Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Controllable hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

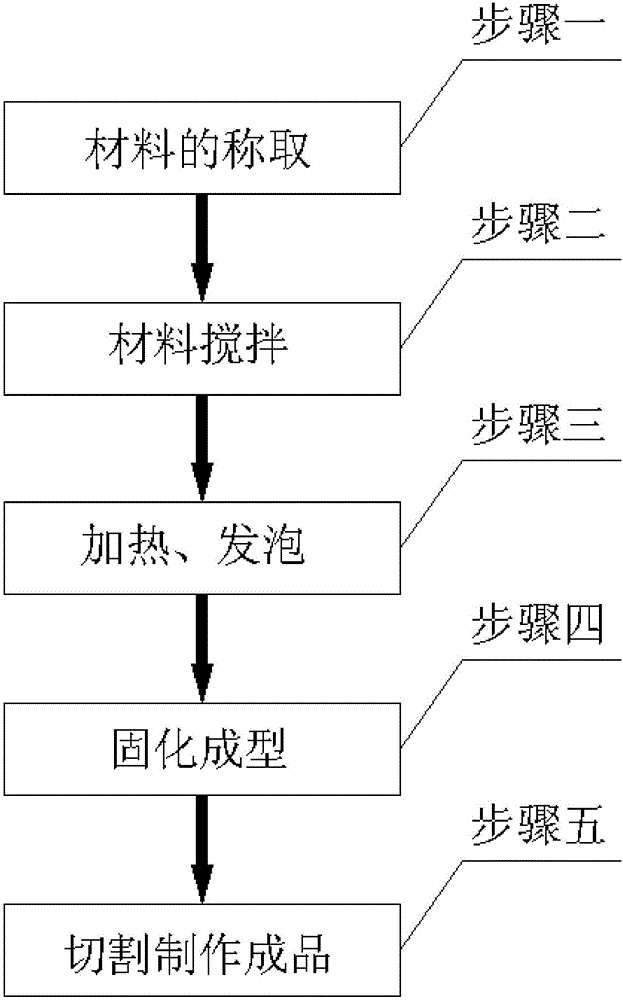

Foaming composite for shoes and preparation method of foaming composite

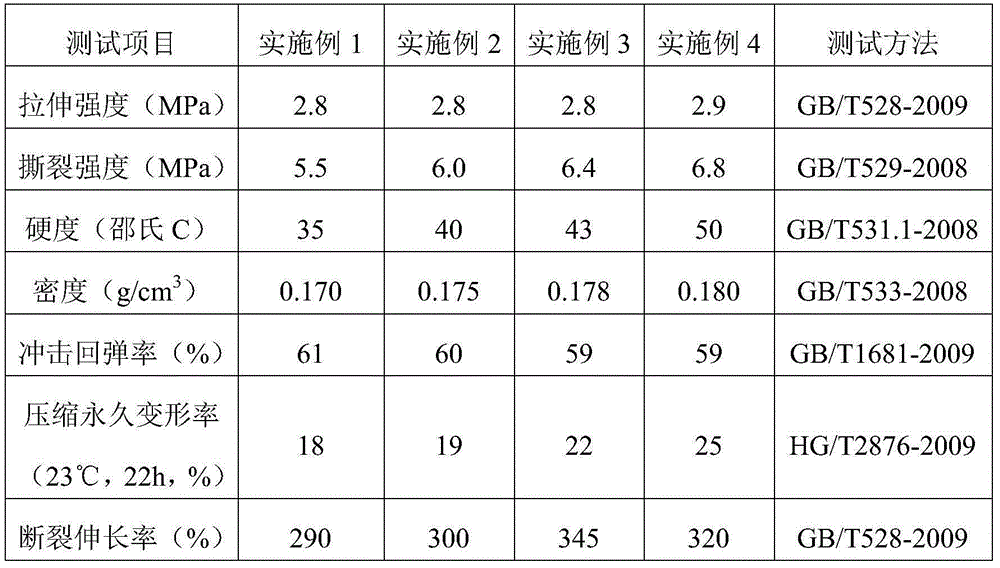

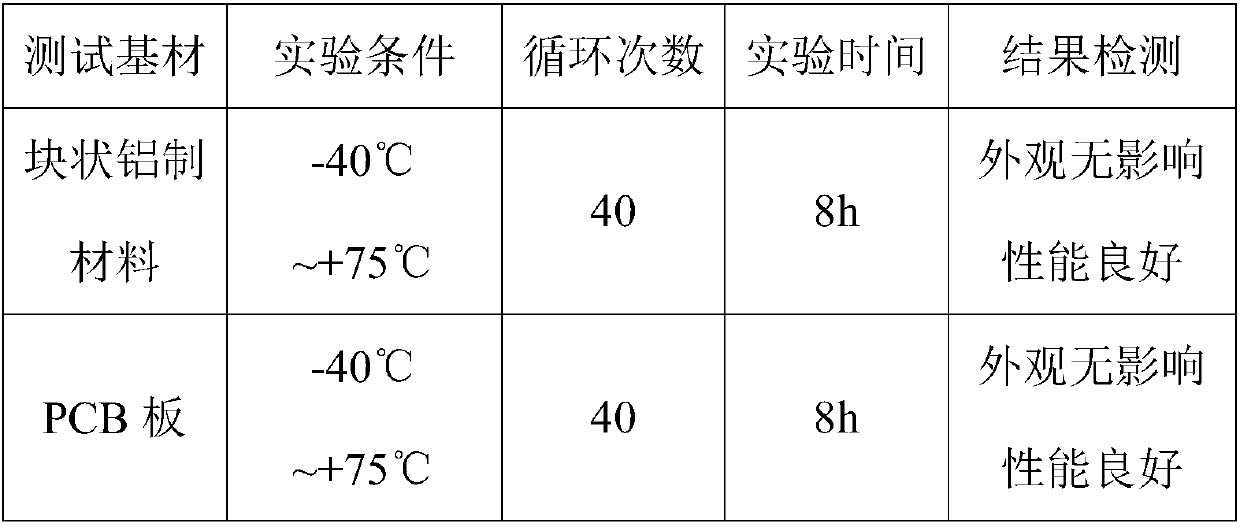

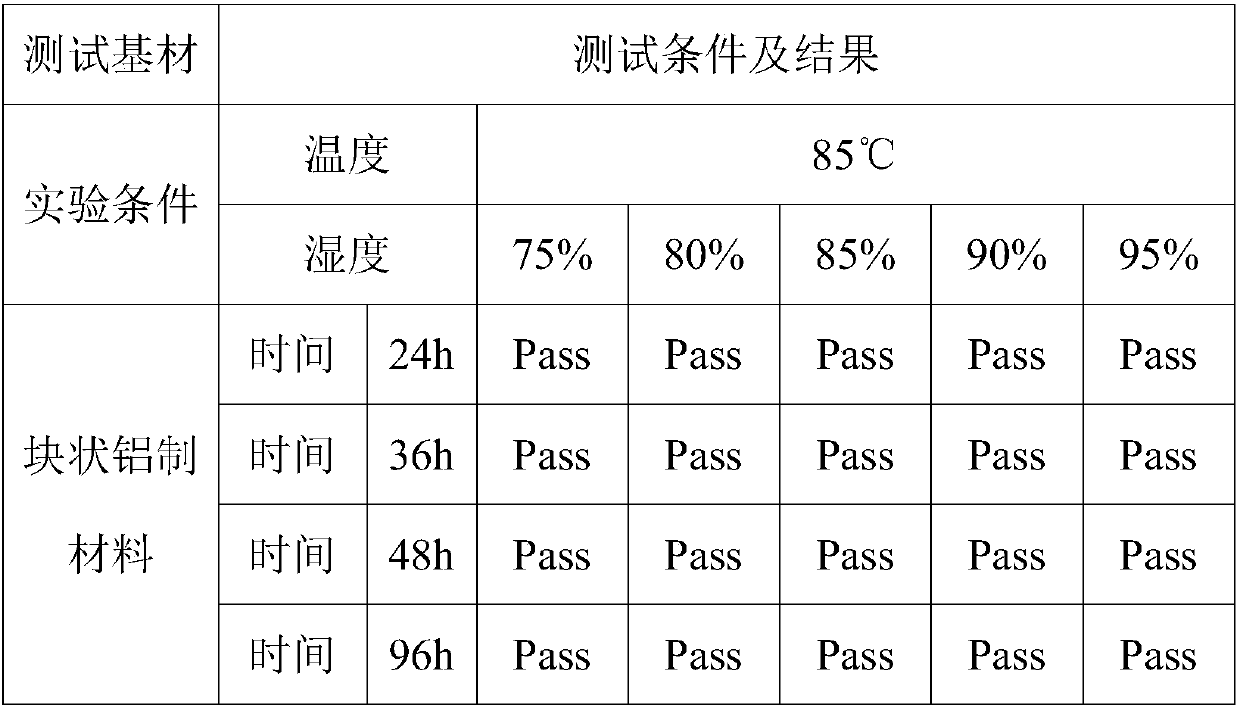

The invention provides a foaming composite for shoes and a preparation method of the foaming composite. The foaming composite for shoes is prepared from base stock, foaming agents, cross-linking agents, assistant crosslinker, activating agents and fillers. The total mass of the base stock is 100%, and 2%-10% of the foaming agents, 0.8%-3% of the cross-linking agents, 0.1%-2% of the assistant crosslinker, 1%-5% of the activating agents and 5%-50% of the fillers. The base stock is prepared from, by mass, 40%-90% of ethylene-octylene block copolymer, 5%-25% of ethylene-octylene random copolymer and 5%-35% of ethylene-vinyl acetate resin. The foaming composite for shoes is light in mass, high in rebound resilience, low in permanent compression deformation rate, low in cost, wide in application range and simple in preparation method. By means of the foaming composite for shoes, the technical problems that existing shoe soles are not resistant to wear or compression, poor in low-temperature toughness, poor in strength, prone to deformation, low in cost performance and the like are solved.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST +1

