Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

161results about How to "Suitable for continuous mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

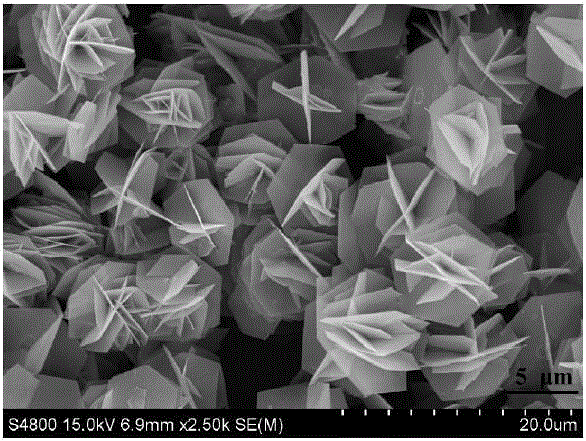

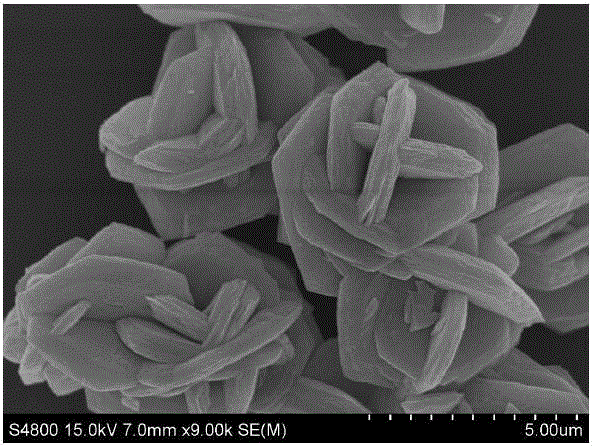

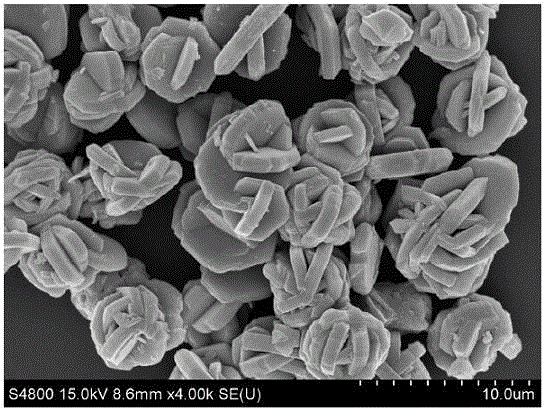

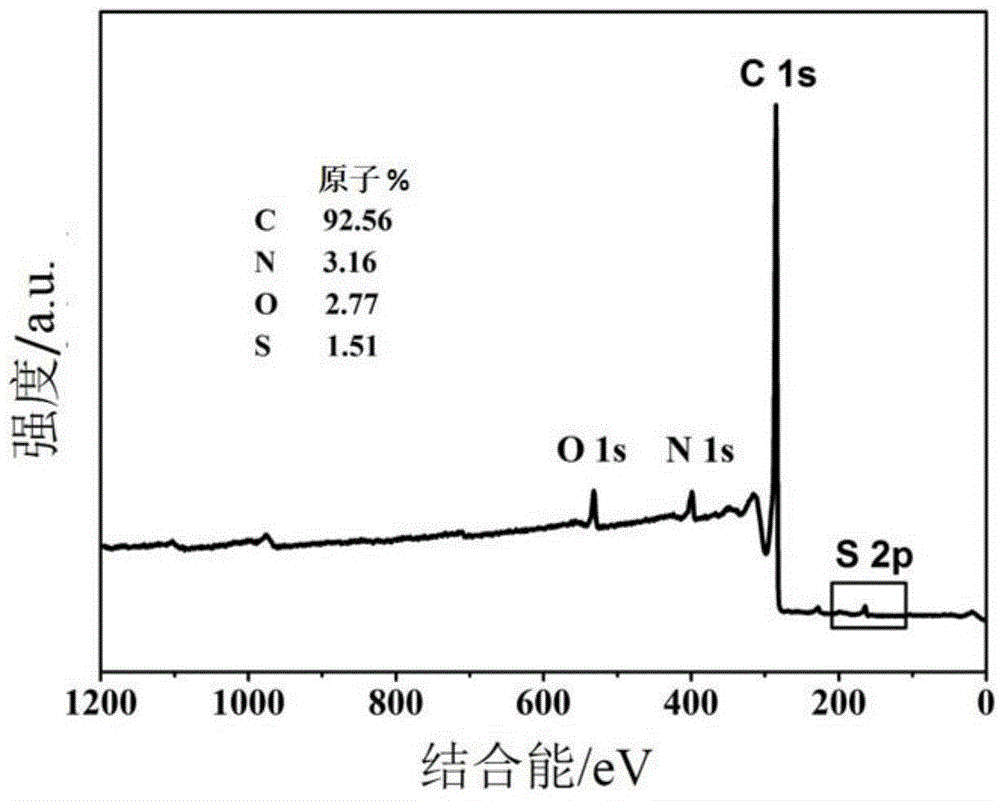

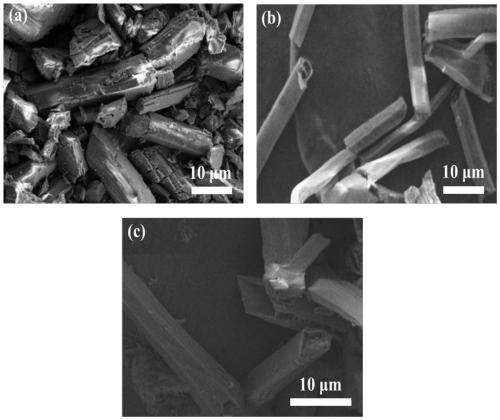

3D-nanostructure NiCo2S4 electrode material for super capacitor and preparation method thereof

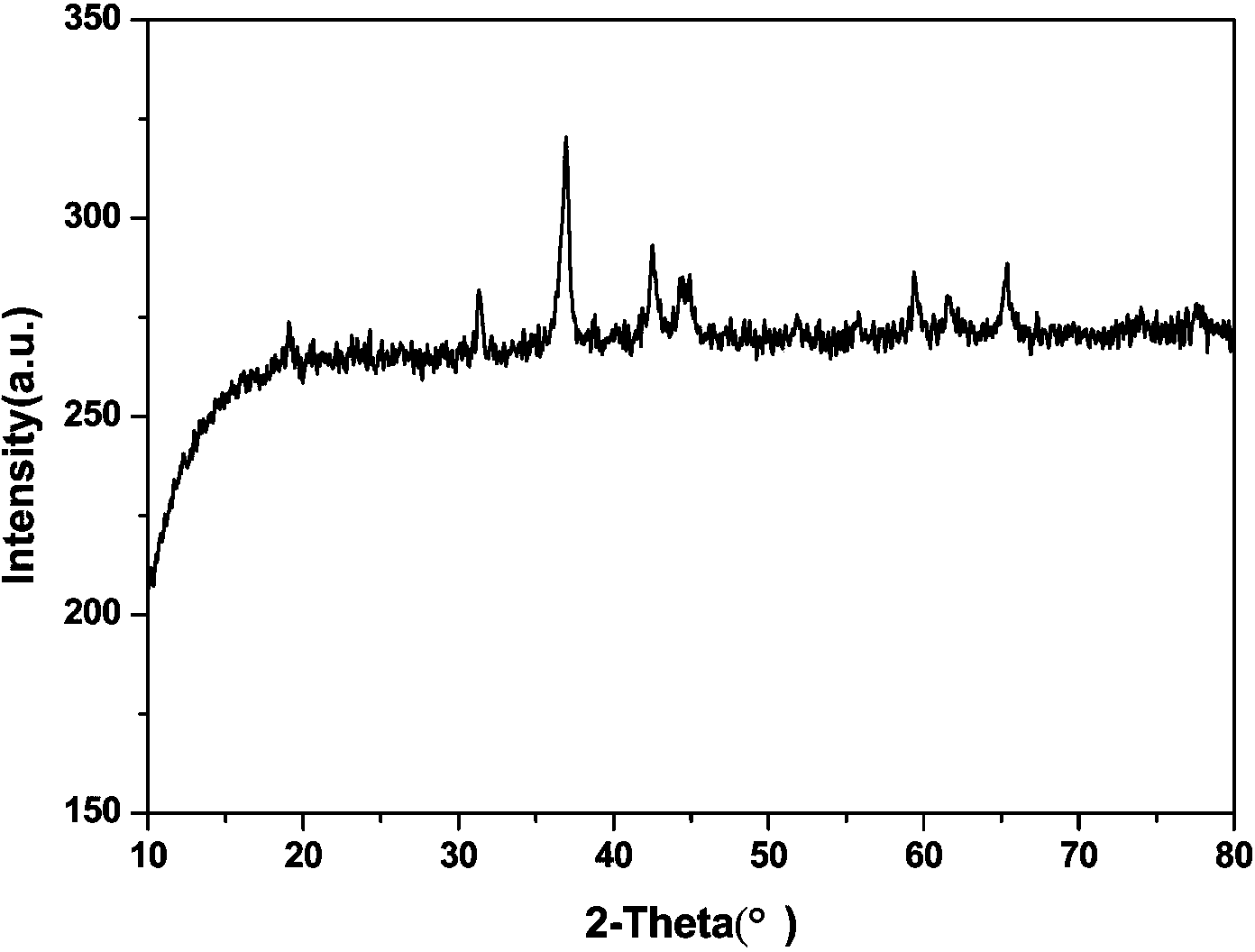

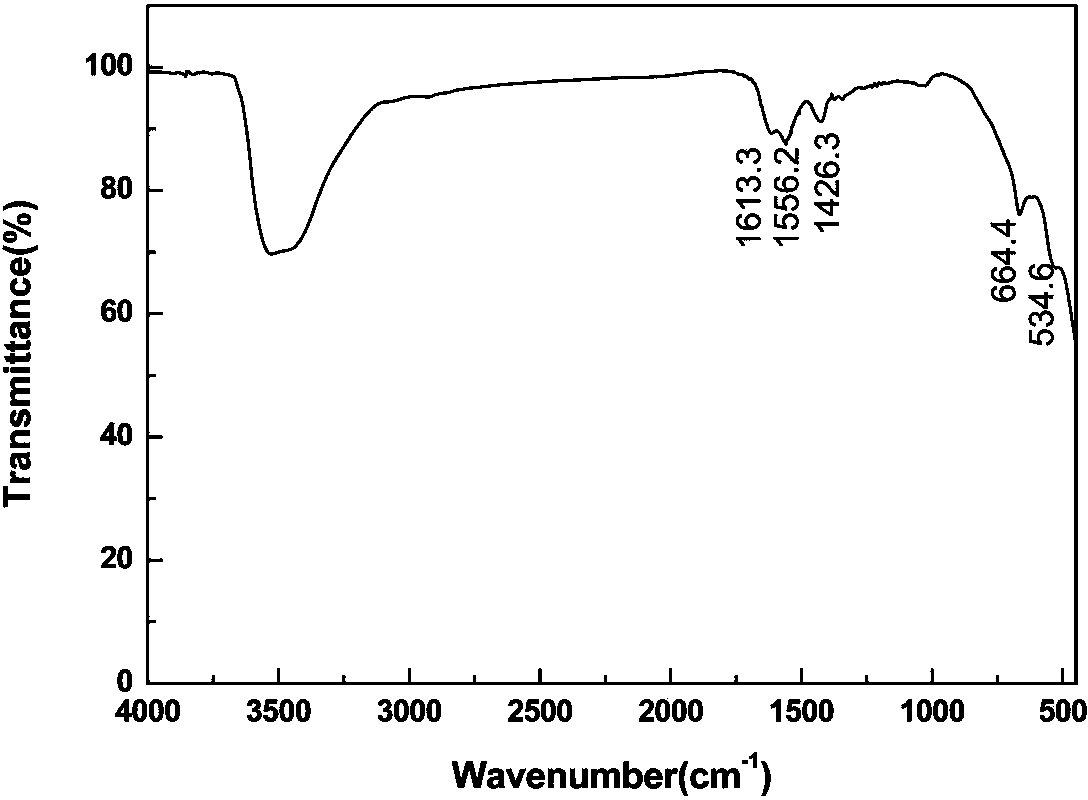

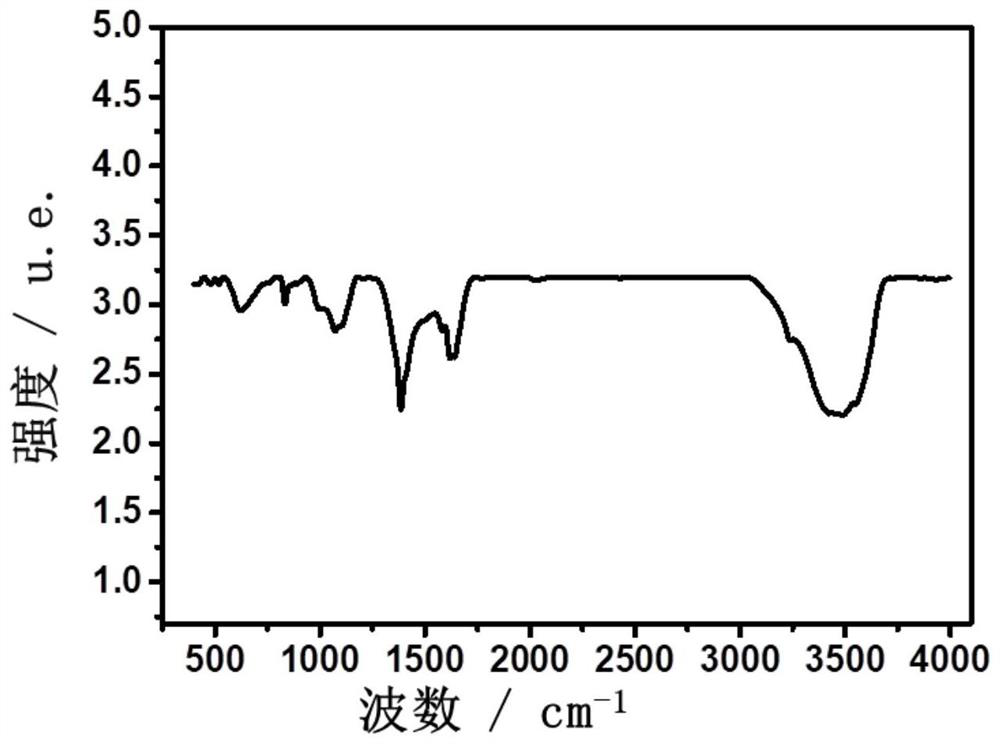

ActiveCN105244177AImprove performanceHigh specific capacitance performanceHybrid capacitor electrodesNickel compoundsCapacitanceNickel salt

The invention relates to a 3D-nanostructure NiCo2S4 electrode material and a preparation method thereof. The 3D-nanostructure NiCo2S4 electrode material is in a three-dimensional nanostructure formed through self-assembly of hexagonal NiCo2S4 nanosheets. The 3D-nanostructure NiCo2S4 electrode material is prepared through a hydrothermal method and a follow-up sulfuration process. The preparation method comprises 1) dissolving divalent cobalt salt and divalent nickel salt into an alkaline aqueous solution, and obtaining an intermediate product in a three-dimensional structure through hydrothermal reaction; and 2) dispersing the obtained intermediate product into a sulfur source solution so as to carry out hydrothermal sulfidizing processing, and thus the 3D-nanostructure NiCo2S4 electrode material can be obtained. On the basis of high seudocapacitance activity and high conductivity of the NiCo2S4 material, specific surface area is improved by forming the 3D nanostructure, and the obtained product is allowed to have excellent super capacitor performance; the hydrothermal and follow-up sulfuration processing processes are simple and are easy to operate and control; and the method is suitable for continuous large-scale production.

