Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

155results about How to "Won't rust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

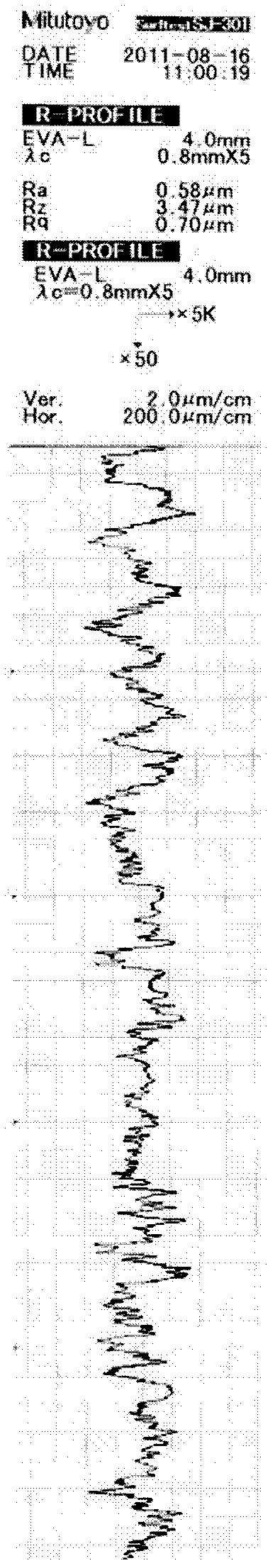

Method of producing stainless steel band for air injection steel reed

InactiveCN101033499AControllable hardnessSmall range of hardnessRoll mill control devicesMetal rolling arrangementsSolution treatmentSS - Stainless steel

The invention discloses a method for producing a kind of stainless steel which is used for jet norm. It manufactures with cold-rolled stainless steel strip with a thickness of 1.0~1.5mm to achieve the stainless steel through semi-finished billets rolling, solution treatment, finished rolling, skim handling, degreasing and drying, straightening, and tensile stress annealing.

Owner:无锡华生精密材料股份有限公司

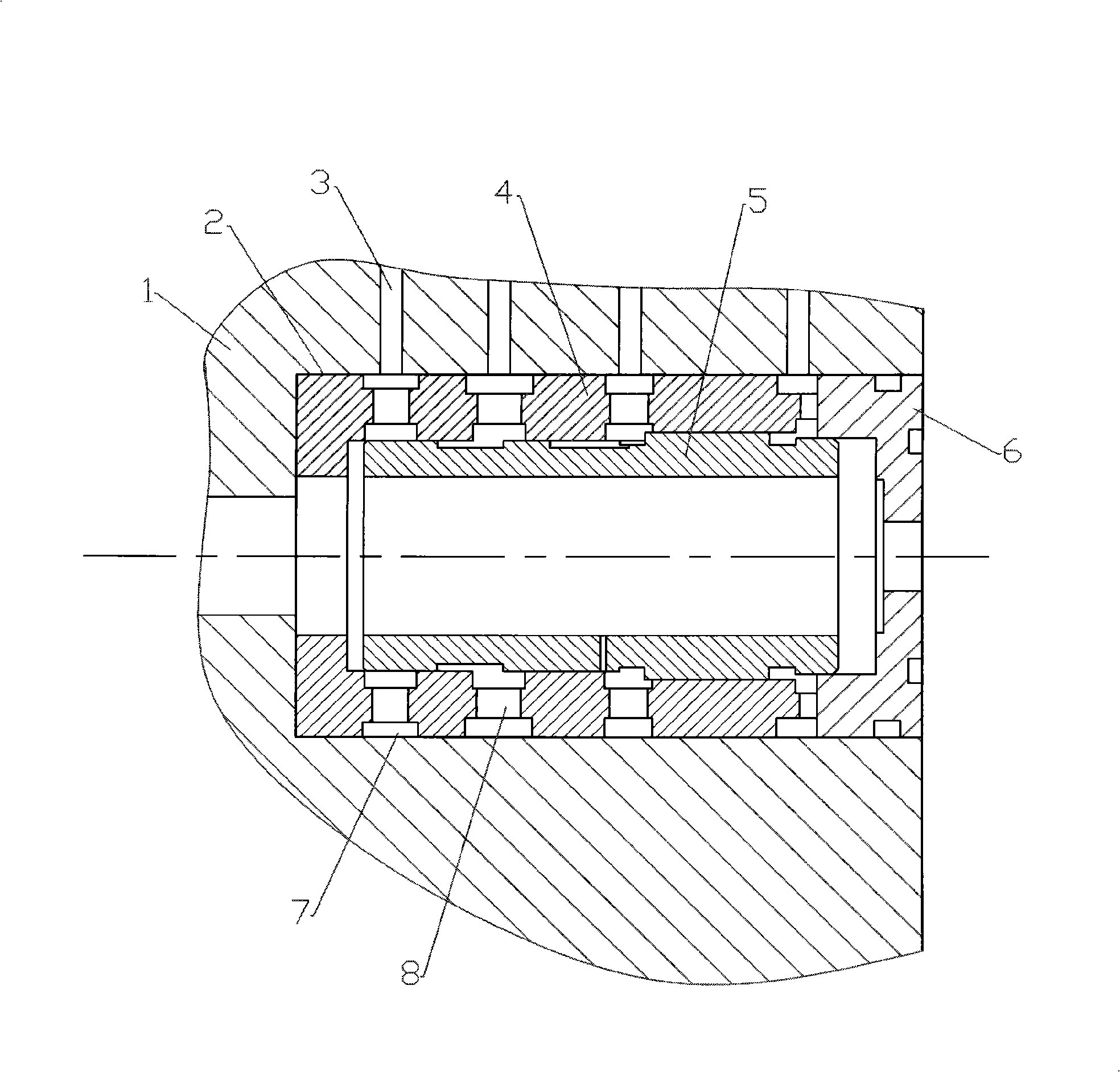

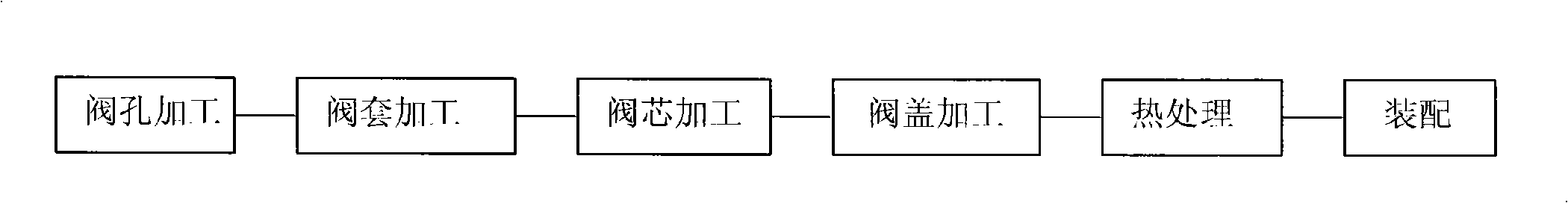

Hydraulic breaking hammer change-over valve and manufacturing method thereof

InactiveCN101324278AReasonable structureLow costServomotor componentsMultiple way valvesCylinder blockProcessing cost

The invention discloses a hydraulic pressure breaking hammer selector valve and a manufacturing method thereof in the technical field of hydraulic components. The hydraulic breaking hammer selector valve takes a middle cylinder body as a valve body; a valve opening is formed on the valve body; an oil duct is communicated with the inner wall of the valve hole and led to a cylinder of the middle cylinder body; a valve jacket is arranged in the valve hole and matched with the valve hole; a valve plug is arranged in the valve jacket; and a valve cover is arranged on the end part of the valve hole. The selector valve is characterized in that the valve hole is an unthreaded hole; an annular groove is formed on the outer wall of the valve jacket corresponding to the position of an opening of the oil duct; and an oil hole communicates the annular groove with a centre hole of the valve jacket. The manufacturing method comprises the steps of processing the valve hole, the valve jacket, the valve plug and the valve cover; conducting heat treatment; and assembling finished products. The method of the hydraulic pressure breaking hammer selector valve has the advantages of processing conveniently, reducing processing difficulty and effectively ensuring precision. The selector valve has the advantages of high functional reliability, lower processing cost and suitability for batch production.

