Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

661 results about "Molybdenum carbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molybdenum carbide (MoC and Mo₂C) is an extremely hard refractory ceramic material, commercially used in tool bits for cutting tools.

Nano powders, components and coatings by plasma technique

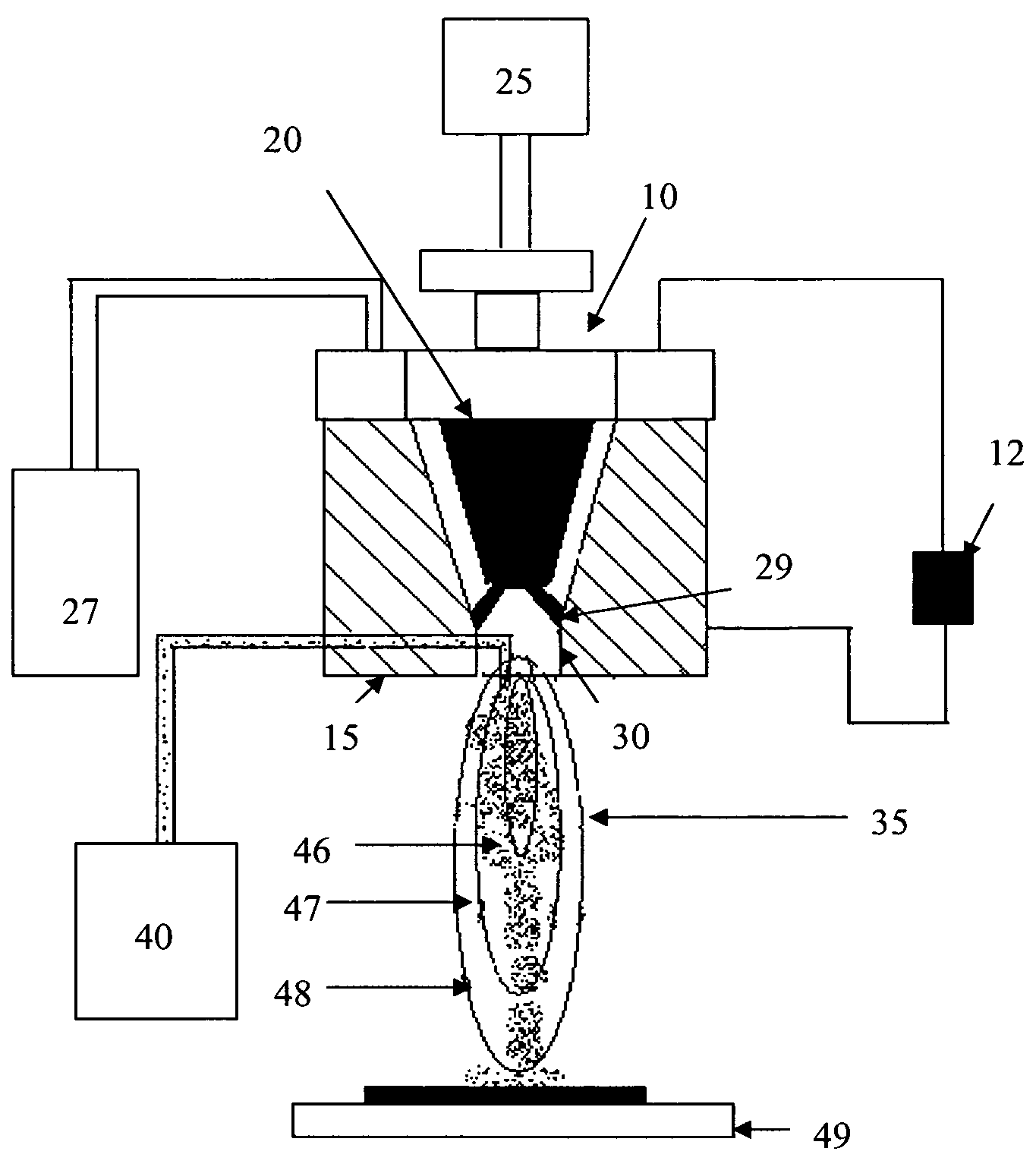

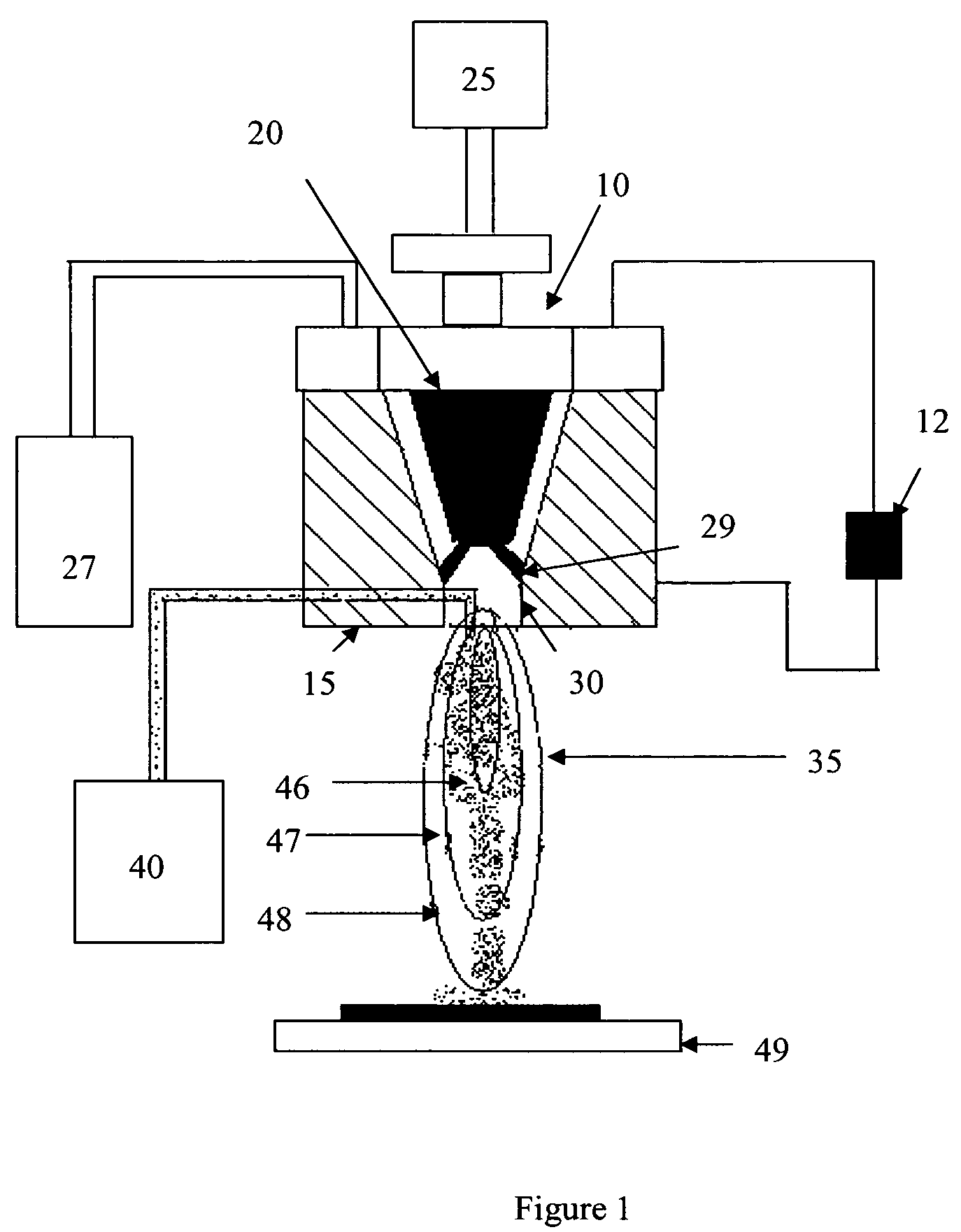

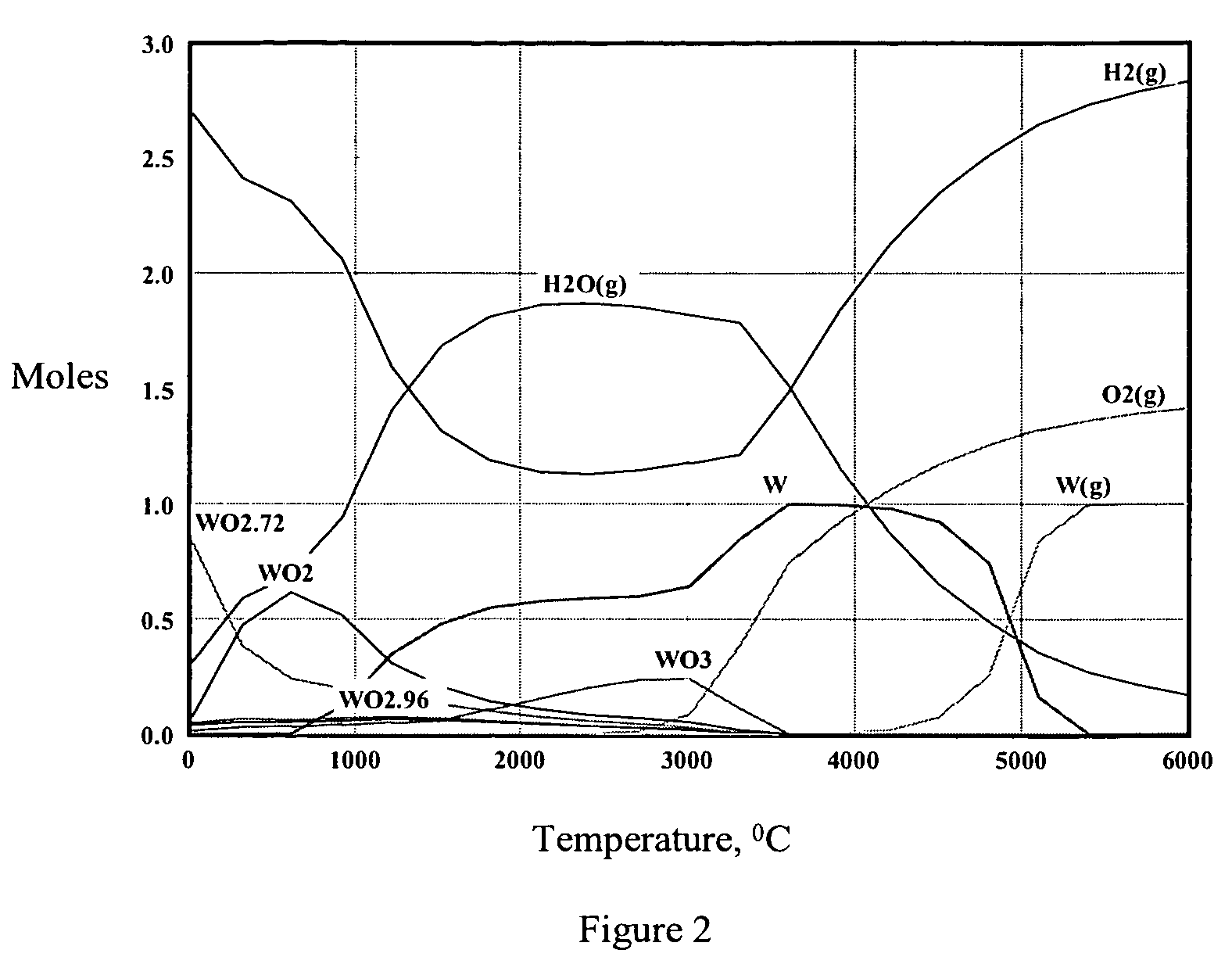

ActiveUS7615097B2Rapid quenching and generationHigh materialLiquid surface applicatorsMolten spray coatingRheniumChemical reaction

Ultra fine and nanometer powders and a method of producing same are provided, preferably refractory metal and ceramic nanopowders. When certain precursors are injected into the plasma flame in a reactor chamber, the materials are heated, melted and vaporized and the chemical reaction is induced in the vapor phase. The vapor phase is quenched rapidly to solid phase to yield the ultra pure, ultra fine and nano product. With this technique, powders have been made 20 nanometers in size in a system capable of a bulk production rate of more than 10 lbs / hr. The process is particularly applicable to tungsten, molybdenum, rhenium, tungsten carbide, molybdenum carbide and other related materials.

Owner:PLASMA PROCESSES

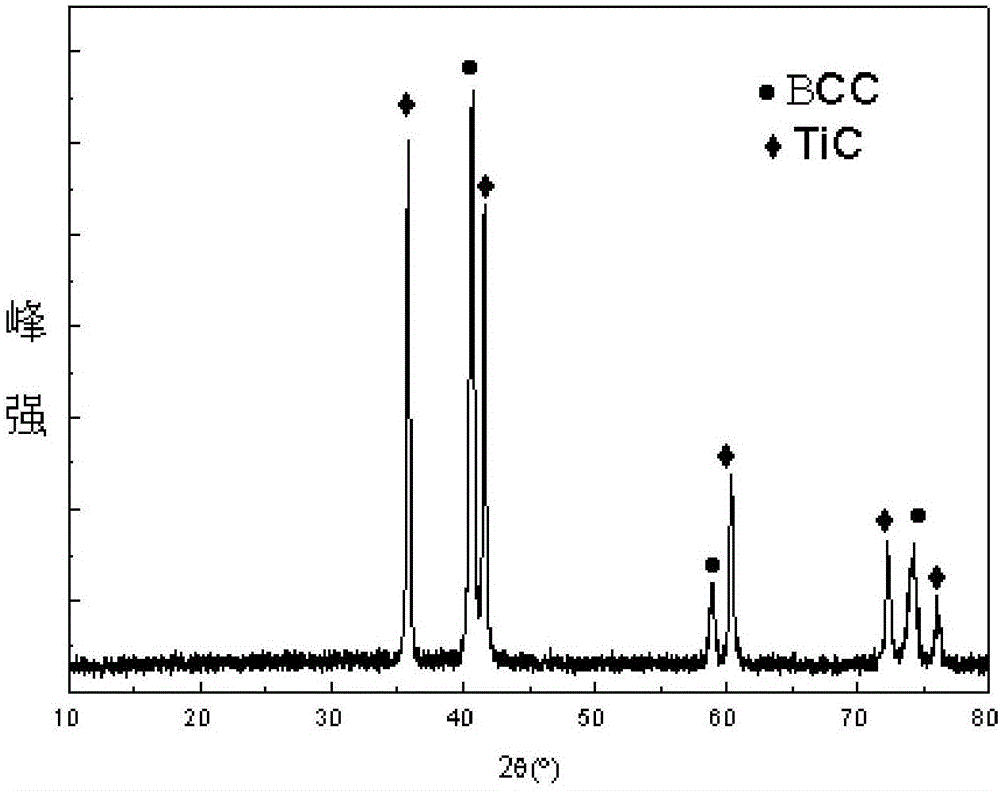

Refractory high-entropy alloy/titanium carbide composite and preparation method thereof

The invention discloses a refractory high-entropy alloy / titanium carbide composite. A refractory high-entropy alloy serves as a matrix phase, and titanium carbide serves as a wild phase; and elements in the refractory high-entropy alloy are selected from at least four kinds of elements of W, Mo, Ta, Nb, V, Ti, Zr, Hf and Cr. A preparation method of the refractory high-entropy alloy / titanium carbide composite comprises the steps that at least four kinds of carbonization metal powder in tungsten carbide, molybdenum carbide, tantalum carbide, niobium carbide, vanadium carbide, the titanium carbide, hafnium carbide, zirconium carbide and chromium carbide are selected and mixed according to the equal molar ratio or the ratio close to the equal molar ratio to form high-entropy matrix powder; and after the high-entropy matrix powder and titanium powder are mixed, alloy mechanization is carried out, then spark plasma sintering or hot-press sintering is carried out, and the refractory high-entropy alloy / titanium carbide composite is obtained. The density and cost of the composite are reduced while the hardness of the composite is improved, excellent high-temperature performance is achieved, and the requirement for manufacturing a high-temperature structural component is met.

Owner:江西咏泰粉末冶金有限公司

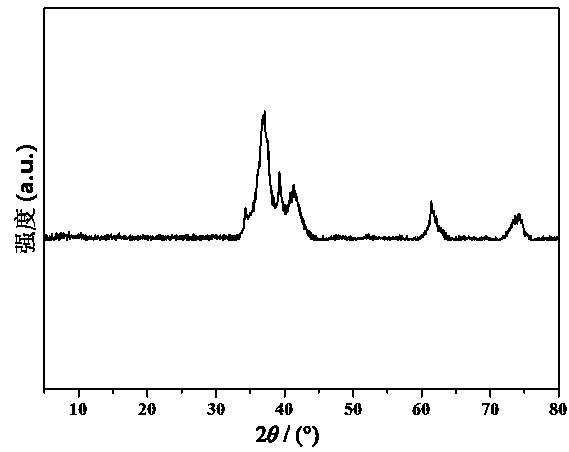

Synthesis method of nano-molybdenum carbide

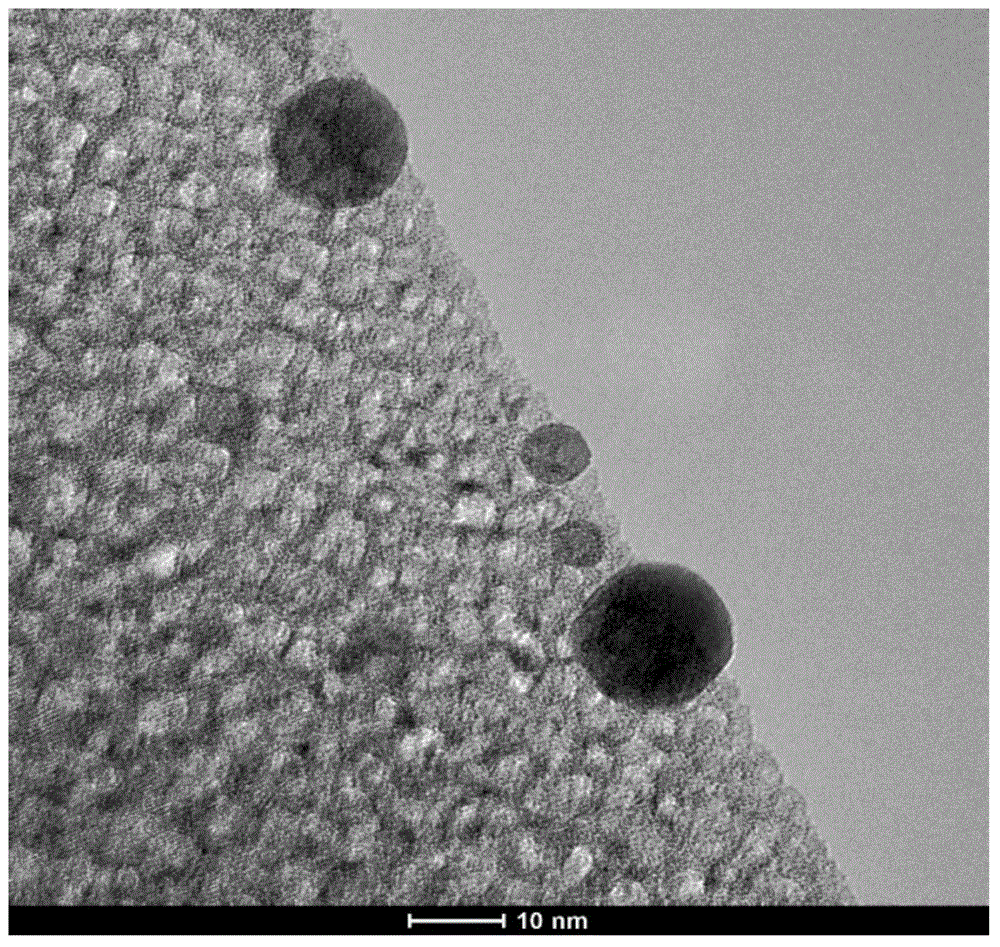

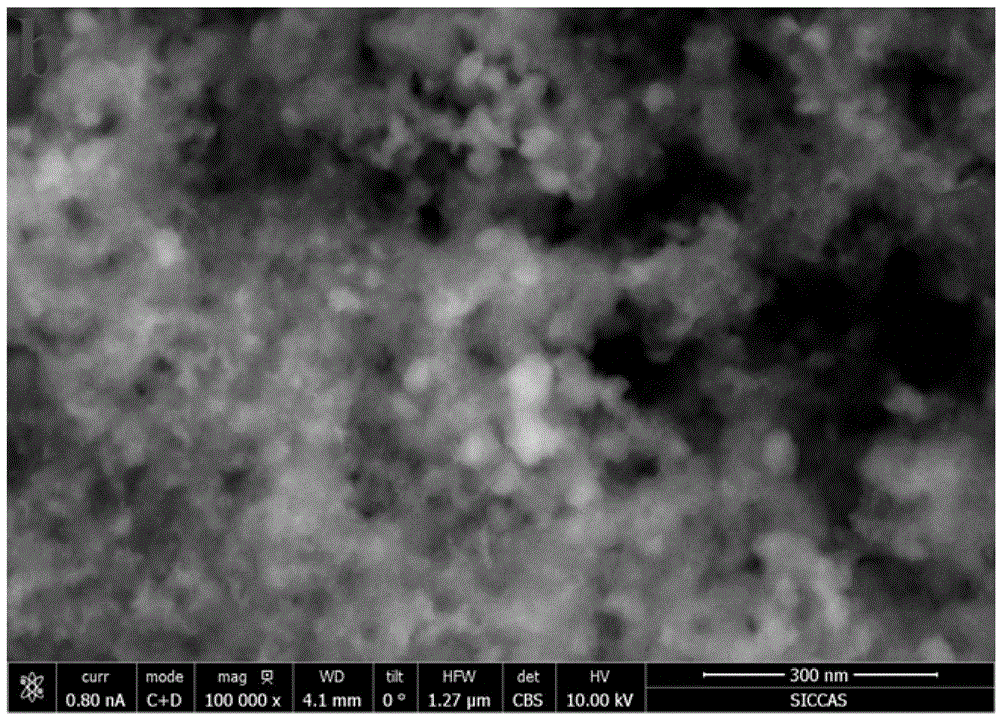

InactiveCN103936008ALarge specific surface areaSmall particle sizeTungsten/molybdenum carbideSynthesis methodsFiltration