Owner:YANGZHOU UNIV

Composite coating with friction-decreasing function and biological-foul and seawater resistances and its production

InactiveCN101074331AImprove the protective effectResistant to microbial foulingAntifouling/underwater paintsPaints with biocidesComposite ceramicAlloy

A composite coating against biological fouling and seawater corrosion and its production are disclosed. The composition consists of oxide based-phase ceramic powder 80-95 wt% and powder against biological fouling 5-20 wt% with Cu, CuO or Cu2O powders. The composite coating comprises binding bottom layer, composite ceramic coating and surface sealing layer; ZnNi alloy powder is sprayed on metal substrate of binding bottom layer by supersonic flame; Composite ceramic power against biological fouling and sea-water corrosion is sprayed on bottom of composite ceramic coating by plasma; Inorganic or organic sealer with low surface energy is sprayed on surface sealing layer. An insulating ceramic transient layer is added between binding bottom layer and composite ceramic coating when Cu powder is adopted. It's simple and cheap and can be used for industrial production.

Owner:WUHAN UNIV OF TECH

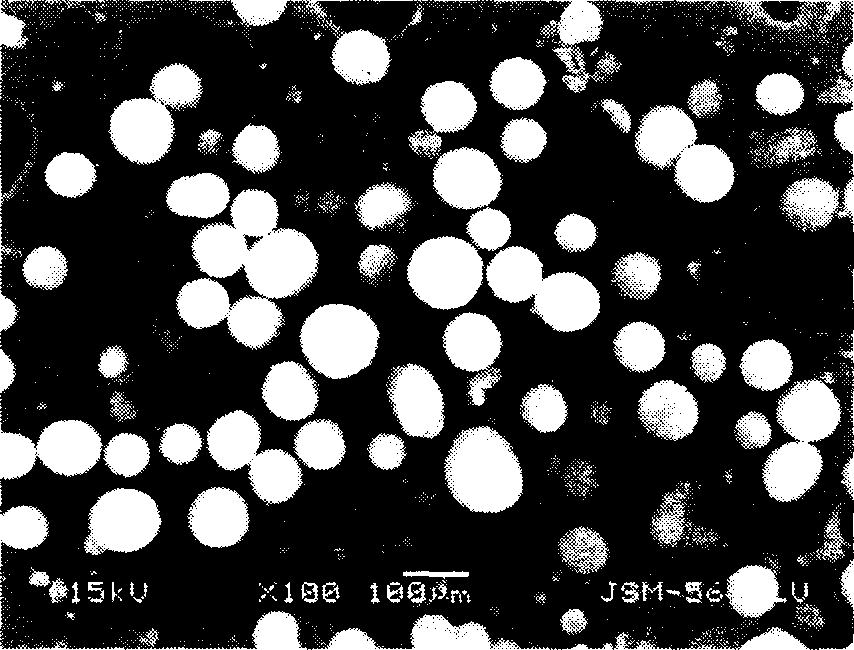

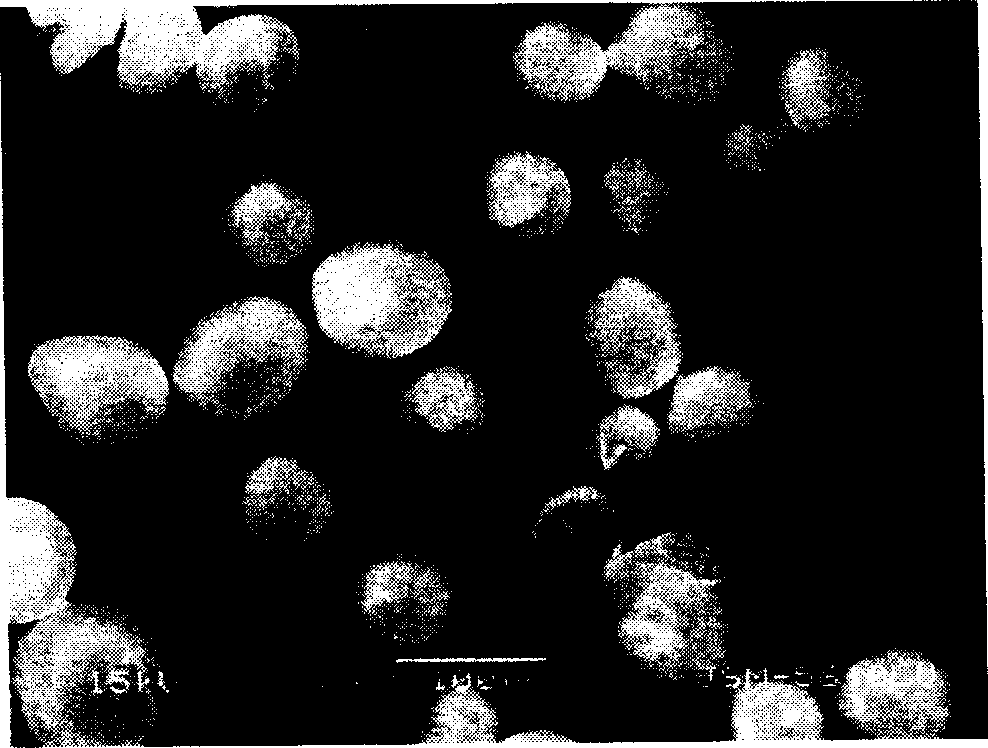

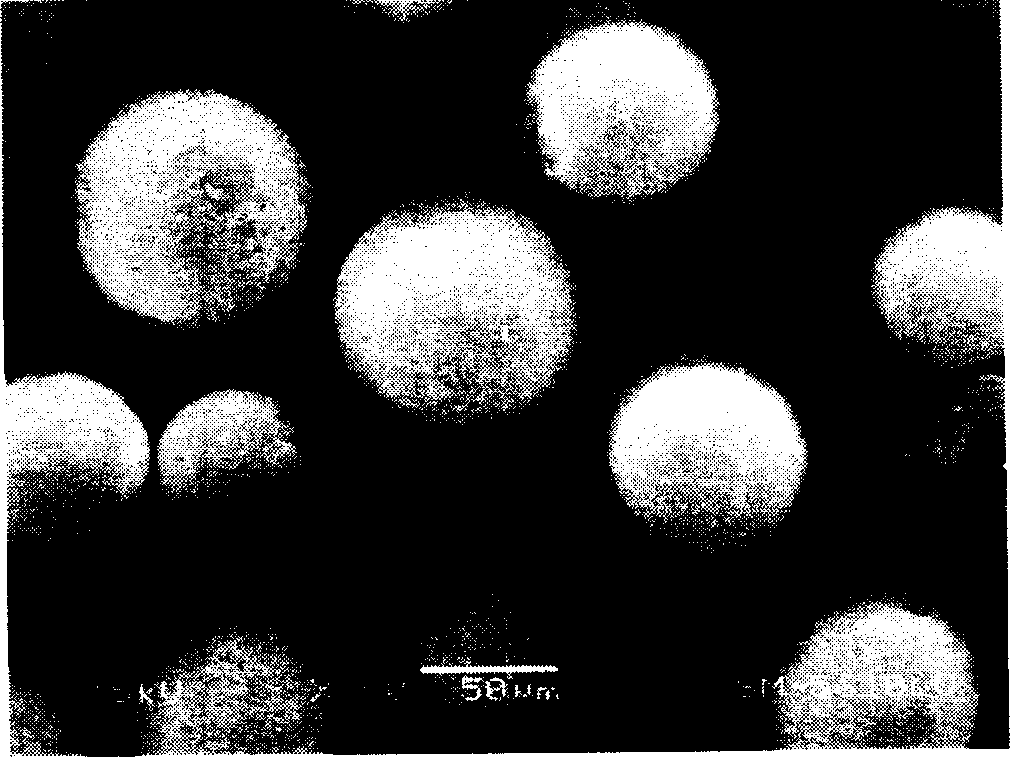

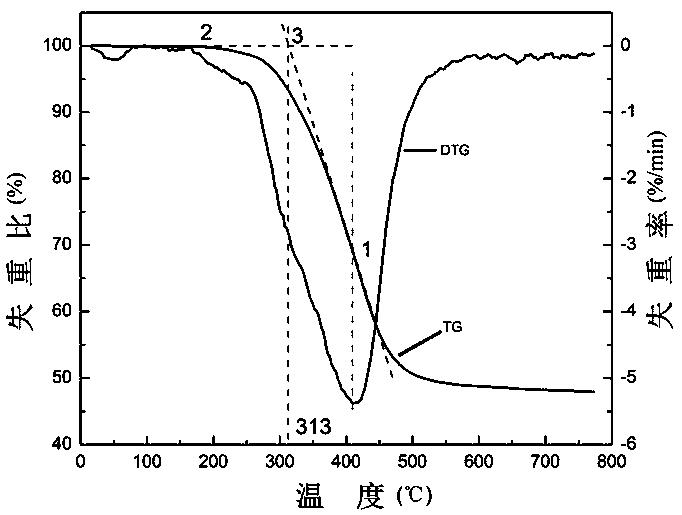

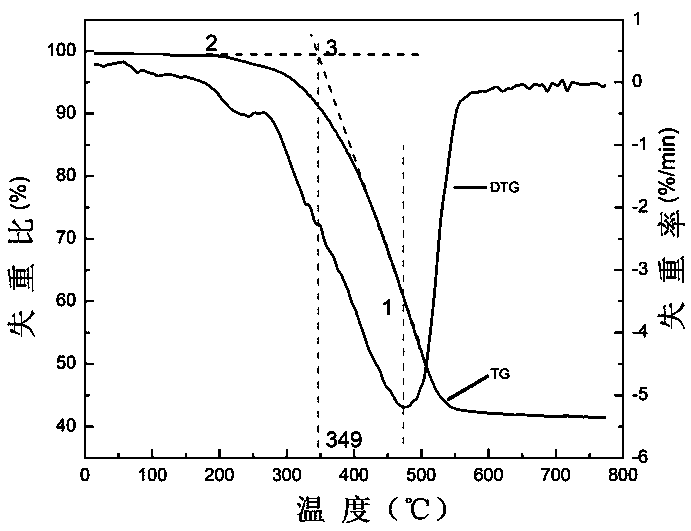

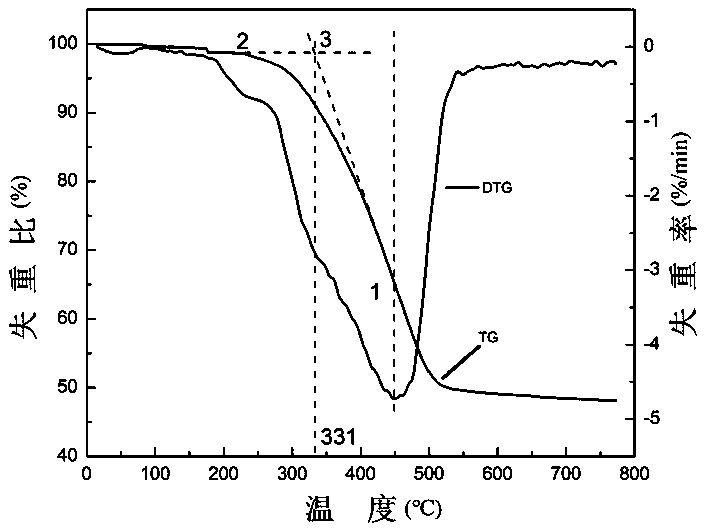

Prepn of nanometer aggregated zirconia powder for hot spraying

InactiveCN1637080AControl growthStructure does not growLiquid surface applicatorsCoatingsThermal sprayingMass ratio

The preparation process of nanometer aggregated zirconia powder for spraying includes: mixing nanometer zirconia powder stabilized with 20-60 nm granularity yttrium oxide and adhesive in the mass ratio of 95:5 to 98:2 and adding pure water of 1-1.3 times the mixture weight to compound slurry; spraying at 110-300 deg.c to form micron level aggregated powder; and final plasma nodulizing or sintering to form compact powder of 40-90 micron granularity and with the nanometer crystal structure maintained. The obtained powder may meet the technological requirement of plasma spraying or flame spraying. The technological process is simple, great in output, safe, reliable, low in cost and suitable for continuous industrial production.