Owner:NANYANG KAITIAN ENG MACHINERY +1

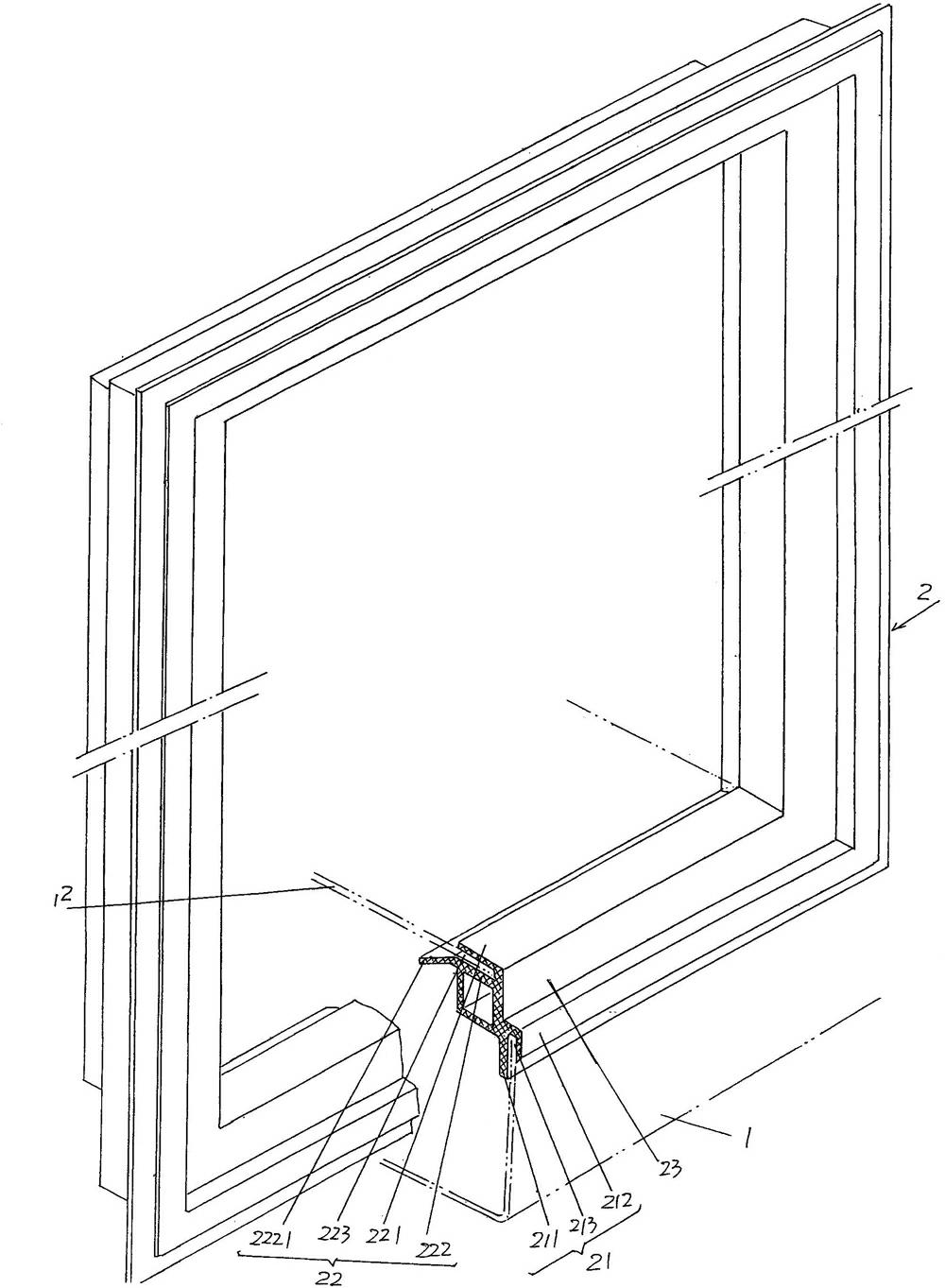

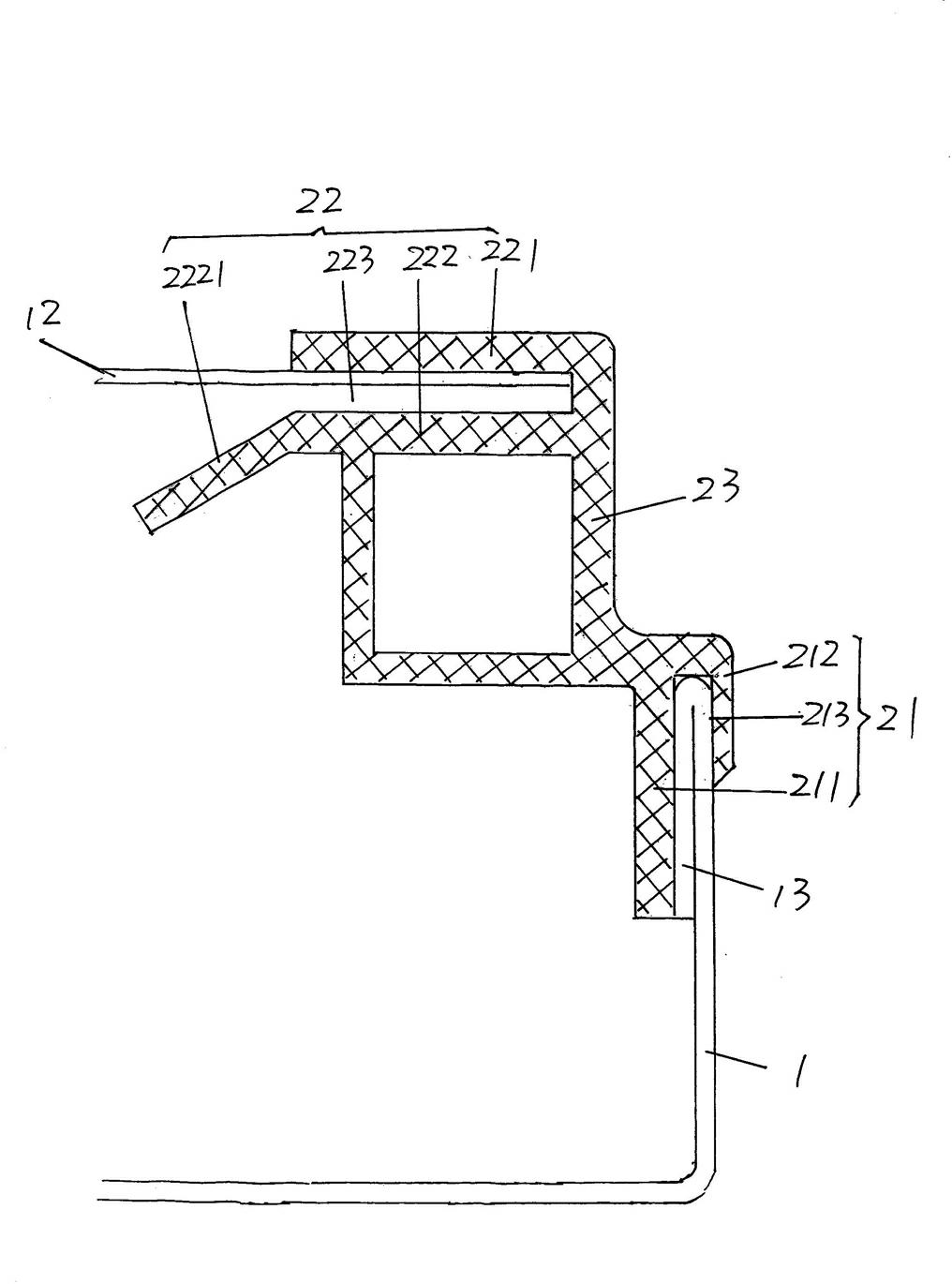

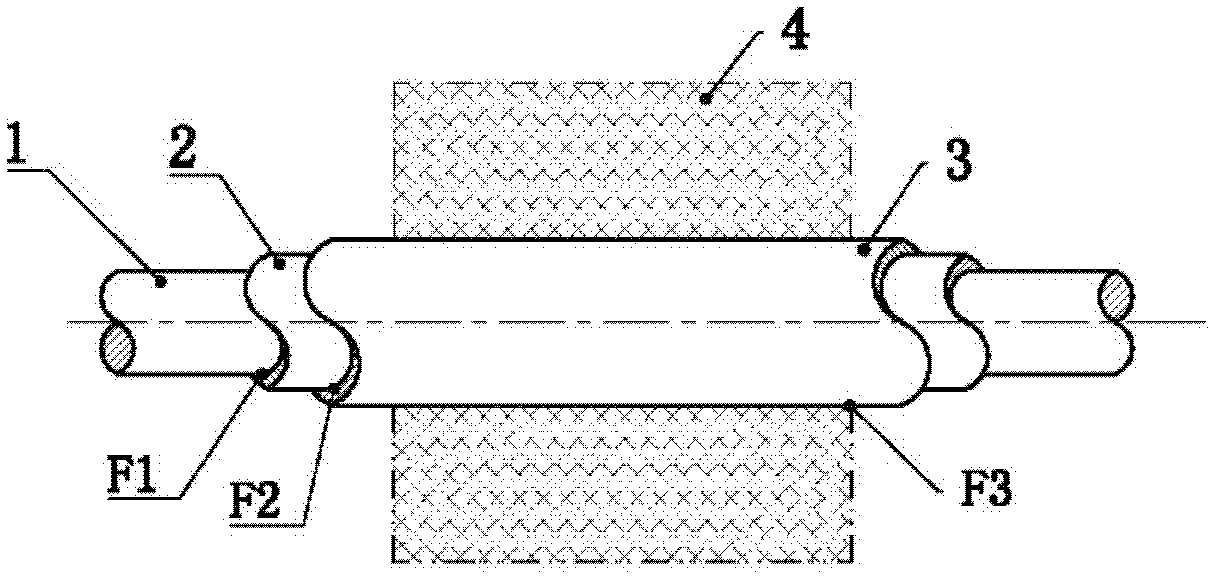

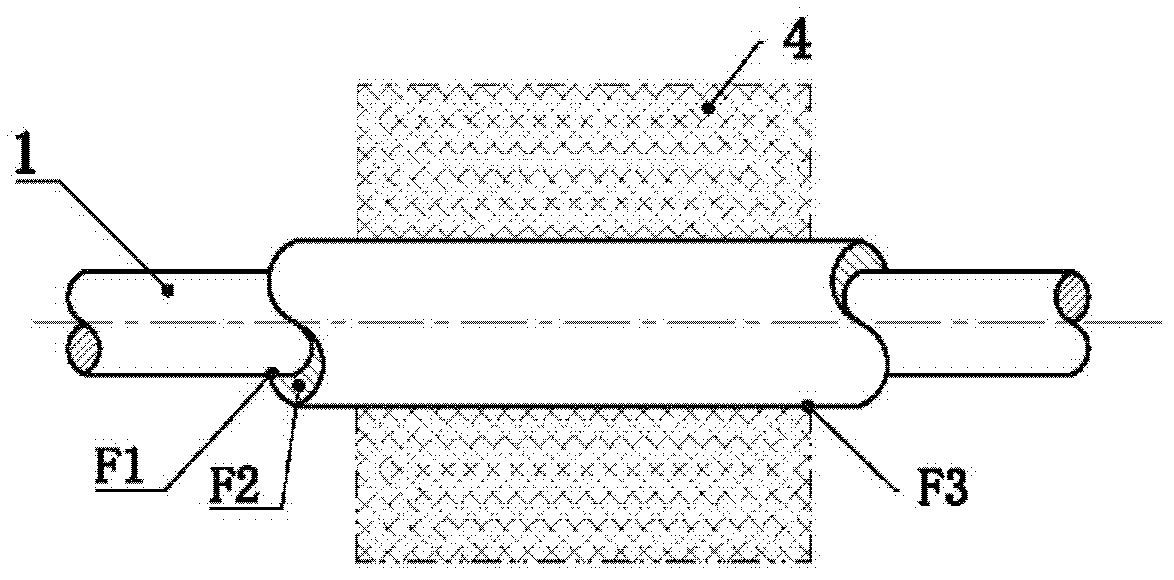

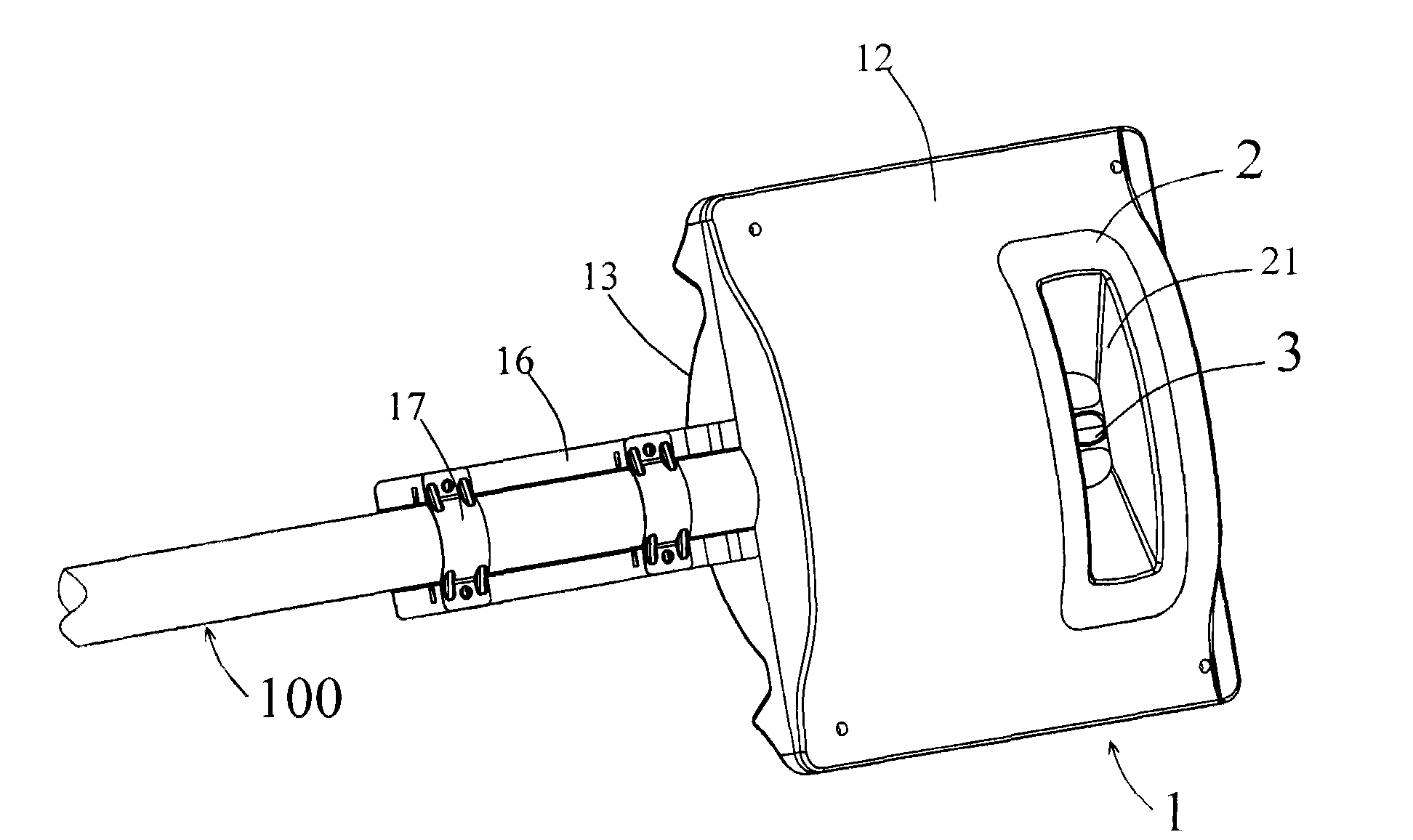

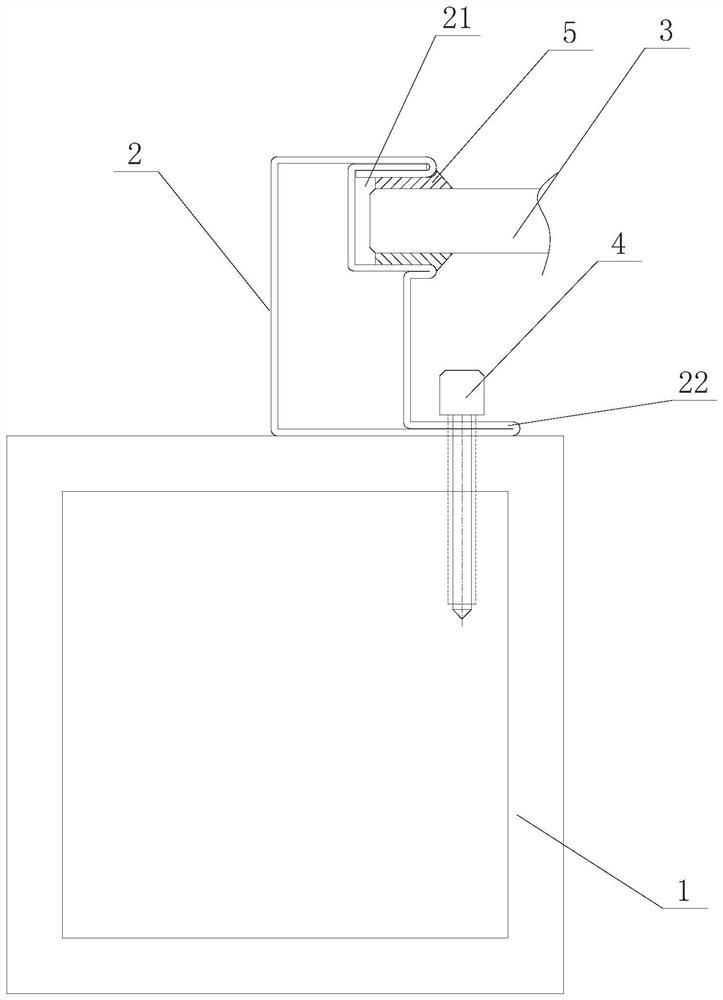

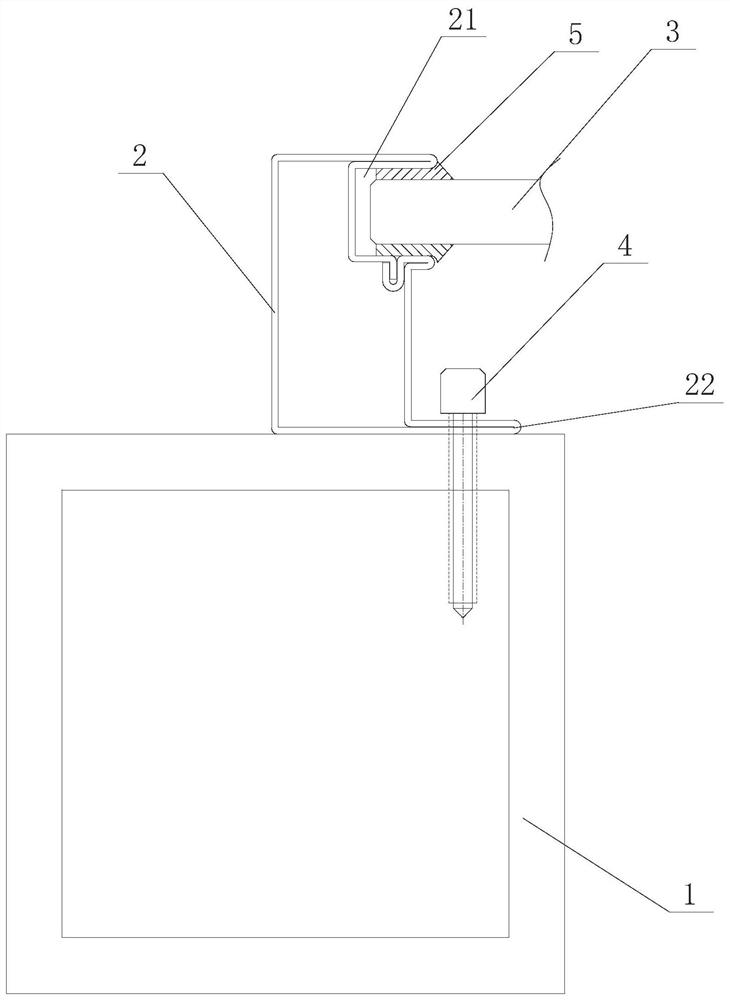

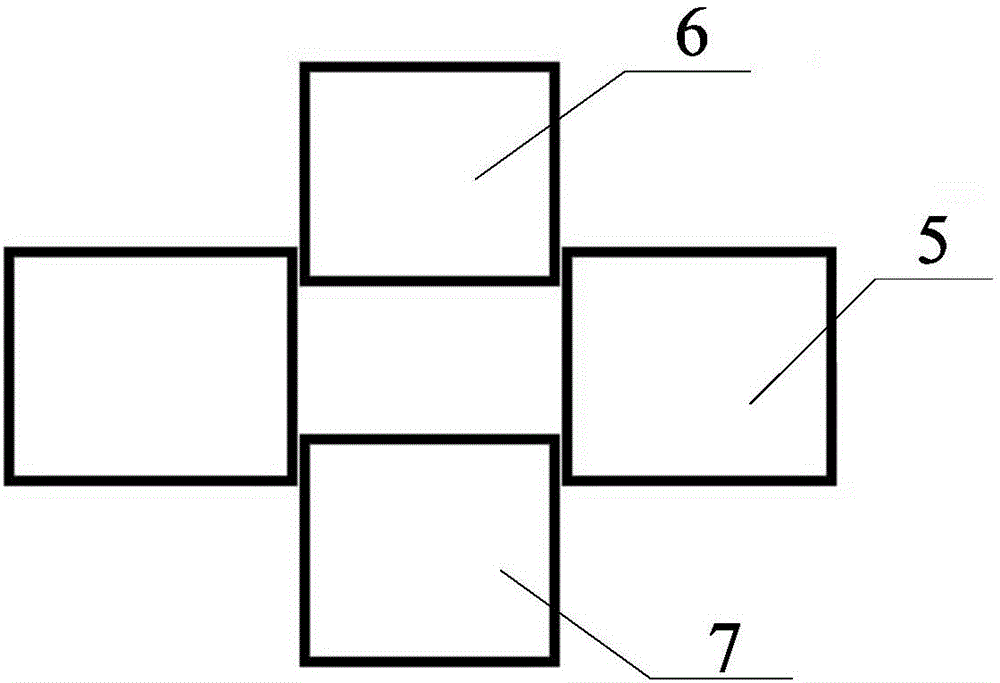

Matched structure of port frame and refrigerator body of refrigerator

InactiveCN102679676AWon't rustGuaranteed service lifeDomestic cooling apparatusLighting and heating apparatusEngineeringHome appliance

The invention relates to a matched structure of a port frame and a refrigerator body of a refrigerator and belongs to the technical field of household electrical appliances. The refrigerator comprises the refrigerator body with an embedded plate. The port frame comprises a port frame body which is provided with a first embedded body and a second embedded body. The matched structure is characterized in that the first embedded body is formed by a first embedded side and a second embedded side, a slot is formed between the first embedded side and the second embedded side, the slot is matched with the refrigerator body in embedded mode, the first embedded side is located on the inner side of the refrigerator body, and the second embedded side is located on the outer side of the refrigerator body. The matched structure has the advantages that after the slot is matched with the refrigerator body in embedded mode, steam cannot enter the refrigerator body from the second embedded side, so that avoiding of pollution is facilitated, further bacterial growth is avoided, the refrigerator body cannot be rusted, and service life of the refrigerator body is ensured. In addition, the structure of the refrigerator body is simplified so that the matched structure is favorable for reducing manufacture difficulty, saving materials and reducing complexity of a mold for processing the refrigerator body.

