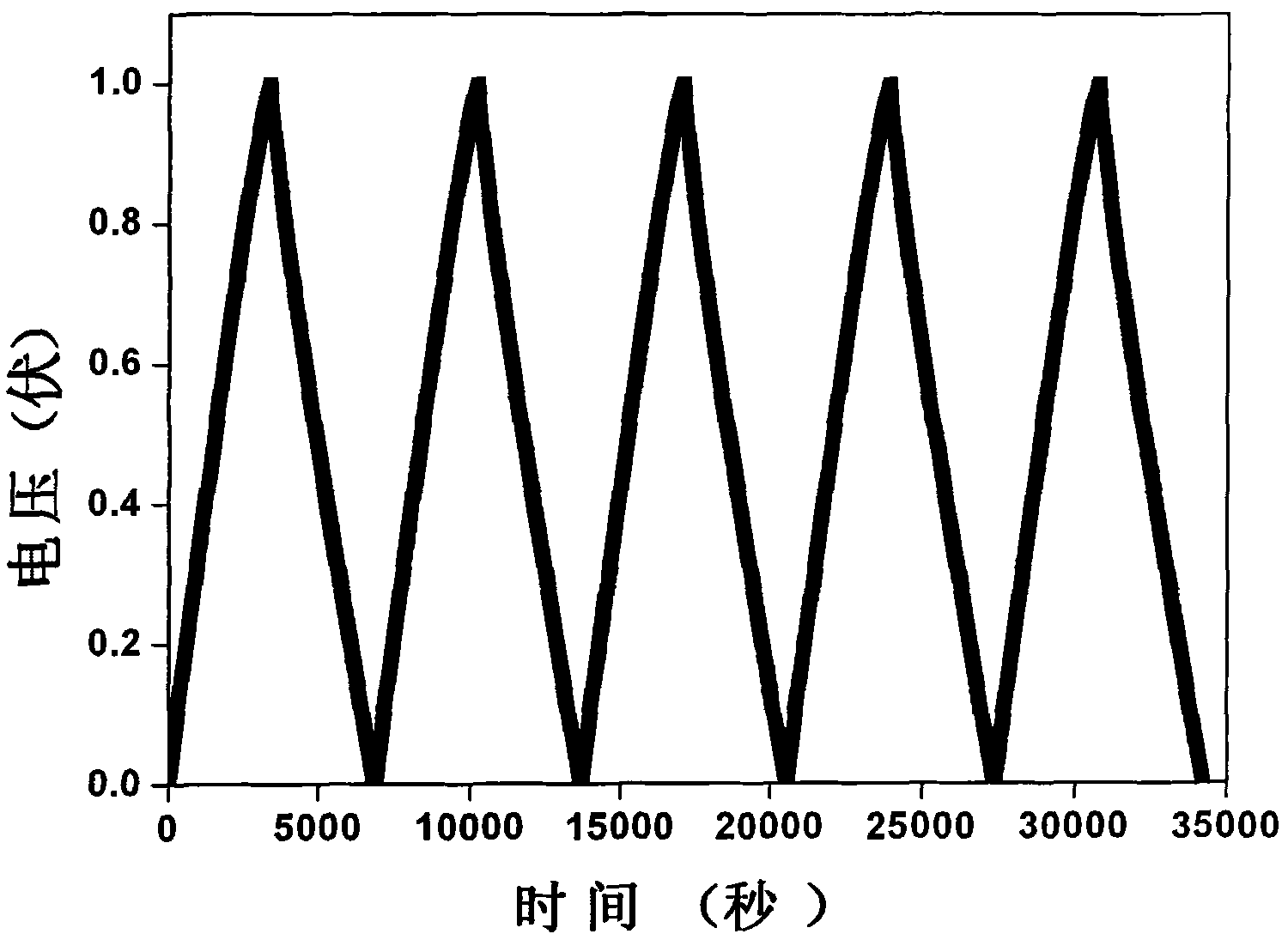

ActiveCN105280394AImprove power densityIncrease energy densityElectrolytic inorganic material coatingHybrid capacitor electrodesCapacitanceElectrical battery

A supercapacitor is energy storage equipment with high power density and low energy density, and generally can satisfy requirements of people for both high power density and high energy density only when used by being matched with a battery to be a system. The invention discloses a novel battery type supercapacitor, and through a method of using a high-specific-energy battery material or / and supercapacitor material such as a metal oxide, a metal hydroxide, a metal sulfide, a conducting polymer and a carbon material to form alternate thin layers with reduced oxidized graphene (rGO) and further manufacture a multilayer structure formed by a plurality of thin layers, a supercapacitor with high specific energy and high specific power is realized. The novel multilayer structure formed by many thin layers made of battery or capacitor material and rGO in an alternate mode can ensure that an electrode that is manufactured is greatly improved in reaction particle diffusion control and has improved dynamic characteristics, so that high power density and high energy density can be obtained when the electrode serves as a capacitor.

Owner:QINGDAO NINEX NEW ENERGY TECH CO LTD

Metal hydroxide coated carbon and sulfur lithium-sulfur battery positive electrode material, and preparation method and application thereof

ActiveCN105118972AImprove cycle lifeHigh electrochemical redox activityMaterial nanotechnologyCell electrodesHexamethylenetetramineLithium sulfur

The invention discloses a metal hydroxide coated carbon and sulfur lithium-sulfur battery positive electrode material, and a preparation method and an application thereof. The preparation method comprises the following steps: uniformly grinding sublimed sulfur and conductive carbon black, and carrying out heat treatment fusion for uniform mixing to obtain sulfur and carbon black composite powder; and dissolving metal salt and hexamethylenetetramine in water, adding polyvinylpyrrolidone and the sulfur and carbon black composite powder, stirring, carrying out ultrasonic treatment to obtain a black mixed liquor, carrying out hydrothermal treatment on the black mixed liquor at 80-100DEG C for 2-5h, cooling, centrifuging, and drying to obtain the material. The metal hydroxide coated carbon and sulfur lithium-sulfur battery positive electrode material prepared in the invention inhibits the shuttle effect of polysulfide, improves the conductive performance of sulfur, and improves the cycle performances of batteries. The metal hydroxide coated carbon and sulfur lithium-sulfur battery positive electrode material is used to make a lithium-sulfur positive electrode, the lithium-sulfur positive electrode is applied in a lithium-sulfur battery, and the lithium-sulfur battery has high capacity and protruding cycle performances.

