Solar photovoltaic panel fixing system

A solar photovoltaic and fixed system technology, applied in the field of solar photovoltaic power generation, can solve problems such as the aluminum frame falling off, the aluminum frame is easy to deform, and the structure of the power generation device is not stable enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

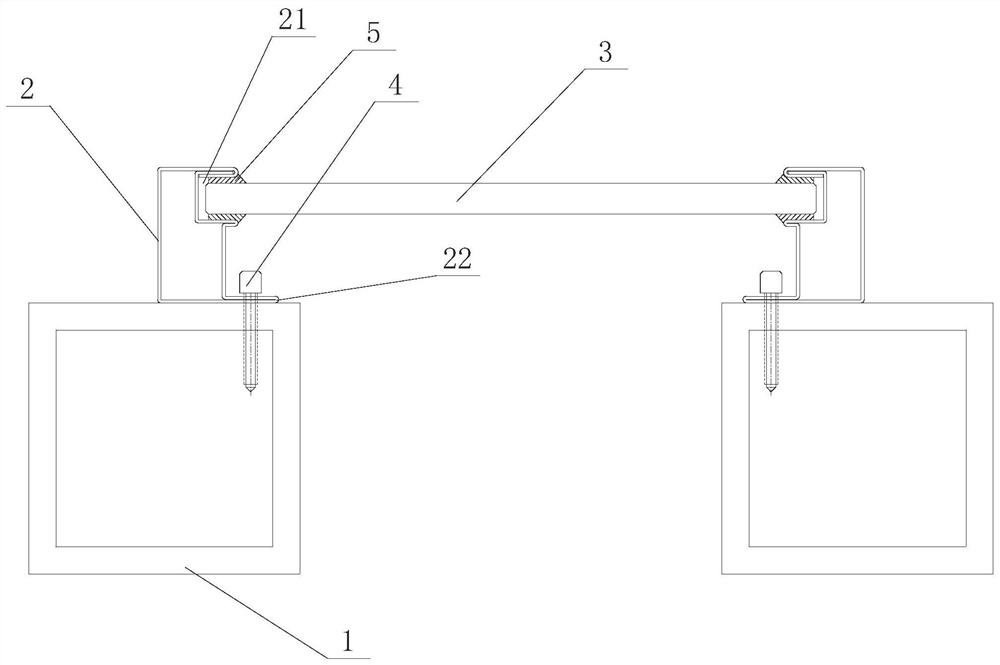

[0030] Such as figure 1 and figure 2 As shown, the first embodiment of the solar photovoltaic panel fixing system of the present invention includes a base 1, a steel frame 2, a photovoltaic panel 3 and fixing bolts 4, and a plurality of steel frames 2 are surrounded and connected to form a steel frame. The quality frame 2 is bent from a steel section bar and the two ends are overlapped and occluded to form a closed frame. The occlusal position is set on the edge of the clamping groove 21, the photovoltaic panel 3 is set in the steel frame, and each edge of the photovoltaic panel 3 is clamped in the clamping groove 21 of the corresponding steel frame 2, and the fixing bolt 4 passes through It is arranged on the connecting edge 22 and is firmly connected with the corresponding base 1 . During installation, first clamp each edge of the photovoltaic panel 3 into the clamping groove 21 of the corresponding steel frame 2, then surround and connect each steel frame 2 to form a ste...