Owner:常熟市德尔电器有限公司

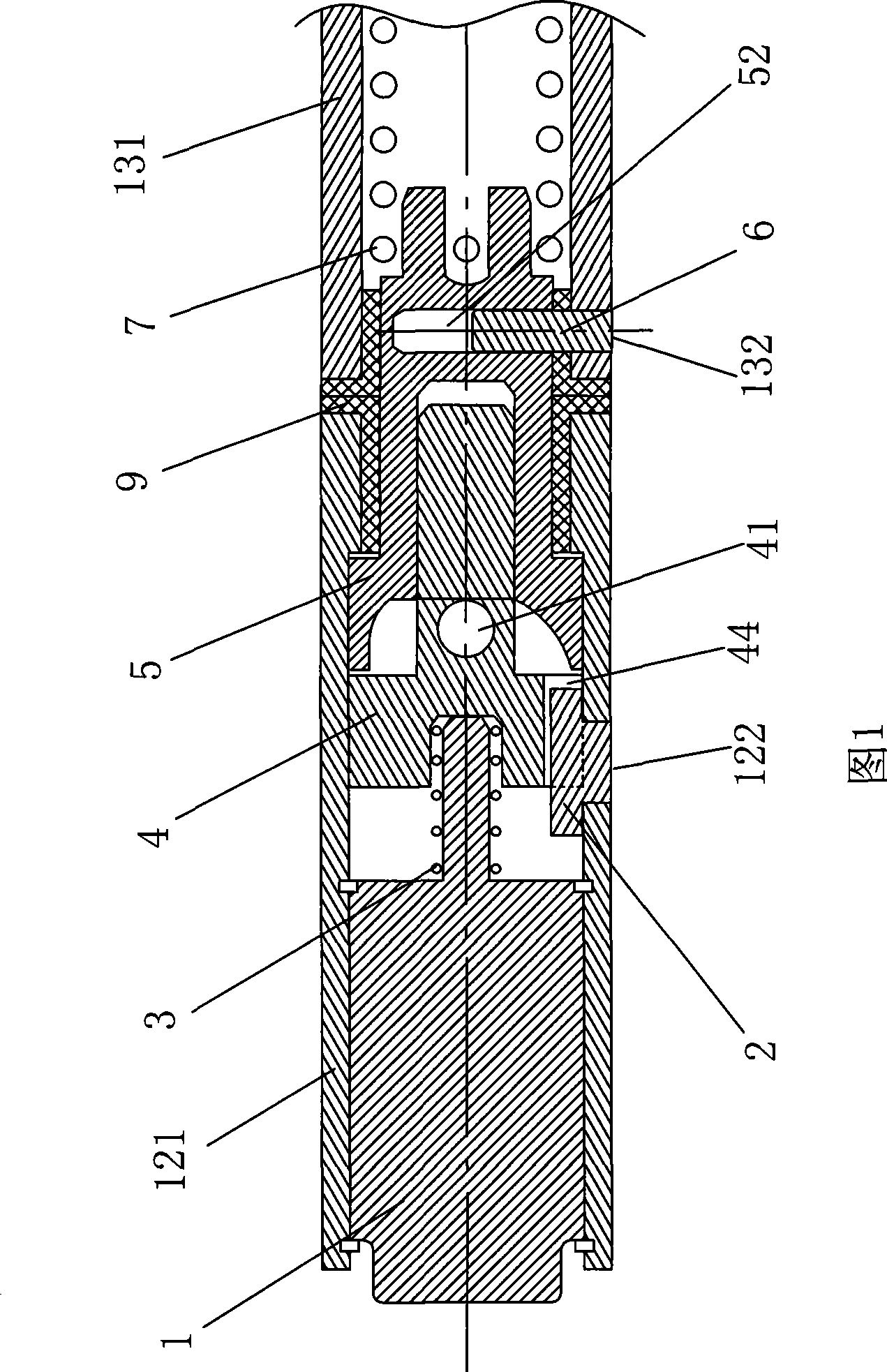

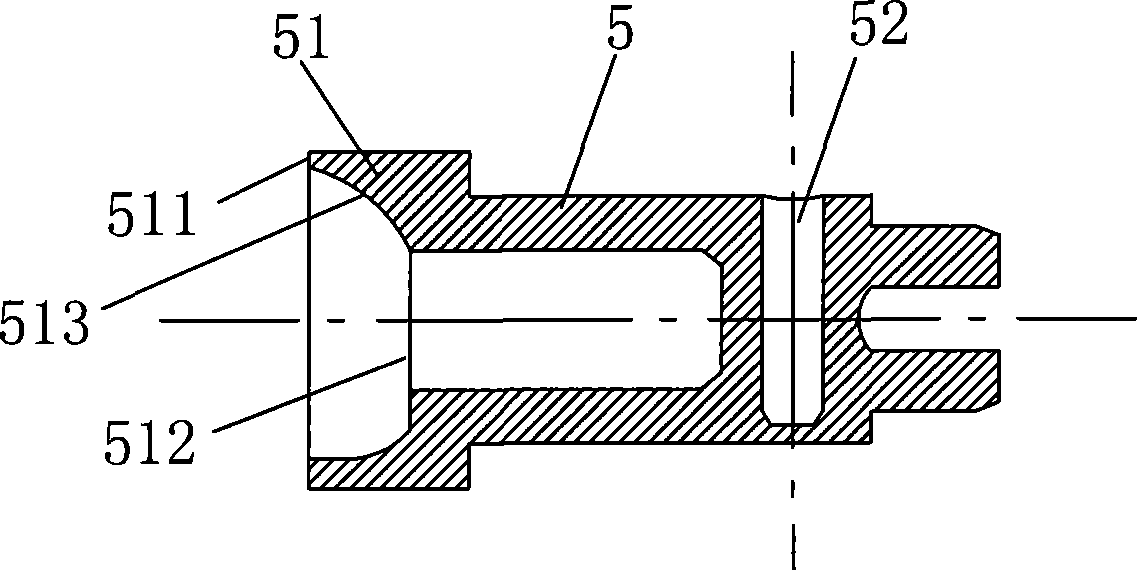

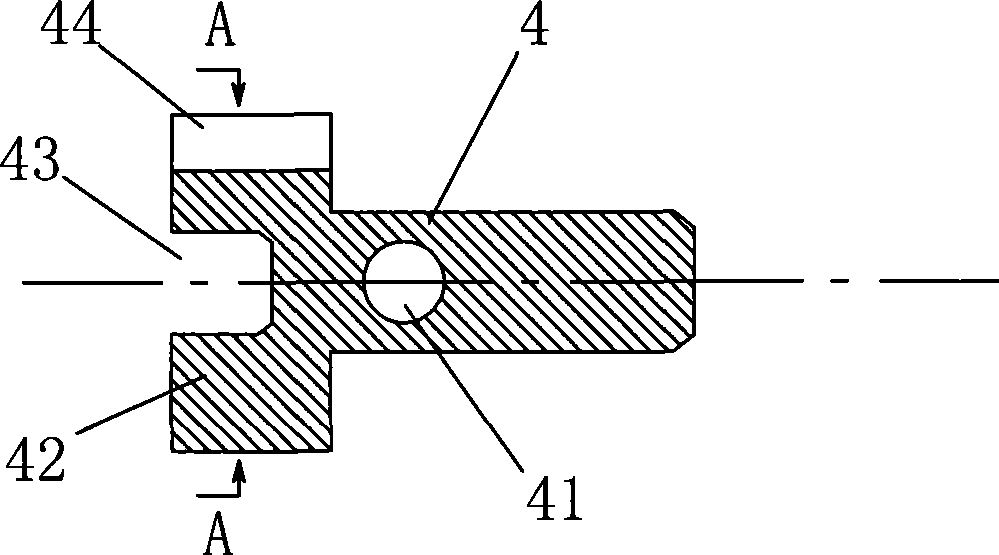

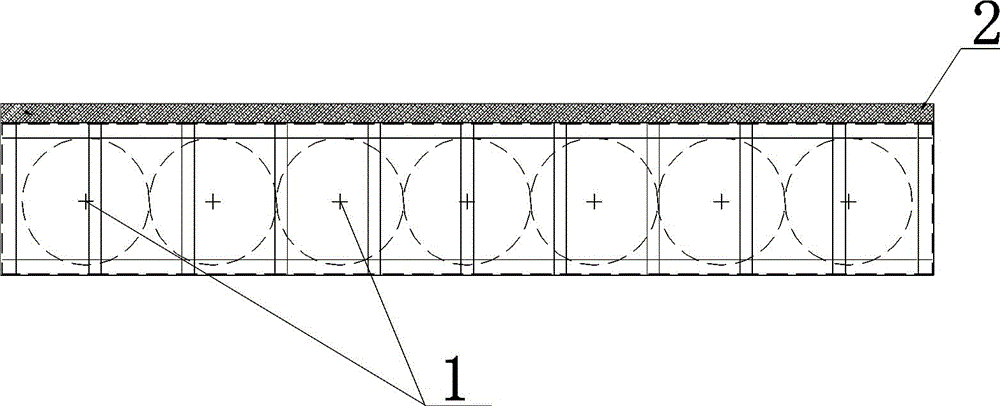

Amortization window hinge

The invention discloses a buffer door window hinge which comprises two hinges with beam barrels and interlocking mechanisms arranged in the beam barrels. The interlocking mechanisms respectively correspond to the integral beam barrels, and are correspondingly interlocked with the two hinge beam barrels. Each interlocking mechanism comprises an interlocking buffer device capable of preventing a door window from being closed at an excessive speed. The interlocking buffer device consists of an axis body, a lifting rod which is capable of lifting and pivoting relative to the axis body along the axis and is arranged at one end of the axis body, and a buffer which buffers the lifting of the lifting rod and consequently buffers the relative pivoting of the lifting rod; wherein the axis body is relatively fixed with one hinge beam barrel and can rotate coaxially, and the lifting rod is connected with the other hinge beam barrel so as to be lifted up and down when the lifting rod rotates fixedly with the hinge. The buffer window hinge which has a simple structure and a small size can be installed on the door window body or inside a door frame without impacting the appearance of the door window.

Owner:陈政 +1

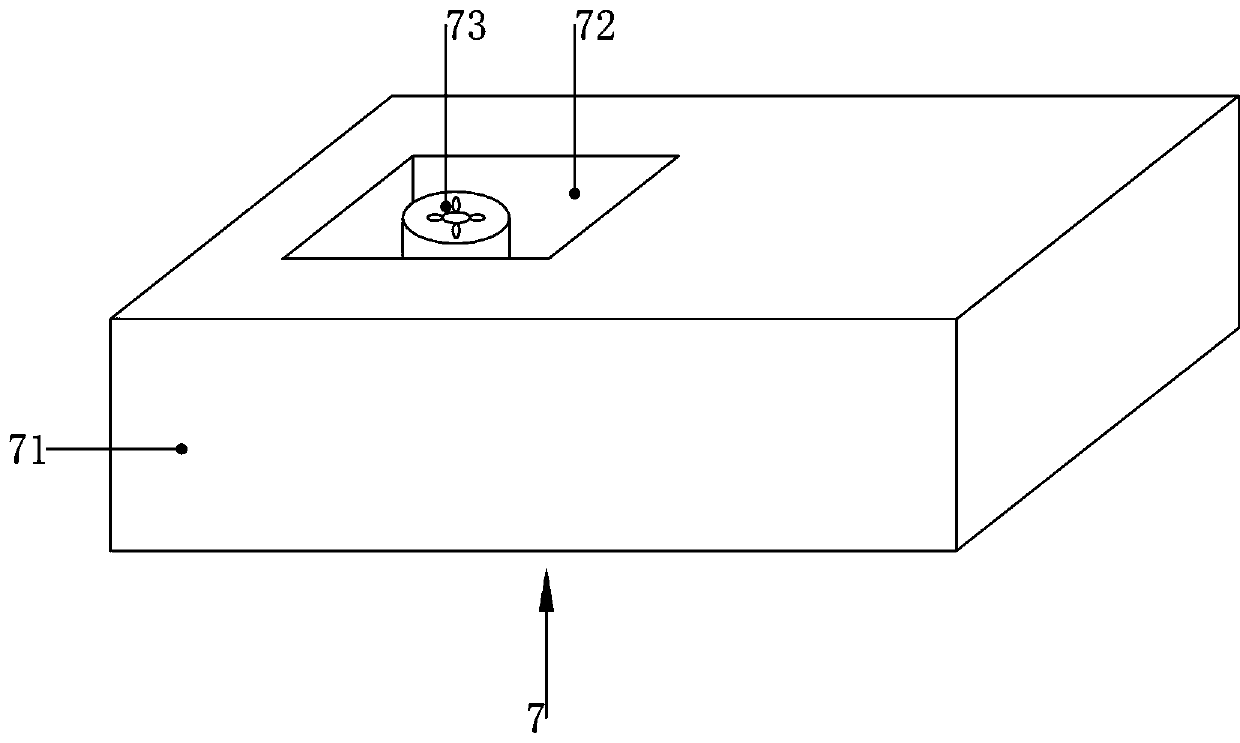

Modular PE pipe water activity platform

InactiveCN104627329ASo as not to damageWill not polluteFloating buildingsPipe waterReinforced concrete

A modular PE pipe water activity platform comprises a PE pipe floating body, single-section floating raft platforms and a floating raft guardrail, wherein the PE pipe floating body is formed by connecting a plurality of hollow PE pipes of which both ends are sealed; each single-section floating raft platform is of a reinforced concrete structure; the single-section floating raft platforms and the PE pipe floating body are connected into a whole by a fixing frame; plurality of the single-section floating raft platforms are fixedly connected into a floating raft platform assembly; and the floating raft guardrail is fixedly installed on the floating raft platform assembly. According to the invention, the characteristics of light weight, corrosion resistance, long service life, capability of being recycled and high strength of reinforced concrete of the PE pipe are fully combined, manufacturing and construction are simple, safety and reliability are realized, and maintenance is simple. Due to the adoption of modular production and flexible assembly, the water-surface construction operation difficulty of a large platform is greatly reduced, the construction cycle is shortened, and economic benefits and environmental benefits are greatly enhanced.