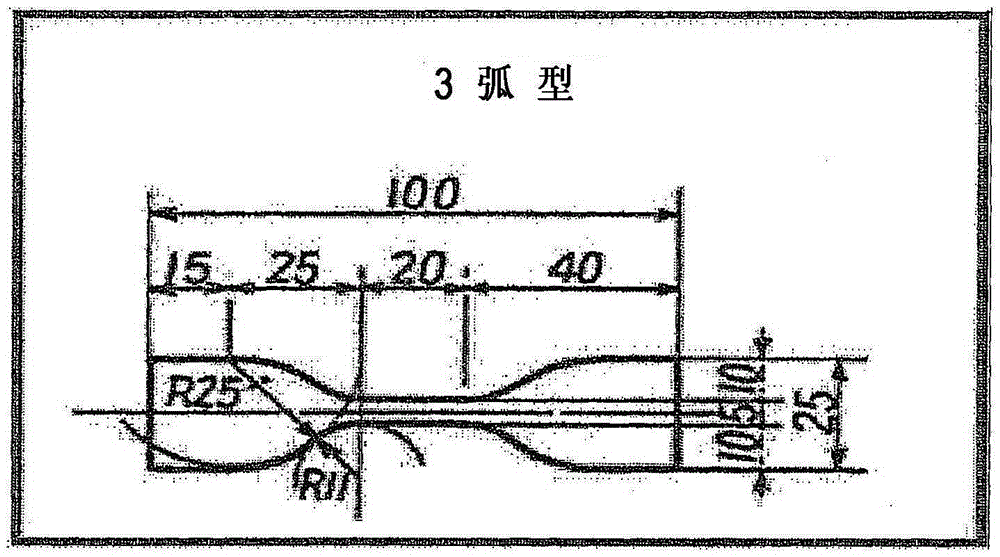

Method of producing stainless steel band for air injection steel reed

InactiveCN101033499AControllable hardnessSmall range of hardnessRoll mill control devicesMetal rolling arrangementsSolution treatmentSS - Stainless steel

The invention discloses a method for producing a kind of stainless steel which is used for jet norm. It manufactures with cold-rolled stainless steel strip with a thickness of 1.0~1.5mm to achieve the stainless steel through semi-finished billets rolling, solution treatment, finished rolling, skim handling, degreasing and drying, straightening, and tensile stress annealing.

Owner:无锡华生精密材料股份有限公司

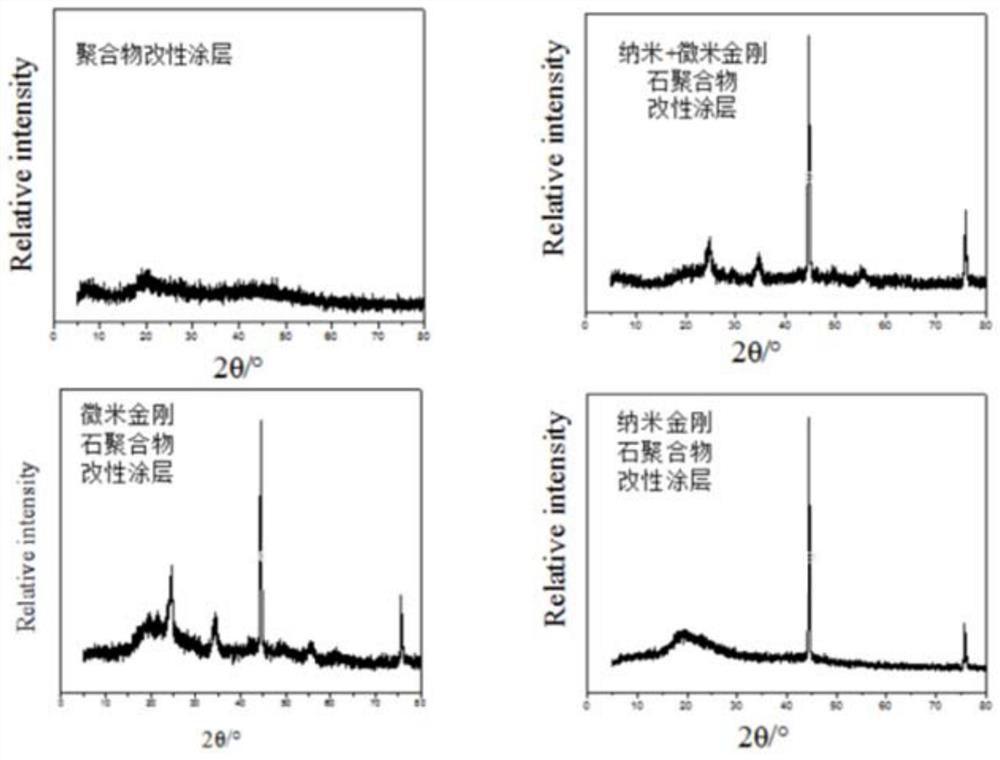

Preparation method of organic silicon nano protective coating of modulation structure

ActiveCN107686986AReduce stressImprove toughnessChemical vapor deposition coatingUnsaturated hydrocarbonDouble bond

The invention provides a preparation method of an organic silicon nano protective coating of a modulation structure and belongs to the technical field of plasmas. In the method, a reaction chamber isvacuumized, inert gas is led into the reaction chamber to enable a base material to move, preparation of an organic silicon coating and preparation of an organic fluorocarbon coating are alternately conducted, and thus the organic silicon-fluorocarbon multi-layer compact modulation structure is formed. Organic silicon monomer steam comprises the components of at least one type of organic silicon monomers comprising the structures containing double bonds, Si-Cl, Si-O-C, Si-N-Si and Si-O-Si or a ring-shaped structure and at least one type of mixtures of unsaturated hydrocarbon with polyfunctionality and hydrocarbon derivatives. According to the formed organic silicon-fluorocarbon multi-layer compact modulation structure, coating stress can be reduced, and the toughness of the coating is improved; meanwhile a transverse interface exists between organic silicon-fluorocarbon, a corrosion medium runs up against the transverse interface in the coating corrosion process and then corrosion transversely develops, so that longitudinal corrosion penetrating through the coating is not prone to being formed, and the situation that the corrosion medium penetrates through the coating to corrode protected materials and devices is avoided.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

