Graphene-based ternary composite film gas sensor and preparation method thereof

A gas sensor, alkenyl ternary technology, applied in the direction of material electrochemical variables, etc., can solve the problems of high price, low specific capacitance value, low conductivity, etc., and achieve the effect of low cost, enhanced system structure, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Preparation of single-layer composite film gas sensor

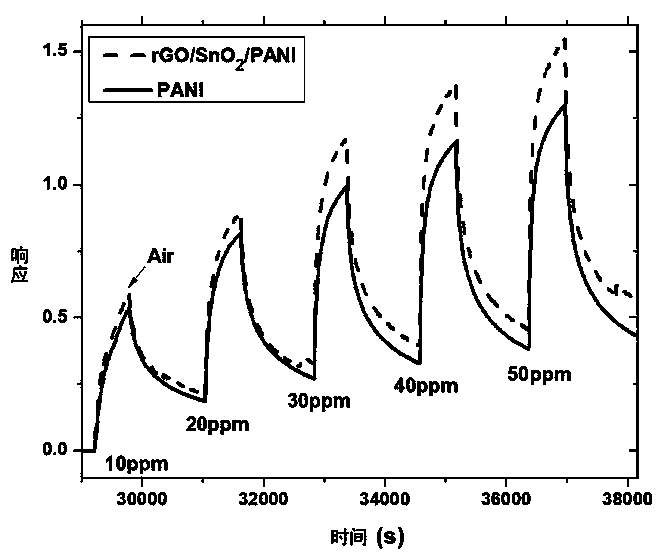

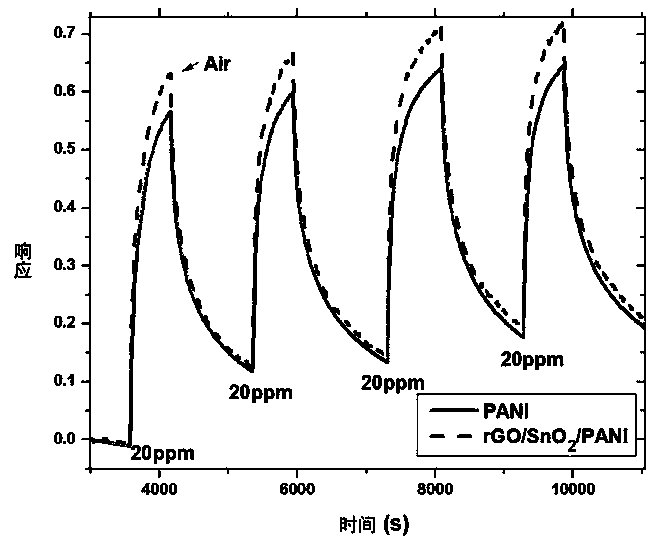

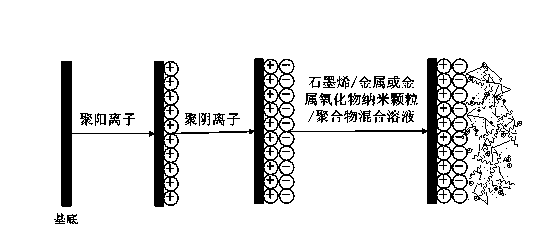

[0035] The gold interdigitated electrode is used as the sensor substrate, and its structure schematic diagram is as follows: figure 1 shown. Preparation of reduced graphene oxide (rGO) / tin dioxide (SnO) on the surface of interdigitated electrodes 2 ) / polyaniline (PANI) ternary composite film gas sensor, the specific implementation steps are as follows:

[0036] 1. Place the gold interdigitated electrode in acetone, ethanol, and deionized water in sequence for 15 minutes;

[0037] 2. For hydrophilic treatment, place the substrate in a mixed solution (1:1:5) of ammonia, hydrogen peroxide, and deionized water, and heat it to 70°C for 1 hour;

[0038] 3. Perform electrostatic treatment, place the interdigitated electrodes after hydrophilic treatment in PDDA and PSS solutions in turn, and keep them for 10 minutes respectively;

[0039] 4. Add 15 mg of graphene and 15 mg of tin dioxide mixed powder into...

Embodiment 2

[0045] Example 2 Preparation of single-layer self-assembled composite thin film gas sensor

[0046] The gold interdigitated electrode is used as the sensor substrate, and its structure diagram is as follows figure 1 shown. Preparation of reduced graphene oxide (rGO) / tin dioxide (SnO) on the surface of interdigitated electrodes 2 ) / polyaniline (PANI) ternary monolayer composite thin film gas sensor, the specific implementation steps are as follows:

[0047] 1. The gold interdigitated electrode was placed in acetone, ethanol, and deionized water for 15min in sequence;

[0048] 2. After hydrophilic treatment, the substrate was placed in a mixed solution (1:1:5) of ammonia water, hydrogen peroxide and deionized water, and heated to 70 °C for 1 h;

[0049] 3. Perform electrostatic treatment, and place the hydrophilic-treated interdigital electrodes in PDDA and PSS solutions in turn for 10 min respectively;

[0050] 4. In 50 ml of 1M HCl solution, 15 mg of graphene and 15 mg...

Embodiment 3

[0054] Example 3 Preparation of layered thin film gas sensor

[0055] 1. The gold interdigitated electrode was placed in acetone, ethanol, and deionized water for 15min in sequence;

[0056] 2. After hydrophilic treatment, the substrate was placed in a mixed solution (1:1:5) of ammonia water, hydrogen peroxide and deionized water, and heated to 70 °C for 1 h;

[0057] 3. Perform electrostatic treatment, and place the hydrophilic-treated interdigital electrodes in PDDA and PSS solutions in turn for 10 min respectively;

[0058] 4. Add 10mg graphene powder to 10ml, 1M HCl solution for sufficient ultrasonic and magnetic stirring to prepare graphene dispersion;

[0059] 5. Using the gas spraying process, the spraying height is 20cm, adding 1ml of the above graphene dispersion to the airbrush, placing the interdigital electrode in the central effective area, and evenly spraying the graphene dispersion on the interdigital electrode;

[0060] 6. 15 mg of tin dioxide mixed pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com