Owner:YICHANG HONGJIAN NEW MATERIAL

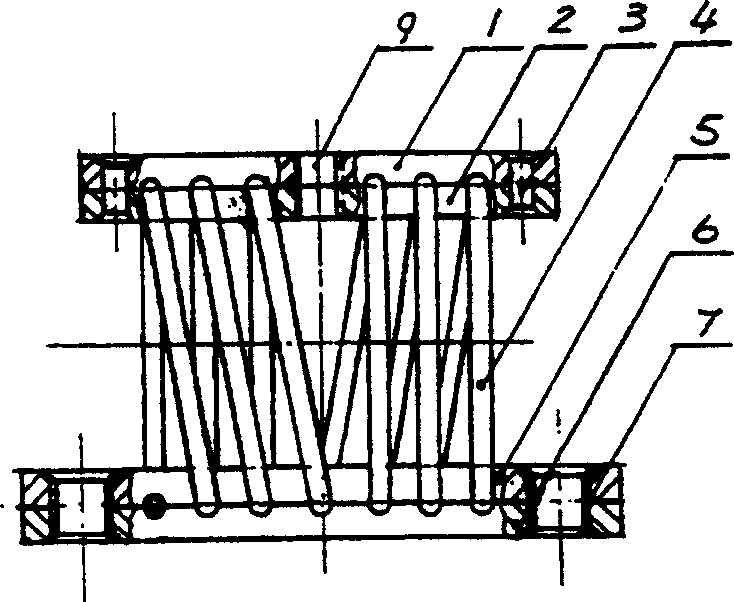

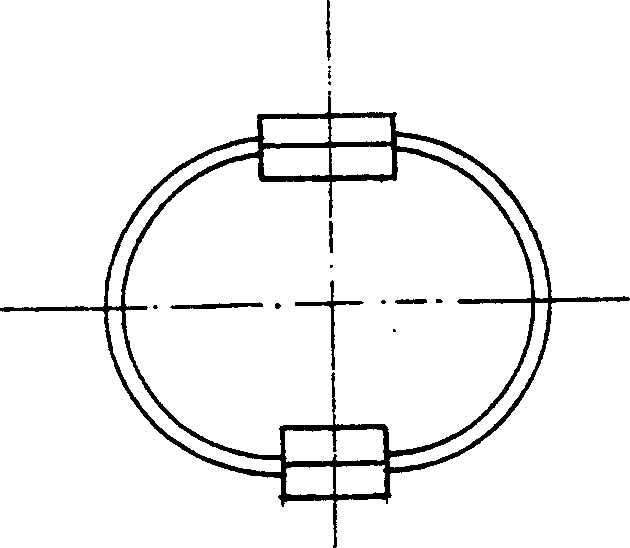

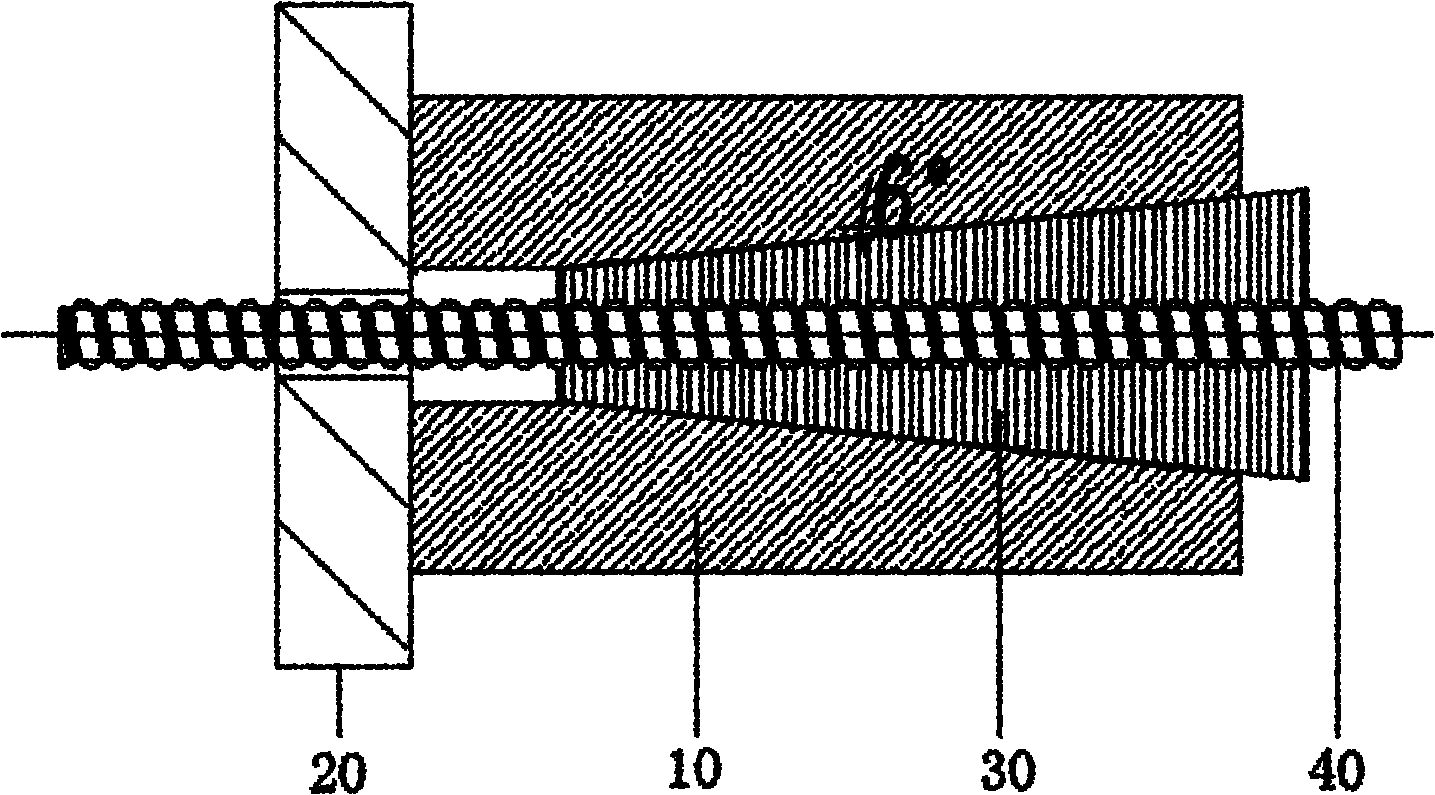

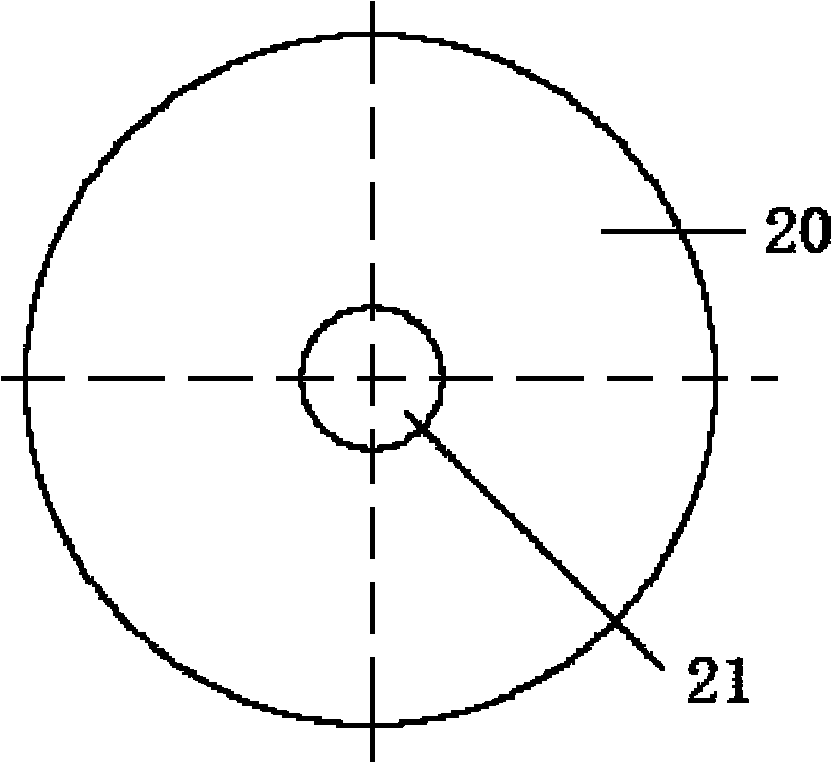

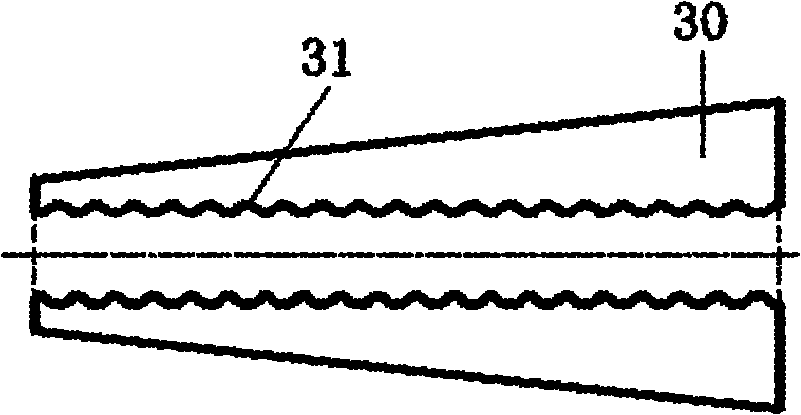

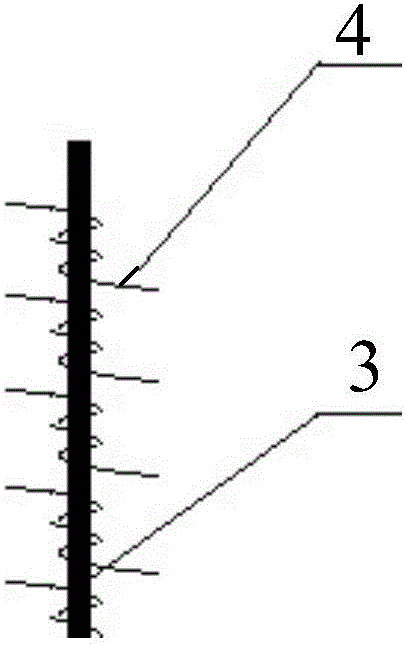

Compostie damp rubber wirerope shock-resistance isolator

InactiveCN1529069ANo strong secondary impactOptimize layoutLow internal friction springsEngineeringShock resistance

The invention is a kind of compound damp rubber steel cable shock resistance and vibration isolating device, belongs to the mechanism field. The skeleton structure of the invention is made up of the upper clamping board, the subjacent clamping board and the spiral high intensity steel cable between the two boards, the two boards are riveted together with clinch and hollow clinch, or connected with head embedded clinch, there sets a tap or straight hole connected to the device and base on the two boards, the above mentioned metal pieces are all covered in the special structure form rubber. The invention solves bid damp, three-dimension deformation and low system free frequency needed by the device, the steel rope won't be rusted, it can use high intensity steel cable to upgrade the intensity, carrying ability, deformation quantity and the binding intensity of rubber.

Owner:SHANGHAI JIAO TONG UNIV

High-strength FRP material and production method and application thereof

InactiveCN101775228AGive full play to the advantages of non-metallic reinforcementGood electromagnetic insulationFibre treatmentBuilding reinforcementsHigh intensityPolymer

The invention discloses a high-strength FRP (Fiber Reinforced Polymer) material and a production method and an application thereof, which relate to an FRP material. The high-strength FRP material is produced by compounding high-performance resin and fibers, which comprises the following components by weight percent: 20 to 40 percent of high performance resin, 10 to 20 percent of chopped fibers and 50 to 60 percent of fiber cloth. The production method comprises the following steps: (1) the high performance resin is blended and uniformly mixed with the chopped fibers to obtain a curing agent; (2) the fiber cloth is gradually laid inside a mould layer by layer, is gradually and adequately steeped by the curing agent layer by layer, is arranged inside a vacuum tank with the vacuum degree of 0.098 MPa or more and is cured and formed under the condition with the temperature of 150 to 250 DEG C so as to obtain a high-strength FRP material. The high-strength FRP material is free from being rusted, has no magnetism, good electromagnetic insulation performance and light weight, can reduce the structural weight and can reduce the cost.

Owner:金文成

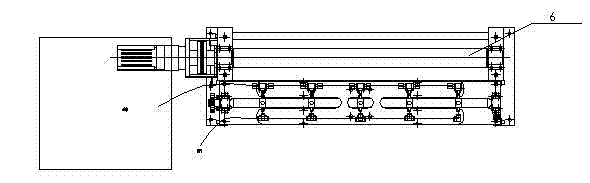

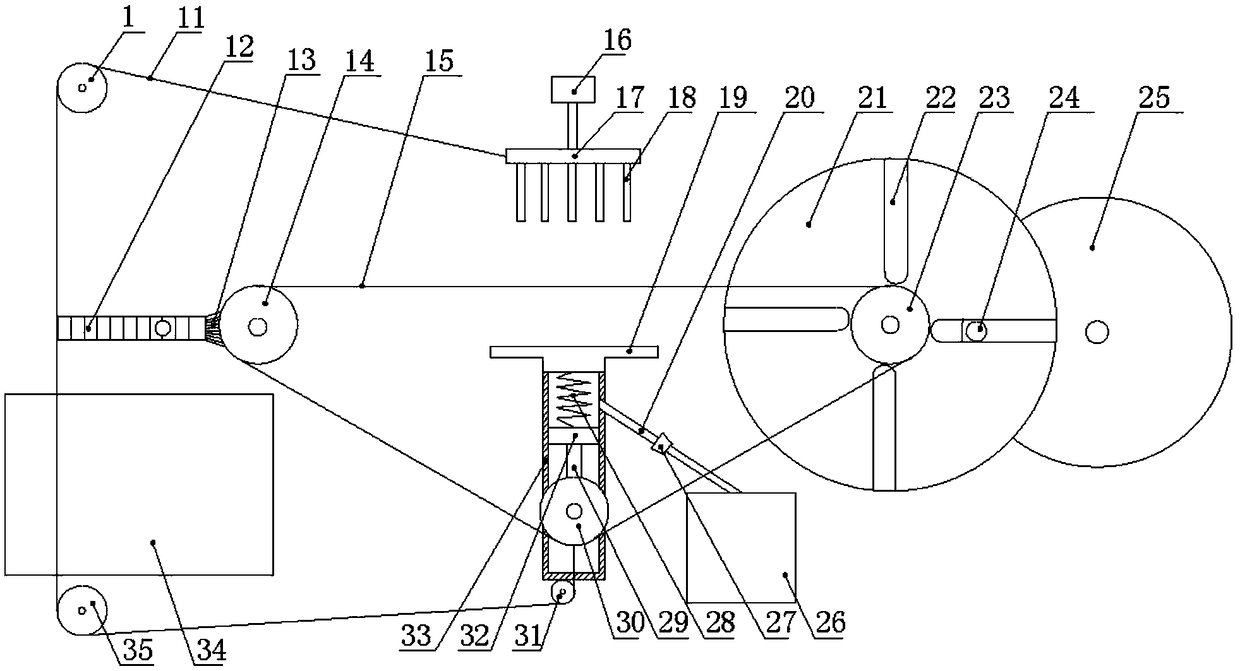

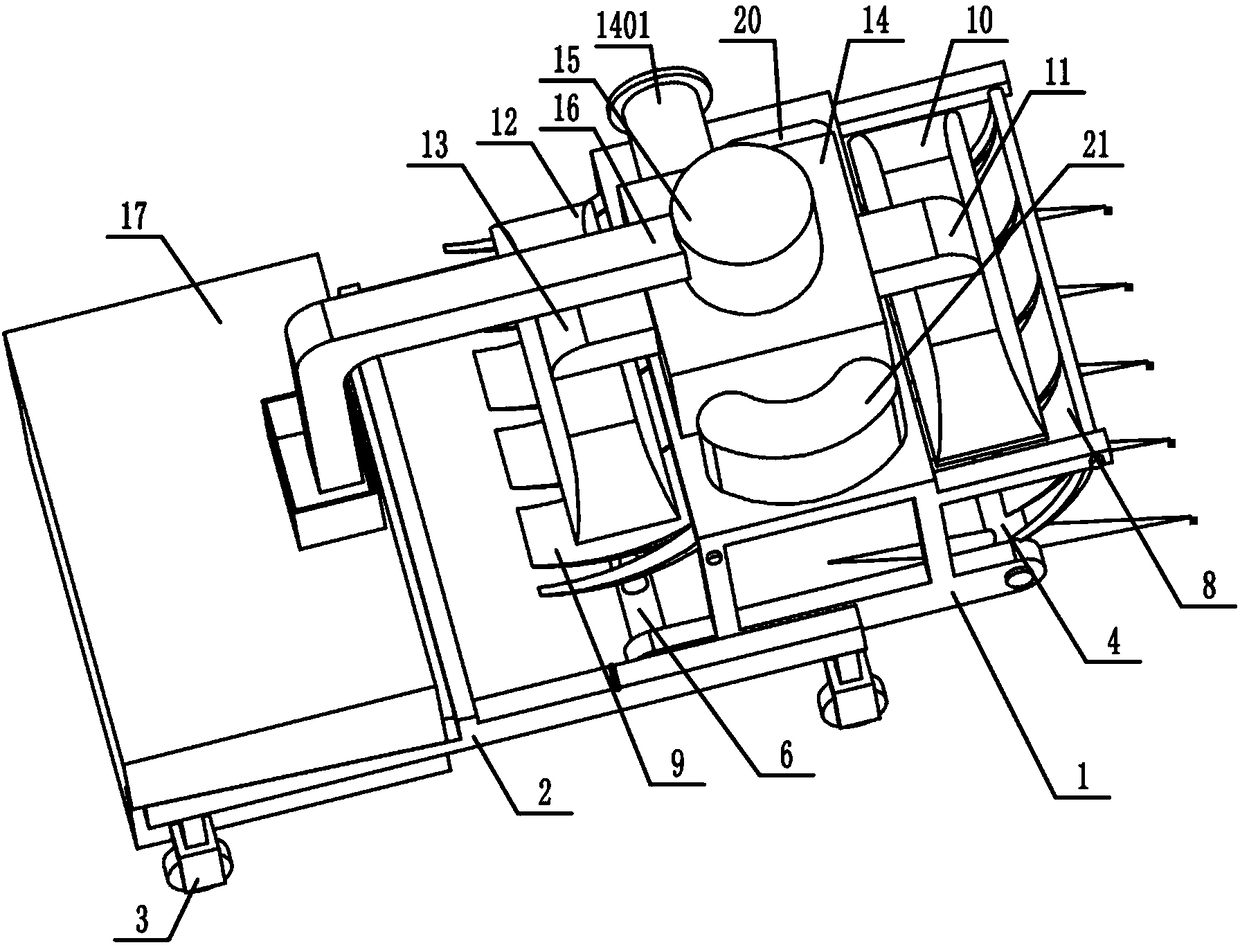

Oil roll machine

InactiveCN102773194AExtended service lifeQuality assuranceLiquid surface applicatorsCoatingsSpray nozzleMechanical equipment

The invention relates to an oil roll machine which is used for processing products by being matched with a punching machine and belongs to the technical field of mechanical equipment. In the invention, due to the arrangement of an oiling roll and an oil balancing roll both driven by a motor reducing gear, mechanical oil is instead of artificial oil, and the oil roll machine is put ahead the punching machine; die oil is sprayed onto the oiling roll via a nozzle, and one layer of even die oil is sprayed on upper and lower surfaces of a sheet material after the sheet material passes through the oiling roll and the oil balancing roll, so that a die is protected, the service life of the die is prolonged, meanwhile, the qualities of products are ensured and the products do not rust in storage and transportation processes. The oil roll machine is simple and compact in structure and beneficial to relieving the labor intensity and increasing the production efficiency and has high practicability.