Owner:杭州亿昇达新能源科技有限公司

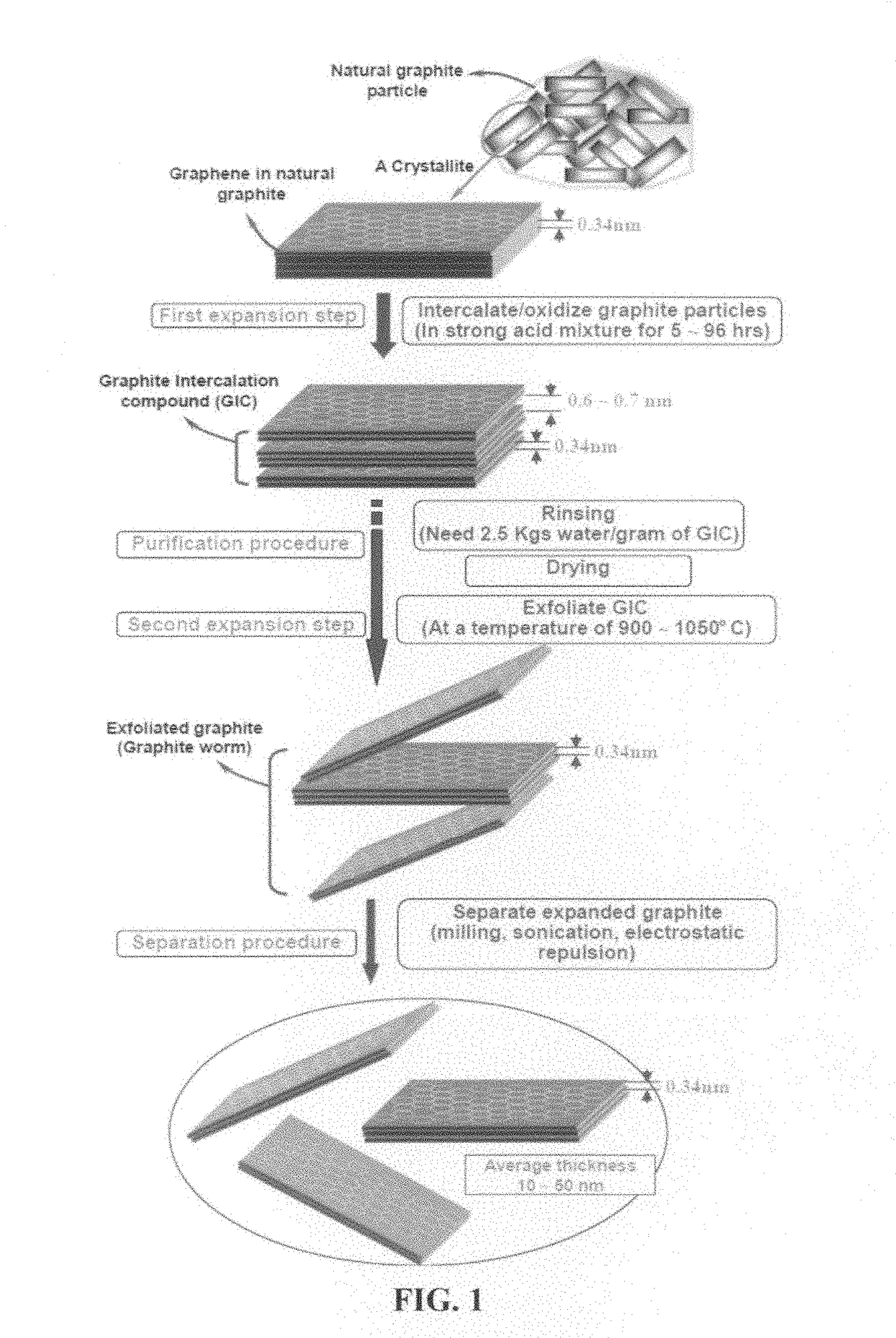

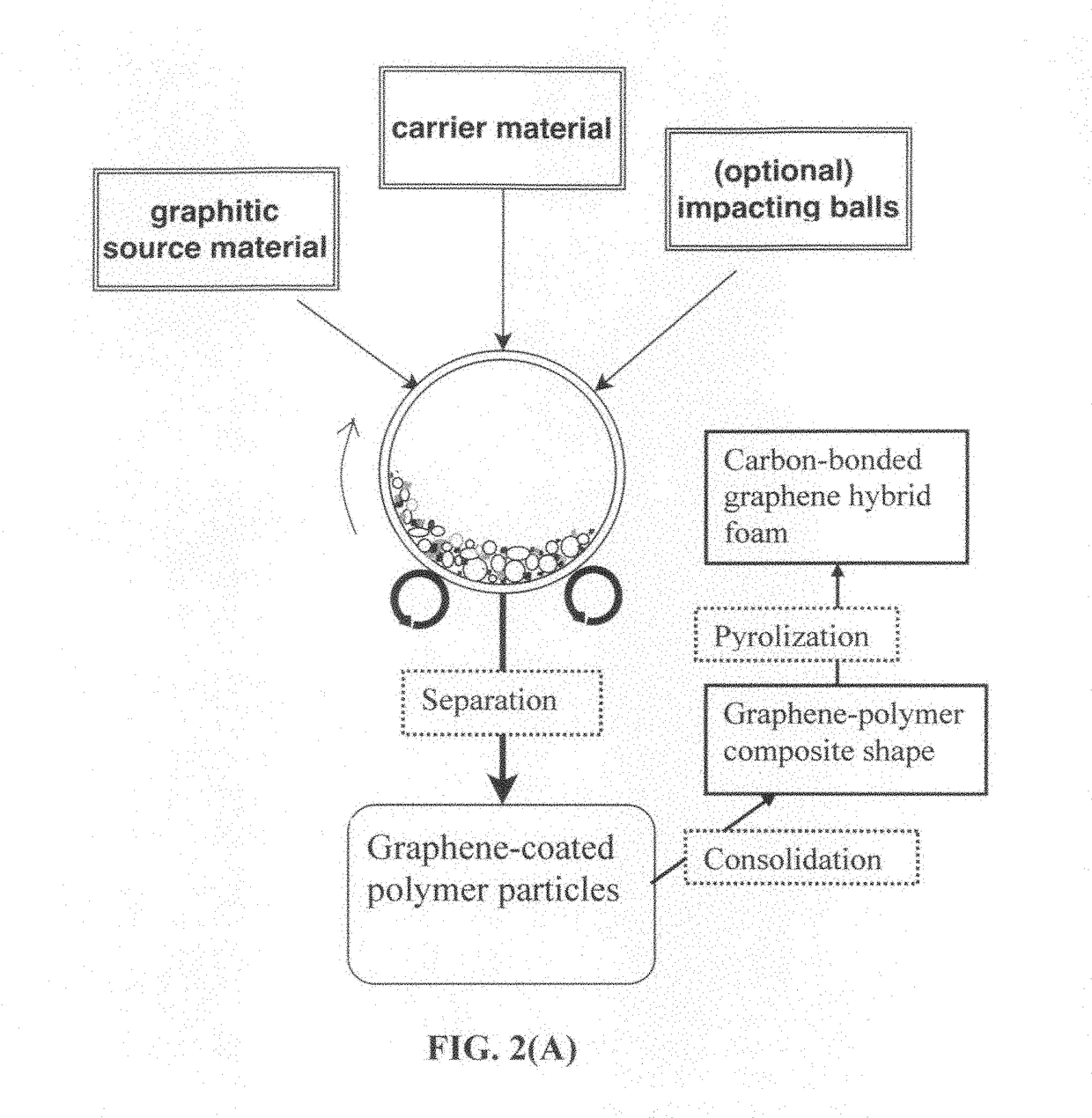

Supercapacitor having an integral 3D graphene-carbon hybrid foam-based electrode

ActiveUS20170194105A1High specific capacitanceHybrid capacitor separatorsHybrid capacitor electrodesDoped grapheneIodide

Provided is a supercapacitor having an anode, a cathode, a porous separator / electrolyte, wherein at least one of electrodes contains an integral 3D graphene-carbon hybrid foam composed of multiple pores and pore walls, wherein the pore walls contain single-layer or few-layer graphene sheets chemically bonded by a carbon material having a carbon material-to-graphene weight ratio from 1 / 100 to 1 / 2, wherein the few-layer graphene sheets have 2-10 layers of stacked graphene planes having an inter-plane spacing d002 from 0.3354 nm to 0.40 nm and the graphene sheets contain a pristine graphene material having essentially zero % of non-carbon elements, or a non-pristine graphene material having 0.01% to 25% by weight of non-carbon elements wherein said non-pristine graphene is selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof.

Owner:NANOTEK INSTR GRP LLC

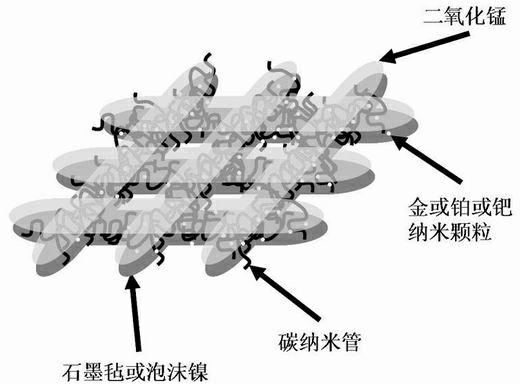

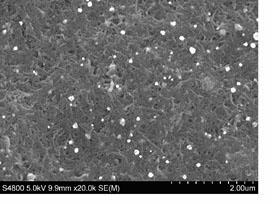

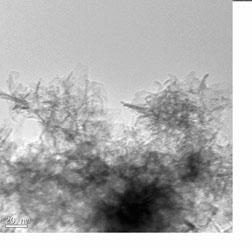

Combined electrode for super capacitor and preparation method thereof

InactiveCN102683044AHigh mechanical strengthLarge specific surface areaElectrolytic capacitorsHybrid capacitor electrodesPlatinumNickel substrate

The invention relates to a nanometer combined electrode material for a super capacitor and a preparation method thereof. The combined electrode material for the super capacitor is as follows: the surface of a graphite felt or a foam nickel substrate material is provided with a carbon nanometer tube layer; the surface of the carbon nanometer tube layer is provided with a layer of trace discontinuous palladium or platinum or gold nanometer particles; and the carbon nanometer tube layer with a layer of trace discontinuous palladium or platinum or gold nanometer particles on the surface is provided with a manganese dioxide layer.

Owner:昆山昆鹏利杰高分子材料技术有限公司

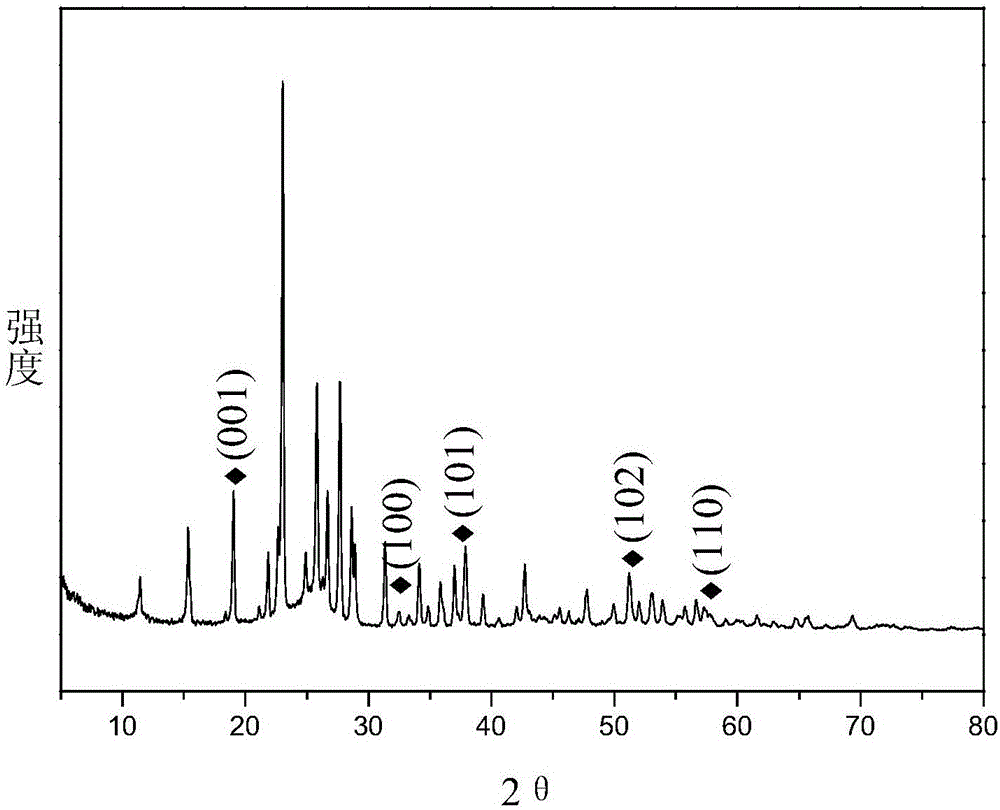

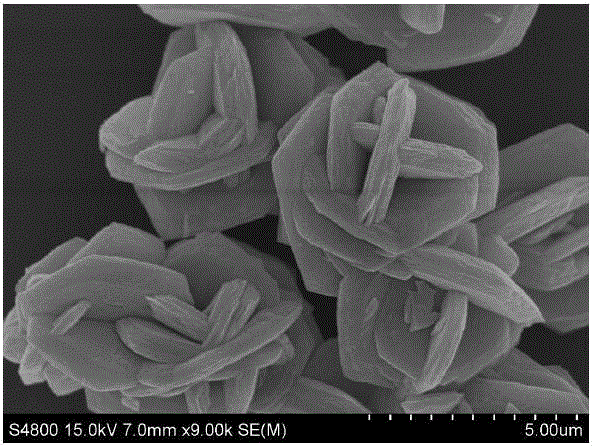

3D-nanostructure NiCo2S4 electrode material for super capacitor and preparation method thereof