Owner:WUHAN UNIV OF TECH

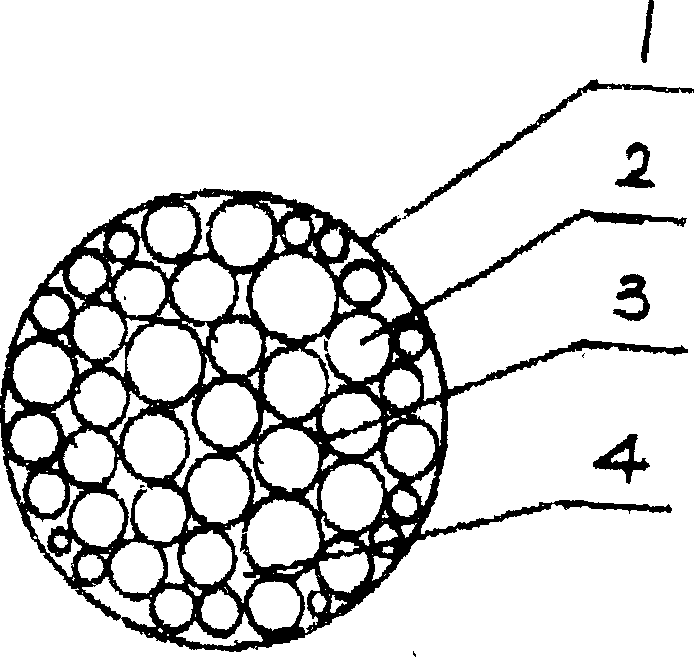

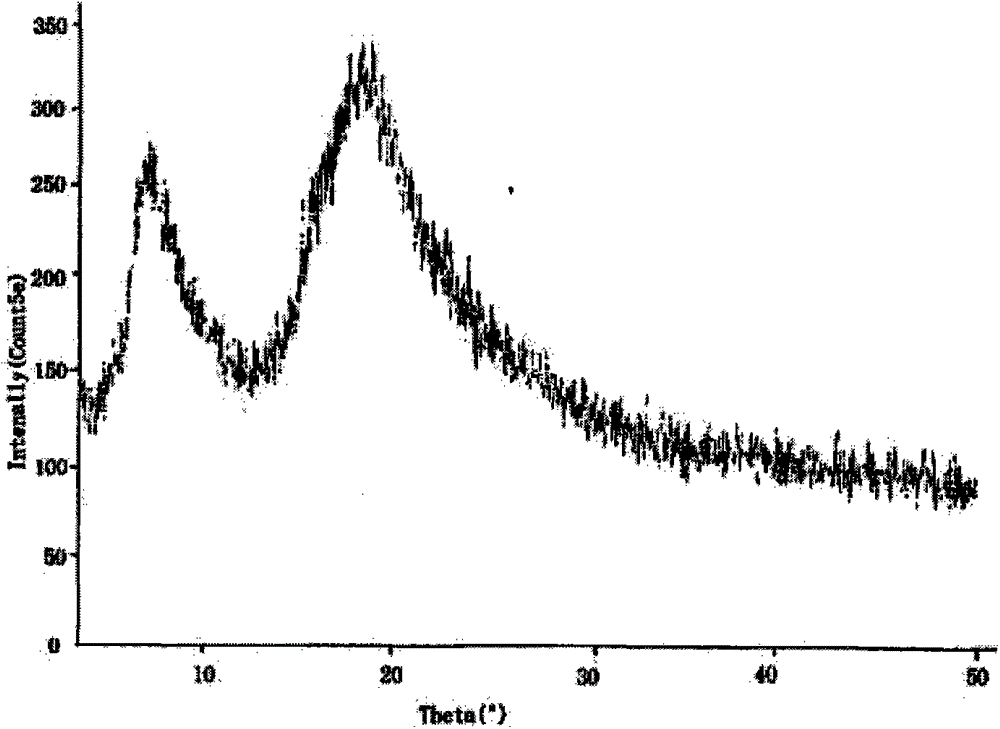

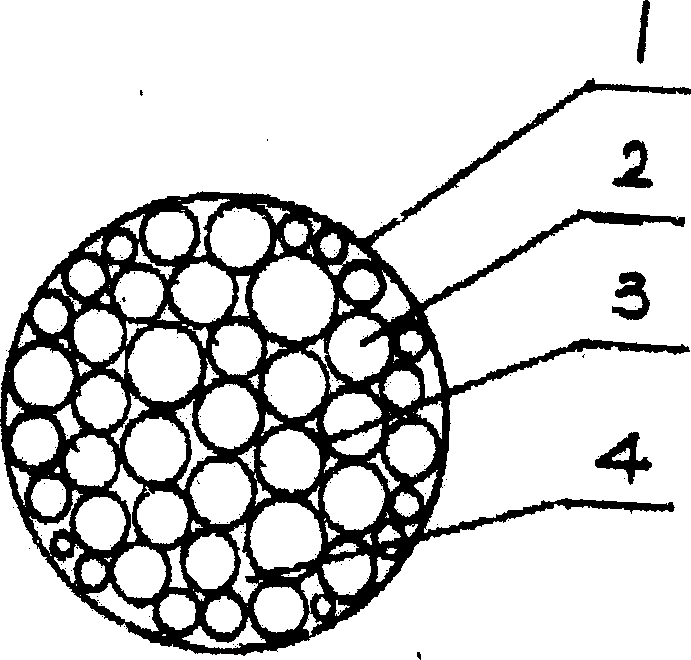

Nano structure yttrium stabilized zirconium oxide aggregated powder and its producing method

InactiveCN1587062AShort manufacturing processSuitable for continuous mass productionTitanium dioxideNano structuringGranularity

The nanometer structure yttrium stabilized aggregated zirconium oxide powder consists of nanometer crystal particle of size smaller than 100 nm and is in aggregated powder structure in granularity of 40-90 microns. Inside the aggregated structure, the nanometer zirconium oxide particles are contacted partially with pure cavity inside. The production process includes adding water into nanometer zirconium oxide particle containing yttrium oxide to obtain aquatic suspended colloid, and subsequent spray drying, sieving, heat treatment and plasma densifying. The production process is simple, low in cost, continuous and suitable for industrial production, and the product is suitable for plasma spraying, flame spraying, etc. and may be used in preparing various kinds of heat resisting coating, wear resisting coating and anticorrosive coating in various industry.

Owner:湖北葛店开发区地大纳米材料制造有限公司

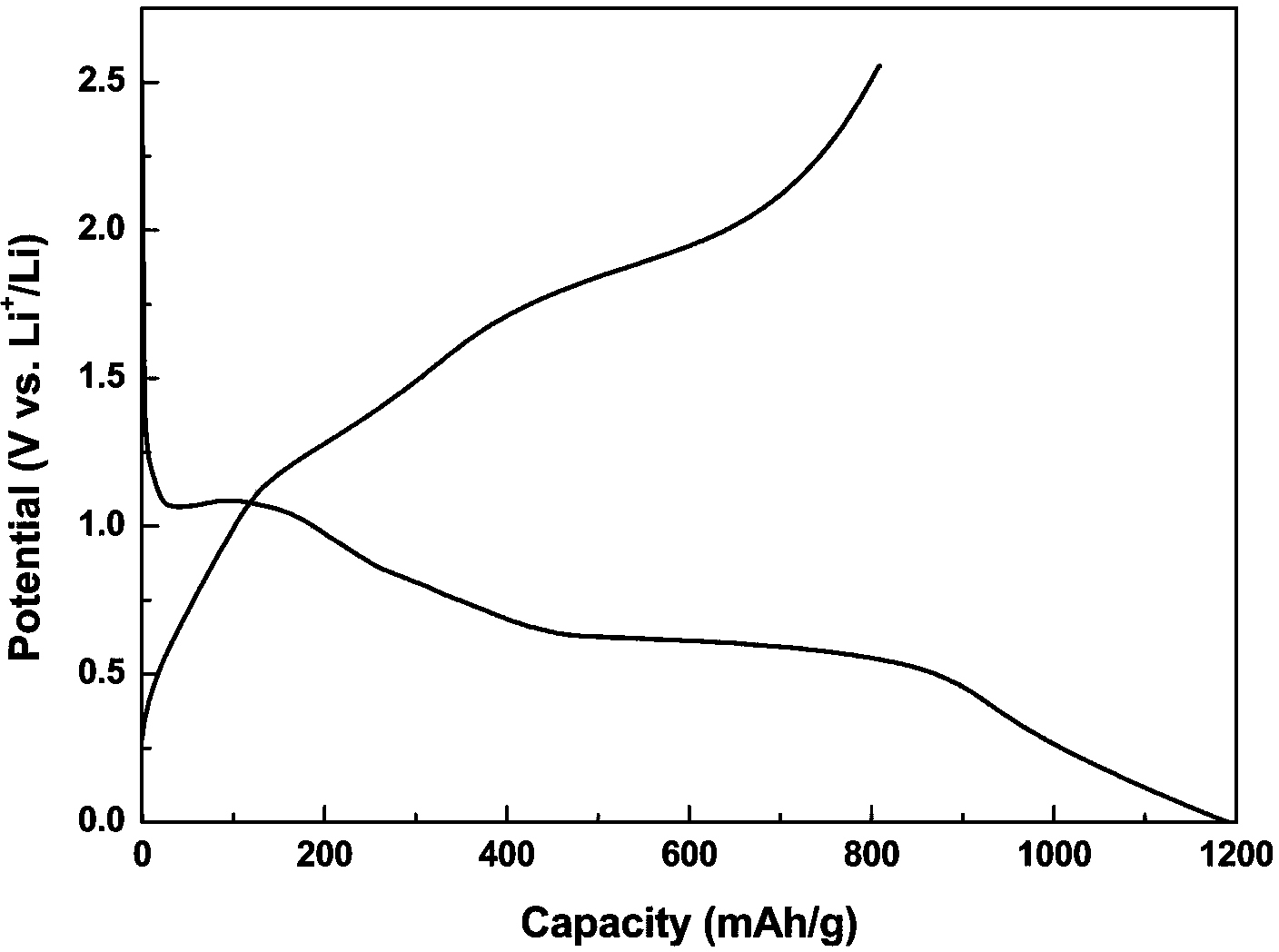

Carbon nanotube, and preparation method and application thereof

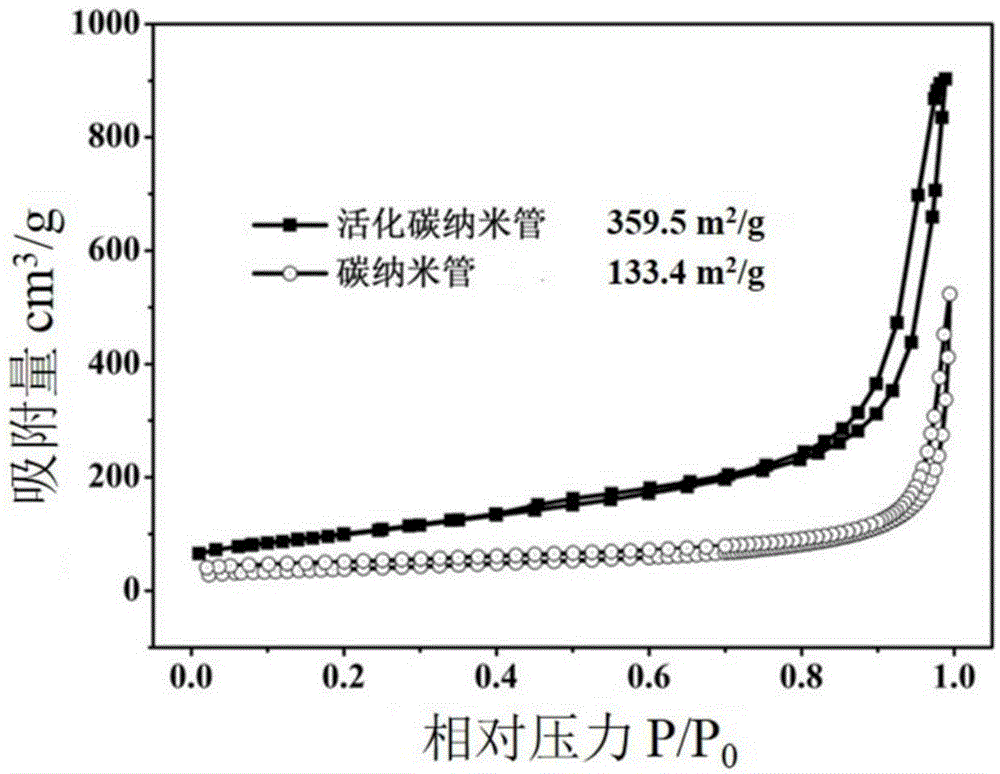

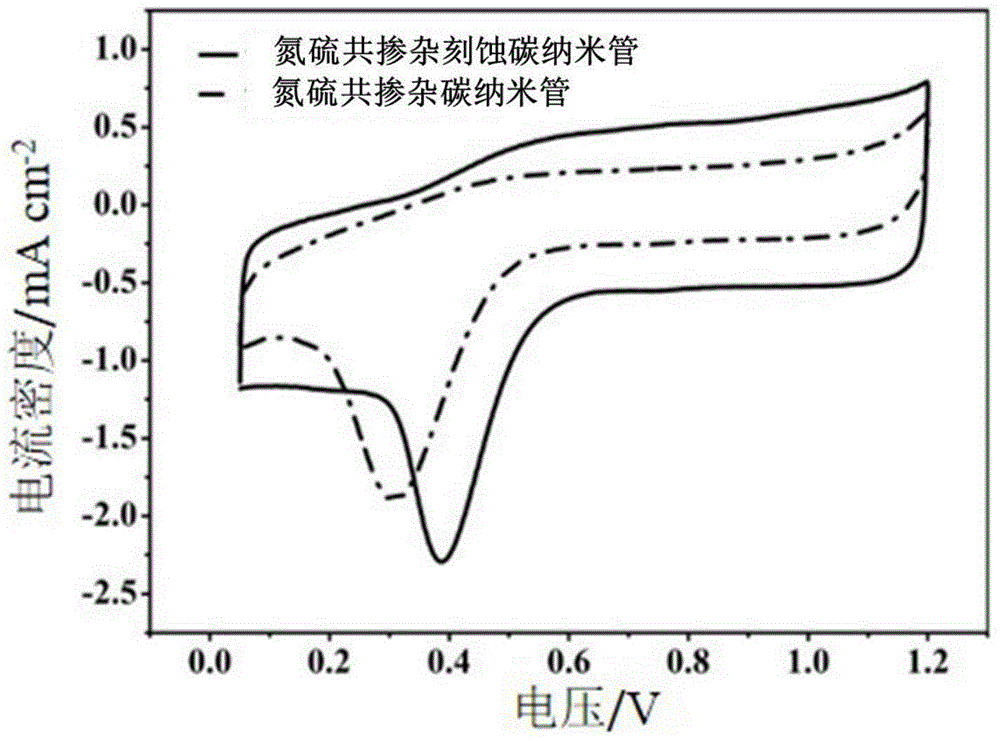

InactiveCN104370279AIncrease power storageHigh specific surface areaMaterial nanotechnologyPhysical/chemical process catalystsHeteroatomOxygen

The invention discloses a carbon nanotube, and a preparation method and an application thereof. The carbon nanotube is a heteroatom-doped carbon nanotube, the mass ratio of heteroatoms is 3%-6%, the surface of the carbon nanotube has a mesoporous structure, the mesoporous average pore size is 2 nm-9 nm, and the specific surface area of the carbon nanotube is 150 m<2> / g-1200 m<2> / g. The preparation method comprises the following steps: (1) evenly mixing the carbon nanotube with an etching agent, and making the mass ratio be 1:3 to 1:5; (2) under an oxygen isolated condition, heating up to 500 DEG C-900 DEG C, and calcining for 1 h-3 h; (3) washing and drying; and (4) carrying out heteroatom doping. The specific surface area of the carbon nanotube can be improved, the catalytic activity of the carbon nanotube is increased, and the carbon nanotube has the advantages of simple process and low cost, and is applied to preparation of electrocatalysts having good performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Fiber reinforced high temperature thermal barrier composite ceramic thick coating material as well as preparation and application thereof

InactiveCN101518968AGood heat insulationIncreasing the thicknessLaminationLamination apparatusAtmospheric layerComposite ceramic

The invention relates to a fiber reinforced high temperature thermal barrier composite ceramic thick coating material. The fiber reinforced high temperature thermal barrier composite ceramic thick coating material has the following structure: spray coating layers having the 'concrete' action and reinforced layers which are arranged between the spray coating layers and have the 'steel bar' action are arranged in turn on the surface of a metallic matrix workpiece of a spray coating and cementing bottom layer; the spray coating layers at least have 3 layers and are prepared from a powdery composite coating material with double effects of high temperature thermal barrier and ablative heat protection by a plasma spraying process; and the reinforced layers are formed by high temperature fibers which wrap the spray coating layers in a paralleled or staggered mode for one or two times, and the use temperature of high temperature fibers is more than or equal to 700 DEG C. The material is prepared by the following steps: preparation of a matrix, spray coating, wrapping and the like. The material can be coated on the surfaces of various aircrafts moving at a high speed in the atmospheric layer through the plasma spraying process so as to have the actions of the high temperature thermal barrier and the ablative composite protective layer. The material can improve the upper limit of the working temperature of a metallic matrix in a high temperature environment and simultaneously prolong the service time of the metallic matrix in a high temperature extreme environment. The material has high practicability and is suitable for the industrialized production.