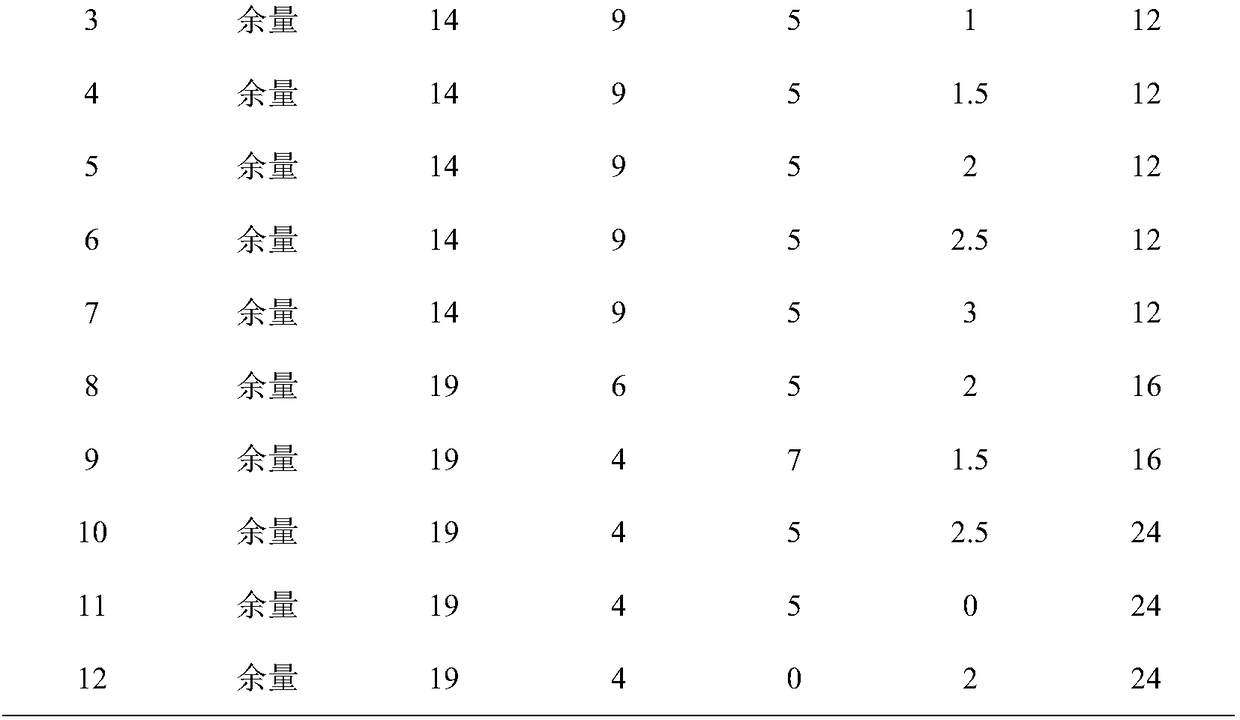

The invention relates to a synthesis method of nano-molybdenum carbide. The synthesis method comprises the following steps: dissolving a molybdenum precursor in hydrogen peroxide, dissolving carbohydrates in water, mixing the molybdenum precursor with the carbohydrates, stirring, loading a mixed solution into a hydrothermal kettle, and performing hydrothermal treatment to obtain a black product; cooling the black product, then washing and performing suction filtration on the product, drying, baking in a passivation gas atmosphere, replacing with passivation gas when the temperature is reduced to room temperature, and performing passivation treatment to obtain the nano-molybdenum carbide. The synthesis method provided by the invention has the advantages of simplicity, easiness in control, economical efficiency, reasonableness and large specific surface area with mesoporous structure.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

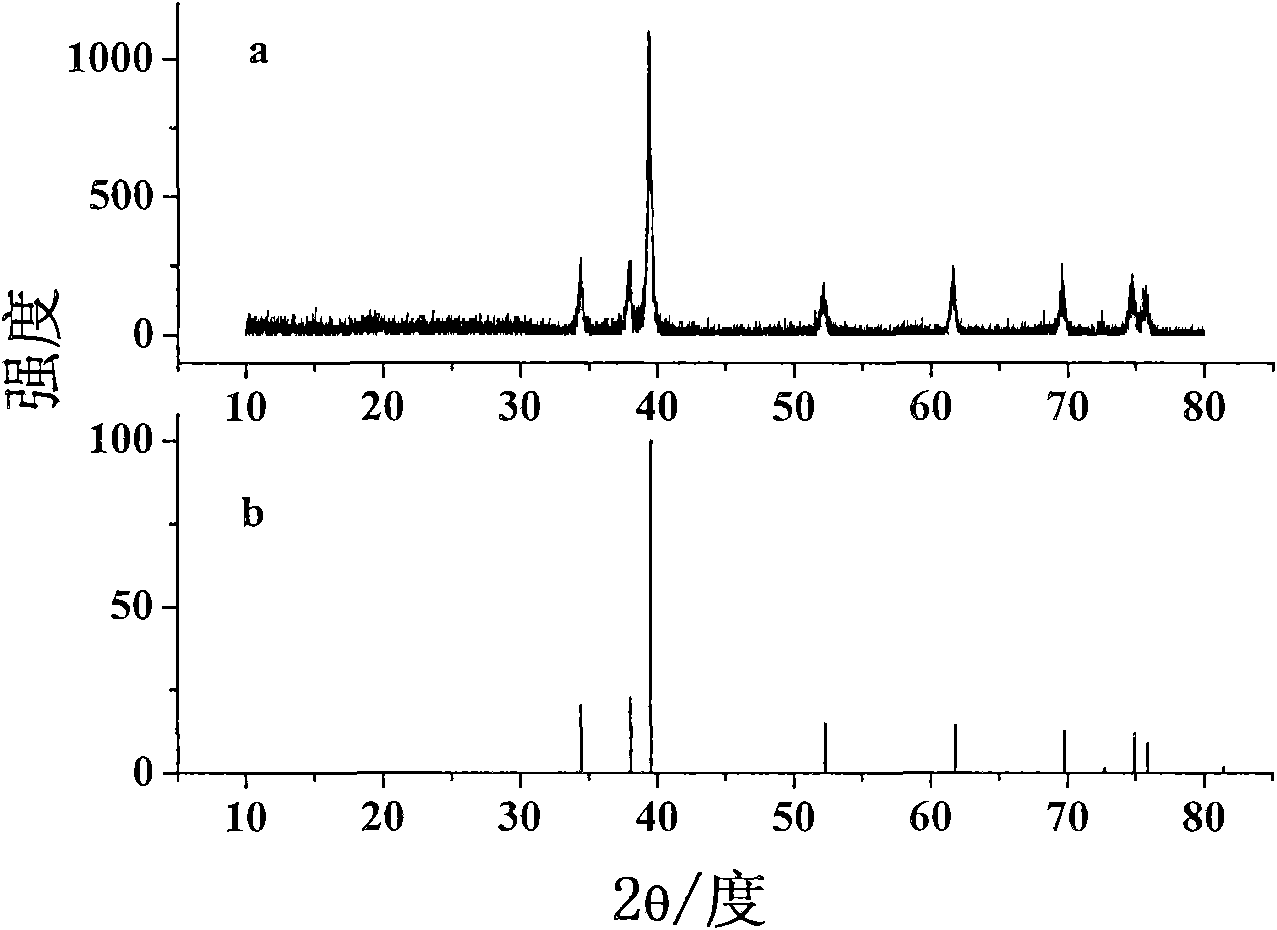

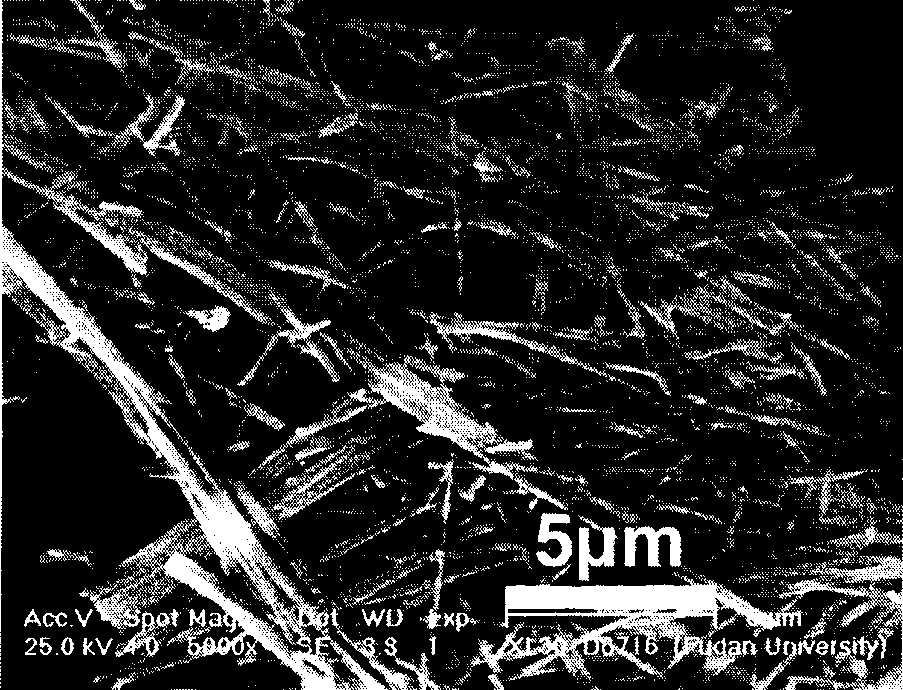

Synthetic method of load type molybdenum carbide catalyst

InactiveCN101829588AFacilitated DiffusionLarger than surfaceHydrogenPhysical/chemical process catalystsCarbon nanotubeMolybdenum carbide

The invention relates to a synthetic method of a load type molybdenum carbide catalyst, which belongs to the field of catalytic materials and comprises the steps of: dispersing organic-inorganic mixed molybdenum oxide-polyaniline used as precursors in H2O / EtO; drying after mixing with carriers, such as carbon nanotubes and the like; and then roasting at an inert atmosphere to obtain the load typemolybdenum carbide catalyst. In the load process, other metal salts can also be added to modify the molybdenum carbide catalyst to obtain a metal modified load type molybdenum carbide catalyst. The molybdenum carbide catalyst prepared by the invention has the advantages of large external surface area, less surface carbon deposition, abundant catalytic performance of precious metal and the like, and can be used for conveniently modifying the catalyst. The loading molybdenum carbide catalyst has important application in various catalytic reactions.

Owner:FUDAN UNIV

Enhanced metal ceramic abrasion-resistant composite material and preparation method thereof

The invention discloses an enhanced metal ceramic abrasion-resistant composite material and a preparation method thereof. The composite material is composed of, by mass, 25-35 parts of nano molybdenum carbide, 15-25 parts of nano ceramic powder, 10-15 parts of glass fiber, 5-10 parts of cobalt, 10-15 parts of chrome, 10-15 parts of titanium carbonitride, 1-3 parts of zirconium oxide, 3-5 parts of silicon oxide, 8-10 parts of cerium oxide, 1-3 parts of aluminium oxide, 5-10 parts of niobium carbide, 5-15 parts of silicon carbide, 1-3 parts of vanadium carbide, 4-9 parts of copper, 1-5 parts of titanium powder, 1-5 parts of coupling agents, 1-3 parts of antistatic agents and 1-3 parts of curing agents. The preparation method of the enhanced metal ceramic abrasion-resistant composite material just comprises mixing, drying, sintering and cooling. The metal ceramic composite material has good properties that the bending resistant strength is up to 2500 MPa and the Rockwell hardness is up to 93; in addition, the metal ceramic composite material also has good properties of abrasion resistance and high temperature resistance; the preparation method is simple and feasible and suitable for application and popularization on a large scale.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

Preparation method of micro-nano molybdenum carbide powder

InactiveCN107352543AGuaranteed to dissolveAvoid contactTungsten/molybdenum carbideMicro nanoMolybdate

The invention discloses a preparation method of micro-nano molybdenum carbide powder. The preparation method comprises the specific steps that an organic precursor serves as a carbon source, molybdate serves as a molybdenum source, fused salt serves as a reaction medium, high-temperature processing, washing and drying are conducted in sequence in an air environment, and the micro-nano molybdenum carbide powder is prepared. The preparation method is quick in reaction speed, and the reaction time is effectively shortened. Besides, the fused salt exists between the generated solid-phase molybdenum carbide particles in the reaction process, so that the mutual bonding between the particles can be stopped, and the agglomeration phenomenon can be reduced. In the method, no special atmospheric conditions are needed, the micro-nano molybdenum carbide material can be prepared at a relatively low temperature; the process is simple, the preparation conditions are mild, and a large scale of production is easy to achieve.

Owner:DONGGUAN UNIV OF TECH

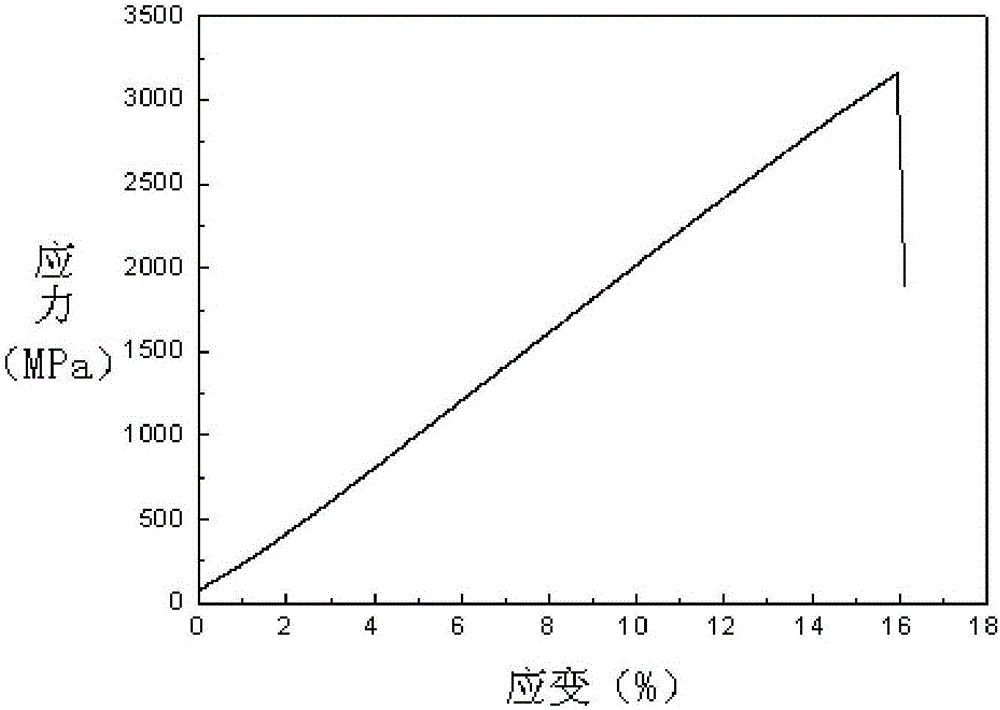

Ti(C,N) base metal ceramic and preparation method thereof

ActiveCN108950342AAdjust machinabilityMachinability satisfactionMilling cuttersWorkpiecesTitanium carbonitrideMolybdenum carbide

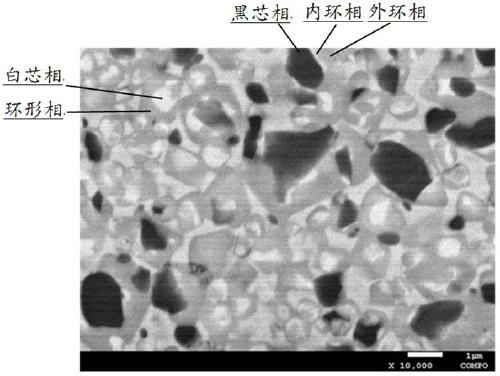

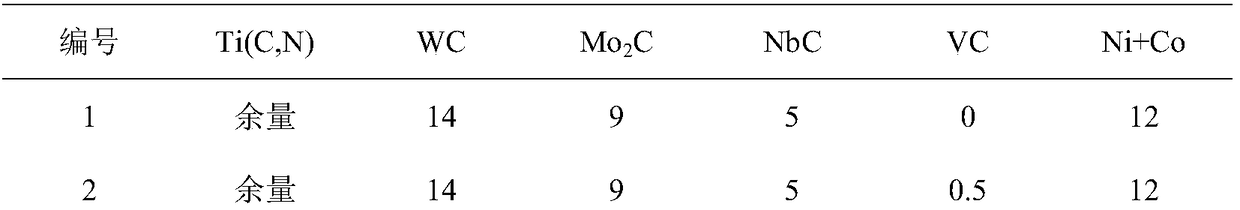

The invention discloses Ti(C,N) base metal ceramic and a preparation method thereof. Raw materials of the metal ceramic comprise titanium carbonitride Ti(0.5 of C and 0.5 of N), tungsten carbide WC, molybdenum carbide / molybdenum Mo2C / Mo, niobium carbide NbC, vanadium carbide VC, cobalt Co and nickel Ni powder, wherein the content of NbC ranges from 3 wt% to 15 wt%, the VC content is 0.3-3%, and the VC content changes along with the content of NbC. Hard phases formed by the materials are of two core-ring structures, one structure is a ring-shaped phase structure containing typical black core phases and inner ring phases, or outer ring phases and black core phases, and the other structure is a ring-shaped phase structure containing white core phases. The total credit of the black core phasesin the ring-shaped phase structure containing the black core phases and the inner ring phases, or the outer ring phases and the black core phases is 10-20%, the total credit of the inner ring phasesis 0.5-2%, and the total credit of the white core phases in the ring-shaped structure containing the white core phases is 5-10%. Chemical components of some or all white core phases are different fromthose of the inner ring phases, and the content of the Nb element in some or all white core phases is 30-40 wt% higher than the content of the Nb element in the inner ring phases. The Ti(C,N) base metal ceramic has thermal shock resistant performance and cutting performance.

