Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

303results about How to "Excellent Electrical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

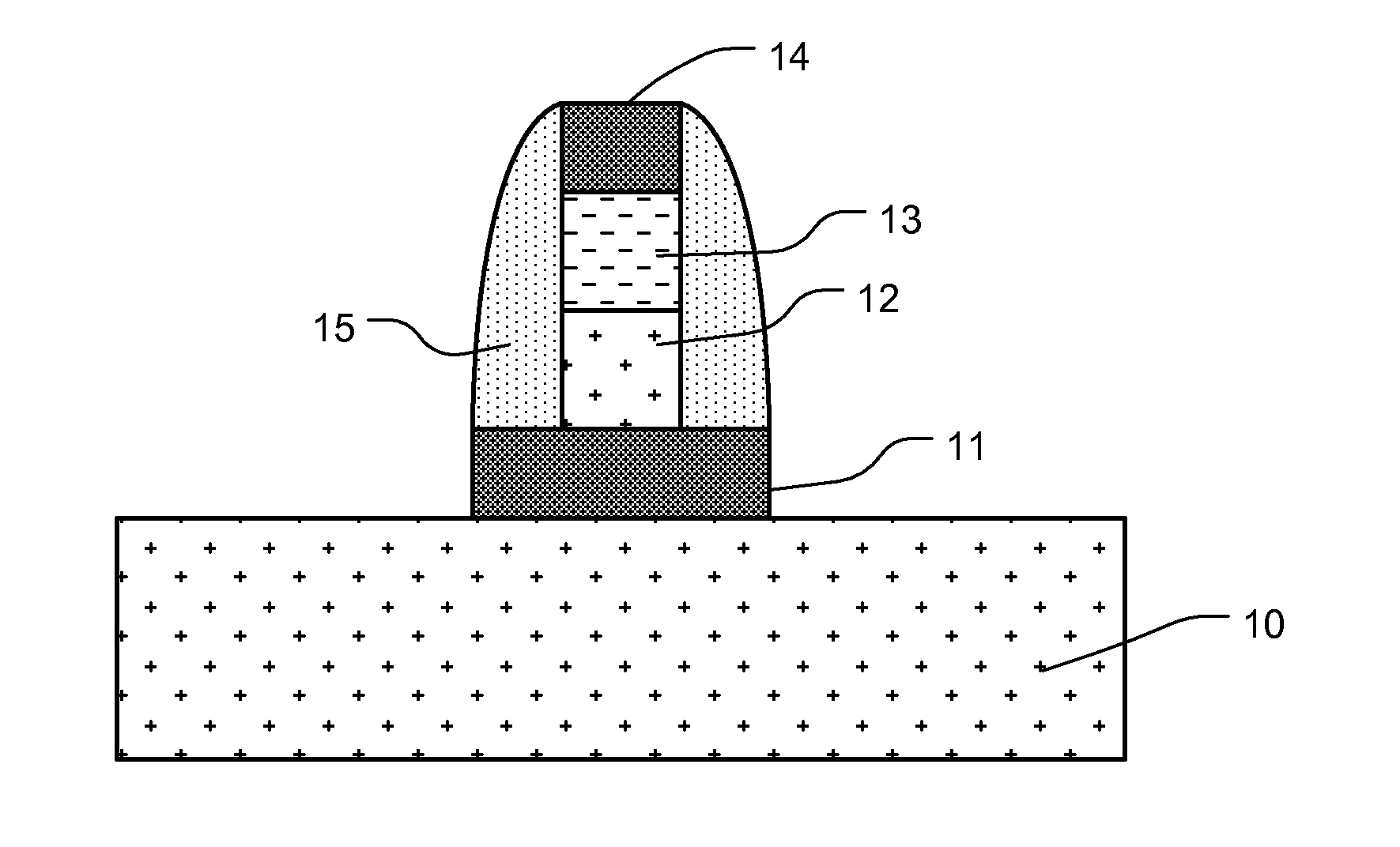

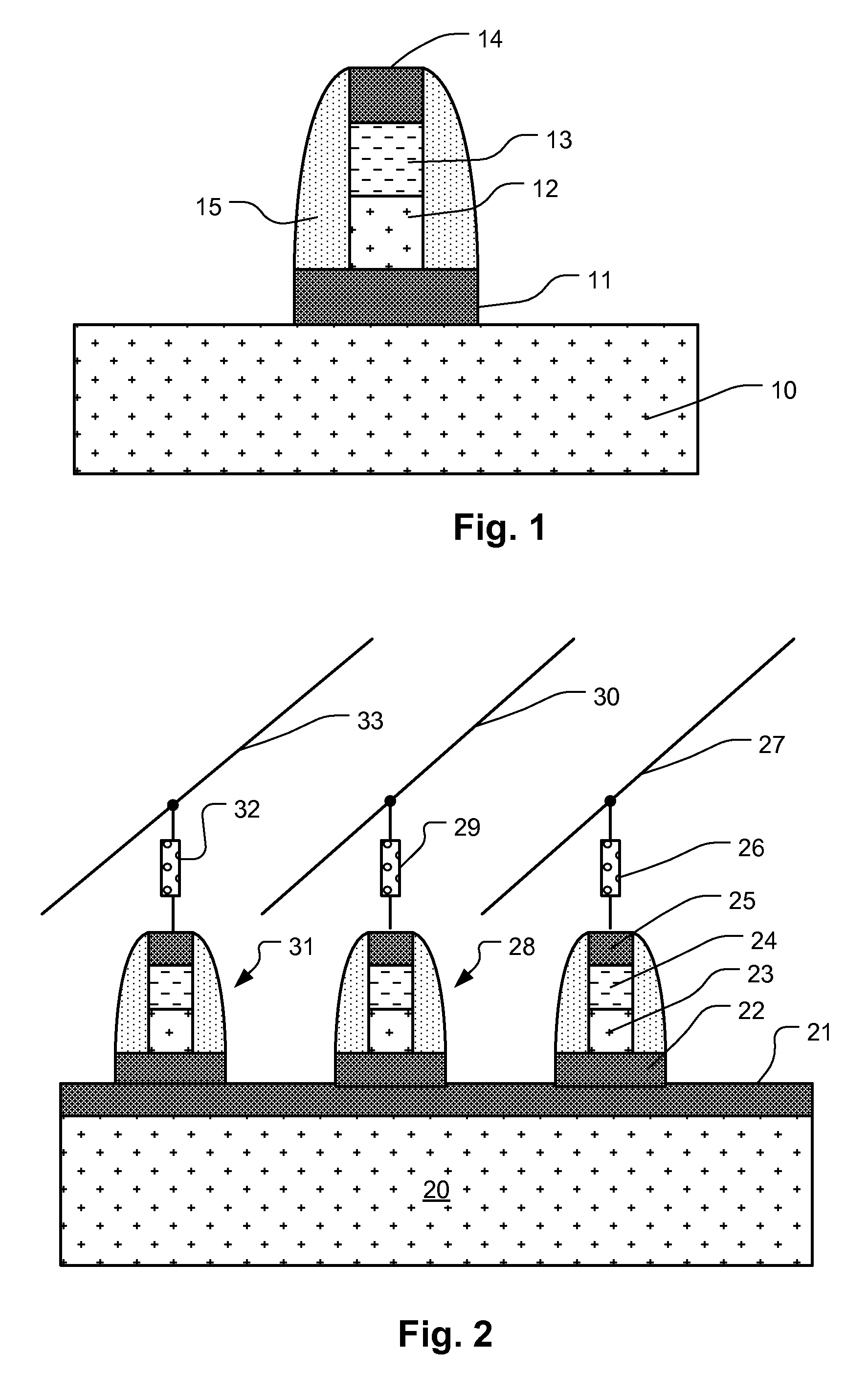

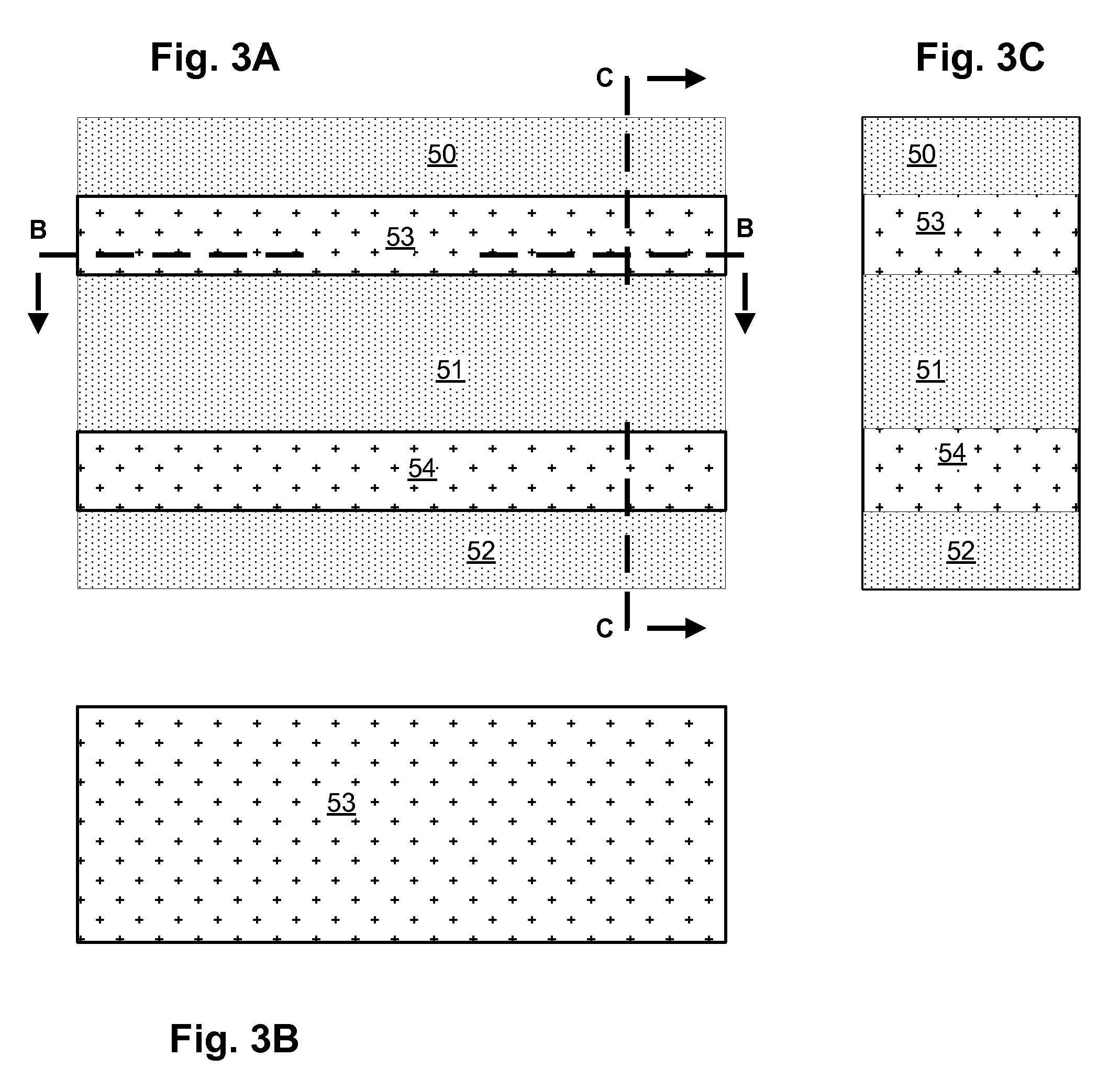

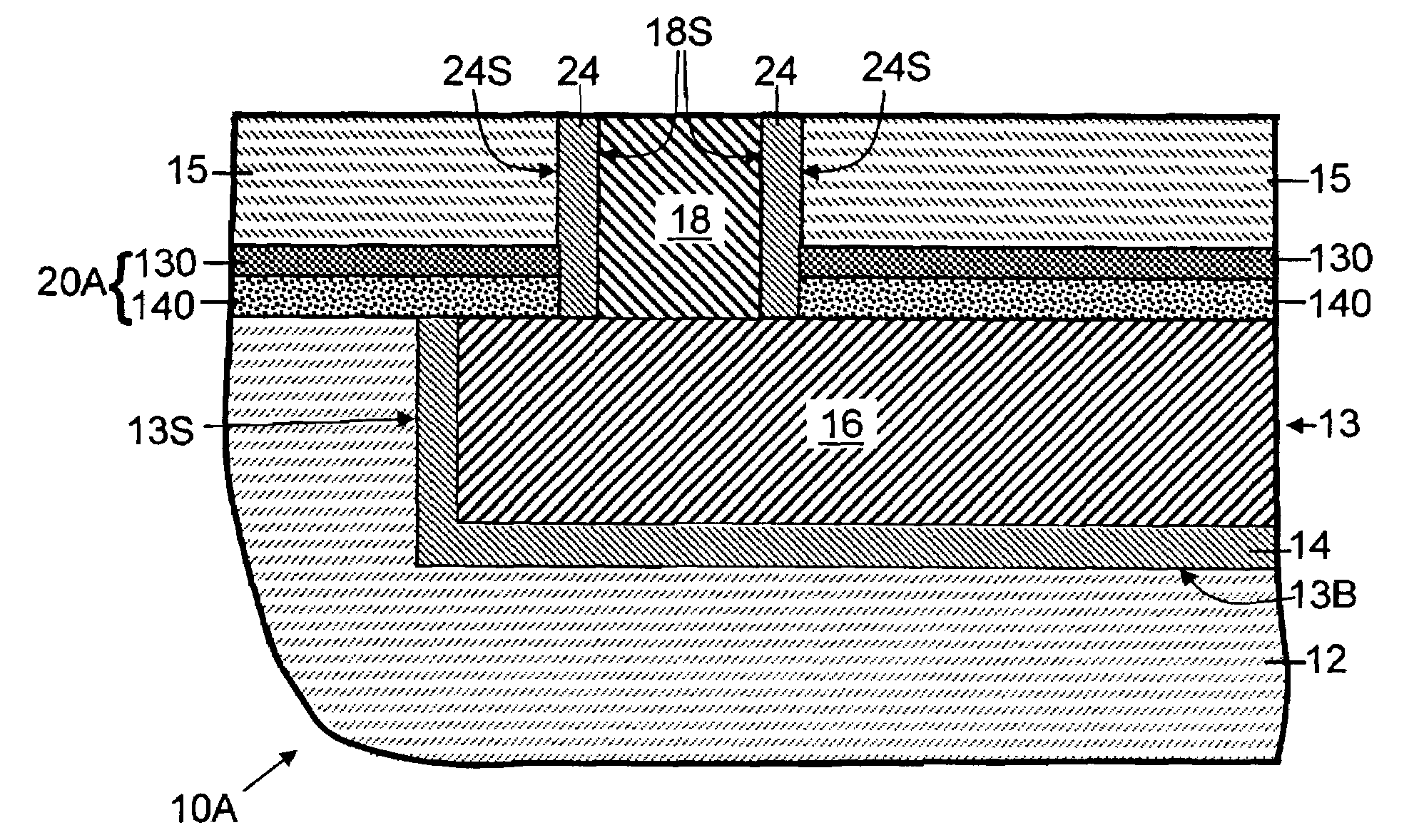

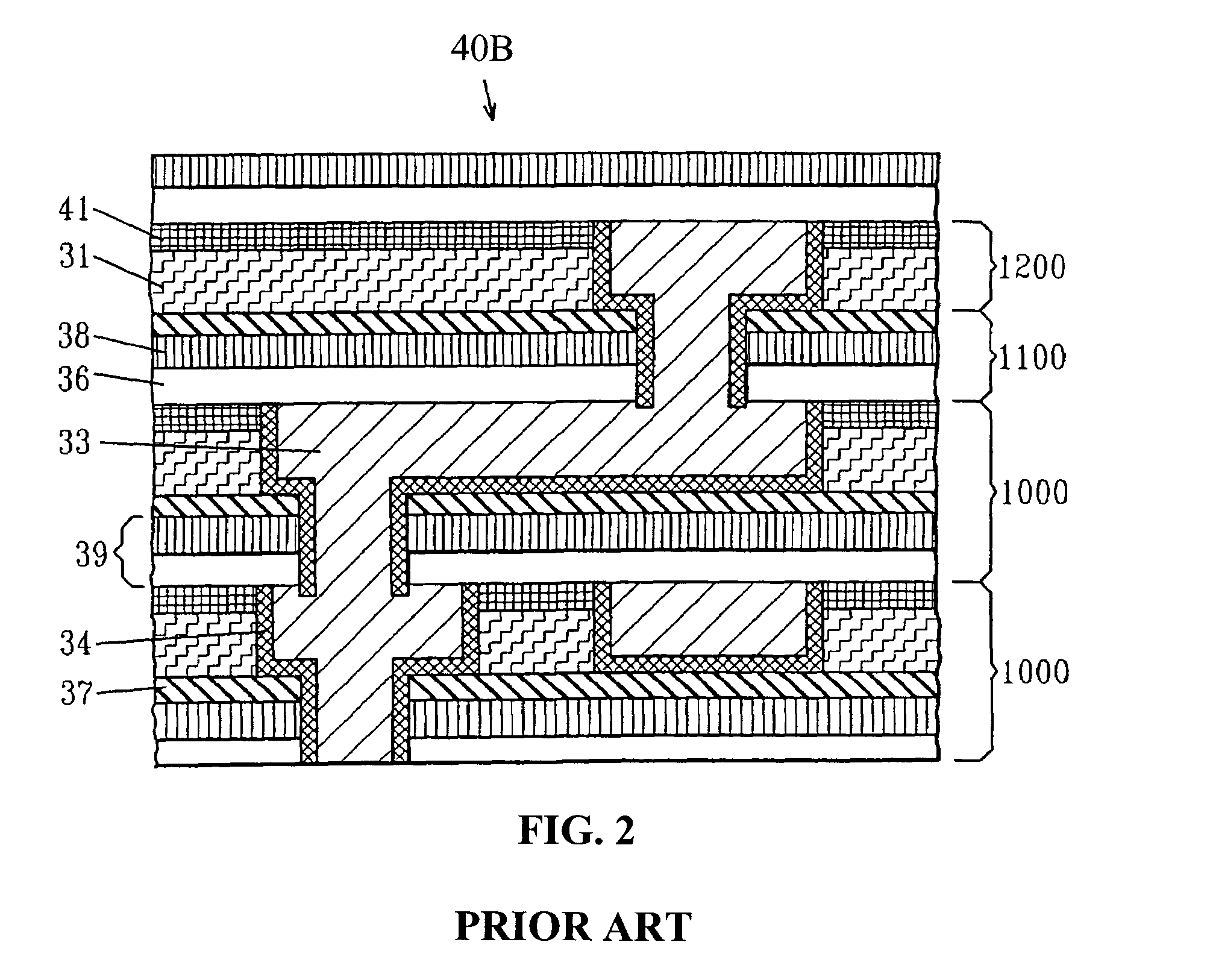

Integrated circuit memory with single crystal silicon on silicide driver and manufacturing method

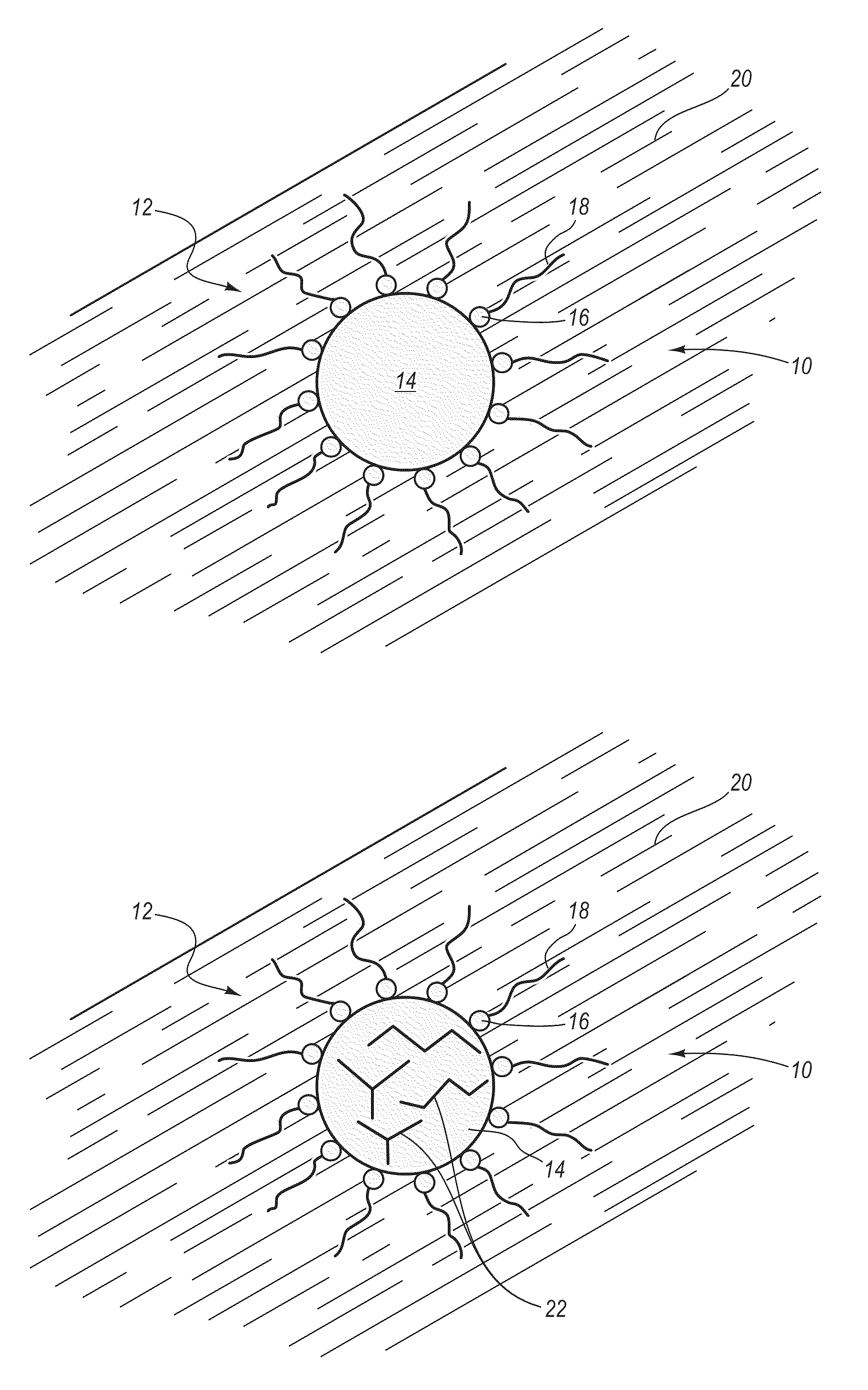

ActiveUS20100171086A1Excellent ElectricalExcellent structural characteristicSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitMonocrystalline silicon

A memory device includes a diode driver and a data storage element, such as an element comprising phase change memory material, and in which the diode driver comprises a silicide element on a silicon substrate with a single crystal silicon node on the silicide element. The silicide element separates the single crystal silicon node from the underlying silicon substrate, preventing the flow of carriers from the single crystal silicon node into the substrate, and is capable of acting as a conductive element for interconnecting devices on the device. The single crystal silicon node acts as one terminal of a diode, and a second semiconductor node is formed on top of it, acting as the other terminal of the diode.

