Amortization window hinge

A technology for doors and windows and buffers, applied in the field of door and window folding, can solve problems such as affecting the appearance of doors and windows, troublesome production and installation, and large volume, and achieve the effects of simple structure, convenient installation and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

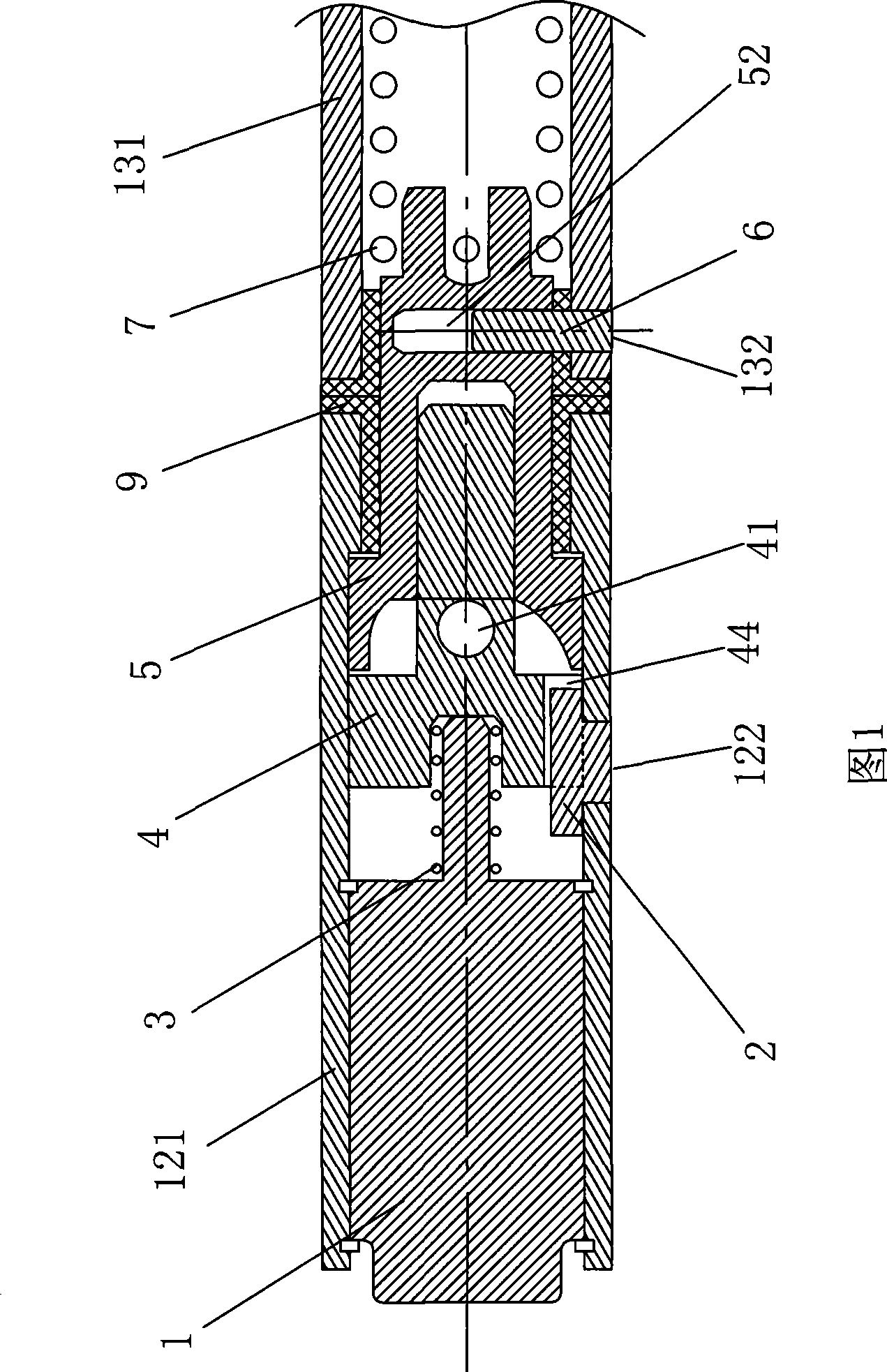

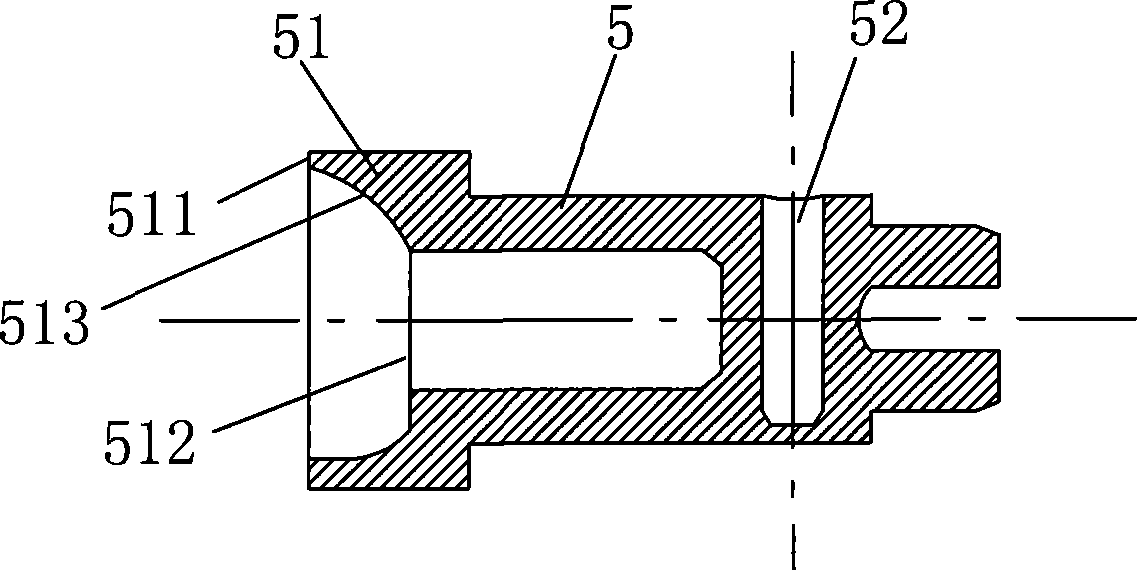

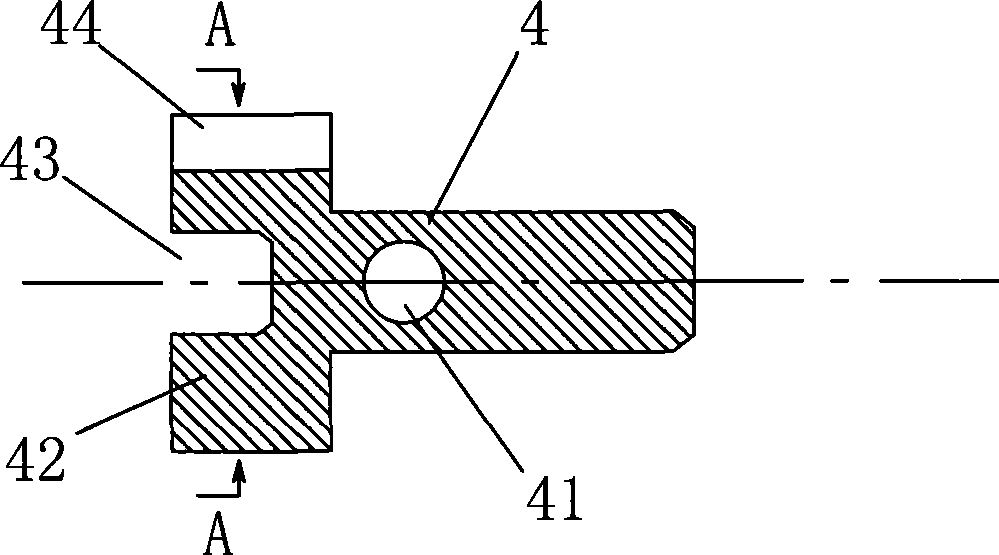

[0039] Figure 1 and Figure 4 As shown, the buffer door and window hinge of the present invention includes two hinges with a shaft cylinder and a linkage mechanism arranged in the shaft cylinder. The two folds of the present invention are double ear hinges 12 and single ear hinges 13 respectively. Corresponding to the integrated shaft tubes 121, 131 (refer to Figure 5) respectively, the linkage mechanism makes the two folding shaft cylinders 121, 131 correspond to the same axis. The device is composed of a shaft body 5, a lifting rod 4 that can be lifted and rotated relative to the shaft body 5 along the shaft at one end of the shaft body 5, and a buffer 1 that buffers the lifting rod 4 to lift and buffer its relative rotation. The shaft cylinder 131 of the leaf 13 is relatively fixed to rotate coaxially, and the lifting rod 4 is engaged with the shaft cylinder 121 of the double-ear hinge 12 so that the lifting rod 4 and the hinge 12 can move up and down when they rotate fixed...

Embodiment 2