Owner:CHINA THREE GORGES UNIV

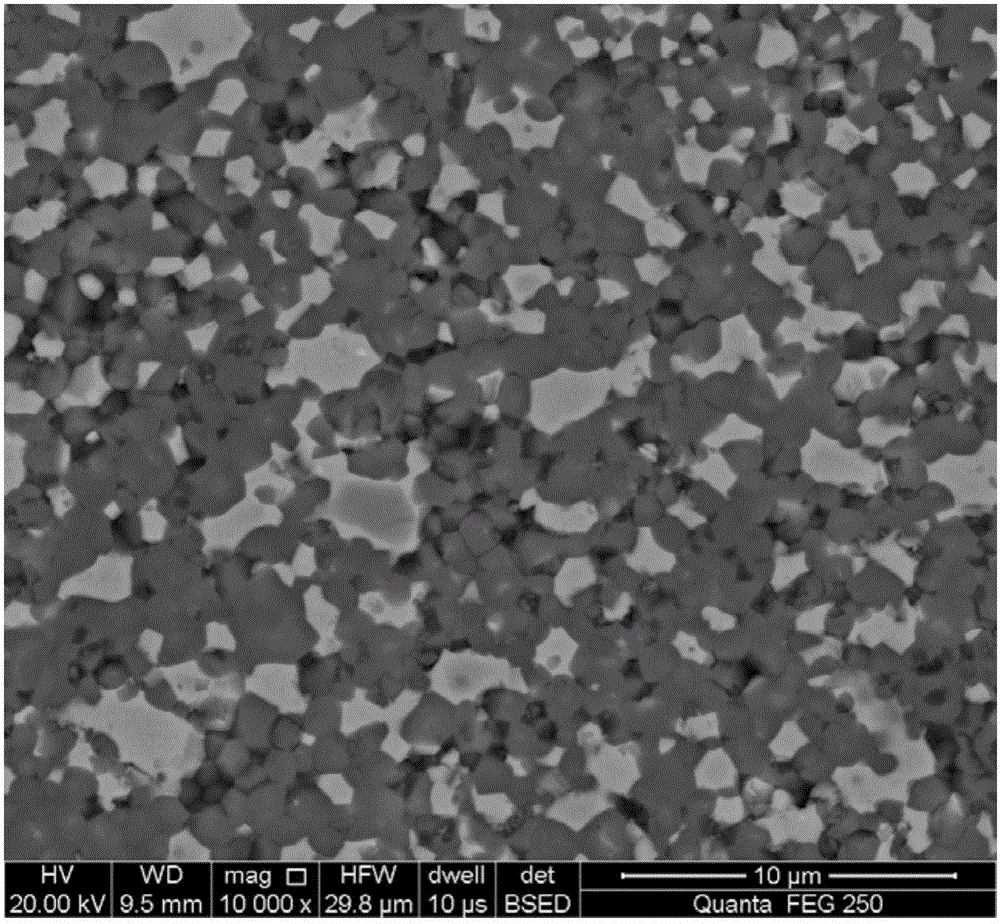

Ultra-fine grain high-entropy metal ceramic composite material and preparing method thereof

InactiveCN110423930AUniform particle sizeImprove mechanical propertiesCeramic compositeHigh entropy alloys

The invention discloses an ultra-fine grain high-entropy metal ceramic composite material and a preparing method thereof. The composite material is made with (MoTiWTaZr)C high-entropy ceramic as a hard phase and FeCoCrNiAl high-entropy alloy as a metal bonding phase. Specifically, five kinds of carbide powder of molybdenum carbide, titanium carbide, tungsten carbide, tantalum carbide and zirconiumcarbide are subjected to high-energy ball milling to form high-entropy ceramic powder, five kinds of metal powder of iron, cobalt, chromium, nickel and aluminum are subjected to high-energy ball milling to form single-phase solid solution high-entropy alloy powder, high-entropy ceramic powder and high-entropy alloy powder are mechanically mixed, through discharge plasma sintering, the ultra-finegrain high-entropy metal ceramic composite material is obtained, and the comprehensive performance of the obtained composite is obviously improved.

Owner:FUJIAN UNIV OF TECH

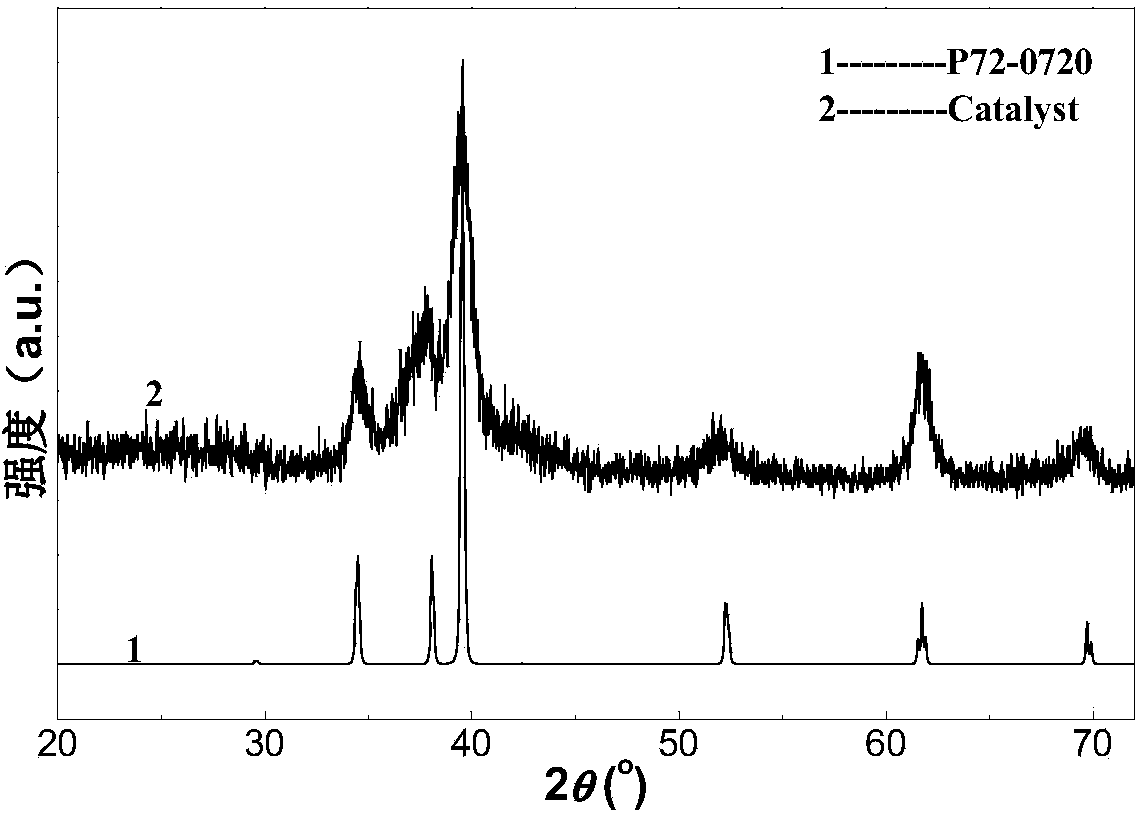

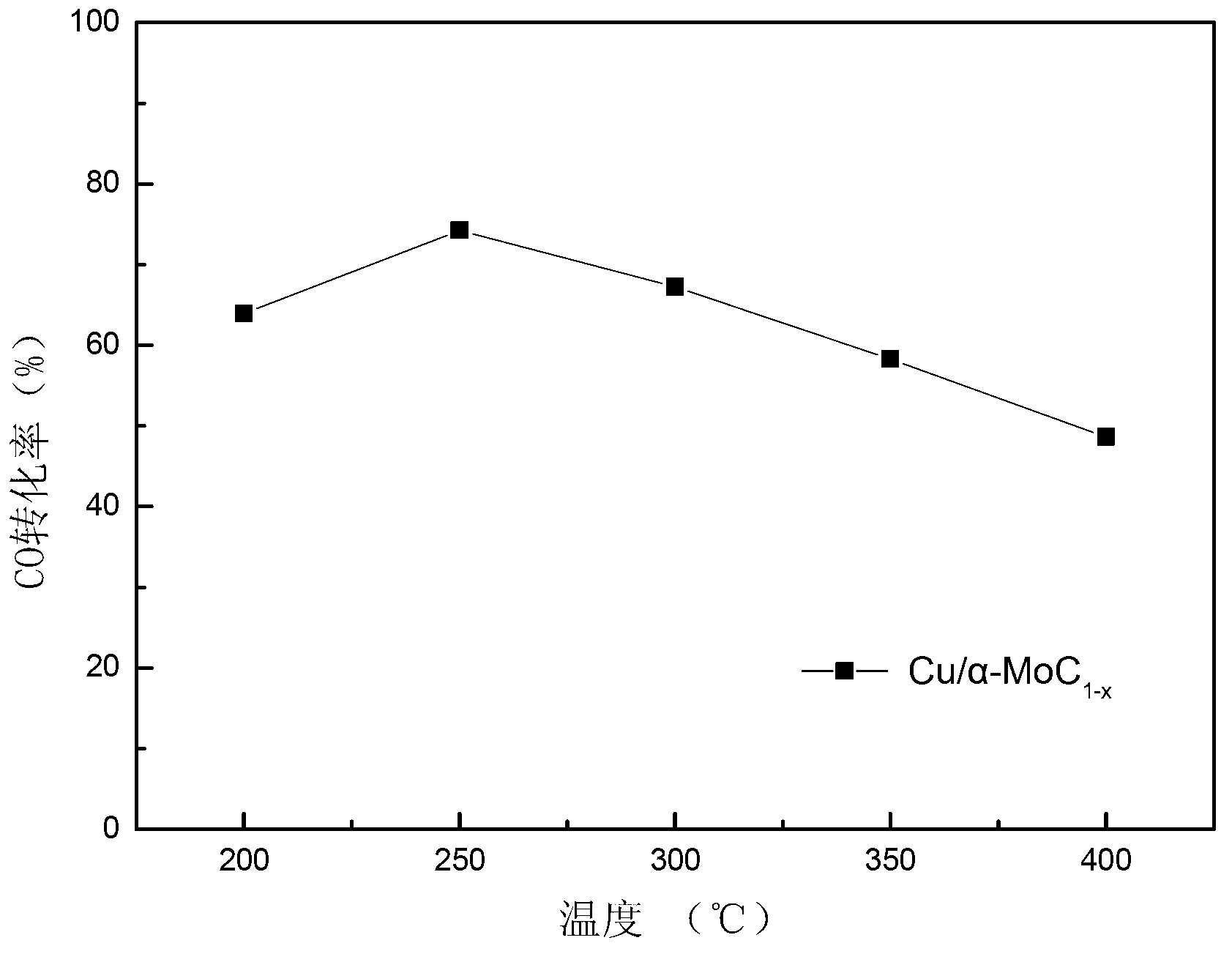

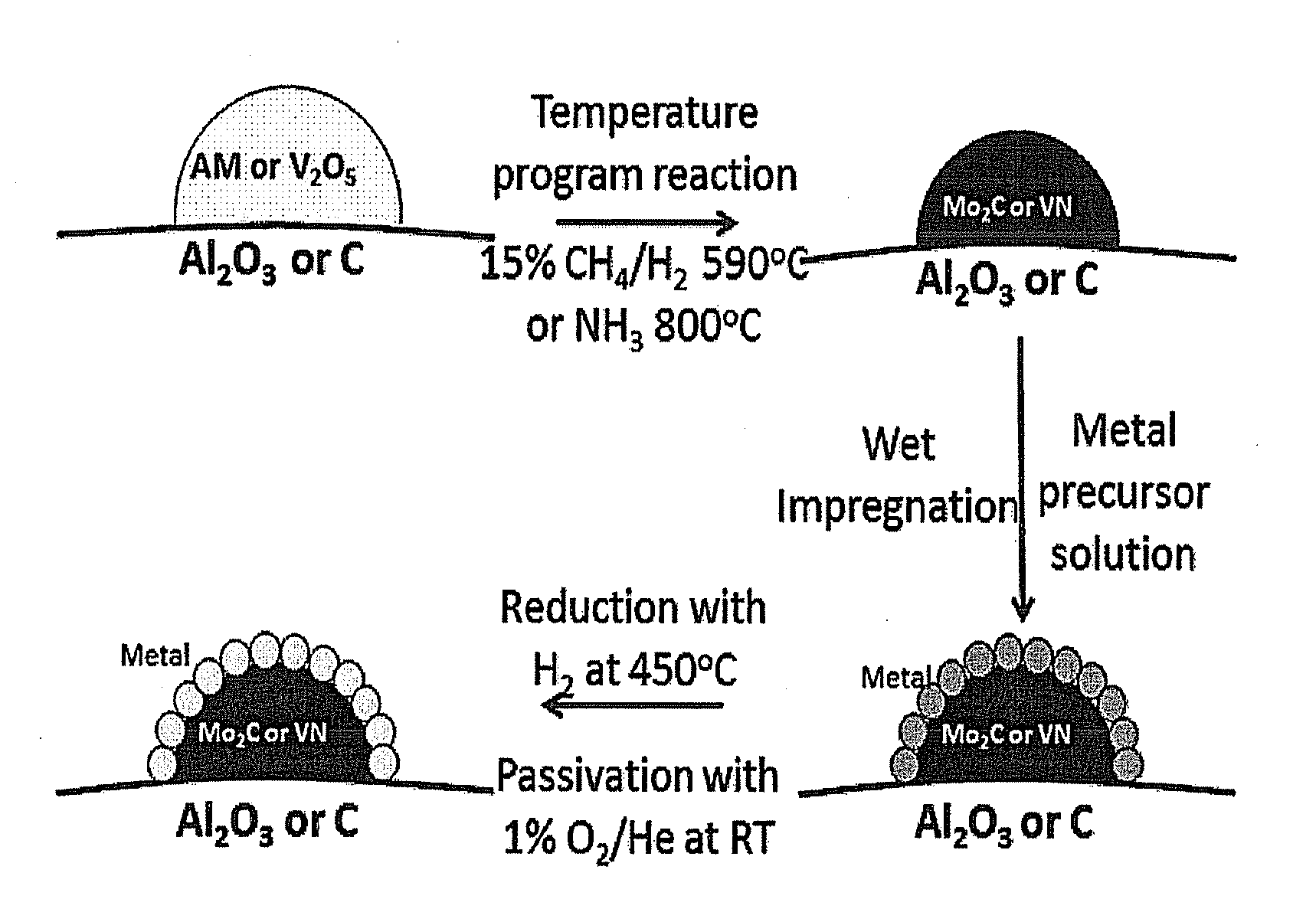

Method for preparing metal-modified alpha type molybdenum carbide catalyst and application of metal-modified alpha type molybdenum carbide catalyst in low-temperature water-gas shift reaction

InactiveCN102698783AImprove stabilityEliminate nitriding processHydrogenPhysical/chemical process catalystsWater-gas shift reactionMolybdenum carbide

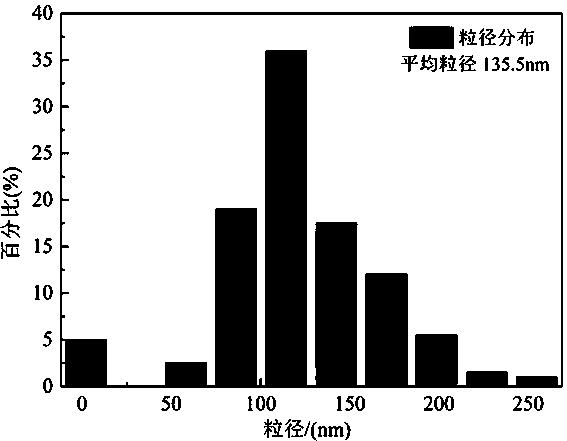

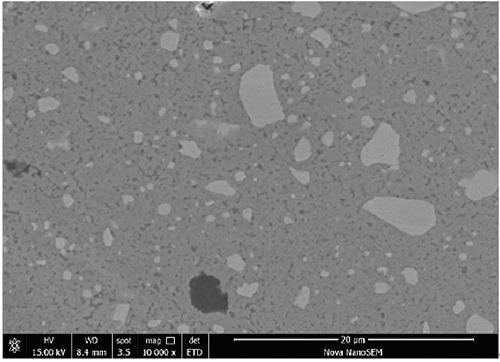

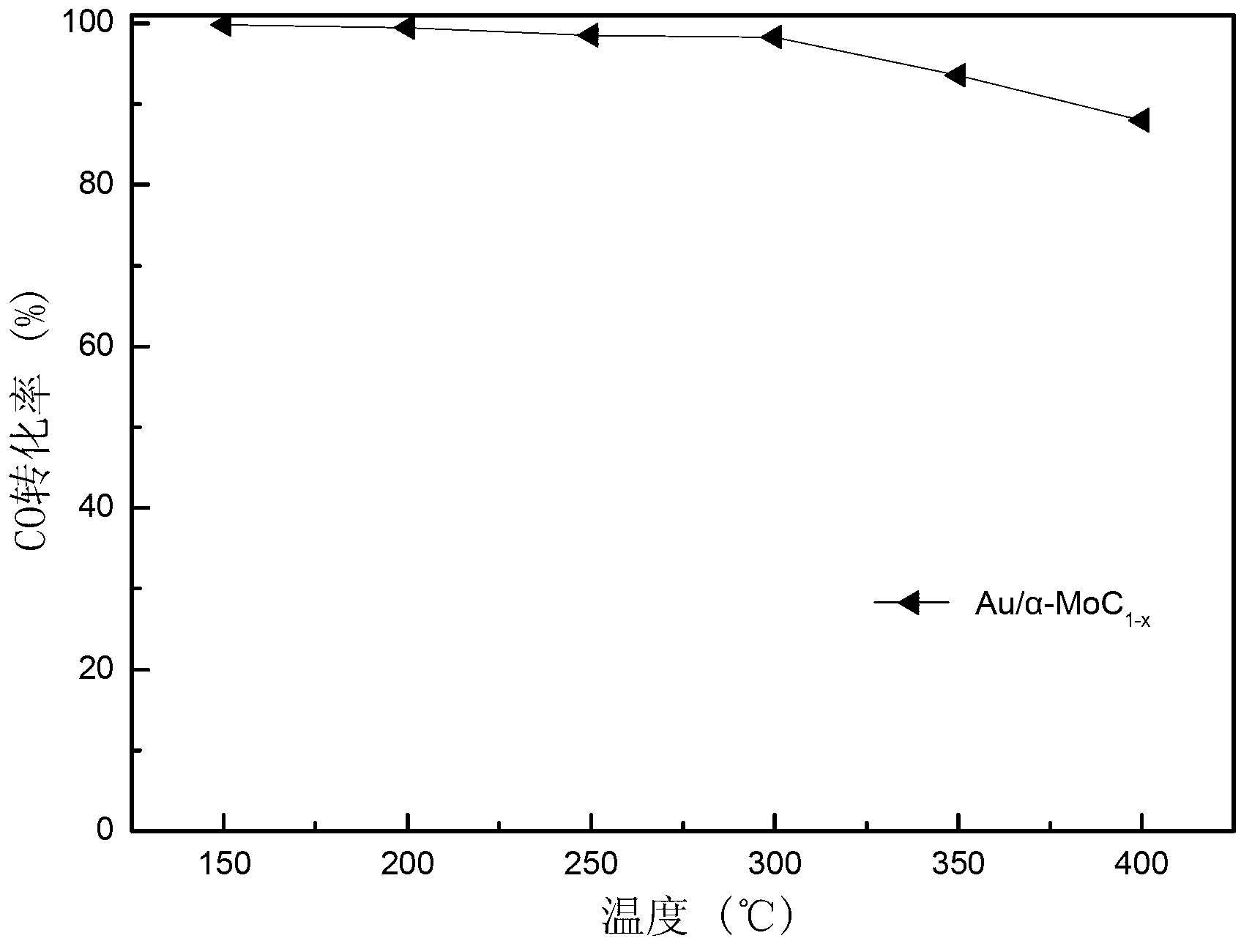

The invention discloses a method for preparing a metal-modified alpha type molybdenum carbide catalyst. The preparation method comprises the following steps of: continuously raising the temperature of a precursor in the presence of 20 percent of CH4 / H2, and carbonizing, wherein a composite oxide of molybdenum and another metal is used as the precursor; and performing an in-situ water-gas shift reaction on the prepared metal-modified alpha type molybdenum carbide catalyst under normal pressure at the operating temperature of 150 to 400 DEG C, wherein feed gas comprises 10.5 percent of CO, 21 percent of H2O and the balance of Ar (serving as balance gas), the total flow is 120ml / min, and the mass space velocity is 18,000ml g<-1> h<-1>. The preparation method has the advantages that the preparation method for the catalyst is simplified, and the production cost is reduced; and simultaneously, the catalyst has the advantages of high low-temperature activity, wide operation temperature range and high stability when used for the water-gas shift reaction.