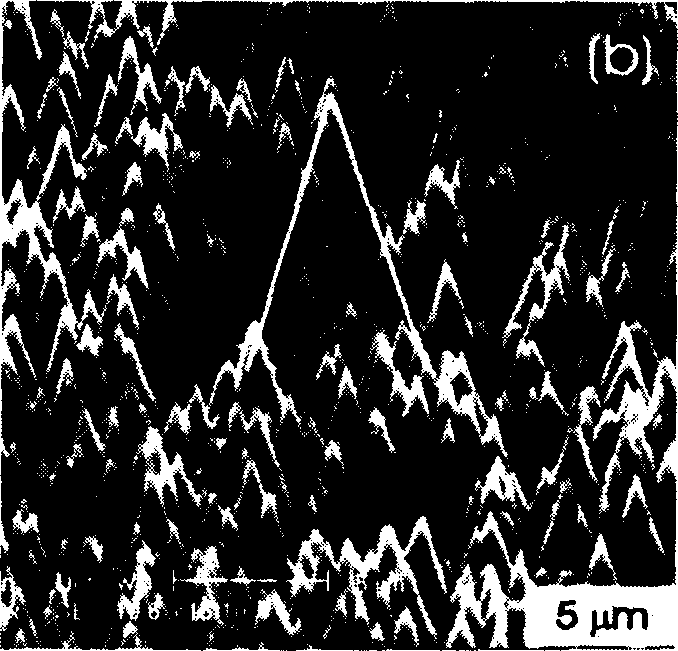

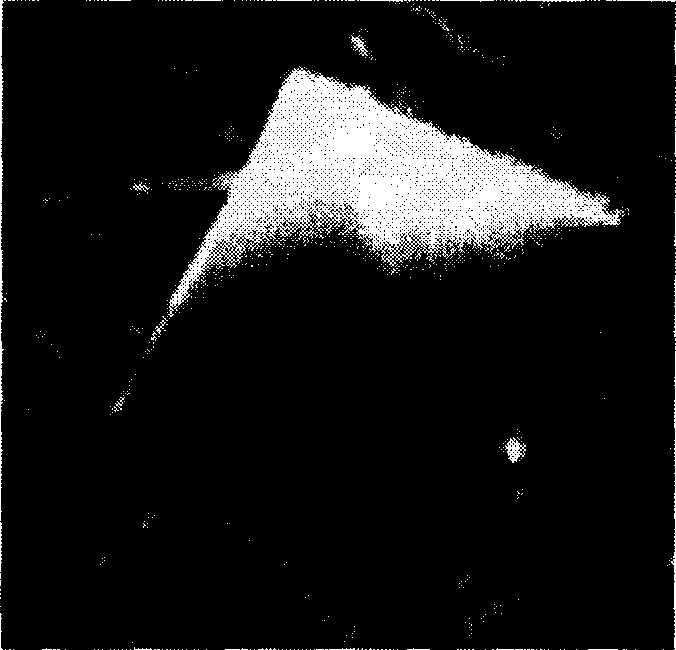

Diamond cone and its making process

InactiveCN1772947AHigh hardnessControllable hardnessPhotomechanical apparatusChemical vapor deposition coatingDiameter ratioHardness

The present invention relates to one kind of diamond cone and its making process, and the diamond cone has length / diameter ratio of 2-8, tip curvature radius smaller than 50 nm, and bottom diameter from 100 nm to decades of microns. The making process includes the following steps: coating one protecting layer onto silicon substrate; etching with focused ion beam to form silicon template with conic holes for making the diamond cones; eliminating the protecting layer with etching agent; and growing continuous diamond film in traditional method to obtain the diamond cones. The diamond cone has high wear resistance, high hardness and controllable shape, and is ideal structure for field emitting device, scanning probe system, nanometer impression and miniature tool. Compared with traditional diamond cone making process, the process of the present invention is simple, efficient and suitable for mass production.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Low-density high-bearing sponge and manufacturing process

The invention relates to a low-density high-bearing sponge. The low-density high-bearing sponge comprises the following materials in parts by weight: 0-50 parts of polyether polyol, 0-50 parts of polymer polyol, 0-15 parts of a flame adhesive, 0-0.5 part of a catalyst, 0-2 parts of silicon oil, 0-10 parts of a foaming gent and 45-56 parts of toluene diisocyanate. The foaming density of the sponge is reduced, while the sponge with the same size is produced, required production materials are greatly reduced, and therefore, production cost is reduced; and the relation between the bearing capacity of the sponge and the density of the sponge is relatively direct, under general conditions, the bearing capacity of the sponge can be reduced along with reduction of the density of the sponge, and once the bearing capacity of the sponge is reduced excessively, the material cannot be used; and by using appropriate polyether, the hardness of the sponge can be controlled, and meanwhile, the shortcomings that the bearing force is difficult to control and the sponge deforms easily due to over-low density are avoided.

Owner:上海馨源新材料科技有限公司

Injectable chitosan composite hydrogel capable of promoting myocardium repair and preparation method of injectable chitosan composite hydrogel

The invention discloses injectable chitosan / keratin composite hydrogel capable of promoting myocardium repair and a preparation method of the hydrogel. The hydrogel consists of four solutions, namely chitosan, sodium beta-glycerophosphate, genipin and keratin according to a volume ratio of 10: (1-5): (1-3): (0.1-0.5). The preparation method comprises the following steps: 1) extracting keratin from human fairs by using peracetic acid and Tris alkaline; 2) adjusting the pH value of a water-soluble chitosan solution by using sodium beta-glycerophosphate so as to be close to a microenvironment in a human body; 3) introducing genipin as a crosslinking agent, and controlling the gelling time of a hydrogel solution by changing the use amount of the genipin so as to achieve the purpose that the mixed solution can be rapidly gelled in situ after being injected into an organism. Experiments prove that the composite hydrogel has favorable biocompatibility and has the capability of remarkably promoting the growth of myocardial cells; the hydrogel is wide in sources of materials and low in cost and has a broad application prospect in the field of tissue engineering repair.

Owner:SOUTHEAST UNIV

Water-coated microcapsule using water-insoluble polymer as capsule material, and preparation method thereof

InactiveCN109012521ALow costReduce energy consumptionMicroballoon preparationMicrocapsule preparationCross-linkWater insoluble

The invention discloses a water-coated microcapsule using a water-insoluble polymer as a capsule material, and a preparation method thereof. The water-coated microcapsule is formed through the following steps: wrapping the outer surface of a core material with a mixed organic solution composed of a water-insoluble polymer compound, a water-insoluble polymerization monomer, an initiator and a cross-linking agent, carrying out a polymerization reaction and removing a solvent, wherein the core material is at least one of pure water and an aqueous solution containing a water-soluble substance. Thediameter of the water-coated microcapsule is 1.5-5.0 mm, and the crush strength of the water-coated microcapsule is 1-5 kpa. The method truly realizes the functions of the coating of the pure water and the aqueous solution containing the water-soluble substance, fills the gap in the field, and has the advantages of easily available raw materials, simple preparation process, low energy consumption, no complicated post-treatment process and low preparation cost, and the crush strength of the capsule is adjustable in a range of 1-5 kpa, and can meet the requirements of different application fields.

Owner:SICHUAN UNIV

Production method of stainless steel band used for internal round diamond blade

The invention discloses a production method of a stainless steel band used for an internal round diamond blade. The production method comprises the following steps: rolling a stainless steel cold-rolled intermediate blank with thickness of 0.6-1.2mm at least once by adopting a 12-roller cold rolling mill unit, thus obtaining a rolled semi-finished stainless steel band with thickness of 0.2-0.6mm, and carrying out solution treatment every time after the rolling; then rolling the semi-finished stainless steel band with thickness of 0.2-0.6mm by using the 12-roller cold rolling mill unit to obtain a finished stainless steel band with thickness of 0.1-0.12mm; and finally, cleaning and continuously relieving stress. By using the production method disclosed by the invention, the stainless steel band can be made after steps such as semi-finished product rolling, solution treatment, finished product rolling, cleaning, stretching, bending, straightening treatment and stress relieving treatment. The produced internal round diamond blade utilizing the stainless steel band has the characteristics that the hardness is easier to control, and the hardness scope can be controlled within Vickers hardness HV+ / -15. Therefore, in the process of manufacturing the internal round diamond blade, deformation and crack are not easy to occur, the blade service life is long. the blade can be used for about 1500 times, and the production cost is also reduced.

Owner:冶科金属有限公司 +2

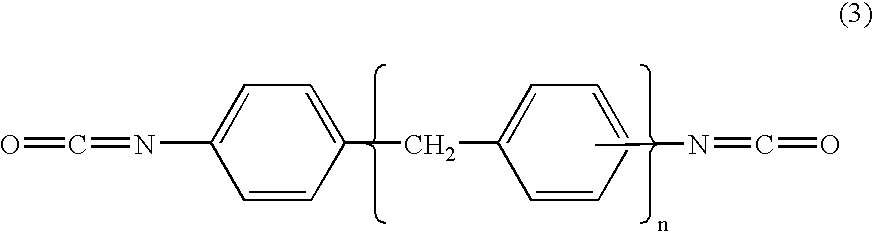

Process for preparing polyurethane powder adhesive by utilizing polyurethane prepolymer reversed phase suspension polymerization method

ActiveCN107083226AReduce processing linksMild reaction conditionsPolyureas/polyurethane adhesivesEnvironmental resistanceWater baths

The invention relates to a process for preparing a polyurethane powder adhesive by utilizing a polyurethane prepolymer reversed phase suspension polymerization method. The process comprises the steps that diamine and a compound chain extender are added into an inert oil phase, and a water-in-oil dispersing system is formed under heating and stirring in a water bath; a polyurethane prepolymer and a waterborne polyurethane hardening agent are sequentially and dropwise added for polymerization reaction, and a powdery polyurethane adhesive can be obtained through filtration and drying. The process has the advantages that oil-phase liquid obtained through filtration can be cyclically used and is economic and environmentally friendly, and the preparation time is shortened. The process route is convenient and easy to operate, the polyurethane powder adhesive can meet the requirements of adhesives in multiple fields, and large-scale production is hopeful in the future.