Owner:WUHAN UNIV OF TECH

Co3O4/graphene electrode material preparation method through hydro-thermal coupling spray pyrolysis

InactiveCN103972496AImprove structural stabilityPrevent growing upMaterial nanotechnologyHybrid capacitor electrodesGraphene electrodeStructural stability

The invention discloses a Co3O4 / graphene electrode material preparation method through hydro-thermal coupling spray pyrolysis. The preparation method comprises the following steps: adding a divalent cobalt salt solution, an aqueous alkali and a mixed solution consisting of metal ions or metallic oxide and a surfactant into a graphene oxide solution, enabling the mixture to be uniform with ultrasound, placing the mixture in a hydrothermal kettle for reaction, cooling to the room temperature, separating and washing products, adding a dispersing agent and the surfactant to prepare a sizing agent with certain solid content, and adopting spray pyrolysis to perform rapid drying process to obtain the Co3O4 / graphene nano-composite electrode material. According to the invention, on the basis of the high conductivity advantage of graphene, the structural stability of Co3O4 is improved by mixing the metal ions or the metallic oxide; dynamic rapid drying is realized through spray pyrolysis to avoid growing and agglomeration of nano-composite material particles, so that the obtained product has excellent dispersibility and fluidity, and the subsequent pole piece preparation technology is facilitated; the hydro-thermal coupling spray pyrolysis technology is simple, easy to operate and control, and suitable for continuous mass production.

Owner:SHANDONG RUNSHENG POWER TECH +1

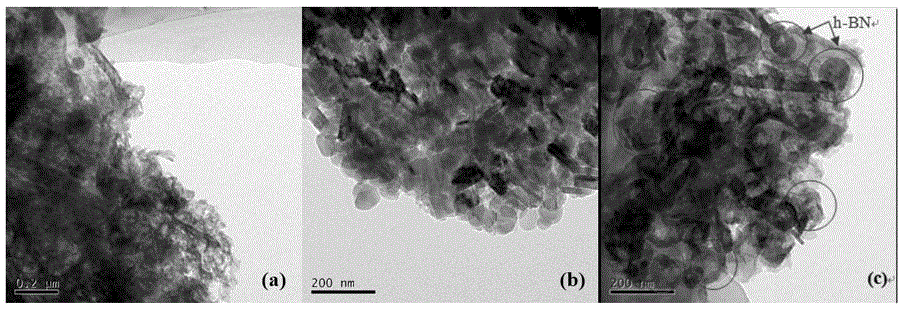

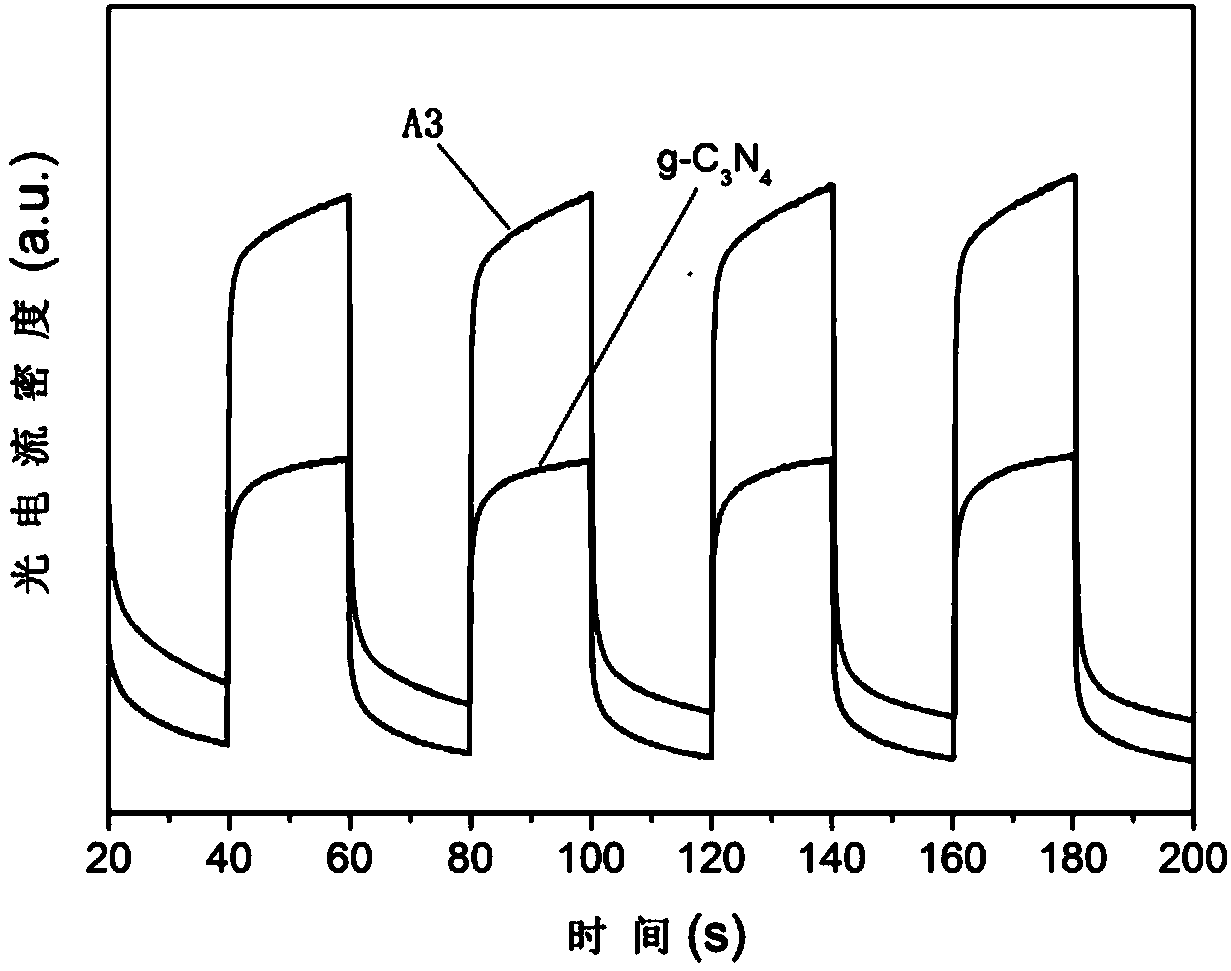

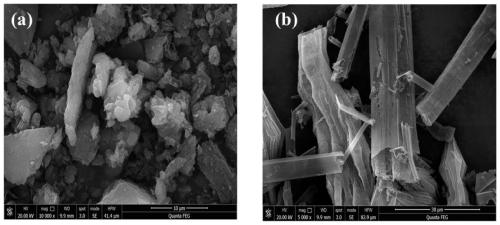

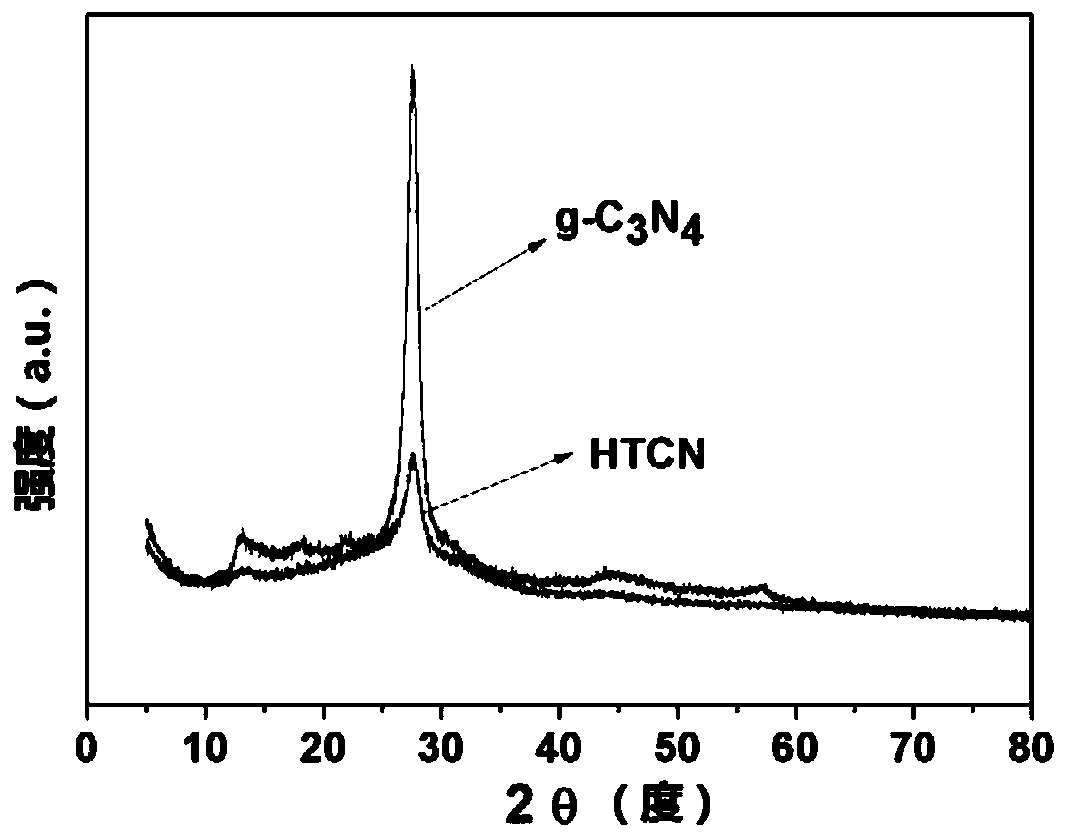

Hexagonal boron nitride modified graphitized carbon nitride composite optical catalyst as well as preparation method and application thereof

ActiveCN106732727AOptimized areaBoost ratePhysical/chemical process catalystsWater/sewage treatment by irradiationElectron holeHexagonal boron nitride

The invention discloses a hexagonal boron nitride modified graphitized carbon nitride composite optical catalyst as well as a preparation method and application thereof. According to the composite optical catalyst, by taking graphitized carbon nitride as a carrier, laminated hexagonal boron nitride modifies the graphitized carbon nitride carrier. The preparation method comprises the following steps: mixing the hexagonal boron nitride with a graphitized carbon nitride precursor; and calcining the mixed precursor to obtain the hexagonal boron nitride modified graphitized carbon nitride composite optical catalyst. The hexagonal boron nitride modified graphitized carbon nitride composite optical catalyst disclosed by the invention has the advantages of being environmentally friendly, fully free of metal doping, large in specific surface area, high in photoproduction electron-hole separating efficiency, high in optical catalytic activity, good in stability, corrosion-resistant and the like. The preparation method has the advantages of being simple, low in cost of raw materials, less in energy consumption, easy to control conditions and the like. The composite optical catalyst disclosed by the invention is used for degrading dye wastewater and has the advantages of being simple in application method, stable in optical catalytic performance, high in corrosion resistance, high in dye wastewater degrading efficiency.

Owner:HUNAN UNIV

Traditional Chinese medicine prescription granule preparation by melted extrusion method

InactiveCN101669974AImprove molding rateImprove liquidityGranular deliveryOil/fats/waxes non-active ingredientsPrillCompressibility

The invention relates to a melted extrusion method for preparing traditional Chinese medicine prescription granules, comprising the following steps: using an auxiliary material with a low melting point as a binding agent and evenly mixing with traditional Chinese medicine extract powder according to a certain ratio; placing the mixture in an extrusion pelletiser to prepare into granules in the extrusion process; straightening granules after cooling to obtain the traditional Chinese medicine prescription granules, wherein 40-70 DEG C is preferably used as the melting point or melting range of the low melting point auxiliary material; and the dosage ratio of the auxiliary material accounts for 10-40% of the total weight of the auxiliary material to the traditional Chinese medicine extract powder. The invention has higher molding efficiency, avoids the phenomena such as change of medicine tincture and active ingredients caused by repeated extrusion, weakened dissolubility and the like, thus especially being suitable for traditional Chinese medicine extract powder with poor viscosity and varieties such as fruit and seeds containing high fatty oil and starch, roots and tubers, parts offlowers and plants, leather and the like. The granules prepared by the invention have fine mobility, compressibility and dissolubility, and the granules prepared by using hydrophobic auxiliary materials have lower hygroscopicity.

Owner:JIANGYIN TIANJIANG PHARMA

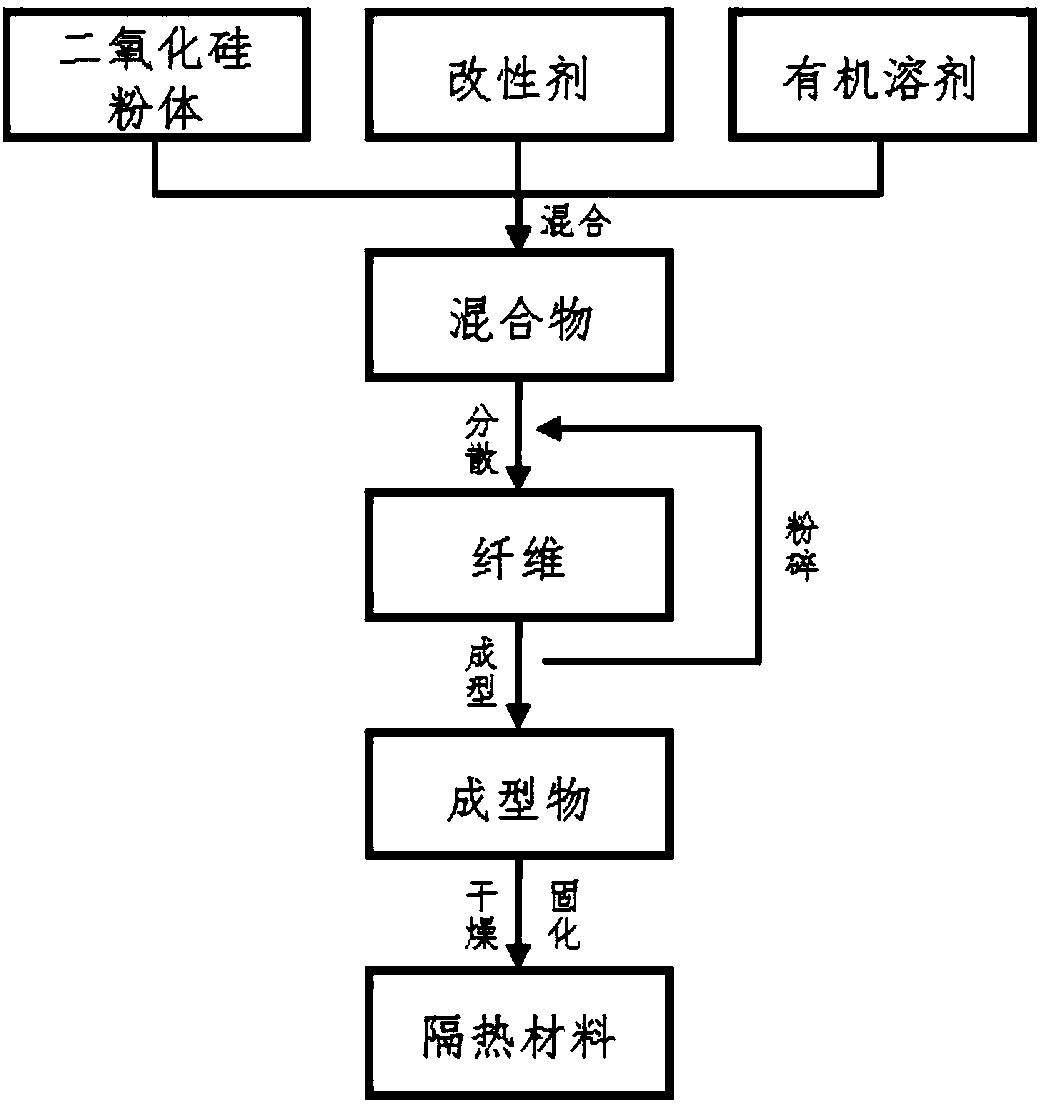

Silica heat-insulation composite material and preparation method thereof

The invention provides a silica heat-insulation composite material and a preparation method thereof. The silica heat-insulation composite material is prepared from the following raw materials: 100wt%of silica powder, 0.5mol% to 20mol% of modifier, 50wt% to 400wt% of organic solvent, 5wt% to 200wt% of reinforcing fiber, 0wt% to 20wt% of opacifier, 0mol% to 10mol% of cross-linking agent and 0wt% to3wt% of thickener. The invention also provides the preparation method of the heat-insulation composite material. An organic-solvent solution of the modifier is added into the silica powder; the reinforcing fiber is added; the agitation and the setting are carried out; the organic solvent is volatilized; curing is carried out, so as to obtain the composite material. The silica heat-insulation composite material is obtained by using the silica powder as a raw material, modifying the silica powder with the modifier, adding the reinforcing fiber, then directly setting, volatilizing the solvent and curing; the preparation method is simple; the procedure is short; problems that the raw material is expensive, a product is fragile and powder falls, and the like, are solved and the silica heat-insulation composite material is suitable for industrialized production.