Owner:DALIAN UNIV OF TECH

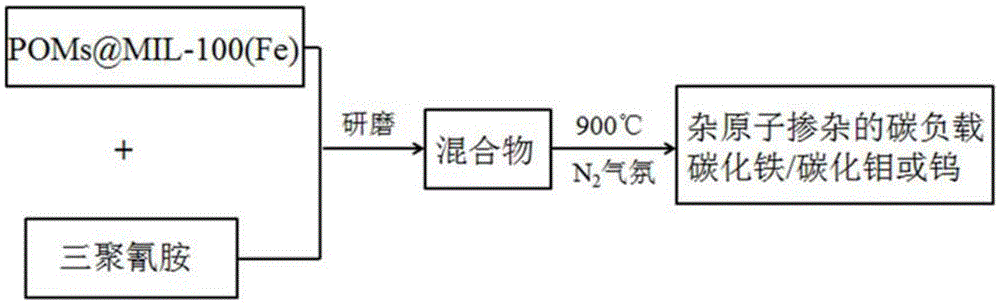

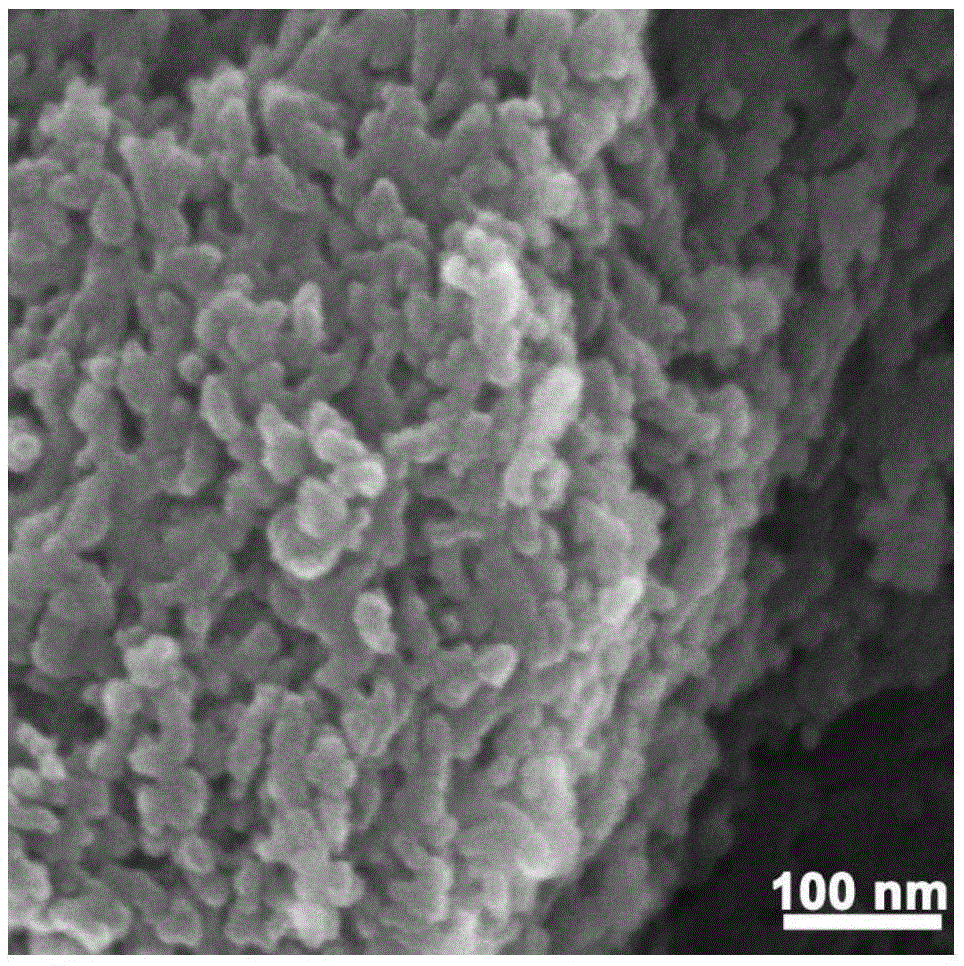

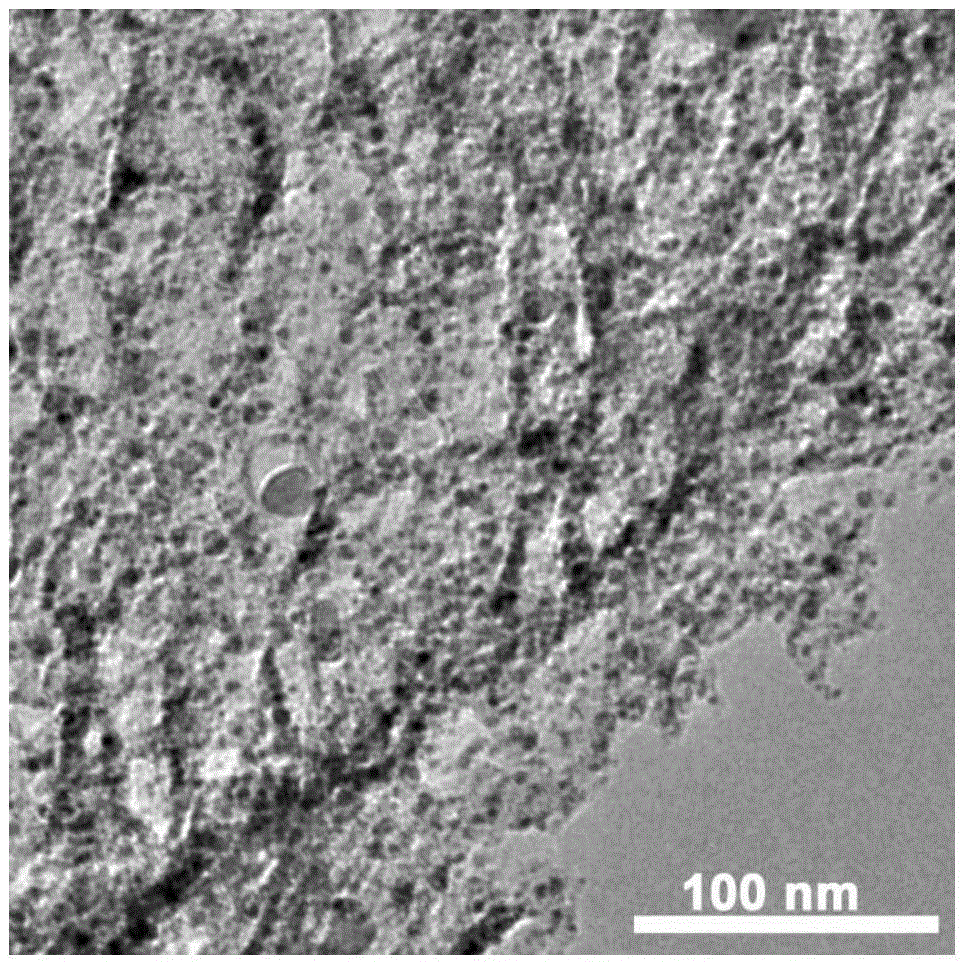

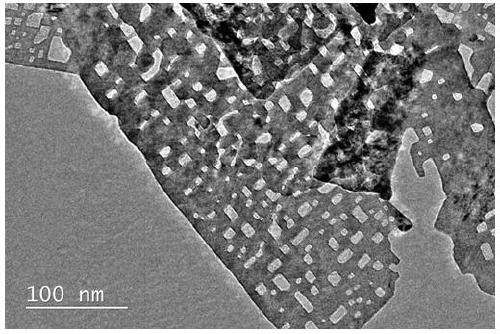

Heteroatom-doped carbon-load iron carbide/ molybdenum or tungsten carbide catalyst and preparation method and application thereof

InactiveCN105536835AGood technical effectSmall sizePhysical/chemical process catalystsElectrodesElectrolysisMetal-organic framework

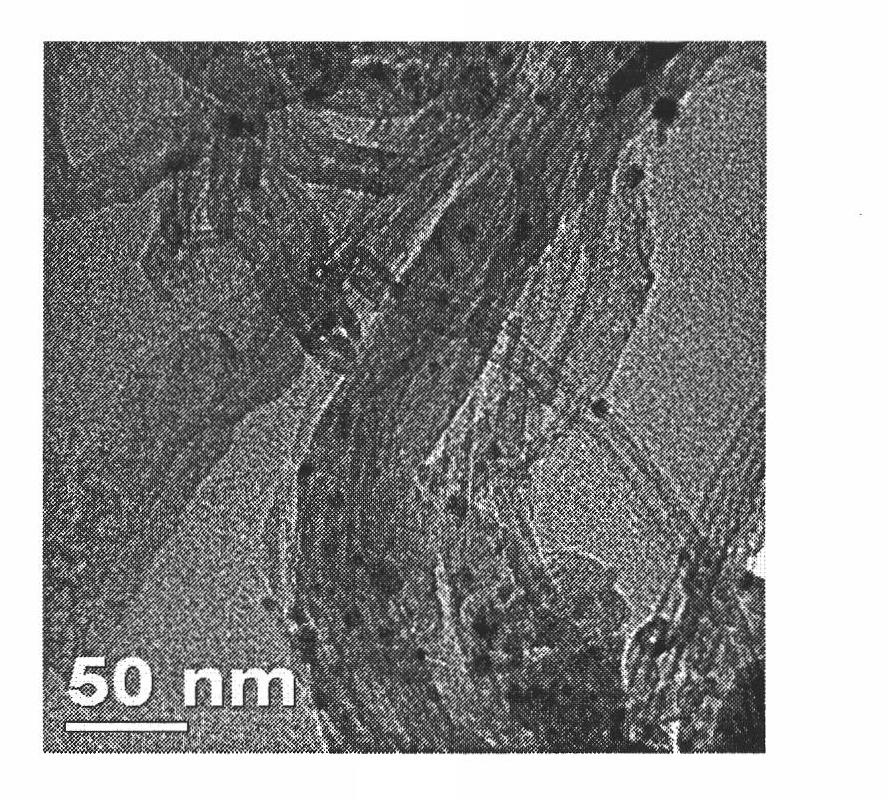

The present invention belongs to the technical field of catalyst preparation, and in particular relates to a heteroatom-doped carbon-load iron carbide / molybdenum or tungsten carbide catalyst and a preparation method and application thereof. The method comprises the following steps: (1) mixing molybdenum or tungsten heteropolyacid-containing @ metal-organic framework composite POMs @ MIL-100 (Fe) with melamine, and grinding; (2) under the protection of an inert gas, thermally treating at 800-1100 DEG C for 2-5h, cooling, and pickling with an acid to obtain heteroatom-doped carbon-load iron carbide / molybdenum or tungsten carbide. The preparation method of the catalyst is simple in process, agglomeration of molybdenum or tungsten carbide nanoparticles can be maximally restricted, by doping of hetero atoms, more active sites can be introduced, the hydrogen production property of the material by electrolysis is excellent, and the heteroatom-doped carbon-load iron carbide / molybdenum or tungsten carbide catalyst can be used in electro-catalytic oxygen reduction, lithium ion battery and other energy storage and conversion research fields.

Owner:JINING UNIV

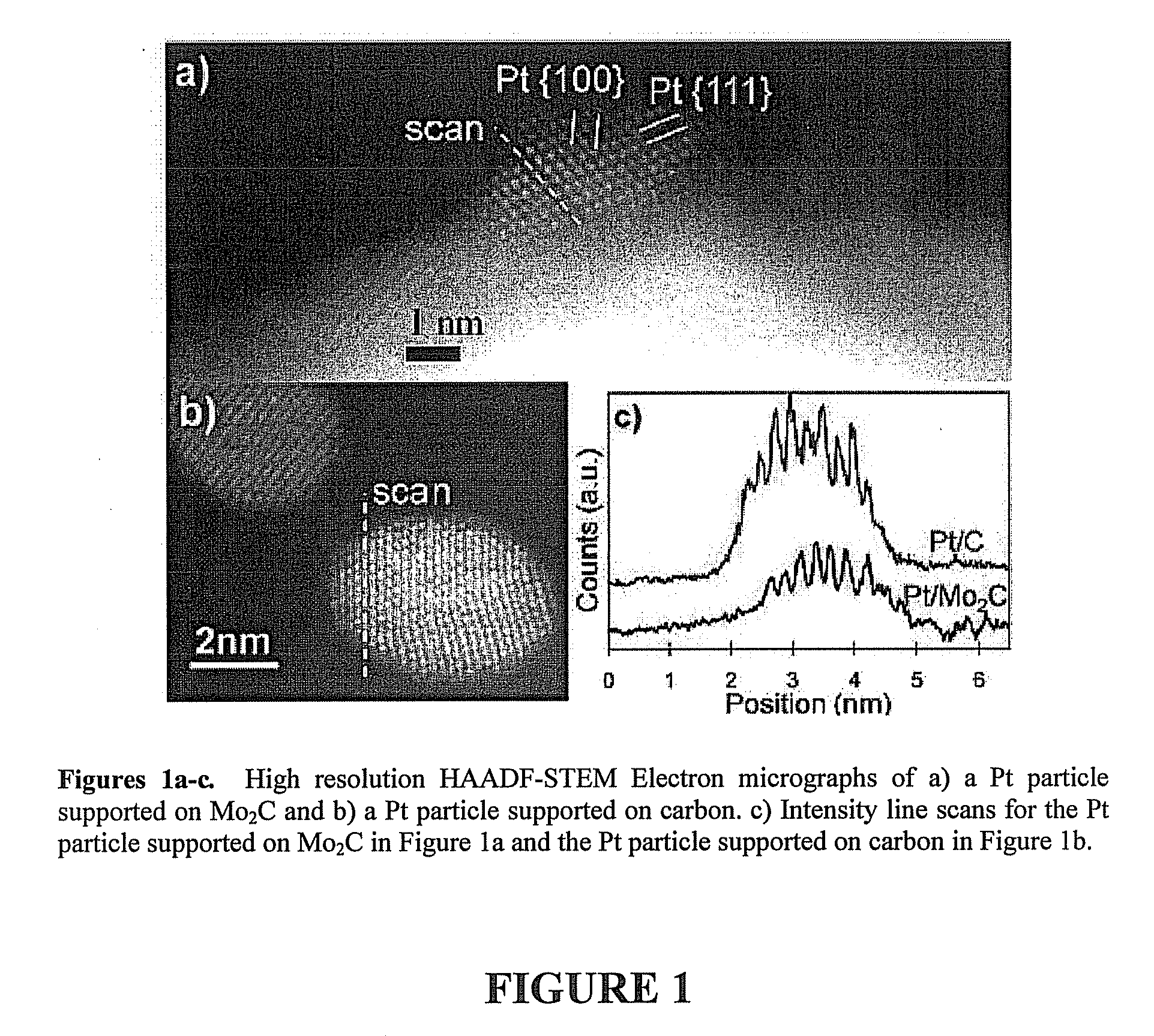

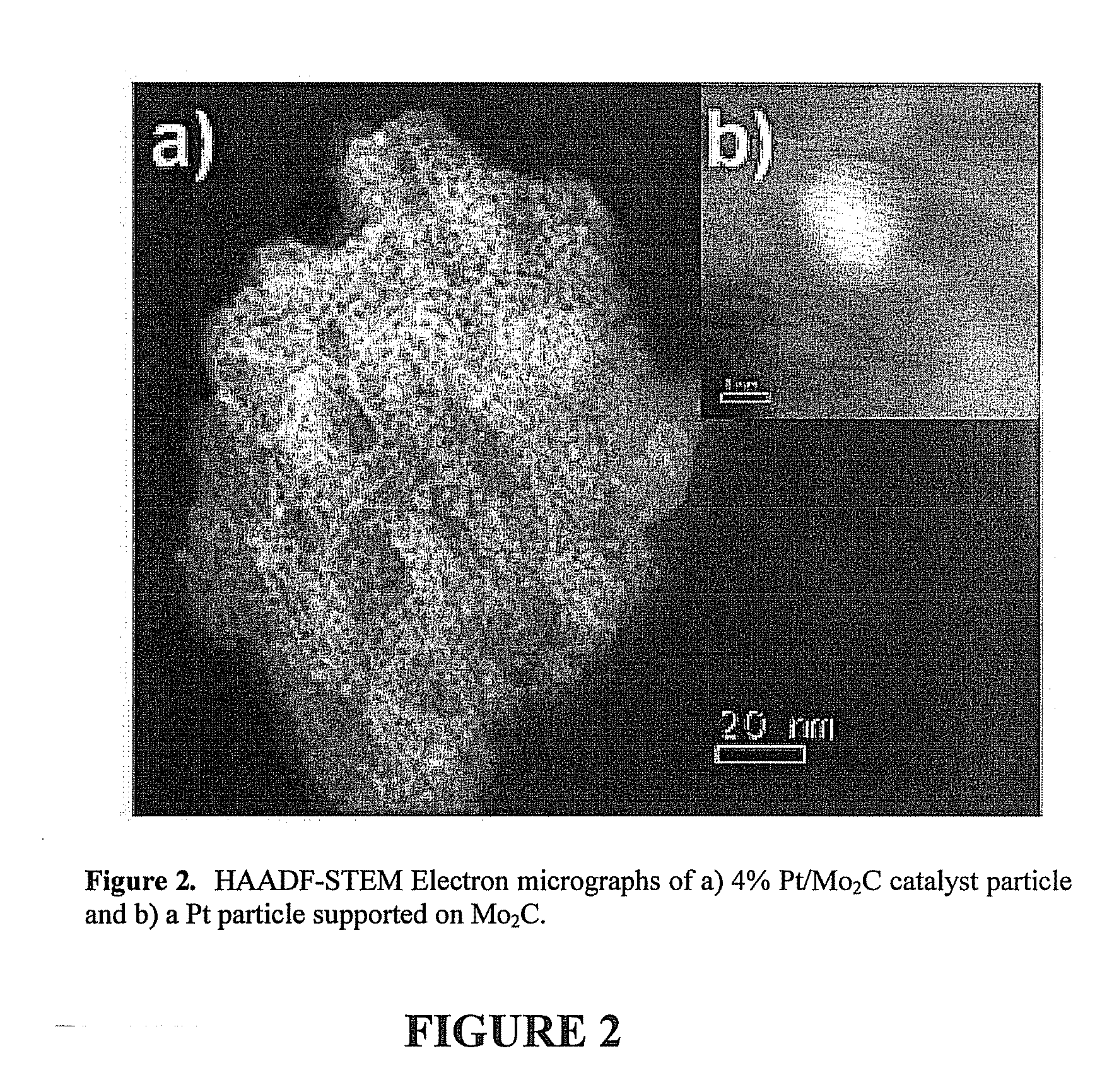

High activity early transition metal carbide and nitride based catalysts

InactiveUS20130045865A1Less-expensive materialReduce the amount requiredHydrocarbon from carbon oxidesOrganic compound preparationTransition metal carbidesWater-gas shift reaction

A catalyst composition contains an active metal on a support including a high surface area substrate and an interstitial compound, for example molybdenum carbide. Pt—Mo2C / Al2O3 catalysts are described. The catalyst systems and compositions are useful for carrying out reactions generally related to the water gas shift reaction (WGS) and to the Fischer-Tropsch Synthesis (FTS) process.