Owner:MACRONIX INT CO LTD

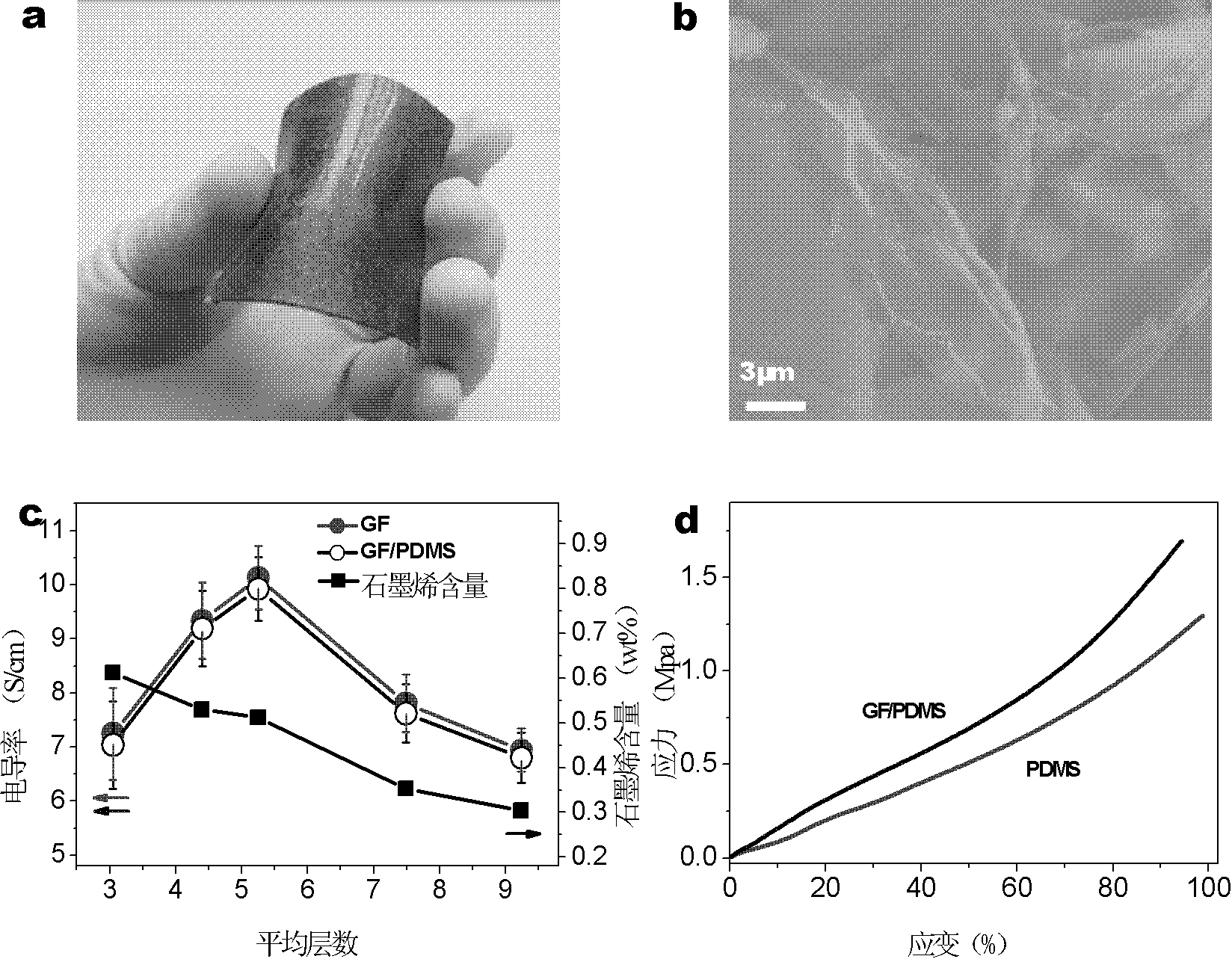

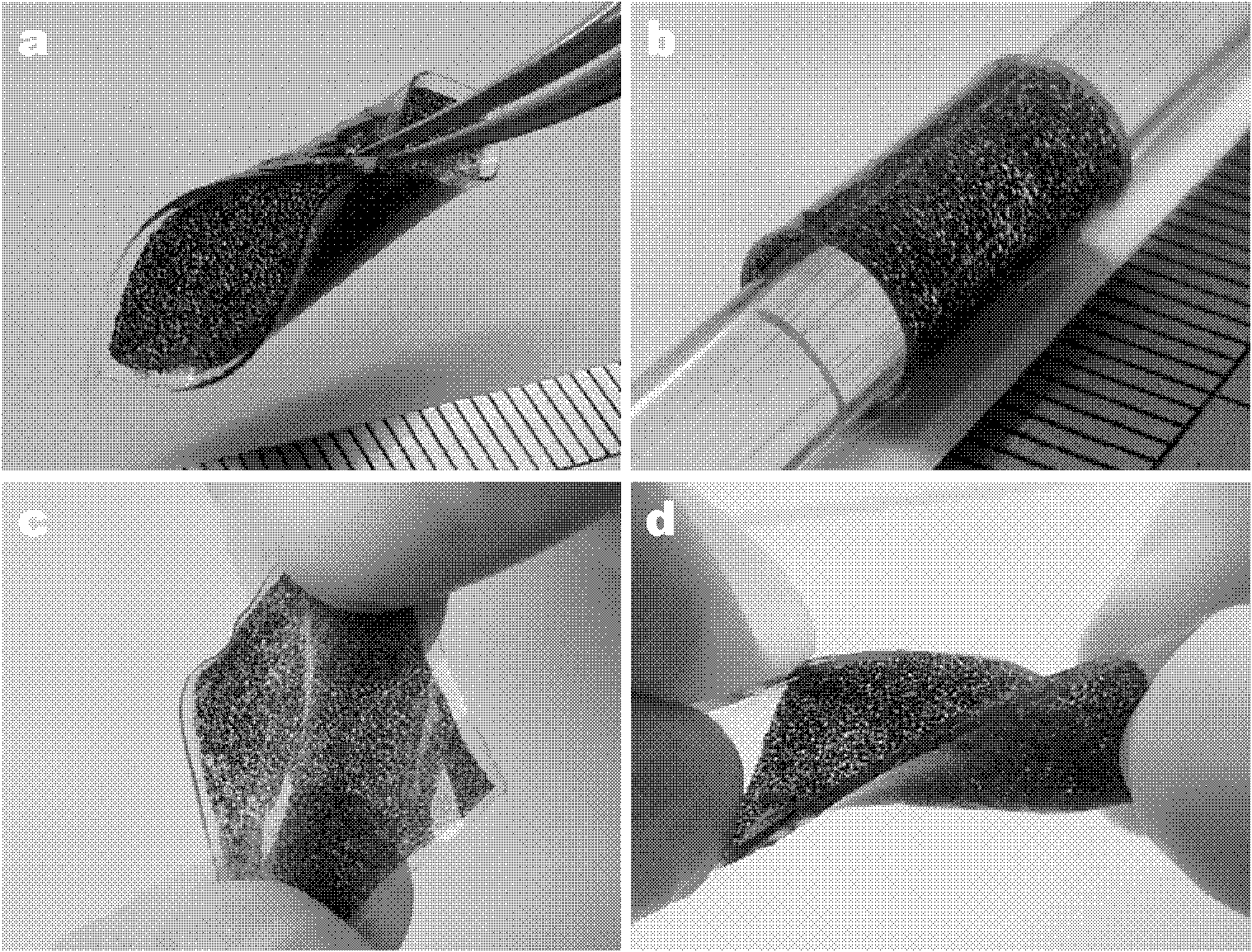

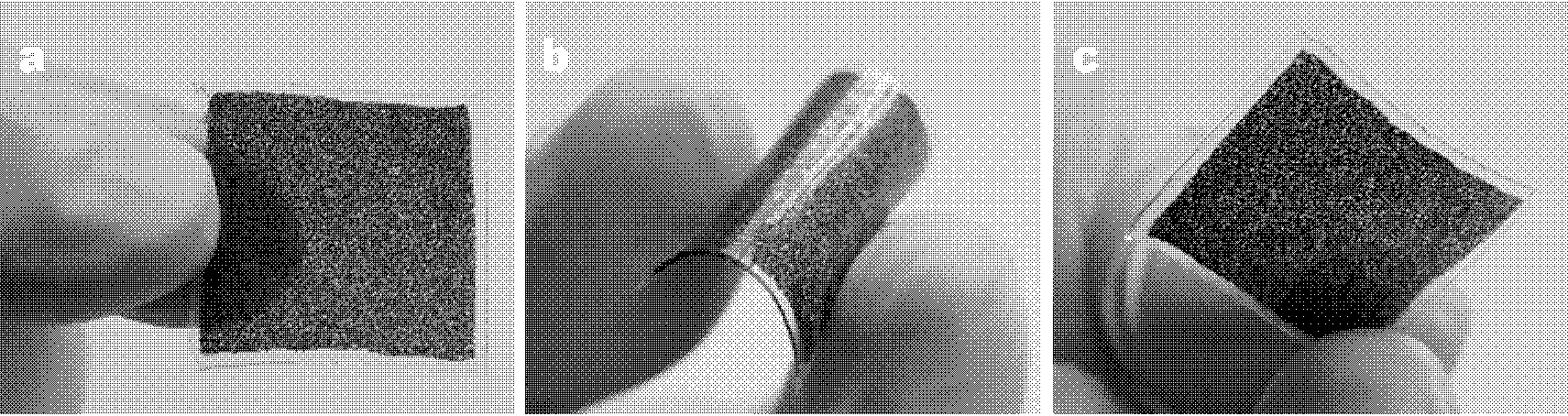

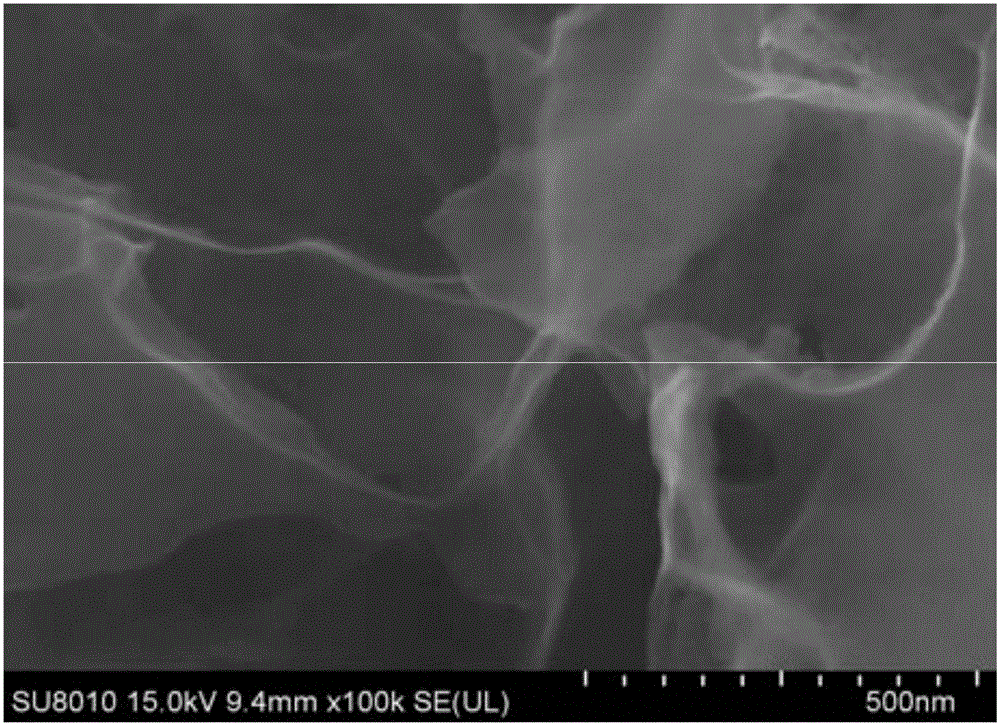

Graphene foam/polymer high-conductivity composite material preparation method and application thereof

ActiveCN102732037AImprove conductivityEasy to manufactureChemical vapor deposition coatingMaterials preparationGraphite

The invention relates to the graphene composite material field, and particularly to a graphene foam / polymer high-conductivity composite material, a preparation method and applications thereof. Steps of the method comprises as follows: providing a fully communicated three-dimension grapheme foam network and a precursor solution of a high-molecular polymer; mixing the graphene foam with the precursor solution of the high-molecular polymer to form a graphene foam / high-molecule polymer precursor mixture; and solidifying the precursor of the high-molecular polymer in the mixture to form a high-conductivity graphene foam composite material. The invention adopts the three-dimension graphene foam to form a fully- communicated graphite rapid transmission network by a seamless connection, which enables the graphene foam composite material to possess great conductivity and mechanical property and can be widely applied to the conductive composite materials and elasticity conductor field.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing electrodes of super capacitor based on nickel foam and products thereof

InactiveCN103258656AHigh specific capacitanceIncrease energy densityHybrid capacitor electrolytesHybrid capacitor electrodesCapacitanceNon symmetric

The invention discloses a method for preparing electrodes of a dissymmetric super capacitor based on nickel foam. The method comprises the steps: washing the nickel foam, soaking the nickel foam into a graphene oxide aqueous solution to obtain nickel foam in which graphene oxide deposits, serving the nickel foam in which the graphene oxide deposits as precursor materials, and respectively adopting a three-electrode method for preparaing a positive electrode and a negative electrode of the dissymmetric super capacitor, wherein the positive electrode is composed of composite materials of graphene, a carbon nanometer tube and the nickel foam, and the negative electrode is composed of composite materials of graphene, manganese dioxide and the nickel foam. The invention further discloses some other methods for preparing the electrodes of the super capacitor based on the similar principle, and products which correspond to the methods. By means of the methods and the products, respective high-ratio capacitance characteristics of the composite materials are fully played, and energy density of the super capacitor is improved. In addition, usage of various combined reagents can be avoided, and accordingly large-batch industrial production is conducted in a mode of convenient control, low cost and low energy consumption.

Owner:HUAZHONG UNIV OF SCI & TECH

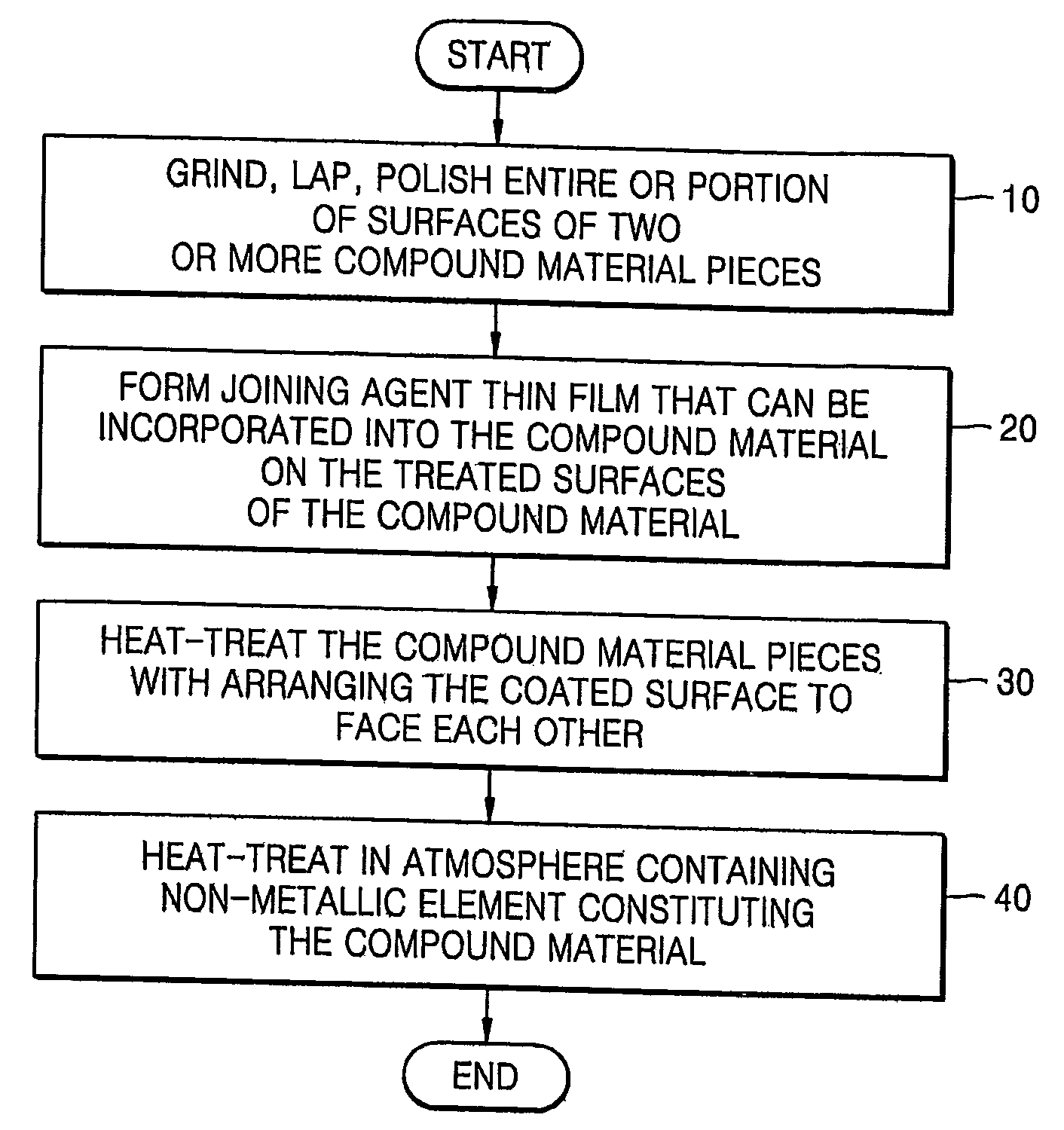

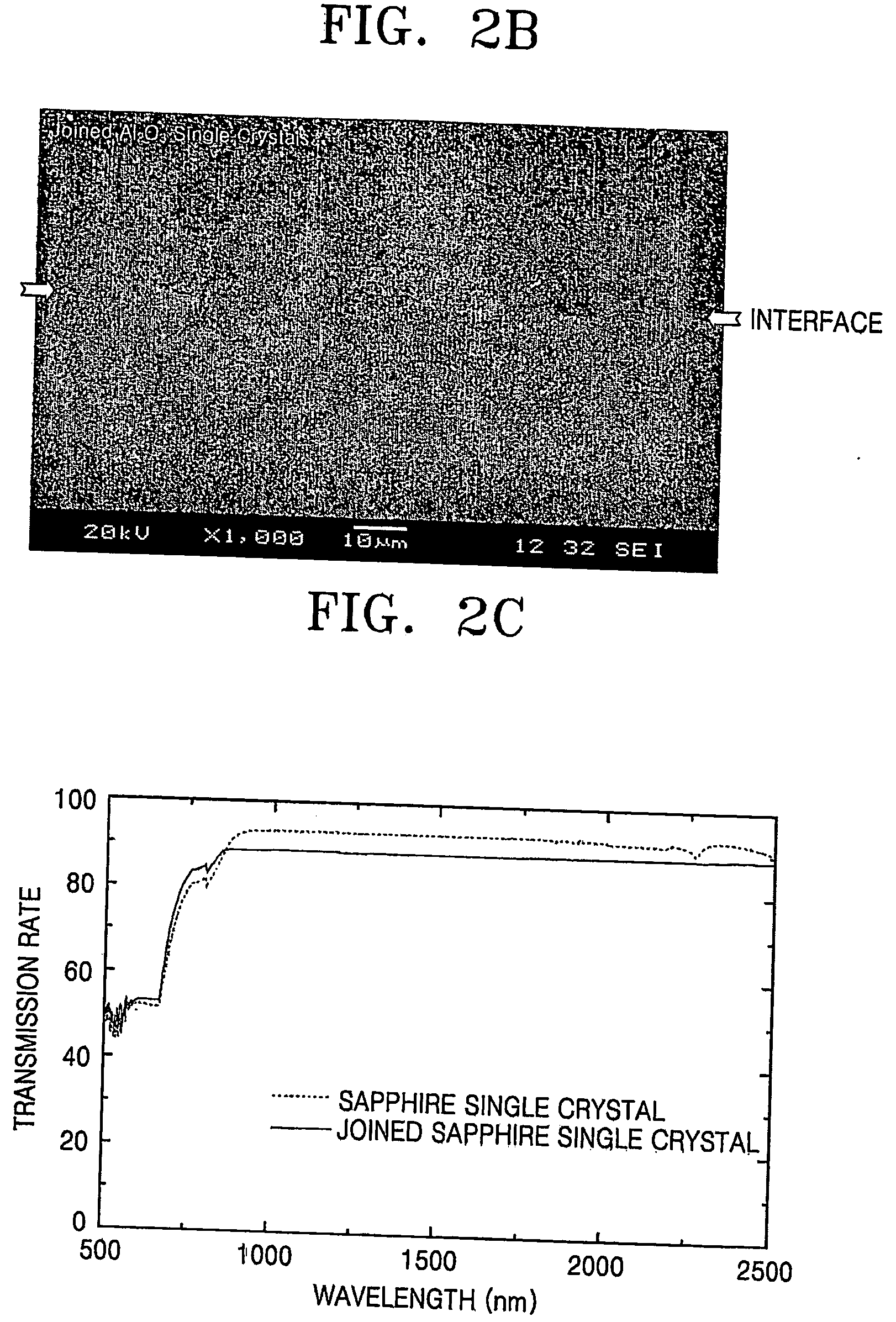

Method of joining ceramics: reaction diffusion-bonding

InactiveUS20060162849A1Suitable characteristicMaintain structural integrityAfter-treatment detailsLamination ancillary operationsBond interfaceSolid solution

Provided is a method of joining compound materials such as ceramics. The method is a combination of diffusion bonding and reaction bonding, which is called reaction diffusion bonding (RDB). The method includes: grinding, lapping, or polishing entire or portions of surfaces to be joined of two or more pieces of a compound material; forming a thin film of a joining agent on one or more of the ground, lapped, or polished surfaces by one of inserting, spreading, depositing, plating, and coating, the joining agent being able to transform into the compound material by being incorporated into the compound material or by forming a solid solution with the compound material upon heat treating; and forming a directly bonded interface without a second phase by heat treating the pieces of the compound material with the to-be-joined surfaces on which the joining agent film is formed arranged to face each other, wherein the joining agent thin film is composed of a material selected from the group consisting of metals, metal organics, and metal compounds.

Owner:CERAWEL

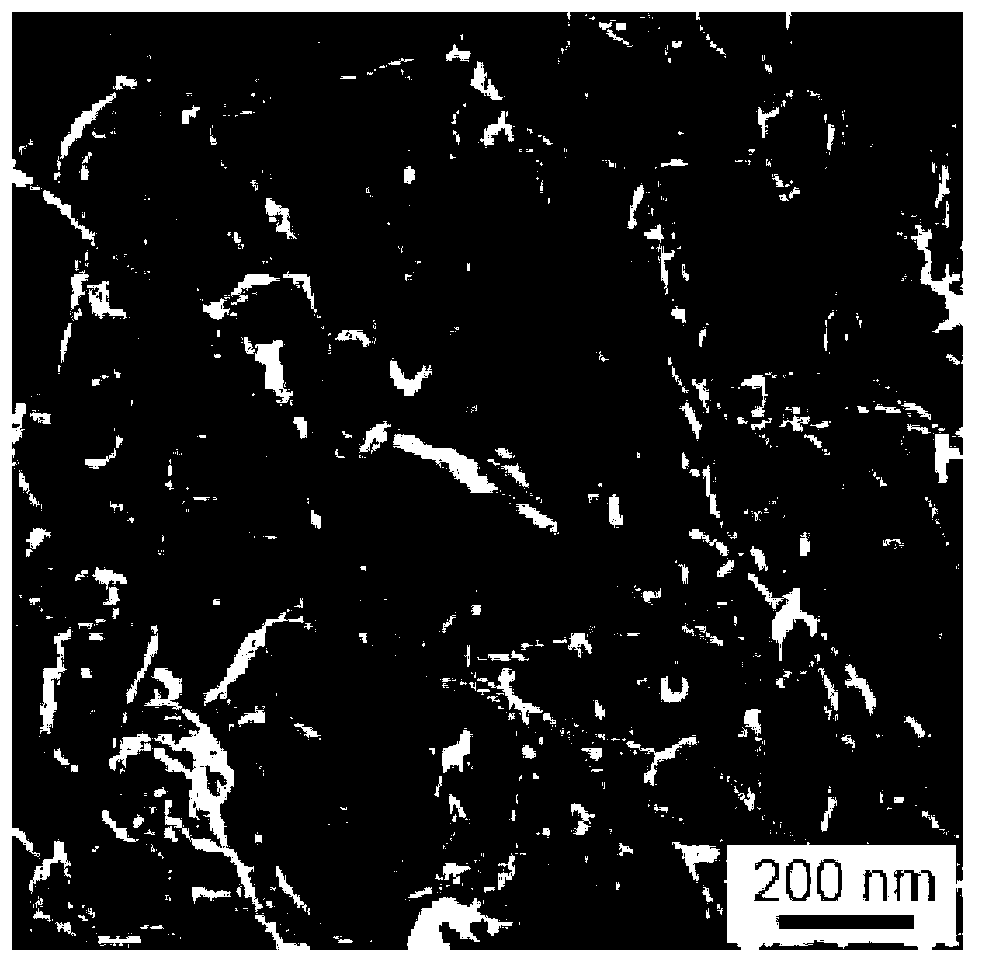

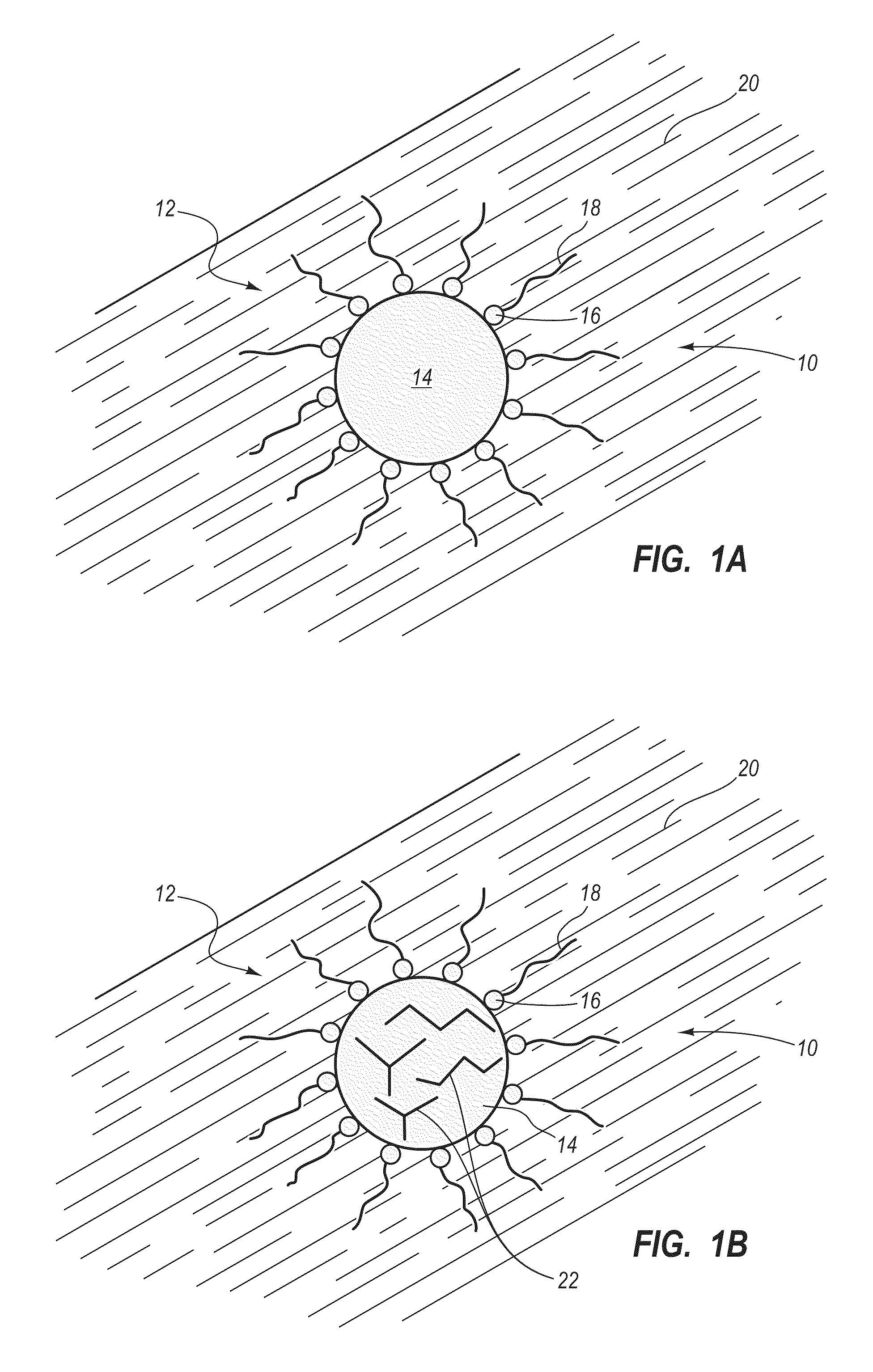

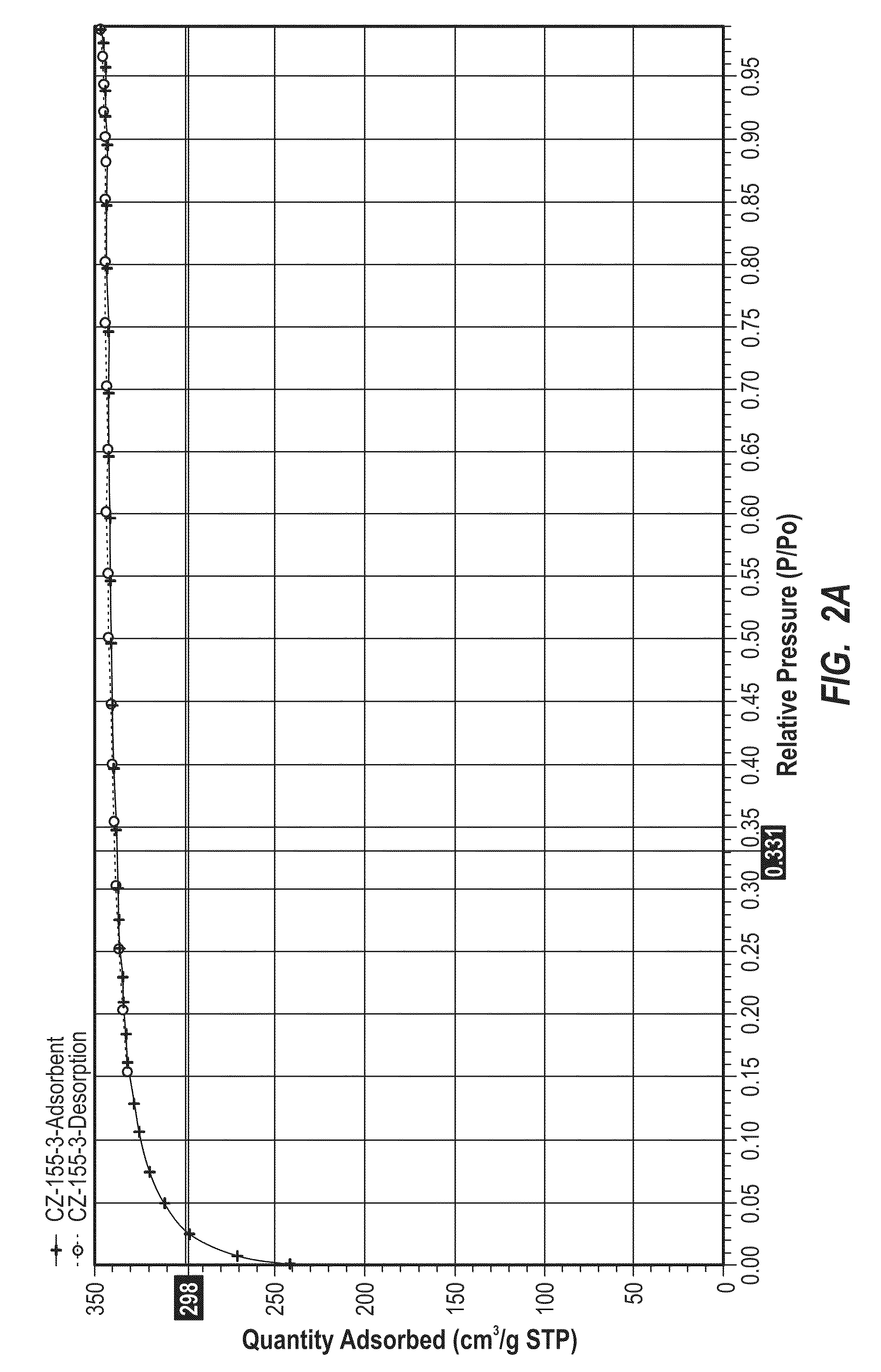

Preparation of a carbon nanomaterial using a reverse microemulsion

InactiveUS20100092370A1Maintain good propertiesExcellent ElectricalMaterial nanotechnologyCarbon preparation/purificationSolventAmorphous carbon

Powdered, amorphous carbon nanomaterials are formed from a carbon precursor in reverse microemulsion that includes organic solvent, surfactant and water. Methods for manufacturing amorphous, powdered carbon nanomaterials generally include steps of (1) forming a reverse microemulsion including at least one non-polar solvent, at least one surfactant, and at least one polar solvent, (2) adding at least one carbon precursor substance to the reverse microemulsion, (3) reacting the at least one carbon precursor substance so as to form an intermediate carbon nanomaterial, (4) separating the intermediate amorphous carbon nanomaterial from the reverse microemulsion, and (5) heating the intermediate amorphous carbon nanomaterial for a period of time so as to yield an amorphous, powdered carbon nanomaterial. Amorphous, powdered carbon nanomaterials manufactured according to the present disclosure typically have a surface area of at least 500 m2 / g, a graphitic content of at least 25%, and a conductivity of at least 150 S / m.

