Two-component condensation-type thermal-conductive silicone gel and preparation method thereof

A condensed, thermally conductive silicon technology, used in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of unstable silicone gel performance, production, transportation and storage hazards, and the mixing ratio is prone to fluctuations, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a method for preparing a two-component condensation type thermally conductive silicone gel, comprising the following steps:

[0054] Preparation of component A:

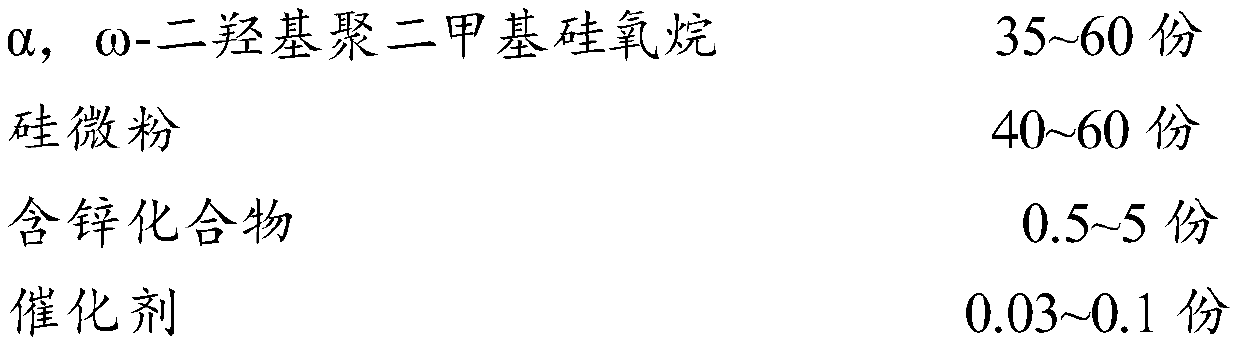

[0055] In parts by weight, stir 35-60 parts of α, ω-dihydroxy polydimethylsiloxane and 40-60 parts of silicon micropowder at 100-150°C, keep the vacuum at 0.05-0.15MPa, and rotate 200~500r / min, stirring for 30~80min;

[0056] Lower the temperature of the material to below 50°C, add 0.5 to 5 parts of zinc-containing compounds, and stir in vacuum for 5 to 20 minutes;

[0057] Add 0.03-0.1 parts of catalyst, and stir in vacuum for 10-30 minutes to obtain component A.

[0058] B component preparation:

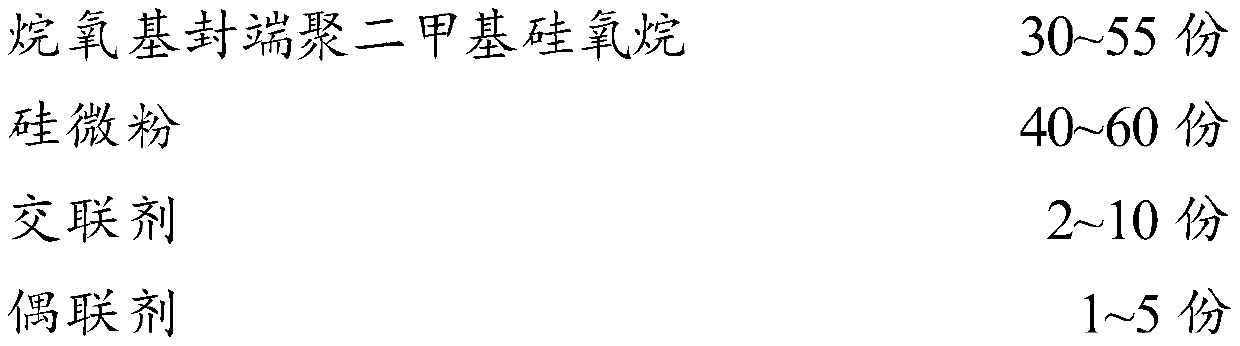

[0059] In parts by weight, stir 30-55 parts of alkoxy-terminated polydimethylsiloxane and 40-60 parts of silicon micropowder at 100-150 °C, keep the vacuum at 0.05-0.15 MPa, and rotate at a speed of 200~500r / min, stirring for 30~80min;

[0060] Lower the temperature of the m...

Embodiment 1

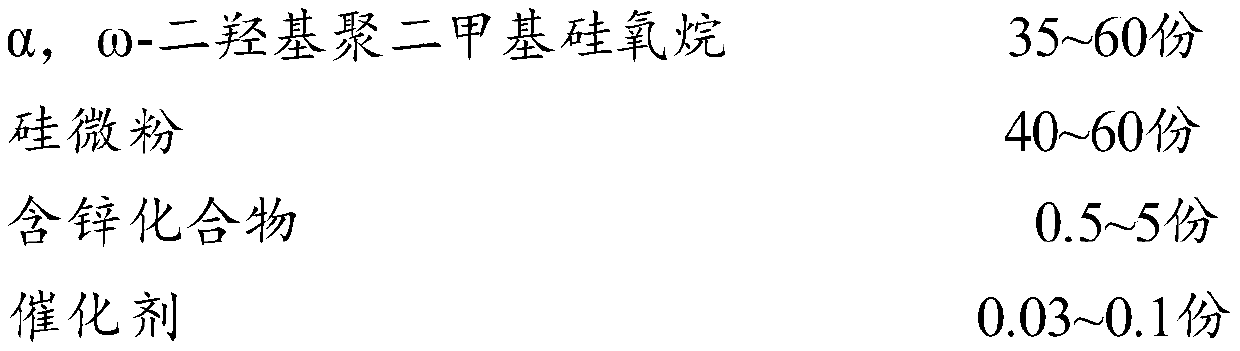

[0078]

[0079] Prepare component A and component B respectively according to the dosage of each raw material in the above table;

[0080] Preparation of component A:

[0081] Put α, ω-dihydroxypolydimethylsiloxane and silicon micropowder into a high-speed disperser, heat to 110°C, keep the vacuum at 0.095MPa, rotate at 300r / min, and stir for 60min;

[0082] Lower the temperature of the material to below 50°C, add the zinc-containing compound, and stir in vacuum for 10 minutes;

[0083] Add the catalyst and stir in vacuum for 20min to obtain component A.

[0084] B component preparation:

[0085] Put alkoxy-terminated polydimethylsiloxane and silicon micropowder into a high-speed disperser, heat to 110°C, keep the vacuum at 0.095MPa, rotate at 300r / min, and stir for 60min;

[0086] Lower the temperature of the material to below 50°C, add a crosslinking agent, and stir in vacuum for 10 minutes;

[0087] Add coupling agent and stir in vacuum for 20min to obtain component ...

Embodiment 2

[0090]

[0091] According to the preparation method in Example 1, using the ratio of raw materials in this example, the silica gel was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com