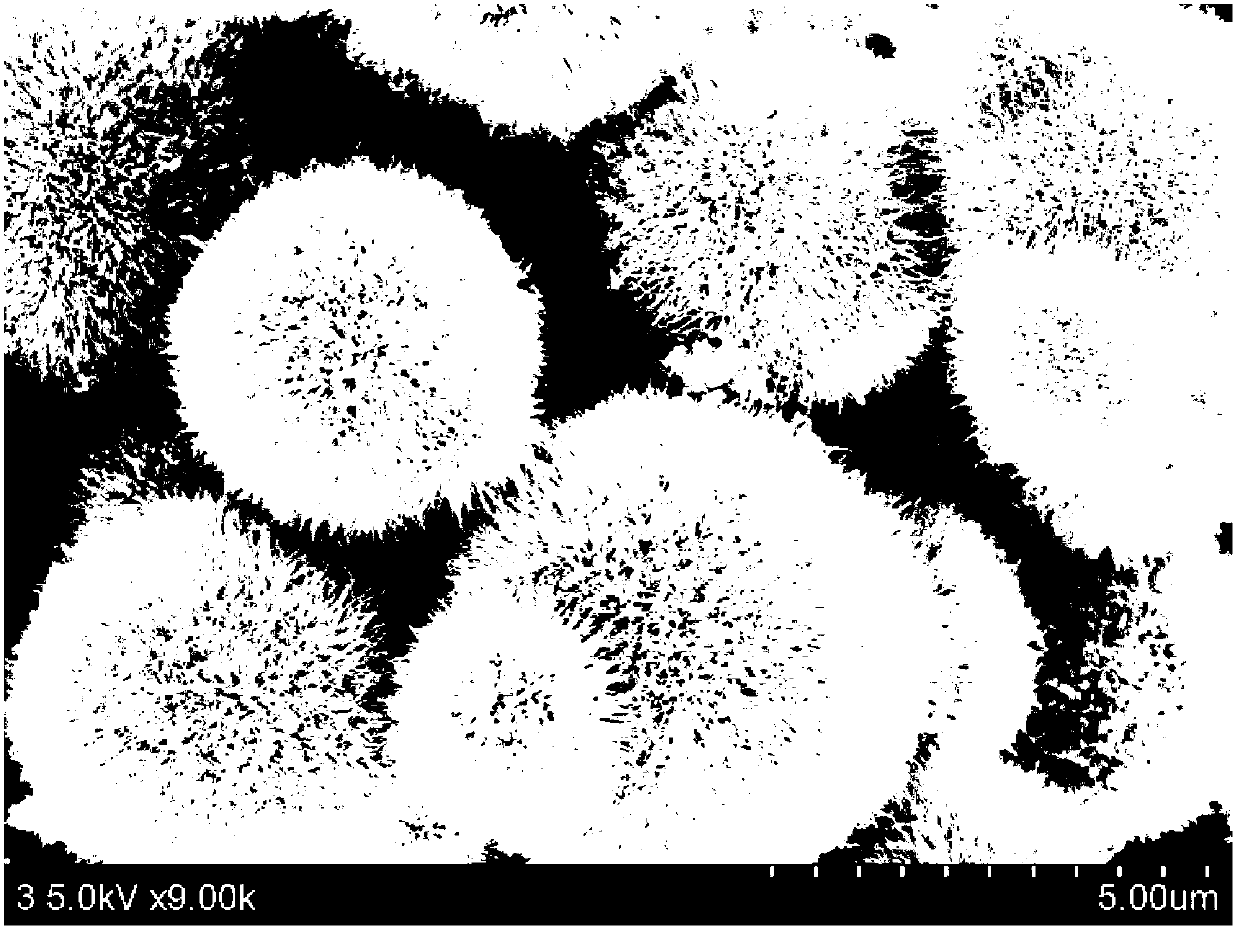

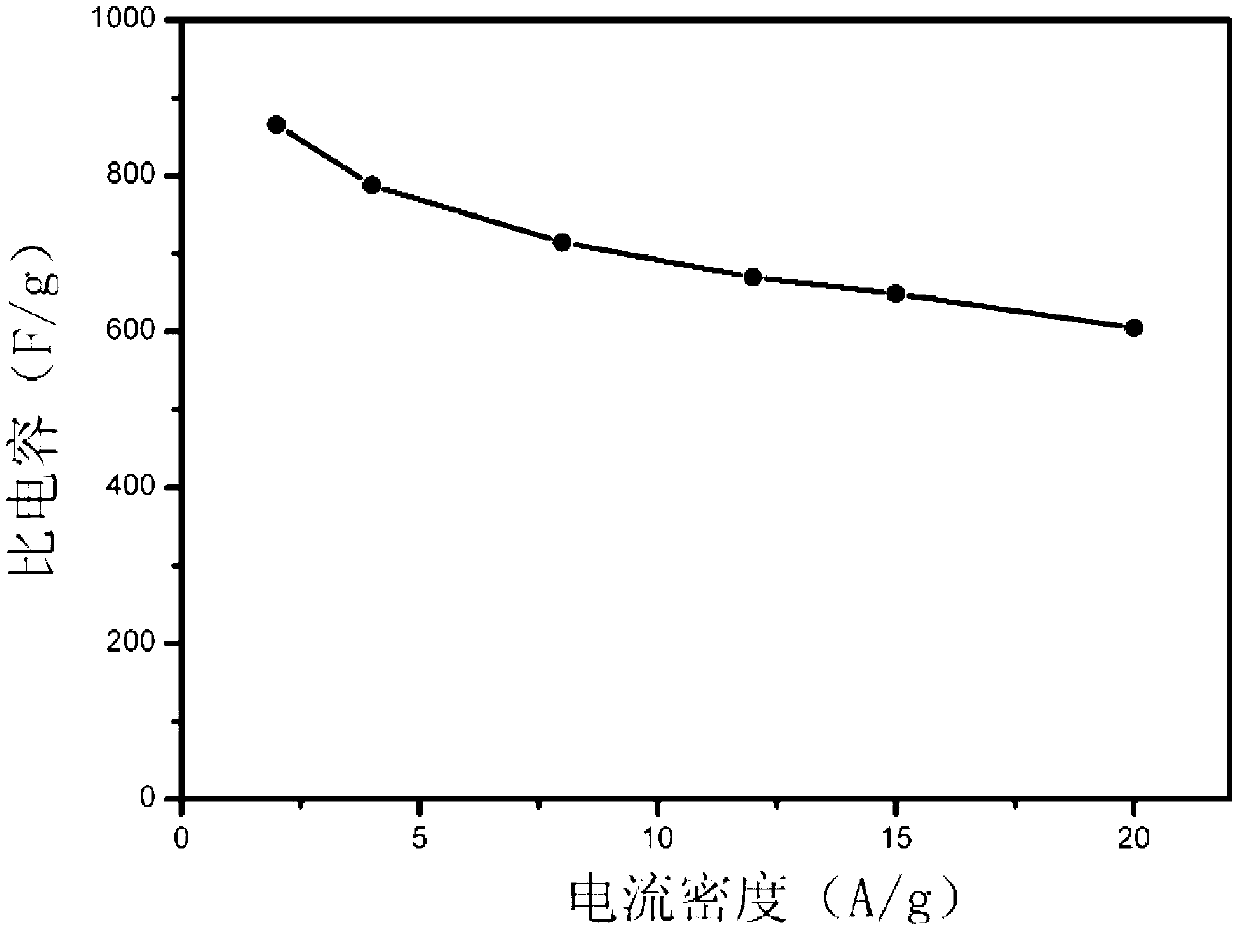

ActiveCN105244177AImprove performanceHigh specific capacitance performanceHybrid capacitor electrodesNickel compoundsCapacitanceNickel salt

The invention relates to a 3D-nanostructure NiCo2S4 electrode material and a preparation method thereof. The 3D-nanostructure NiCo2S4 electrode material is in a three-dimensional nanostructure formed through self-assembly of hexagonal NiCo2S4 nanosheets. The 3D-nanostructure NiCo2S4 electrode material is prepared through a hydrothermal method and a follow-up sulfuration process. The preparation method comprises 1) dissolving divalent cobalt salt and divalent nickel salt into an alkaline aqueous solution, and obtaining an intermediate product in a three-dimensional structure through hydrothermal reaction; and 2) dispersing the obtained intermediate product into a sulfur source solution so as to carry out hydrothermal sulfidizing processing, and thus the 3D-nanostructure NiCo2S4 electrode material can be obtained. On the basis of high seudocapacitance activity and high conductivity of the NiCo2S4 material, specific surface area is improved by forming the 3D nanostructure, and the obtained product is allowed to have excellent super capacitor performance; the hydrothermal and follow-up sulfuration processing processes are simple and are easy to operate and control; and the method is suitable for continuous large-scale production.

Owner:YANGZHOU UNIV

Highly porous activated carbon with controlled oxygen content

ActiveUS8541338B2High specific capacitanceCarbon compoundsHybrid capacitor electrodesActivated carbonPhysical chemistry

Nanoporous activated carbon material having a high specific capacitance in EDLCs and controlled oxygen content, and methods for making such activated carbon material. Reduction of oxygen content is achieved by (a) curing a carbon precursor / additive mixture in an inert or reducing environment, and / or (b) refining (heating) activated carbon material after synthesis in an inert or reducing environment. The inert or reducing environment used for curing or refining is preferably substantially free of oxygen.