Owner:ZHUHAI COLLEGE OF JILIN UNIV

Quantum-dot dispersed resin forming body, preparation method thereof and quantum-dot dispersed body

PendingCN108546314AReduce the problem of poor water resistanceGood compatibilityQuantum dotResin matrix

The invention discloses a quantum-dot dispersed resin forming body, a preparation method thereof and a quantum-dot dispersed body, wherein the quantum-dot dispersed resin forming body comprises quantum dots dispersed in a polymeric material; a molecular chain of the polymeric material comprises a hydrophilic resin chain segment, an amphiphilic resin chain segment and a hydrophobic resin chain segment. The quantum-dot dispersed resin forming body, the preparation method thereof and the quantum-dot dispersed body disclosed by the invention have the beneficial effects that by the amphiphilic resin chain segment, the hydrophilic resin chain segment and the hydrophobic resin chain segment are introduced into a same dispersed system, so that when better compatibility of the dispersed system is ensured, the defects generated by single resin matrix is solved.

Owner:NANJING TECH CORP LTD

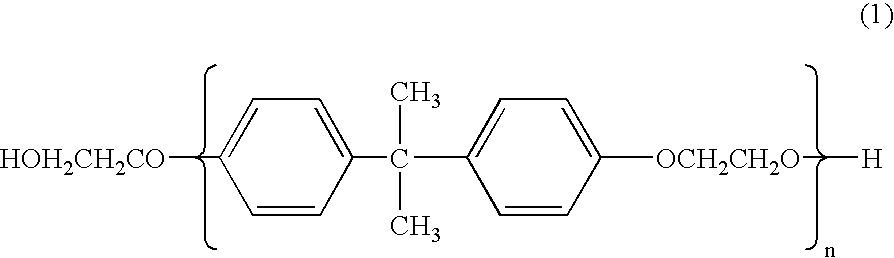

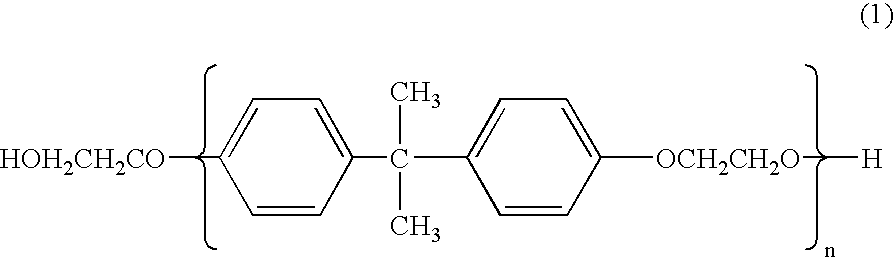

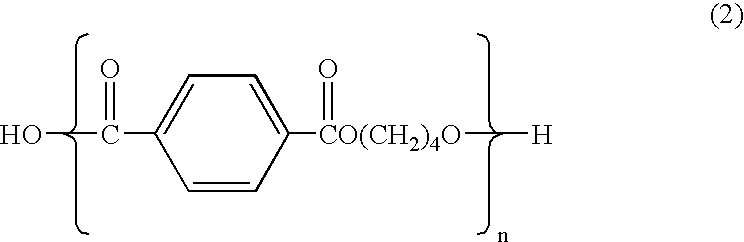

Thermoplastic elastomer resin

ActiveUS20060047089A1Improve hydrolysis resistanceImprove heat resistancePolyester coatingsElastomerHeat resistance

The present invention relates to a thermoplastic elastomer resin which has good melt viscosity, melt tension, and thermal resistance, wherein it is prepared by introducing a chain extender and a stabilizer for hydrolysis to a thermoplastic elastomer resin produced through melt polymerization in the presence of hydroxy carboxylic acid compound and subjecting the mixture to reactive extrusion to increase the molecular weight and crosslinking degree of the elastomer resin. The thermoplastic elastomer resin according to the present invention has good properties for automobile parts, particularly constant velocity joint boots and bellows.

Owner:SAMSANG CORP

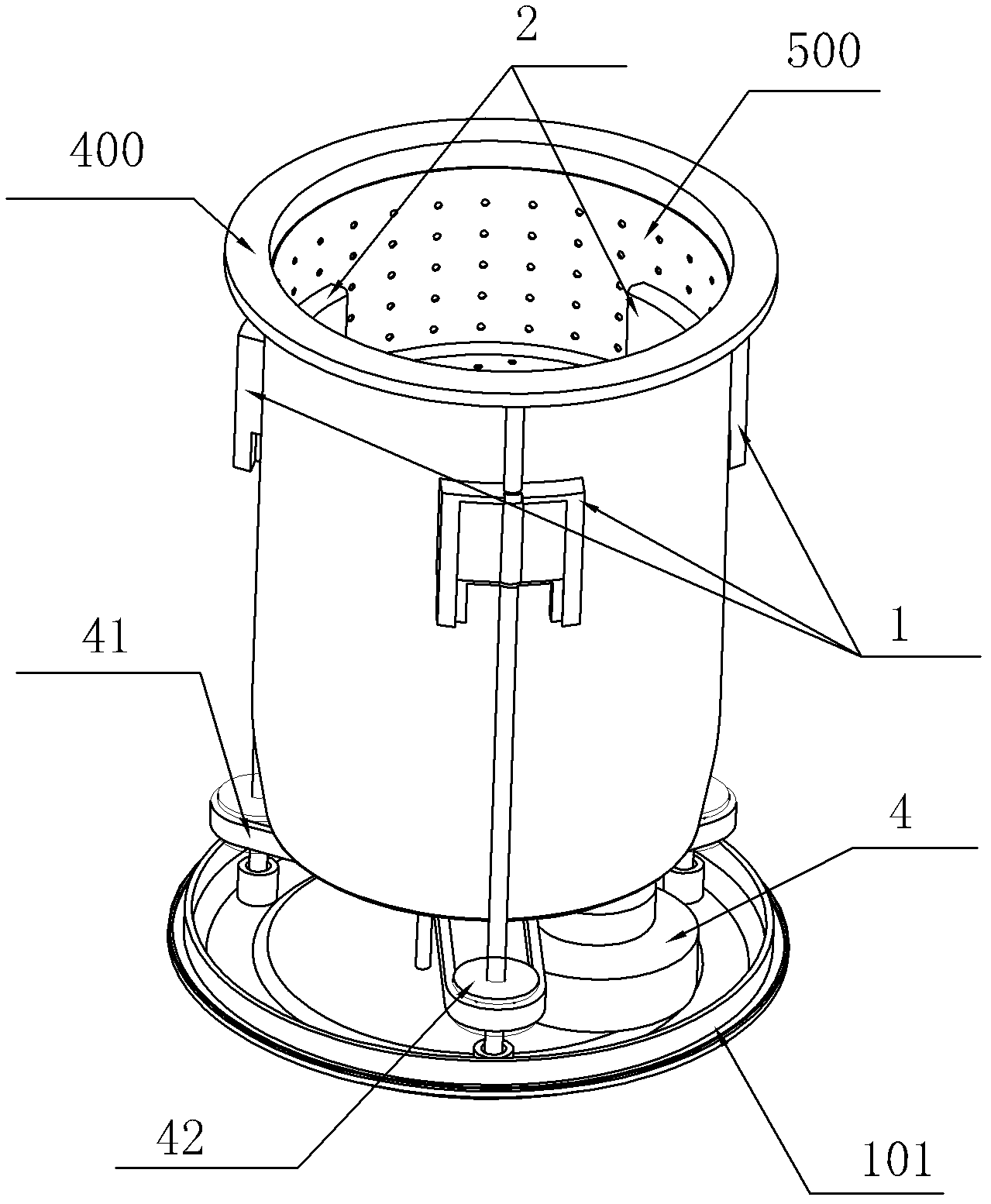

Bean curd machine

ActiveCN102550703AHardness controllableEasy to useKitchen equipmentCheese manufactureDrive motorSoybean oil

The invention discloses a bean curd machine which can prevent a mesh screen lifting drive mechanism from polluting made bean curd in processes of separating soybean milk from soybean dregs and squeezing bean curd. The bean curd machine comprises a machine head, a soybean milk barrel and a mesh screen, wherein screw rods are vertically arranged on the outer side surface of the soybean milk barrel,an active magnetic coupling assembly capable of moving along each screw rod up and down is arranged on each screw rod, the lower end of each screw rod is connected with a synchronization wheel arranged on a bean curd machine bottom shell, the synchronization wheel is connected with a drive motor arranged below the soybean milk barrel through a synchronization belt, slave magnetic coupling assemblies are fixedly arranged on the side wall in the mesh screen and are arranged corresponding to the active magnetic coupling assembly. In the whole process of separating the soybean milk from the soybean dregs, lifting the mesh screen and taking bean curd out, parts in a drive mechanism can not be always in contact with bean curd jelly or bean curd in the mesh screen, thus the made bean curd is safe and sanitary and is controllable in softness or harness, ad the bean curd machine has the advantages of time-saving property, convenience for use, low cost, and capability of enabling people to enjoy the interest of making the bean curd per se.