Owner:HEADWATERS TECH INNOVATION GRP

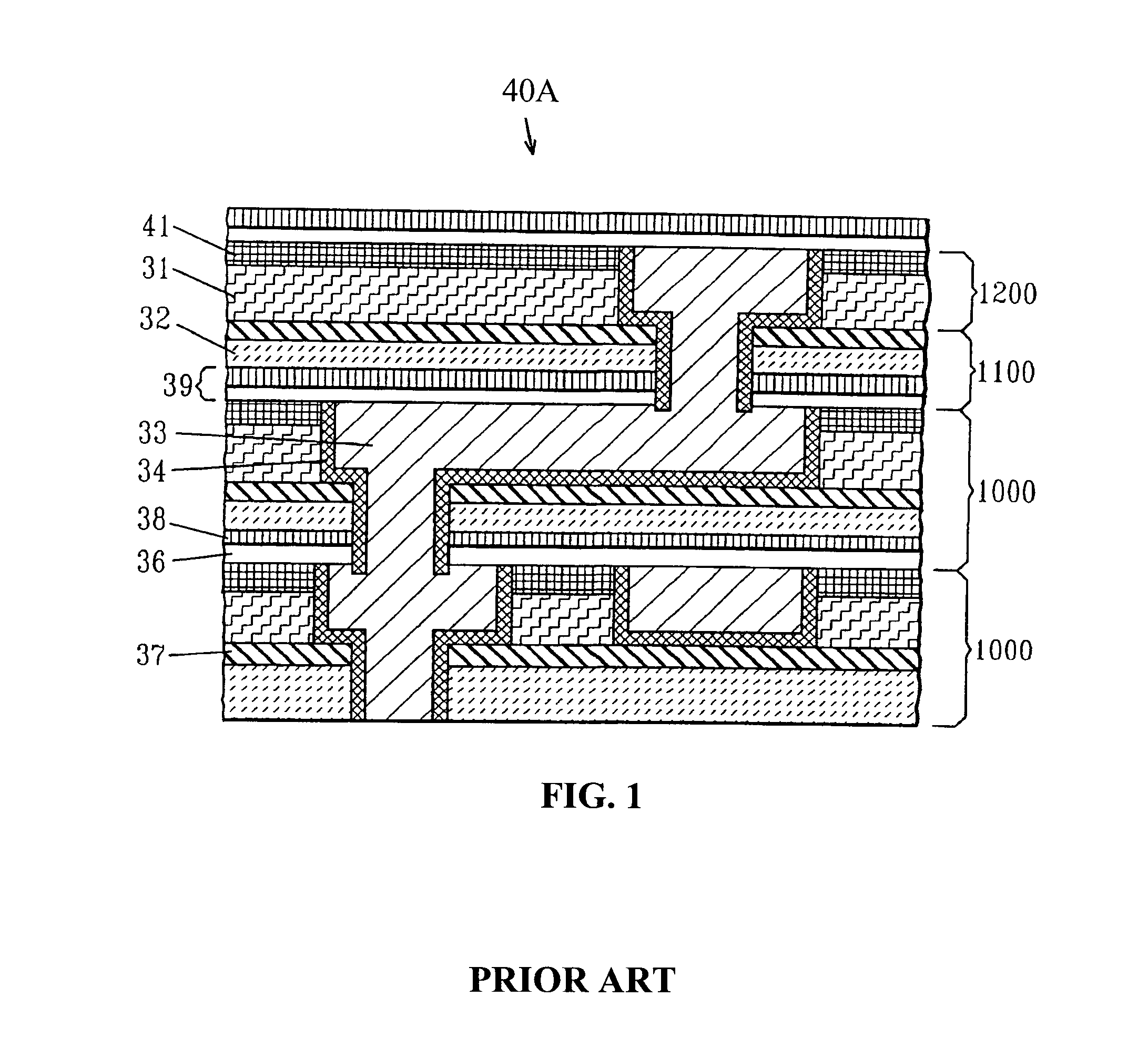

Embedded NANO UV blocking barrier for improved reliability of copper/ultra low k interlevel dielectric electronic devices

InactiveUS20080122103A1Prevention of UV/e-beam modificationChange is minimalSemiconductor/solid-state device detailsSolid-state devicesDielectricCopper conductor

An interconnect in provided which comprises a copper conductor having both a top surface and a lower surface, with caps formed on the top surface of the metallic conductor. The cap is formed of dual laminations or multiple laminations of films with the laminated films including an Ultra-Violet (UV) blocking film and a diffusion barrier film. The diffusion barrier film and the UV blocking film may be separated by an intermediate film.

Owner:GLOBALFOUNDRIES INC

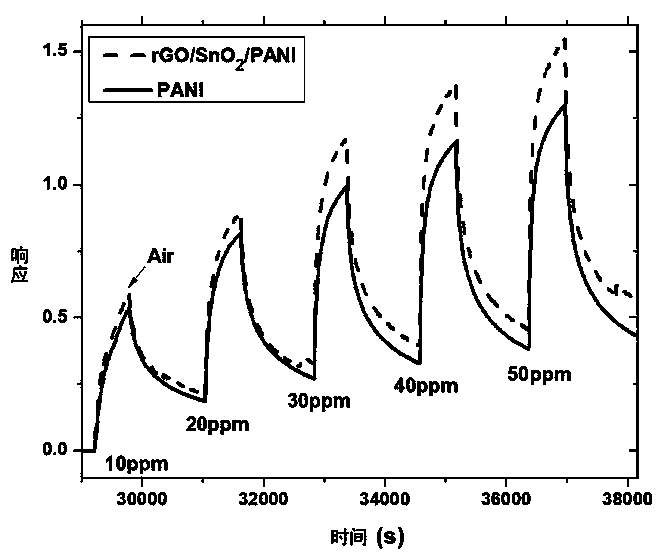

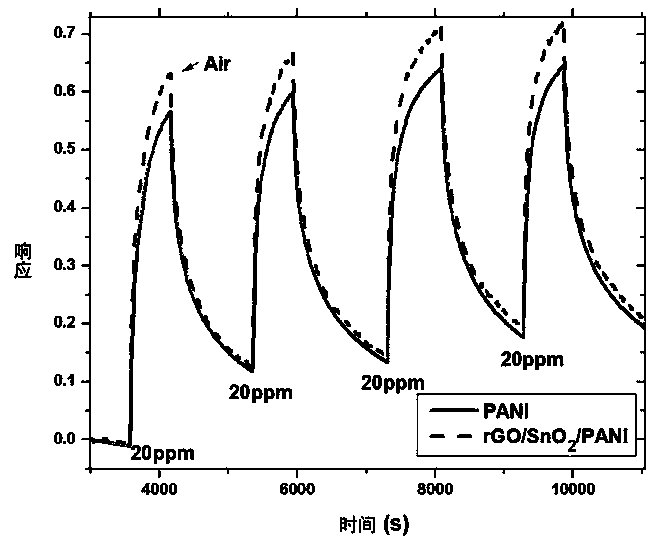

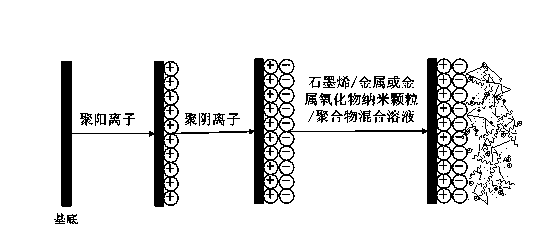

Graphene-based ternary composite film gas sensor and preparation method thereof

ActiveCN103926278ALow resistivityGood electrical propertiesMaterial electrochemical variablesMetal oxide nanoparticlesComposite film

The invention discloses a graphene-based ternary composite film gas sensor and a preparation method thereof. The graphene-based ternary composite film gas sensor consists of a ternary composite film and a substrate, wherein the ternary composite film is formed by compounding graphene, metal or metal oxide nanoparticles and conducting polymers. The high specific surface area and excellent electric and physicochemical characteristics of the graphene and the nanoparticles and the specific gas-sensitive response characteristic of the conducting polymers are fully utilized, a gain complementary mechanism is formed between different materials due to ternary compounding, and the gas-sensitive characteristic and stability of the system are enhanced. Meanwhile, the preparation method is combined with a self-assembling process with high ordering property and can be used for preparing the high-sensitivity room temperature detection gas sensor.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

High-thermal conductivity lubricating oil and preparation method thereof

ActiveCN102911762AImprove anti-friction and anti-wear effectImprove thermal conductivityAdditivesGrapheneBase oil

The invention relates to high-thermal conductivity lubricating oil and a preparation method thereof. The lubricating oil contains base oil and fluorinated graphene nanosheets, wherein the weight percent of content of the fluorinated graphene nanosheets is 0.01 to 10.0 %; and the preparation method comprises the steps as follows: firstly, preparing the fluorinated graphene nanosheets; and secondly, preparing the lubricating oil containing the fluorinated graphene nanosheets. The lubricating oil provided by the invention has the advantages of excellent antifriction effect, extremely high heat conduction capability and excellent stability and dispersibility.

Owner:青岛康普顿石油化工有限公司

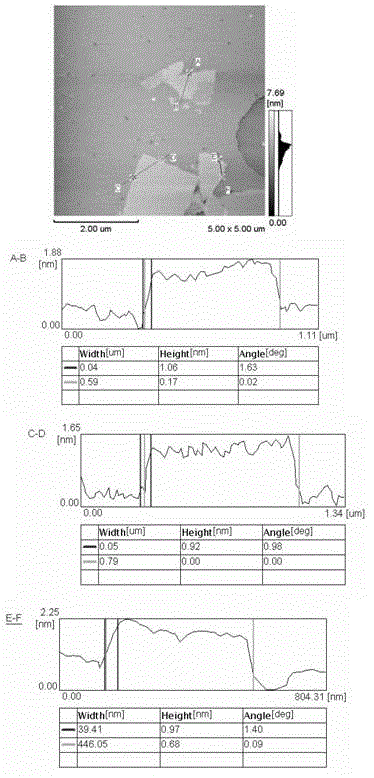

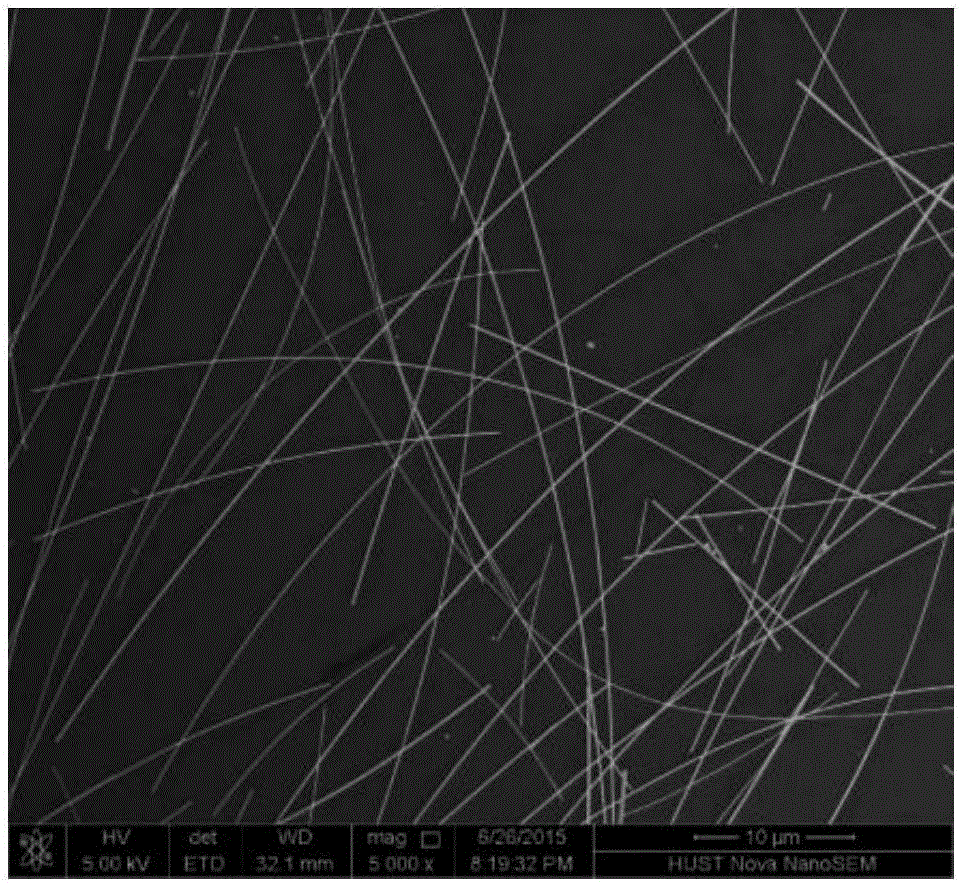

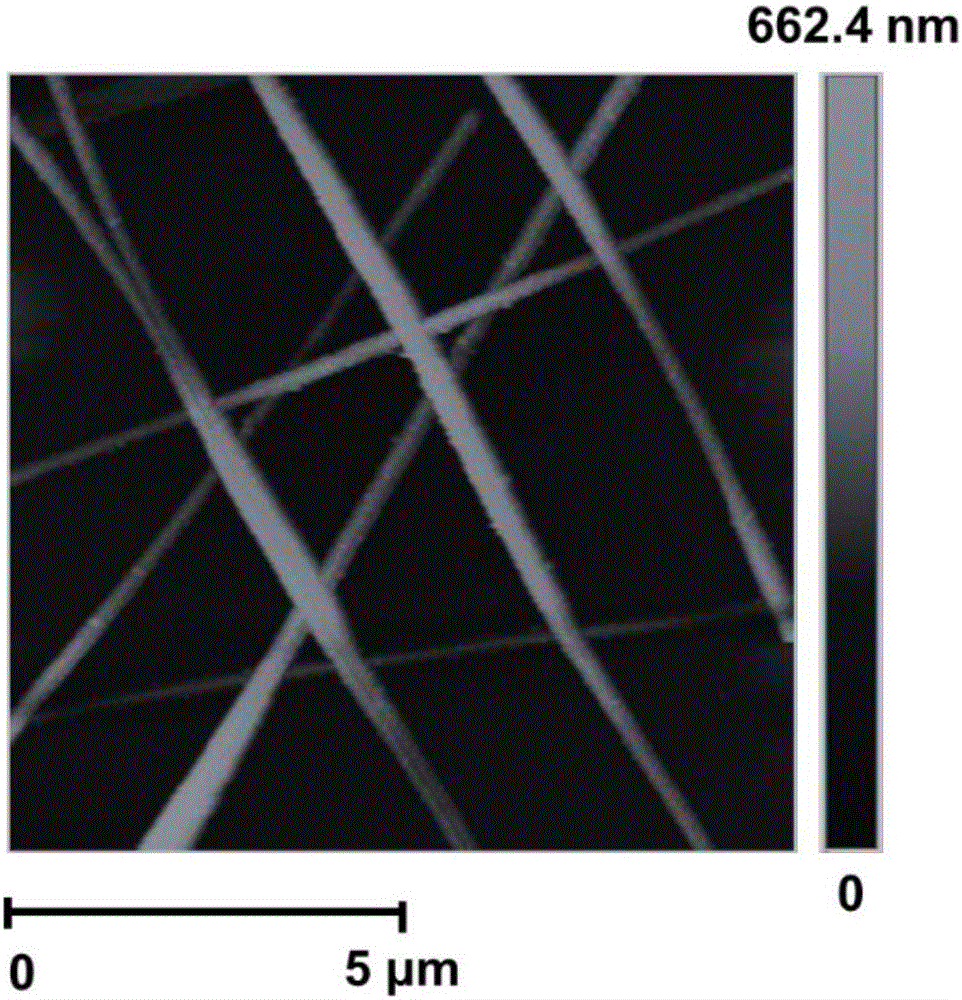

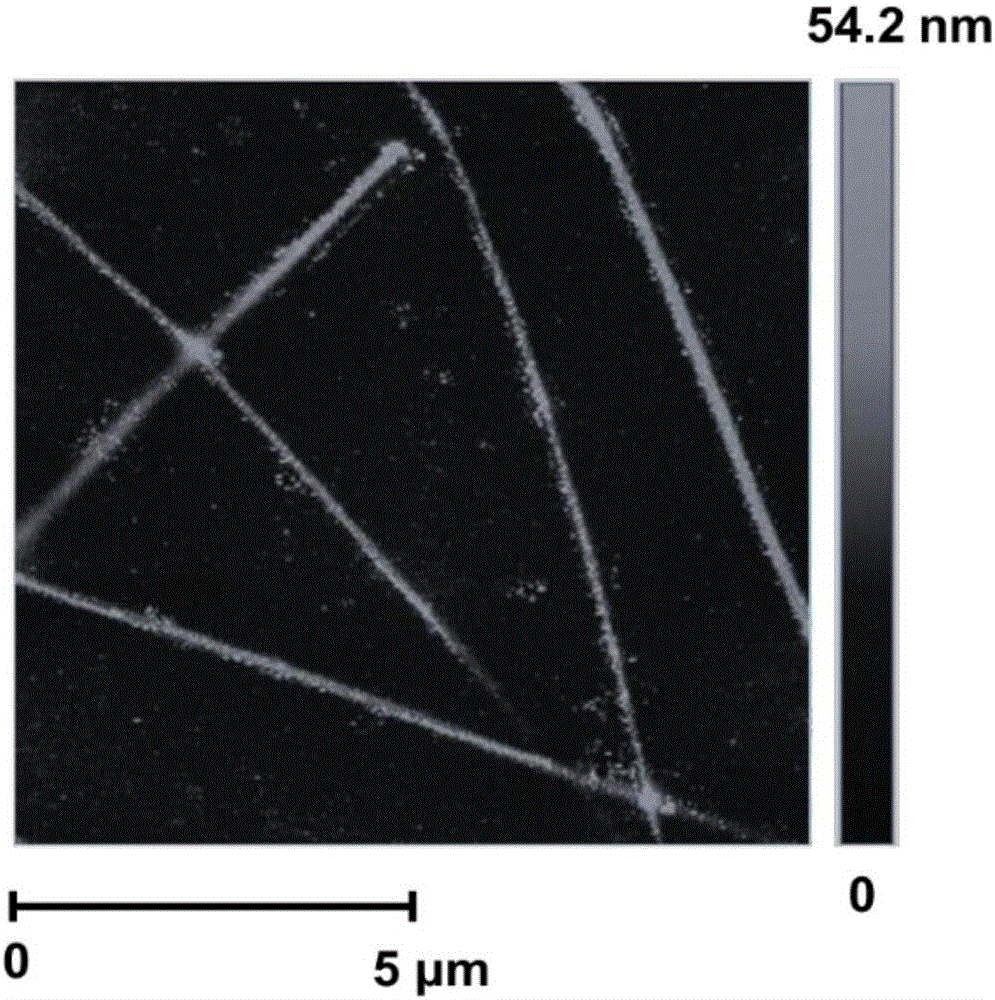

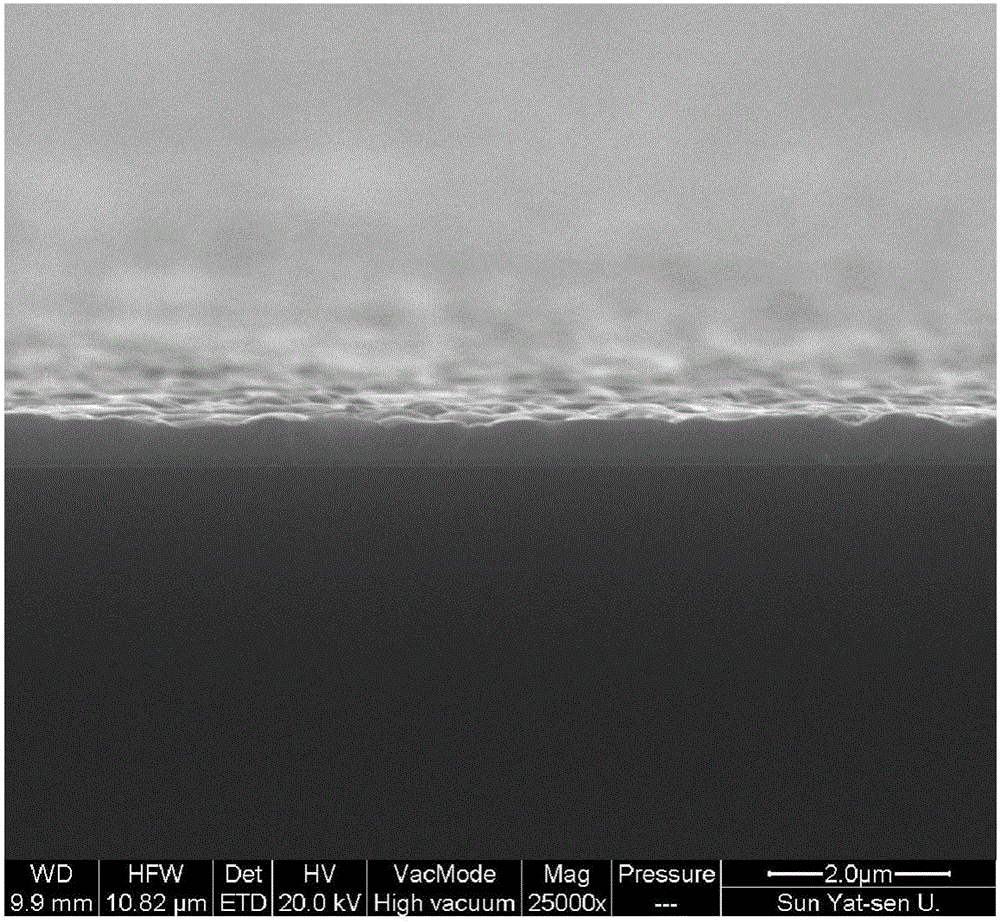

Low-roughness and low-square-resistance flexible transparent conductive composite thin film and preparation method therefor

ActiveCN106782769AReduce roughnessImprove conductivityConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersPolymer thin filmsSolar battery

The invention belongs to the technical field of photo-electronics, and more specifically relates to a low-roughness and low-square-resistance flexible transparent conductive composite thin film, wherein the thin film adopts a three-layer composite structure; the lowest bottom layer is provided with a transparent polymer thin film; the middle layer is provided with a conductive network formed by metal nanowires; the topmost layer is a provided with a transparent conductive layer which uniformly covers the transparent polymer thin film and the conductive network; the flexible transparent conductive composite thin film is less than 20-nanometer in average roughness, less than 30-ohm / square meter in square resistance, and greater than 80% of light transmittance within a visible light range; and the transparent conductive thin film can bear bending with radius of curvature of 2mm. The invention also discloses a preparation method for the flexible transparent conductive composite thin film. The flexible transparent conductive composite thin film provided by the invention has low roughness, high conductivity, high light transmittance, simple preparation method and low cost, and is particularly suitable for flexible display and illumination, a flexible solar battery and flexible touch equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

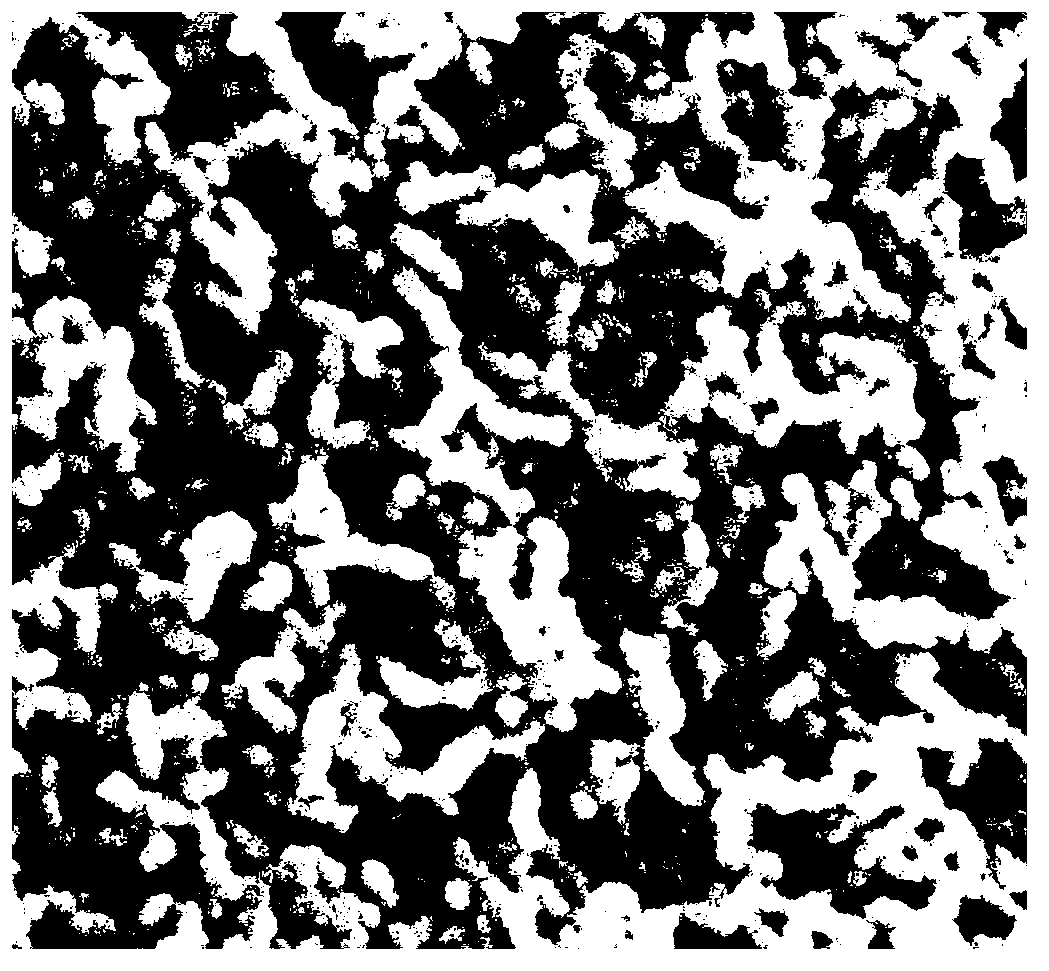

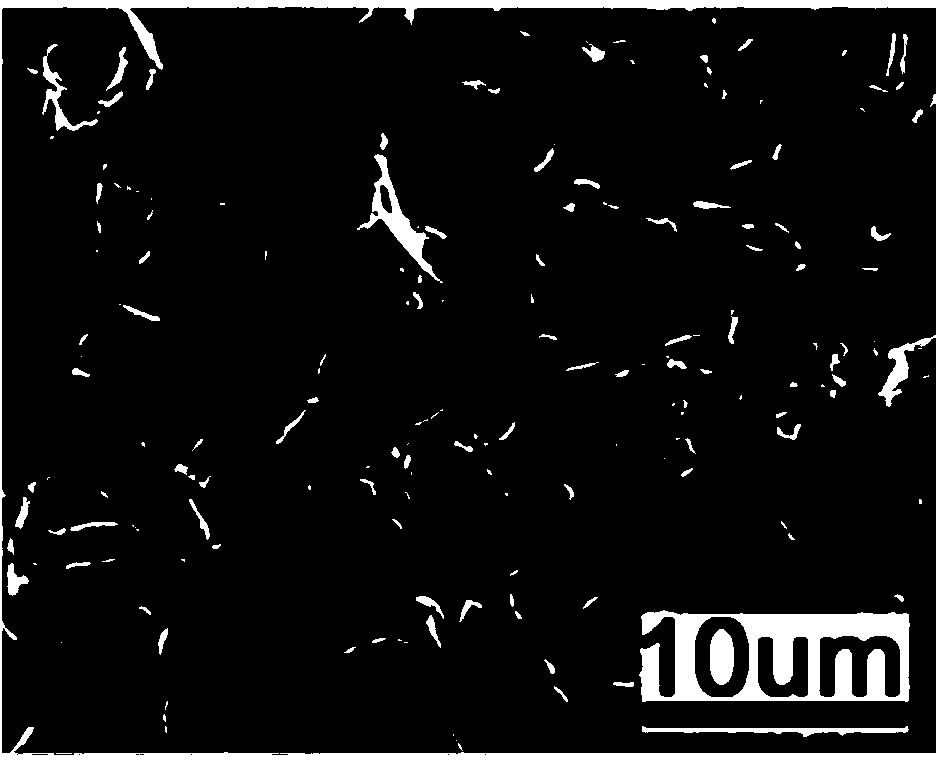

High-quality graphene dispersion method and film preparation method

ActiveCN103449420AHigh dispersible concentrationNo dispersant residueGrapheneHigh concentrationProtonation

The invention relates to the field of graphene, particularly a high-quality graphene dispersion method and a method for preparing a film from a corresponding graphene dispersion solution or slurry. Graphene powder or aggregation-state slurry is added into a micromolecule amine compound solution to carry out dispersion treatment, so that the three amine micromolecule compounds are utilized to implement dispersion of the graphene; and in the dispersion solution, the molecules of the compounds are combined with the graphene under the pai-pai interaction, the amino group protonation is utilized to electrically charge the graphene, and the electrostatic repulsion action is utilized to prevent aggregation, thereby implementing the stable dispersion of the graphene. The dispersion solution or slurry can be subjected to spray coating, roller coating, scratch coating or any other conventional coating preparation method to obtain a graphene film on the substrate surface. The method can implement high-concentration efficient dispersion on high-quality graphene with the carbon / oxygen atom ratio of greater than 20 in multiple solvents; and after the film is formed and dried, no solvent or dispersant residue exists.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

In situ polymerization preparing method for carbon nano tube and polytene composite material

InactiveCN1640923AExcellent ElectricalImprove mechanical propertiesIn situ polymerizationCarbon nanotube

The present invention relates to the preparation process of one kind of composite carbon nanotube / polyethylene material. Single or multiple wall carbon nanotube is treated with oxidant to obtain functional carbon nanotube with hydroxyl, carbonyl and carboxyl groups on the surface; and further reacted with alkyl metallizing compound in inert atmosphere to connect metal organic matter component capable of catalyzing ethylene polymerization to obtain carbon nanotube supporting olefin polymerization catalyst. In the presence of alkyl metallizing compound as catalyst assistant, the prepared carbon nanotube supporting olefin polymerization catalyst catalyzes ethylene polymerization to obtain the composite carbon nanotube / polyethylene material. The composite material has two components homogeneously dispersed, electric and mechanical performance higher than other polyethylene material.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