Owner:CORNING INC

Production method of 3003-brand cathode aluminum foil

InactiveCN101519760AEvenly distributedImprove plasticityElectrolytic capacitorsCapacitanceMetallurgy

The invention relates to a production method of 3003-brand cathode aluminum foil, which includes the following steps: a. raw materials are refined and rolled into a blank with the thickness of 6.5 mm to 8.5 mm; b. the blank obtained in step a is rolled into the blank with the thickness of 3.5 mm to 4.3 mm in a cooling mode to be uniformly annealed; c. the uniformly-annealed blank is rolled into the blank with the thickness of 0.3 mm to 0.5 mm in a cooling mode to be recrystallized and annealed; and d. the recrystallized-and-annealed blank is rolled into the 3003-brand cathode aluminum foil with the required thickness. The method of the invention enables the cost to be lower and the product quality to be better, the specific capacitance of the product is increased to be higher than 530 microfarads / cm<2>, and the highest specific capacitance can be 560 microfarads / cm<2>. The invention greatly improves the product competitive strength, reduces the disparity with abroad products, and makes a contribution for the trade progress.

Owner:登电集团铝加工有限公司

Method for preparing carbide film by carbonizing graphene reinforced polyimide resin

ActiveCN102560453AIncrease internal stressReduce brittlenessSolid/suspension decomposition chemical coatingCapacitancePolymer science

The invention discloses a method for preparing a carbide film by carbonizing graphene reinforced polyimide resin, and relates to a method for preparing a carbide film. The method solves the technical problems of high carbonizing temperature, high energy consumption, long carbonizing period and low carbonizing rate and low strength of the carbide film in the conventional method for preparing the carbide film. The method comprises the following steps of: 1, adding 4,4'-diamino diphenyl ether (ODA) and 3,3',4,4'-benzophenonetetracarboxylic dianhydride (BTDA) into N,N-dimethyl acetamide (DMAC), and performing mechanical stirring to obtain a polyamide acid (PAA) solution; 2, adding graphene into the PAA solution, and performing in-situ polymerization reaction to obtain a solution A; 3, spreading the solution A on a clean glass plate, heating to the temperature of 60 DEG C and preserving the heat for 2 hours, heating to the temperature of 100 DEG C and preserving the heat for 1 hour, heating to the temperature of 200 DEG C and preserving the heat for 1 hour, heating to the temperature of 300 DEG C and preserving the heat for 1 hour, and thus obtaining a composite film; and 4, carbonizing, naturally cooling to room temperature, and thus obtaining the carbide film. The carbide film has excellent mechanical properties; and because the adding proportion of the graphene is increased, the mechanical properties of the carbide film are improved, the specific capacitance of the graphene is also improved, and the carbide film is suitable to be used as an electrode material.