Owner:深圳市北鼎晶辉科技有限公司

Pole seal material for lithium ion batteries and preparation method of pole seal material for lithium ion batteries

The invention discloses a pole seal material for lithium ion batteries and a preparation method of the pole seal material for the lithium ion batteries. Fluorous rubber serving as a main matrix and auxiliary materials including auxiliary rubber, conductive filler, processing auxiliary agents, a peroxide vulcanizing agent, an auxiliary cross-linking agent and the like are mixed through an open mixing mill or an internal mixing mill to obtain low-compression-set high-conductivity rubber composite material. Under the condition that low resistance and high electrolyte resistance are guaranteed, consumption of the conductive filler is decreased, and the composite material integrates low compression set and high conductivity. The material has excellent conductivity and compressive deformation characteristics, a volume resistance range is 10<2> omega cm-10<4> omega cm, and high-temperature compressive deformation is 30% or below (150 DEG C*70h). In addition, the material is excellent in physical and mechanical property, heat resistance, ageing resistance and electrolyte resistance and is quite suitable for conductive pole sealing of the lithium ion batteries.

Owner:广州国机智能橡塑密封科技有限公司 +1

Brushing electroplating process method, clad layer and application

The invention provides a brushing electroplating process method, a clad layer and application, and relates to the technical field of brushing electroplating. The brushing electroplating process methodcomprises the steps that after a plated part is ground and polished, electric purifying treatment and activating treatment are carried out; and then after brushing electroplating treatment is carriedout, treatment after plating is carried out. The process is easy to operate, and all the steps of the brushing electroplating process method and the composition and dosage of brushing plating liquidare limited, so that the clad layer brush-plated on the surface of the plated part is controllable in thickness and hardness; and the obtained clad layer is bright, dense and good in adhesive force and comprehensive performance, and therefore the stability of the quality of products of all batches is guaranteed, and the problem that in the prior art, the thickness of a coating is hard to control,and the product batch quality is unstable is relieved. The clad layer is further provided and is manufactured through the brushing electroplating process method, and the clad layer is smooth, bright,dense, good in adhesive force, controllable in thickness and hardness and good in comprehensive quality.

Owner:STATE GRID HUBEI ELECTRIC POWER CO XIAOGAN POWER SUPPLY CO

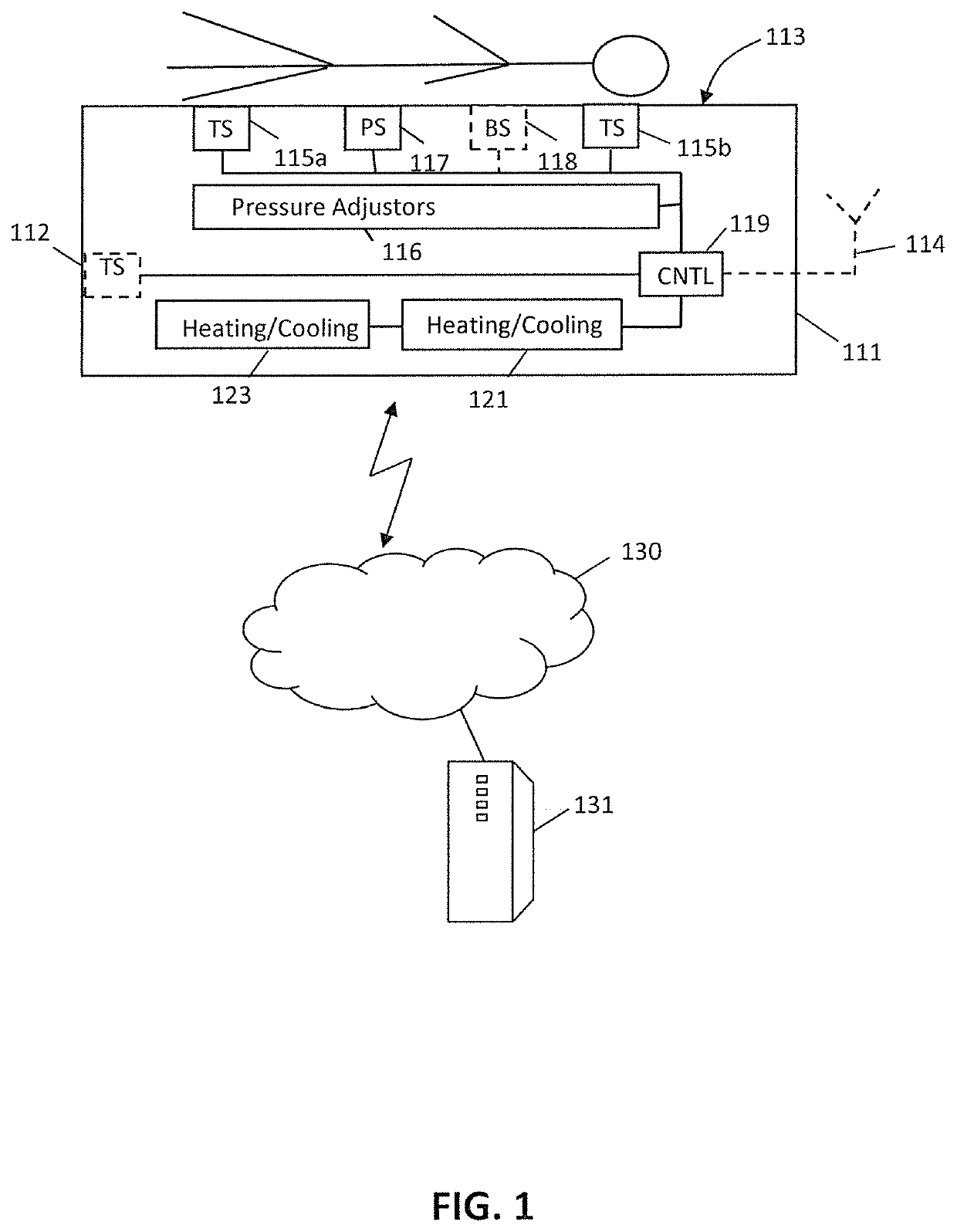

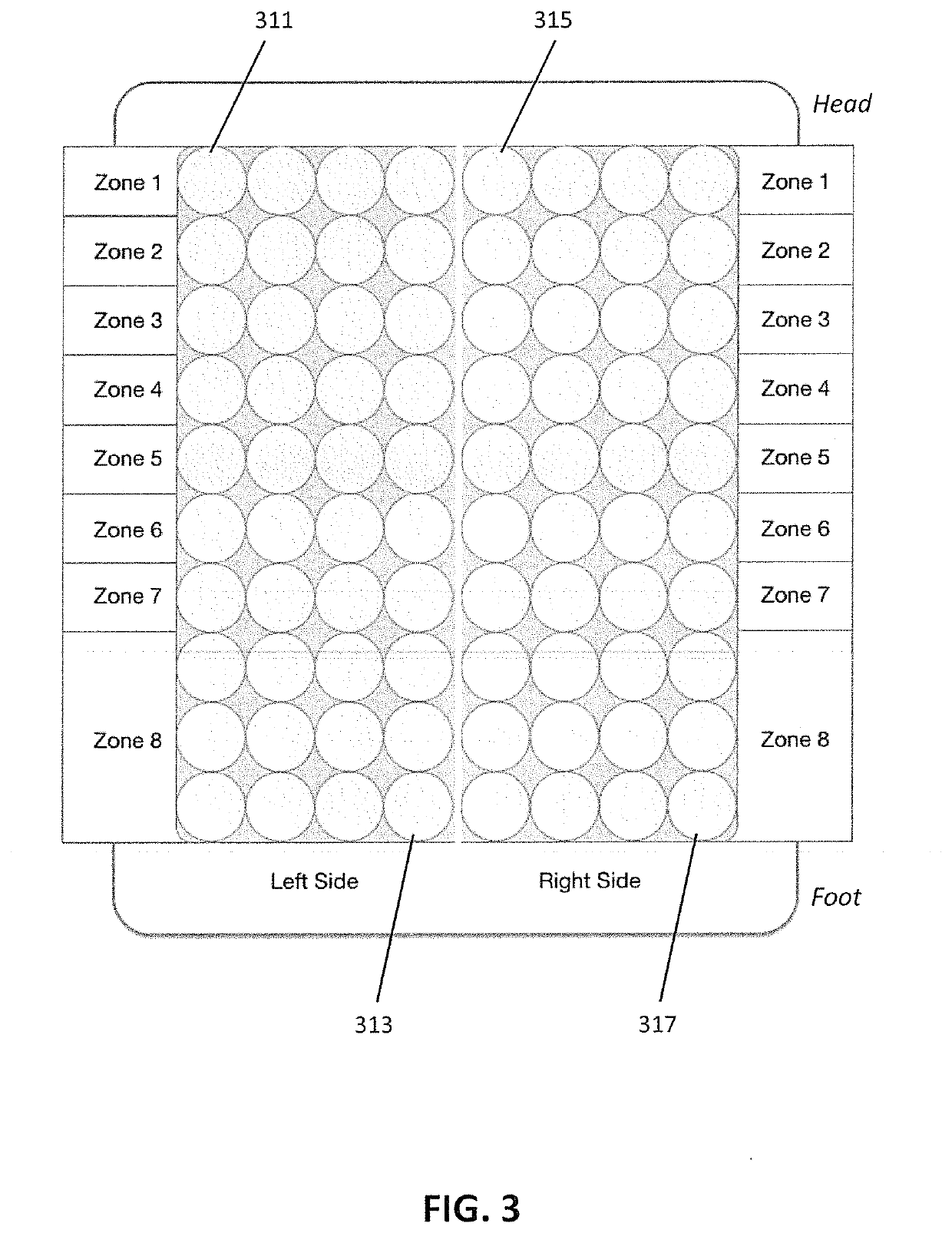

Sleep phase dependent pressure control and learning methods to optimize sleep quality

