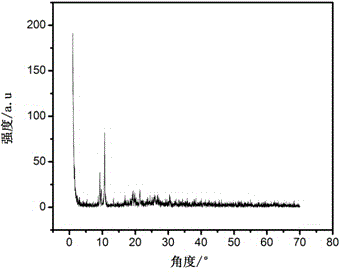

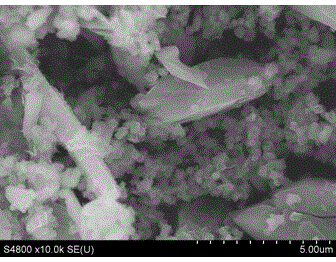

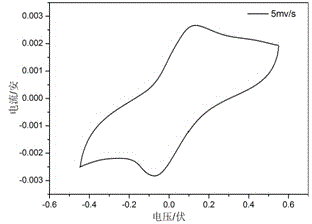

Graphene / Fe-MOFs composite material and preparation method thereof

A composite material and graphene technology is applied in the field of preparation of Fe-MOFs materials, which can solve the problems of high price and low electric capacity, and achieve the effects of simple raw materials, mild conditions and low production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of graphene / Fe-MOFs composite material specifically comprises the steps:

[0028] (1) Preparation of graphene oxide

[0029] After mixing 2g of flake graphite, 2g of sodium nitrate and 96ml of concentrated sulfuric acid, put it in an ice-water bath and stir evenly, then add 12g of potassium permanganate, continue to stir in the ice-water bath for 1-2h, then raise the temperature to 35°C for 2h of reaction, Then add 0.01g of hydrogen peroxide, continue to react for 10min, then suction filter the obtained reaction solution, wash the obtained filter cake with distilled water until the effluent is neutral, and finally ultrasonicate for 30min under a 600W ultrasonic wave to obtain graphene oxide;

[0030] The amount of potassium permanganate, calculated by mass ratio, potassium permanganate: flake graphite is 6:1;

[0031] The amount of hydrogen peroxide added is calculated by mass ratio, hydrogen peroxide: potassium permanganate is 1:1200;

[...

Embodiment 2

[0038] A kind of preparation method of graphene / Fe-MOFs composite material specifically comprises the steps:

[0039] (1) Preparation of graphene oxide

[0040] With the step (1) of embodiment 1;

[0041] (2), 0.15g graphene oxide, 3gFeCl 3 Add 6g of terephthalic acid into 150ml of N,N-dimethylformamide (hereinafter referred to as DMF) solvent, ultrasonically dissolve for 1h under 600W ultrasonic power, then transfer to a reaction kettle and seal it, and control the temperature at 150°C The hydrothermal reduction reaction was carried out for 15 hours, and the reaction solution obtained was suction filtered, and the obtained filter cake was repeatedly washed and suction filtered with DMF until there were no unreacted graphene oxide, FeCl or FeCl in the filter cake. 3 and terephthalic acid, and then control the temperature at 80°C for drying to obtain graphene / Fe-MOFs composite materials;

[0042] Graphene oxide, FeCl used in the above-mentioned hydrothermal reduction reactio...

Embodiment 3

[0046] A kind of preparation method of graphene / Fe-MOFs composite material specifically comprises the steps:

[0047] (1) Preparation of graphene oxide

[0048] With the step (1) of embodiment 1;

[0049] (2), 0.3g graphene oxide, 3gFeCl 3 Add 6g of terephthalic acid into 150ml of N,N-dimethylformamide (hereinafter referred to as DMF) solvent, ultrasonically dissolve for 1h under 600W ultrasonic power, then transfer to a reaction kettle and seal it, and control the temperature at 150°C The hydrothermal reduction reaction was carried out for 15 hours, and the reaction solution obtained was suction filtered, and the obtained filter cake was repeatedly washed and suction filtered with DMF until there were no unreacted graphene oxide, FeCl or FeCl in the filter cake. 3 and terephthalic acid, and then control the temperature at 80°C for drying to obtain graphene / Fe-MOFs composite materials;

[0050] Graphene oxide, FeCl used in the above-mentioned hydrothermal reduction reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com