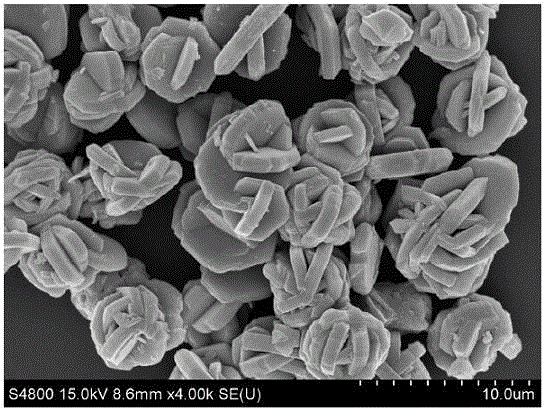

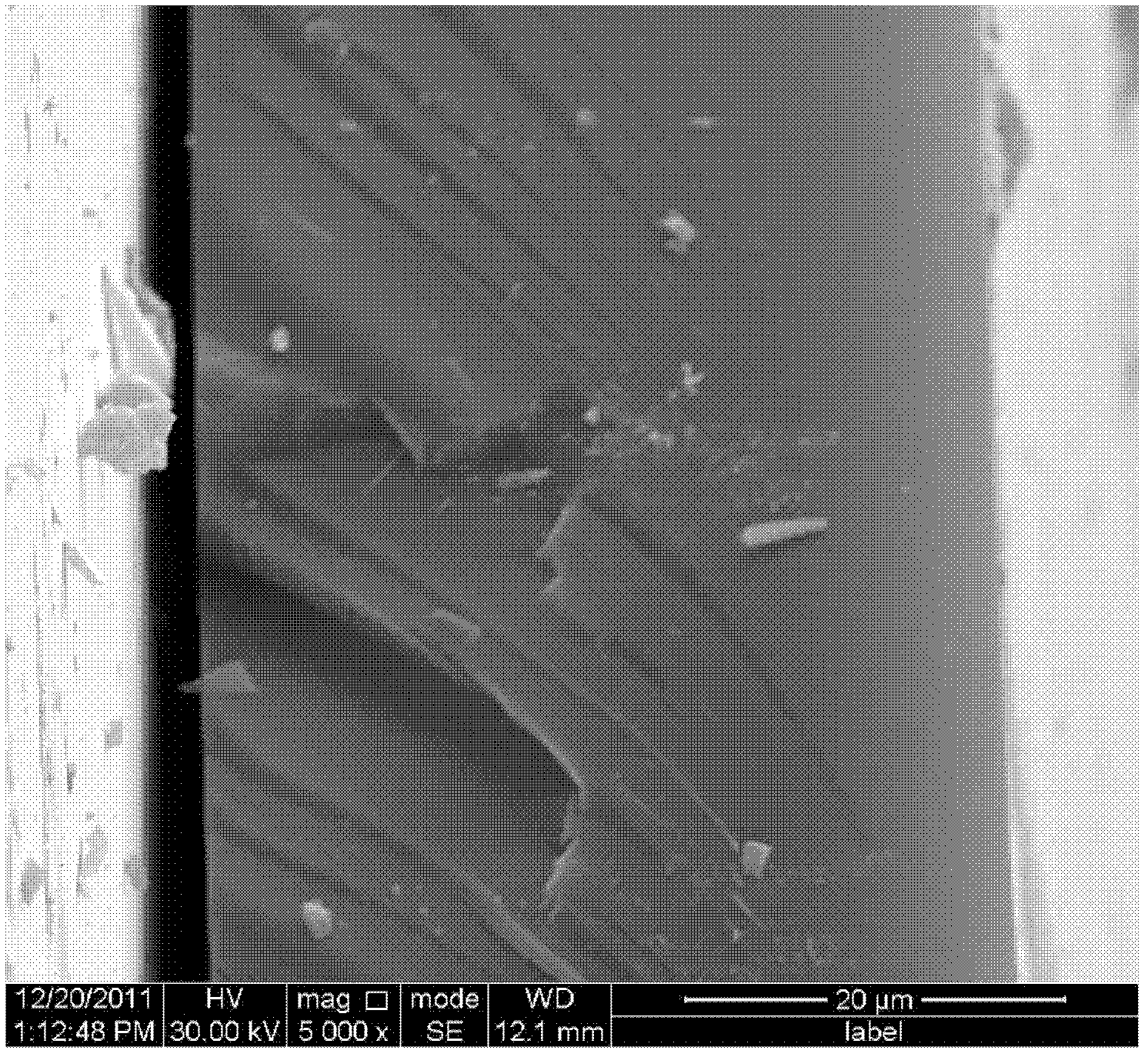

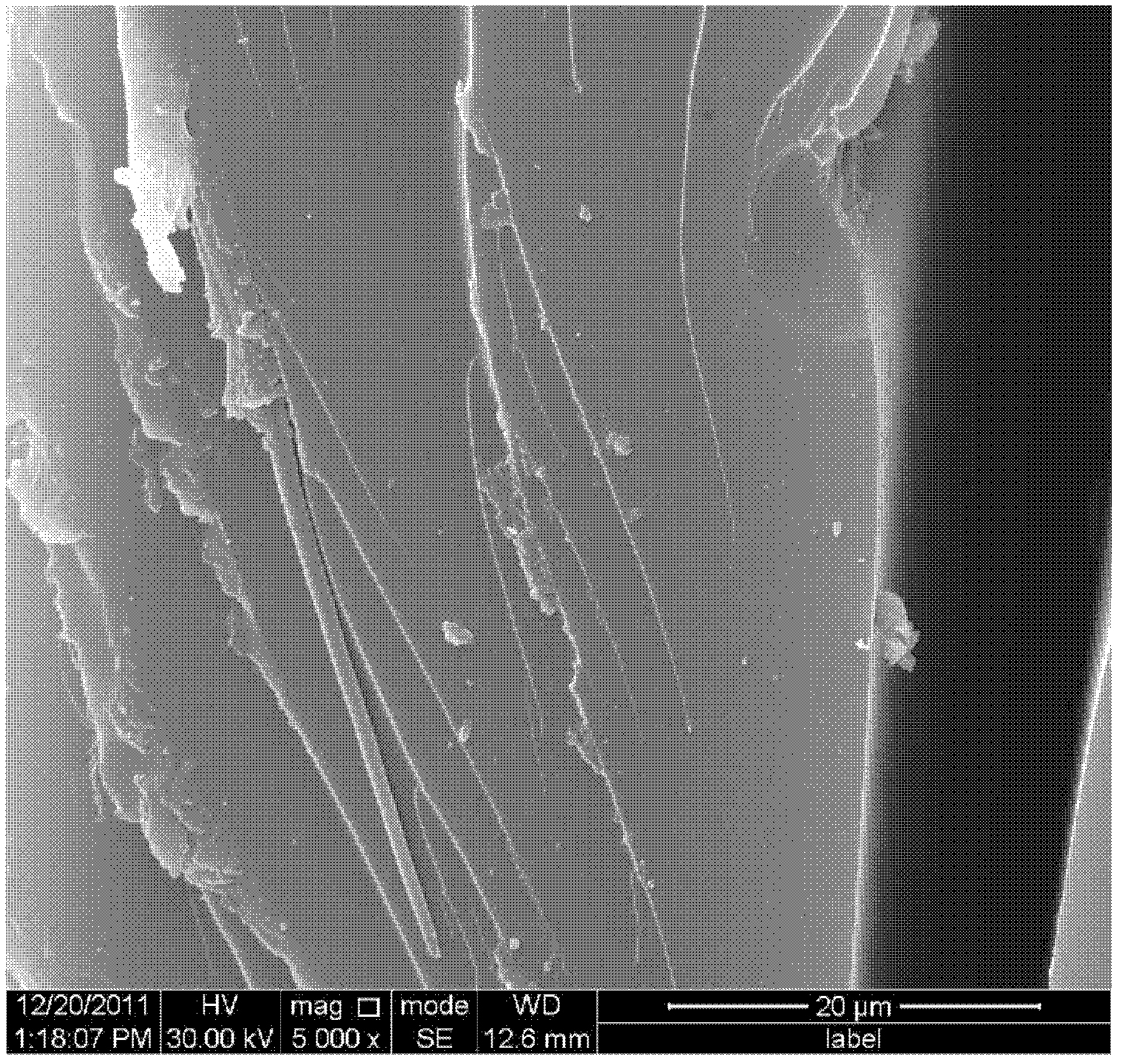

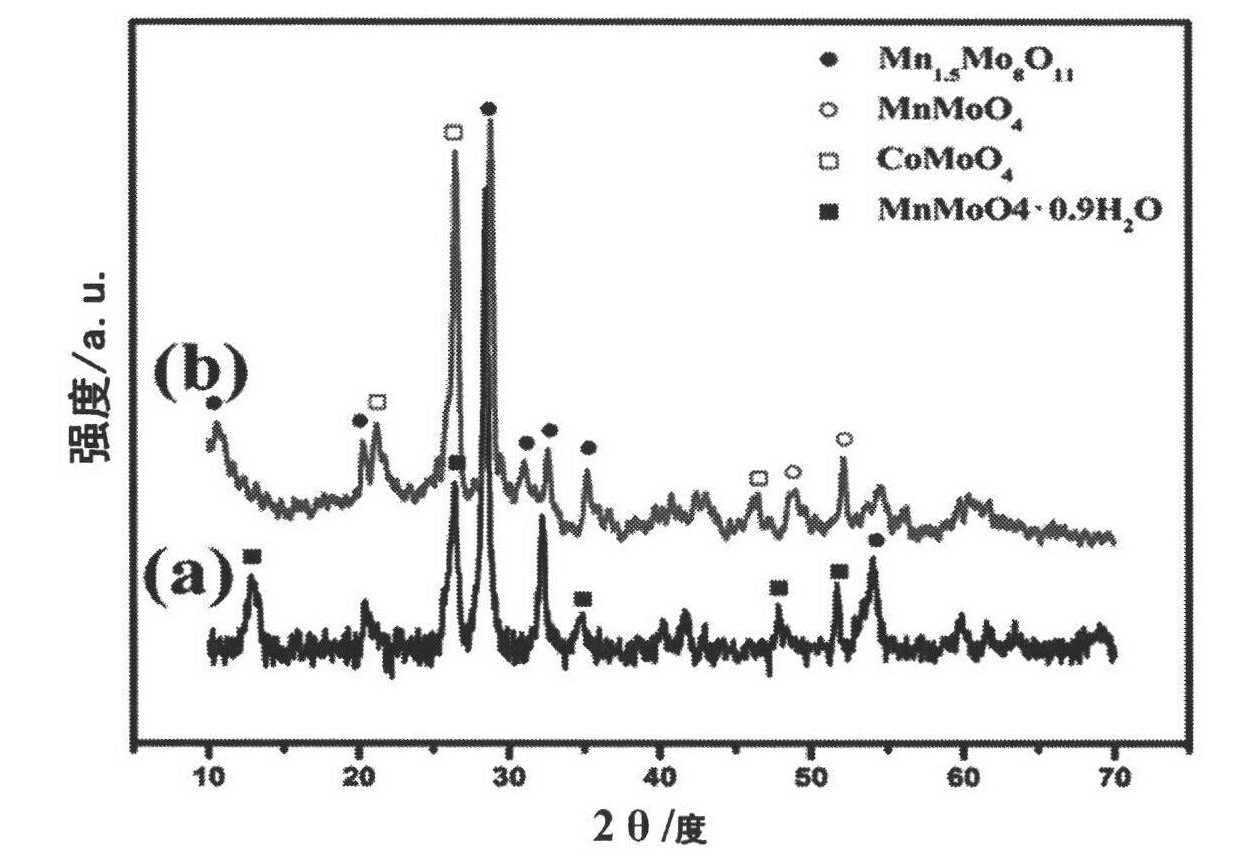

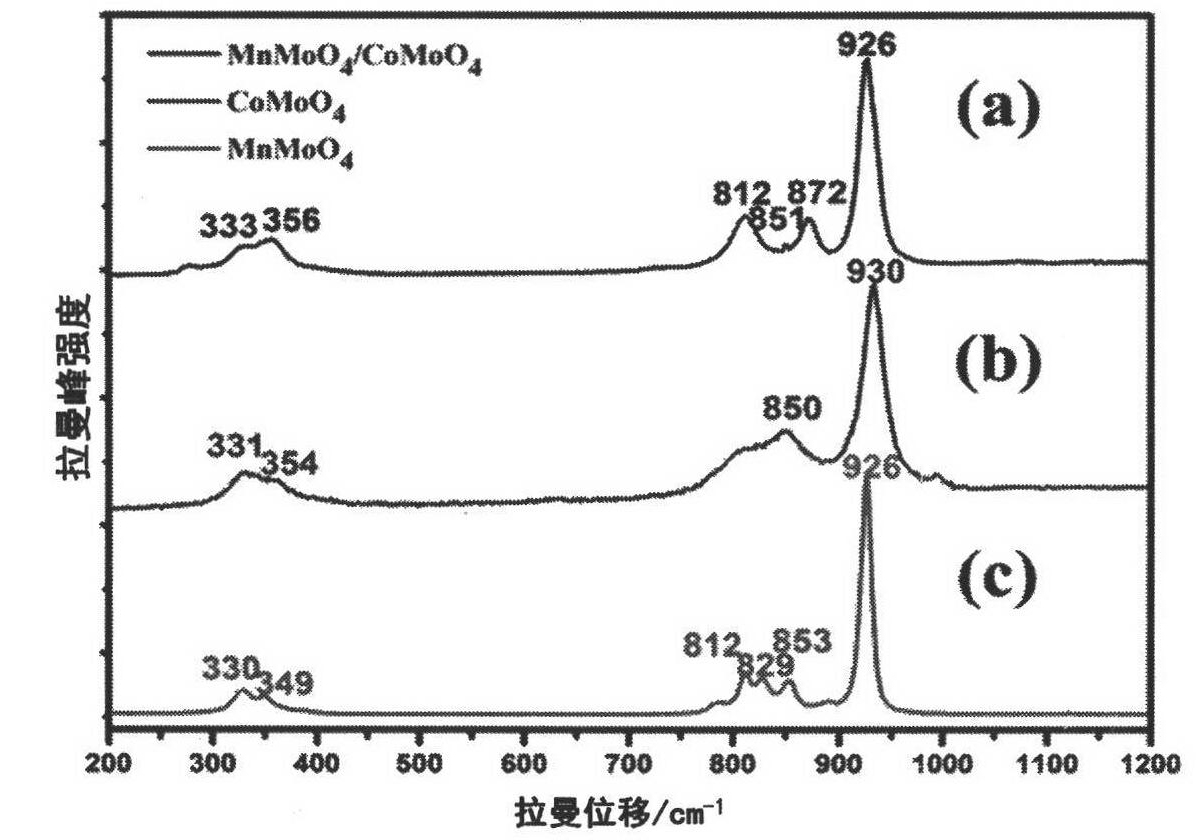

Method for preparing manganese molybdate/cobalt molybdate hierarchical heterostructure nanowires

ActiveCN102154701AAchieving controllable synthesisHigh specific capacitancePolycrystalline material growthFrom normal temperature solutionsNanowireMolybdate

The invention discloses a method for preparing manganese molybdate / cobalt molybdate hierarchical heterostructure nanowires. The method comprises the following steps of: preparing a NaMoO4 aqueous solution and a MnCl2aqueous solution; proportioning in a certain ratio of the NaMoO4aqueous solution to the MnCl2 aqueous solution to CTAB (Cetyltrimethyl Ammonium Bromide) to n-butyl alcohol to isooctane and preparing manganese molybdate nanorods by using a microemulsion method; adding the manganese molybdate nanorods into distilled water, stirring and ultrasonically cleaning to obtain transparent liquid; and adding the liquid into a flask, placing the flask in an oil bath of between 60 and 80 DEG C, condensing and refluxing, adding a CoCl2 solution and a Na2MoO4 solution with different concentrations in turn every certain time, stirring to react so as to obtain a product, separating and drying the product to obtain the manganese molybdate / cobalt molybdate hierarchical heterostructure nanowires, wherein the lengths of the nanowires reach 10 microns and the diameters of the nanowires are between 500 and 1,000nm; the manganese molybdate nanorods in the hierarchical heterostructure nanowires are used as a main material and the diameters of the manganese molybdate nanorods are between 300 and 500; and the cobalt molybdate is branch nanorods which orderly grow on the surfaces of the manganese molybdate nanorods and the diameters of the cobalt molybdate nanorods are between 30 and 50nm. The material has excellent electrochemical performance and can be used as an active material for electrodes of electrochemical super capacitors. The method has the advantages of low-cost raw materials, simple process and environmental friendliness.

