Room temperature curing adhesive based on silazane and its modified polymer and its preparation method

A room temperature curing, polymer technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of high curing temperature of adhesives, limited power of curing equipment, insufficient curing depth, etc., to achieve High shear strength, good toughness, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation process of the binder is:

[0032] Add a certain amount of auxiliary filler to 100 parts of silazane and its modified polymer and mix it evenly, then add the corresponding curing agent, mix thoroughly and degas for 5-10 minutes, then it can be used as room temperature curing high temperature resistant adhesive , Curing at room temperature for 3-7 days.

[0033] Silazane and its modified polymers are converted into ceramic materials by pyrolysis at high temperature. They have excellent temperature resistance and oxidation resistance. It is precisely because of the excellent properties of the precursor polymer itself that it can be prepared by compounding the corresponding fillers. High temperature resistant adhesive.

Embodiment 1

[0036] Add 100 parts of polysilazane with a viscosity of 45000 centipoise, 5 parts of TDI, and 100 parts of SiO in the beaker 2 , 50 parts of ZrB 2 , 5 parts SiC, 15 parts TiC, 3 parts SiO 2 Chopped fiber, 5 parts Fe 2 O 3 As a pigment, it can be used to bond plastics, metals, graphite, ceramics and their composite materials after being thoroughly mixed. After curing at room temperature, the bonding performance is measured.

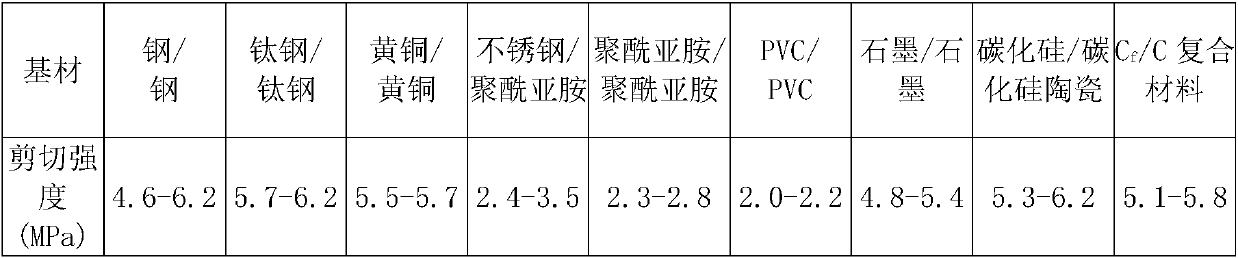

[0037] Table 1 shows the room temperature bonding strength of the polysilazane binder to metals, graphite, polymer materials, ceramics and composite materials.

[0038] Table 1 The bonding strength of organosilicon binders to metals, polymer materials, ceramics and composite materials

[0039]

Embodiment 2

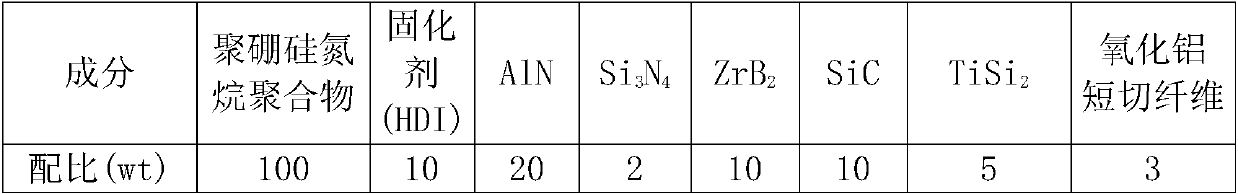

[0041] According to the ratio of each component of the binder given in Table 2, the viscosity of the polyborosilazane polymer is 950 centipoise. After mixing and degassing, it is used as the binder of the graphite matrix material to make 5 sets of bonding parts were tested for room temperature and high temperature performance, and the results are shown in Table 3.

[0042] Table 2 Composition and ratio of binder

[0043]

[0044] Note: The viscosity of polyborosilazane polymer is 950 centipoise

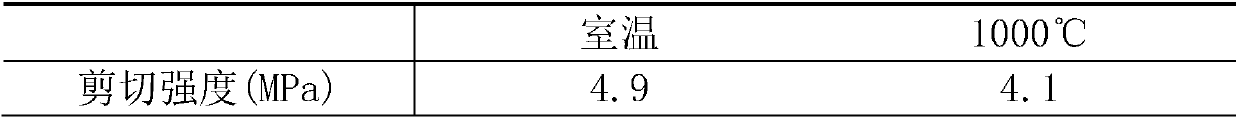

[0045] Table 3 Shear strength of binder at room temperature and 1000℃

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com