Owner:RGT UNIV OF MICHIGAN

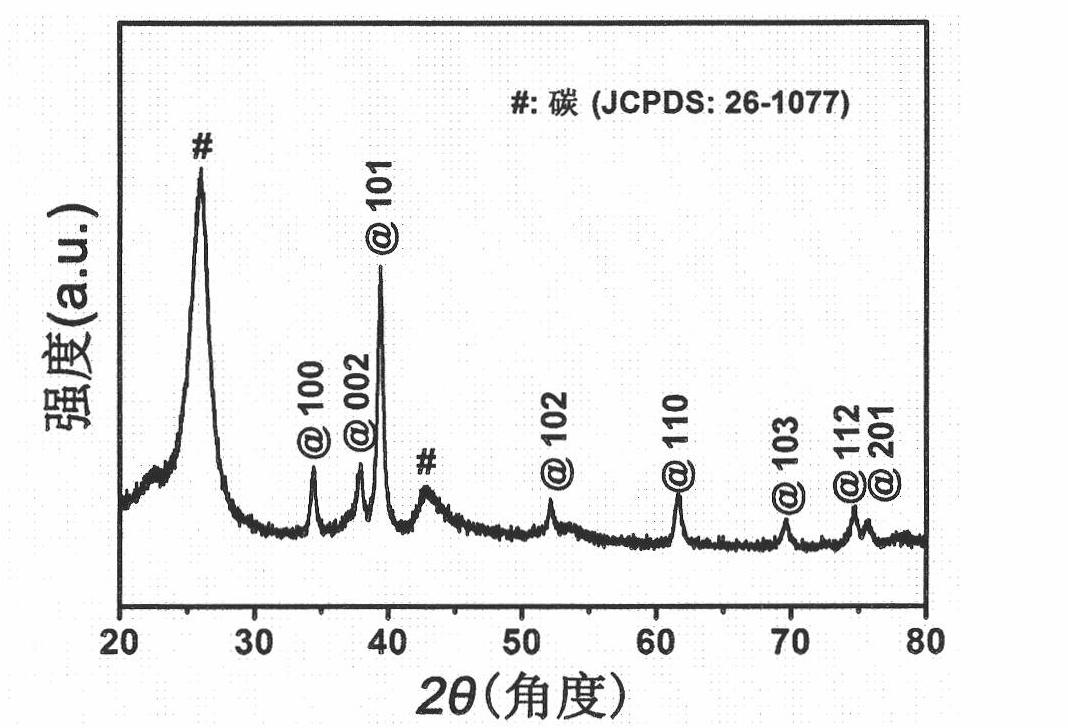

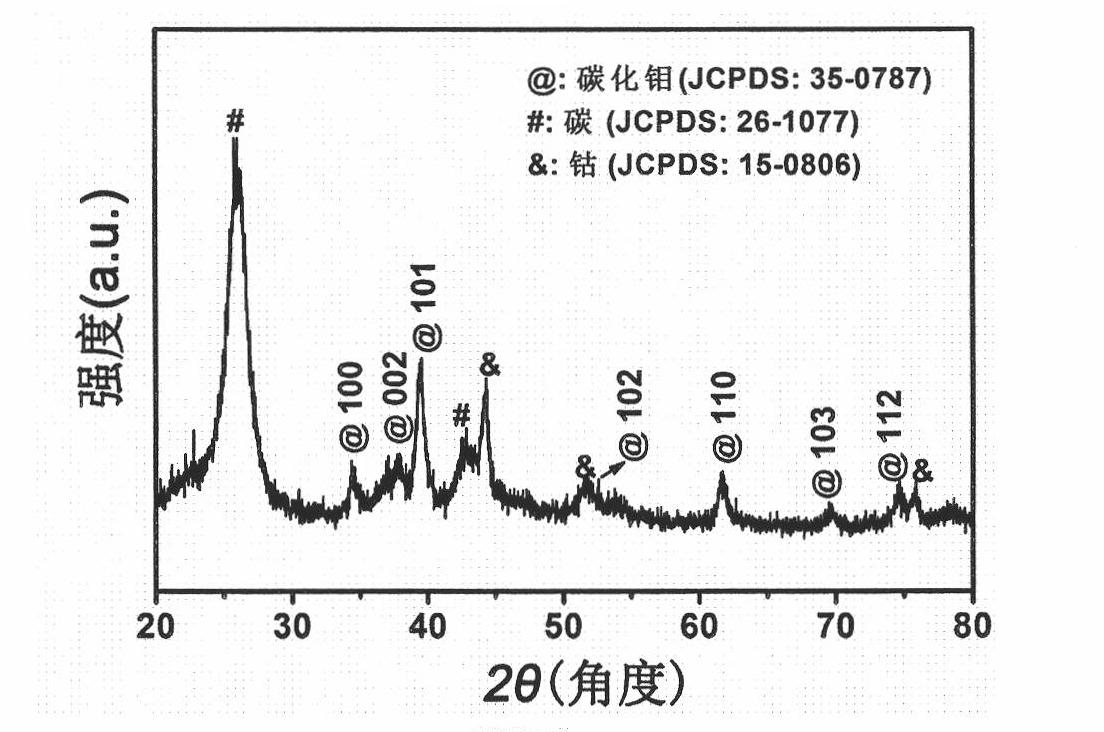

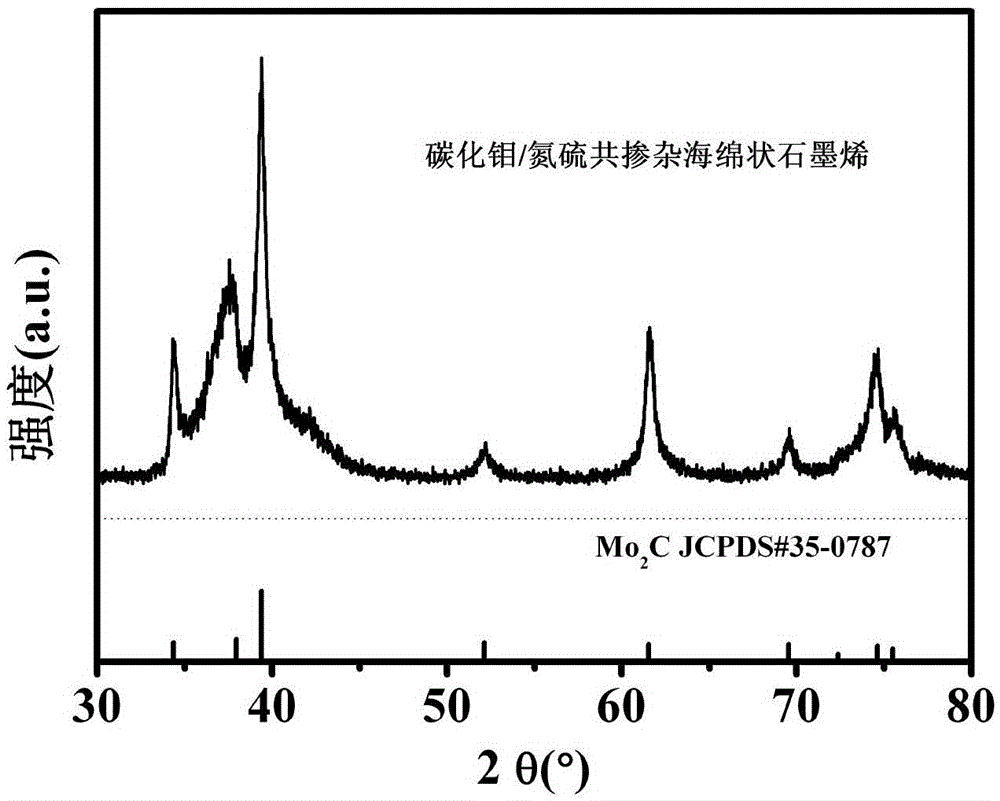

Preparation method of molybdenum carbide/nitrogen-sulfur codoped spongy graphene cathode composite for sodium-ion battery

ActiveCN105591077ASmall volume expansionImproved magnification performanceCell electrodesSecondary cellsDoped grapheneFreeze-drying

The invention discloses a preparation method of a molybdenum carbide / nitrogen-sulfur codoped spongy graphene cathode composite for a sodium-ion battery. According to the molybdenum carbide / nitrogen-sulfur codoped spongy graphene cathode composite prepared through the preparation method, molybdenum carbide particles are uniformly distributed in carbide / nitrogen-sulfur codoped spongy graphene which has a great number of surface folds, has a great number of active sites and is of a three-dimensional structure. The preparation method comprises the steps of dissolving a molybdenum source and a carbon source into a graphene oxide solution, adding a nitrogen source and a sulfur source, adjusting ph value, then conducting a hydrothermal reaction on an obtained mixed solution, conducting freeze-drying on a product, then putting the product in a quartz crucible for high temperature heat treatment, and conducting natural cooling after a reaction is ended, so that the composite is obtained. In the hydrothermal reaction process, graphene doping and reduction, formation of a precursor and composition of the precursor and doped graphene are conducted synchronously. The composite can be obtained by combining the hydrothermal method with the subsequent heat treatment process, and the preparation method is simple in process and low in cost and has good research prospect.

Owner:CENT SOUTH UNIV

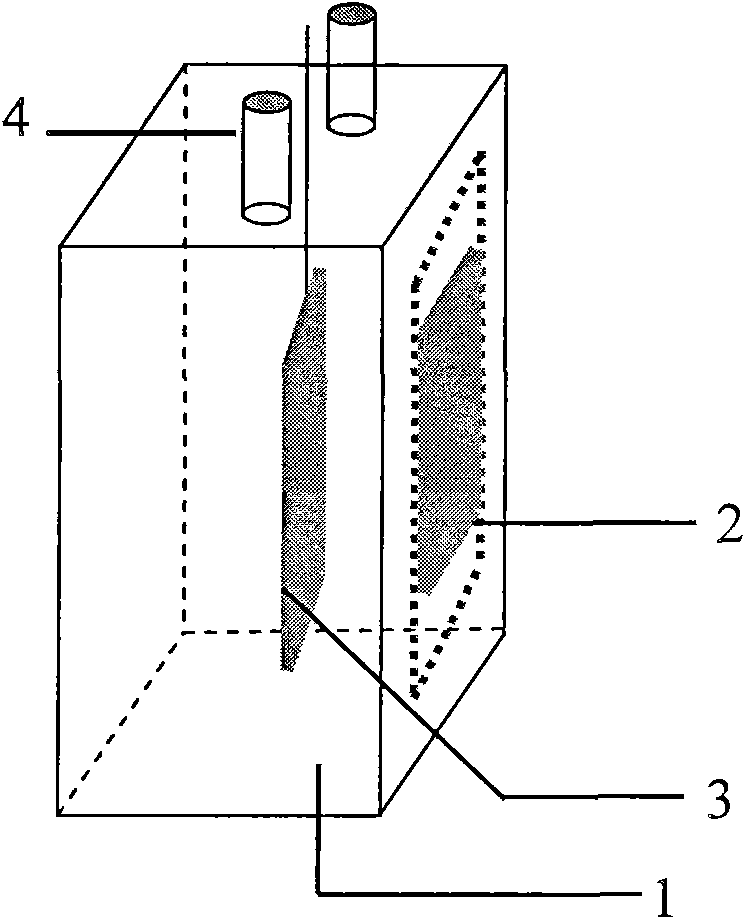

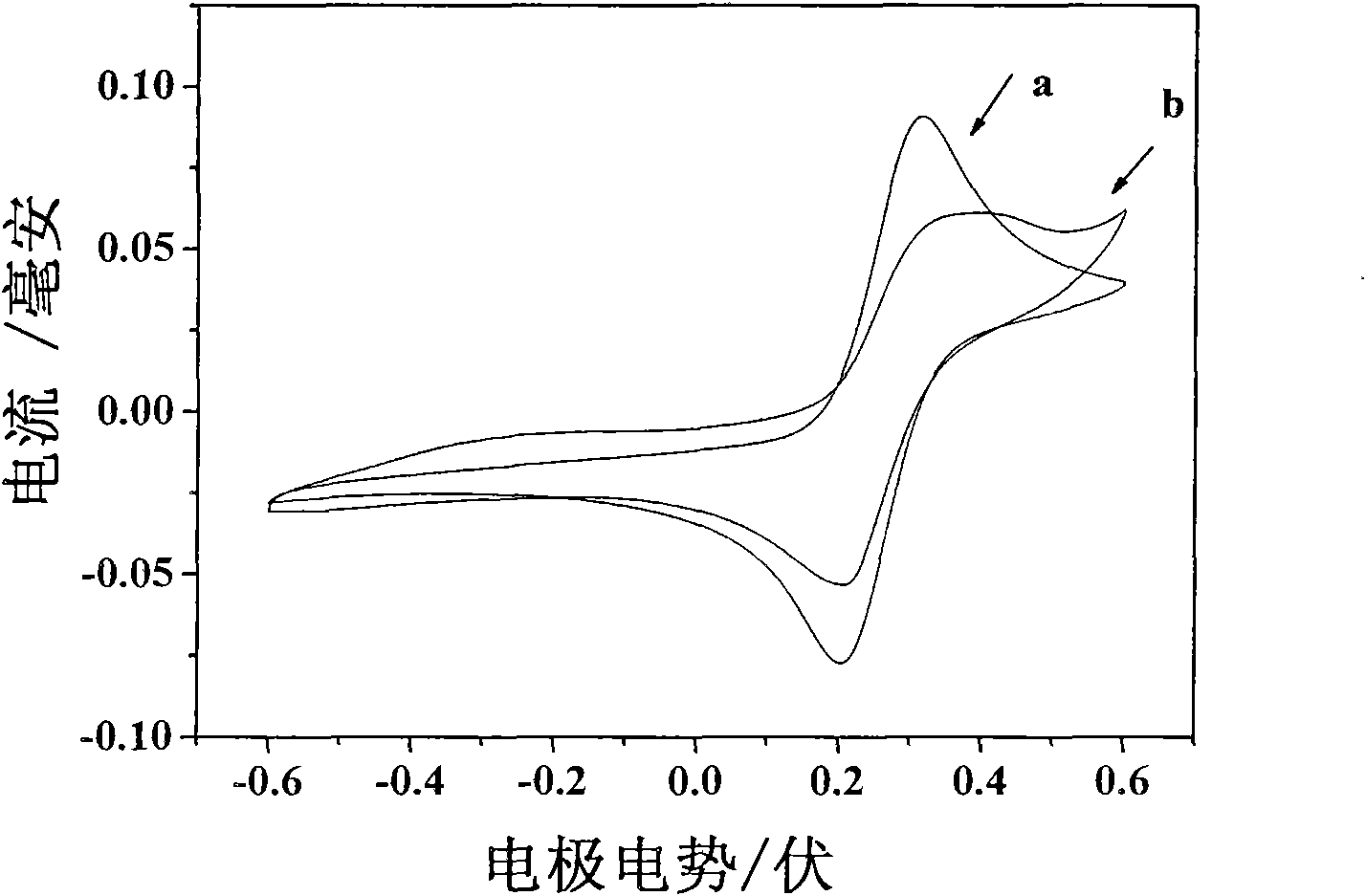

Application of molybdenum carbide in preparing anode of microbial fuel cell

InactiveCN101656314AIncrease power outputWide variety of sourcesCell electrodesBiochemical fuel cellsMicrobial fuel cellPtru catalyst

The invention discloses the application of molybdenum carbide in preparing the anode of a microbial fuel cell, in particular to a method for preparing the anode of the microbial fuel cell, in which the molybdenum carbide is used as a catalyst and the mixture of the molybdenum carbide and a binder are coated on a conductive base. Compared with a non-catalytic electrode, the molybdenum carbide is used as an anode catalyst to catalyze hydrogen to be oxidized, thereby greatly enhancing the electric energy output of microbial fuel cell; compared with a conventional Pt catalyst, the molybdenum carbide has low price and extensive source, and the microbial fuel cell assembled by taking the molybdenum carbide as the anode catalyst can stably work for a long time and has high power output. The application of the molybdenum carbide in preparing the anode of the microbial fuel cell provides the good foundation for the commercialization application of the microbial fuel cell.

Owner:SOUTH CHINA NORMAL UNIVERSITY

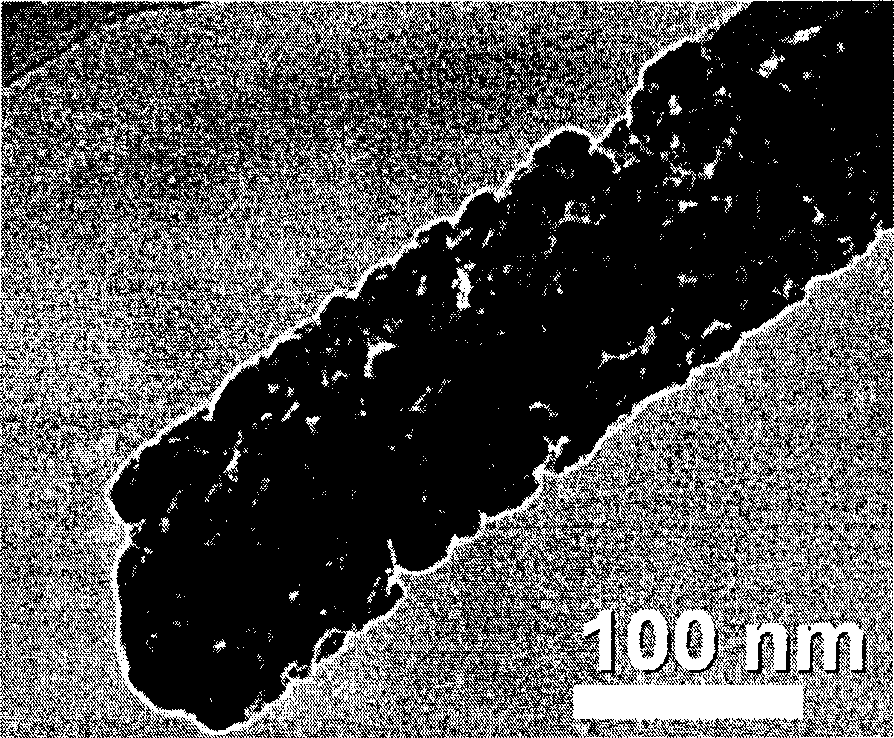

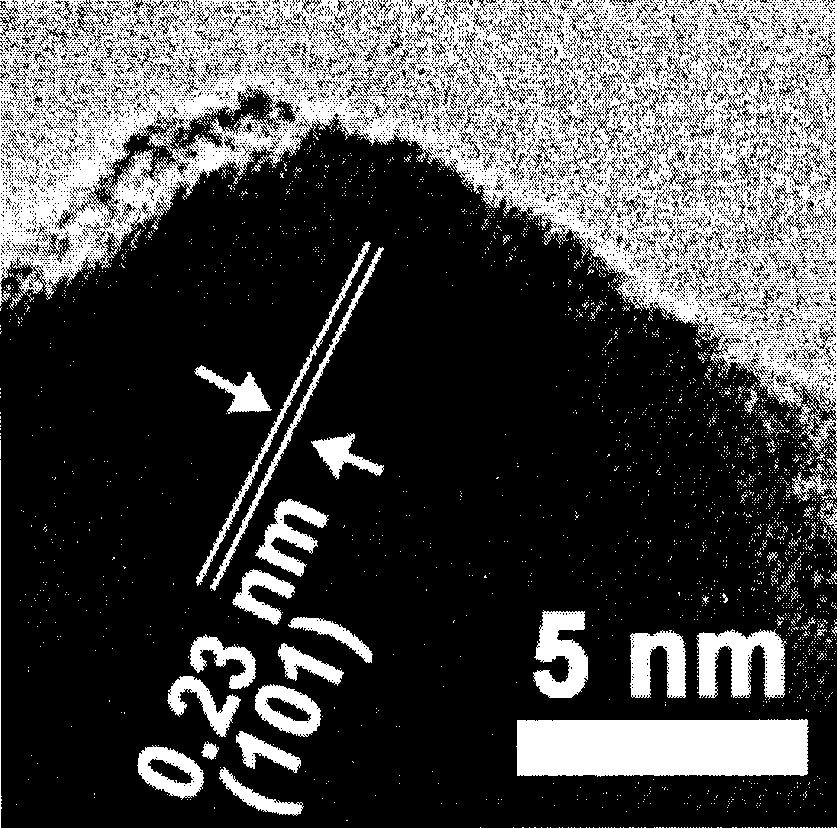

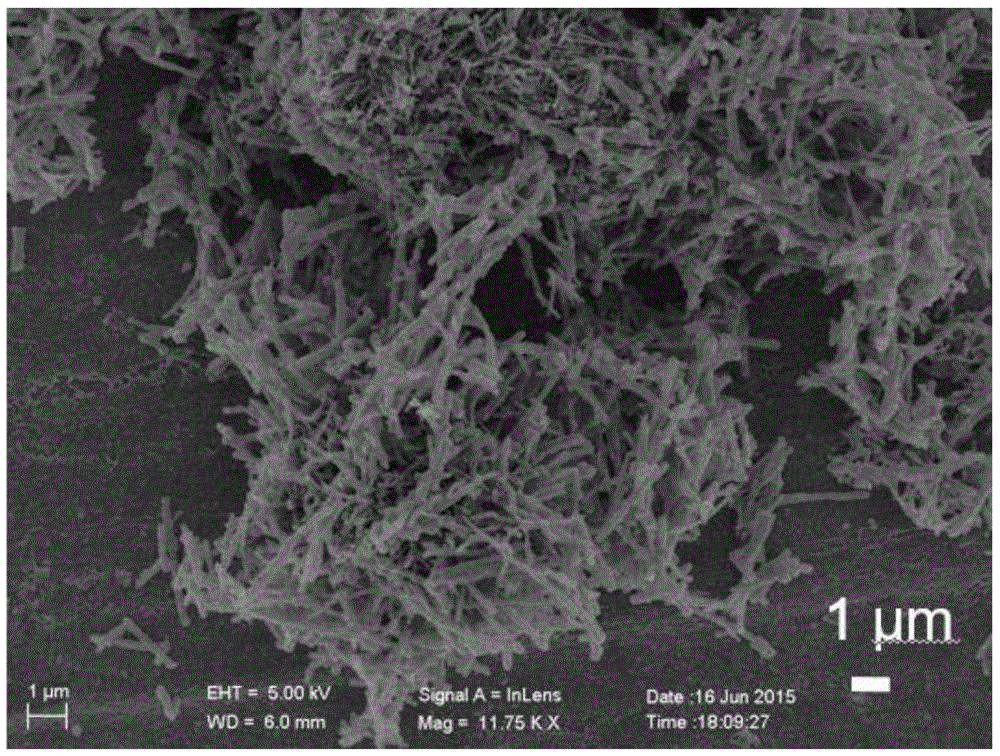

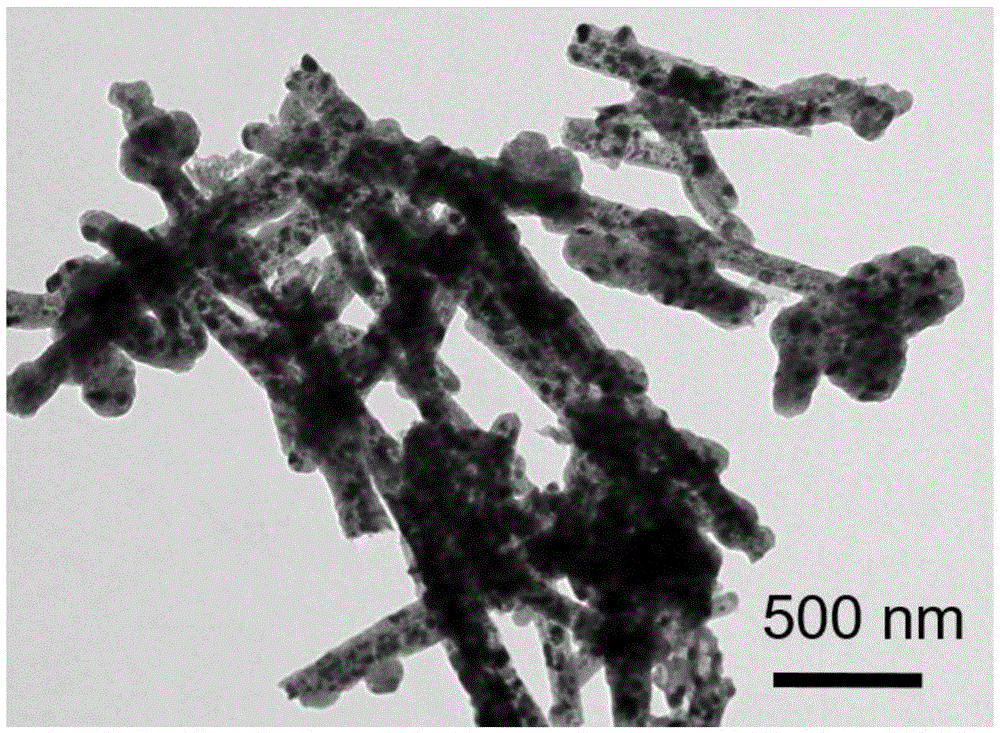

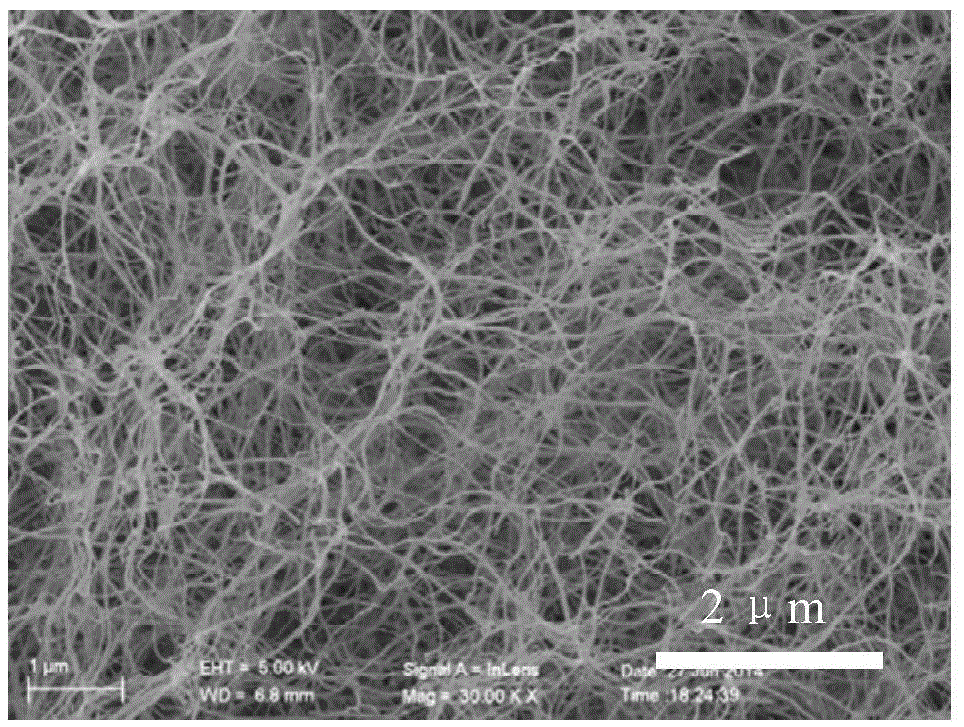

Synthesis of stephanoporate molybdenum carbide nano-wire

InactiveCN101367521AHigh surface areaSmall surface areaTungsten/molybdenum carbideMolybdateGranularity