Owner:武汉经开科创运营有限公司

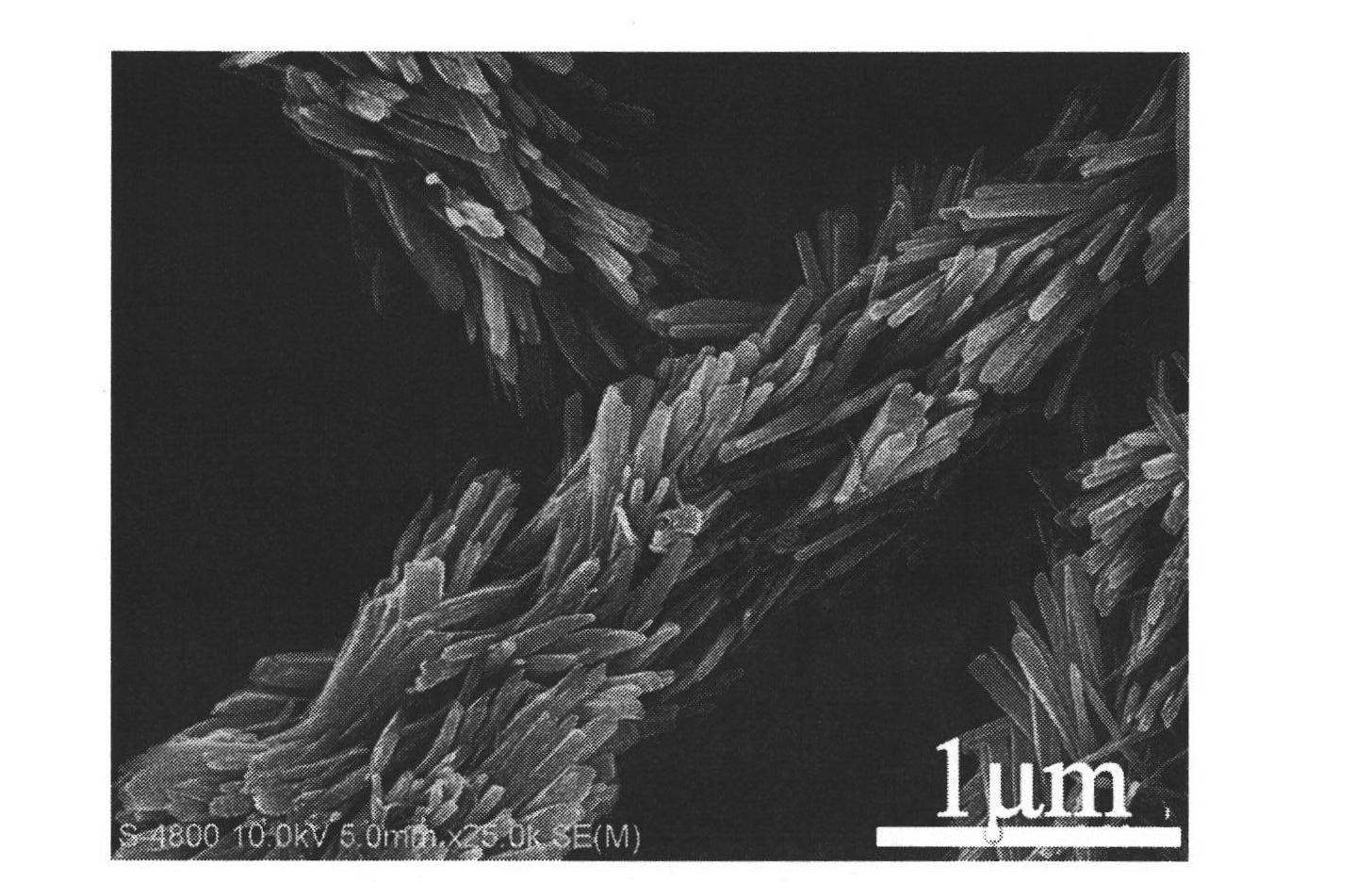

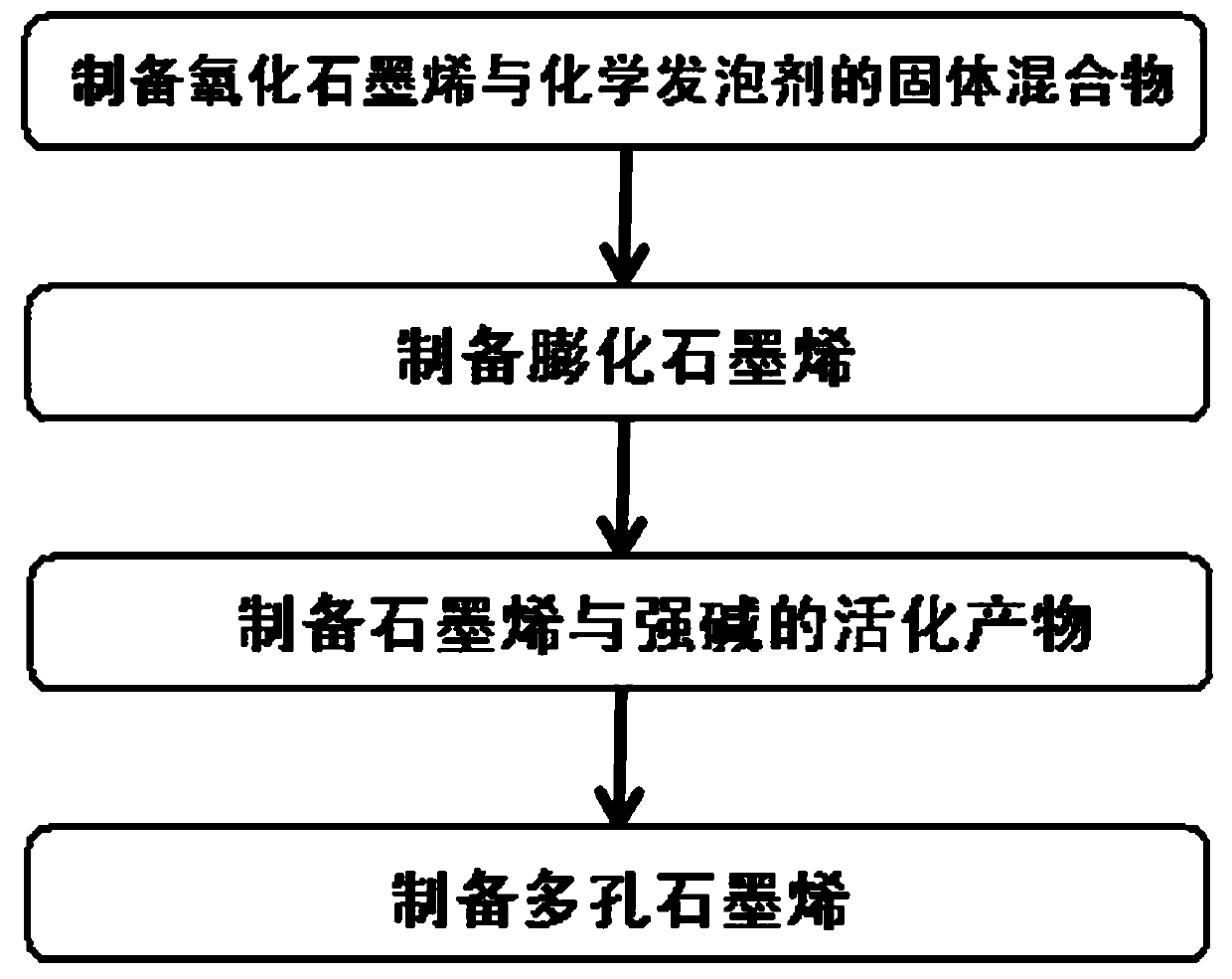

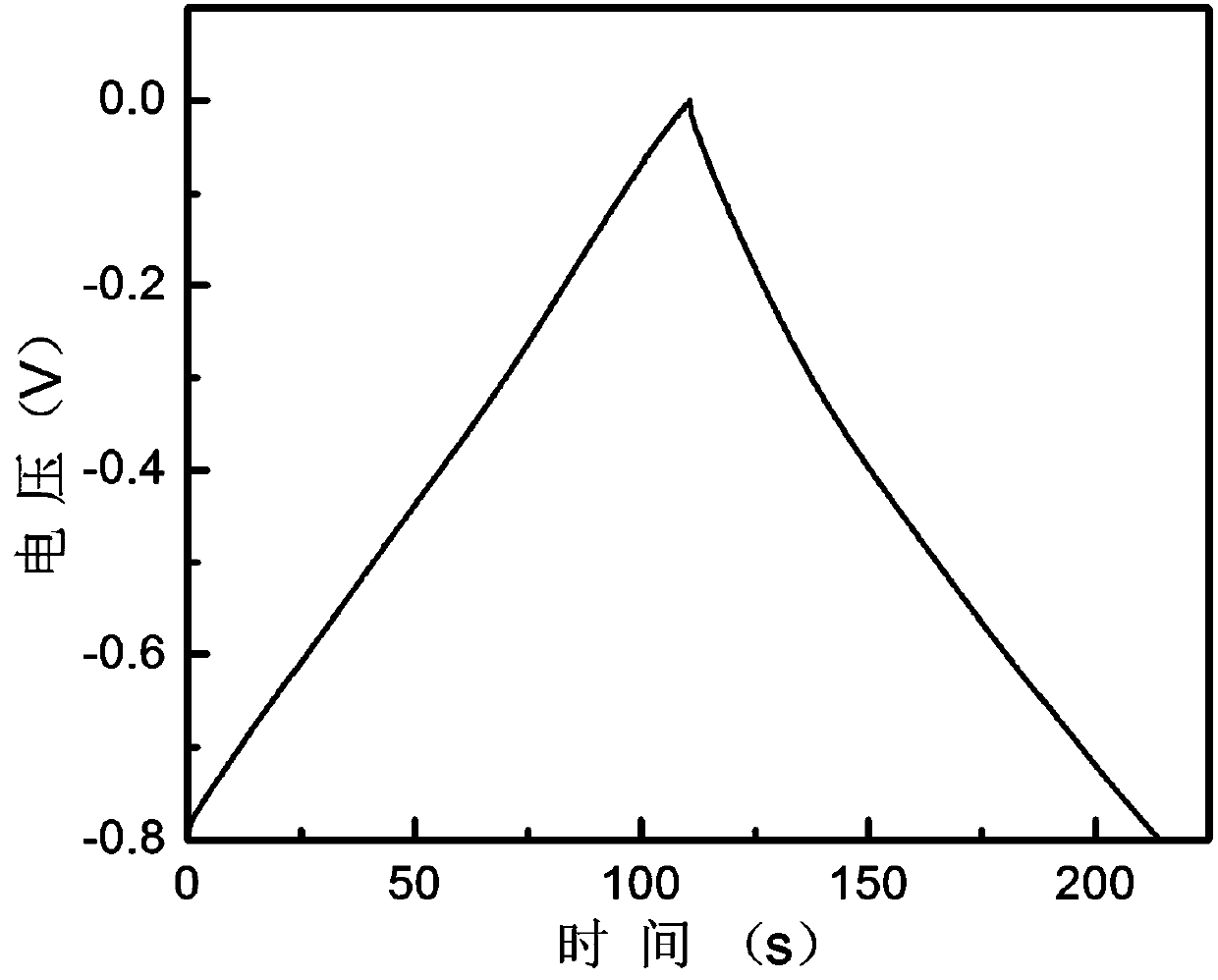

Preparation method of porous graphene

InactiveCN103466604AInhibit high temperature agglomeration effectHigh degree of peelingCarbon compoundsPorous grapheneCapacitance

The invention discloses a preparation method of porous graphene. The method comprises the steps of: (1) stripping graphite oxide in a water / ethanol mixed solution with pH of 9-10, adding a chemical foaming agent and mixing them uniformly, carrying out filtering and drying to obtain a solid mixture; (2) placing the mixture in a reducing atmosphere, and performing heating expansion reduction to obtain expanded graphene; (3) blending the expanded graphene with strong base, and conducting high temperature activation; and (4) washing the product with hydrochloric acid and deionized water, and performing drying so as to obtain porous grapheme. The porous graphene prepared by the method involved in the invention has a specific surface area up to 2075m<2> / g, a pore volume up to 1.8cm<3> / g, and an average pore size of 1-7nm. As a supercapacitor electrode material, the specific capacitance can reach 155F / g under a current density of 1Ag<-1>. As a porous graphene electrode, the specific capacitance can reach 84.4% along with the increase of current density from 0.2Ag<-1> to 20Ag<-1>. The porous graphene has high specific capacitance and cycle stability. The preparation method disclosed in the invention has the advantages of simple process, low cost, and easy scale production.

Owner:EAST CHINA UNIV OF SCI & TECH

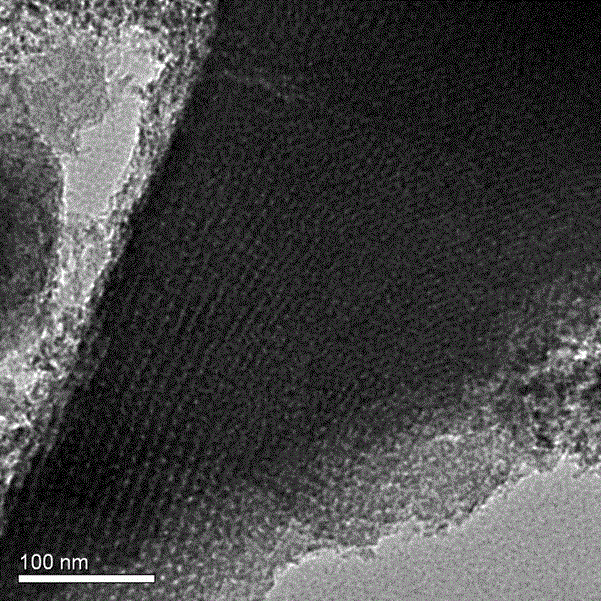

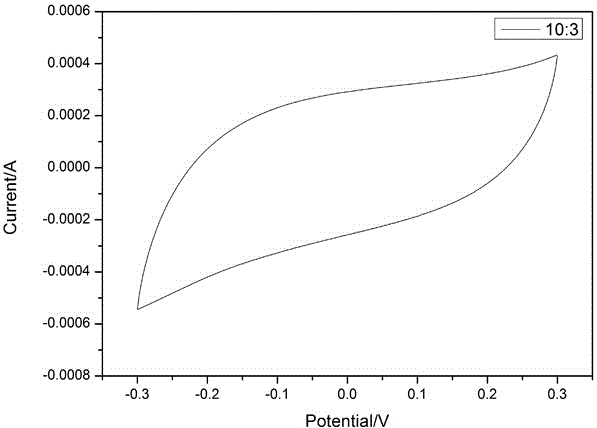

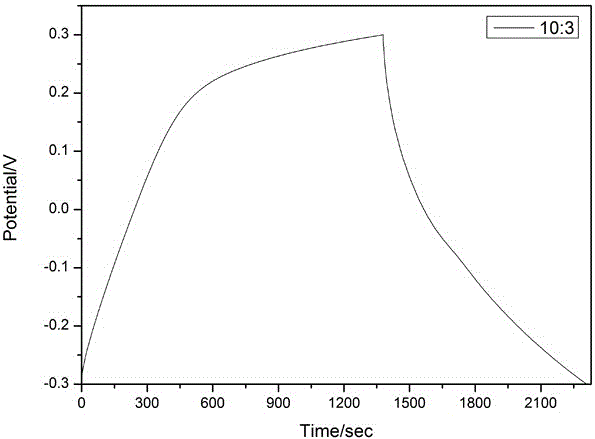

Graphene / Fe-MOFs composite material and preparation method thereof

InactiveCN104538200AImprove electrochemical performanceHigh specific capacitanceHybrid capacitor electrodesHybrid/EDL manufactureSupercapacitorTerephthalic acid