ActiveUS20190336720A1Controllable hardnessFully comprehendedElectrocardiographyStuffed mattressesSleep statePhysiology

A bed includes components to control pressure of a sleep surface, for example based on sleep position and sleep stages of a user. In some embodiments target pressures for the sleep surface are iteratively adjusted over multiple sleep sessions so to achieve improvements in sleep states and / or sleep quality for the user.

Owner:BRYTE INC

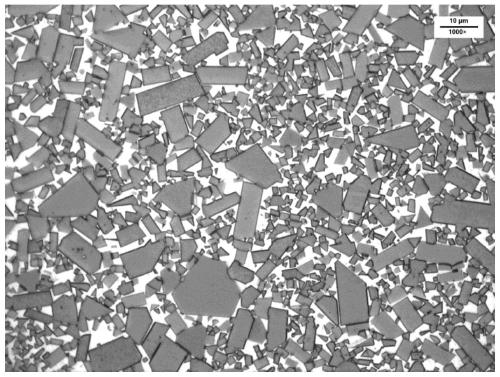

Hard alloy and preparation method and application

ActiveCN108441737AImproves adhesive wear resistancePlay a reinforcing roleChromium carbideCemented carbide

The invention discloses hard alloy. The hard alloy comprises 5-10wt% of cobalt, 0.5-1.5wt% of chromium carbide and the balance tungsten carbide, wherein tungsten carbide comprises non-flaky tungsten carbide grains and flaky crystal tungsten carbide, and flaky crystal tungsten carbide accounts for 18-40wt% of the total mass of the hard alloy. Since the hard alloy contains flaky crystal tungsten carbide in an appropriate quantity, adhesive wear resistance of the alloy can be remarkably improved, and applying the hard alloy to roll collars for stainless steel wire rolling can realize a 30% raiseof stainless steel wire rolling tonnage.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Thermoplastic elastomer resin

ActiveUS7157525B2Improve heat resistanceImprove hydrolysis resistancePolyester coatingsElastomerThermoplastic elastomer

The present invention relates to a thermoplastic elastomer resin which has good melt viscosity, melt tension, and thermal resistance, wherein it is prepared by introducing a chain extender and a stabilizer for hydrolysis to a thermoplastic elastomer resin produced through melt polymerization in the presence of hydroxy carboxylic acid compound and subjecting the mixture to reactive extrusion to increase the molecular weight and crosslinking degree of the elastomer resin. The thermoplastic elastomer resin according to the present invention has good properties for automobile parts, particularly constant velocity joint boots and bellows.

Owner:SAMSANG CORP

Thermoplastic rubber composition and molded product using same

The present invention relates to a thermoplastic rubber composition, comprising, (A) with respect to 100 weight parts of a block terpolymer of an aromatic vinyl compound and an alkene compound, (B) 50-100 weight parts of paraffin oil, (C) 30-70 weight parts of an inorganic additive (D) 5-30 weight parts of a polyolefin-based resin, and (E) 30-70 weight parts of an acryl-based resin. The thermoplastic rubber composition has freely adjustable hardness, and has increased thermoplastic resin bond strength even without an adhesive since the bond strength, which is measured using UTM according to a KS M 6518 peeling test, is 2-4 N / mm.

Owner:LOTTE ADVANCED MATERIALS CO LTD

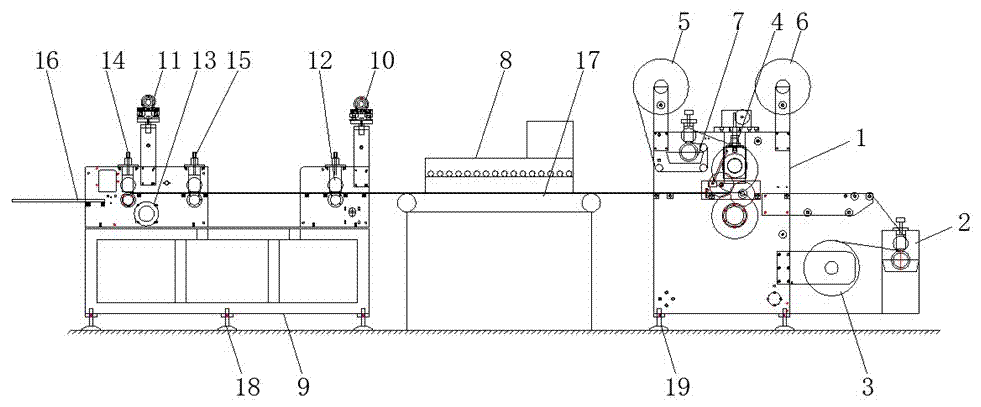

Heat conduction silica gel gasket calendering line

The invention discloses a heat conduction silica gel gasket calendering line. The heat conduction silica gel gasket calendering line comprises a calendering machine. The right side of the front face of the calendering machine is fixedly connected with a treating agent gluing device. A lower film is fixedly connected to the part, located on the left side of the treating agent gluing device, of the front face of the calendering machine. The part, located on the top of the lower film, of the front face of the calendering machine is fixedly connected with a calendering device. The part, located on the left side of the calendering device, on the top of the calendering machine is provided with an upper film. The part, located on the right side of the calendering device, on the top of the calendering machine is provided with glass fiber cloth. The part, located on the left side of the calendering device, on the front face of the calendering machine is provided with a glue groove. The heat conduction silica gel gasket calendering line can completely replace a press vulcanizer and a manual glass die blade coating technology, the product production efficiency of an improved heat conduction silica gel gasket calendering machine is 3-4 times of the product production efficiency of the two previous kinds, produced products are controllable in softness and hardness, the thickness can be controlled, and the problem that softness, hardness and thickness of the products produced by the existing press vulcanizer and the manual glass die blade coating technology are not controllable, and consequently the production efficiency is low is solved.

Owner:东莞市森捷智能装备有限公司

Titanium and titanium alloy surface hardening and surface functionalization process

ActiveCN111690925AWide range of optionsControllable hardnessHeat inorganic powder coatingTitaniumCoated surface

The present invention relates to a method of forming a surface coating by hydrogen treatment of titanium. The method comprises the steps of loading a to-be-processed workpiece A into a rigid mold, designing the size of an inner cavity of the mold to have a certain gap with the workpiece, and filling titanium-containing mixed powder B into the gap between the rigid mold and the workpiece to obtainan assembly C; loading the assembly into a high-temperature furnace, introducing hydrogen, and absorbing hydrogen; and then carrying out vacuum annealing dehydrogenation on the workpiece and the mold,shrinking the size of the workpiece after dehydrogenation, and conveniently taking out the workpiece from the mold. According to the mentod, in order to improve the quality of the coating, high-temperature sintering can be carried out after the dehydrogenation; and the high temperature sintering temperature is greater than the hydrogen absorption temperature and the dehydrogenation temperature. The invention provides the brand-new coating preparation method for the first time, the coating can be added with a plurality of functions and is convenient for large-scale application, meanwhile, thesurface hardness, density, thickness and porosity of the obtained coating are controllable, the uniformity is good, the surface of a complex shape can be treated, and the performance is obviously improved.