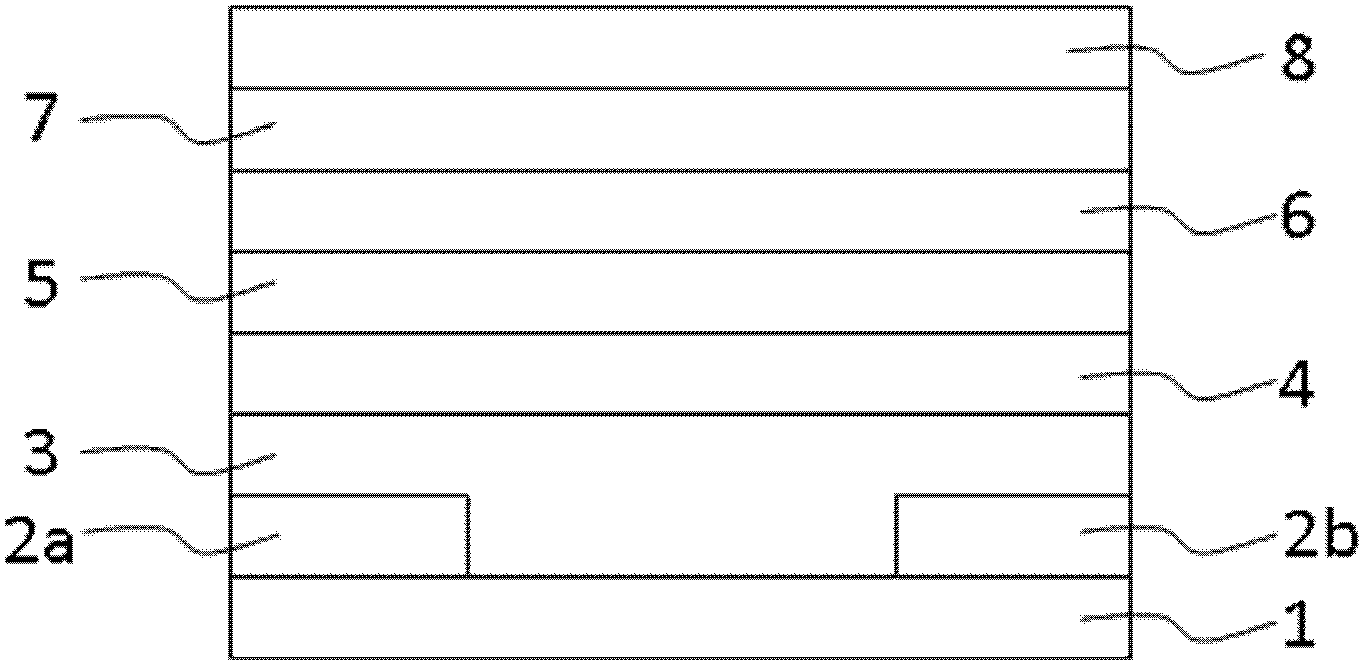

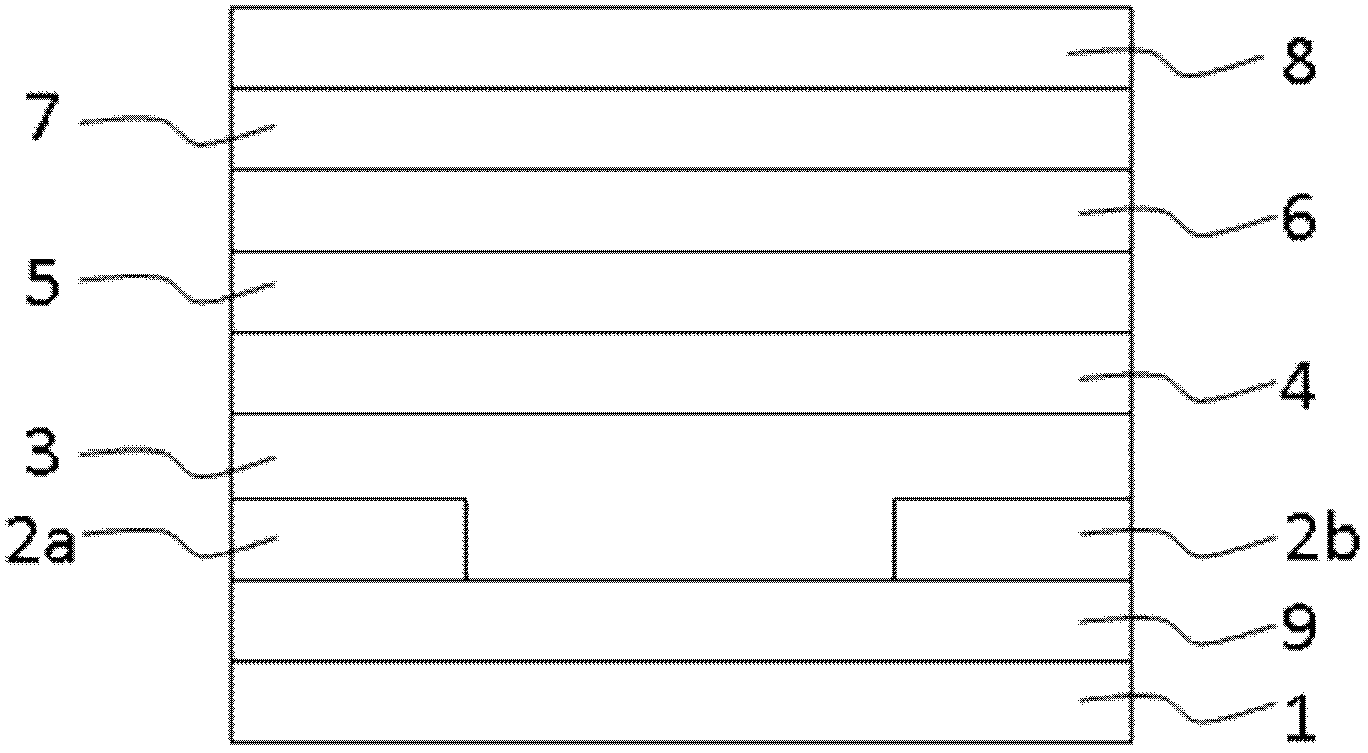

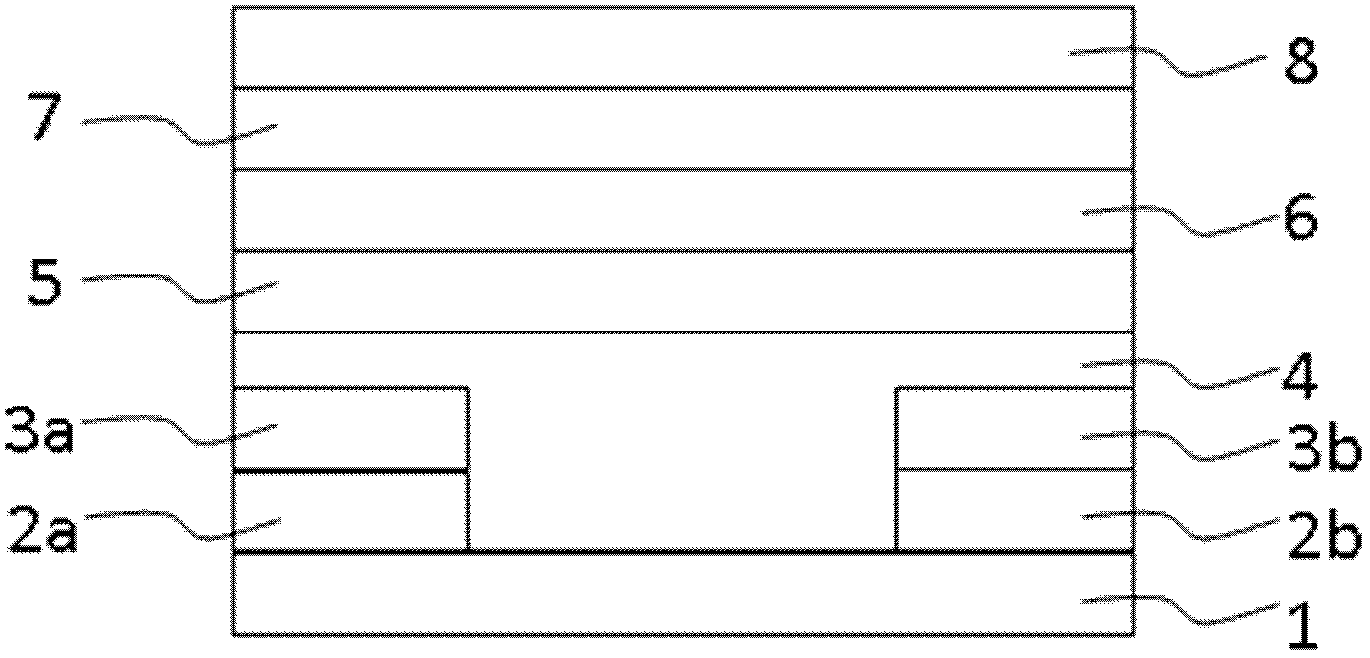

Flexible organic light emitting transistor display device

ActiveCN102709310AExcellent ElectricalImprove mechanical propertiesSolid-state devicesSemiconductor/solid-state device manufacturingCharge injectionActive matrix

The invention relates to a flexible organic light emitting transistor display device, which comprises a substrate (1), a source electrode layer (2a), a drain electrode layer (2b), a charge injection layer (3), organic semiconductor layers (4, 5 and 6), a gate insulating layer (7) and a gate electrode layer (8), wherein the source and drain electrode layers (2a and 2b) are made of graphene. The charge injection layer is added, a charge injection material is selected, the drain and source electrode layers are made of the graphene, so that the flexible active matrix organic light emitting transistor display device is transparent and high in aperture opening ratio and brightness, low in operating voltage and long in service life.

Owner:常州第六元素半导体有限公司

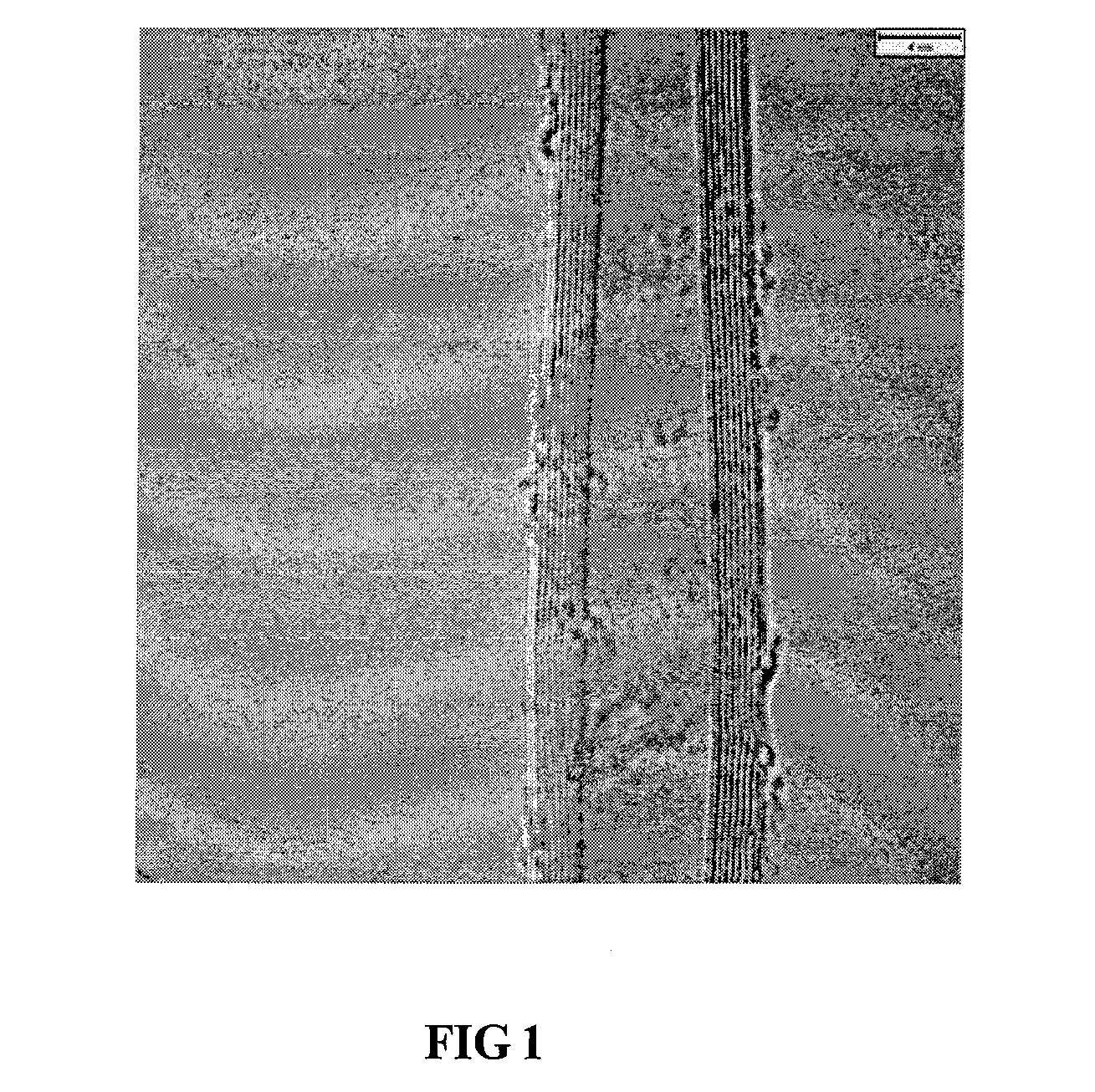

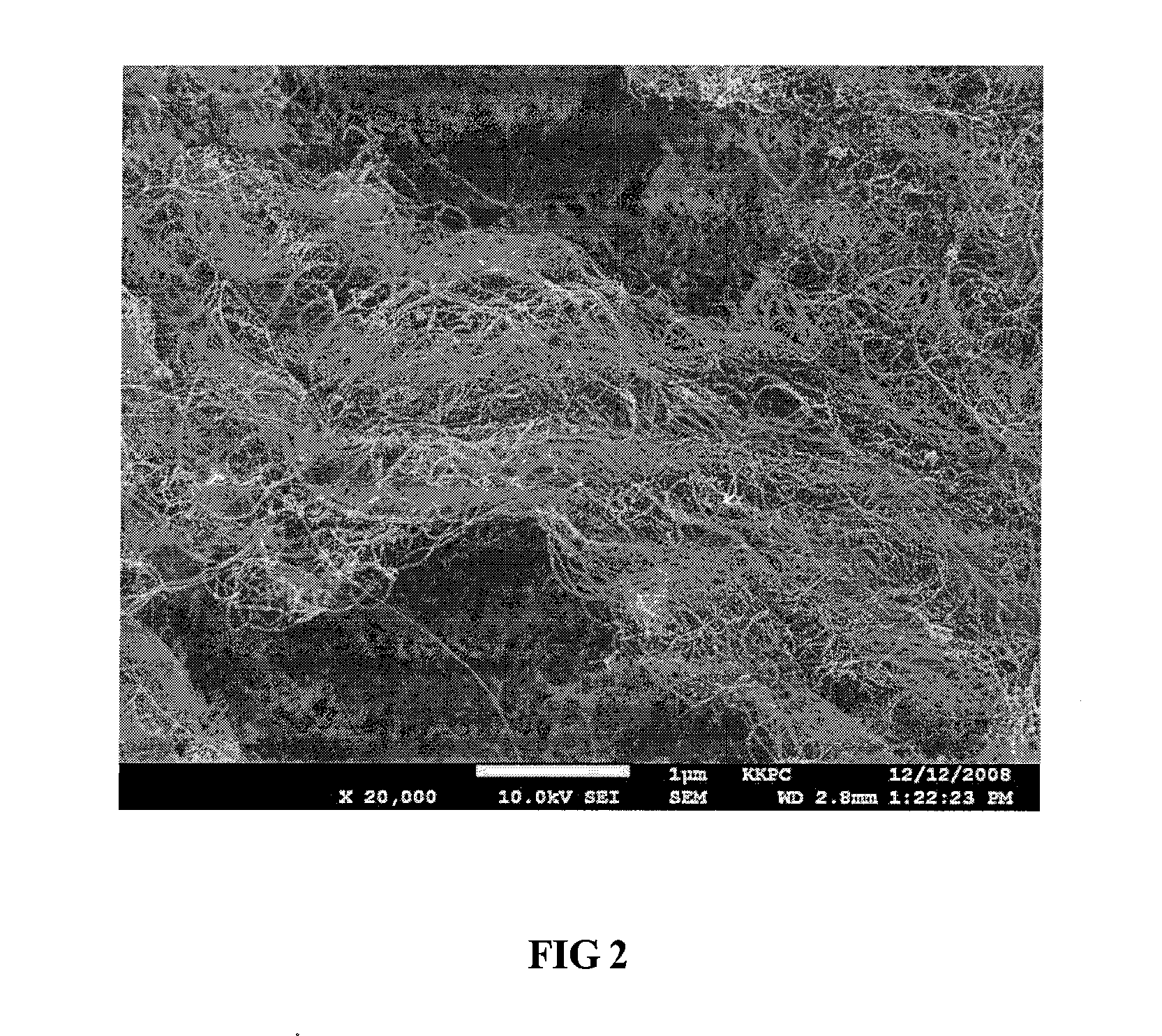

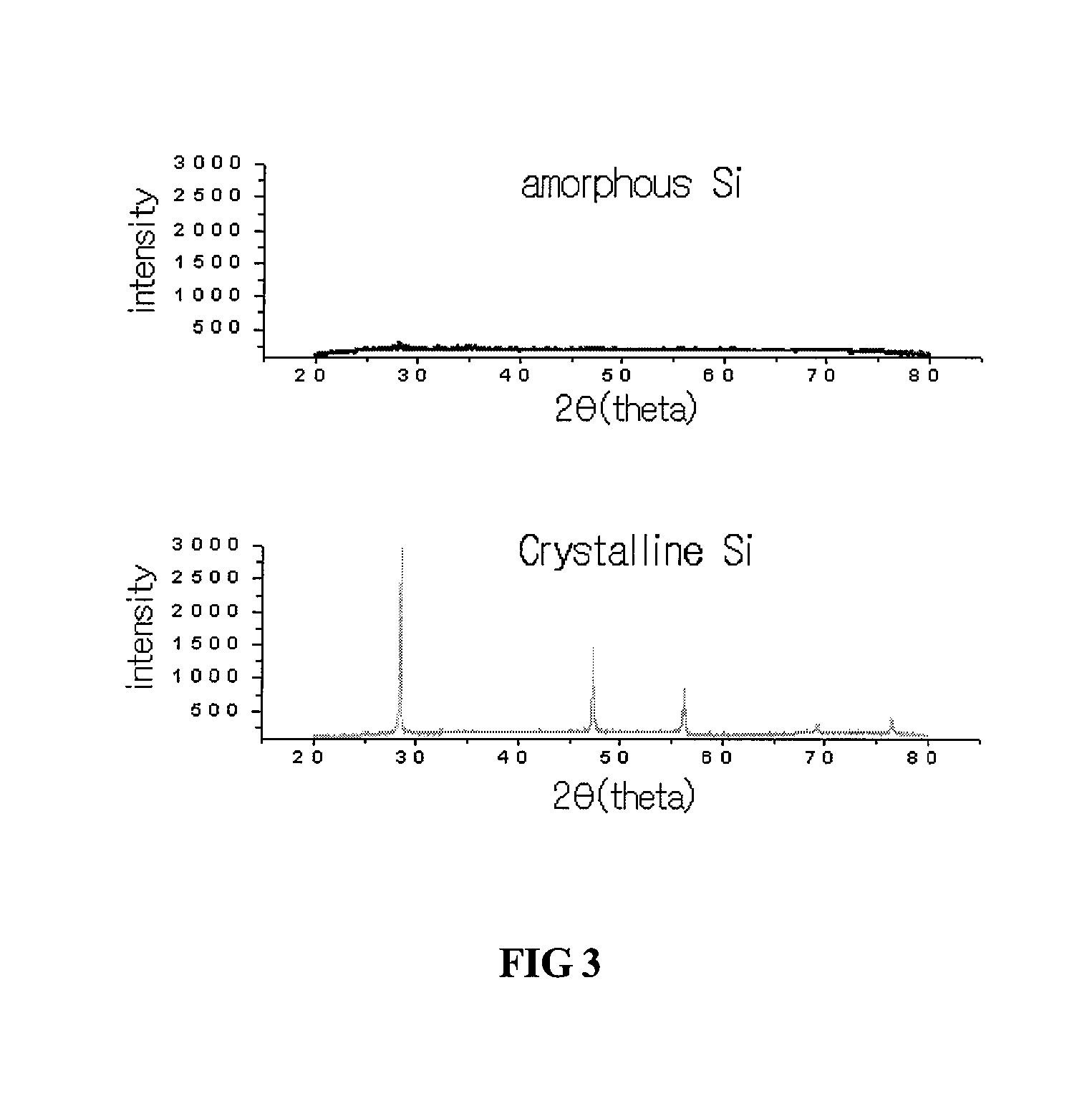

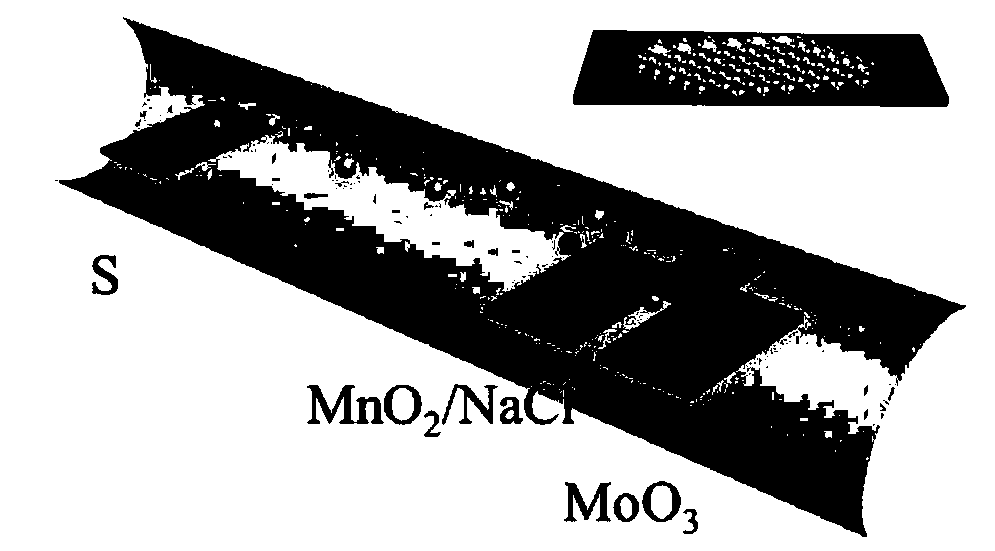

Catalyst for preparing carbon nanotube comprising multi-component support materials containing amorphous silicon particles and the bulk scale preparation of carbon nanotube using the same

InactiveUS20100230642A1Excellent ElectricalImprove thermal conductivityMaterial nanotechnologyCarbon compoundsPtru catalystAmorphous silicon

The present invention relates to a catalyst composition for preparing carbon nanotube containing multi-component support materials of amorphous Si, Mg and Al as well as a bulk scale preparation process for preparing carbon nanotube using said catalyst composition. More specifically, this invention relates to a process for preparing carbon nanotube using the catalyst composition comprising a transition metal catalyst and support materials of amorphous Si, Mg and Al.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

Hardener for Epoxy Resin and Epoxy Resin Composition

ActiveUS20070244268A1Excellent characteristic in reliabilityImprove water resistanceOrganic chemistryPolymer scienceFirming agent

An amine hardener for epoxy resins which comprises an amine adduct (A) and a low-molecular amine compound (B) as major components, wherein the molecular weight distribution of the amine adduct (A), which is defined by the ratio of the weight-average molecular weight to the number-average molecular weight, is 3 or lower and the low-molecular amine compound (B) is contained in an amount of 0.001 to 1 part by mass per 100 parts by mass of the amine adduct (A).

Owner:ASAHI KASEI CHEM CORP

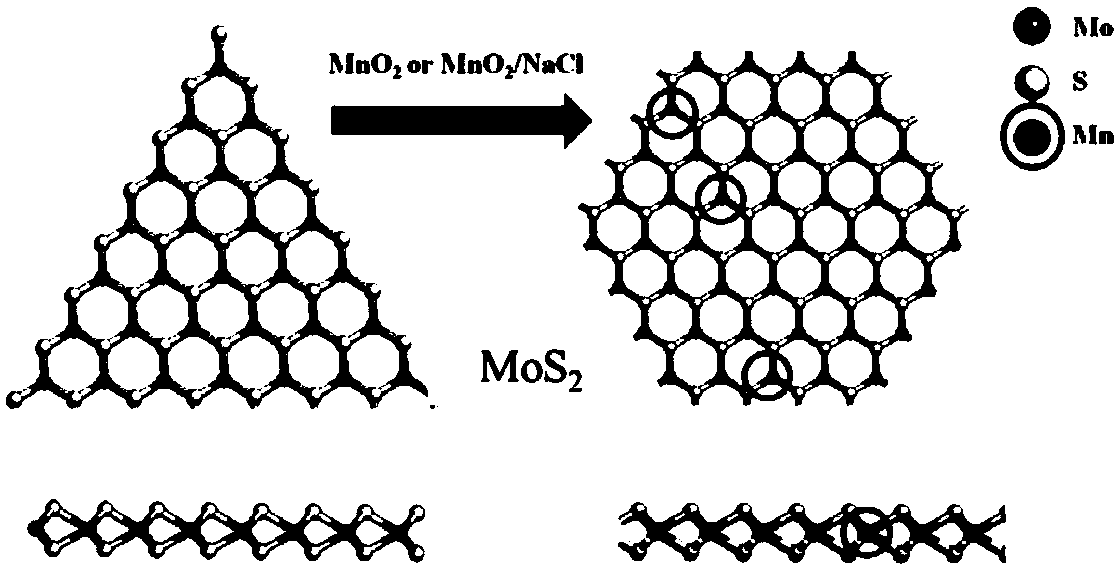

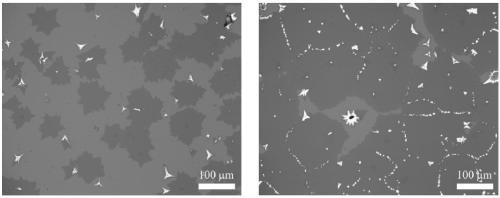

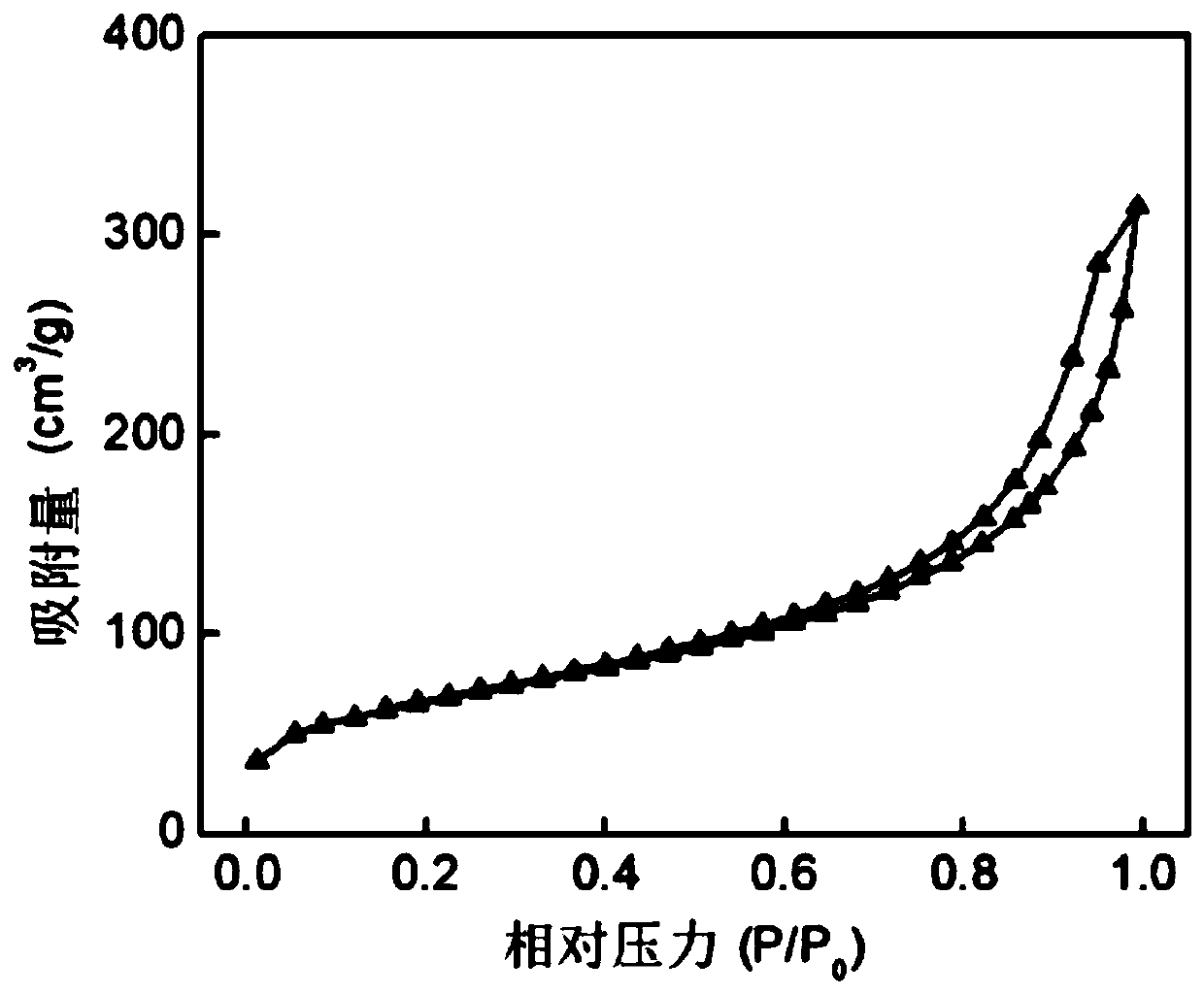

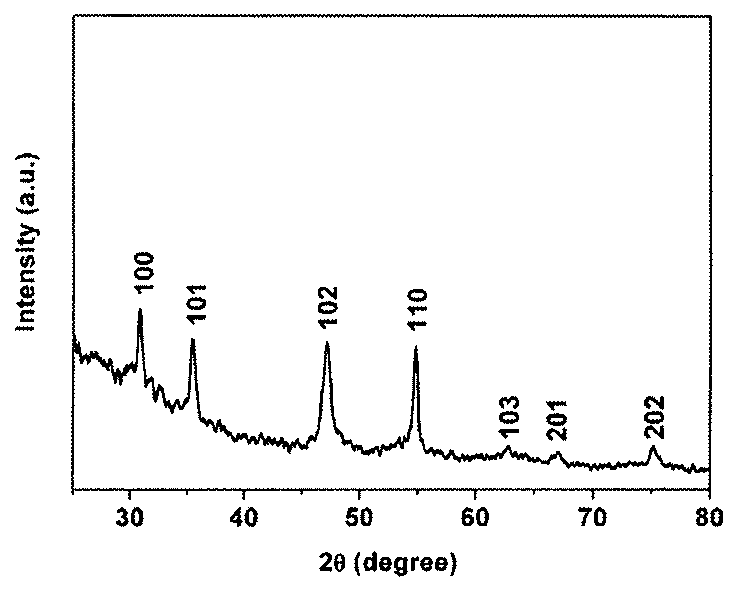

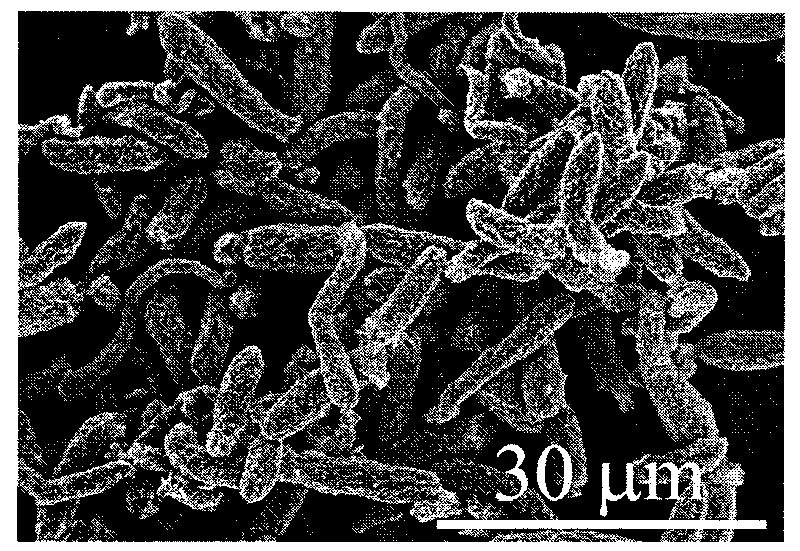

Transition metal-doped molybdenum disulfide thin-layer material as well as preparation method and application thereof