Owner:金光虎

Supramolecular polymerized carbon nitride photocatalyst and preparation method and application thereof

ActiveCN110465315AHigh specific surface areaImprove photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationUreaChemistry

The invention discloses a supramolecular polymerized carbon nitride photocatalyst and a preparation method and an application thereof. The supramolecular polymerized carbon nitride photocatalyst is prepared from melamine, cyanuric acid, urea and dimethyl sulfoxide through a molecular polymerization reaction and calcination. The supramolecular polymerized carbon nitride photocatalyst has the advantages of high specific surface area, high photocatalytic activity and the like, can efficiently degrade organic wastewater and is a novel visible light catalyst. The preparation method has the advantages of simple synthetic method, low raw material cost, less energy consumption, short time consumption, easy control of conditions and the like, is suitable for continuous large-scale batch productionand facilitates the industrial use. the supramolecular polymerized carbon nitride photocatalyst of the invention can be used for degrading the organic wastewater, has the advantages of good degradation effect and good stability, and has good practical application prospects.

Owner:HUNAN UNIV

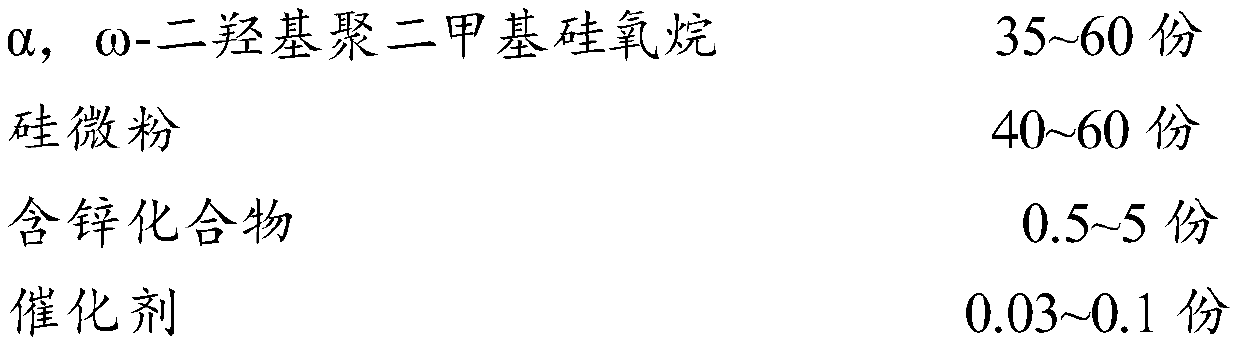

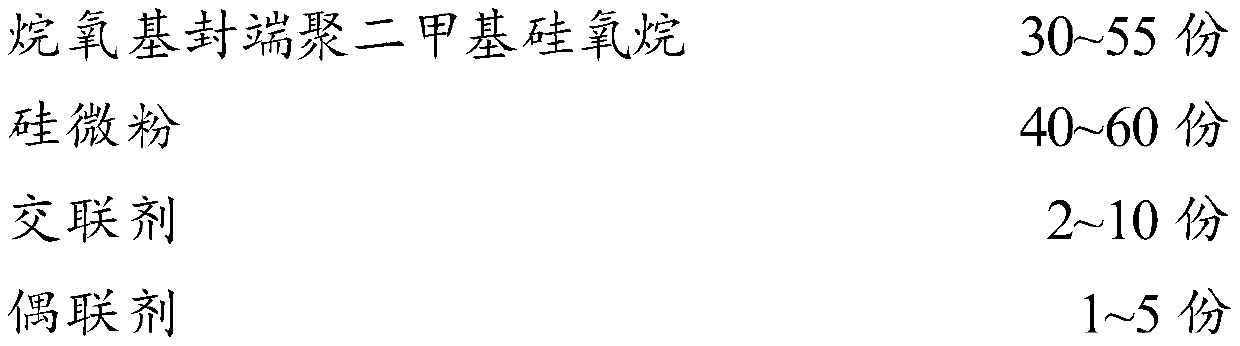

Two-component condensation-type thermal-conductive silicone gel and preparation method thereof

PendingCN110240888AAchieve deep curingImprove performanceNon-macromolecular adhesive additivesCross-linkPolymer science

The invention provides two-component condensation-type thermal-conductive silicone gel and a preparation method thereof. The silicone gel comprises an A component and a B components; the A component comprises the following raw materials, in parts by weight: 35-60 parts of alpha,omega-dihydroxy polydimethylsiloxane, 40-60 parts of silicon micropowder, 0.5-5 parts of a zinc-containing compound, and 0.03-0.1 part of a catalyst; and the B component comprises the following raw materials, in parts by weight: 30-55 parts of alkoxy-terminated polydimethylsiloxane, 40-60 parts of silicon micropowder, 2-10 parts of a cross-linking agent, and 1-5 parts of a coupling agent. According to the silicone gel provided by the invention, the zinc-containing compound is used in the formula, so that deep curing of the silicone gel is realized, and has better comprehensive performance than gel prepared by adding water, precipitated white carbon and glycerol organic phosphate; and the thermal conductive silicone gel has not high requirements for measurement accuracy of mixing equipment and simple and convenient operation during use, the stable performance of the silica gel after being mixed is ensured, and the thermal conductive silicone gel is suitable for continuous mass production in an automatic line.

Owner:浙江励德有机硅材料有限公司

Magnesium nitrate-calcium nitrate complex salt type compound fertilizer and preparation method thereof

ActiveCN103833444AImprove fluidityGood anti-caking performanceFertilizer mixturesAgricultural engineeringCaking

The invention relates to the production technology of granular fertilizers, and specifically relates to a magnesium nitrate-calcium nitrate complex salt type compound fertilizer and a preparation method thereof. The magnesium nitrate-calcium nitrate complex salt type compound fertilizer is characterized in that the total mass percent of magnesium nitrate and calcium nitrate in the compound fertilizer ranges from 50% to 90%, the mass percent of crystal water in the compound fertilizer ranges from 10% to 50%, and the mass ratio of magnesium nitrate to calcium nitrate is (3.5-0.1):1. Compared with the prior art, the magnesium nitrate-calcium nitrate complex salt type compound fertilizer and the preparation method thereof have the beneficial effects that (1) the magnesium nitrate-calcium nitrate complex salt type compound fertilizer is far better than compound fertilizers obtained by doping and pelletizing by a mechanical pressing method in free-running property and anti-caking property, the caking time of the product is above 30 days and therefore, the product can be used very conveniently; (2) the preparation method is lower in cost than a process of batch crystallization as well as mechanical mixing and pelletizing, and also applicable to continuous large-batch production, and therefore, a convenient condition is provided for automatic process control.

Owner:山西东锦肥业有限公司

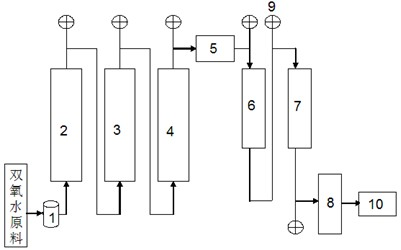

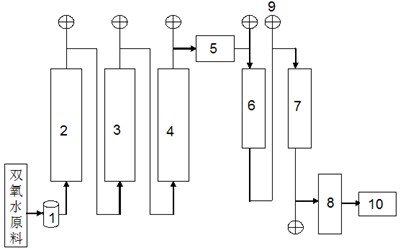

Method for continuous production of ultrapure hydrogen peroxide

InactiveCN102556976AAvoid damagePlay a protective effectPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesFiltrationIon exchange

The invention relates to a method for continuous production of ultrapure electronic-grade hydrogen peroxide. The ultrapure hydrogen peroxide is obtained through preprocessing industrial grade hydrogen peroxide adopted as a raw material by a macroporous adsorption resin, carrying out first-stage ion exchange by a cation exchange resin and an anion exchange resin, allowing the obtained solution to enter a multi-stage mixed anion and cation exchange resin column, and carrying out ultrafine filtration. The method which has the advantages of good safety, simple operation and stable product quality is suitable for the large-scale continuous production.

Owner:SHANGAI HUAYI MICROELECTRONICS MATERIAL +1

Composite coating material for high temperature heat barrier and ablation barrier, and its uses

InactiveCN1884405AAct as a thermal barrierActs as a thermal barrier coatingFireproof paintsPolyester coatingsMetallurgyErosion

The invention relates the surface coating material with heat-insulating property. The material is made by the 55-85wt% ZrO2 / Y2O3 powder, 15-45wt% erosion findings, binder and water. The binder is 2-5wt% of ZrO2 / Y2O3 powder and erosion findings, and the weight of water is 1-1.3 times than ZrO2 / Y2O3 powder and erosion findings and binder. The invention has the advantages of long life and easy operability.

Owner:WUHAN UNIV OF TECH

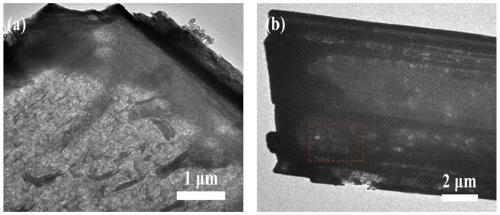

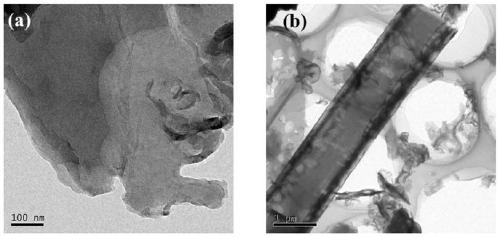

Hollow tubular graphite-phase carbon nitride photocatalyst containing nitrogen defects, preparation method and applications thereof

PendingCN111085238AIncreased recombination rateEasy to separatePhysical/chemical process catalystsWater/sewage treatment by irradiationPtru catalystPotassium hydroxide

The invention discloses a nitrogen defect-containing hollow tubular graphite phase carbon nitride photocatalyst, a preparation method and applications thereof. The preparation method comprises: carrying out a hydrothermal reaction by using melamine as a raw material, then adding KOH, and carrying out high-temperature calcination. According to the invention, the one-dimensional morphology of the catalyst is of a hollow tubular structure containing nitrogen vacancies, the diameter is 3-7 microns, and the length is 20-50 microns; the nitrogen vacancy is a defect and is introduced by adding potassium hydroxide in the calcining process; and the catalyst provided by the invention has the advantages that the photocatalytic performance is high, and the catalyst can be effectively applied to removal of antibiotics in wastewater.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Device for eliminating aflatoxin

ActiveCN101151990AGuarantee product qualityGood for storageFood preservationFood preparationDecompositionUltraviolet

The invention discloses a device to remove aflatoxin, which is provided with an ultraviolet radiation schizolysis device on a pipeline. The body case center of the device is provided with an ultraviolet radiation generator. A gap is formed between the body case and ultraviolet radiation generator. A plurality of ultraviolet radiation schizolysis devices are connected in series on the pipeline. The ultraviolet radiation generator is formed by parallel connection of a plurality of ultraviolet radiation generators. The pipeline behind each of schizolysis devices is provided with a cooling device and the inner wall of the body case is a reflector. The invention is characterized in that the invention adopts a psychical method and takes the ultraviolet radiation to enable full decomposition and removal of the aflatoxin, is not polluted by the outside during the operational process, not changes nutrition ingredients and original favor of treated food, and has high mechanical degree and treatment ability, which is suitable for continuous and lager-scaled production.