Owner:CENT SOUTH UNIV

Preparation method of chewable tablets containing chitosan oligosaccharide

InactiveCN105455126AControllable hardnessControllable intensityFood ingredient functionsVacuum pumpingGelatin film

The invention discloses a preparation method of chewable tablets containing chitosan oligosaccharide. In terms of the total weight of the chewable tablets containing the chitosan oligosaccharide, the ratio of the chitosan oligosaccharide to collagen to gelatin is (1%-5%):(20%-40%):(60%-80%). The method comprises steps as follows: (1) the chitosan oligosaccharide, the collagen and the gelatin are mixed in solid states; (2) a chitosan oligosaccharide, collagen and gelatin mixture obtained in Step (1) is added to purified water with the weight 20-40 times that of the mixture, and a mixture is stirred at the temperature of 61-85 DEG C for 10-20 min and introduced to a filter net for press filtering treatment twice; (3) chitosan oligosaccharide, collagen and gelatin homogenate obtained in Step (2) is poured into a die, and the thickness of a homogenate layer is controlled to range from 5 mm to 30 mm; (4) the die containing the chitosan oligosaccharide, collagen and gelatin homogenate in Step (3) is placed into a freezing dryer to be prefreezed at the temperature of subzero 40 DEG C for 40-60 min and then subjected to vacuum pumping for freeze-drying until the moisture content of a freeze-dried film is controlled to range from 3wt% to 8wt%; (5) the chewable tablets are prepared from the chitosan oligosaccharide, collagen and gelatin film prepared in Step (4) with a die cutting method.

Owner:LIAONING SANHE WINE

Bean curd machine

ActiveCN102550703BControllable hardnessEasy to useKitchen equipmentCheese manufactureCouplingEngineering

The invention discloses a bean curd machine which can prevent a mesh screen lifting drive mechanism from polluting made bean curd in processes of separating soybean milk from soybean dregs and squeezing bean curd. The bean curd machine comprises a machine head, a soybean milk barrel and a mesh screen, wherein screw rods are vertically arranged on the outer side surface of the soybean milk barrel,an active magnetic coupling assembly capable of moving along each screw rod up and down is arranged on each screw rod, the lower end of each screw rod is connected with a synchronization wheel arranged on a bean curd machine bottom shell, the synchronization wheel is connected with a drive motor arranged below the soybean milk barrel through a synchronization belt, slave magnetic coupling assemblies are fixedly arranged on the side wall in the mesh screen and are arranged corresponding to the active magnetic coupling assembly. In the whole process of separating the soybean milk from the soybean dregs, lifting the mesh screen and taking bean curd out, parts in a drive mechanism can not be always in contact with bean curd jelly or bean curd in the mesh screen, thus the made bean curd is safe and sanitary and is controllable in softness or harness, ad the bean curd machine has the advantages of time-saving property, convenience for use, low cost, and capability of enabling people to enjoy the interest of making the bean curd per se.

Owner:深圳市北鼎晶辉科技有限公司

Flexible dual-curing resin composition and preparation method of molded body thereof

PendingCN114349922AHigh activityShort exposure timePolyurea/polyurethane coatingsPolymer sciencePrepolymer

The invention relates to a flexible dual-curing resin composition and a preparation method of a molded body of the flexible dual-curing resin composition. A, a polyurethane prepolymer; b, a nitrogen-containing heterocyclic acrylic acid compound; c. A chain extender; wherein the molar ratio of the-NCO group contained in the polyurethane prepolymer a to the nitrogen-containing heterocyclic acrylic acid compound b is 0.98-1.02, and the molar ratio of the-NCO group contained in the polyurethane prepolymer a to the-OH group contained in the chain extender c is 0.98-1.02. The composition disclosed by the invention can be used for preparing a molded product with relatively high precision and complexity, and the molded product obtained after light and heat dual curing has the characteristics of good molding effect, flexibility and comprehensive performance.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

Irbesartan hydrochlorothiazide composite preparation and preparation method thereof

ActiveCN110898021AImprove diffusion abilityControllable hardnessOrganic active ingredientsPharmaceutical non-active ingredientsLACTOSE MONOHYDRATEMedicine

The invention provides a compound preparation of irbesartan hydrochlorothiazide and a preparation method thereof. The composite preparation comprises a tablet core, which includes the following ingredients (by weight): 150.0 parts of irbesartan, 12.5 parts of hydrochlorothiazide, 24.0-29.0 parts of microcrystalline cellulose, 10.0-17.0 parts of lactose monohydrate, 15.0-19.5 parts of croscarmellose sodium, 12.0-18.0 parts of hydroxypropyl methylcellulose, 8.0-11.0 parts of colloidal silicon dioxide and 7.0-9.0 parts of magnesium stearate. Compared with the equivalent weight of irbesartan and hydrochlorothiazide, microcrystalline cellulose and lactose monohydrate are also used as fillers in the tablet core of theinvention, and the sum of maximum total weights of microcrystalline cellulose and lactose monohydrate is less than 50, thus greatly reducing the amount of the fillers and lowering the material cost of the composite preparation; moreover, a proper amount of hydroxypropyl methylcellulose ensures the dissolution of the effective components.

Owner:瀚晖制药有限公司

Pearlite rail having superior abrasion resistance and excellent toughness

This pearlite rail consists of a steel including: in terms of percent by mass, C: 0.65 to 1.20%; Si: 0.05 to 2.00%; Mn: 0.05 to 2.00%; P‰¤ 0.0150%; S‰¤ 0.0100%; Ca: 0.0005 to 0.0200%, and Fe and inevitable impurities as the balance, wherein a head surface portion which ranges from surfaces of head corner portions and a head top portion to a depth of 10 mm has a pearlite structure, a hardness Hv of the pearlite structure is in a range of 320 to 500, and Mn sulfide-based inclusions having major lengths in a range of 10 to 100 µm are present at an amount per unit area in a range of 10 to 200 / mm 2 in a cross-section taken along a lengthwise direction in the pearlite structure.

Owner:NIPPON STEEL CORP

Injectable chitosan composite hydrogel for promoting myocardial repair and preparation method thereof

The invention discloses injectable chitosan / keratin composite hydrogel capable of promoting myocardium repair and a preparation method of the hydrogel. The hydrogel consists of four solutions, namely chitosan, sodium beta-glycerophosphate, genipin and keratin according to a volume ratio of 10: (1-5): (1-3): (0.1-0.5). The preparation method comprises the following steps: 1) extracting keratin from human fairs by using peracetic acid and Tris alkaline; 2) adjusting the pH value of a water-soluble chitosan solution by using sodium beta-glycerophosphate so as to be close to a microenvironment in a human body; 3) introducing genipin as a crosslinking agent, and controlling the gelling time of a hydrogel solution by changing the use amount of the genipin so as to achieve the purpose that the mixed solution can be rapidly gelled in situ after being injected into an organism. Experiments prove that the composite hydrogel has favorable biocompatibility and has the capability of remarkably promoting the growth of myocardial cells; the hydrogel is wide in sources of materials and low in cost and has a broad application prospect in the field of tissue engineering repair.

Owner:SOUTHEAST UNIV

A preparation method of organosilicon nano protective coating with modulated structure

ActiveCN107686986BReduce stressImprove toughnessChemical vapor deposition coatingPlasma technologyDouble bond

A preparation method for an organosilicon nano-protective coating having a modulation structure, belonging to the field of plasma technology. In the method, the vacuum degree within a reaction chamber is adjusted, an inert gas is introduced, a base material is caused to move, and organosilicon coating preparation and organic fluorocarbon coating preparation are performed alternately to form an organosilicon-fluorocarbon modulation multi-layer compact structure. An organosilicon monomer vapour component is a mixture of at least one organosilicon monomer containing a double bond, Si-Cl, Si-O-C, Si-N-Si or Si-O-Si structure or an annular structure and at least one polyfunctional unsaturated hydrocarbon or hydrocarbon derivative. The formed organosilicon-fluorocarbon modulation multi-layer compact structure reduces coating stress and increases coating toughness. Lateral interfaces are present between the organosilicon and the fluorocarbon, corrosive media encounter the lateral interfaces during corrosion of the coating, and corrosion develops laterally, so that longitudinal corrosion which penetrates the coating is not prone to forming, thereby preventing the corrosive media from passing through the coating and corroding protected materials and devices.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