Owner:JIANGSU YAWEI MACHINE TOOL

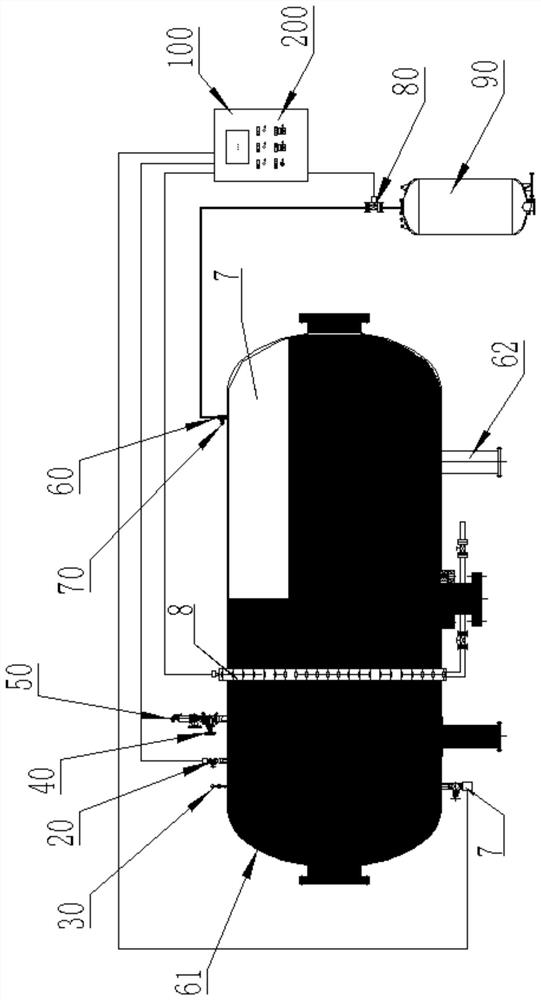

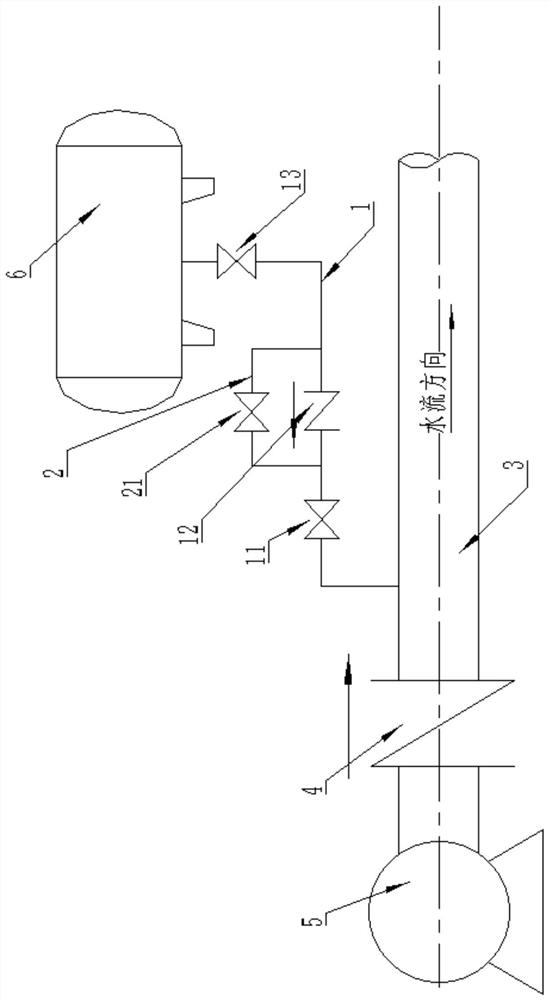

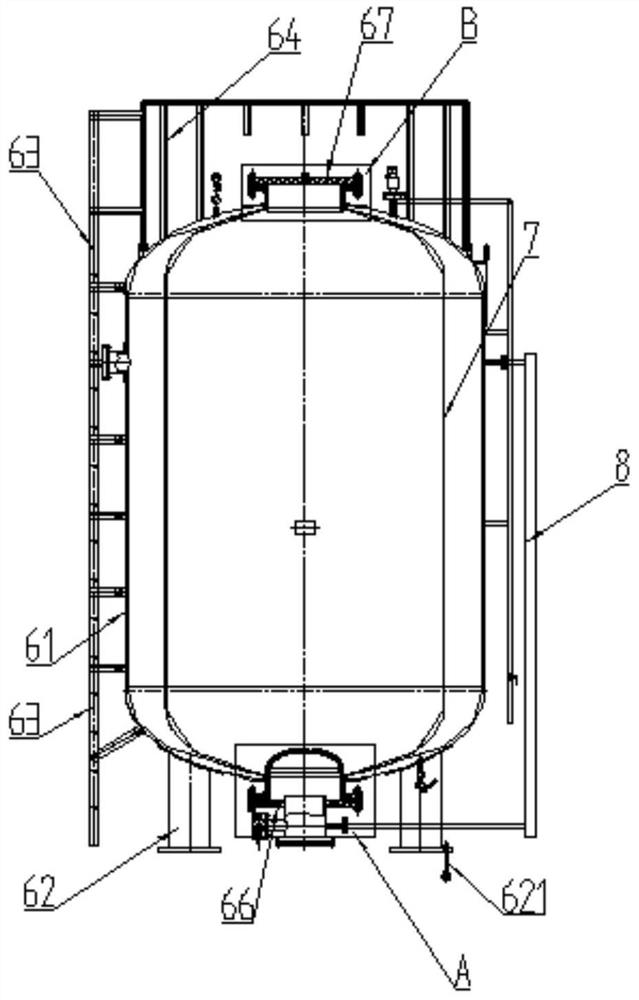

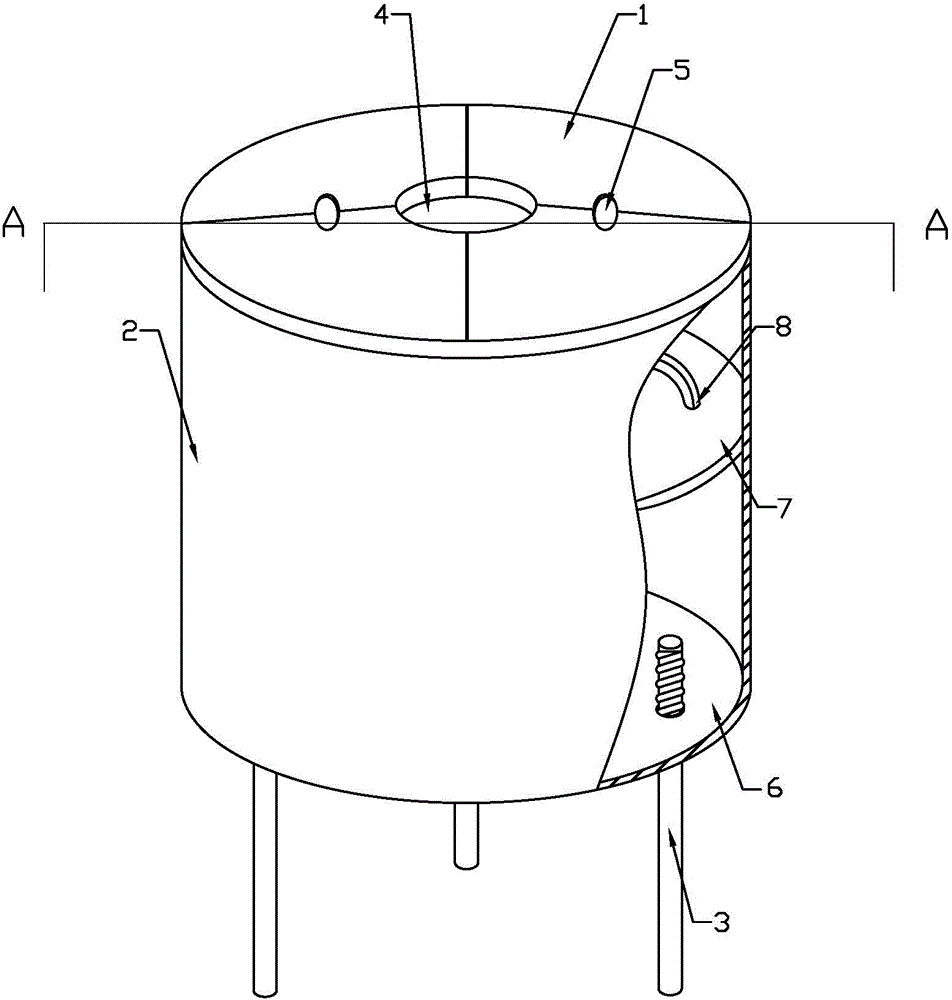

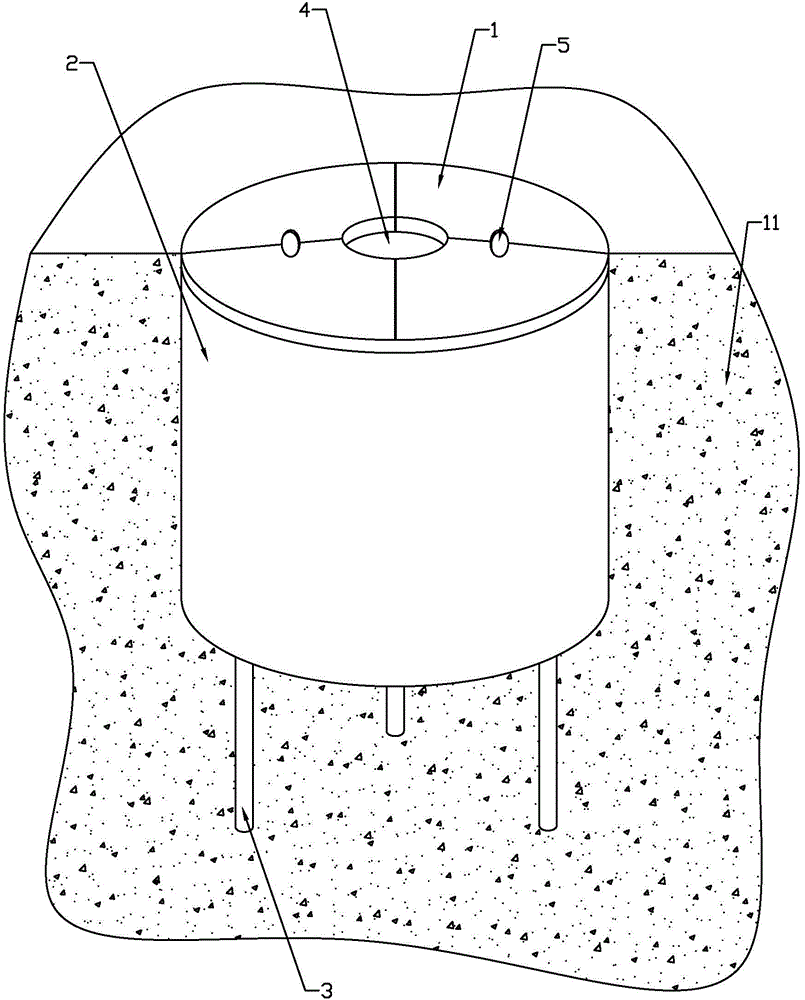

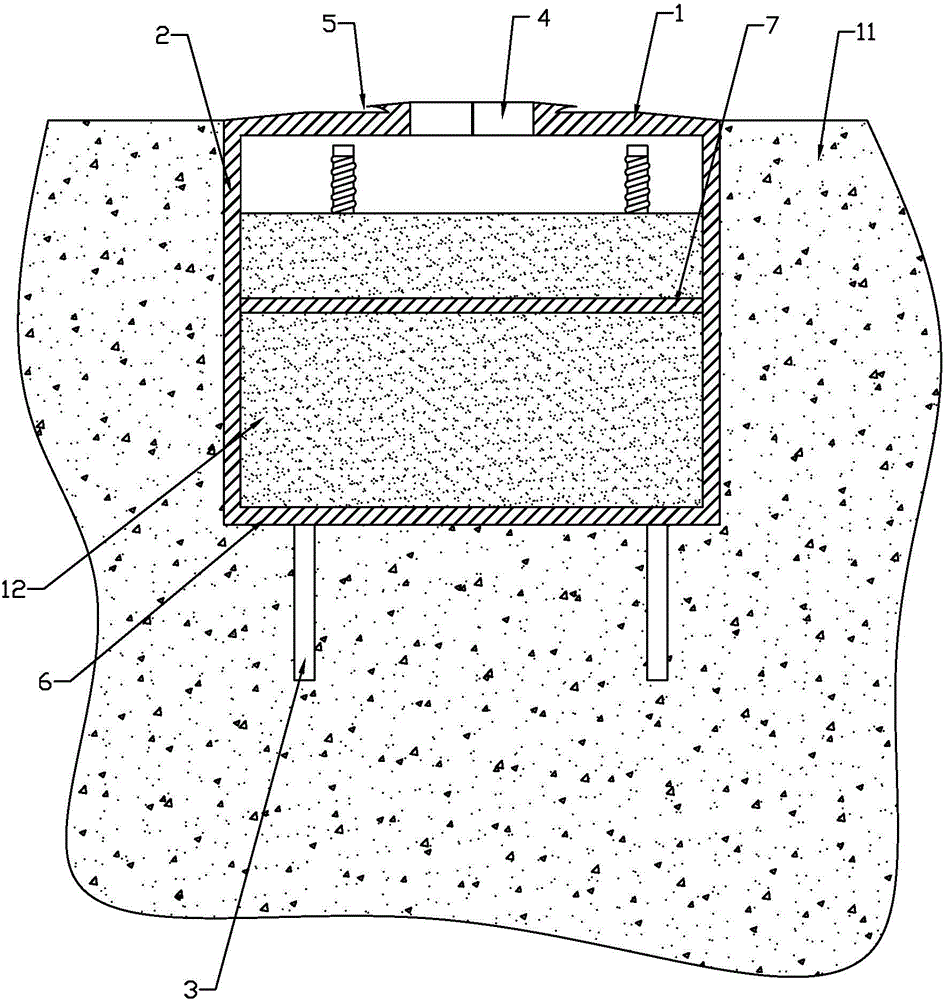

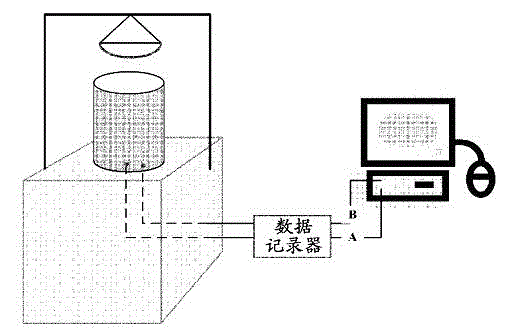

Intelligent water hammer eliminating tank system and use method

PendingCN111928052AReal-time monitoring of working pressureReal-time monitoring of liquid level heightMeasurement of fluid loss/gain ratePipe elementsWater leakageWater hammer

The invention provides an intelligent water hammer eliminating tank system and a using method, and belongs to the field of pipeline conveying equipment. The intelligent water hammer eliminating tank system comprises a body and an air bag arranged in the body, an outlet of the air bag communicates with a medium conveying pipeline, an impedance assembly is arranged between the outlet of the air bagand the medium conveying pipeline; a liquid level sensor for collecting liquid in the body is arranged on the side surface of the body; a pressure sensor is arranged at the upper end of the body and used for collecting the pressure of gas in the body; the upper end of the body is further provided with an inflation nozzle for supplementing air to the body, and the bottom of the body is provided with a leakage detection sensor; and the liquid level sensor, the pressure sensor, a gulp valve actuator and the leakage detection sensor are all electrically connected with a control center through control circuits. The intelligent water hammer eliminating tank system and the using method can monitor the working pressure, liquid level height, conditions that whether water leakage and air leakage exist, actuator state and the like of the water hammer eliminating tank in real time, has early warning and protection effects, can automatically carry out real-time accurate air supplement, can detect theoretical parameters of the water hammer eliminating tank, and optimizes the use effect.

Owner:BENSV VALVE CO LTD

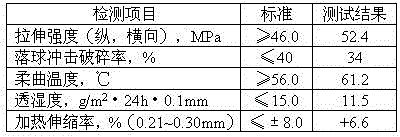

Magnesium-aluminum-zinc environment-friendly stabilizer special for U-PVC calendered sheet

The invention discloses a special environment-friendly stabilizer for U-PVC calendered sheet, which is prepared from the following components in weight ratio: 260-300 kg of magnesium-aluminum-zinc composition, 50-150 kg of zinc stearate, and 1010-15-15 kg of antioxidant. 20kg, calcium acetylacetonate 40~68kg, tris(2-hydroxyethyl) isocyanurate 80~130kg, oxidized polyethylene wax 50~250kg, polyethylene wax 30~100kg. The stabilizer of the invention is suitable for continuous calendering and extrusion production of U-PVC sheet, and has moderate dosage, low cost, good production process stabilization effect, good rolling effect, smooth processing, smooth sheet surface, good plasticization, and satisfactory mechanical properties. The requirements of the national standard also have the advantages of non-toxicity and high environmental protection performance; the U-PVC sheet prepared by the stabilizer of the present invention has stable chemical properties, no rust, good impact resistance, and good transparency. Good insulation and low thermal conductivity; good formability and colorability, and low processing cost; the PVC sheet produced conforms to GB / T15267 "PVC Rigid Sheets and Films for Food Packaging" and conforms to YBB00212005 Polyethylene Vinyl chloride solid medicinal tablet.

Owner:广东森德利环保新材料科技有限公司

Carbon fiber umbrella and manufacturing method thereof

The invention relates to the technical field of articles for daily life, in particular to a carbon fiber umbrella manufacturing method. The carbon fiber umbrella manufacturing method comprises the following steps of manufacturing umbrella ribs, an umbrella rod, a handle, umbrella beads, an umbrella top and hook-and-loop buckles by using carbon fibers to be reserved; inspecting cloth; roughly tailoring; rolling edges; preciously tailoring: tailoring umbrella cloth into pieces of triangular cloth; printing an umbrella cover; combining pieces: sewing the pieces of the umbrella cloth by a sewing machine to form the umbrella cover; mounting the umbrella beads, an umbrella band and the hook-and-loop buckles: mounting the umbrella beads at corners of the umbrella cloth, sewing the umbrella band on the umbrella cover, and then sewing the hook-and-loop buckles at appropriate positions of the umbrella band and the umbrella cloth; topping; mounting the ribs: connecting the umbrella cloth and the umbrella ribs; mounting the umbrella rod: connecting the umbrella ribs and the umbrella rod; mounting the handle: connecting the umbrella rod and the handle; and mounting the umbrella top: connecting the umbrella rod and the umbrella top. The carbon fiber umbrella manufacturing method is high in production efficiency; products are high in quality; the method is suitable for mass production; a carbon fiber umbrella manufactured by using the method is light in weight and high in quality, cannot be rusted, cannot be conductive, and can arrest lightning.