The invention discloses a graphene / Fe-MOFs composite material and a preparation method thereof. Adding oxidized graphene, FeCl3 and terephthalic acid into N, N-dimethyl formamide according to the corresponding ratio of 1-15 g : 100 g: 200 g : 150 ml, ultrasonically dissolving the mixture at a power of 600 W for 1 h, and then controlling the temperature to be at 150 degrees to conduct hydrothermal reduction reaction for 15 h; conducting suction filtration on the obtained reaction liquid, conducting repeated washing and suction filtration on the filter cake with N, N-dimethyl formamide till the filter does not contain incompletely reacted oxidized graphene, FeCl3 and terephthalic acid, controlling the temperature to be at 80 degrees to conduct drying, and then the graphene / Fe-MOFs composite material with good electro-chemical performance is obtained and can be used for super capacitor electrode materials. The graphene / Fe-MOFs composite material is simple and controllable in preparation technology, mild in conditions, low in production cost and suitable for industrial production.

Owner:SHANGHAI INST OF TECH

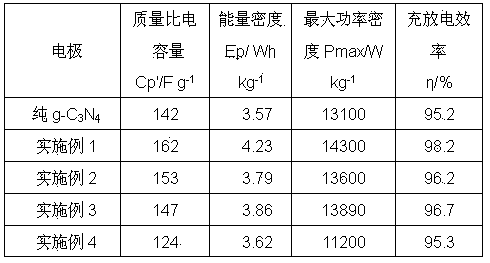

A method for preparing a g-C3N4/carbon quantum dot composite electrode

ActiveCN103745836AImprove performanceNot easy to decomposeHybrid/EDL manufactureCapacitanceElectron transfer

Provided is a method for preparing a g-C3N4 / carbon quantum dot composite electrode. The method comprises: adding carbon quantum dots into ethanol in order to prepare carbon quantum dot ethanol solution; mixing urea with the carbon quantum dot ethanol solution, performing ultrasonic dispersion on the mixed solution and then transferring the mixed solution to a crucible; warming the mixed solution to 350 to 700 degree centigrade with a muffle furnace step by step, maintaining the temperature for one to three hours and then decreasing the temperature of the mixed solution to room temperature; and grinding the obtained substance with ethanol and filtering the same so as to obtain g-C3N4 / carbon quantum dot composite material. The method has advantages of simpleness, no by-products, raw material easy to obtain, and low price. The obtained composite material is stable in performance, uneasy to decompose, and nontoxic. The method may increase the electron transfer rate of the g-C3N4 material, has good conductive performance, enhances electrode specific area, improves the electron adsorption capability of an electrode surface, and effectively increases the specific capacitance of a capacitor.