The invention provides a transition metal-doped molybdenum disulfide thin-layer material as well as a preparation method and application thereof. The two-dimensional size of the thin-layer material is50-500 microns, and the thickness ranges from 0.7-2.2 nanometre; and the method comprises the following steps that a molybdenum source and an inorganic salt mixture, a transition metal doping sourceand the inorganic salt mixture as well as a sulfur source are subjected to chemical vapor deposition reaction in a protective gas, and a transition metal doped molybdenum disulfide thin layer materialis obtained on the surface of a substrate. According to the method and the application, an inorganic salt assisting chemical vapor deposition method is adopted, the molybdenum source, the transitionmetal doping source and the inorganic salt are mixed, and then the chemical vapor deposition reaction is carried out, so that the metal replacement type doping of transition metal sulfide is realized,so that the doped molybdenum disulfide thin-layer material with large size distribution is prepared; and the method is simple and easy to operate, the process is controllable, the obtained material is good in morphology, optical, electrical and other performances are excellent, and the method and the application have a wide application prospect.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

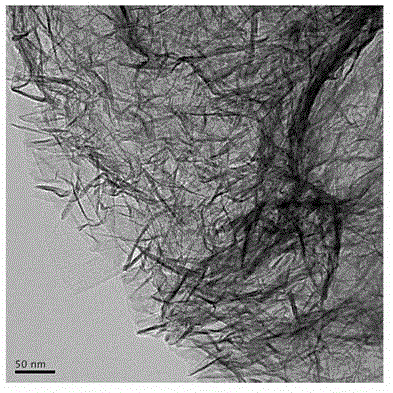

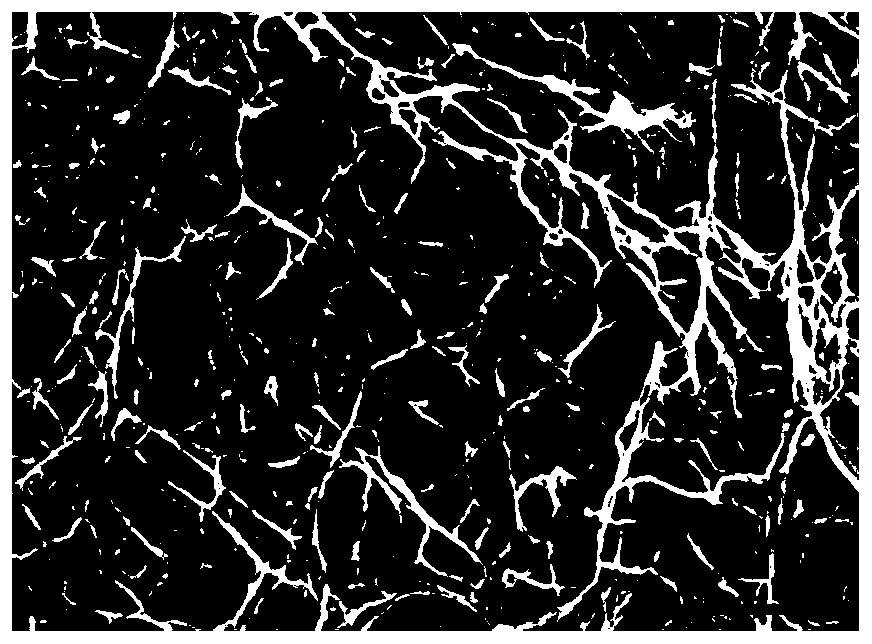

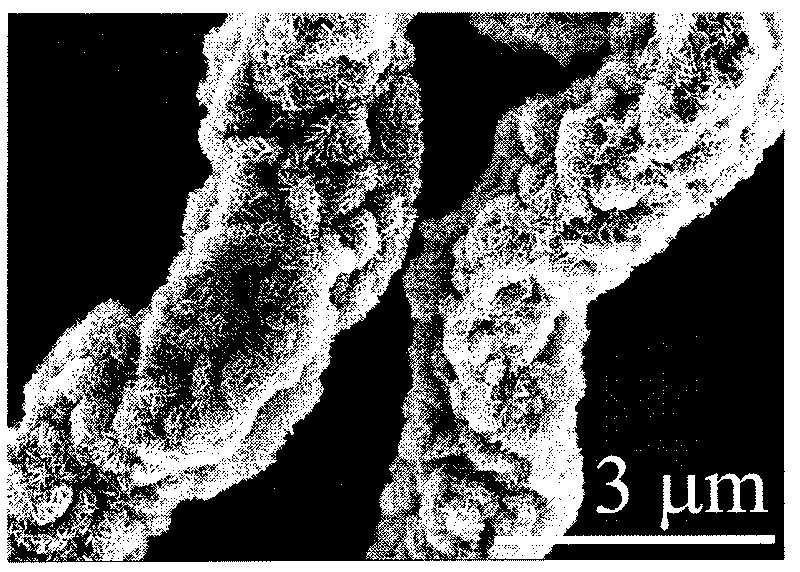

Aramid fiber/carbon nanotube hybrid aerogel film and preparation method and application thereof

ActiveCN110982114AImprove mechanical propertiesExcellent ElectricalCarbon compoundsNanofiberHydrophobe

The invention discloses an aramid fiber / carbon nanotube hybrid aerogel film and a preparation method and application thereof. The aramid fiber / carbon nanotube hybrid aerogel film comprises a communicating three-dimensional network-shaped porous structure and a hydrophobic layer covering the three-dimensional network-shaped porous structure, wherein the three-dimensional network-shaped porous structure is formed by mutually overlapping aramid fiber nanofibers and carbon nanotubes. The preparation method comprises the following steps: mixing a carbon nanotube dispersion liquid and an aramid nanofiber dispersion liquid to form a mixed dispersion liquid; applying the formed mixed dispersion liquid to a substrate, transferring the substrate to a coagulating bath, and carrying out sol-gel replacement to form a hybrid gel film; performing drying treatment to obtain a hybrid aerogel film; and finally, infiltrating the hybrid aerogel film with a hydrophobic resin solution to obtain the aramid fiber / carbon nanotube hybrid aerogel film. The hybrid aerogel film provided by the invention has good mechanical, electrical and hydrophobic properties and excellent Joule heat effect and electromagnetic shielding performance, and can be applied to the fields of intelligent films, personal thermal management, wearable electromagnetic protection and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

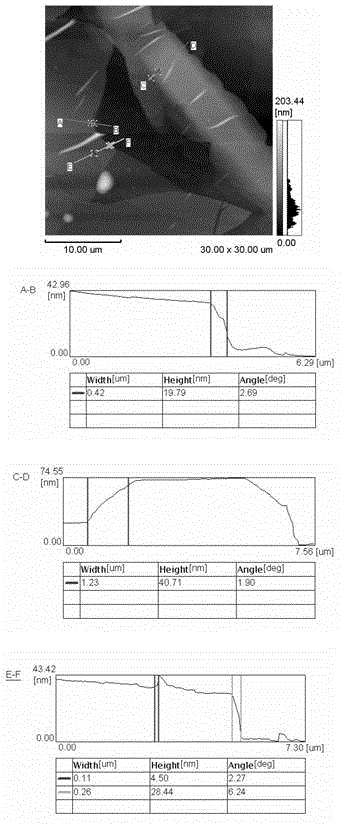

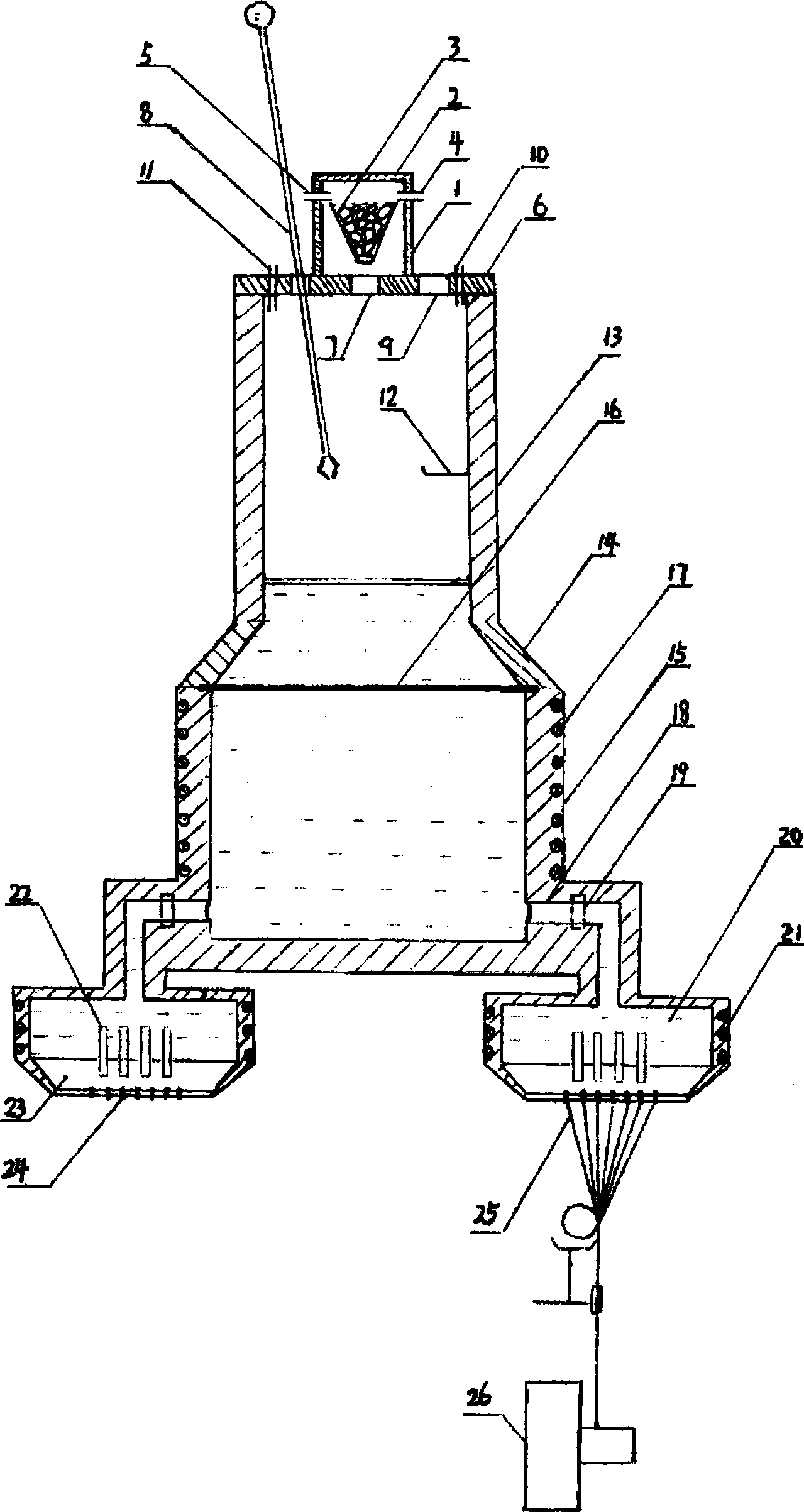

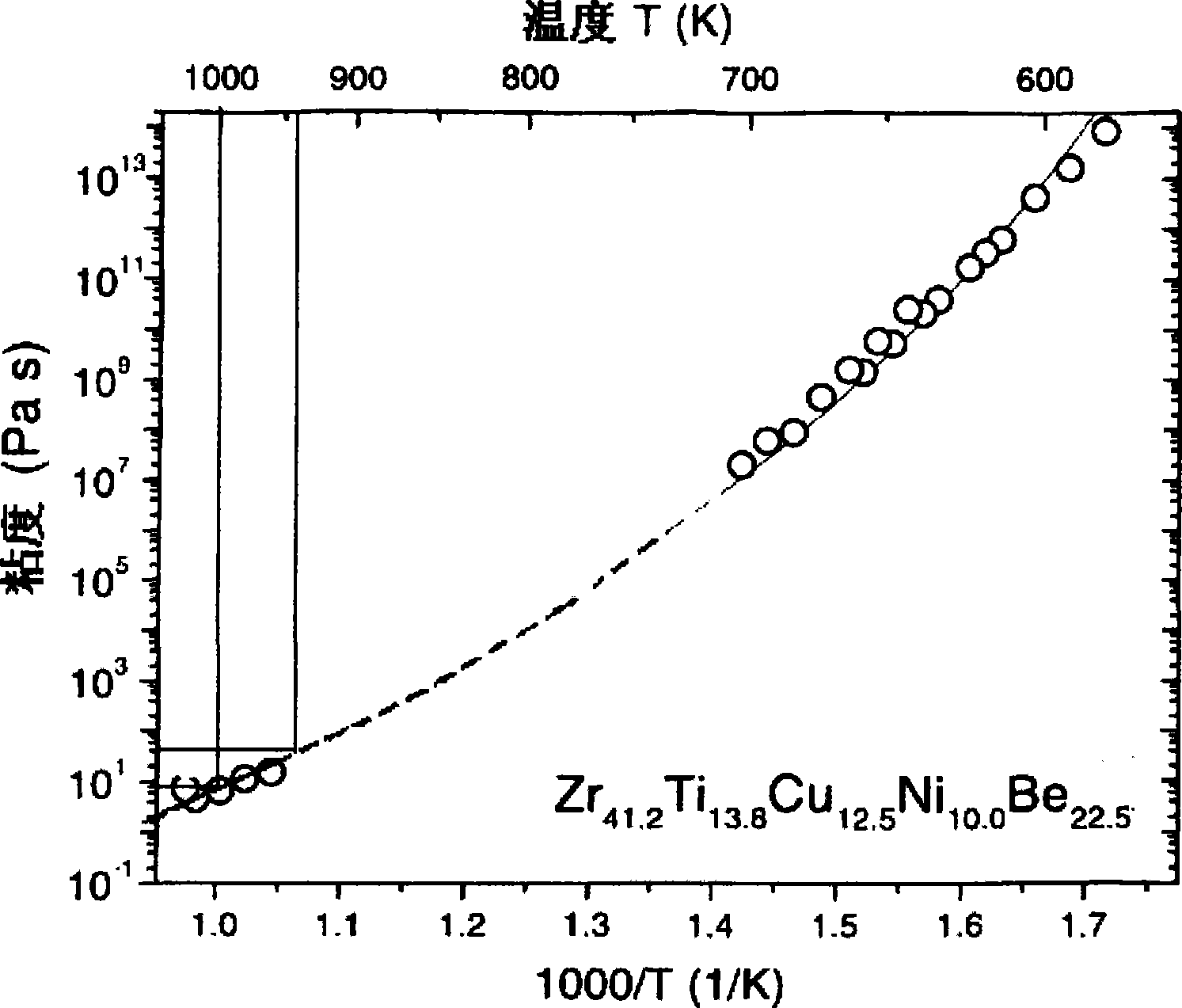

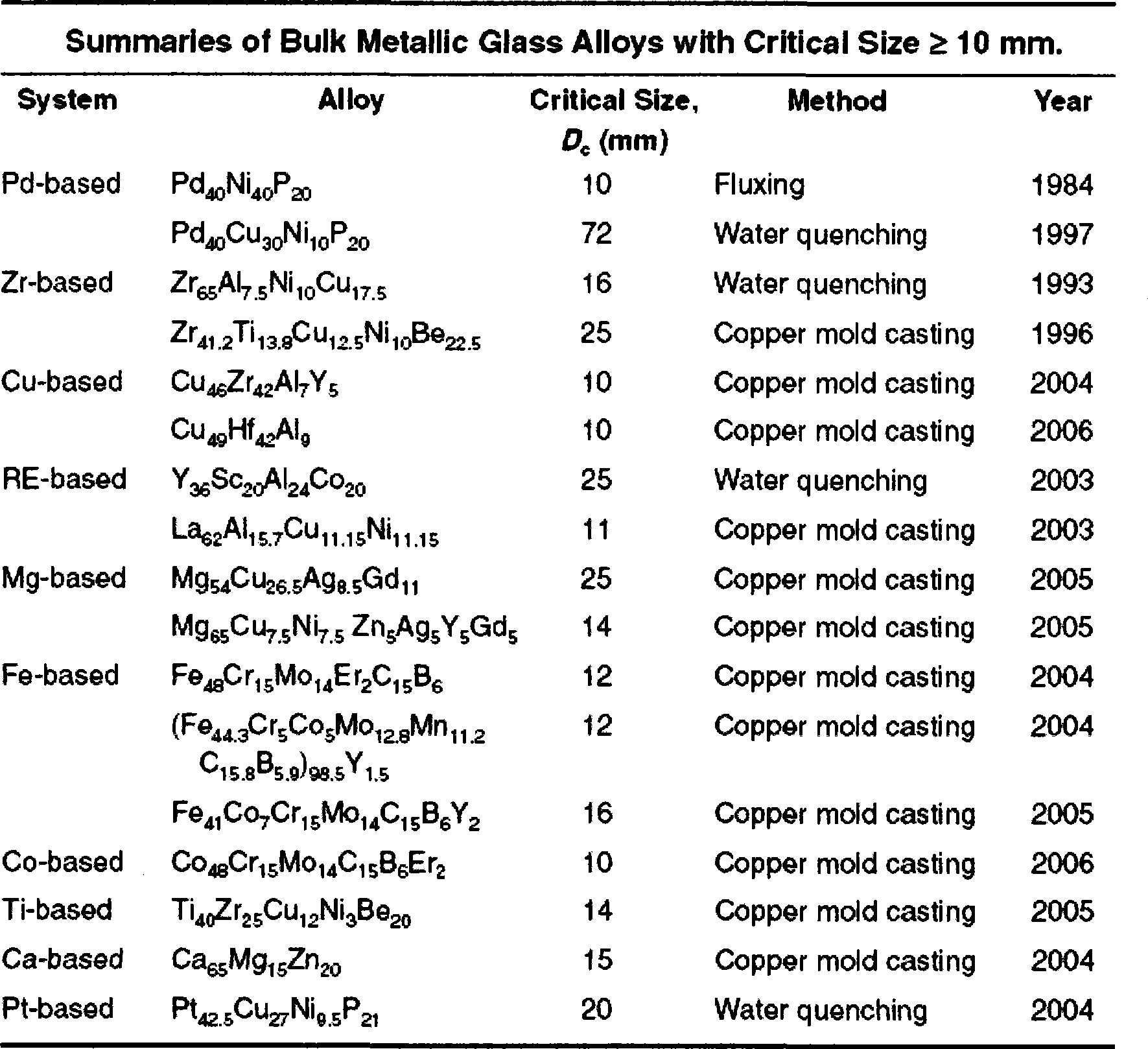

Continuous metallic glass fiber and preparing method thereof

The invention provides a continuous metallic glass fiber and a preparing method thereof. The alloy component of the metallic glass fiber is one of palladium base, platinum base, gold base, calcium base, magnesium base, copper base, aluminum base, titanium base, iron base, cobalt base, nickel base, zirconium base, hafnium base, yttrium base and lanthanide series rare earth base, the diameter of the cross section of the fiber is 2 to 50 mu m, the length thereof is more than 100m, and the volume content of amorphous phase thereof is not less than 90 percent. Super-cooled metallic glass alloy melt is drawn into the metallic glass fiber of a certain diameter at a tremendous speed through a porous wire-drawing bushing. The metallic glass fiber has excellent comprehensive mechanical property. The continuous metallic glass fiber can be made into primary products such as rope, cloth, net, felt, short-cut yarn, and the like, in the application mode which is similar to that of oxide glass fiber; or on the basis, the fiber can be used as fiber reinforcing material to be combined with resin, ceramics, metal, cement, plaster, asphalt, and the like, thus producing various composite materials with rich and changeful performances.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

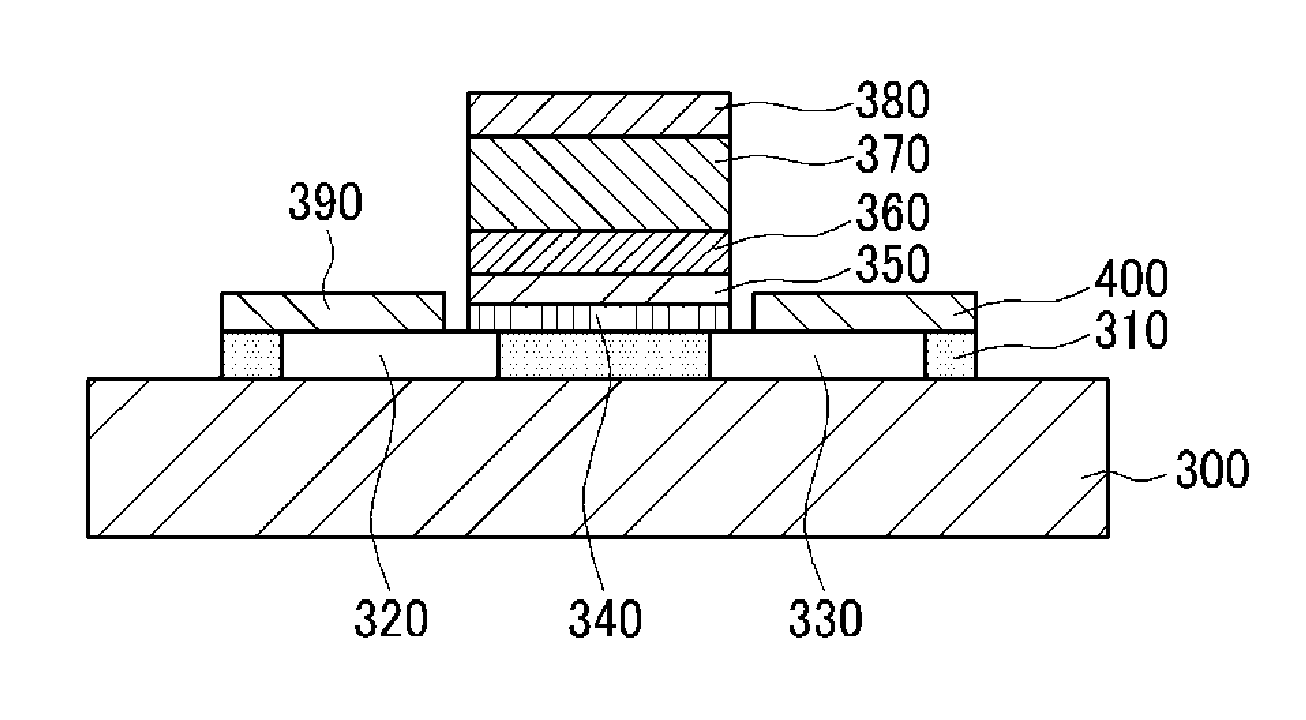

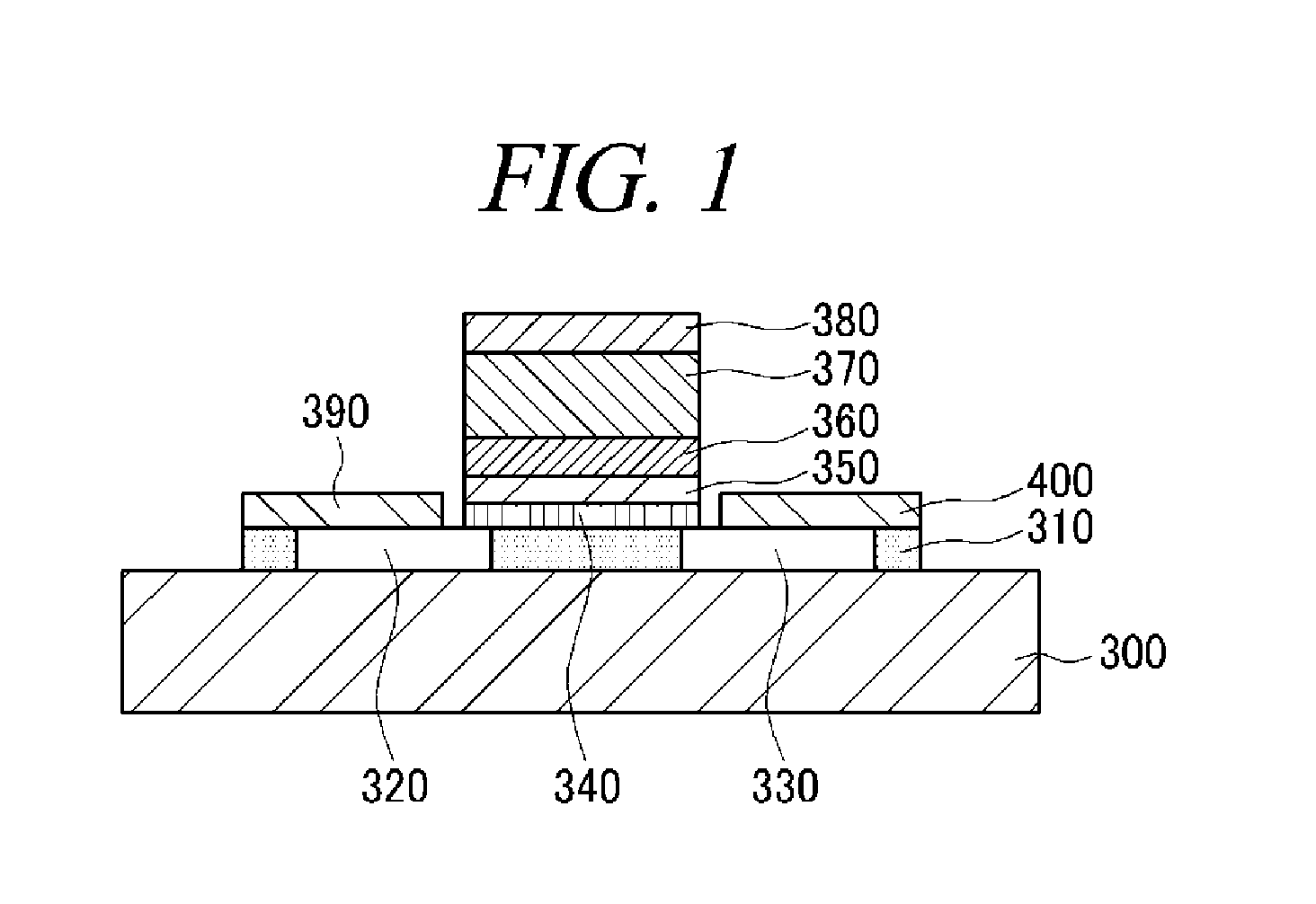

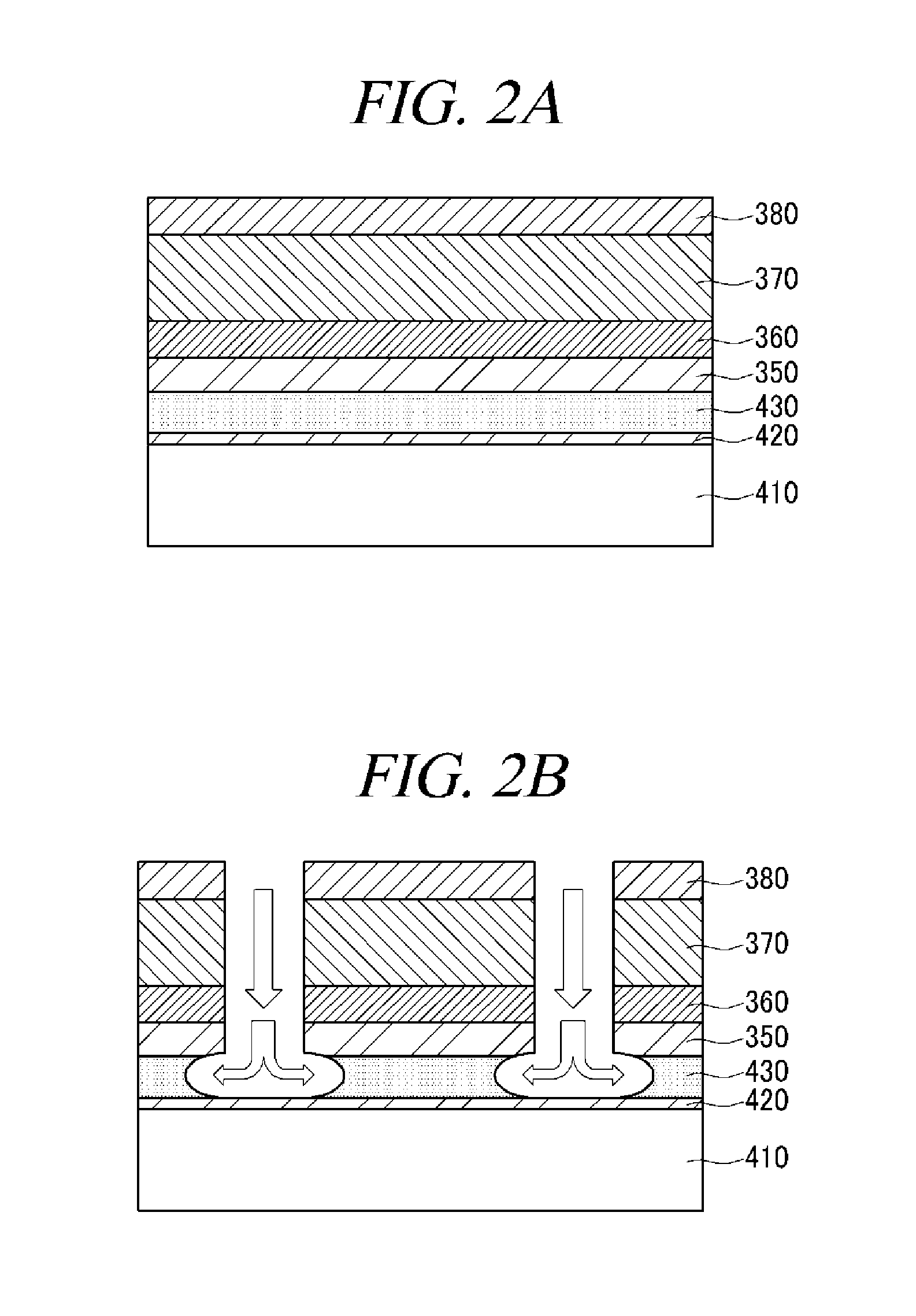

Flexible ferroelectric memory device and manufacturing method for the same

InactiveUS20110316059A1Excellent ElectricalEasy to processSolid-state devicesSemiconductor/solid-state device manufacturingBiomedical engineering