Owner:王娟

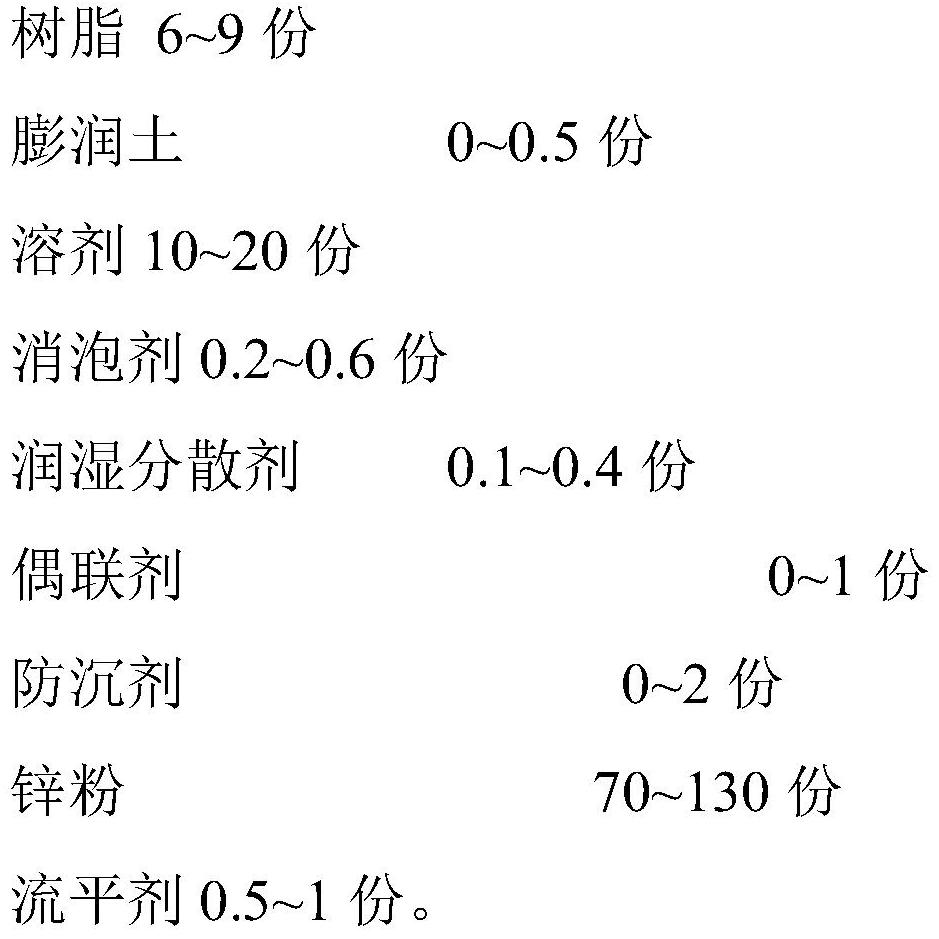

Water-based metallic paint with rustproof function for outer walls and preparation method thereof

ActiveCN103965726AWith anti-rust functionImprove waterproof performanceAnti-corrosive paintsWater basedEmulsion

The invention provides water-based metallic paint with a rustproof function for outer wall painting. The water-based metallic paint comprises the following components in parts by weight: 40-60% of silicone resin emulsion, 1-2% of film-forming agent, 10-20% of pearl pigment, 0.5-1% of flash-rust inhibitor, 0.3-0.6% of dispersant, 0.2-0.4% of wetting agent, 0.2-0.5% of defoaming agent, 0.3-1.0% of thickener, 0-5% of extinction powder and 25-35% of deionized water, wherein the silicone resin emulsion is water dilution type pure silicone resin emulsion, and the flash-rust inhibitor is modified zinc chelate. The water-based metallic paint provided by the invention has the advantages that the pure silicone resin emulsion is used as a film-forming agent, and meanwhile, the modified zinc chelate is added to the metallic paint and serves as the flash-rust inhibitor, so that a paint film has a good rustproof property, good stain resistance weather resistance and a very good decoration effect on outer walls and prolongs the service life of the walls relatively well. The invention aslo provides a preparation method with the rustproof function for the outer walls.

Owner:广东龙湖科技股份有限公司

Distribution box for electrical engineering

InactiveCN110707561AEasy to detect wind and rain conditionsEasy to detectSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsGear wheelElectrical connection

The invention discloses a distribution box for electrical engineering, and belongs to the electrical technical field. The distribution box comprises a box body, a box door and a single-chip microcomputer. The box door is mounted at the left corner angle of the front end of the box body, an opening is formed at the lower portion of the box body, and the single-chip microcomputer is fixed at the inner bottom end of the box body. A cooling driving mechanism is mounted at the lower end of the box and comprises a base plate, the bottom plate is fixed with the lower end of the box body, and an air duct is formed on the bottom plate. A cover plate is arranged at the upper end of the bottom plate, a transmission block is fixed at one end of the cover plate, and a first servo motor is fixed on therear inner wall of the box body and is electrically connected with the single-chip microcomputer. A driving gear is fixed to the output end of the first servo motor, and a plurality of evenly-distributed driven gears are fixed to the upper end of the cover plate and the upper end of the transmission block. The distribution box can automatically cool according to a temperature threshold value, meanwhile, when the strong wind and heavy rain are detected, closes the air holes automatically, so that the interior of the distribution box is not rusted easily.

Owner:CHINA THREE GORGES UNIV

Flameproof surface phosphating process and used phosphating solution

The invention relates to the technical field of flameproof surface treatment processes, and in particular relates to a flameproof surface phosphating process for electrical equipment. The process comprises the steps of preparing phosphating slurry: accommodating warm water with a plastic container, sequentially adding basic copper carbonate, nitric acid, phosphoric acid, zinc oxide, hexamethylene tetramine, sodium fluoride and zinc nitrate, and adding the prepared phosphating solution into talc powder to form paste; brushing the prepared phosphating solution slurry on a flameproof surface in a manner that the thickness of the slurry is not less than 2mm; ensuring the retention time of the phosphating solution slurry on the flameproof surface according to the ambient temperature and the following standards, and wiping the phosphating solution slurry on the flameproof surface, thus phosphating the flameproof surface, namely forming a layer of phosphating film on the flameproof surface. The flameproof surface treated through the phosphating process provided by the invention can not be rusted over more than two years, so that the use safety of underground equipment is greatly improved.

Owner:CHANGZHOU LIANLI AUTOMATION TECH

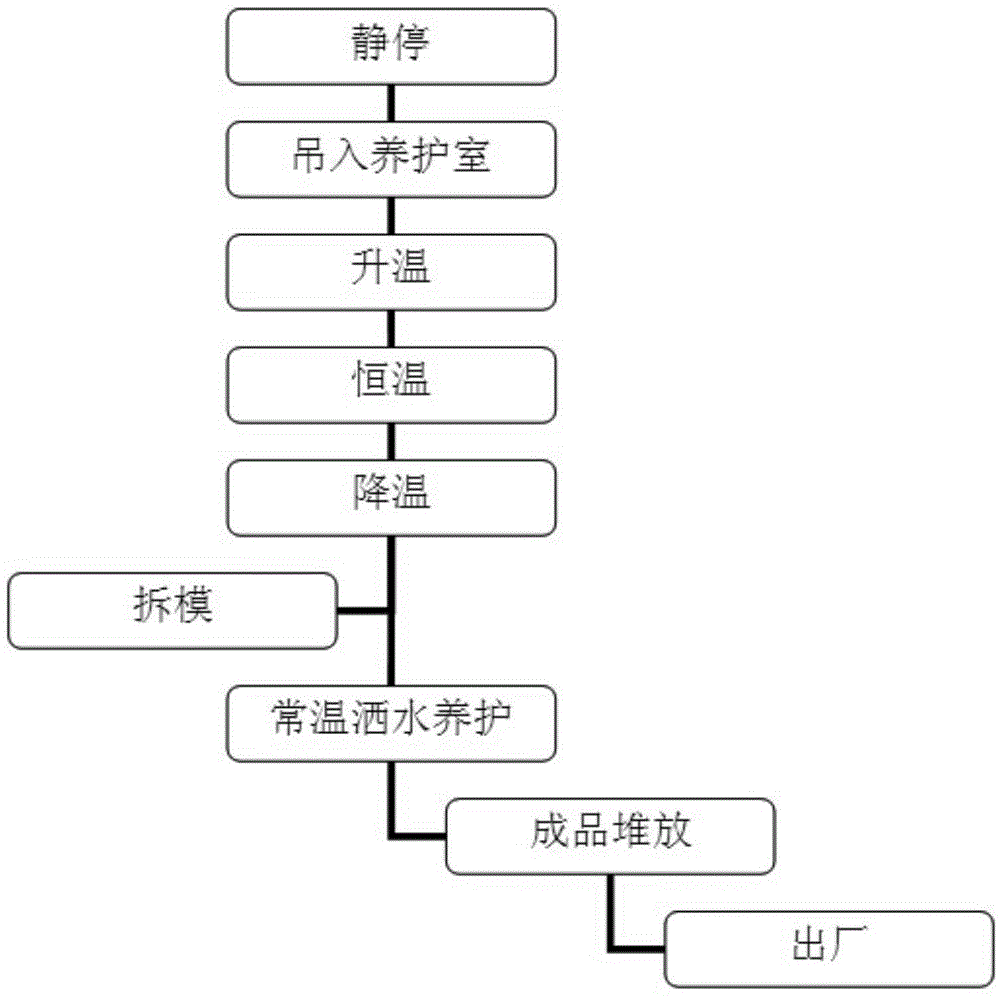

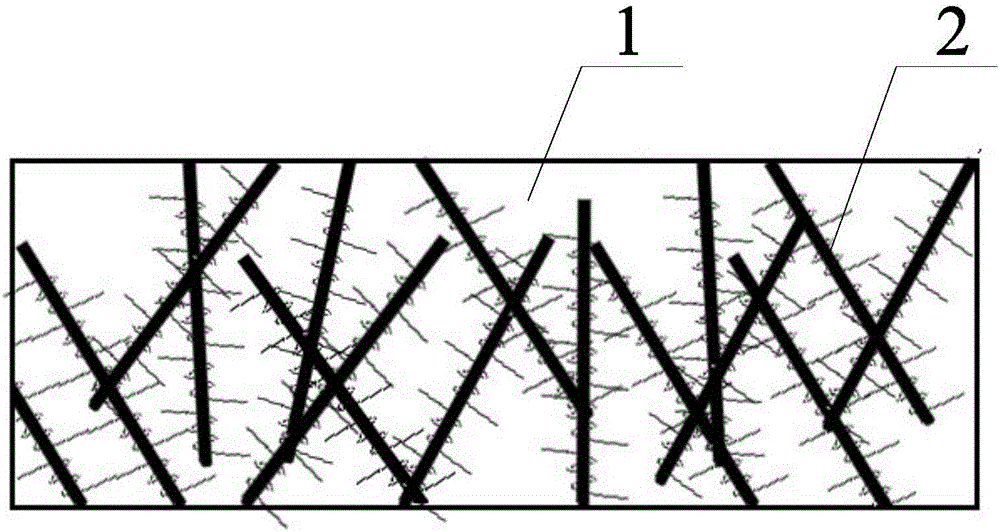

High-strength concrete composite material as well as preparation method and application thereof

InactiveCN102050603AWon't rustGood electromagnetic insulationSolid waste managementBuilding reinforcementsHigh strength concreteMagnetic disturbance

The invention discloses a high-strength concrete composite material as well as a preparation method and an application thereof, and relates to a concrete material. The high-strength concrete composite material comprises the following components in percentage by weight: 4.9-5.3% of water, 17-19% of cement, 15-25% of sand, 2.0-2.4% of silicon ash, 2.0-3.0% of quartz powder, 0.18-0.20% of high efficiency water reducing agent, 45-55% of calcined alumina aggregate, 0.1-0.85% of chopped aramid fiber and 0.5-4.0% of fiber cloth. The preparation method comprises the following steps: (1) stirring; (2) forming; and (3) curing. The high-strength concrete composite material is a non-metal material which can not be rusted; the electromagnetic insulation property of the high-strength concrete composite material is favorable, thus the high-strength concrete composite material can fully display the advantage under the condition that the structure requires no magnetic disturbance; the elastic modulus of the high-strength concrete composite material is similar to that of normal concrete, and the prepared anchorage device and other accessories can be well matched with other components; and due to light weight, the high-strength concrete composite material can lower the structure dead-weight and manufacturing cost.

Owner:湖北金力工程复合材料有限公司

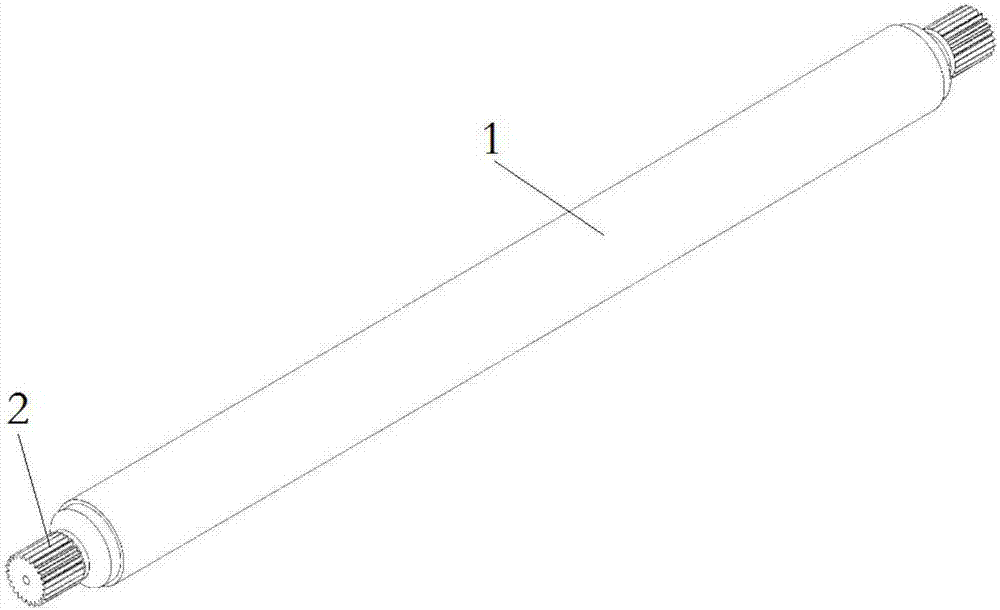

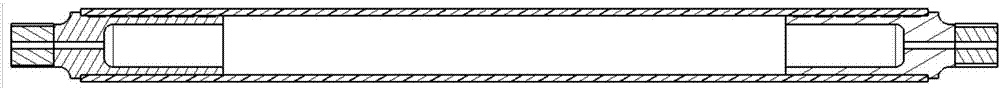

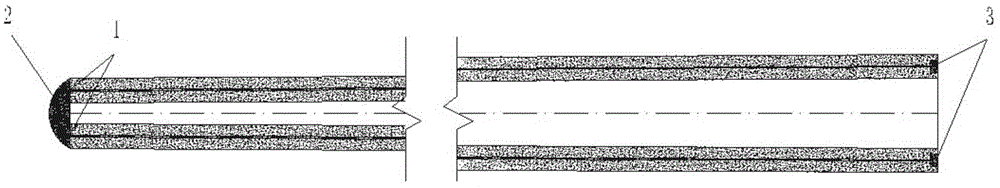

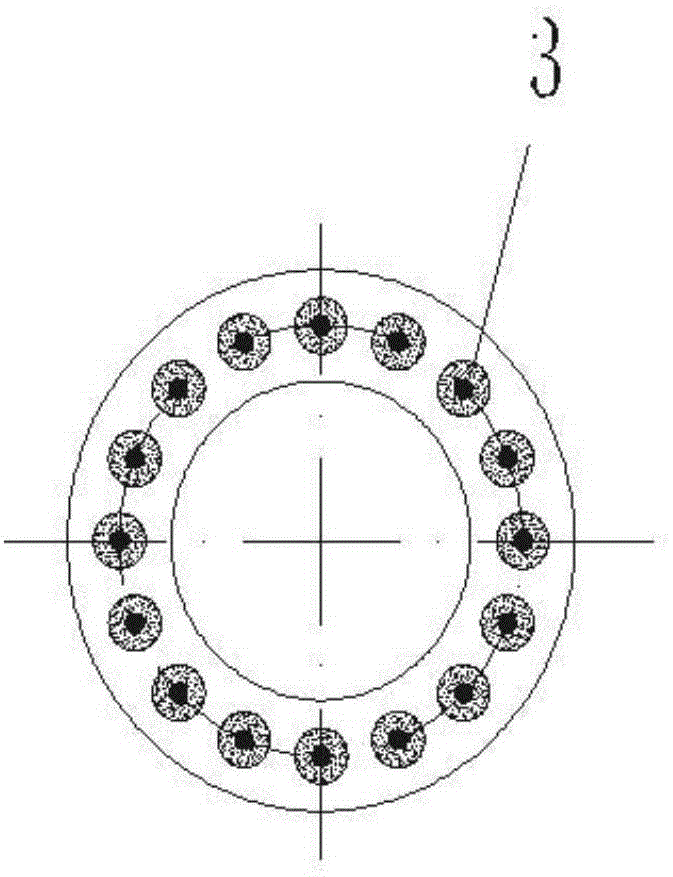

Formula car carbon fiber half shaft bearing large torque and preparation method thereof

ActiveCN107031068AImprove acceleration performanceSmall moment of inertiaYielding couplingShaftsFiberCarbon fibers

The invention discloses a formula car carbon fiber half shaft bearing large torque and a preparation method thereof. The carbon fiber half shaft comprises a carbon fiber half shaft body and a half shaft connector. The carbon fiber half shaft body is in a hollow sleeve shape. The half shaft connector is made of metal and comprises a spline section and a glue joint section connected with the carbon fiber half shaft body. The glue joint section comprises a glue joint groove and centering bosses of which the inner diameter is the same as that of the carbon fiber half shaft body. The carbon fiber half shaft is low in weight, less in rotating inertia, good in corrosion resistance, high in fatigue resistance and long in life.

