Method for continuous production of ultrapure hydrogen peroxide

An ultra-pure hydrogen peroxide, hydrogen peroxide technology, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, etc., can solve the problem of peroxide Hydrogen does not meet the SEMIC12 standard, the exchange resin loses its purification ability, explosion and other problems, to achieve the effect of reasonable combination sequence, stable product quality and reducing resin damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

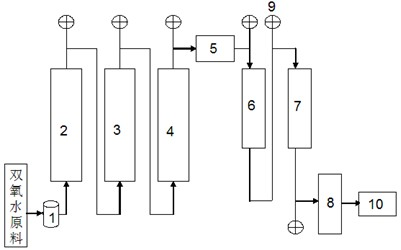

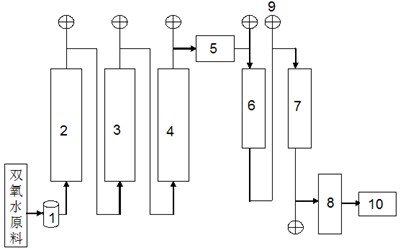

[0031] The temperature is controlled at 5℃, and 30wt% industrial-grade hydrogen peroxide passes through the macroporous polystyrene adsorption resin column at a flow rate of 200kg / h to pre-treat the industrial-grade hydrogen peroxide raw materials, and remove the organic impurities in the raw materials (with organic carbon Calculated) content is reduced to less than 200ppm. cool down.

[0032] Under the same process conditions, the pretreated hydrogen peroxide passes through a strong acid cation exchange resin column and a strong basic anion exchange resin column; the hydrogen peroxide after ion exchange enters the anion and cation exchange resin mixed column (anion exchange resin and The volume ratio of cation exchange resin is 1:1) for secondary ion exchange;

[0033] Maintain a temperature of 5-20℃, and pass the second-stage ion exchange liquid material after the central control analysis is passed into the polytetrafluoroethylene ultrafiltration membrane (0.1μm) filter. The fil...

Embodiment 2

[0035] The temperature is controlled at 5℃, 30wt% industrial grade hydrogen peroxide passes through the macroporous polystyrene adsorption resin column at a flow rate of 300kg / h to pretreat the industrial grade hydrogen peroxide raw materials, and remove the organic impurities in the raw materials (with organic carbon Calculated) content is reduced to less than 200ppm. cool down.

[0036] Referring to Example 1, the pretreated hydrogen peroxide is passed through a strongly acidic cation exchange resin column and a strongly basic anion exchange resin column; the hydrogen peroxide after ion exchange enters the anion and cation exchange resin mixed column (anion exchange resin and cation The exchange resin volume ratio is 1:1.5) Perform secondary ion exchange;

[0037] Maintain a temperature of 5-20℃, and pass the second-stage ion exchange liquid material after the central control analysis is passed into the polytetrafluoroethylene ultrafiltration membrane (0.1μm) filter. The filtere...

Embodiment 3

[0039] The temperature is controlled at 5℃, and 30wt% industrial grade hydrogen peroxide passes through the macroporous polystyrene adsorption resin column at a flow rate of 400kg / h to pretreat the industrial grade hydrogen peroxide raw materials, and remove the organic impurities in the raw materials (with organic carbon Calculated) content is reduced to less than 200ppm. cool down.

[0040] Referring to Example 1, the pretreated hydrogen peroxide is passed through a strongly acidic cation exchange resin column and a strongly basic anion exchange resin column; the hydrogen peroxide after ion exchange enters the anion and cation exchange resin mixed column (anion exchange resin and cation The volume ratio of the exchange resin is 1:2) Perform secondary ion exchange;

[0041] Maintain a temperature of 5-20℃, and pass the second-stage ion exchange liquid material after the central control analysis is passed into the polytetrafluoroethylene ultrafiltration membrane (0.1μm) filter. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com