Owner:BOHAI UNIV

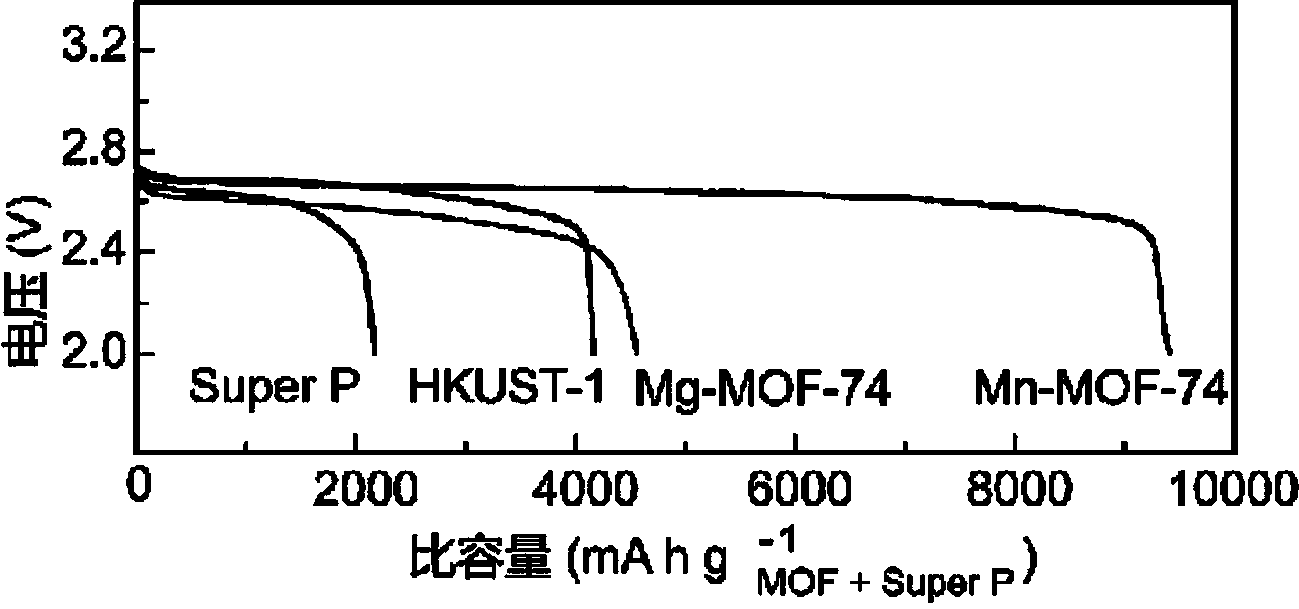

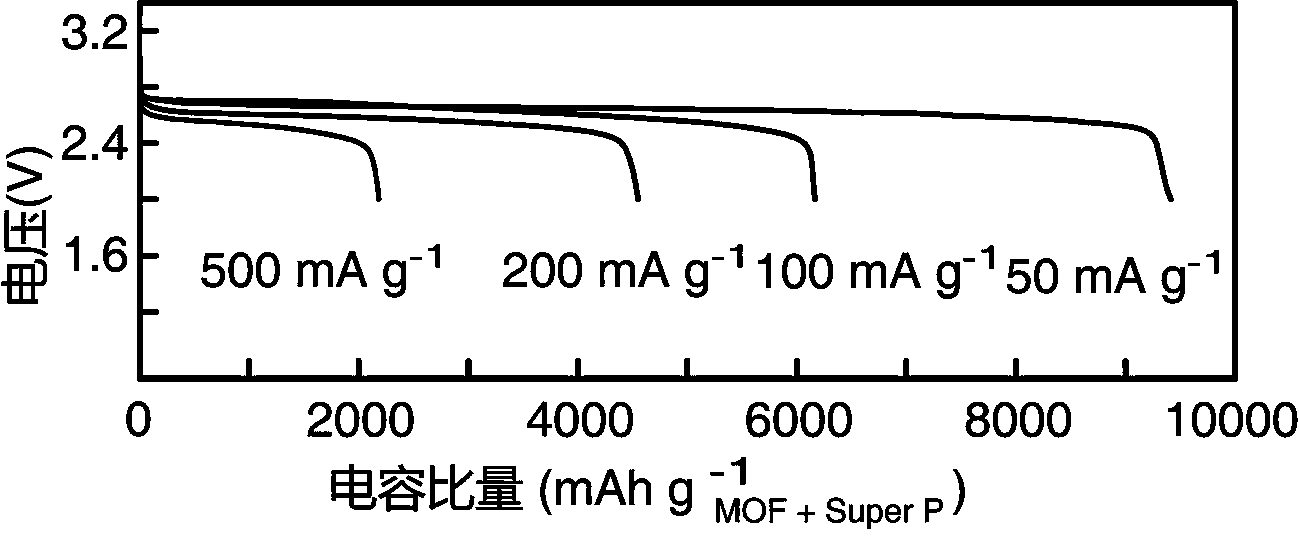

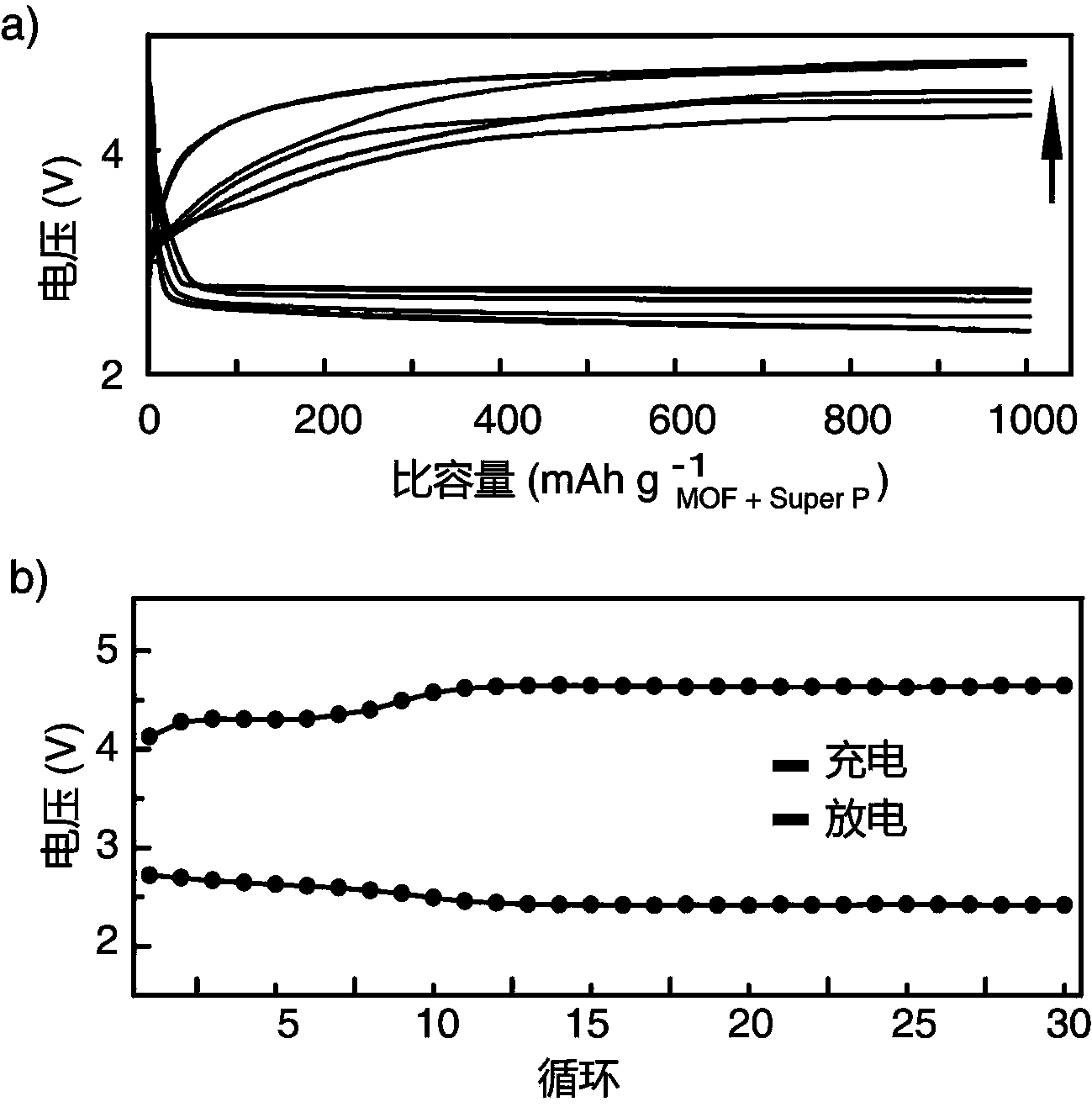

Lithium-oxygen battery electrode based on metal organic framework material and preparation method of lithium-oxygen battery electrode

ActiveCN103956502AEasy to prepareHigh specific capacitanceFuel and secondary cellsCell electrodesCapacitanceLithium

The invention belongs to the technical field of lithium-oxygen batteries, and particularly relates to a lithium-oxygen battery electrode based on a metal organic framework material and a preparation method of the lithium-oxygen battery electrode. The lithium-oxygen battery electrode provided by the invention is prepared by compounding the metal organic framework material, a porous carbon material, an adhering agent and the like, wherein the metal organic framework material provides an ordered micropore structure for the lithium-oxygen battery electrode, and thus transmission of a reaction gas is facilitated; the carbon material provides unordered pore passages (micropore, mesopore and macropore) when providing the conduction performance, thereby providing a storage space for a reaction product. The preparation method is simple; the prepared electrode is used for testing a battery, results indicate that compared with other batteries, a lithium-oxygen battery has the advantage that the specific capacitance of the lithium-oxygen battery containing the metal organic framework material is greatly improved.

Owner:FUDAN UNIV

Method for preparing iron/nitrogen-codoped ordered mesoporous carbon material

ActiveCN106517136AImprove wettabilityImprove electrochemical performanceCarbon preparation/purificationEtchingReaction temperature

The invention provides a method for preparing an iron / nitrogen-codoped ordered mesoporous carbon material. The method comprises the following steps: taking a triblock copolymer F127 as a template, under acidic condition, a silicon source-tetraethoxysilane, a carbon source-phenolic resin, a nitrogen source 1-urea, a nitrogen source 2-pyrroles monomer and an iron source-ferric trichloride are added, the micelle having a three-dimensional porous structure is synthesized with one step by a solvent volatilization induction self-assembly method, and the ordered mesoporous carbon material is obtained through high temperature carbonization and hydrofluoric acid etching. The method of the ordered mesoporous carbon material has the advantages of simple operation, low reaction temperature, and controllable condition, the prepared ordered mesoporous carbon material has the ordered three-dimensional tunnel structure, high specific surface area and excellent electrochemistry performance, and has good application prospect in the field of electrochemistry.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com