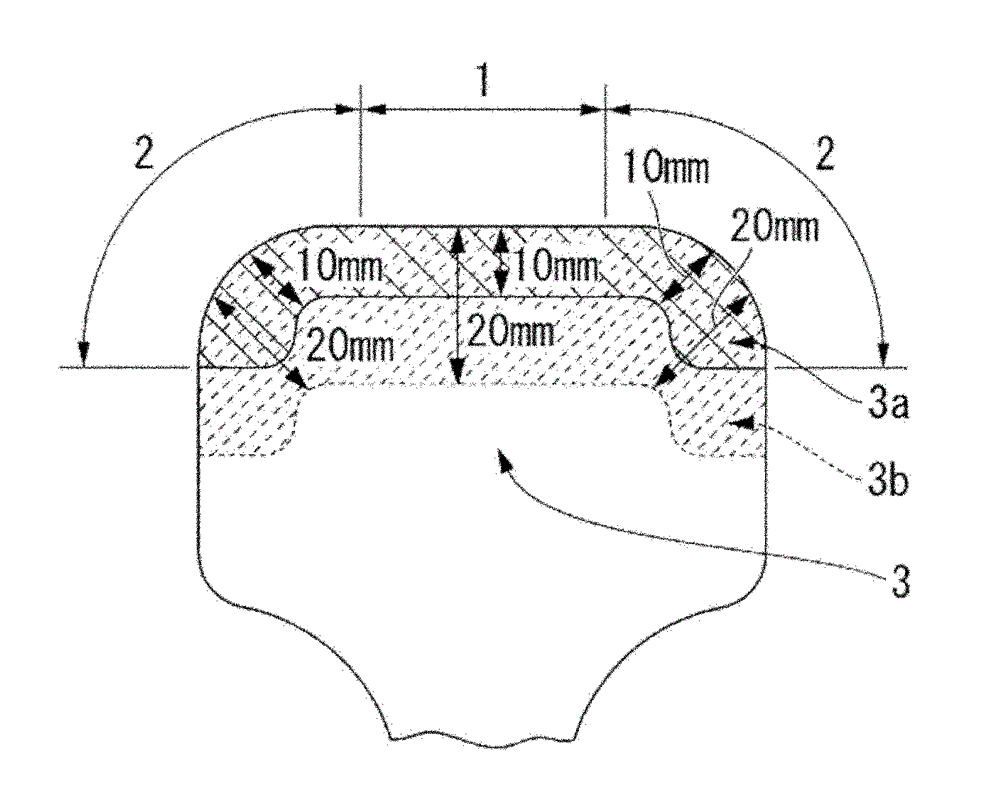

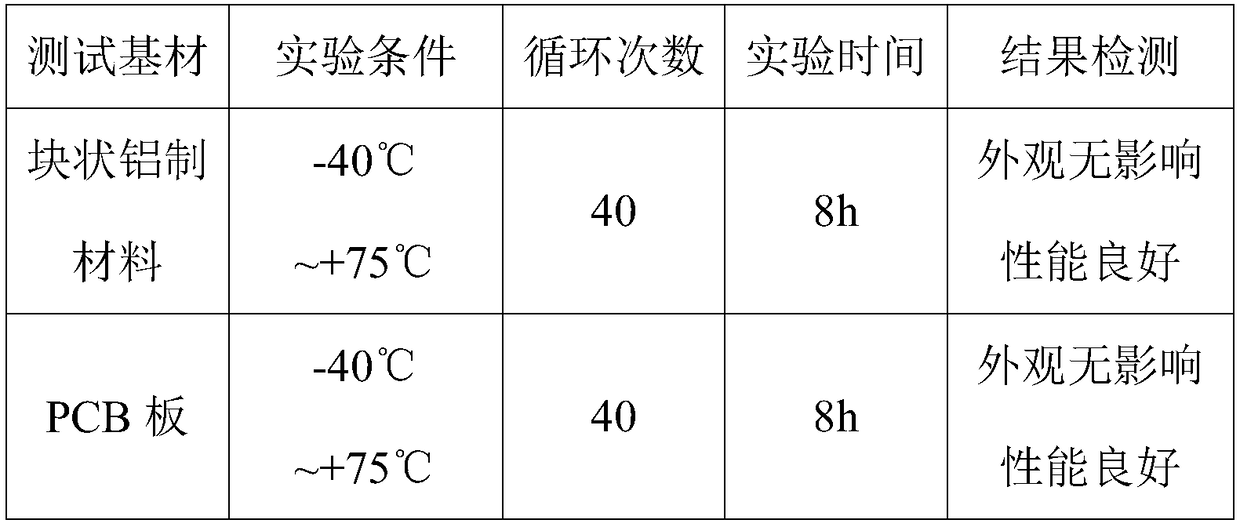

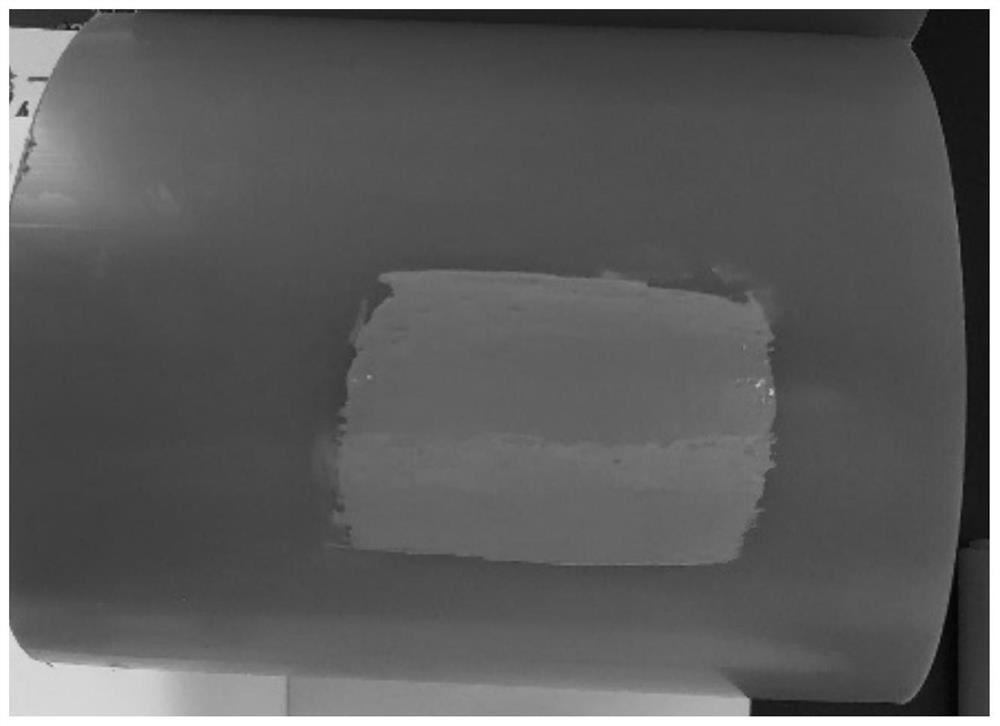

Method for controllably preparing MPP trenchless pipe surface coating by using diamond powder

ActiveCN113563791AControllable hardnessHigh hardnessPolyurea/polyurethane coatingsIsocyanateSilane coupling

The invention discloses a method for controllably preparing an MPP trenchless pipe surface coating through diamond powder, and relates to the technical field of pipe surface coating preparation. A silane coupling agent with amino as an end group and micron and nano diamond powder are used for pretreatment, a water-based dispersion is formed in hyperbranched polyester, the water-based dispersion is compounded with water-based polyisocyanate, and then the surface of a MPP trenchless pipe is coated with a compounded material, so that a high-hardness coating is formed on the surface of the MPP trenchless pipe. The MPP trenchless pipe surface coating which is controllably prepared from the diamond powder is successfully obtained through an organic / inorganic composite material forming method. The modified coating with controllable hardness is obtained by regulating and controlling the proportion of different modified powder, then the high-hardness MPP trenchless pipe surface coating is successfully prepared, and the MPP trenchless pipe surface coating has the characteristics of controllable hardness, safe and environment-friendly manufacturing process, simple coating process, uniform shape and the like.

Owner:安徽明能电气有限公司 +1

A process for preparing polyurethane powder adhesive by using polyurethane prepolymer reverse phase suspension polymerization method

ActiveCN107083226BReduce processing linksMild reaction conditionsPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention relates to a process for preparing a polyurethane powder adhesive by utilizing a polyurethane prepolymer reversed phase suspension polymerization method. The process comprises the steps that diamine and a compound chain extender are added into an inert oil phase, and a water-in-oil dispersing system is formed under heating and stirring in a water bath; a polyurethane prepolymer and a waterborne polyurethane hardening agent are sequentially and dropwise added for polymerization reaction, and a powdery polyurethane adhesive can be obtained through filtration and drying. The process has the advantages that oil-phase liquid obtained through filtration can be cyclically used and is economic and environmentally friendly, and the preparation time is shortened. The process route is convenient and easy to operate, the polyurethane powder adhesive can meet the requirements of adhesives in multiple fields, and large-scale production is hopeful in the future.

Owner:ZHUHAI COLLEGE OF JILIN UNIV

A kind of cemented carbide and its preparation method and application

The invention discloses hard alloy. The hard alloy comprises 5-10wt% of cobalt, 0.5-1.5wt% of chromium carbide and the balance tungsten carbide, wherein tungsten carbide comprises non-flaky tungsten carbide grains and flaky crystal tungsten carbide, and flaky crystal tungsten carbide accounts for 18-40wt% of the total mass of the hard alloy. Since the hard alloy contains flaky crystal tungsten carbide in an appropriate quantity, adhesive wear resistance of the alloy can be remarkably improved, and applying the hard alloy to roll collars for stainless steel wire rolling can realize a 30% raiseof stainless steel wire rolling tonnage.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com