[0046] As shown in Figure 5, the structure and connection relationship of the buffer device is the same as that of Embodiment 1, but the linkage mechanism also includes a linkage device installed on the other end of the shaft cylinder, and the linkage device includes a pin 11 fixed to the ear fold The fixed end face gear 10 in the page shaft barrel 121, and the adjusting end face gear 8 corresponding to the fixed end face gear 10 and linked to the two folding leaf shaft barrels 121, 131, the shaft body 5 and the adjusting end face gear 8 pass through the two folding leaf shaft barrels 121, 131, play a linkage role, the closed end of the shaft body 5 and the closed end of the adjustment face gear 8 are corresponding in the single-ear folding shaft cylinder 131, and there is a twist spring between the two to make the two folding pages automatically close 7. Through the adjustment of the gears at both ends, the elastic coefficient of the twist spring can be adjusted as required; i...

Embodiment 3

[0049] Such as Image 6 with Figure 8 As shown, the lifting rod 4 of the present invention can also be an integral cylindrical structure, with a horizontal pin 41 in the middle, one end is arranged in the shaft body 5, and the other end is directly connected with the buffer 1, which is a buffer spring. There is no round platform at this end, and a clamping seam (not shown in the figure) is chiseled directly on the cylinder, and the clamping protrusion 123 cast in the double ear folding shaft cylinder 121 can be locked by the clamping joint. The rest of the structure is the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com