The invention relates to the technical field of the nanometer material, and relates to a method for synthesizing the porous molybdenum carbide nanometer wire, and adopts the following steps: molybdate is dissolved in the water, and the mol concentration of the molybdenum atom is 0.02 to 1.5 mol / L; organic amine is filled in, and the mol ratio between the organic amine and the molybdenum atom is 20.0 to 1.0: 1; inorganic acid is dropped into the solution, and the pH value is adjusted to be 3 to 6 until the white precipitate appears; the reaction solution is moved into an oil bath with the temperature of 30 to 60 DEG C to be reacted for 6 to 24 hours; (5) the product is washed, pumped, filtered and dried; the product is baked in the inert gases atmosphere at the temperature of 675 to 750 DEG C for 4 to 10 hours. The invention has the advantages that abundant nanometer hole structure is arranged between the nanometer particles, the granularity of the molybdenum carbide is small, the molybdenum carbide has rich porous structure and large specific surface area, the carbon on the surface is small, thereby favoring the secondary assembling of the catalyst and having wide application fields; the productivity can reach 95 percent or more; the conditions are simple and easy to be controlled; the preparation efficiency is high; the invention has favorable application and industrialization prospect.

Owner:FUDAN UNIV

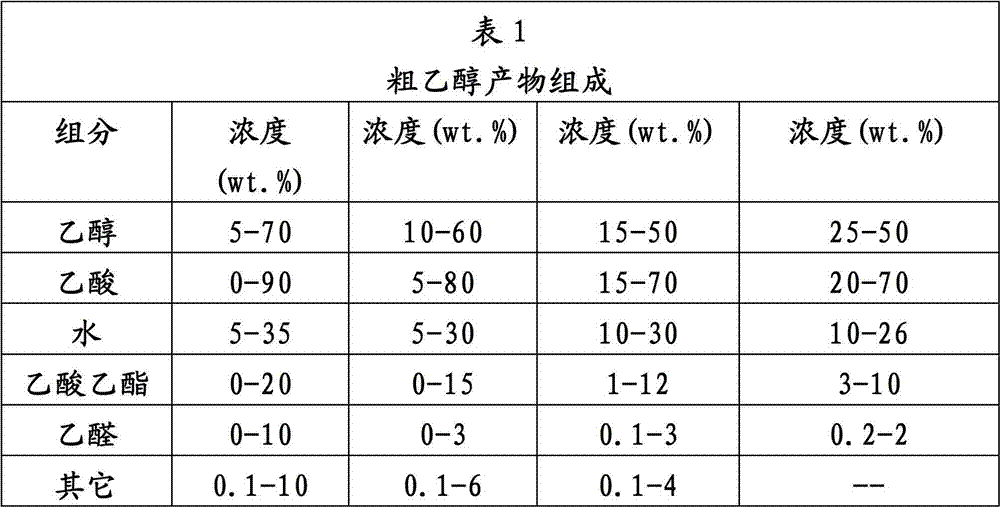

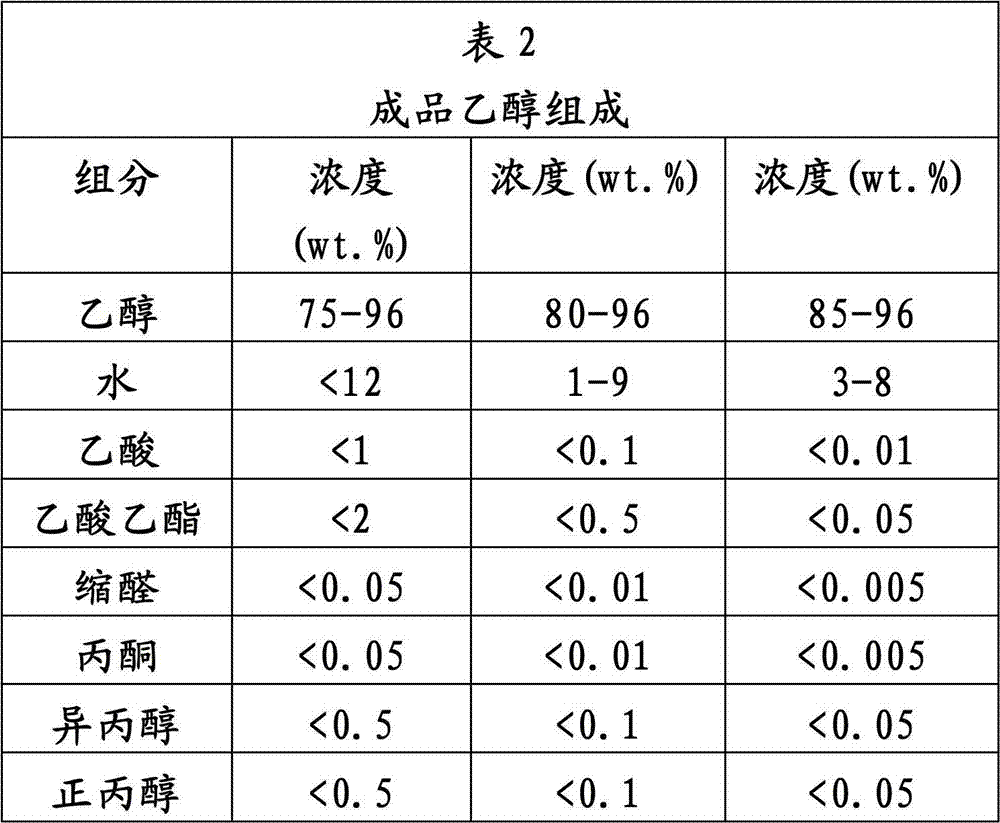

Ethanol Production from Acetic Acid Utilizing a Molybdenum Carbide Catalyst

InactiveUS20120253085A1Organic compound preparationOxygen compounds preparation by reductionRheniumIridium

A process for the selective and direct formation of ethanol from acetic acid comprising contacting a feed stream containing acetic acid and hydrogen in vapor form at an elevated temperature with a hydrogenation catalyst comprising molybdenum carbide and one or more promoter metals selected from the group consisting of copper, iron, cobalt, nickel, ruthenium, rhodium, palladium, osmium, iridium, platinum, titanium, zinc, chromium, rhenium, potassium, tin and tungsten on a catalyst support

Owner:CELANESE INT CORP

Ethanol production from acetic acid utilizing a molybdenum carbide catalyst

A process for the selective and direct formation of ethanol from acetic acid comprising contacting a feed stream containing acetic acid and hydrogen in vapor form at an elevated temperature with a hydrogenation catalyst comprising molybdenum carbide and one or more promoter metals selected from the group consisting of copper, iron, cobalt, nickel, ruthenium, rhodium, palladium, osmium, iridium, platinum, titanium, zinc, chromium, rhenium, potassium, tin and tungsten on a catalyst support.

Owner:CELANESE INT CORP

Porous-carbon loaded metal composite material and preparing method and application thereof

ActiveCN105642326AExcellent Catalytic Electrochemical Hydrogen and Oxygen ProductionExcellent total water splitting performancePhysical/chemical process catalystsElectrodesPorous carbonDecomposition

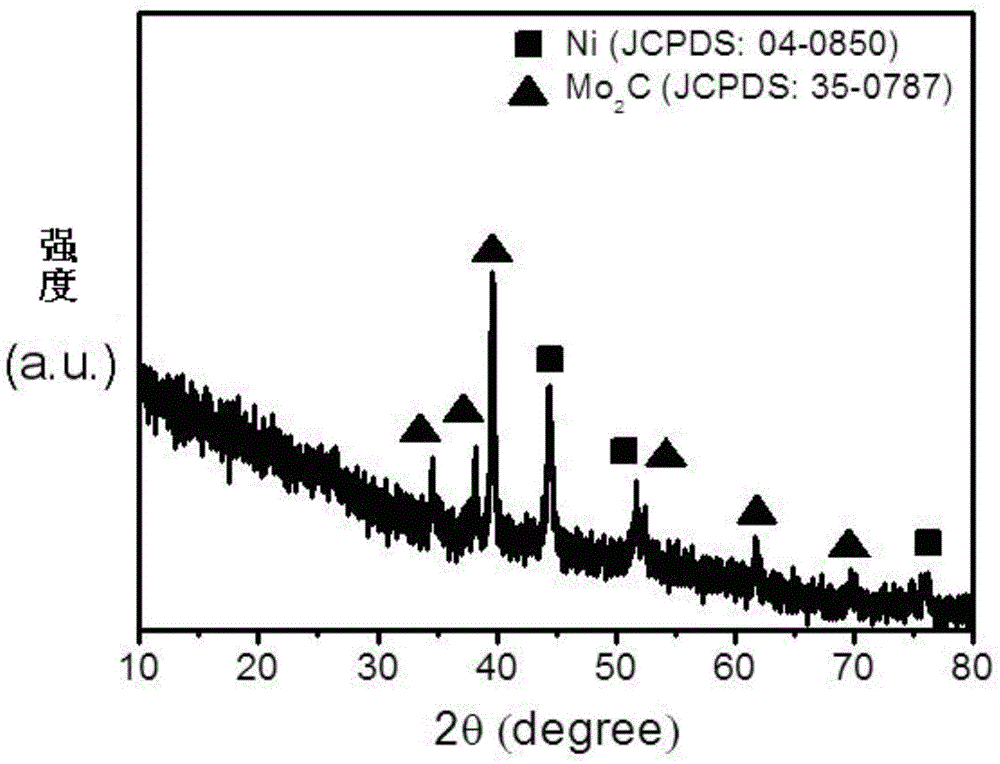

The invention provides a porous-carbon loaded metal composite material and a preparing method and application thereof. The method includes the steps that NiMoO4 nanometer rods and carbon-source monomers are reacted in Tris reagent solutions to obtain NiMoO4 / carbon source precursors; the NioMO4 / carbon source precursors are calcined to obtain the porous-carbon loaded metal composite material. The porous-carbon loaded metal composite material comprises porous-carbon carriers, nickel and molybdenum carbide, wherein the nickel and the molybdenum carbide are loaded to the porous-carbon carriers. The method is simple in step and easy to operate, and has the advantages of being convenient, rapid and the like. The porous-carbon loaded nickel and molybdenum carbide composite material has the excellent catalyzing electrochemistry hydrogen-producing and oxygen-producing performance and the excellent full water decomposition performance. An experiment shows that when the composite material serves as a catalyst in a hydrogen producing reaction, and when the overpotential is 0.25 V, the electric current density can be 52 mA / cm<2>; in a full hydrolysis reaction, when the electric potential is 1.68 V, the electric current density can be 10 mA / cm<2>, the performance is excellent, and the porous-carbon loaded metal composite material has the good application prospect in the field of electro-catalysis hydrogen producing and oxygen producing and the field of full water decomposition.

Owner:UNIV OF SCI & TECH OF CHINA

Application of alpha-molybdenum carbide and metal-modified alpha-molybdenum carbide catalyst to reaction for preparing carbon monoxide through hydrogenation of carbon dioxide

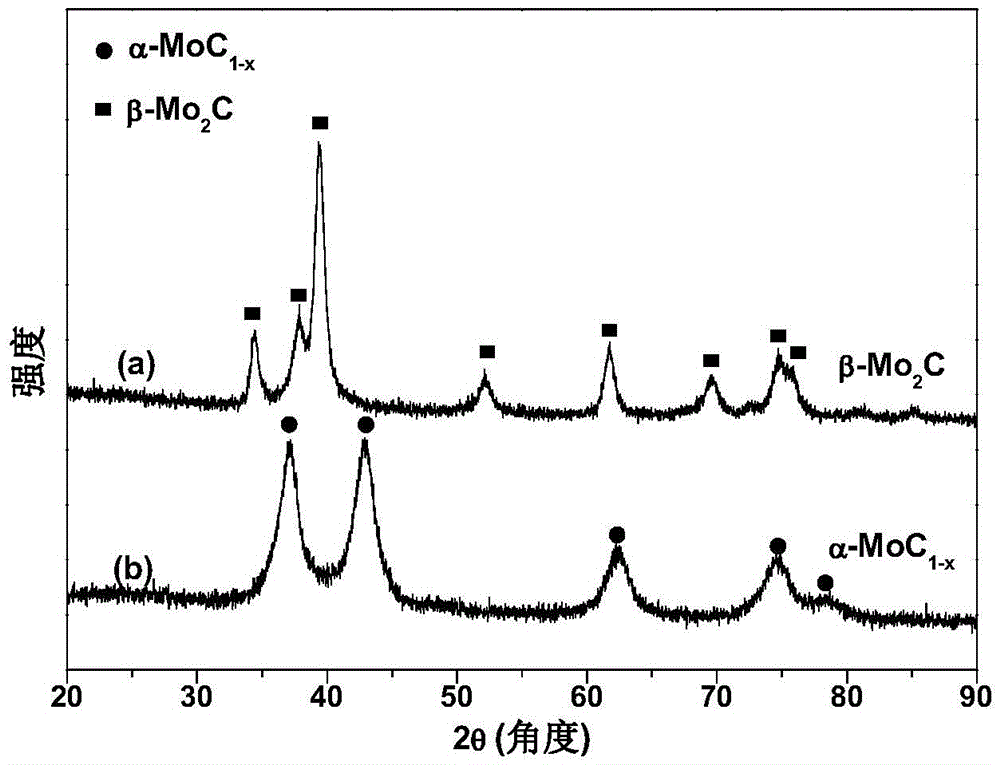

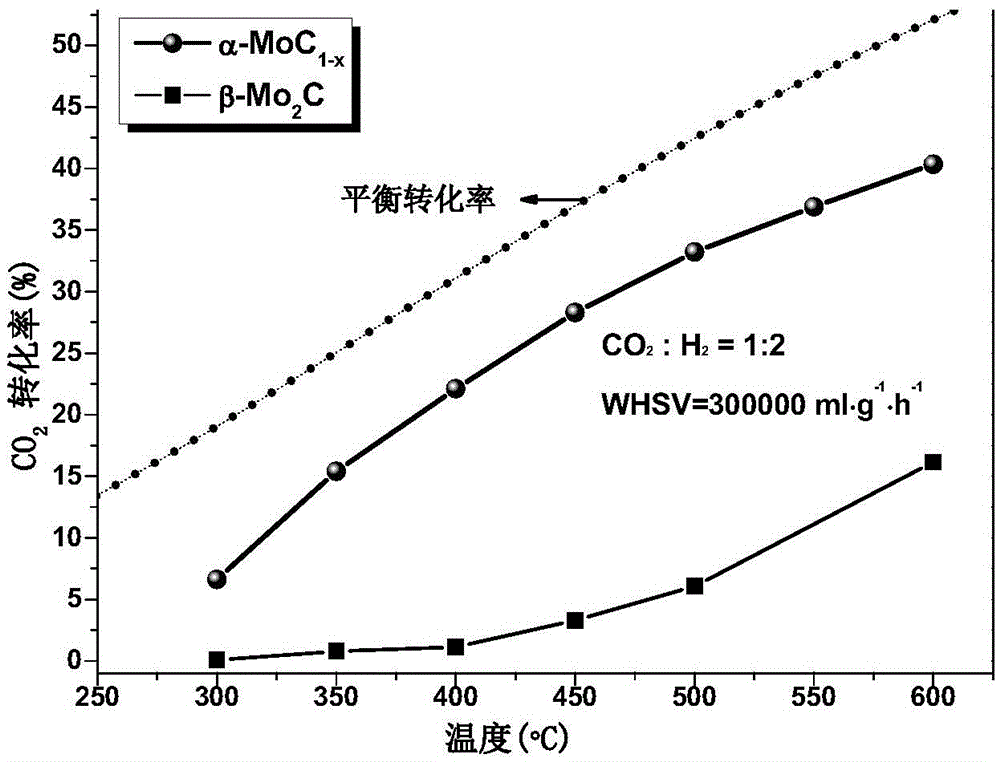

ActiveCN105540588AHigh low temperature activityEasy to makePhysical/chemical process catalystsCarbon monoxideReaction temperatureThermal stability

The invention discloses an application of alpha-molybdenum carbide or metal-modified alpha-molybdenum carbide as a catalyst to a reaction for preparing carbon monoxide through hydrogenation of carbon dioxide. In the reaction for preparing carbon monoxide through hydrogenation of carbon dioxide, the reaction atmosphere is a mixed gas of CO2 and H2, the reaction pressure is normal pressure, and the reaction temperature is 300-600 DEG C. The alpha-molybdenum carbide and metal-modified alpha-molybdenum carbide catalysts are low in cost and easy to prepare, and have relatively high low-temperature activity and CO selectivity and excellent thermal stability when applied to the reaction for preparing carbon monoxide through hydrogenation of carbon dioxide. The catalyst can meet the operating requirements of reaction situations of high temperature and strong reduction in the reaction for preparing carbon monoxide through hydrogenation of carbon dioxide, and therefore, has bright application prospects in the field of CO2 catalytic conversion and utilization.