Owner:SHANDONG LUHUA GROUP

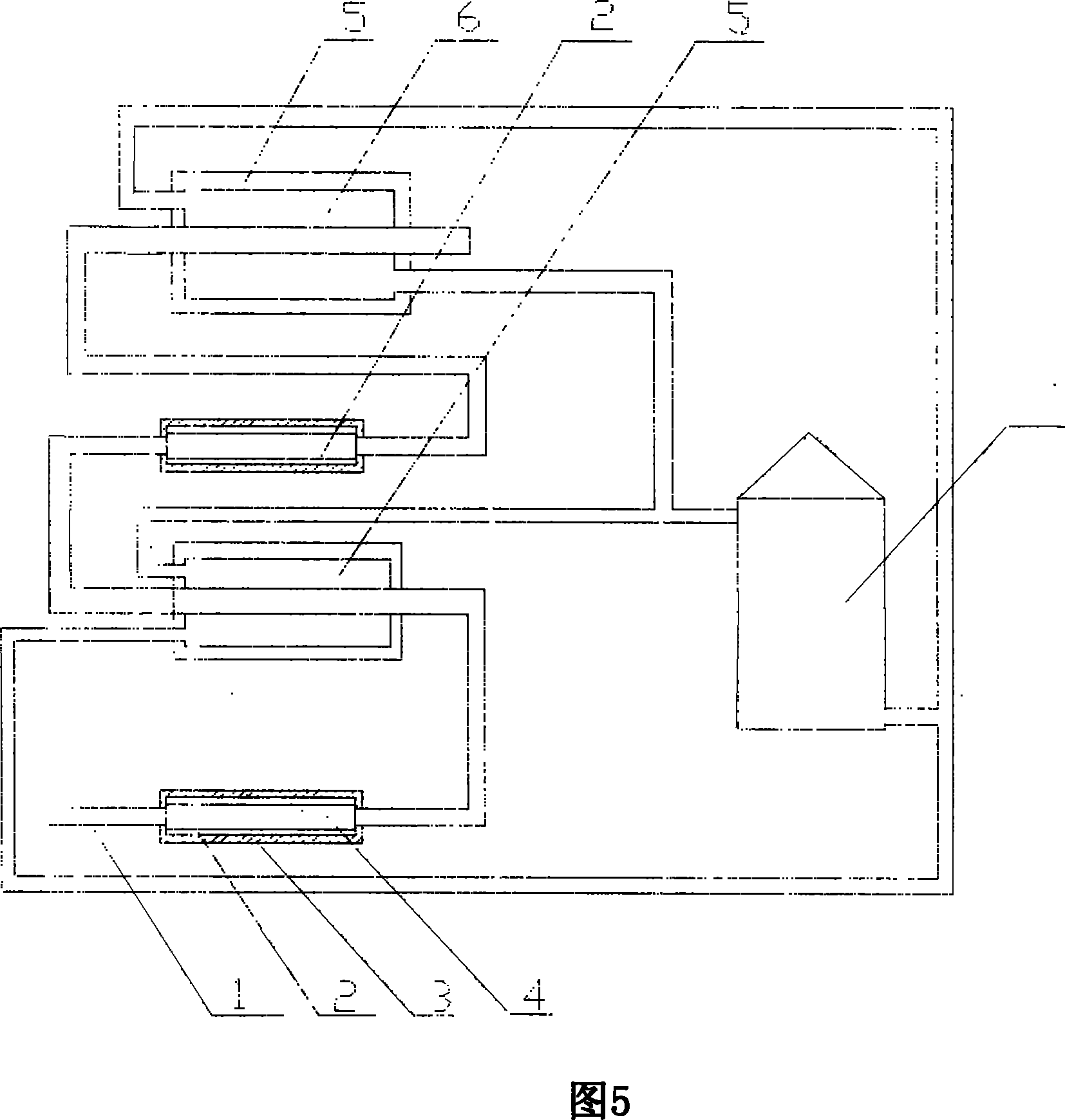

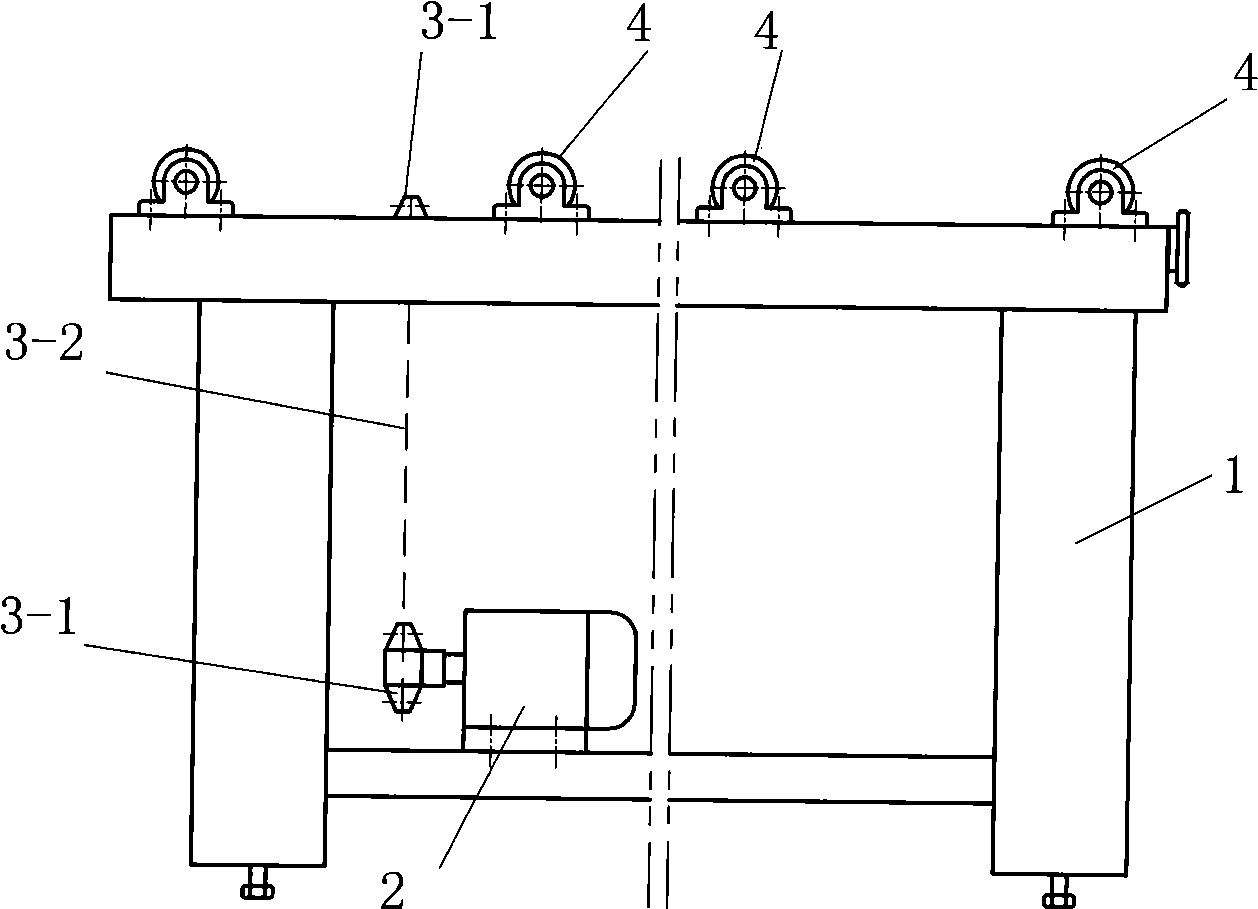

Method for electrolytically etching pictures and text on metal plate and device thereof

ActiveCN101545132AImprove production environmentReasonable structureElectrolysis componentsMetalElectrolyte

The invention discloses a method for electrolytically etching pictures and text on a metal plate and a device thereof. The method comprises the following steps: putting a metal plate with an electrolytically etched picture and text layer on the upper surface on a conveyer roller and moving to an electrolytic region with an upper negative electrode and a lower positive electrode which are arranged to be staggered in the vertical direction; simultaneously jetting electrolyte in a gap between the upper surface of the metal plate and the negative electrode along the moving direction of the metal plate and a gap between the lower surface of the metal plate and the positive electrode; and applying voltages on the positive electrode and the negative electrode so that the electrolytic etching region on the upper surface of the metal plate is electrolytically etched. The device comprises a stand, a motor, a transmission device, the conveyer roller, the positive electrode, the negative electrode, an electrolyte pipeline, an upper nozzle and a lower nozzle. The invention hardly generates short circuits and has high etching efficiency, high radiation speed and reasonable structure.

Owner:常州正成机电科技有限公司

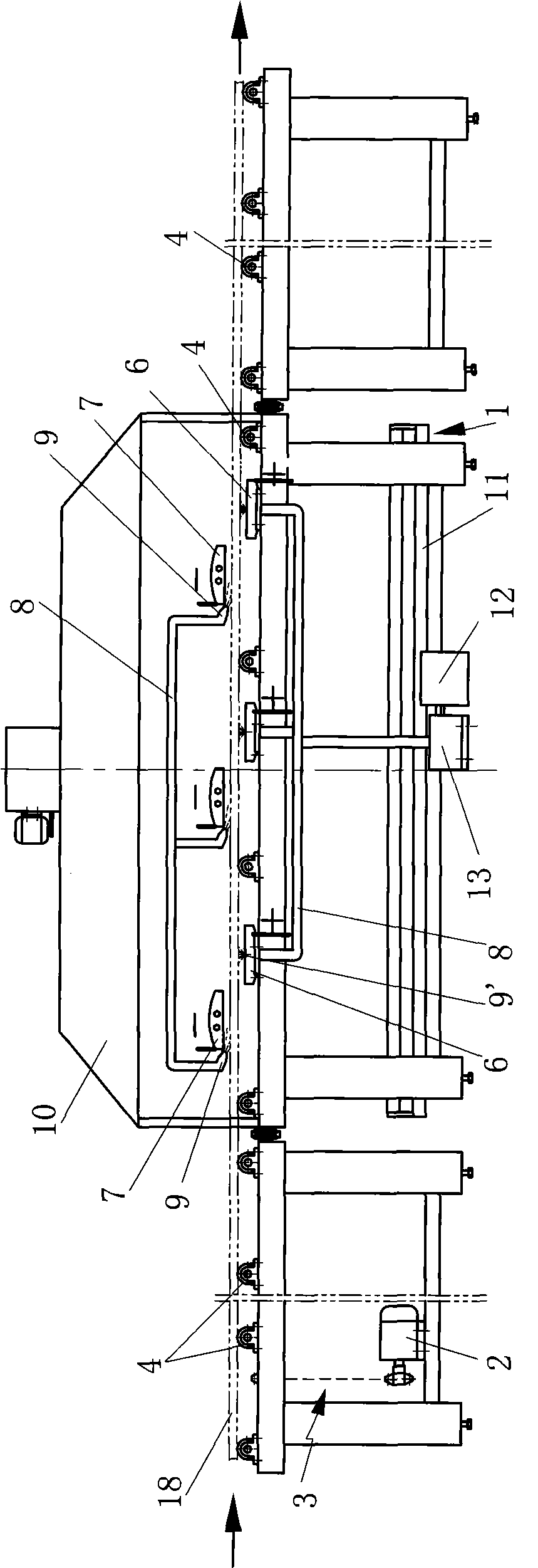

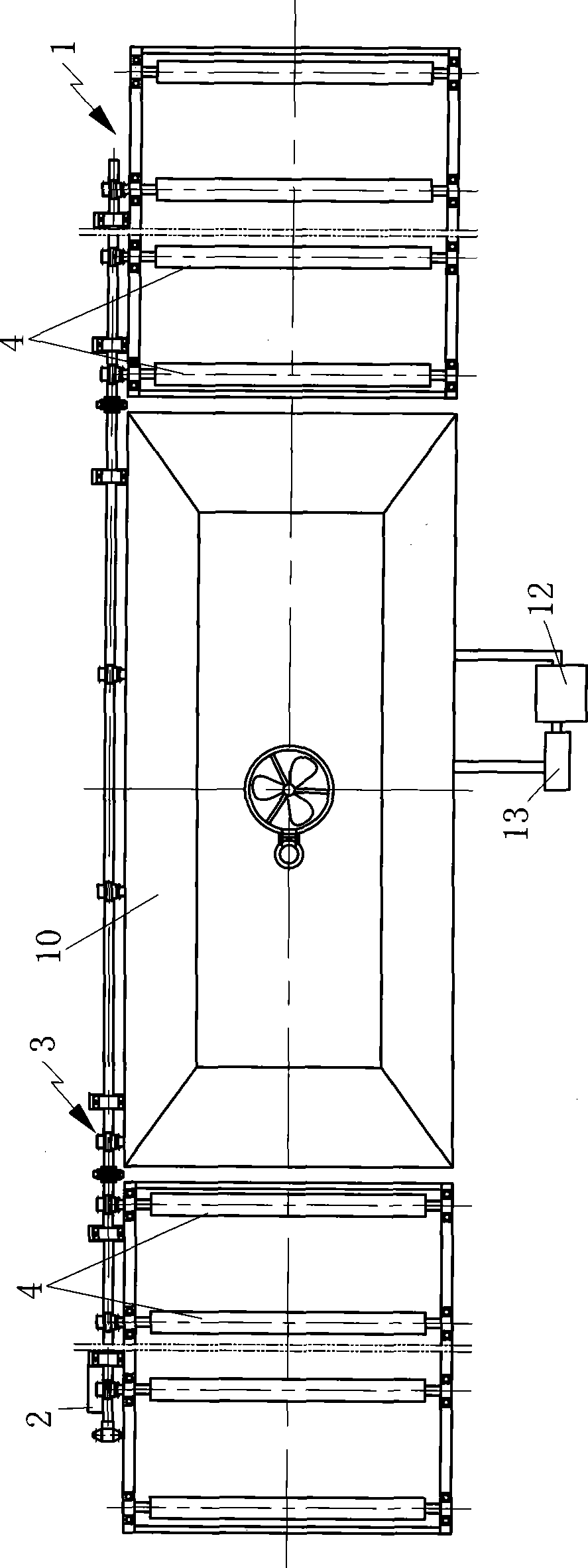

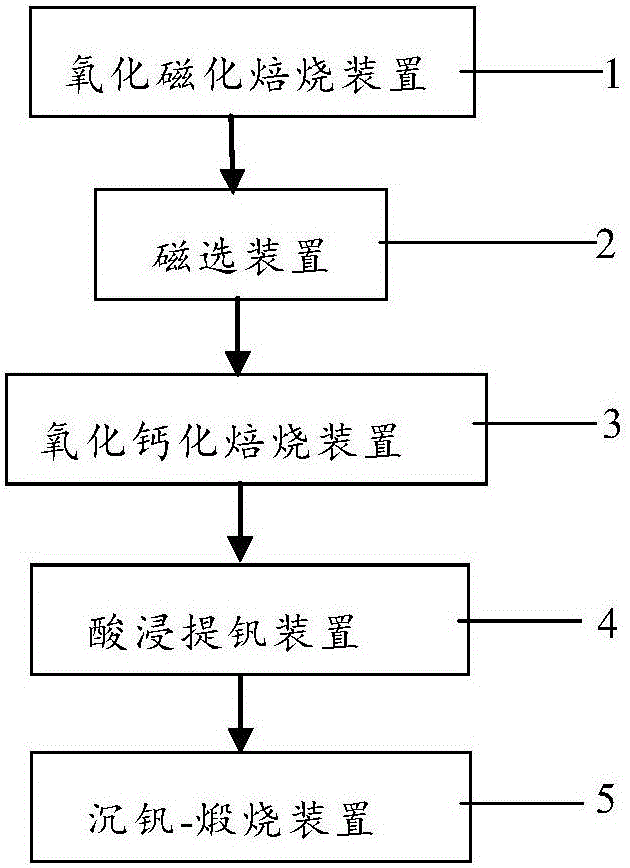

Method and system for treating vanadium slag

InactiveCN106065436AHigh recovery rateAchieve recyclingProcess efficiency improvementSlagCalcification

The invention discloses a method and system for treating vanadium slag and belongs to the field of extracting of valuable metal in the vanadium slag. The invention firstly discloses the method for treating the vanadium slag. The method includes the steps that the vanadium slag is subjected to oxidization magnetizing roasting firstly so that iron in the vanadium slag can be converted into magnetic ferroferric oxide to be subjected to magnetic separation recycling, vanadium can be enriched through the vanadium slag obtained after iron recycling, and non-magnetic vanadium-enriched slag is obtained; and calcium salt is mixed into the vanadium-enriched slag, then vanadium in the vanadium-enriched slag is recycled through an oxidization roasting-acid leaching vanadium extracting method, and therefore the iron and the vanadium in the vanadium slag can be extracted step by step. The invention further discloses the system for implementing the method for treating the vanadium slag. The system comprises an oxidization magnetizing roasting device, a magnetic separation device, an oxidization calcification roasting device, an acid leaching vanadium extracting device and a vanadium precipitation-roasting device. By means of the method and system for treating the vanadium slag, the recovery rate of the iron and the vanadium in the vanadium slag is high, the vanadium slag can be comprehensively utilized, and operation is simple.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

