3D-nanostructure NiCo2S4 electrode material for super capacitor and preparation method thereof

A supercapacitor, three-dimensional nanotechnology, applied in the direction of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, chemical instruments and methods, etc., can solve the problems of complex preparation process and inability to overcome the sharp decline of charge and discharge rate performance, and achieve The preparation process is simple, the supercapacitor performance is excellent, and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

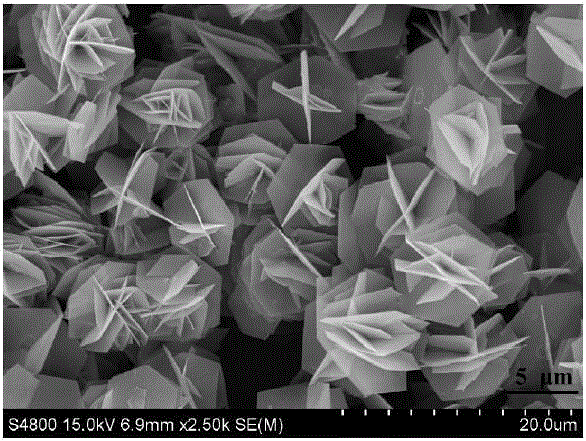

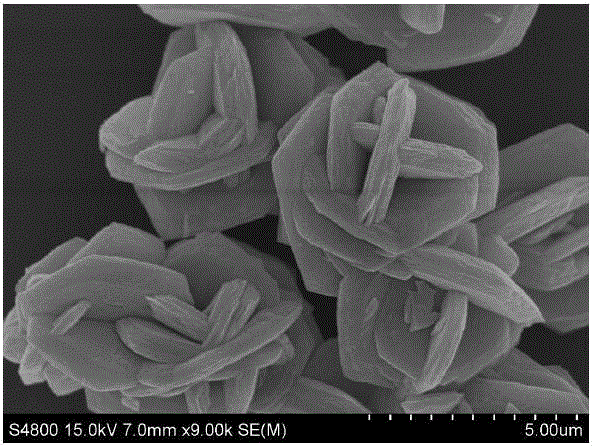

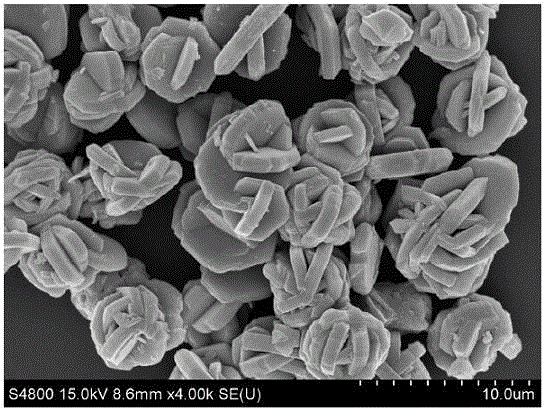

[0029] The invention relates to a three-dimensional nanostructure NiCo 2 S 4 Electrode material and its preparation method. Three-dimensional nanostructured NiCo 2 S 4 The electrode material consists of hexagonal NiCo 2 S 4 The nanosheets self-assemble to form three-dimensional nanostructures.

[0030] Three-dimensional nanostructured NiCo 2 S 4 Electrode materials are prepared by hydrothermal method and subsequent vulcanization process, including:

[0031](1) Dissolve divalent cobalt salt and divalent nickel salt in alkaline aqueous solution, and obtain a three-dimensional intermediate product through hydrothermal reaction; (2) Disperse the obtained intermediate product in the sulfur source solution for hydrothermal vulcanization treatment, Three-dimensional nanostructured NiCo can be obtained 2 S 4 Material.

[0032] The present invention utilizes NiCo 2 S 4 On the basis of the high pseudocapacitive activity and high conductivity of the material, the specific su...

Embodiment 1

[0034] (1) Select cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) 2mmol, nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) 1mmol and, urea 15mmol and ammonium fluoride (NH 4 F) Mix 6 mmol dissolved in 35 ml deionized water and obtain a clear solution by magnetic stirring.

[0035] (2) Transfer the solution to a 46ml polytetrafluoroethylene stainless steel reaction kettle, conduct a hydrothermal reaction at 100°C for 3 hours, wash the resulting precipitate with deionized water and absolute ethanol, and dry it at 60°C for 8 hours .

[0036] (3) Weigh 40mg of the above dried product, add it to 0.02mol / L (30ml) sodium sulfide solution, transfer it to a 46ml volume polytetrafluoroethylene stainless steel reaction kettle, and heat it in water at 160°C for 6 hours. After the product precipitate was washed with deionized water and absolute ethanol, it was vacuum-dried at 60 °C for 6 hours to obtain NiCo 2 S 4 .

Embodiment 2

[0038] (1) Select cobalt acetate tetrahydrate (Co(CH 3 COO) 2 4H 2 O) 2mmol, nickel acetate tetrahydrate (Ni(CH 3 COO) 2 4H 2 O) 1mmol and, urea 20mmol and ammonium fluoride (KF) 24mmol were mixed and dissolved in 35ml deionized water, and a clear solution was obtained by magnetic stirring.

[0039] (2) Transfer the solution to a 46ml polytetrafluoroethylene stainless steel reaction kettle, conduct a hydrothermal reaction at 120°C for 6 hours, wash the resulting precipitate with deionized water and absolute ethanol, and dry it at 60°C for 8 hours .

[0040] (3) Weigh 40mg of the above dried product, add it to 0.02mol / L (30ml) thiourea solution, transfer it to a 46ml volume polytetrafluoroethylene stainless steel reaction kettle, and heat it in water at 140°C for 4 hours. After the product precipitate was washed with deionized water and absolute ethanol, it was vacuum-dried at 60 °C for 6 hours to obtain NiCo 2 S 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com