Owner:WUHAN UNIV OF TECH

High-strength anti-seepage and anti-freezing concrete electric pole

The invention provides a high-strength anti-seepage and anti-freezing concrete electric pole. The electric pole comprises a reinforced framework and a concrete layer, wherein the reinforced framework comprises erection rings equidistantly-arranged in the vertical direction of the electric pole and longitudinal pre-stressed reinforcing bars wound by spiral ribs; a seal cover is arranged at the top end of the electric pole; each longitudinal pre-stressed reinforcing bar is shorter than the concrete layer coated outside the longitudinal pre-stressed reinforcing bar; the concrete layer at the bottom end of the electric rod is provided with a circular or square blind hole which is coaxial with the concrete layer and is filled with a corrosion-resistant material corresponding to each reinforcing bar. According to the concrete electric pole provided by the invention, the little ends of the reinforcing bars are protected in concrete and other corrosion-resistant materials in the blind holes, and the reinforcing bars are not exposed and sealed in the blind holes, so that reinforcing bars at the root of the concrete electric pole are not collided; as a protective layer is provided, corrosion cannot occur. The concrete of the concrete electric pole has the early-stage, middle-stage and later-stage strengths, so that the optimal performance of a cementitious material is achieved, and the optimal strength during the whole life cycle and durability are improved.

Owner:CHINA ELECTRIC POWER RES INST +2

Production method of anti-corrosion steel

InactiveCN112934639AReduce consumptionImprove performanceAnti-corrosive paintsSpecial surfacesProduction lineProduct inspection

The invention discloses a production method of anti-corrosion steel. The production method of the anti-corrosion steel comprises the following steps: (1) cooling rolled steel on a factory production line; (2) conducting cleaning treatment on surfaces of the steel; (3) coating the steel with anti-corrosion paint, and conducting drying; and (4) conducting finished product inspection on the steel and coatings thereof, and conducting packaging, warehousing and delivery. According to the production method of the anti-corrosion steel, the steel produced on the production line is immediately coated with the anti-corrosion paint, thus each piece of steel is coated with one corresponding anti-corrosion coating before leaving a factory, moreover, it is guaranteed that the coatings have good performance, the steel cannot be rusted due to absence of protection before use, and cannot be rusted due to coating film damage, thus subsequent coating project can be directly carried out, rust removal processes are omitted, and not only can the rust removal cost be reduced to reduce environmental pollution, but also steel consumption can be reduced, so that the service lives of steel structures are prolonged.

Owner:深圳市嘉达节能环保科技有限公司

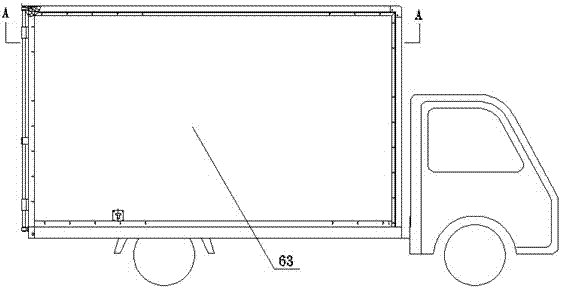

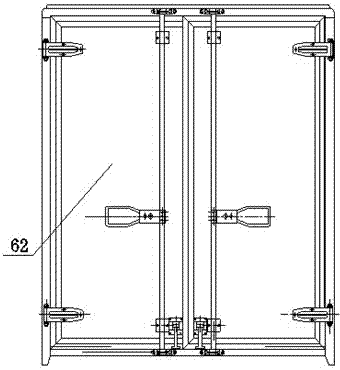

Truck carriage

ActiveCN103204185ALight in massReduce the weight of the carriageLoading-carrying vehicle superstructuresTruckMechanical engineering

The invention discloses a truck carriage. The truck carriage comprises a carriage skeleton, wherein the carriage skeleton is provided with a door frame, a front frame, two upper beams and two lower beams; vertical columns of the door frame are provided with door-frame vertical column embedding grooves; an upper cross beam of the door frame is provided with a door-frame upper cross beam embedding groove; the two sides of each vertical column profile are provided with two vertical-column embedding grooves; upper profiles and lower profiles are respectively provided with upper embedding grooves and lower embedding grooves; each upper profile is also provided with a supporting plate; the three end surfaces of a top plate of the carriage are arranged on the supporting plates of the three upper profiles; the fourth end surface of the top plate is embedded in the upper cross beam embedding groove of the door frame; the left side surface, the right side surface and the front side surface of the carriage skeleton are provided with a left side plate, a right side plate and a front side plate; the four end parts of the left side plate and the right side plate are respectively embedded in the door-frame vertical column embedding grooves, the upper embedding grooves, the lower embedding grooves and the vertical column embedding groove in the left side surface and the right side surface; the four end parts of the front side plate are respectively embedded in the vertical-column embedding grooves, the upper embedding grooves and the lower embedding grooves formed in the side surface; a carriage door device is arranged at the door frame; and the left side plate, the right side plate and the front side plate are made of PVC (Poly Vinyl Chloride) plastic boards, and the top board of the carriage is made of a waterproof material. The truck carriage disclosed by the invention is water-proof and moisture-proof and is long in service life.

Owner:重庆勇图机械工业有限公司

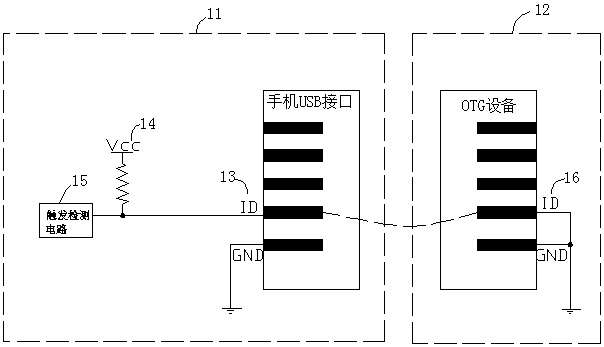

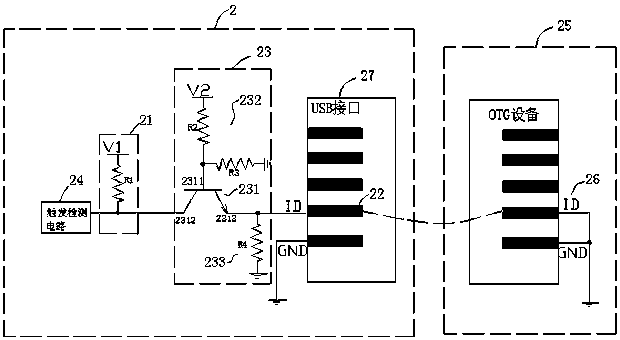

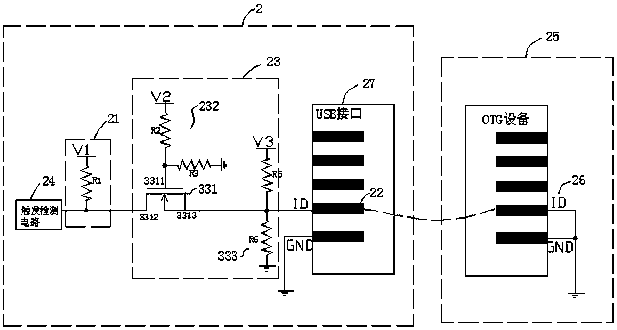

USB interface circuit and mobile terminal

ActiveCN108399142ARealize identificationWon't rustSubstation equipmentElectric digital data processingElectricityComputer terminal

The invention provides a USB interface circuit. The USB interface circuit comprises a power supply circuit, a USB interface, an isolating circuit and a triggering detecting circuit, wherein the USB interface is provided with an ID contact; the isolating circuit is positioned between the power supply circuit and the ID contact; the isolating circuit comprises a first biasing circuit, a second biasing circuit and a transistor; a control end of the transistor is electrically connected to a voltage output end of the first biasing circuit; a first end of the transistor and an output end of the power supply circuit are jointly electrically connected to an input end of the triggering detecting circuit; and a second end of the transistor and a voltage output end of the second biasing circuit are jointly electrically connected with the ID contact. When OTG equipment is not connected to the USB interface, the transistor works in an amplifying or stopping state so as to isolate the power supply circuit from the ID contact, and the ID contact cannot be rust; and when the OTG equipment is connected into the USB interface, the transistor works in a saturated conduction state, the triggering detecting circuit detects change of level from high to low, and thus, recognition of the OTG equipment is realized.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

Method for machining stainless steel sewage pump impeller

The invention discloses a method for machining a stainless steel sewage pump impeller. According to the machining technology, the method includes the following steps that step1, impeller blades, an upper cover plate and a lower cover plate are formed in a punching mode, and integral forming between the impeller blades, the upper cover plate and the lower cover plate is performed through the combination of a hydraulic machine and a punching die; step2, impeller welding: the impeller blades, the upper cover plate and the lower cover plate are welded through a welding machine, wherein the impeller blades, the upper cover plate and the lower cover plate are formed in the punching mode; step3, acid pickling and passivation are performed on the welded impeller; step4, the passivated impeller is washed through a washing machine; step5, air drying is performed on the impeller. The method has the advantages that the punching assembly and welding forming are adopted, so that the method is high in product quality, good in uniformity, short in manufacturing period, few in machining process, high in machining efficiency, free of pollution in the production process, high in operation efficiency of a water pump, high in corrosion resistant capacity and long in service life and saves consumable items.

Owner:浩溪机械(上海)有限公司

High-strength tin-plated bronze tire bead steel wire and preparation method thereof

InactiveCN102517581AProtect against rustImprove adhesionLiquid/solution decomposition chemical coatingSuperimposed coating processTinningCentrifugation

The invention discloses a high-strength tin-plated bronze tire bead steel wire which comprises a steel wire base body. The surface of the steel wire base body is provided with at least two plating layers, tin content of the plating layers is reduced layer by layer from inside to outside, tin content of the plating layer closely attached to the surface of the steel wire base body is high, the adhesive force between the plating layer and the steel wire base body is high, and the plating layer which is high in tin content can effectively prevent the steel wire base body from being rusted. The plating layers with the tin content gradually reduced from inside to outside are closely combined with each other, and a high adhesive force exists between the outermost plating layer with the relatively lowest tin content and tire rubber. Accordingly, the tire bead steel wire in the technical scheme can guarantee that the steel wire base body in the plating layers is not rusted, the high adhesive force between the tire bead steel wire and the tire rubber can be guaranteed, a tire can bear acting force such as high-strength stretching, compression, twisting and centrifugation during the automobile running process, and safety of automobile running is guaranteed.

Owner:SHANDONG DAYE

Raw material grinding aid used in cement clinker firing process

The invention is applicable to the technical field of cement production admixtures, and provides a raw material grinding aid used in a cement clinker firing process, the raw material grinding aid is brown liquid and comprises the following components in percentage by mass: 0.1-1% of triterpenoid saponin, 1-10% of aliphatic water reducer, 2-8% of potassium carbonate, 1-3% of sodium carbonate, 2-10% of sodium formate, 20-35% of caprolactam and the balance of water. A certain amount of water is taken to enter a reaction kettle, then stirring is started, heating is conducted till the liquid temperature reaches 70 DEG C, caprolactam is added, hydrolysis ring opening is conducted, sodium formate, sodium carbonate and potassium carbonate are sequentially added, stirring is conducted for 1-1.5 h, triterpenoid saponin and an aliphatic water reducer are added, stirring continues to be conducted for 1 h, the product is obtained, and the product is filtered and guided into a finished product storage tank. After the raw material grinding aid is adopted, the desulfurization efficiency can be up to 98% or above, the desulfurization cost is reduced, the yield of a raw material mill can be increased by 12-25%, the yield in the prior art can only be increased by about 10%, the cement clinker kiln yield can be increased by 10% or above, or standard coal can be saved by 5 kilograms or above, while the yield in the prior art can only be increased by about 5% or coal can be saved by about 3 kilograms.

Owner:山西天润恒德新材料有限公司

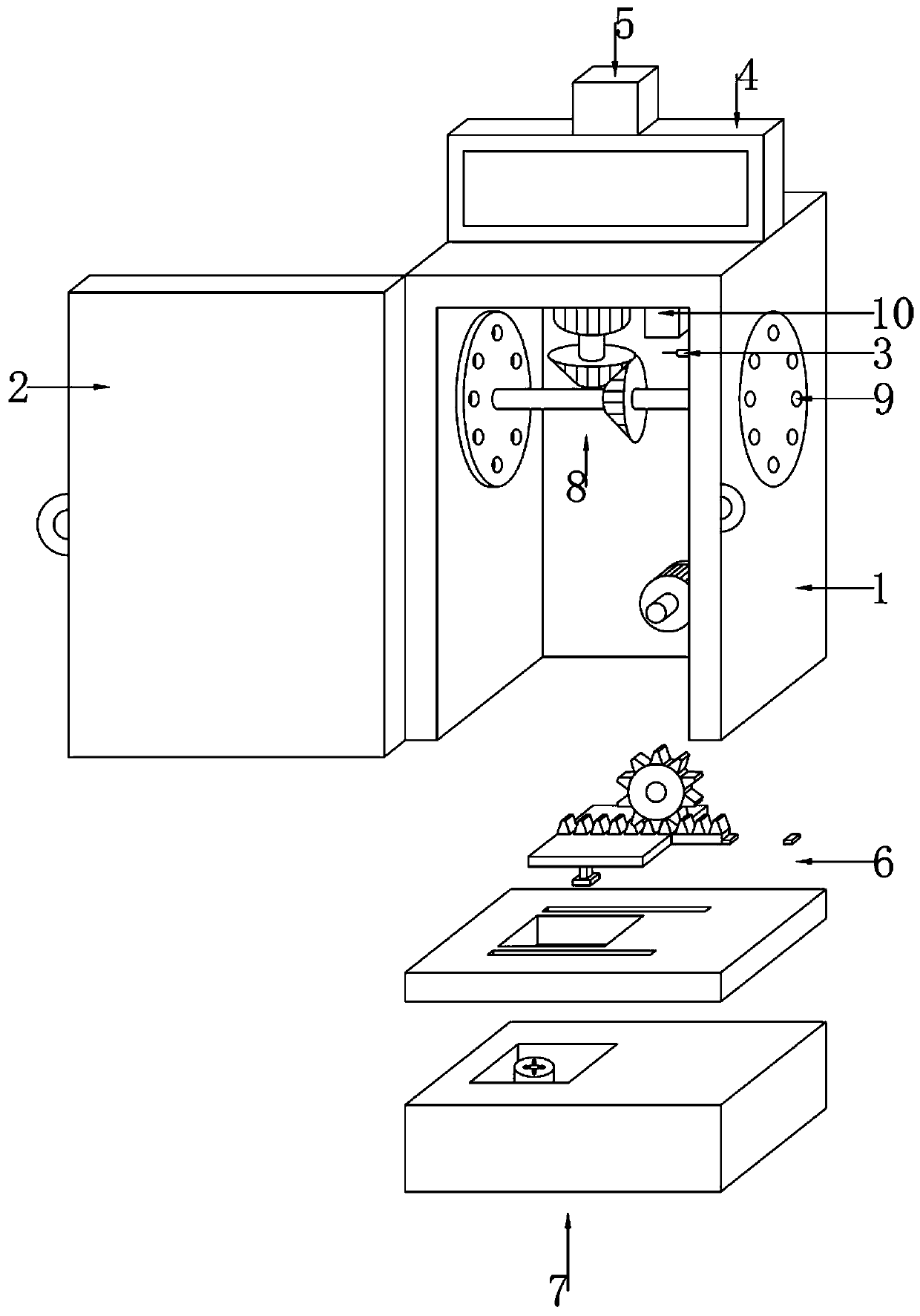

Bletilla striata producing and processing device

ActiveCN108908471AAvoid deformationPrevent movementConveyorsMetal working apparatusDrive wheelBletilla striata

The invention relates to the technical field of medicinal material processing, in particular to a bletilla striata producing and processing device. The bletilla striata producing and processing devicecomprises a driving wheel, a driven wheel is arranged on one side of the driving wheel, a conveying belt is tensioned on the driving wheel and the driven wheel, a cutter rest is arranged above the conveying belt and is evenly provided with a plurality of cutters, a sleeve is arranged below the conveying belt, a tensioning wheel is arranged on the sleeve in a sliding manner, and the conveying beltis tensioned on the tensioning wheel; and one side of the driven wheel is provided with a first bearing roller, a second bearing roller is arranged below the first bearing roller, a pull rope is tensioned on the first bearing roller and the second bearing roller, one end of the pull rope is connected with the cutter rest, the other end of the pull rope is located in the sleeve and is connected with the tensioning wheel, and a reset piece is connected to the tensioning wheel. The bletilla striata producing and processing device solves the problem that in the prior art, a conveying belt is impacted by the cutters and generates deformation, and consequentially the bletilla striata cutting effect is influenced.