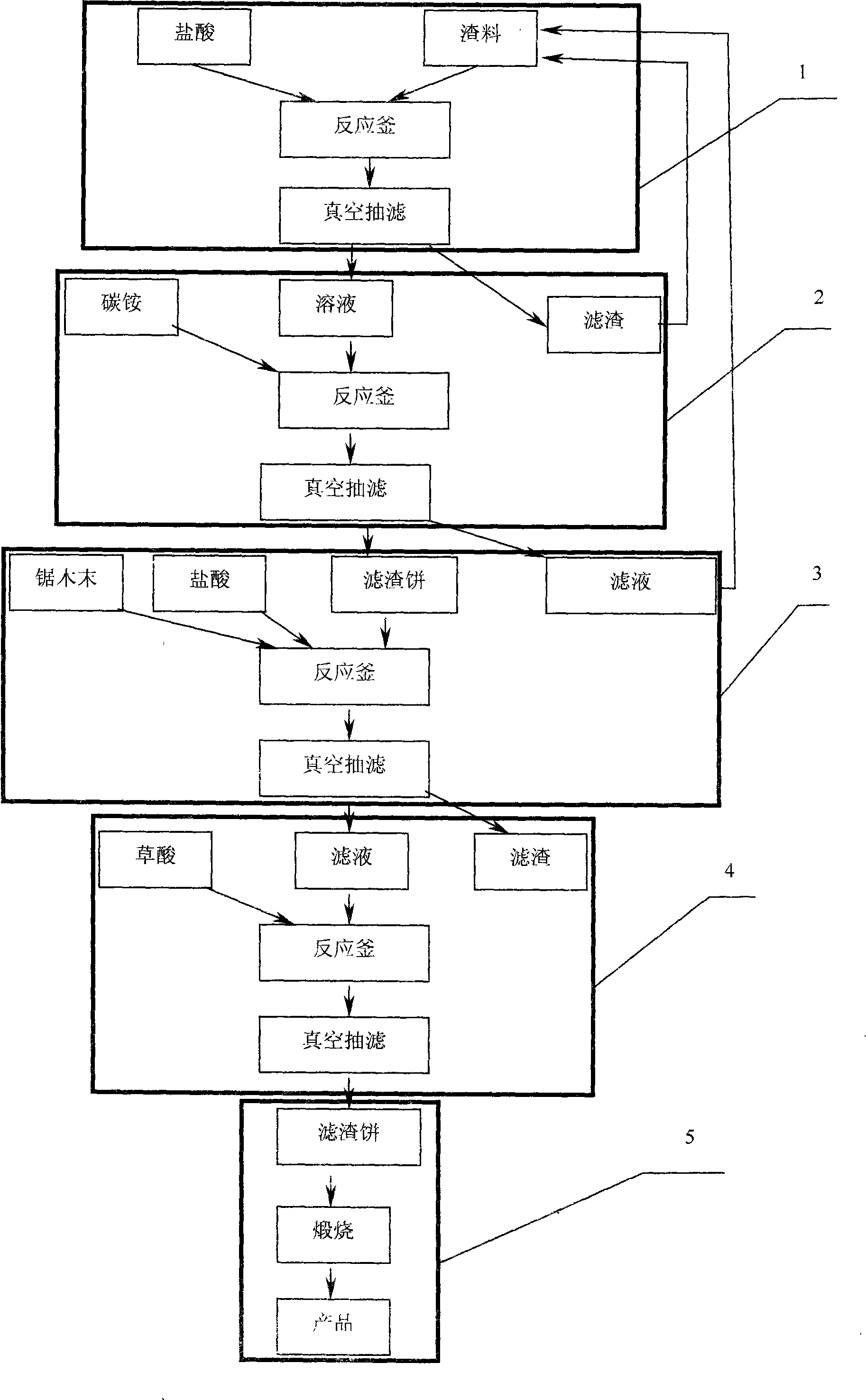

Technique for producing 99% praseodymium-neodymium oxides by using Nd-Fe-B smelting slag

The invention relates to a production process of extracting Pr-Nd oxide by utilizing NdFB to smelt waste slag and magnetic slurry. The invention is characterized in that: according to chemical characteristics of rare metal ion, the valuable elements are separated and extracted by acid leaching, ammonium bicarbonate sedimentation, selective dissolution, oxalate sedimentation, and burning procedures, so as to produce high purity Pr-Nd oxide. The invention has the advantages of high purity (reaching 99%), high utilization ratio of raw materials (reaching 98%), simple process (two dissolutions and two sedimentations, and then burning are performed to obtain high purity products), no solid waste slag for polluting environment, and being suitable for large-scale production.

Owner:什邡市虹雨化工有限公司

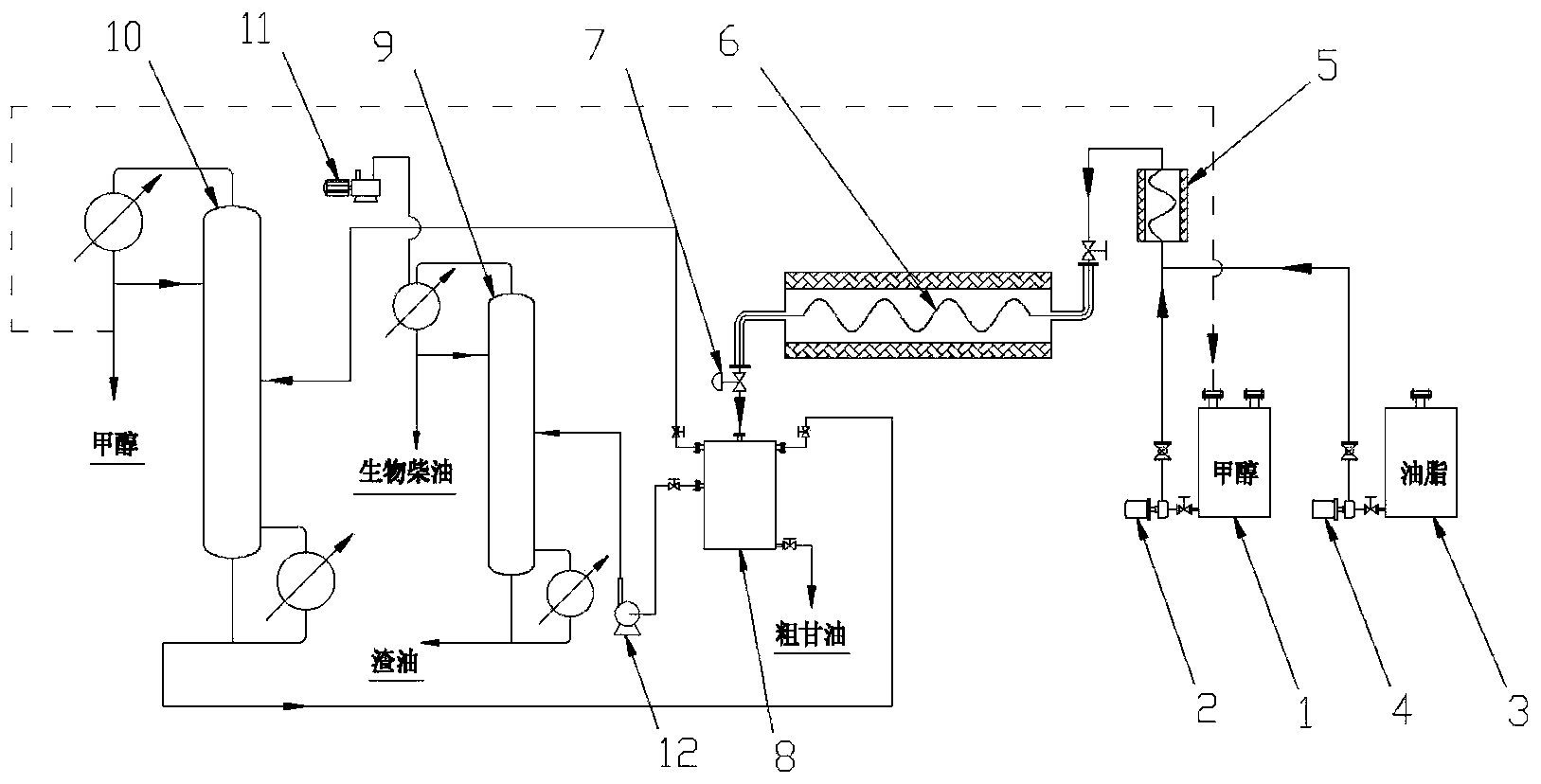

Method and device for producing biodiesel according to coal-based methanol and palm oil supercritical method

InactiveCN103666774AQuality improvementPromote conversionFatty acid esterificationBiofuelsBiodieselCoal

The invention discloses a method and device for producing biodiesel according to the coal-based methanol and palm oil supercritical method, and belongs to the technical field of renewable energy resources. The coal-based methanol and palm oil are sent into a preheater continuously for mixing and preheating, then sent into a tube-type reactor to ensure that transesterification reaction of coal-based methanol is carried out under a supercritical condition; reaction products enter a gas-liquid separator after being decompressed through a reducing valve, so as to generate crude biodiesel and crude methanol; the crude biodiesel is sent into a decompression rectifying tower for rectification to obtain biodiesel and resid; the crude methanol enters a methanol rectifying tower to obtain methanol of which the purity is 99 percent. The method and device have the advantages that the raw materials are easy to obtain and low in price; no catalyst is added; high-quality biodiesel can be obtained through decompression rectifying of the crude biodiesel; the problems, such as corrosion of acid-base catalyst on equipment and difficulty in separating a catalyst, of the conventional catalysis supercritical method are solved; environmental pollution is avoided; the biodiesel is good in quality; the methyl ester conversion is high.

Owner:TSINGHUA UNIV +1

Nanostructured yttrium stable zirconium oxide agglomerate type powder and its production method

ActiveCN1762901AShort manufacturing processSuitable for continuous mass productionGranularityColloid

The Yt stabilized zirconia aggregate powder consists of nanometer crystal particles smaller than 100 nm and has grain size of 40-90 microns. The nanometer zirconia particles inside aggregate powder contact to form cavities among them. The Yt stabilized zirconia aggregate powder is prepared through adding water into nanometer zirconia particle containing yttrium oxide to obtain suspended colloid, spraying drying, sieving, heat treatment, and plasma densifying. The present invention has simple technological process, simple operation and low cost and is suitable for continuous industrial production. The product is suitable for making various kinds of high temperature heat barrier coating and heat resistant antiwear anticorrosive coating through different kinds of hot spraying process, and is applied in various industries.

Owner:深圳地大纳米材料科技有限公司

Metal organic framework modified stannous sulfide composite photocatalyst as well as preparation method and application thereof

ActiveCN107913675ALarge specific surface areaIncreased toxicityWater/sewage treatment by irradiationOther chemical processesMetal-organic frameworkWastewater

The invention discloses a metal organic framework modified stannous sulfide composite photocatalyst as well as a preparation method and application thereof. The composite photocatalyst takes a metal organic framework MIL-53(Fe) as a carrier and is loaded with stannous sulfide. The preparation method of the composite photocatalyst comprises the following steps: mixing MIL-53(Fe) with stannous sulfide, adding solution containing S<2->, and carrying out precipitation reaction, so that the metal organic framework modified stannous sulfide composite photocatalyst is obtained. The composite photocatalyst disclosed by the invention has the advantages of environment friendliness, large specific surface area, many reaction sites, high photogenerated electron-hole utilization rate, high photocatalytic activity, good stability and corrosion resistance, and the preparation method has the advantages of simplicity in operation, low raw material cost, low energy consumption, short consumed time and easy-to-control conditions. The composite photocatalyst disclosed by the invention can be used for degrading hexavalent chromium wastewater, has the advantages of high degradation efficiency, simple application method, low cost and no secondary pollution and has a good practical application prospect.

Owner:HUNAN UNIV

Metallic surface modification process

InactiveCN101338429ALow costImprove antioxidant capacityMetallic material coating processesCarbon nanotubeChemical vapor deposition

A metal surface modification method belongs to the technical field of metal materials and is used for solving the problems of the high technical manufacturing cost, the complicated process and the difficult control of a composite carbon nano-tube with a metal surface. The technical proposal of the invention is that the raw material of the carbon nano tube is selected and the raw material is manufactured by the method of the deposition of catalyst chemical vapor containing iron catalyst, and the composite layer of the directional carbon nano tube with the thickness of 0.05 to 1.0mm is obtained on the metal surface by the processes of the grinding of the raw material, the preparation of the fused mass of the composite layer of the carbon nano tube, the magnetophoresis deposition of the superposed layer of the directional carbon nano tube, press-rolling cold-insertion, etc. The modification method can lead the carbon nano tube with the composite metal surface to be in ordered direction and can adjust the thickness of the composite layer; and the method combines the advantages of the common metal surface for the carbon nano-tube, thus improving the technical data of the carbon nano tube greatly, such as anti-oxidation, wear-resisting property, self-lubricity and strength, etc. Compared with the prior art, the modification method has low material cost and little investment in equipment, and the process of the modification method is easy to be controlled, so the modification method is suitable for continuous mass production.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

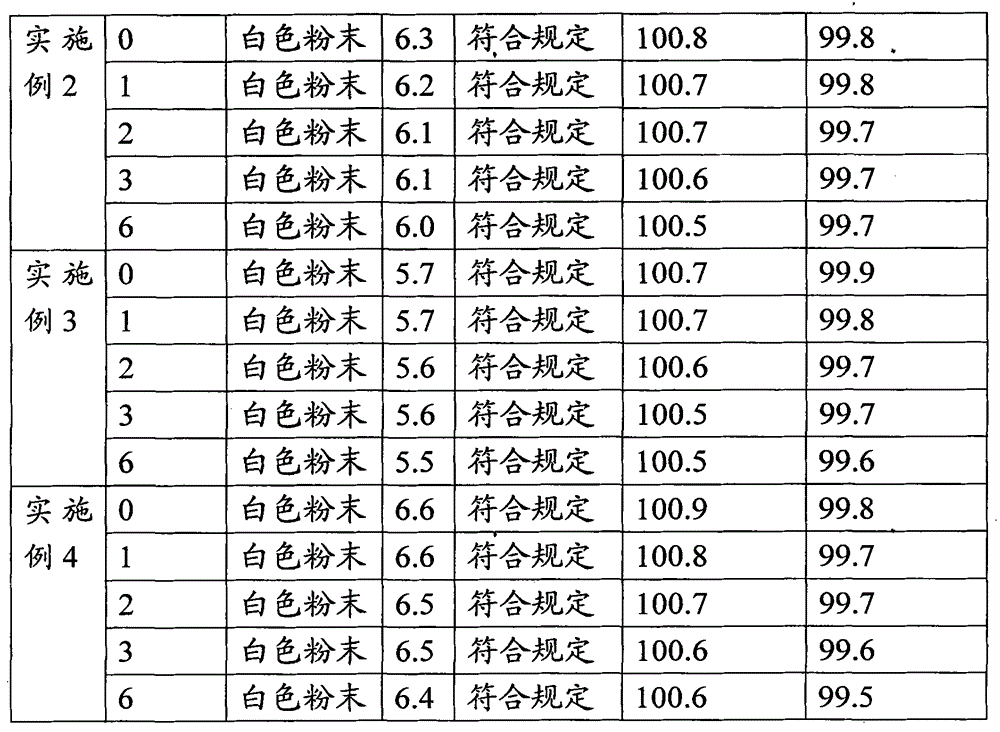

Piperacillin sodium and tazobactam sodium pharmaceutical composition and preparation method thereof

ActiveCN103550216AEasy to controlDry fastAntibacterial agentsPowder deliveryPiperacillin Sodium/ Tazobactam SodiumPowder injection

The invention discloses a piperacillin sodium and tazobactam sodium pharmaceutical composition and a preparation method thereof. The pharmaceutical composition mainly comprises piperacillin sodium and tazobactam sodium, as well as a disodium hydrogen phosphate-sodium dihydrogen phosphate buffer pair, and the powder injection is prepared by spraying and drying. The disodium hydrogen phosphate-sodium dihydrogen phosphate buffer pair is adopted for playing a role in buffering the pH of a solution, thus ensuring the content stability of piperacillin sodium, and no generation of carbon dioxide; the preparation technology is simple, convenient to control, fast to dry, and applicable to continuous large-scale production. The piperacillin sodium and tazobactam sodium powder injection is fast to dissolve, stable in quality, free from crystallization and degradation products, and the solution clarity meets the specification.

