Technique for producing 99% praseodymium-neodymium oxides by using Nd-Fe-B smelting slag

A technology of praseodymium neodymium oxide and neodymium iron boron, which is applied in the field of extraction of praseodymium neodymium oxide, can solve the problems of pollution, low recovery rate, low metal recovery rate, etc., and achieve simple process, high raw material utilization rate and high product purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

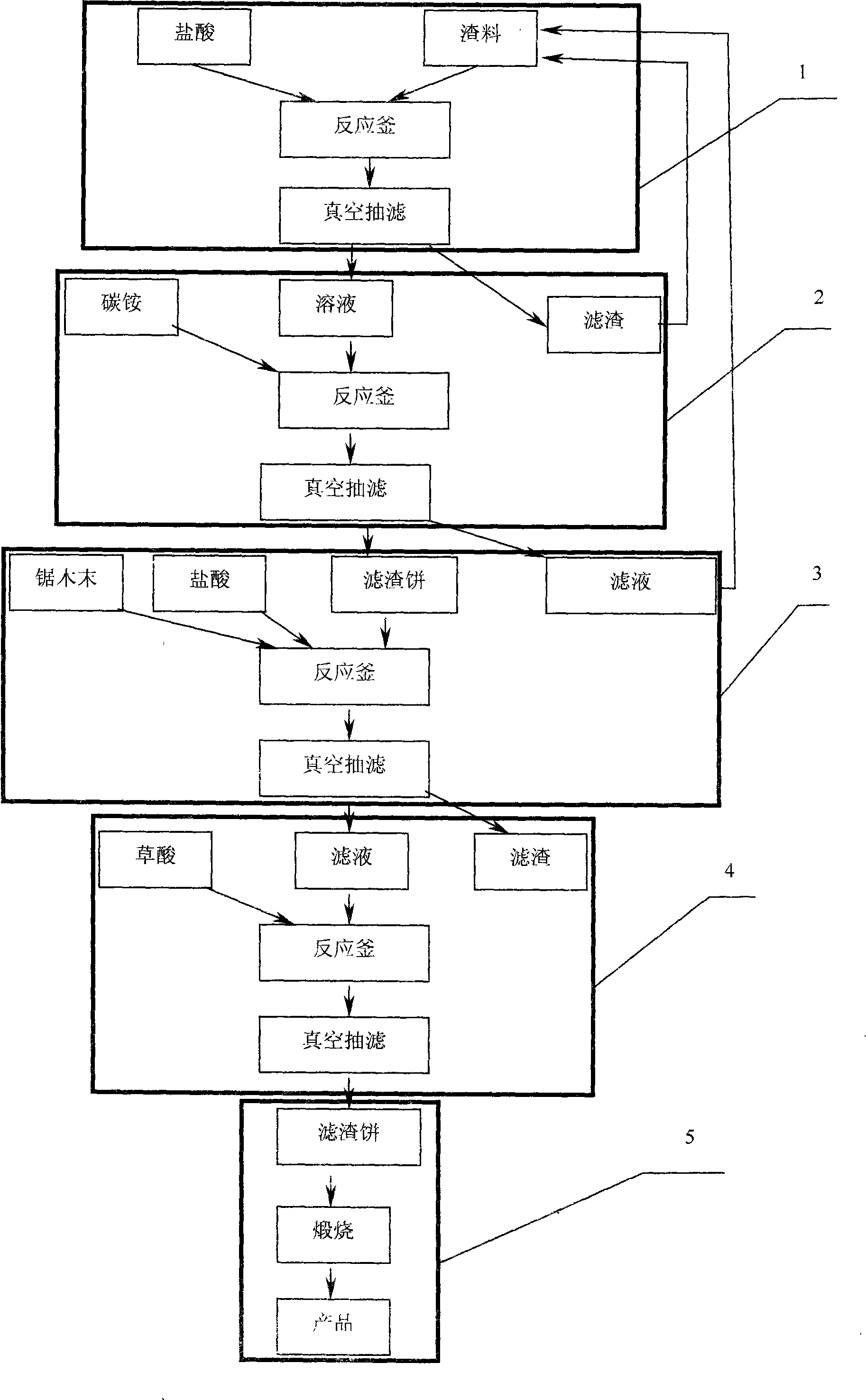

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment and process flow chart, the invention is described further. Step A, acid leaching, put 1.2 cubic meters of 6mol / L hydrochloric acid in a reaction kettle with a volume of 3 cubic meters, and slowly put 800 kg of NdFeB smelting waste residue and waste magnetic mud into the hydrochloric acid for 40 minutes. In the reaction kettle, after the feeding is completed, wait for it to react for 2 hours, then add water to dilute to 1.8 cubic meters, stir for 15 minutes, and then add ammonium bicarbonate to adjust the pH value to 2;

[0025] Its chemical reaction equation is: RE 2 o 3 +6HCL=2RECL 3 +3H 2 o

[0026] In this step, the praseodymium and neodymium oxides in the refining waste slag and waste magnetic mud are dissolved by HCL into water-soluble RECL 3 , so that the praseodymium and neodymium are separated from the impurities.

[0027] Step B, ammonium bicarbonate precipitation, the temperature of the solution with a pH va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com