Embodiment 2

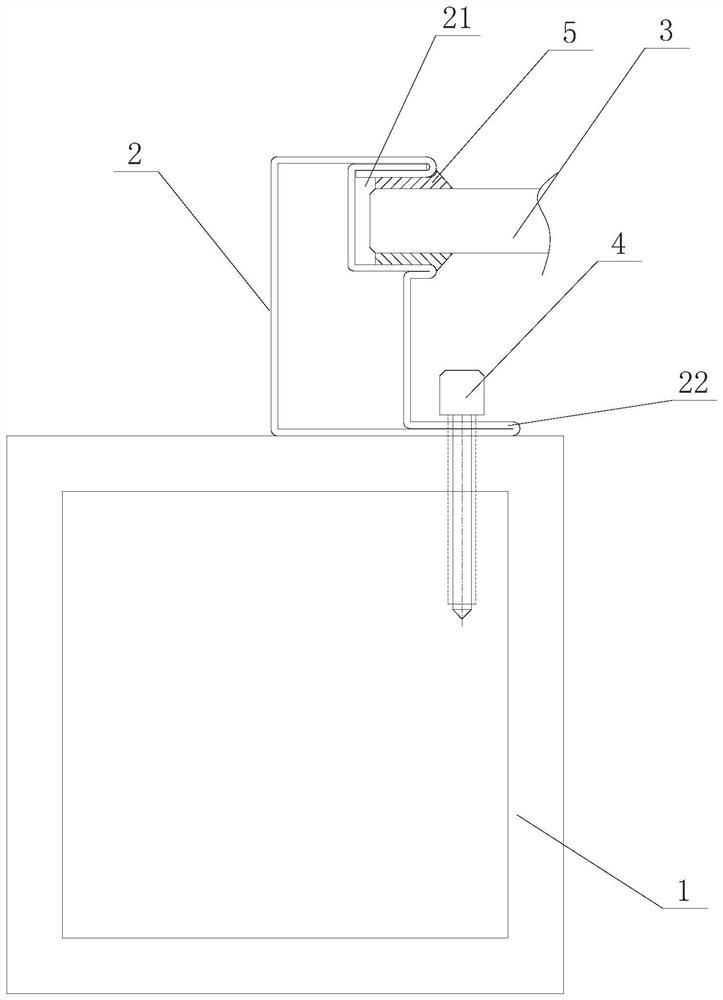

[0038] Such as image 3 As shown, the second embodiment of the solar photovoltaic panel fixing system of the present invention is basically the same as that of Embodiment 1, the only difference is that in this embodiment, the overlapping joint position is set at the lower clamping of the clamping groove 21 side. The clamping strength to the lower surface of the photovoltaic panel 3 is improved.

[0039] In this embodiment, the bite opening is set as a vertically facing bite opening. Its structure is simple and reliable.

Embodiment 3

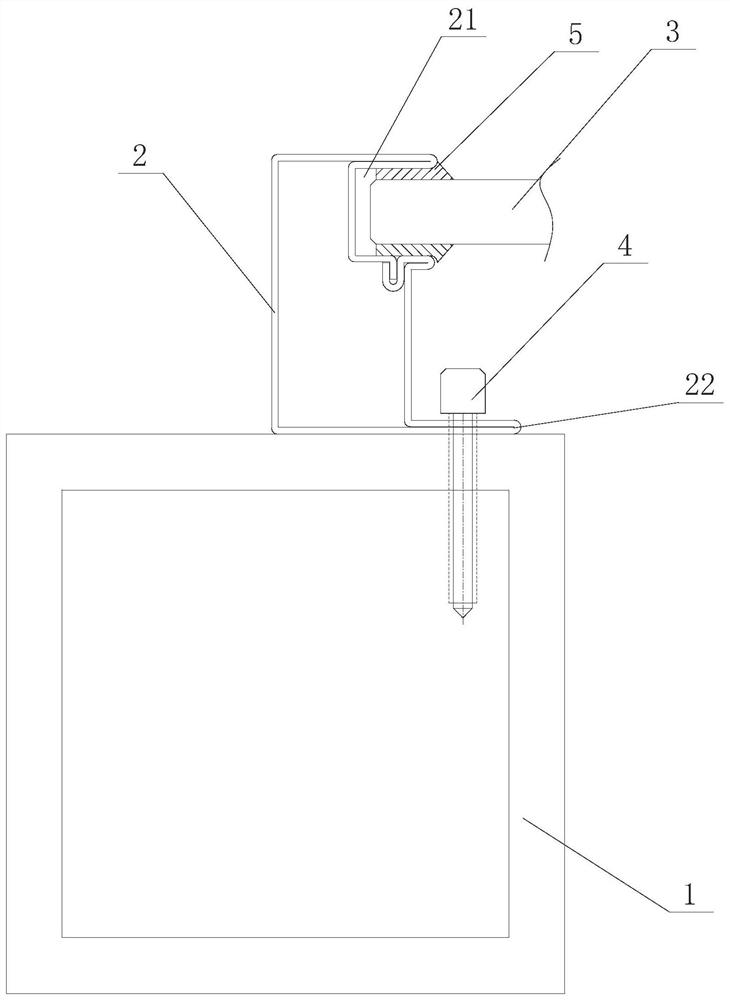

[0041] Such as Figure 4 As shown, the third embodiment of the solar photovoltaic panel fixing system of the present invention is basically the same as the first embodiment, the only difference is that in this embodiment, the overlapping joint position is set at the bottom edge of the clamping groove 21 superior. Increased overall notch strength.

[0042] In this embodiment, the bite is set as a bite facing obliquely. Its structure is simple and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com