Owner:REYOUNG PHARMA

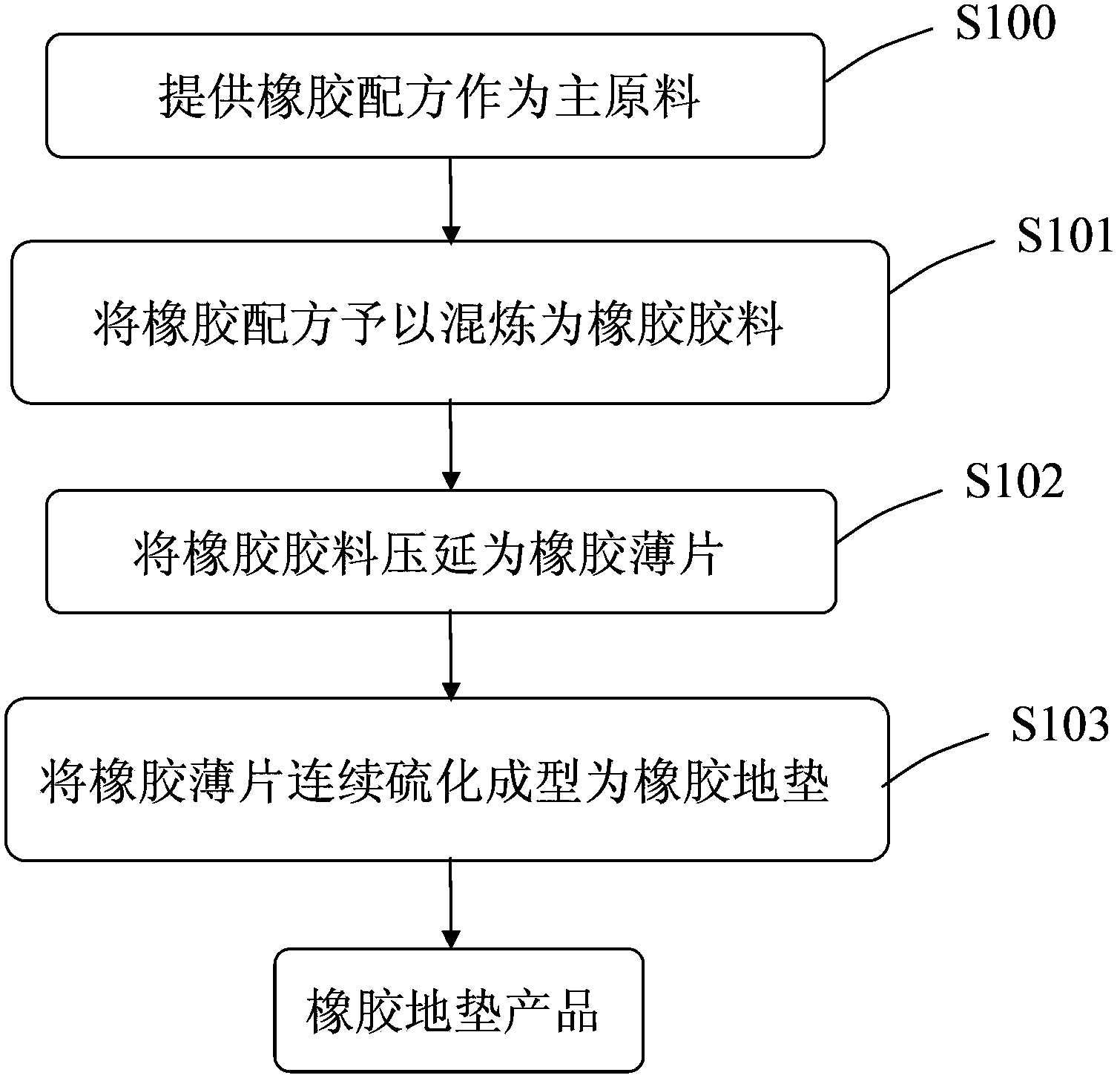

Production method of continuous type rubber flooring mat

The invention relates to a production method of a continuous type rubber flooring mat. According to the method, rubber thin sheets are manufactured through a calendaring technology from a rubber material prepared by mixing according to a rubber formula, and then the rubber flooring mat is manufactured by continuous sulfuration and moulding. Unlike traditional rubber flooring mat products manufactured by compression molding, the rubber flooring mat subjected to the continuous sulfuration and moulding benefits large-scale construction, reduces the time and labor for pavement of the flooring mat, and largely reduces the number of seams among flooring mats, and therefore the rubber flooring mat is easier to clean, and damage caused by dirt accumulation in seams and liquid penetration along the seams is reduced. Accordingly, the rubber flooring mat produced by the method is more suitable as floor materials for public places such as hospitals, airports and trains, or residence balconies, passages, stairs, elevators, and the like.

Owner:FORMOSAN RUBBER GRP

Molybdenum carbide modified tubular carbon nitride photocatalytic material and preparation method and application thereof

ActiveCN109759119AOptimizing the band structureImprove utilization efficiencyWater/sewage treatment by irradiationWater contaminantsHeterojunctionMetallurgy

The invention discloses a molybdenum carbide modified tubular carbon nitride photocatalytic material and a preparation method and application thereof. The molybdenum carbide modified tubular carbon nitride photocatalytic material comprises molybdenum carbide and tubular carbon nitride, wherein the surface of the tubular carbon nitride is modified with the molybdenum carbide. The preparation methodcomprises the steps: suspending the tubular carbon nitride in methanol, so as to obtain a suspension; dispersing the molybdenum carbide in the suspension, carrying out intensive mixing, and carryingout drying, thereby obtaining the molybdenum carbide modified tubular carbon nitride photocatalytic material. According to the molybdenum carbide modified tubular carbon nitride photocatalytic material disclosed by the invention, an energy band structure of the carbon nitride is improved to form molybdenum carbide / carbon nitride heterojunction, so that the effective separation of photoproduction electron-hole pairs is achieved, the utilization efficiency of photoproduction electron-holes is increased, and the effect of photocatalytic degradation is promoted; the molybdenum carbide modified tubular carbon nitride photocatalytic material can be applied to degradation of antibiotics or dyes in wastewater.

Owner:HUNAN UNIV

Nano-structured aggregate powder of AI/Yt/Zr ternary compound oxides and its production method

ActiveCN1754976AGrain size unchangedExtended service lifeMolten spray coatingNano structuringColloid

The Al / Yt / Zr three-element composite oxide aggregate powder of nano structure comprises 0.3-30wt% Al2O3, 3-9wt% Y2O3 and nano ZrO2 powder particle with average size 5n-60nm. Wherein, the nano oxide particle is body surface contact, other is pure cavity. The opposite preparation method comprises: adding water into the composite oxide for water suspended colloid; spray drying, sieve separating, heat treating, and plasma densifying. This invention is simple and low cost for continual production in scale. The product can satisfy plasma spraying, flame spraying, and other heat spraying technique.

Owner:深圳地大纳米材料科技有限公司

Biomass solid clean fuel as well as preparation method and application thereof

The invention discloses a biomass solid clean fuel as well as a preparation method and application thereof. A percentage of carbon atoms in the biomass solid clean fuel is 37.15%-50.24%, and the highcalorific value is 13.50 MJ / kg-22.22 MJ / kg; and the clean fuel is prepared by the following steps: sludge and biomass waste are used as raw materials, pre-treatment is performed, acid-base treatment is performed, hydrothermal carbonization treatment is performed, hot press molding is performed, and therefore the clean fuel is prepared. The biomass solid clean fuel disclosed by the invention has the advantages of a high carbon content, a low nitrogen content, a high calorific value, less pollution, simple and easy preparation and low costs, and is a novel clean material; the preparation methodhas the advantages of a simple and easy preparation process, low costs, less energy consumption, short consumed time and conditions easy to control; and the biomass solid clean fuel has the advantagesof simple operation, high energy conversion efficiency and less secondary pollution when being used for combustion to generate energy as a fuel, and the energy clean utilization of the biomass solidclean fuel can be realized.

Owner:湖南大学深圳研究院 +1

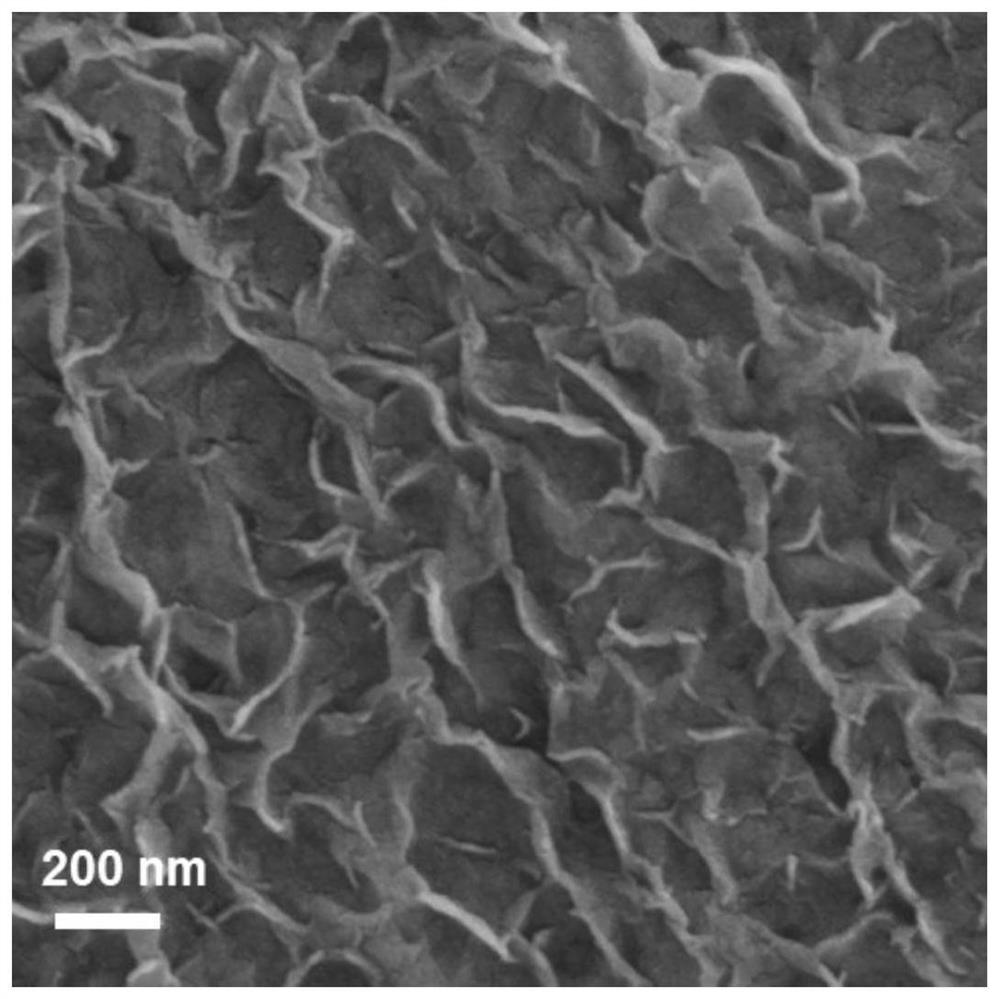

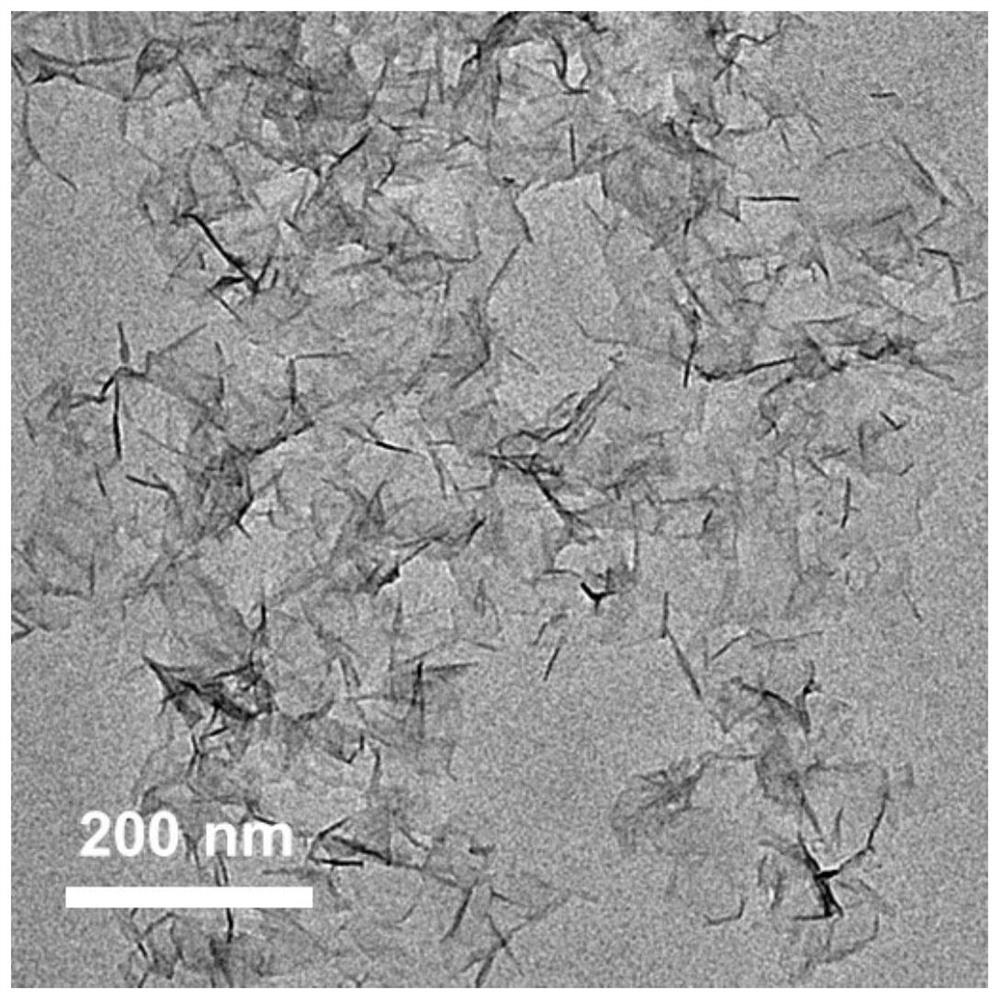

Bimetal organic framework nanosheet and application thereof in supercapacitor

The invention discloses a bimetal organic framework nanosheet and application thereof in a supercapacitor. The nanosheet is a Co-M bimetal organic framework nano-sheet, wherein M comprises manganese,iron, nickel, copper and zinc in a fourth period; the morphology of the nanosheet is a two-dimensional nanosheet; and the thickness is 2-5 nm. The bimetal organic framework nanosheet electrode material disclosed by the invention is prepared by a simple precipitation reaction; adopted raw materials are non-toxic, environment-friendly and low in cost, and a preparation process is simple, easy to operate and control and suitable for continuous large-scale production, the preparation process is green and environment-friendly, and tests prove that the ultrathin bimetal organic framework nanosheet shows good electricity storage performance when being applied to the supercapacitor.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com