Owner:DALIAN UNIV OF TECH

Molybdenum carbide material and molybdenum carbide@molybdenum sulfide composite material, and preparation methods and applications thereof

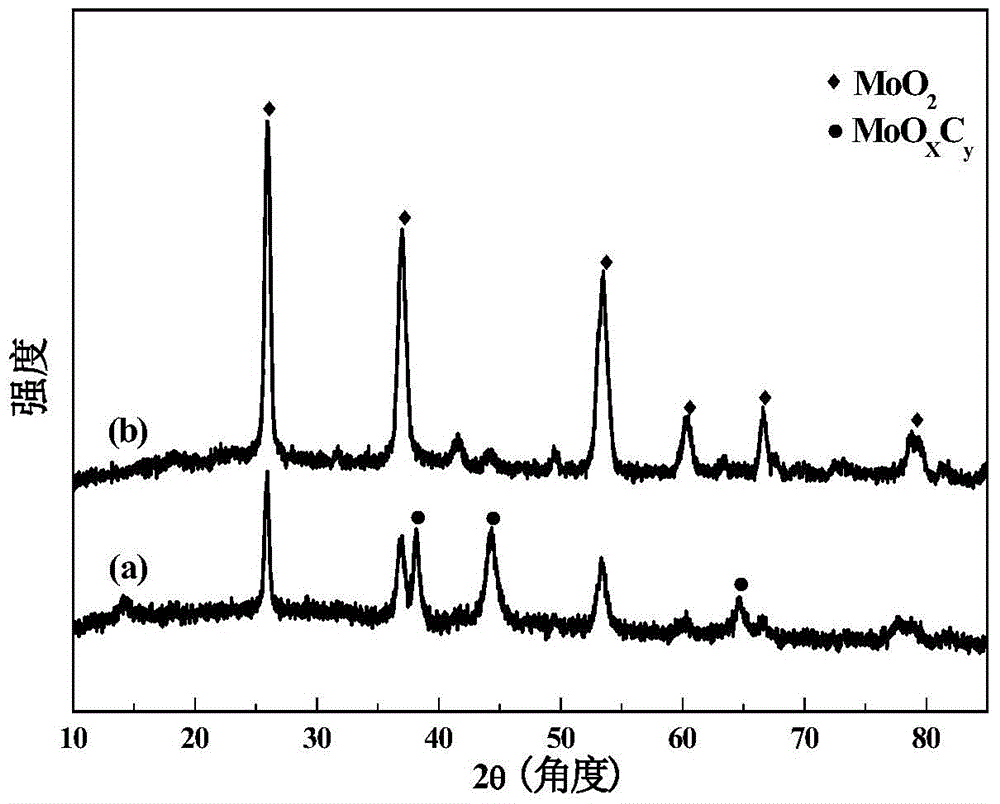

ActiveCN109019602AIncrease the active siteImprove conductivityMaterial nanotechnologyTungsten/molybdenum carbideMolybdenum carbideElectrolysis of water

The invention discloses a molybdenum carbide material and a molybdenum carbide@molybdenum sulfide composite material, and preparation methods and applications thereof. The preparation method of the molybdenum carbide material comprises the following steps: adding a carbon source and a molybdenum source to a dispersion liquid, performing stirring for 6-12 h, drying the obtained mixture at 80-120 DEG C, grinding the dried mixture, and collecting the ground mixture to form a molybdenum carbide precursor; and performing temperature programming on the molybdenum carbide precursor to 400-900 DEG C from room temperature in an inert atmosphere, calcining the precursor at 400-900 DEG C for 1-3 h, grinding the calcined precursor, and collecting the ground calcined precursor to obtain molybdenum carbide. The molybdenum carbide is vulcanized at 160-400 DEG C by using a vulcanizing agent to obtain molybdenum carbide@molybdenum sulfide. The molybdenum carbide and the molybdenum carbide@molybdenum sulfide respectively have the morphology of a porous nanosheet structure, and the microstructure facilitates storage of an electrolyte and reduction of the charge transfer impedance and provides a lot of electrocatalytic activity sites; and the material and the composite material can be used as an HER electrocatalyst, have a high catalytic activity and a good stability, and are expected to replace aPt-based catalyst for electrolysis of water to produce hydrogen.

Owner:SHENZHEN UNIV

Method for preparing nano molybdenum carbide (Mo2C) flake powder with regular-hexagon structure

ActiveCN105217633AAchieve synthesisWell mixedMaterial nanotechnologyTungsten/molybdenum carbideSucroseMetallurgy

The invention relates to a method for preparing nano molybdenum carbide (Mo2C) flake powder with a regular-hexagon structure. According to the method, water-soluble ammonium dimolybdate (or ammonium heptamolybdate) and glucose (or saccharose) are respectively adopted as a molybdenum source raw material and a carbon source raw material; and through precursor solution drying, molecular-level uniform mixing of all elements in a reactant system is realized, the temperature for carbothermal reduction reaction is lowered, the reaction time for the carbothermal reduction reaction is shortened, and the synthesis of nano Mo2C is realized. In addition, during the reaction, a molten halogenating agent provides a uniformly-heated stable-state system for a reaction system, so that the homogeneous growth of regular-hexagonal nano flaky Mo2C is promoted.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

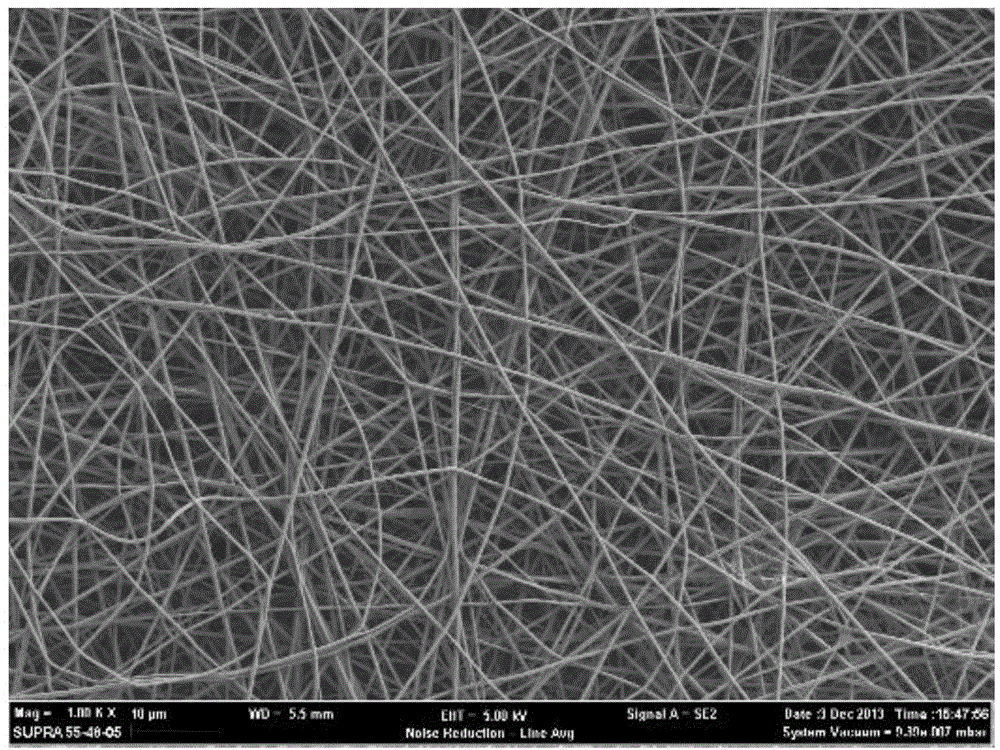

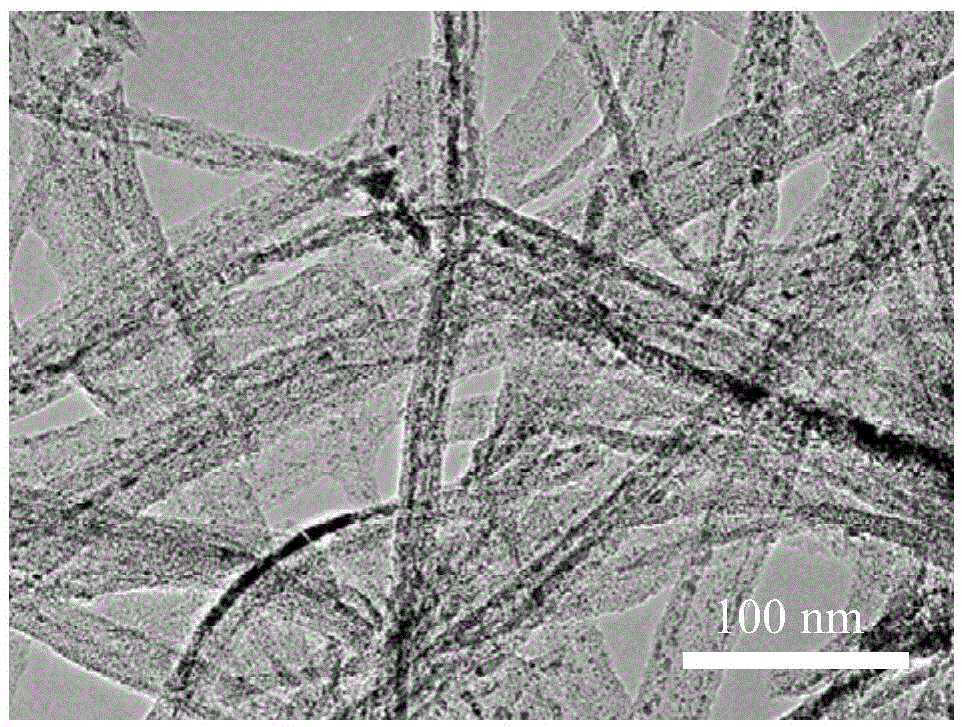

Method for preparing porous molybdenum carbide nanofiber by adopting electrostatic spinning

InactiveCN104357937AEasy to operateFacilitate multiple recycling and reuseMonocomponent polyethers artificial filamentFilament/thread formingFiberPolymer science

The invention discloses a method for preparing a porous molybdenum carbide nanofiber by adopting electrostatic spinning, and belongs to the technical field of nano materials. The method comprises the following steps: with water-soluble molybdate as a molybdenum source, and a water-soluble high-molecular polymer as a carbon source, dissolving and evenly mixing the water-soluble molybdate and the water-soluble high-molecular polymer at room temperature; and preparing a molybdate nano fiber by adopting an electrostatic spinning method; burning in an inert atmosphere or a reducing atmosphere; and simultaneously achieving high-temperature thermal decomposition, reduction and carbonization, so as to obtain the porous molybdenum carbide nanofiber in one step. According to the method, cheap molybdate and water-soluble high-molecular polymer are taken as raw materials; the method is artfully combined with a relatively mature electrostatic spinning technology in industry; and the method is high in preparation efficiency and product quality, low in cost, simple and easy to control, friendly to environment, free of pollution, and suitable for industrial production, and has important application value and industrial prospect in a plurality of fields such as catalysts, electrode materials, super capacitors and sensors.

Owner:SHANGHAI JIAO TONG UNIV

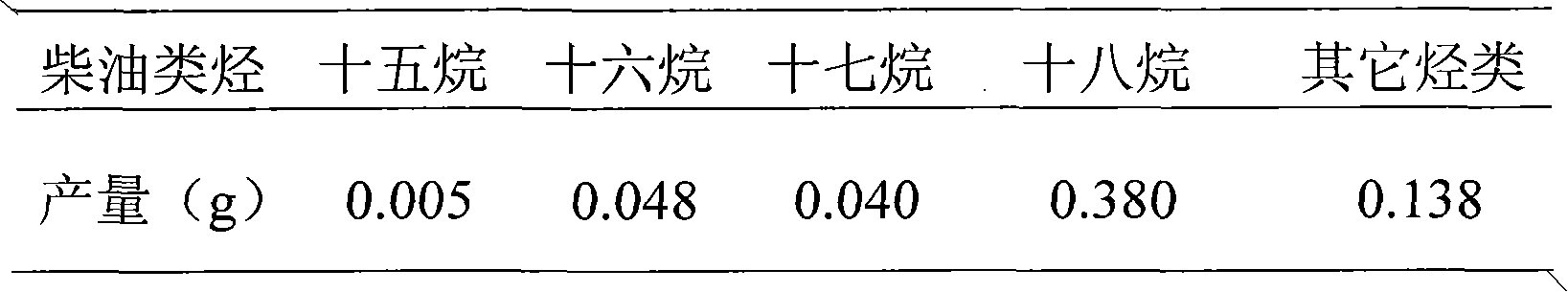

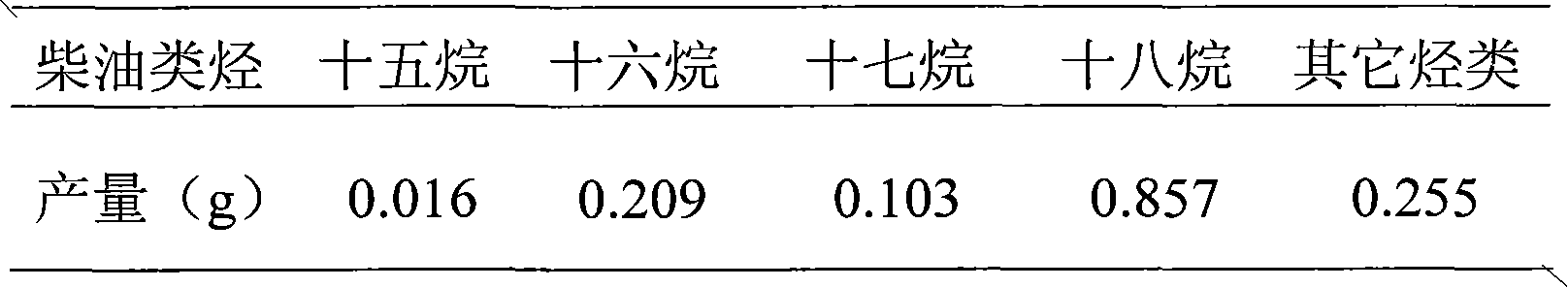

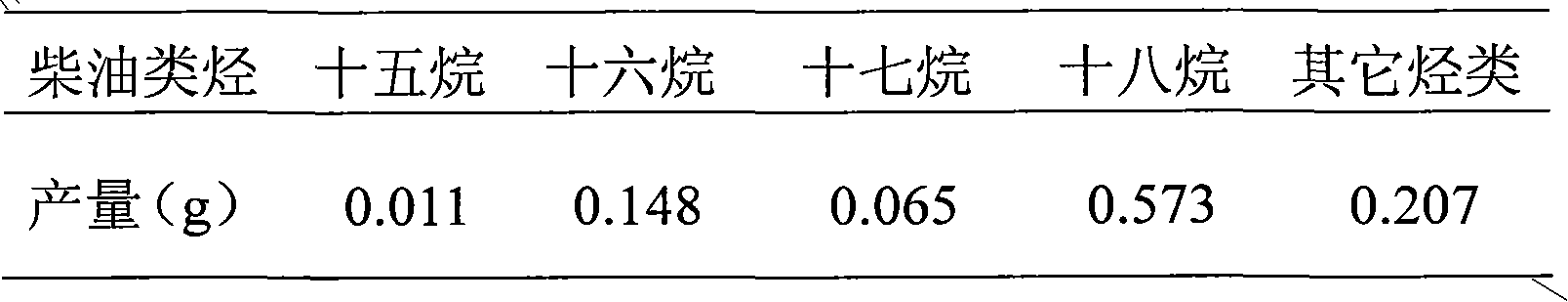

Method for preparing diesel hydrocarbons from vegetable fat through catalytic hydrogenation and deoxygenation

InactiveCN101899318AReduce manufacturing costConducive to large-scale industrialization promotionBiofuelsLiquid hydrocarbon mixture productionAlkaneHydrogen

The invention discloses a method for preparing diesel hydrocarbons from vegetable fat through catalytic hydrogenation and deoxygenation, is a method for preparing alkane with a high calorific value from vegetable fat through catalytic hydrogenation and deoxygenation, and adopts a one-pot method reaction process, comprising the following steps: adding a molybdenum carbide catalyst, vegetable fact and solvent in a reactor, filling hydrogen in the reactor, stirring and heating, reacting for 3-10h with the reaction pressure of 1-10MPa and the reaction temperature of 250-350 DEG C, stopping reaction, cooling to room temperature, filtering and separating the catalyst out to obtain the diesel hydrocarbons with alkane at a high calorific value. By adopting the technical scheme in the invention, the method has low production cost and high product combustion value, is favor of large-scale industrialized popularization and is a clean and regenerative diesel alternative fuel.

Owner:ZHEJIANG UNIV

Preparation method and application of molybdenum carbide/ zinc indium sulfide composite photocatalyst

InactiveCN108043436ALow costImprove photocatalytic hydrogen production performanceCatalyst activation/preparationHydrogen productionHydrogenIndium

The invention discloses a MoC / ZnIn2S4 composite photocatalyst and a preparation method thereof, and belongs to the technical field of a photocatalytic material. The composite photocatalyst is made bytaking two-dimensional ZnIn2S4 nanometer sheets as a main catalyst and two-dimensional MoC nanometer sheets as a cocatalyst and adopting MoC hydrothermal induction growth ZnIn2S4 method. The method isavailable in raw materials, and is simple. The prepared composite photocatalyst is good in stability and excellent in photocatalytic activity, can be used for water decomposition via visible light toproduce hydrogen, and has bright application prospects in the photocatalytic field.

Owner:FUZHOU UNIV

Hydrogen-induced-cracking resistant and sulphide-stress-cracking resistant steel alloy

The invention relates to a quench-and-temper steel alloy for use in casing for oil and gas wells wherein such casing is exposed to low pH environments. The steel alloy has a carbon range by weight of 0.15% to 0.35%, a manganese range by weight of 0.60% to 1.10%, a molybdenum range by weight of 0.15% to 0.65%, and a sulphur range by weight of less than 0.002%. The steel alloy has a quench-and-temper micro-structure and features precipitated spheroidal molybdenum carbides in manganese- and carbon-rich bands. The steel alloy also has, by weight, a chromium range of less than 0.50%, an aluminum range of less than or equal to 0.08% and a calcium range of less than or equal to 0.0045%.

Owner:IPSCO ENTERPRISES

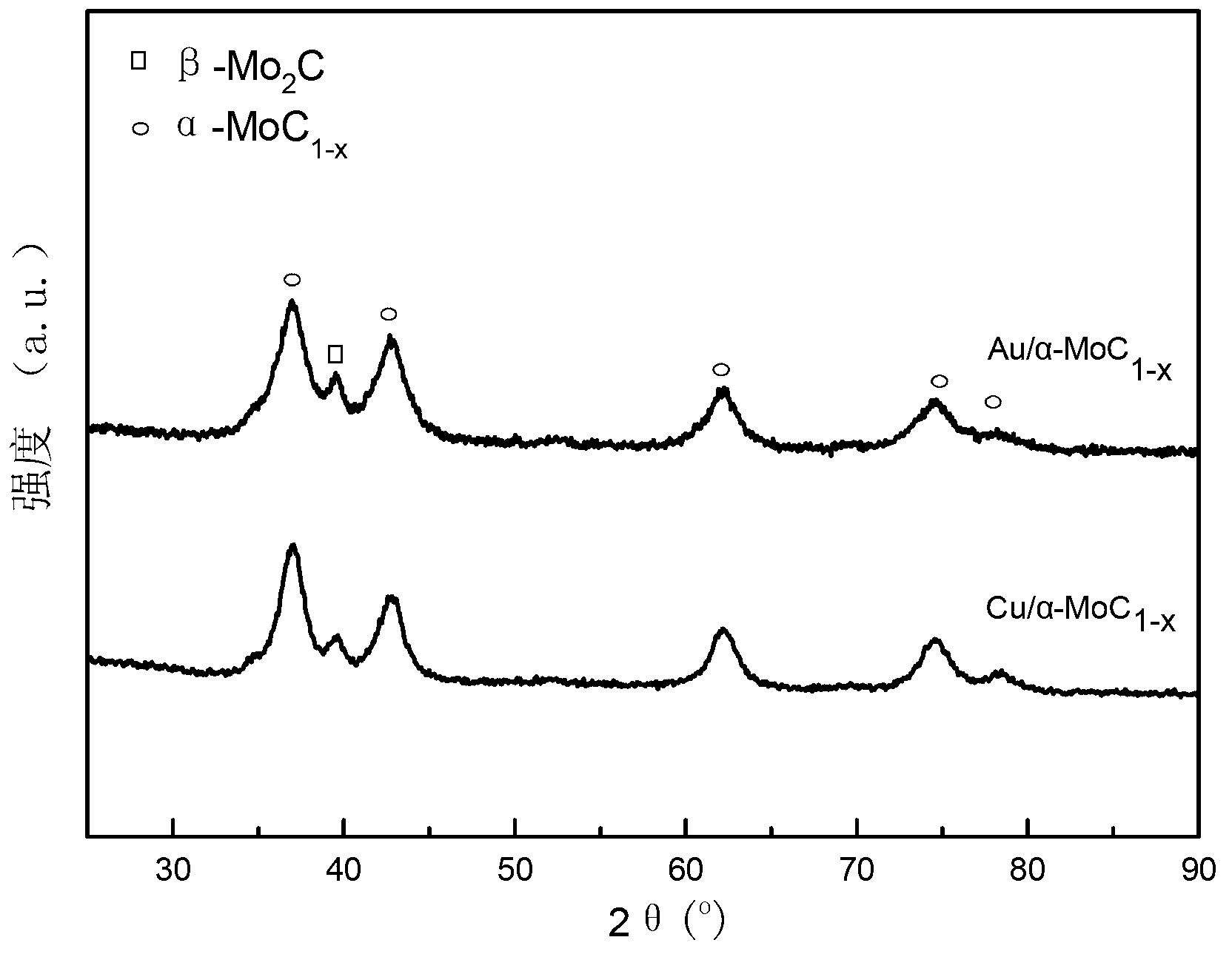

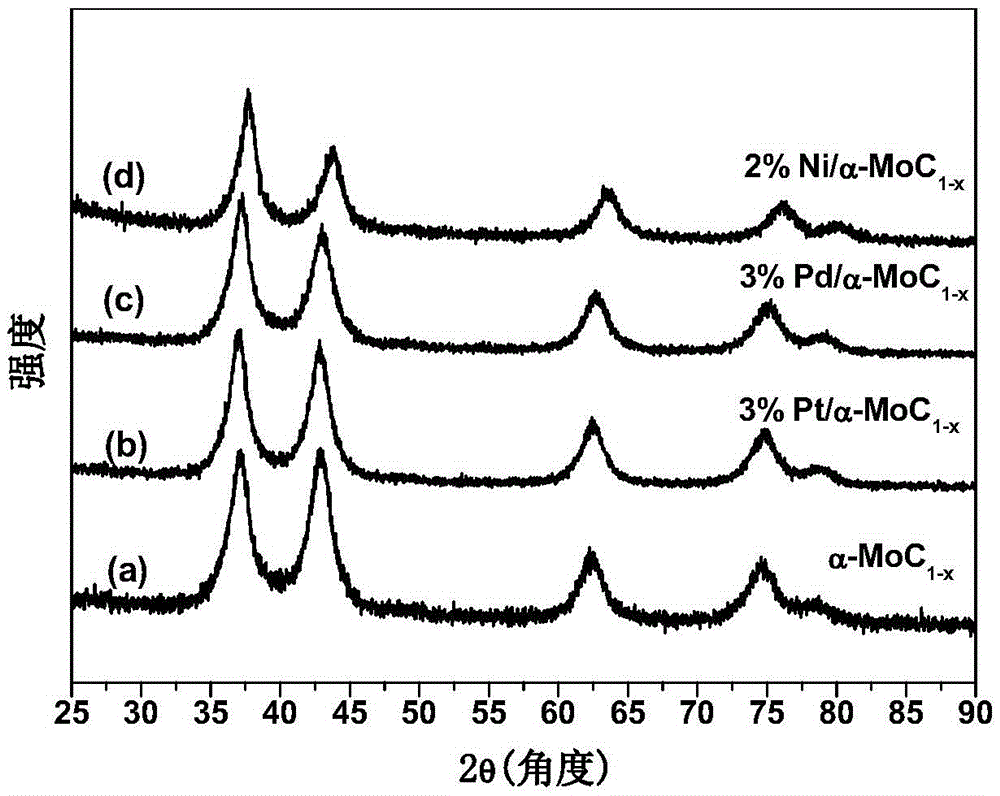

Pure alpha-phase molybdenum carbide-loaded noble metal catalyst, and preparation method and application thereof

ActiveCN104923274AImprove catalytic performanceEliminate highly polluting nitriding processPhysical/chemical process catalystsCombustible gas catalytic treatmentWater-gas shift reactionCarbonization

The invention discloses a pure alpha-phase molybdenum carbide-loaded noble metal catalyst, and a preparation method thereof. The preparation method comprises the following steps: (1) a noble metal salt solution is mixed with an ammonium paramolybdate water solution, and stirring is carried out; filtering and washing are carried out; and an obtained precipitate is dried, such that a precursor is obtained; (2) the precursor obtained in the step (1) is subjected to a non-equilibrium plasma treatment, such that noble metal-loading molybdenum oxide is obtained; and (3) the noble metal-loading molybdenum oxide obtained in the step (2) is carbonized with a carbon source gas under a temperature of 580-800 DEG C. According to the invention, a traditional roasting process is replaced by the non-equilibrium plasma treatment process. The pure alpha-phase molybdenum carbide-loaded noble metal catalyst can be directly obtained through a one-step carbonization process of the noble metal-loading molybdenum oxide obtained by the treatment process, such that a highly polluting nitridation process is eliminated. The invention also discloses an application of the prepared pure alpha-phase molybdenum carbide-loaded noble metal catalyst in a water gas shift reaction. As a result, the catalyst has excellent water gas shift performance.