Owner:务川县天门山农业开发有限公司

Street lamp embedded part installing and positioning device

The invention discloses a street lamp embedded part installing and positioning device which comprises a positioning cover, a positioning body and a positioning support. A round sealing opening matched with a street lamp pole is arranged in the middle of the positioning cover, the two sides of the positioning cover are provided with handles enabling a cover body to be opened conveniently, the positioning body is provided with a bottom plate and a middle plate, the bottom plate is connected with the positioning support, vertical holes used for installing an embedded part are formed in the periphery of the middle plate, a vertical first round hole is formed in the middle of the middle plate, and the cover body is located on the positioning body. The device is simple in structure and low in manufacturing cost, the embedded part can be conveniently installed, and installation accuracy of the embedded part is guaranteed. The embedded part and a street lamp base can be prevented from being blown by wind, shone by the sun and wetted by rain, the embedded part and the street lamp base are not prone to rust, and repair and maintenance are convenient.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

Magnesium-based inorganic heat insulation coating and preparation method thereof

The invention discloses a magnesium-based inorganic heat insulation coating and a preparation method thereof. The magnesium-based inorganic heat insulation coating comprises a cementing material, a functional material and a modifier. The cementing material provided in the embodiment of the invention does not contain Cl<->, and a heat insulation coating layer made by using the coating does not corrode steel bar parts in the service process. The coating is characterized in that solid components of the coating can be produced in a factory only, and a required component can be obtained through taking tap water in proportion in the construction field. The preparation method is convenient for packaging, transporting and storing the coating, and reduces the cost of relevant production, storage and transportation links.

Owner:SHENZHEN CHAMELEON NEW BUILDING MATERIALS CO LTD

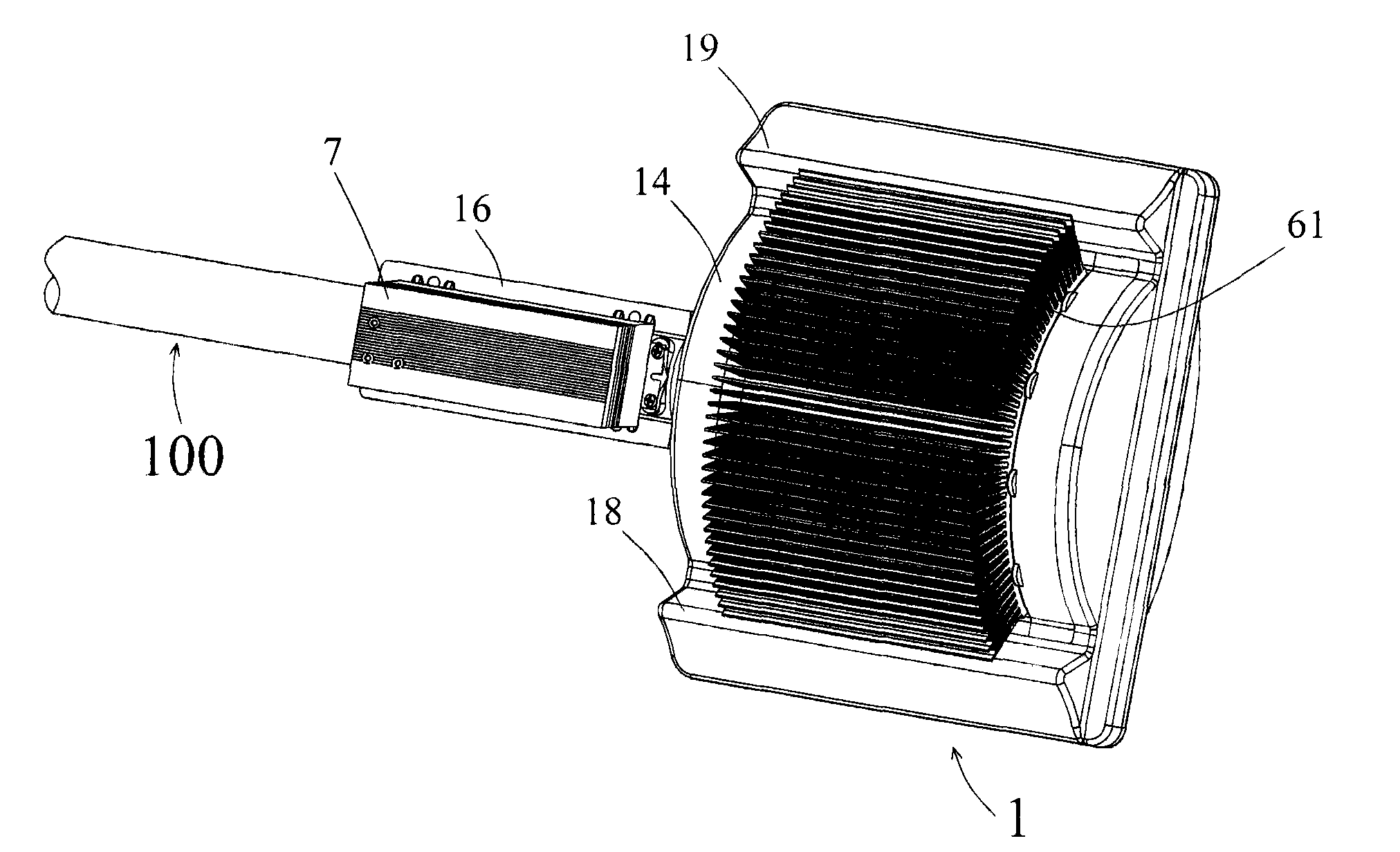

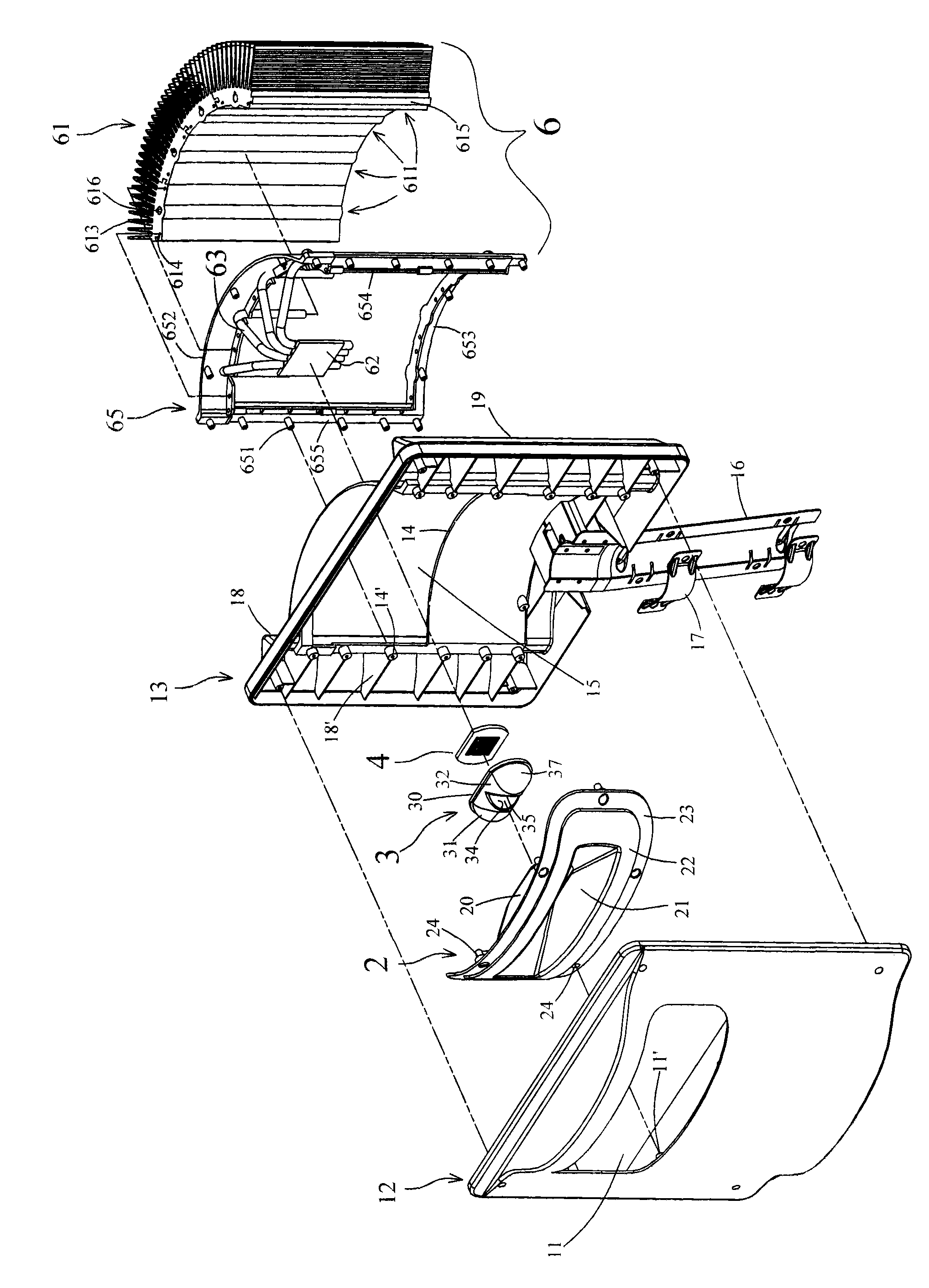

Street lamp with high-power light-emitting diode (LED) single polycrystalline chip die set

InactiveCN101988655AImprove cooling effectReduce weightMechanical apparatusPoint-like light sourceEffect lightUltraviolet

The invention relates to a street lamp with a high-power light-emitting diode (LED) single polycrystalline chip die set, which comprises a shell body formed by a back shell and a surface shell, a light field photomask, a high-power LED single polycrystalline chip die set, light scattering lenses, and a heat radiating device provided with an arc-shaped heat radiator and a superconductive heat pipe, wherein the surface shell is provided with a first window; the light field photomask is arranged in the first window of the shell body; the light scattering lenses are solid core lenses taking the flat bottom surface as the light incidence surface and are arranged in the bottom mouth in the light field photomask; the flat bottom surfaces of the light scattering lenses tightly contacts with the silica gel on the surface of the high-power LED single polycrystalline chip die set without gap so as to form a batwing rectangular light field distribution curve flux by utilizing a primary light source; and the heating radiating device is arranged on the hogged part of the back shell. The high-power LED single polycrystalline chip die set is taken as a light source and is matched with the light field photomask and the single light scattering lens to reach the requirement of the batwing rectangular light field distribution curve flux street lamp by using the primary light source; the brightness uniformity is enhanced, and the lighting effect is good; the shell body is prepared by adopting ultraviolet-resistance aging-resistance reinforced and toughened plastics; the weight is greatly reduced; and the street lamp is conveniently installed and safely used.

Owner:杨然森 +1

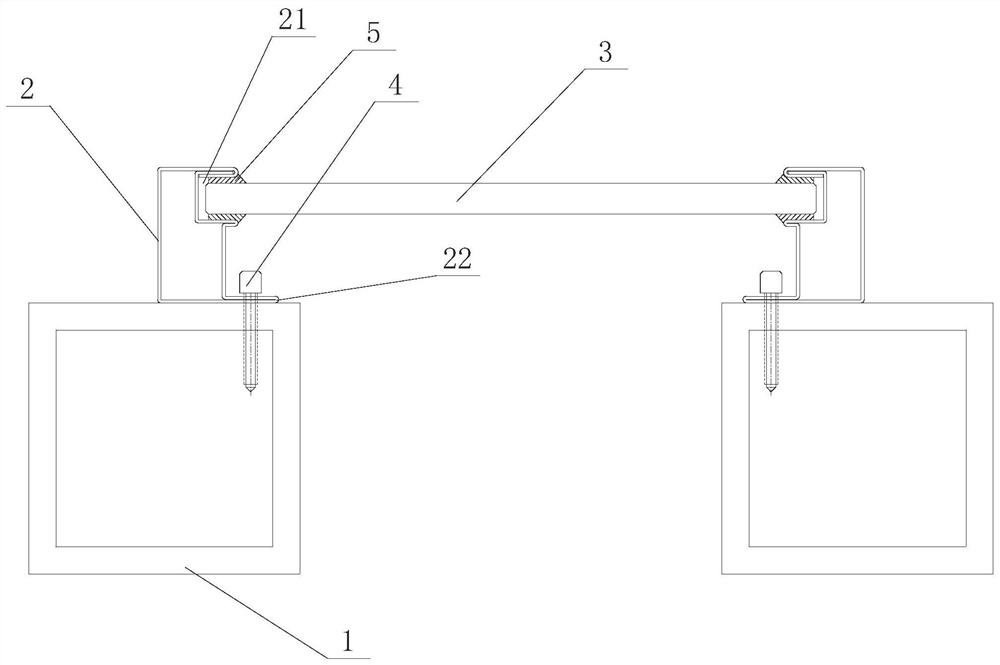

Solar photovoltaic panel fixing system

PendingCN112803885AWon't rustHigh strengthPhotovoltaic supportsPhotovoltaic energy generationEngineeringSteel frame

A solar photovoltaic panel fixing system disclosed by the invention comprises a base, a plurality of steel frames, a photovoltaic panel and fixing bolts, wherein the plurality of steel frames are enclosed and connected to form a steel frame, the steel frame is a closed frame formed by bending a steel profile and overlapping and meshing two ends of the steel profile, the upper position and the lower position of the same side of the steel frame are bent to form a clamping groove and a connecting edge respectively, the overlapping and meshing positions at the two ends are arranged on the groove edge of the clamping groove, the photovoltaic panel is arranged in the steel frame, the edges of the photovoltaic panel are clamped in the clamping grooves of the corresponding steel frame, and the fixing bolts are arranged on the connecting edges in a penetrating mode and connected with the corresponding base in a fastened mode. The solar photovoltaic panel fixing system has the advantages that the structure is stable and reliable, corrosion can be prevented, and the connecting strength and the clamping strength can be improved.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD +1

Forest fallen leaf cleaning vehicle

ActiveCN108221799AImplement collection processingImprove cleaning efficiencyRoad cleaningEngineeringLeaf fall

The invention relates to a forest fallen leaf cleaning vehicle, belongs to the field of environmental protection devices, and particularly relates to a device which picks up fallen leaves by the aid of hooked needles, collects and treats the picked up fallen leaves. The cleaning vehicle has the advantages that fallen leaves in a forest can be collected and treated, manual sweeping by traditionaltools is omitted, a plurality of hooked needles are arranged on a front rotating shaft, an unidirectional cleaning range is wider, the cleaning vehicle is provided with two groups of hooked needles, so that the fallen leaves are thoroughly cleaned, missing of fallen leaf cleaning is avoided, the fallen leaves are picked up by the hooked needles, burden of bend down picking up of workers is reduced, barbs are arranged on the hooked needles, the fallen leaved stuck on the ground can be picked up and cannot slide out, the fallen leaves on the hooked needles are more conveniently and rapidly takendown by the aid of a front scraper and a rear scraper, fallen leaf taking frequency of the front scraper and positions of the hooked needles are coordinated by bumps, and a storage box suffered fromjolting does not easily slip by the aid of a rear inclined bump of a frame.

Owner:滁州华冶机电科技有限公司

Friction material and friction goods

ActiveCN106634834AImprove structural strengthGuaranteed high temperature performanceOther chemical processesFriction liningMetal fibersPetroleum coke

The invention provides a friction material and friction goods. The friction material comprises, by weight, 25-35 parts of metal fibers, 2-4 parts of phenolic resin, 1-2 parts of nitrile rubber, 37-64 parts of barium sulfate, 1-4 parts of aluminum oxide, 1-4 parts of chromite, 2-5 parts of graphite, 2-5 parts of petroleum coke particles and 2-6 parts of mica. Each metal fiber comprises a plurality of composite nickel-tin metal fiber threads in disordered arrangement. A nickel fiber serves as a main body of each composite nickel-tin metal fiber thread. Tin fibers are divided into multiple segments which are wound around the nickel fibers from bottom to top. The head end and the tail end of each segment of tin fiber are protruded out of two sides of the corresponding main body respectively. The friction goods are obtained through pressurized heating of the friction material in a specific mold. The friction goods have high heat resistance performance while hardness can be guaranteed, the manufacture process is simple and convenient, and the friction goods do not contain iron and do not rust.

Owner:HUBEI FEILONG FRICTION & SEALING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com