The present disclosure relates to a flexible nonvolatile ferroelectric memory device, a 1T-1R (1Transistor-1Resistor) flexible ferroelectric memory device, and a manufacturing method for the same.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

Preparation method of cobalt sulfide micro tube with hiberarchy structure

InactiveCN101746837ALarge specific surface areaHigh specific capacitanceSemi-permeable membranesFixed microstructural devicesEthylenediamineSynthesis methods

The invention belongs to an inorganic chemical synthesis method and in particular relates to a preparation method of a cobalt sulfide micro tube with hiberarchy structure; in the invention, water-soluble cobalt salt is used as a metal source, thioacetamide is used as a sulphur source, ethanediamine is used as metal chelating agent, and cetyl trimethylammonium bromide CTAB is used as a template agent, in a closed reactor, hydro-thermal reaction is carried out under a certain temperature condition, so as to synthesize the micron tube-like cobalt sulfide with the hiberarchy structure, the outer diameter of the tube is about 1.5micron, the thickness of the tube wall is about 400nm, the average length is about 15micron, the tube wall is a nanoscale hexagonal sheet, and the length and the thickness of the sheet are 90nm and 22nm respectively; the synthesis method has the advantages of cheap and easy-obtaining raw material, simple equipment, low reaction temperature and good process repeatability and overcomes the problem of environment pollution caused by organic solvent in the previous synthesis method; the obtained product has wide application prospect in the field of biology, catalysis and material science and the like.

Owner:NORTHEAST NORMAL UNIVERSITY

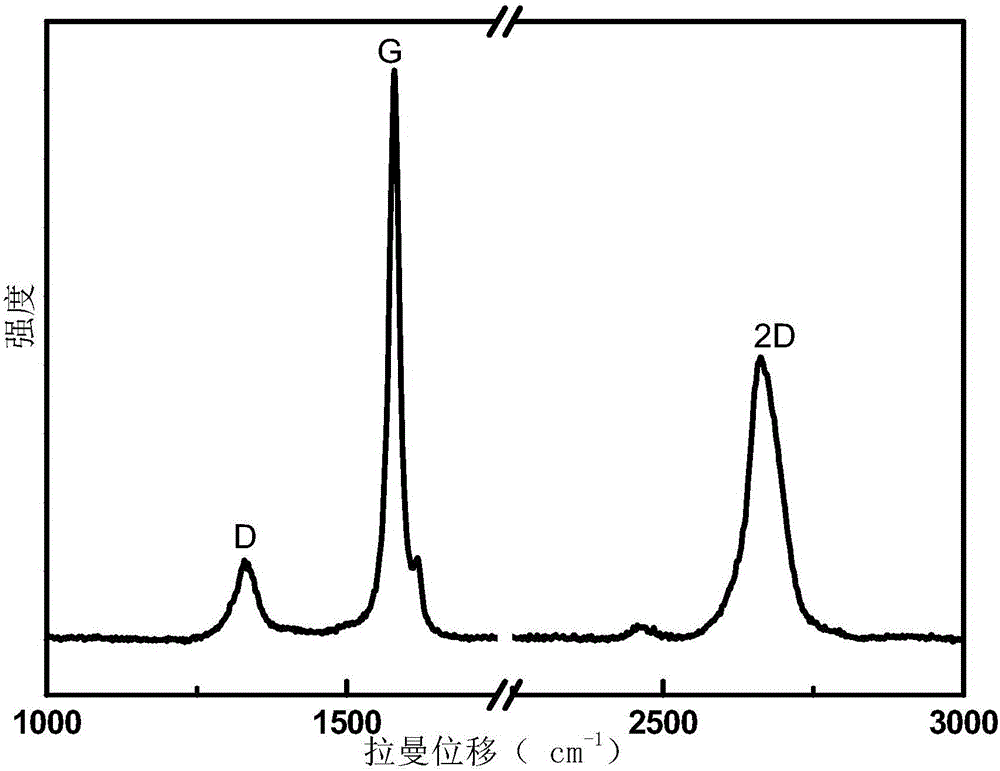

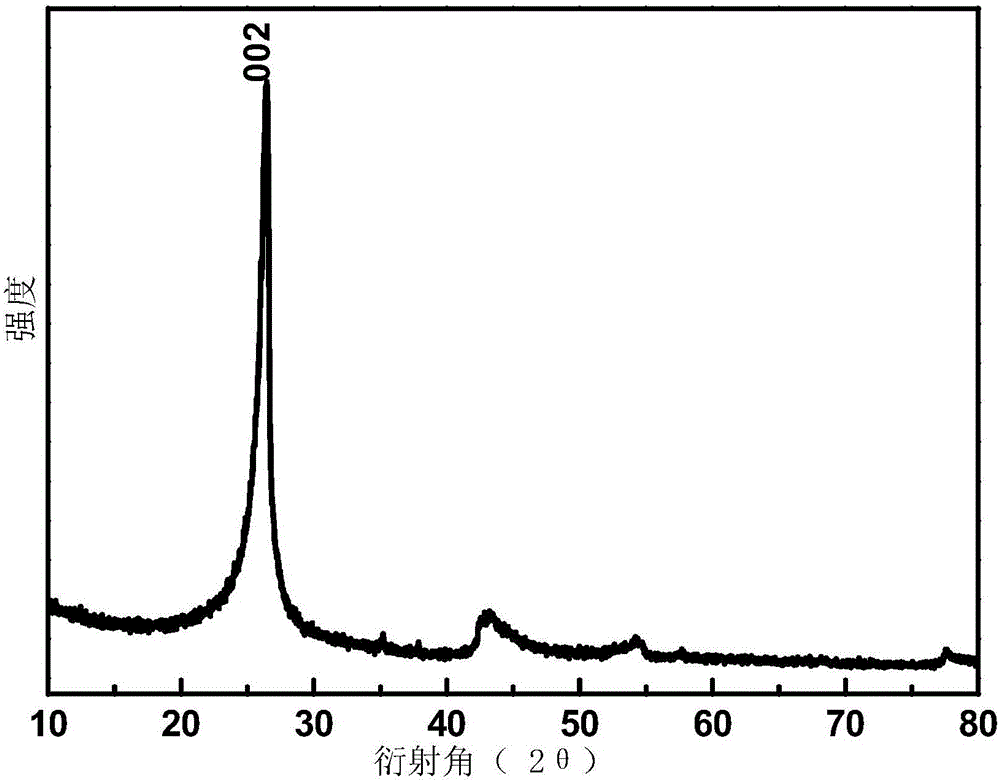

Method for preparing graphene by using lignin

The invention belongs to the technical field of carbon material manufacturing technology, and in particular relates to a method for preparing graphene by using lignin as a raw material. The method is as follows: a layered or powdered material is used as a substrate, the lignin and a catalyst precursor are alternately assembled on the surface of the substrate by a layer-by-layer electrostatic self-assembly method, then a lignin / catalyst precursor / substrate composite is put into a double-temperature-zone tubular furnace, a H2 / Ar mixed gas is introduced into the double-temperature-zone tubular furnace at a certain speed, at the same time the double-temperature-zone tubular furnace is heated by a certain procedure, after the double-temperature-zone tubular furnace is heated to target temperature, the temperature of the double-temperature-zone tubular furnace is held for a certain time, when the double-temperature-zone tubular furnace is cooled to room temperature, the sample is taken out, and is soaked in an acid for catalyst removal, and after a plurality of times of washing and vacuum drying, the graphene is obtained. The method has the advantages of simple process and convenient operation, and the prepared graphene is good in growth, controllable in layer number and considerable in yield.

Owner:SOUTH CHINA UNIV OF TECH

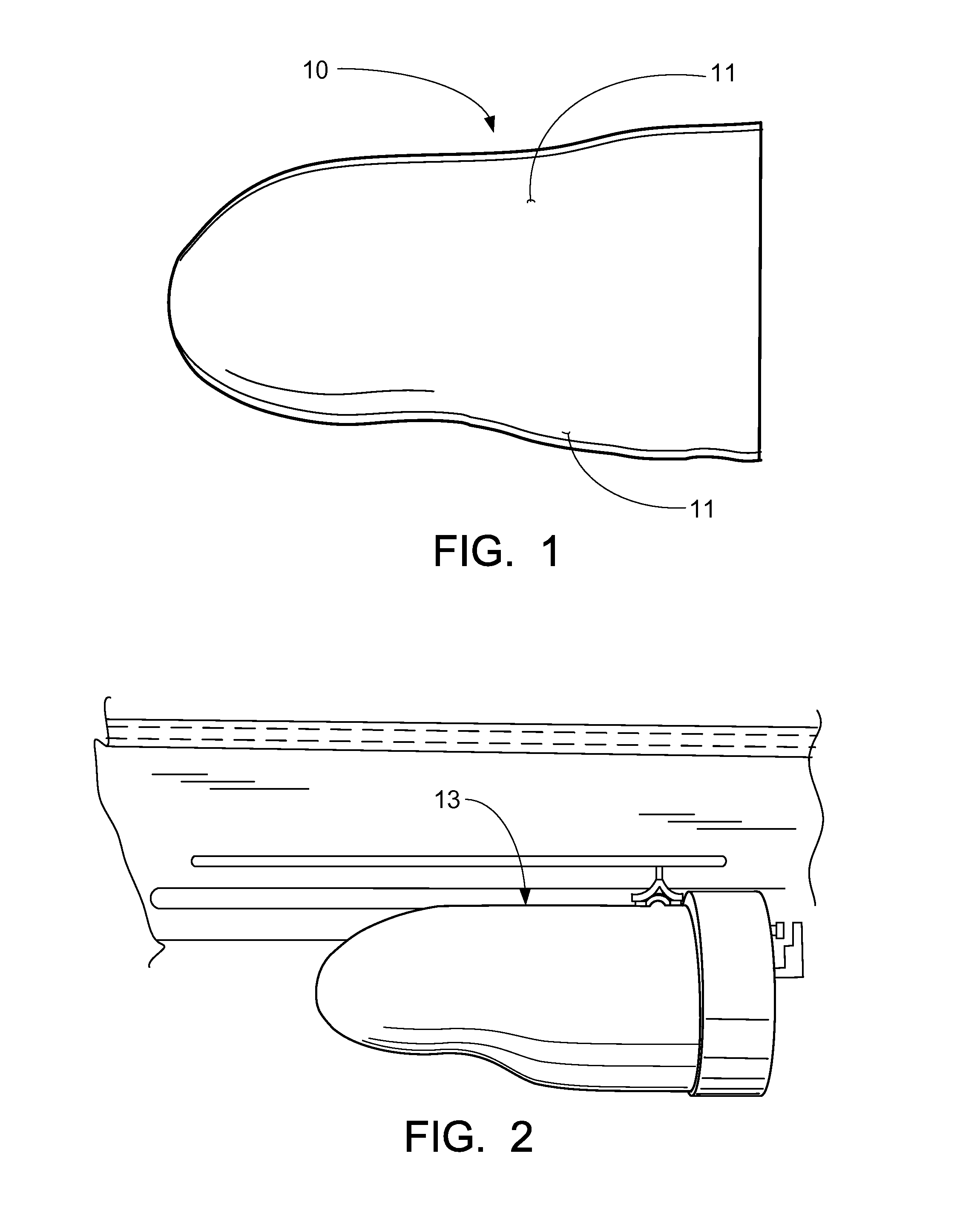

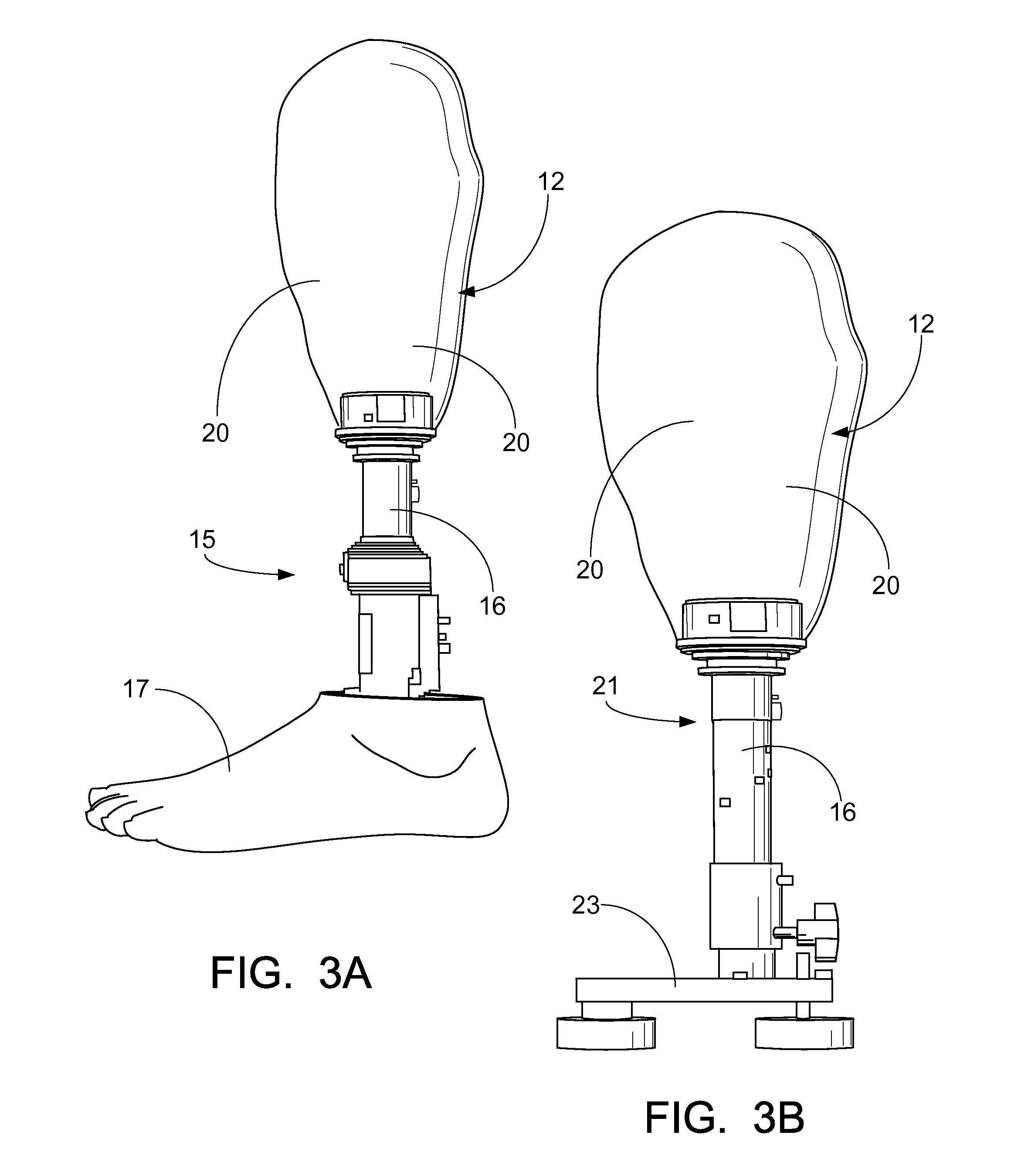

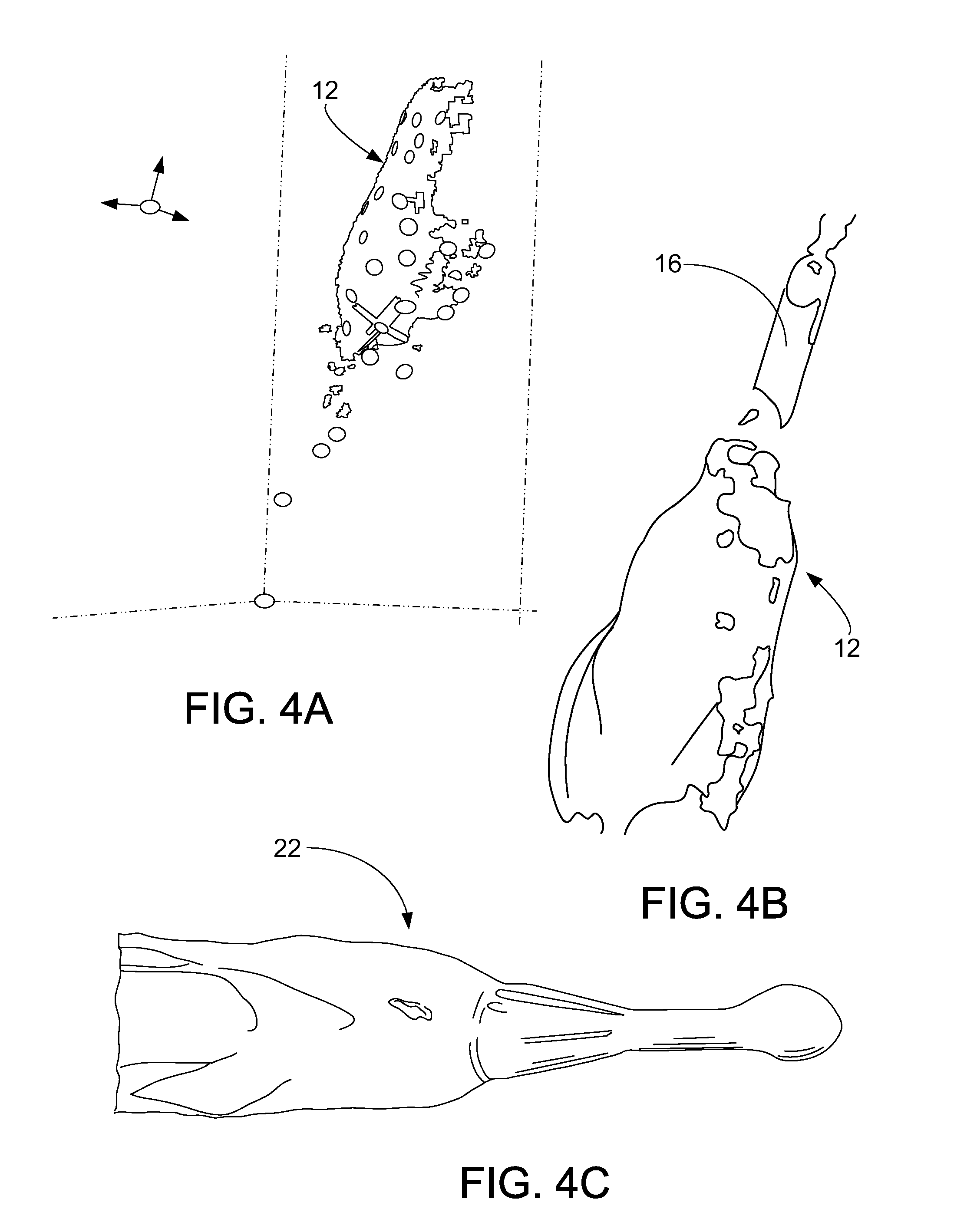

Method of digitally constructing a prosthesis

ActiveUS20150142150A1The process is simple and clearImprove toughnessComputer aided designManufacturing data aquisition/processingBiomedical engineeringFiber

A prosthetic limb and process to digitally construct a prosthetic limb which includes first, digitally producing a modified mold of a residual limb via 3d scanners and software known to the industry; constructing a test socket from the digitally modified mold and be equipped with an alignable system; for example, a pylon, along with the desired prosthetic foot; accurately scanning the test socket, preferably with a 3D scanner, along with finalized alignment that has been recorded and adjusted by a certified practitioner to provide a 3-D Image of the finalized prosthetic alignment; transferring the finalized digital alignment of the test socket to the finalized digitally modified mold; once the modified model has received the transferred alignment, fabricating the type of hookup in the socket; i.e., plug fit, four hole, support drop lock, or any other type of industry standard connection or accommodation via basic 3D software; and once the desired prosthetic attachment is finalized, the next step is to send the finished file to a 3-D printer to produce the definitive prosthetic device. The 3-D printed socket would then be placed in a vibratory finishing system to smooth out the interior and exterior surfaces of the printed socket; and the walls of the 3-D printed socket would be sealed by applying a mixture of epoxy sealant, for example, TC-1614, to the inside and outside walls of the socket, and placing the socket into an oven for a sufficient amount of time to seal the walls of the socket. Preferably, the prosthesis would be printed out of Nylon 12 material or of a strong plastic, such as ULTEM®, or carbon fiber, or other material of equivalent or greater strength that may be known or developed in the future.

Owner:LAYMAN WILLIAM STRATFORD +1

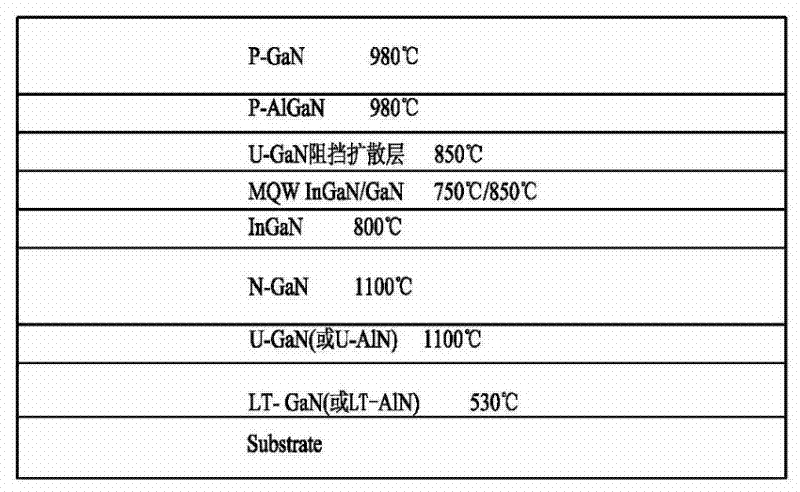

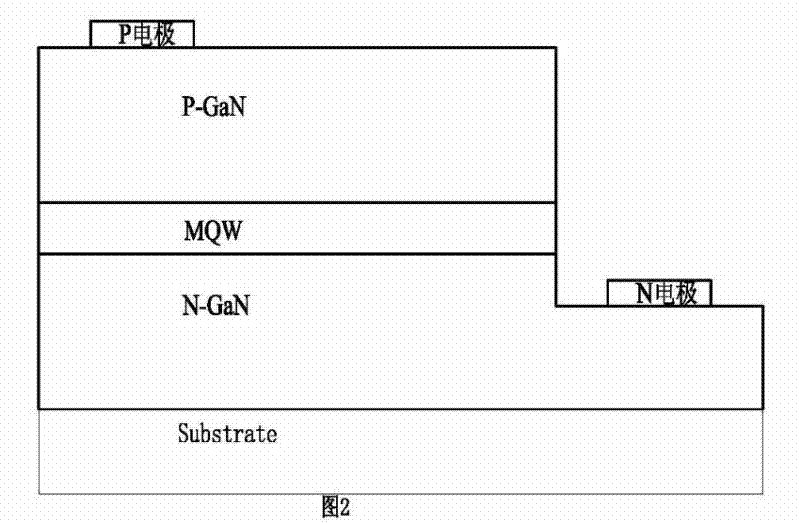

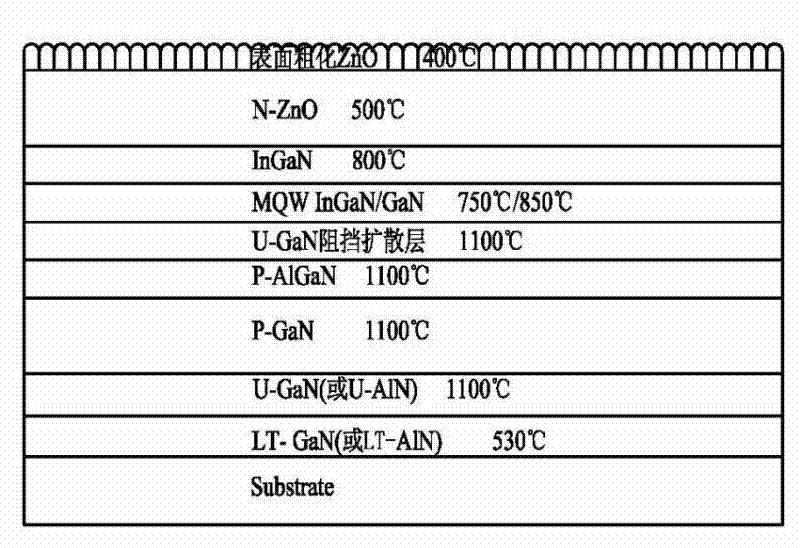

Light-emitting diode (LED) epitaxial structure and manufacturing method thereof

InactiveCN102208503AExcellent ElectricalGood optical performanceSemiconductor devicesQuantum efficiencyOptical property

The invention discloses a light-emitting diode (LED) epitaxial structure and a manufacturing method thereof. The LED epitaxial structure successively comprises an epitaxial substrate, a leukotriene (LT)-GaN nucleating layer, a high-temperature non-doped buffer layer, a P-GaN layer, a P-AlGaN layer, a diffusion barrier layer, a multiple quantum well (MQW) luminous layer, an InGaN current expansion layer, an N-ZnO layer and a surface-coarsened ZnO layer. The manufacturing method comprises the following steps: pre-treating the epitaxial substrate; growing the nucleating layer; growing the buffer layer; growing the P-GaN layer; growing the P-AlGaN layer; growing the diffusion barrier layer; growing the MQW luminous layer; growing the InGaN current expansion layer; growing the N-ZnO layer; and growing the surface-coarsened ZnO layer. By using the LED epitaxial structure obtained by virtue of the manufacturing method provided by the invention, an excellent electrical property and a good optical property are obtained, the internal quantum efficiency and the electronic static discharge (ESD) resistance capability are improved, the lost light caused by total reflection is lowered, the external quantum efficiency is greatly improved, a high-brightness LED is obtained, and the purposes of development and sustainable development of the LED industry are greatly promoted.