Owner:DALIAN UNIV OF TECH

Preparation method of composite diamond fretsaw

InactiveCN101838838AImprove control abilityImprove sharpnessElectrolytic coatingsFine working devicesHydrogenGranularity

The invention relates to a preparation method of a composite diamond fretsaw, which comprises the following steps: 1, taking protogenetic diamond micro powder with the granularity of 5-45 Mu m and crushed diamond micro powder, mixing uniformly according to the proportion to obtain mixed diamond micro powder; taking the mixed powder of tungstic oxide powder and molybdenum powder as well as the mixed diamond micro powder, and mixing uniformly according to the proportion; 2, heating the product generated in step 1 and leading in rinsed hydrogen to form a diamond micro powder matrix / tungsten-molybdenum carbide interface / surface-metallized mixed diamond micro powder of tungsten-molybdenum alloy; and 3, taking electronickelling watt solution added with the surface-metallized mixed diamond micro powder as the electroplate liquid and taking a steel wire rope as a cathode to carry out the composite plating of metallized diamond and matrix nickel on the surface of the steel wire rope so as to obtain the composite diamond fretsaw of the invention. The invention has the advantages of simple process and easy operation, the prepared product has good edging performance, excellent wear-resisting compressive property, high processing speed and long service life, the utilization rate of the diamond fretsaw is high, the section flatness and the glossiness are high, the method is suitable for industrial production, and the prepared product is particularly suitable for the cutting processing with high efficiency, high quality and high cost performance on gems and other high-value materials.

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

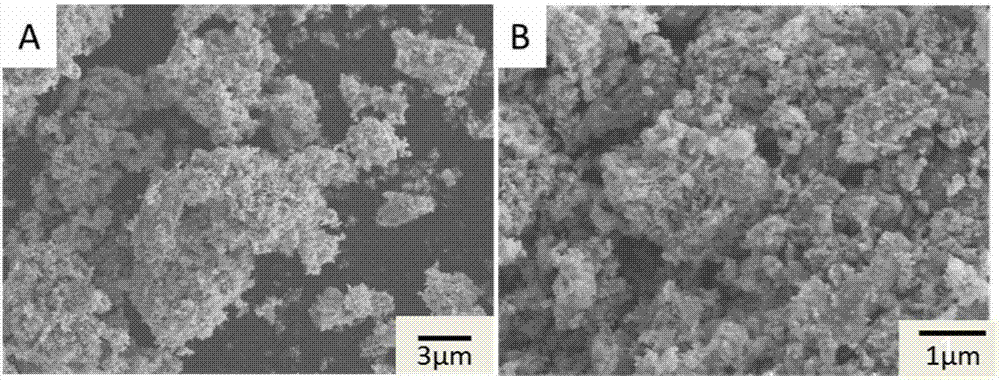

Preparation of highly dispersed molybdenum carbide/carbon composite electro-catalyst by adopting oxidation, reduction and fixation method

ActiveCN106694006AGood dispersionEasy to synthesizePhysical/chemical process catalystsElectrodesCarbon compositesMass ratio

The invention relates to a preparation method of a highly dispersed molybdenum carbide / carbon composite electro-catalyst by adopting an oxidation, reduction and fixation method. The preparation method comprises the following steps that 1, reducing organic matter and ammonium heptamolybdate are dissolved in water to prepare a mixed solution, wherein the mass ratio of the reducing organic matter to the ammonium heptamolybdate is 1: (0.1-2); 2, the mixed solution is subjected to hydrothermal treatment at the temperature of 120-200 DEG C for 4-24 hours, solid is separated out, and washing and drying are performed; 3, the dried solid is calcined in a protective atmosphere at the temperature of 600-1000 DEG C for 2-10 hours to obtain the highly dispersed molybdenum carbide / carbon composite electro-catalyst. The used raw materials are safe, non-toxic, simple to obtain and convenient to prepare and can be synthesized into molybdenum carbide nanomaterials in a large-scale mode.

Owner:江苏先进无机材料研究院

Preparation method of nitrogen-doped carbon nanofiber aerogel with inlaid molybdenum carbide particles

ActiveCN105413729AIncrease the areaHigh porosityMaterial nanotechnologyPhysical/chemical process catalystsCarbon nanofiberAmmonium heptamolybdate

The invention discloses a preparation method of nitrogen-doped carbon nanofiber aerogel with inlaid molybdenum carbide particles. The preparation method comprises the following steps of immersing bacterial cellulose in deionized water for removing acid, then immersing the bacterial cellulose in an ammonium heptamolybdate aqueous solution, conducting absorption till saturation, and obtaining ammonium heptamolybdate / bacterial cellulose; freezing the ammonium heptamolybdate / bacterial cellulose with liquid nitrogen, then conducting drying in a freeze dryer, and obtaining bacterial cellulose aerogel hybridized with ammonium heptamolybdate; finally, placing the hydridized bacterial cellulose aerogel in a tube furnace, conducting high temperature pyrolysis, and obtaining the nitrogen-doped carbon nanofiber aerogel with the inlaid molybdenum carbide particles. According to the method, the ammonium heptamolybdate and the bacterial cellulose are combined for being applied to preparation of functional carbon nano-materials, the method has the advantages of being simple, low in price, green, environmentally friendly, easy to produce on a large-scale and the like, and the prepared nitrogen-doped carbon nanofiber aerogel with the inlaid molybdenum carbide particles can serve as a catalyst for electric hydrogen production.

Owner:UNIV OF SCI & TECH OF CHINA

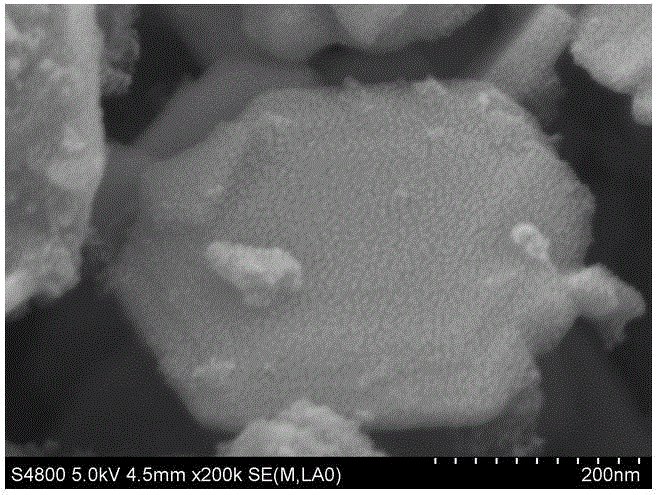

A preparation method of N-doped carbon-coated Mo2C/C functional composite material and application thereof in lithium sulfur battery

ActiveCN109037664AShape is easy to controlUniform sizeCell electrodesCarbon coatingMolybdenum carbide

The invention discloses a preparation method of an N-doped carbon-coated Mo2C / C functional composite material and application thereof in a lithium sulfur battery. By adjusting the carbon content in acarbon layer, obtaining the precursor through self-assembly and polymer polymerization, then carbonizing and carbon coating to obtain nanospheres, the N-doped carbon-coated Mo2C / C functional compositematerial with better performance is obtained. A lay of N-doped carbon layer is coat on the surface of the molybdenum carbide nanosphere through the polymerization of macromolecules, so that the shapecan be control, A double-shell hybrid hollow Mo2C / C nanosphere composite with uniform size and good structural stability, The double-shell hybrid hollow Mo2C / C nanosphere composite exhibits excellentelectrochemical properties as cathode material for lithium sulfide batteries, including good cycle stability and high reversible specific capacity, due to its excellent double-layer absorption and protection after S loading.

Owner:SOUTH CHINA UNIV OF TECH

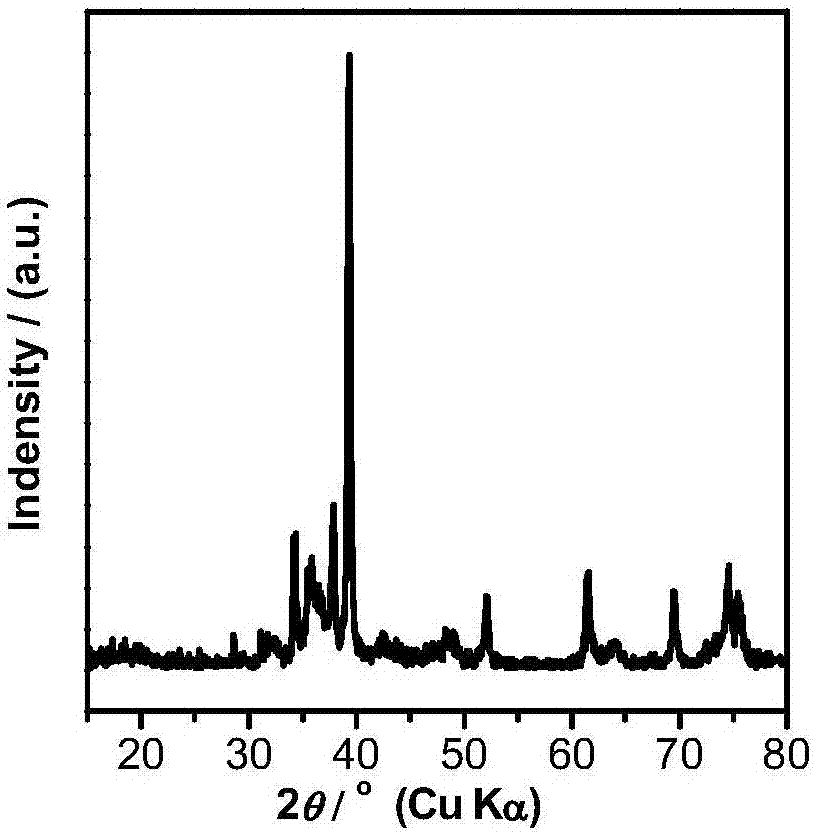

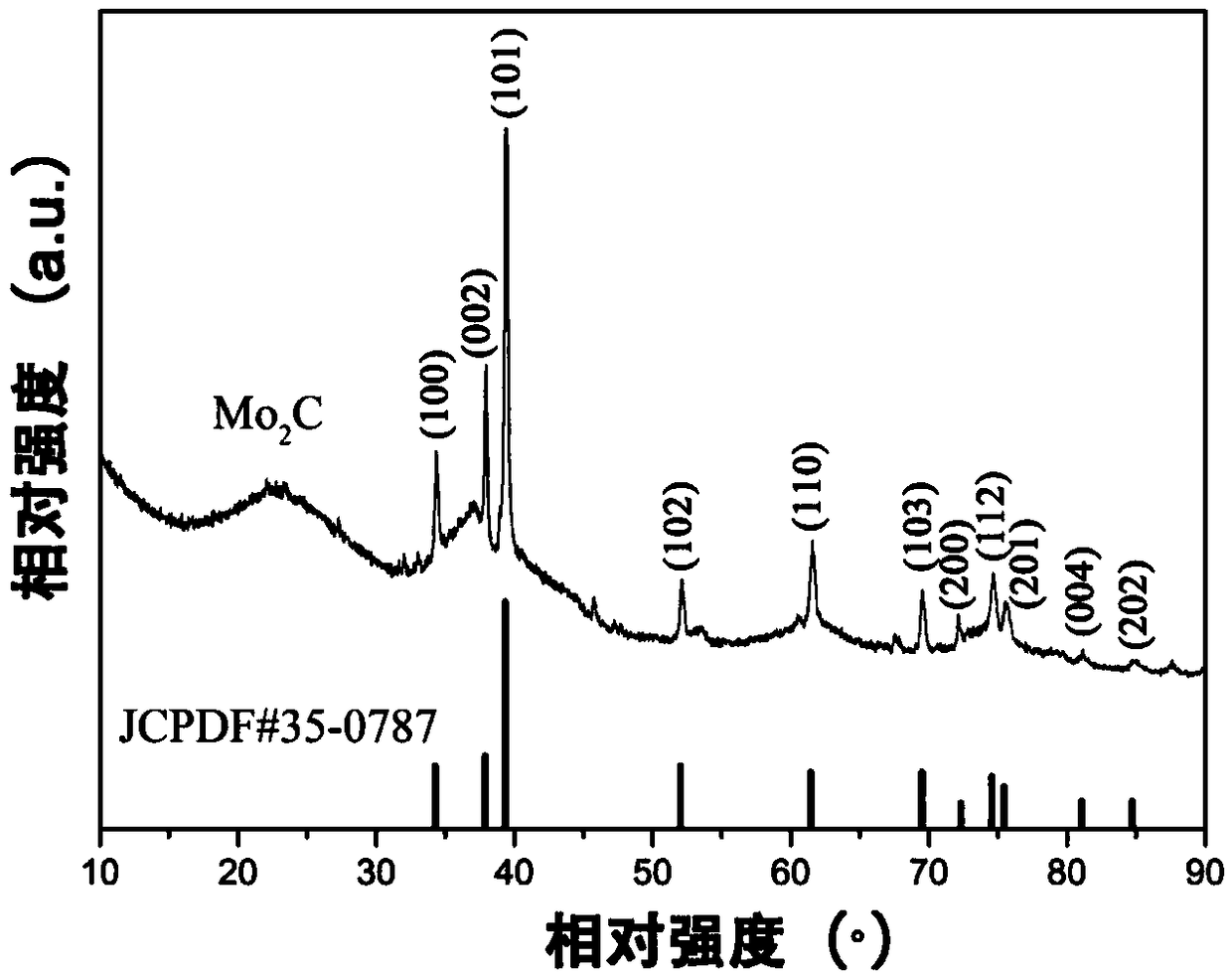

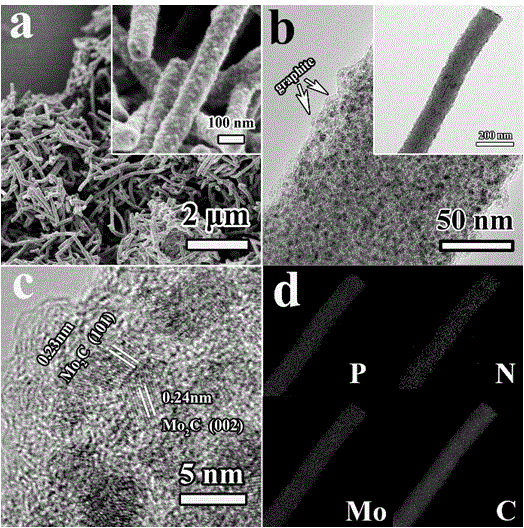

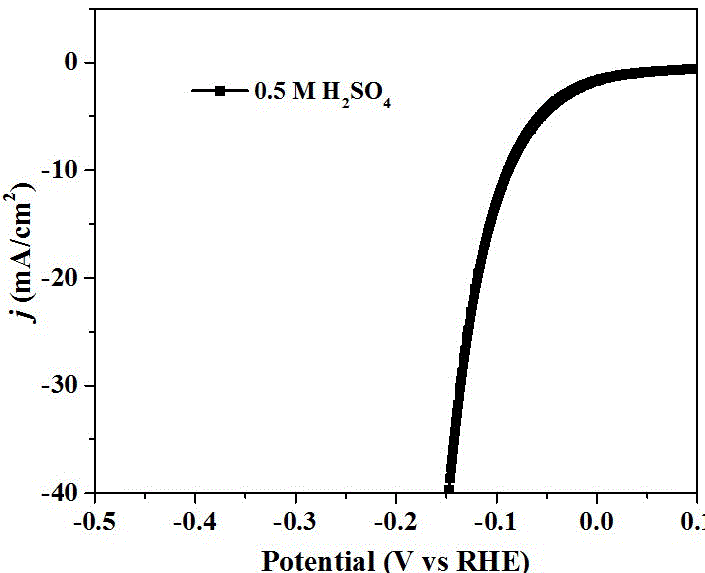

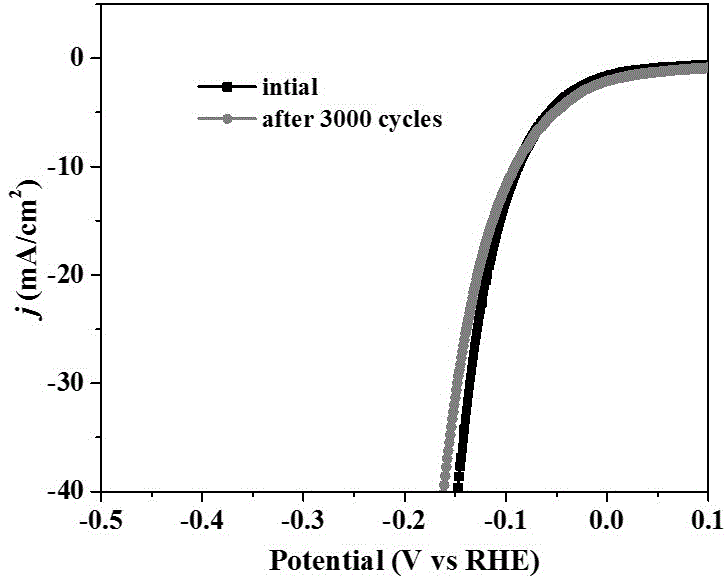

Nitrogen-doped graphite-loaded phosphorus-doped molybdenum carbide nanowire electrocatalytic hydrogen production catalyst and preparation method thereof

The invention belongs to the technical field of electrocatalytic hydrogen production, and in particular relates to a nitrogen-doped graphite-loaded phosphorus-doped molybdenum carbide nanowire electrocatalytic hydrogen production catalyst and a preparation method thereof. The catalyst has a rough-surface nanowire structure with a diameter of 100-200nm on the whole, the particle size distribution of an active centre beta-Mo2C is 2-10nm, and beta-Mo2C particles are closely embedded on the surface of nitrogen-doped graphite, phosphorus is evenly doped into a beta-Mo2C structure by means of a phosphorus-molybdenum bond. The nitrogen-doped graphite is generated in place in a high-temperature carbonation process of polyaniline in MoOx-phytic acid-polyaniline hybrid precursor. The catalyst has very high electrocatalytic hydrogen production activity and stability under the acidic condition; the preparation method of the catalyst is simple in operation, high in adjustability, low in raw material price and low in production process risk, thus being suitable for large scale production and industrial hydrogen production by using electrolysis of water.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com