Owner:中山大学佛山研究院 +1

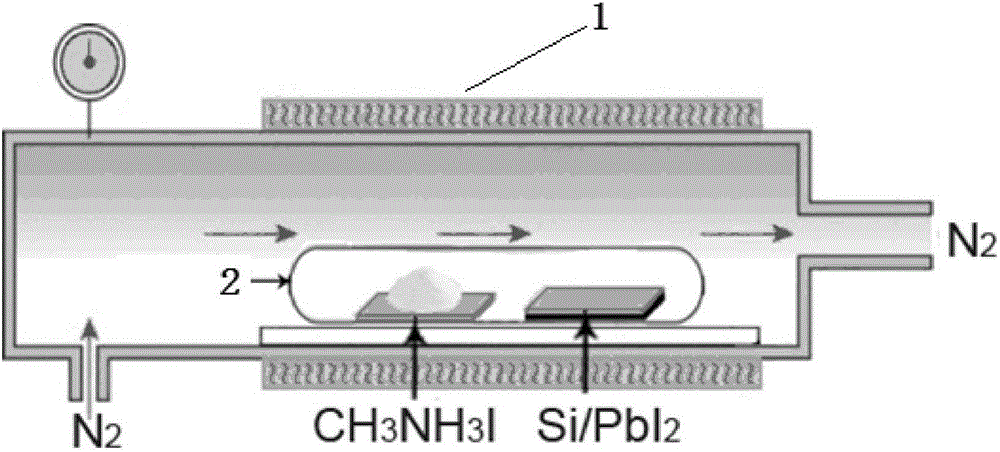

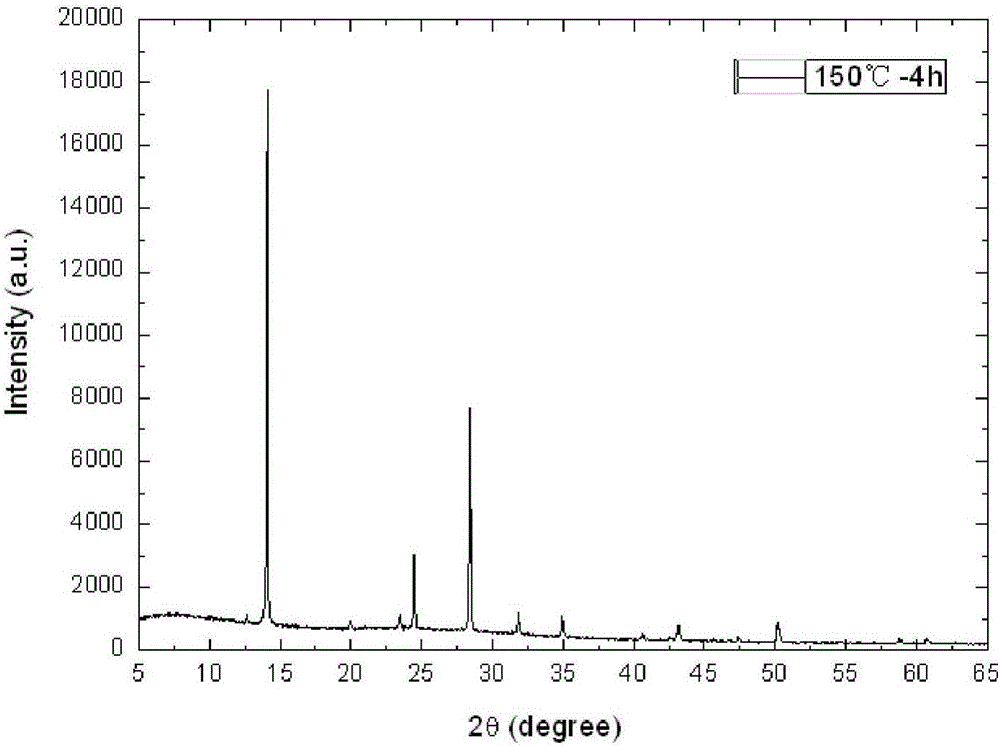

Silica-based perovskite heterojunction solar cell and preparation method thereof

ActiveCN104993059AFully absorbedPromote absorptionFinal product manufactureSolid-state devicesHeterojunctionSilver electrode

The invention discloses a silica-based perovskite heterojunction solar cell and a preparation method thereof. The silica-based perovskite heterojunction solar cell includes an aluminum electrode, a gold conducting film, perovskite, aluminum oxide, an N-type silicon wafer and a silver electrode arranged from top down, wherein the perovskite is CH3NH3PbI3. Compared with a traditional silica-based heterojunction solar cell material, silica-based perovskite heterojunction solar cell provided by the invention has better electric and optical performance. According to the invention, as to a transmitting electrode of the silica-based perovskite heterojunction solar cell, perovskite can absorb visible light while silicon can absorb infrared light, so that segmented light absorption can be realized and utilization of sunlight becomes more adequate. The invention also discloses a preparation method of the silica-based perovskite heterojunction solar cell.

Owner:江苏润阳悦达光伏科技有限公司

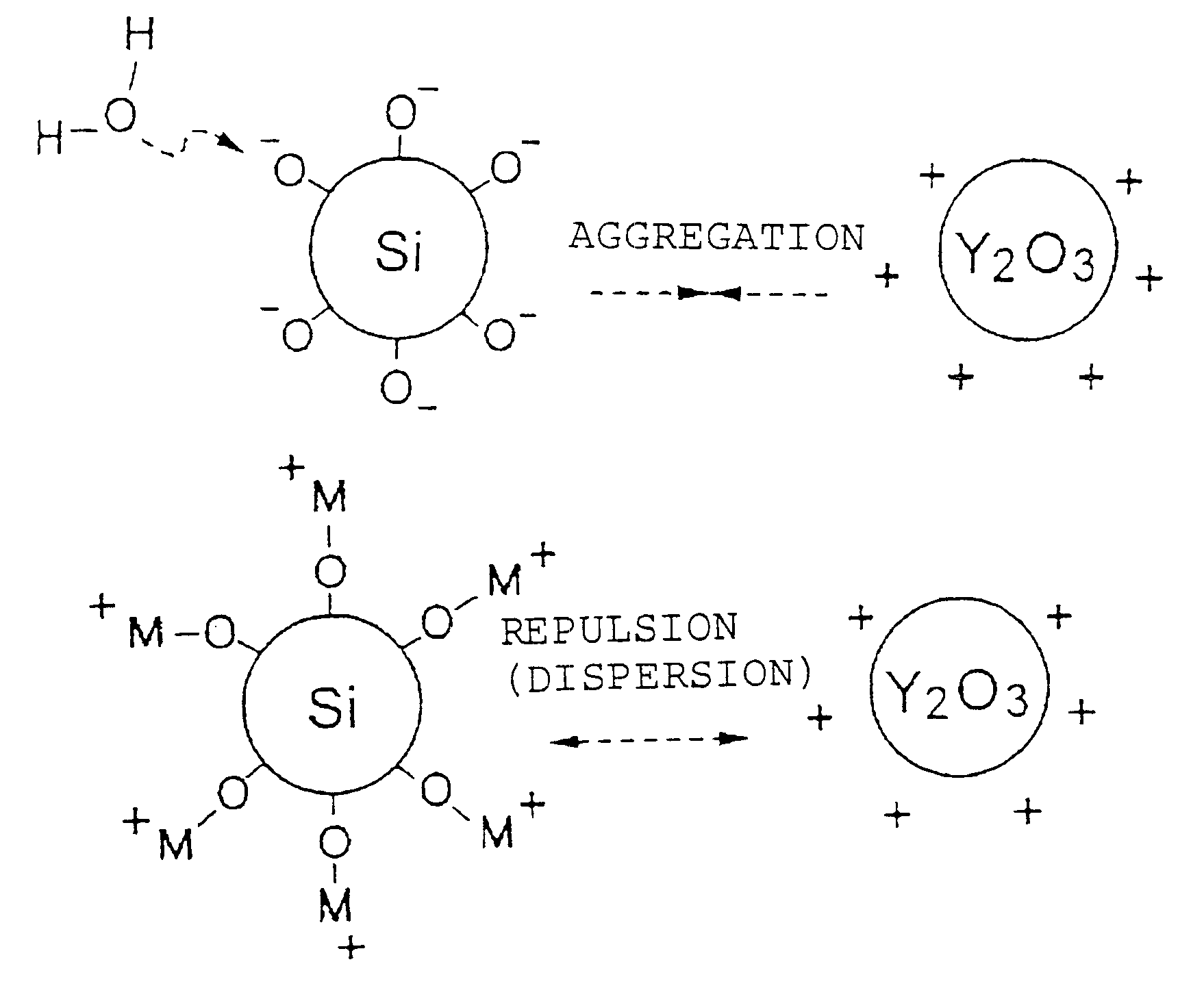

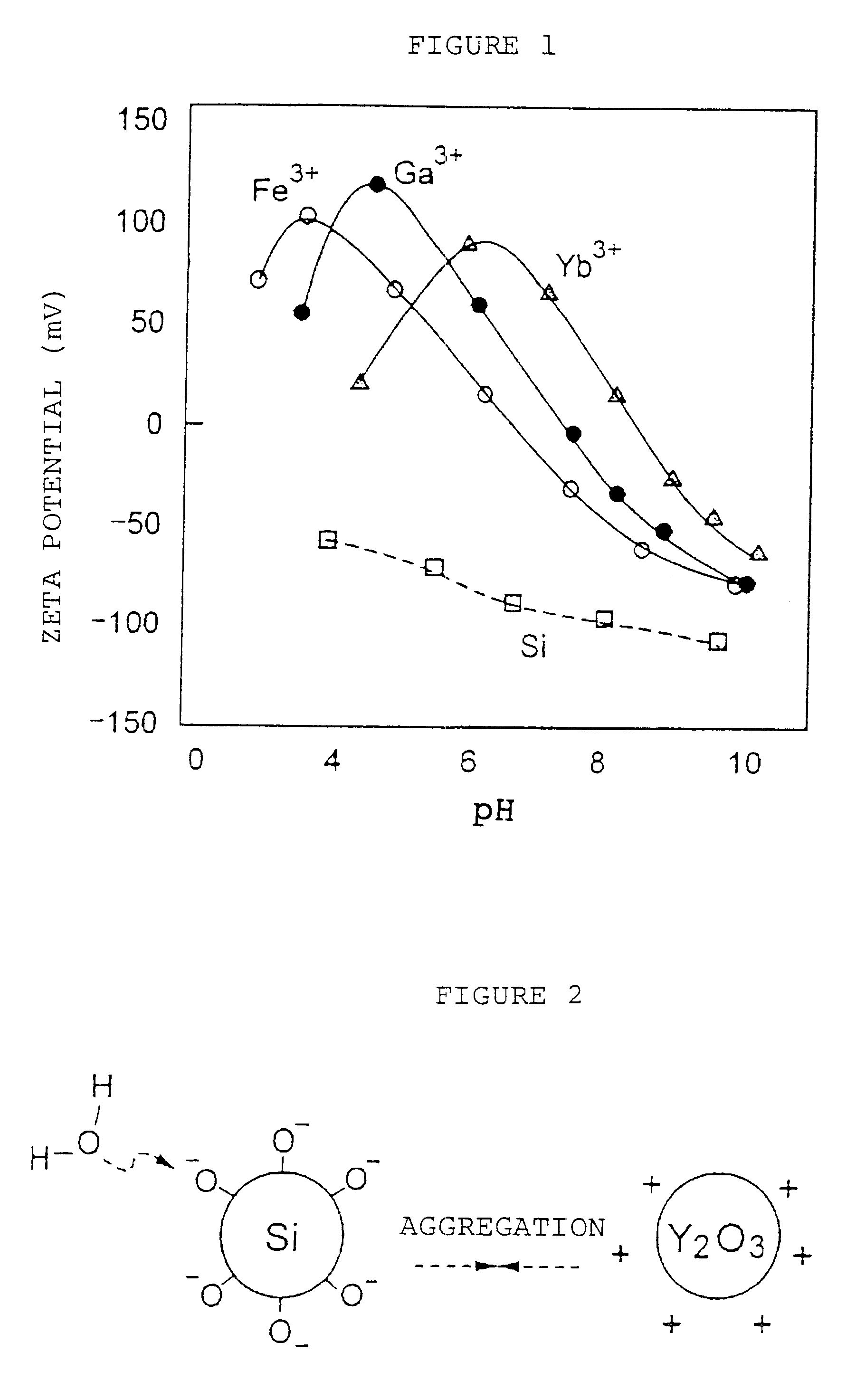

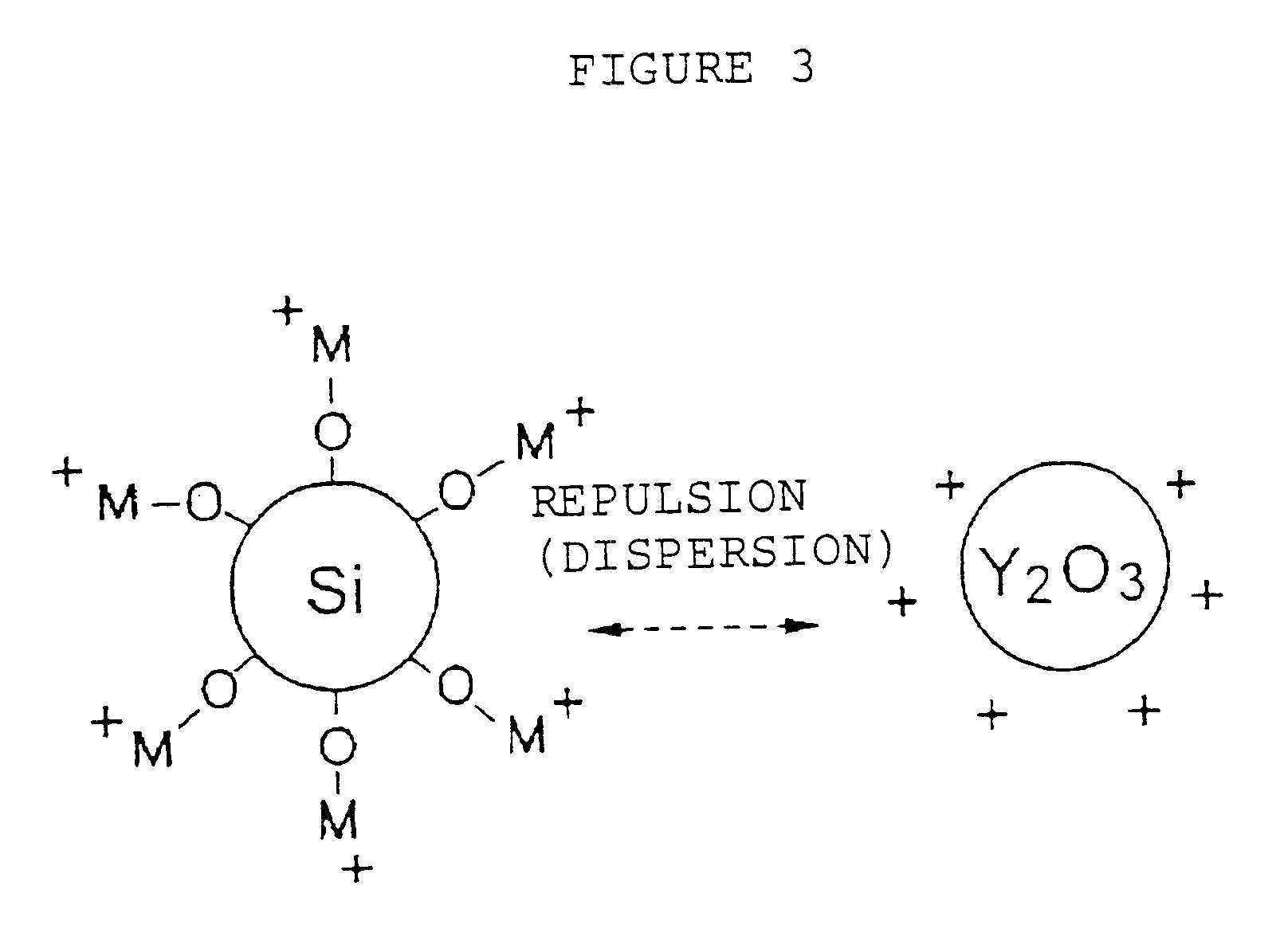

Si3N4 ceramic, Si-base composition for its production, and method for its production

InactiveUS6544917B1Improve oxidation resistanceImprove dispersion propertyMaterial nanotechnologySlurryOxygen

The invention provides a slurry composition suitable for the manufacture of Si.sub.3 N.sub.4 sintered bodies, wherein the dispersion properties and oxidation resistance of Si powder in water are improved, resulting in the homogenous dispersion of a sintering aid powder and a fine Si powder with less oxygen. Si powder, a sintering aid, water in an amount of 50 to 90 wt % relative to the total weight of the composition, and a surface coating agent in an amount of 0.05 to 10 wt % relative to the Si powder are added, the pH is adjusted to between 3 and 8, and the ingredients are milled and mixed. Trivalent metal ions such as Fe or Ga, or a polysiloxane with a BHL of no more than 10 is used as the surface coating agent. The resulting slurry composition can be used to prepare Si.sub.3 N.sub.4 sintered bodies with better electrical, thermal, and mechanical properties.

Owner:SUMITOMO ELECTRIC IND LTD

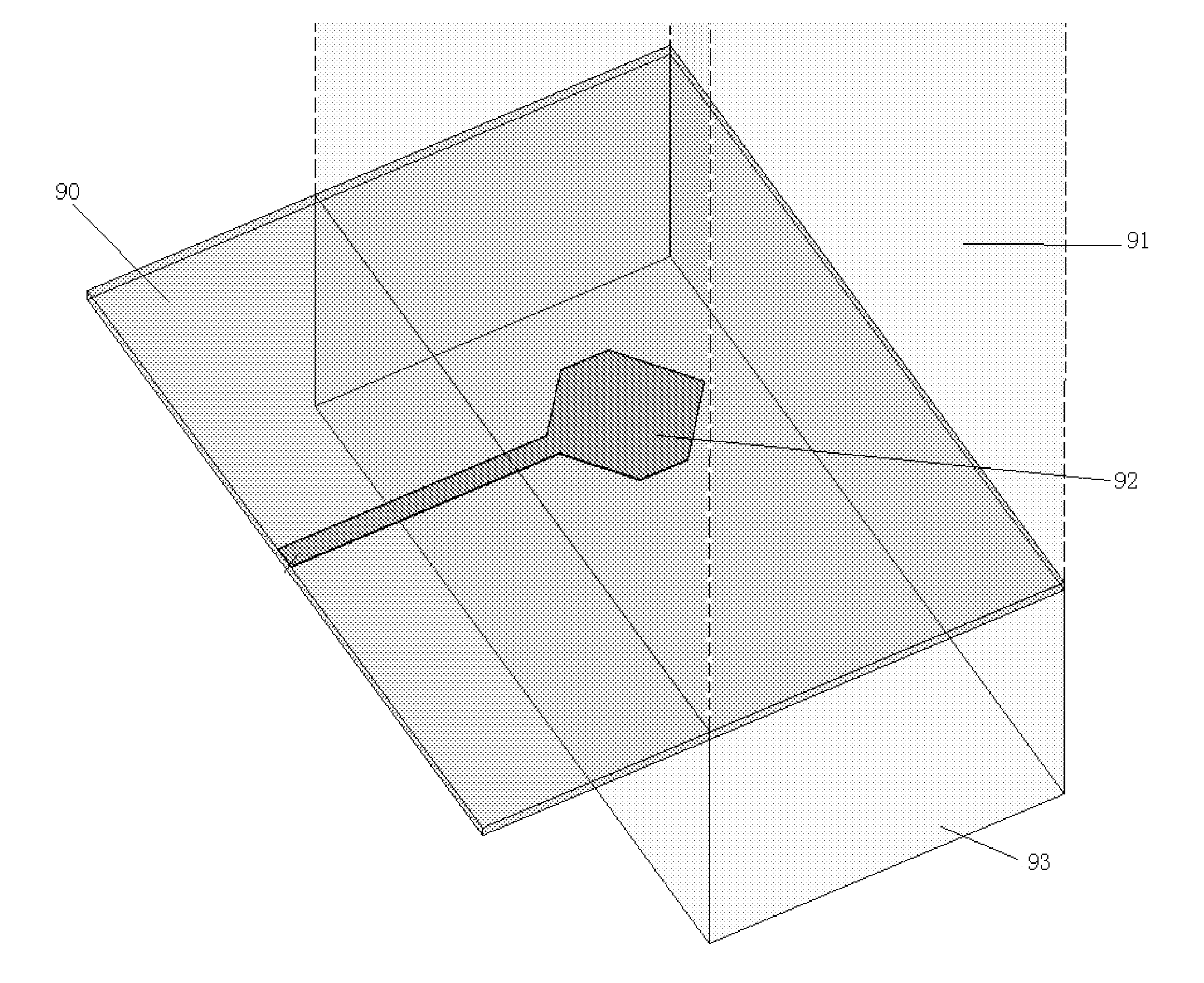

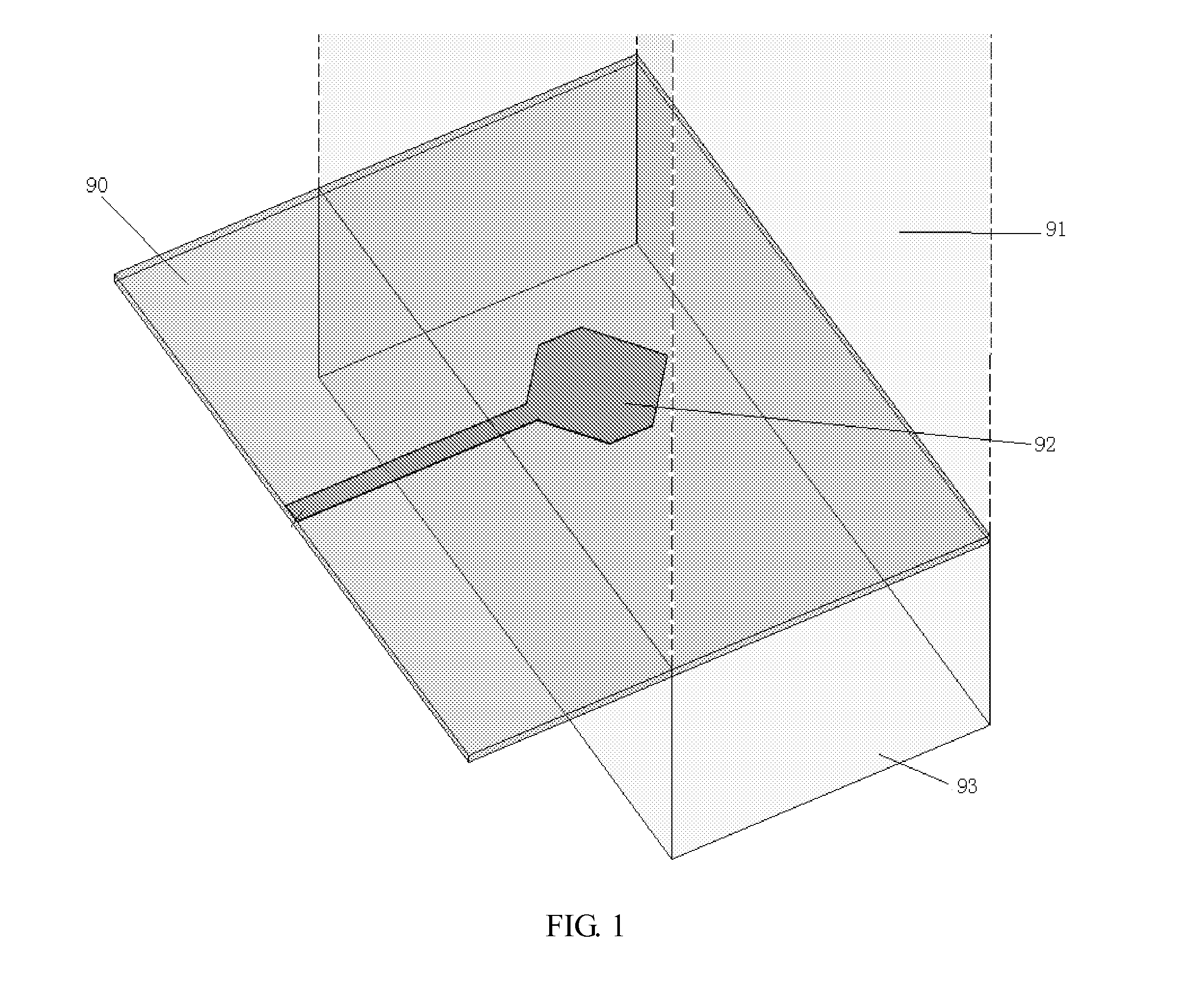

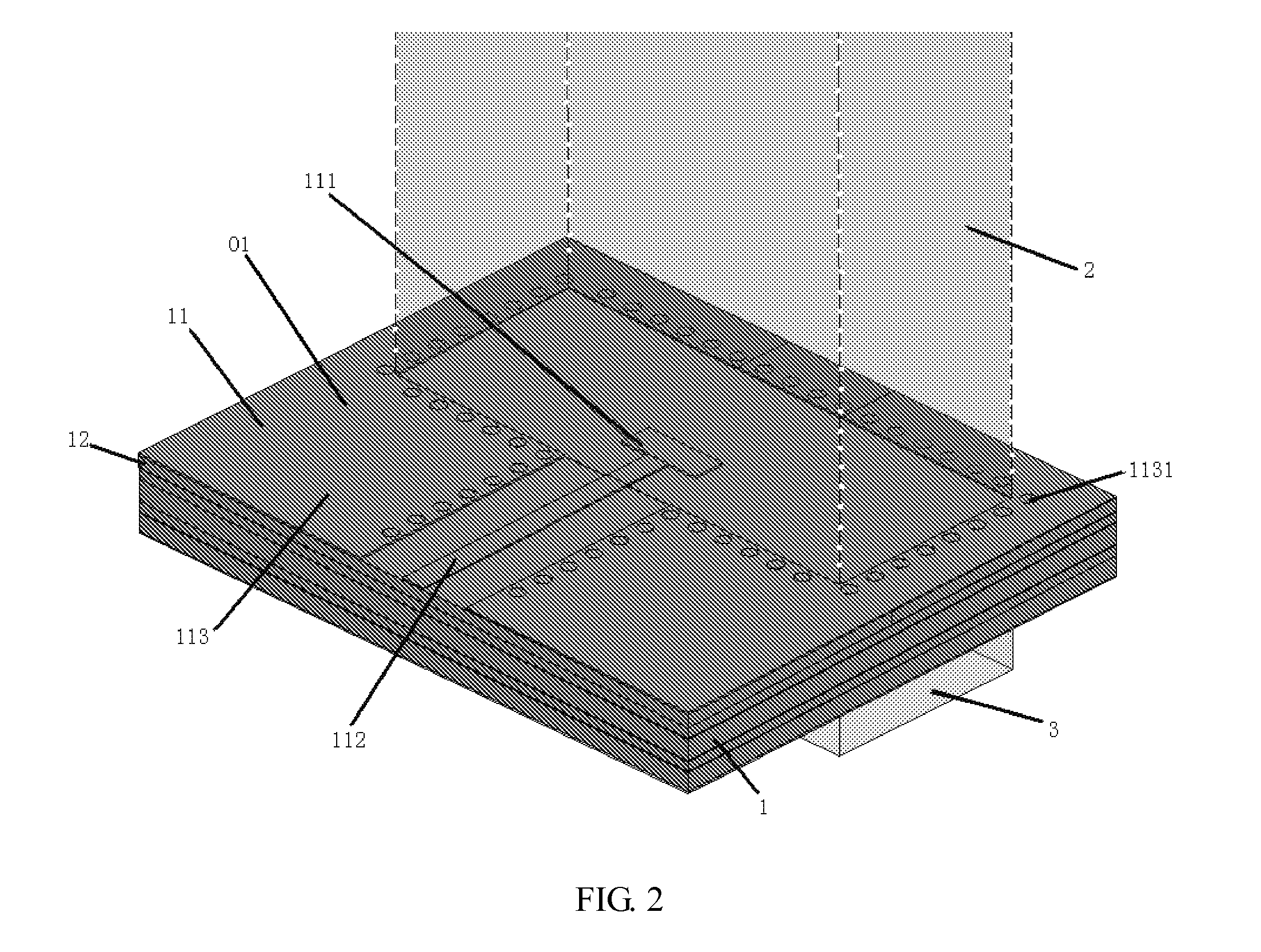

Waveguide conversion device

InactiveUS20120188030A1Improve electrical performance consistencyReduce the difficulty of assemblyWaveguidesCoupling devicesEngineeringMicrostrip

Embodiments of the present application disclose a waveguide conversion device. The waveguide conversion device includes: a multi-layer circuit board; and a waveguide cavity and a metal reflection cavity, located at two lateral sides of the multi-layer circuit board. The waveguide cavity and the metal reflection cavity are embedded in the multi-layer circuit board. The multi-layer circuit board is disposed with a micro strip line or a strip line and a match patch connected to the micro strip line or the strip line. The match patch is located in the waveguide cavity.

Owner:HUAWEI TECH CO LTD

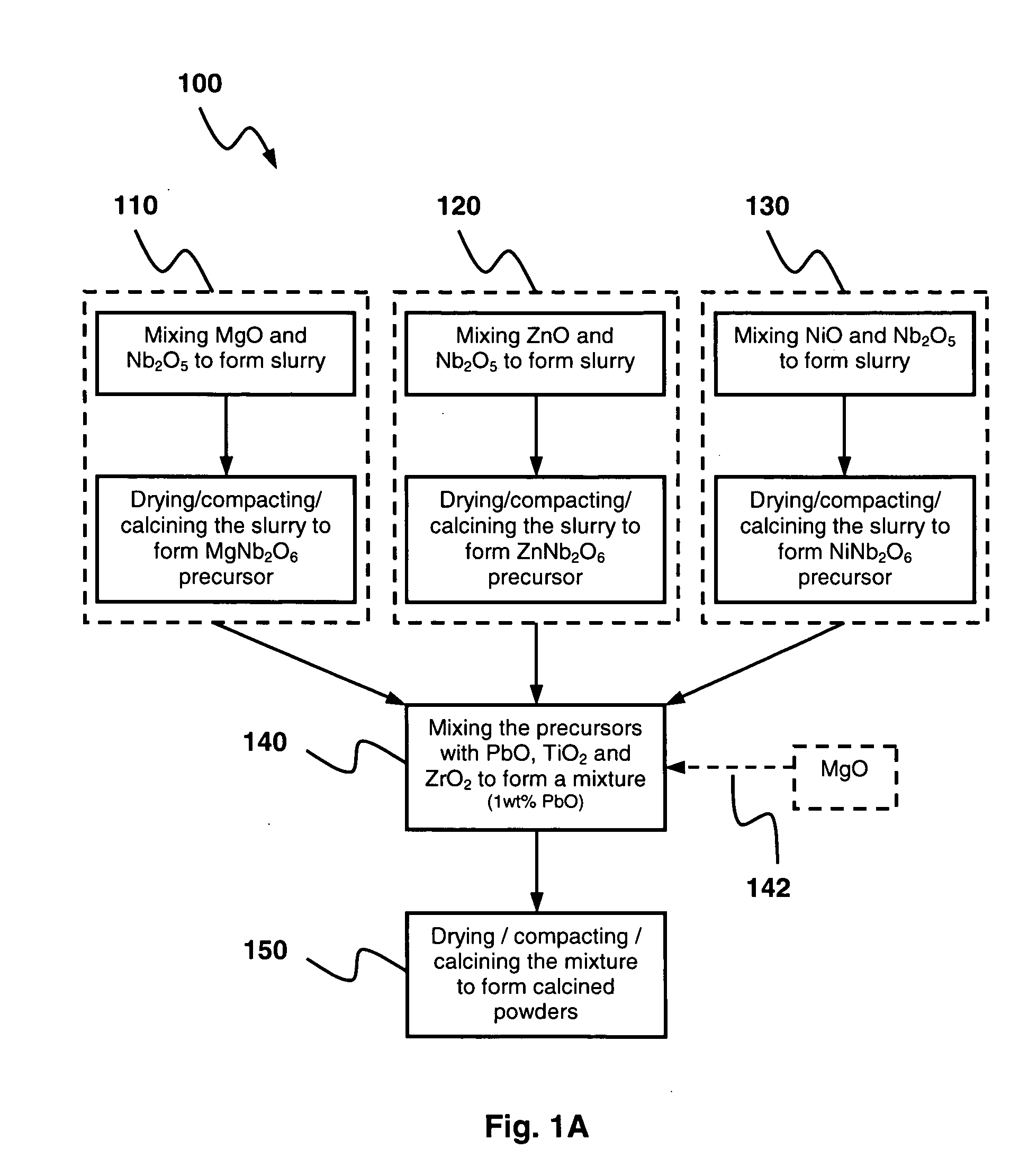

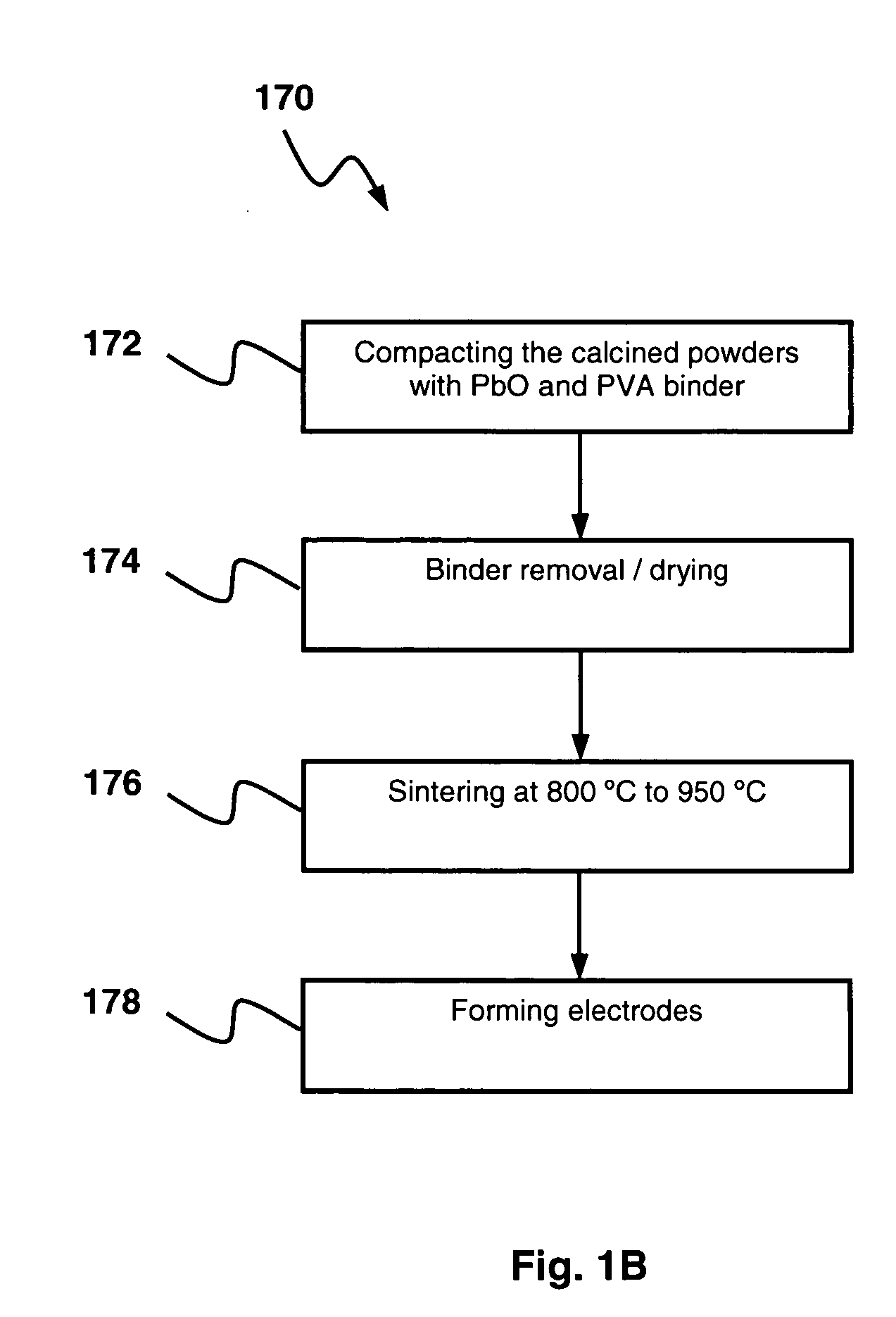

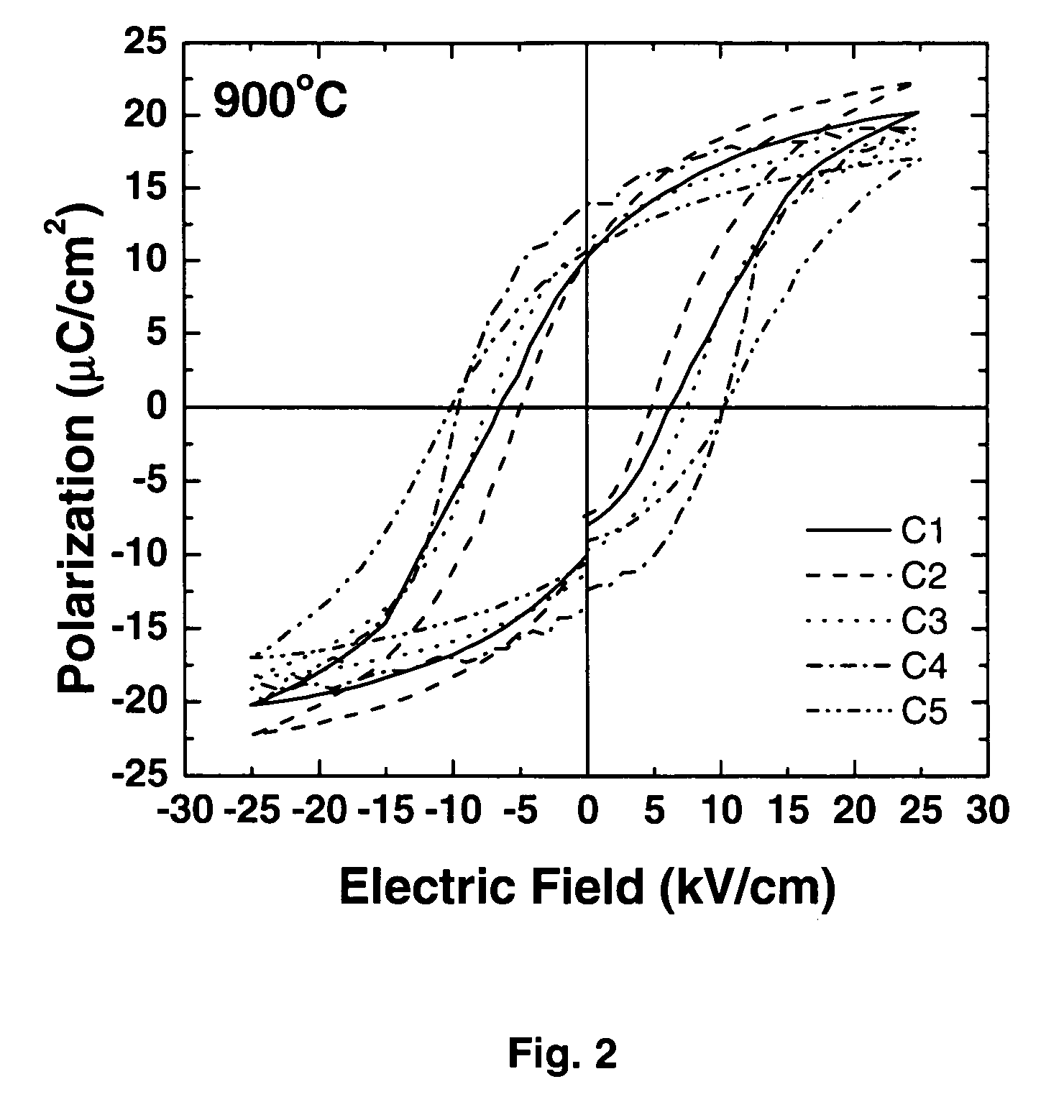

Ferroelectric ceramic material with a low sintering temperature

ActiveUS20070241304A1Promote formationSuppress formationPiezoelectric/electrostrictive device manufacture/assemblyDevice formSintering

The present invention provides new ferroelectric ceramic materials which can be sintered at a temperature lower than that of the conventional ferroelectric ceramic materials and upon sintering, devices formed of the new ferroelectric ceramic materials possesses excellent piezoelectric properties which are suitable for many industrial applications. The ferroelectric ceramic material includes a composition with a general formula of wPb(Ni1 / 3Nb2 / 3)O3−xPb(Zn1 / 3Nb2 / 3)O3−yPb(Mg1 / 3Nb2 / 3)O3−zPbZrO3−(1−w−x−y−z)PbTiO3, in which 0<w<1, 0<x<1, 0≦y<1, 0<z<1, w+x+y+z<1, and 0.5≦w+x+y. A method of preparing a ferroelectric ceramic material includes preparing MgNb2O6, ZnNb2O6 and NiNb2O6 powder precursors, mixing the precursors with PbO, TiO2 and ZrO2 to form a mixture and calcining the mixture.

Owner:AGENCY FOR SCI TECH & RES

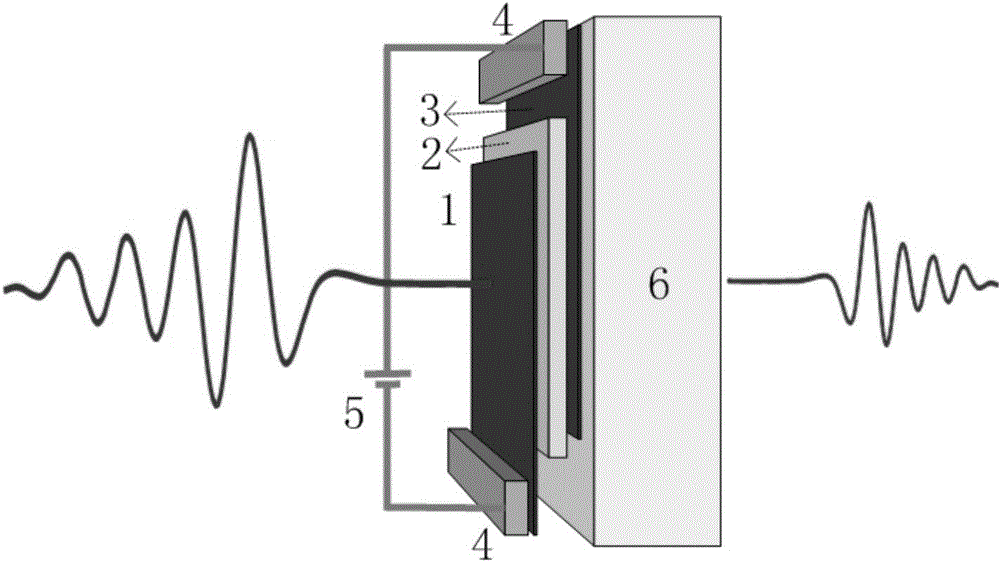

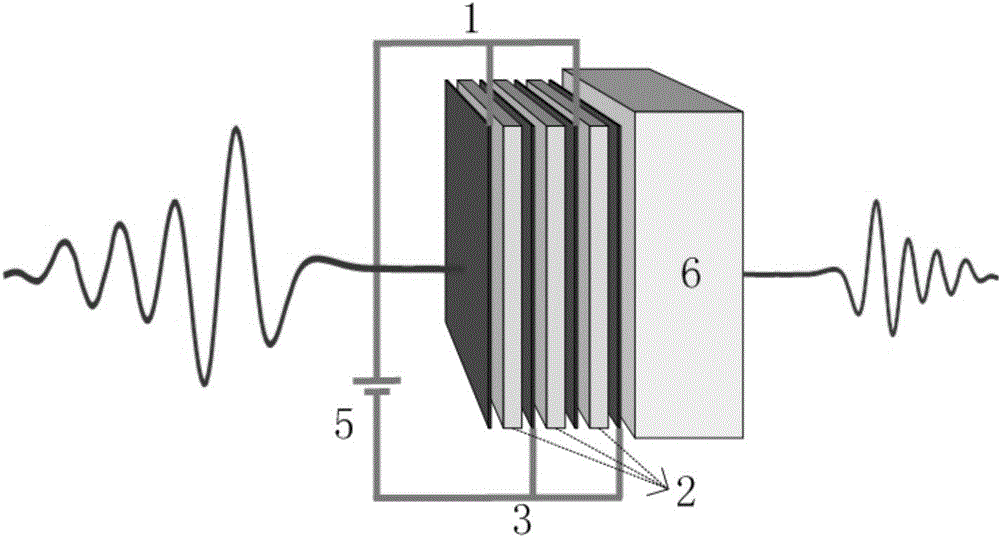

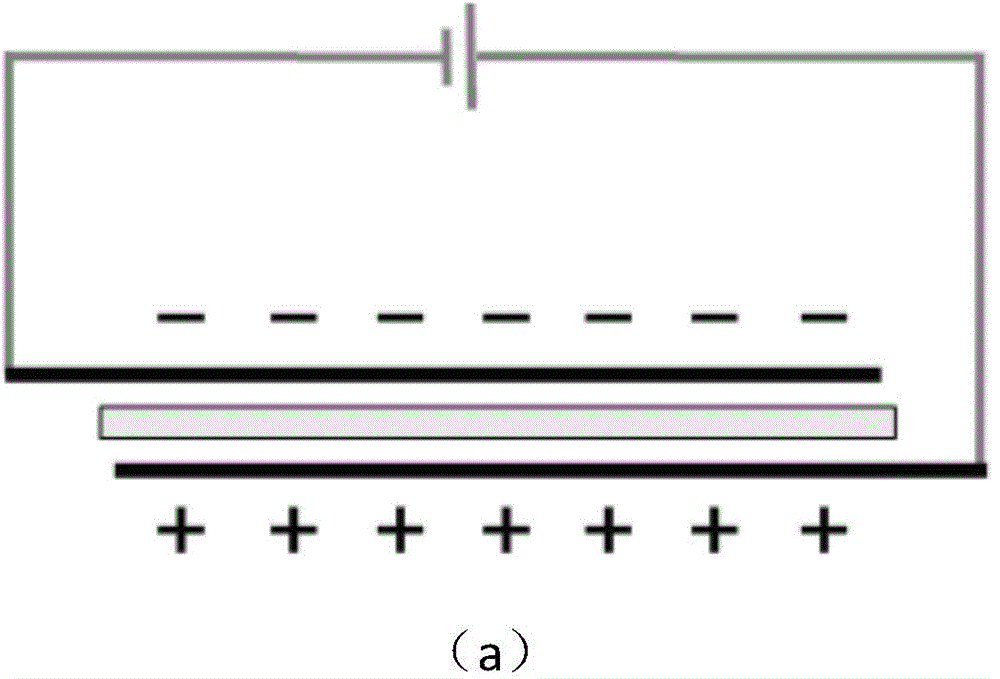

Grapheme based electronically controlled terahertz attenuation piece, preparation method and utilization method

InactiveCN103984125AConvenient lightingExcellent ElectricalNon-linear opticsUltrasound attenuationMedia layer

The invention discloses a grapheme based electronically controlled terahertz attenuation piece, a preparation method and a utilization method. The attenuation piece comprises a substrate; at least two layers of grapheme layers are paved on the substrate; a layer of medium layer is paved between every two adjacent layers of grapheme layers; the mediums layers separate the two layers of grapheme layers. According to the grapheme based electronically controlled terahertz attenuation piece, the regulation range of device attenuation degrees can be changed through different layers of the grapheme, a high attenuation degree is achieved theatrically, the attenuation degree parameters can be controlled due to control of the attenuation degree of the attenuation piece through voltage, and the application accuracy of the attenuation piece products is high and flexible.

Owner:NORTHWEST UNIV(CN)

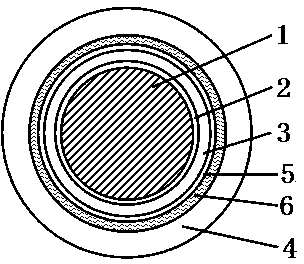

Double-sheath high voltage connecting cable used in electric vehicle and provided with ultra-soft aluminum conductor and method for manufacturing double-sheath high voltage connecting cable

ActiveCN104167254AGood flexibilityExcellent ElectricalPower cables with screens/conductive layersFlexible cablesElectrical conductorPolyolefin

The invention belongs to the technical field of cables, and relates to a double-sheath high voltage connecting cable used in an electric vehicle and provided with an ultra-soft aluminum conductor. The double-sheath high voltage connecting cable comprises the conductor, a wrapping tape, an insulating layer, an aluminum foil layer, a shielding layer and a sheath layer, and is characterized in that the conductor is formed by intertwisting the fifth kind of soft aluminum wires obtained after annealing treatment, and the cross sectional area of the conductor ranges from 1.5 mm<2> to 120 mm<2>; materials of which the insulating layer and the sheath layer are made meet one of the conditions that (1) both the insulating layer and the sheath layer are made of environment-friendly flame-retardant thermoplastic elastomers (TPEs) at the temperature of 125 DEG C, (2) both the insulating layer and the sheath layer are made of environment-friendly flame-retardant irradiation crosslinking polyolefin at the temperature of 125 DEG C and (3) the insulating layer is made of environment-friendly flame-retardant irradiation crosslinking polyolefin at the temperature of 125 DEG C and the sheath layer is made of environment-friendly flame-retardant thermoplastic elastomers (TPEs) at the temperature of 125 DEG C. The double-sheath high voltage connecting cable has the advantages of being softer, easier to bend, lower in self weight, lower in cost, highly resistant to high voltage and high currents, better in flame retardant effect and safer to use.

Owner:JIANGSU ZHONGLI GRP CO LTD

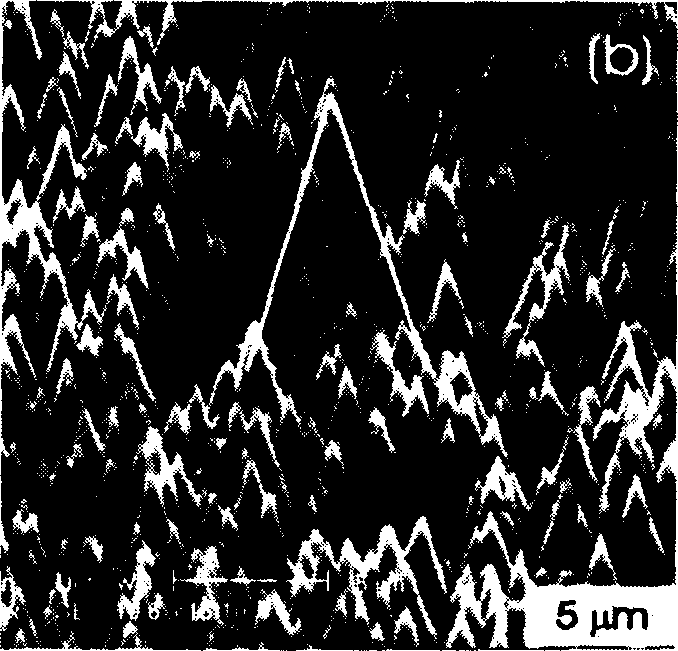

Diamond cone and its making process

InactiveCN1772947AHigh hardnessControllable hardnessPhotomechanical apparatusChemical vapor deposition coatingDiameter ratioHardness

The present invention relates to one kind of diamond cone and its making process, and the diamond cone has length / diameter ratio of 2-8, tip curvature radius smaller than 50 nm, and bottom diameter from 100 nm to decades of microns. The making process includes the following steps: coating one protecting layer onto silicon substrate; etching with focused ion beam to form silicon template with conic holes for making the diamond cones; eliminating the protecting layer with etching agent; and growing continuous diamond film in traditional method to obtain the diamond cones. The diamond cone has high wear resistance, high hardness and controllable shape, and is ideal structure for field emitting device, scanning probe system, nanometer impression and miniature tool. Compared with traditional diamond cone making process, the process of the present invention is simple, efficient and suitable for mass production.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

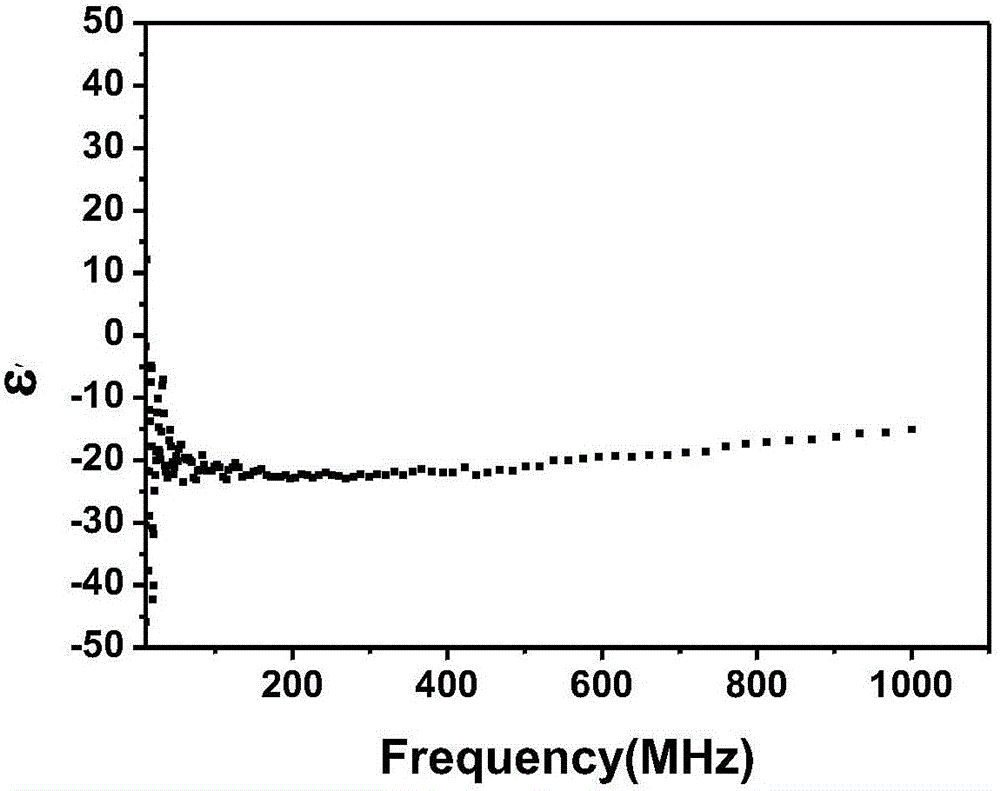

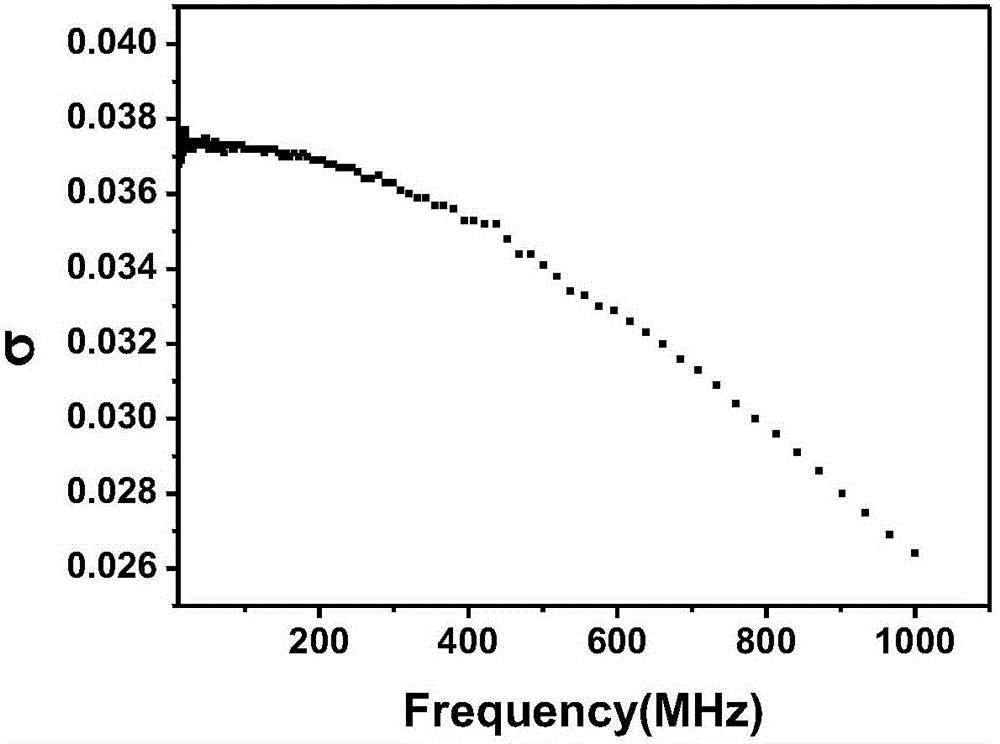

Method for preparing negative permittivity material from graphene, carbon nanometer tubes and phenolic resin

InactiveCN105802123APromotes conductive behaviorLimit leakage conduction currentDielectric lossCarbon nanotube

The invention discloses a method for preparing a negative permittivity material with graphene, carbon nanometer tubes and phenolic resin.The method includes the steps that graphene powder, carbon nanometer tube powder and phenolic resin powder are subjected to ball mill mixing, then a PVA solution is added, and the mixture is ground to be even; the powder is poured into a mold to be pressed into a sheet.A certain quantity of functional groups exist on the surface of the graphene in the composite material prepared with the method, and are not connected with each other and free of electric conduction, repulsive force exists between the functional groups, the functional groups are attached between sheet layers of the graphene and distributed on the surface of the graphene to form an interface layer used for limiting leakage conductive currents, and therefore dielectric losses are decreased.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com