Preparation of highly dispersed molybdenum carbide/carbon composite electro-catalyst by adopting oxidation, reduction and fixation method

A technology of electrocatalyst and immobilization method, which is applied in the field of electrocatalysis, can solve problems such as harsh conditions and complicated preparation, and achieve the effects of simple process, convenient preparation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Choose citric acid as reducing carbon source, take by weighing citric acid 2.5g, and ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 .4H 2 O) 0.5g in a beaker, add 50mL of water to ultrasonically dissolve, then transfer to a hydrothermal kettle, heat at 180°C for 8h, after cooling, wash the black product with water, centrifuge, and dry. The dried product was subjected to H 2 / Ar atmosphere calcined to 800°C, the heating rate is 5°C / min, and kept for 5h, the molybdenum carbide / carbon composite catalyst can be obtained, denoted as MoC x -1.

[0037] The electrochemical test of the prepared highly dispersed molybdenum carbide / carbon composite catalyst for electrolysis of water to produce hydrogen is carried out in the following steps:

[0038] First, weigh 4mg of the above catalyst and disperse it in a mixed solution containing 1mL of absolute ethanol and 40uL Nafion solution (5%), ultrasonically obtain a uniformly dispersed suspension, then take 30uL of the above suspe...

Embodiment 2

[0040] Preparation process and steps in embodiment 2 are basically the same as above-mentioned embodiment 1, and difference is: the molybdenum source ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 .4H 2 O) quality is 2.5g, and the catalyst made is denoted as MoC x -2. The catalytic performance of the catalyst for hydrogen production by electrolysis of water is the same as in Example 1.

Embodiment 3

[0042] Preparation process and steps in embodiment 3 are basically the same as above-mentioned embodiment 1, and difference is: the molybdenum source ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 .4H 2 O) quality is 4g, and the catalyst made is denoted as MoC x -3. The catalytic performance of the catalyst for hydrogen production by electrolysis of water is the same as in Example 1.

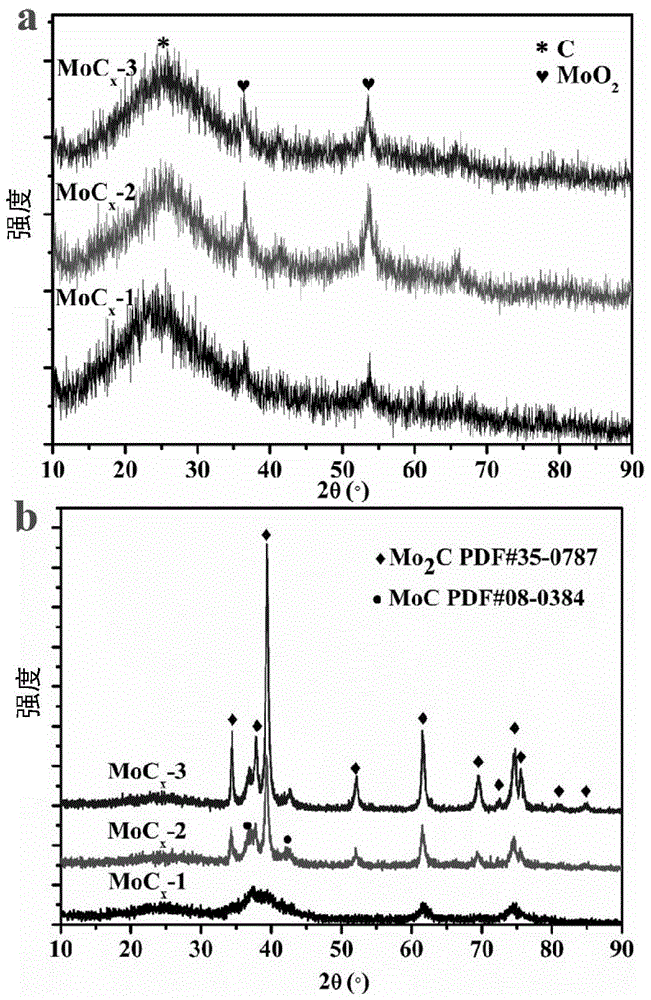

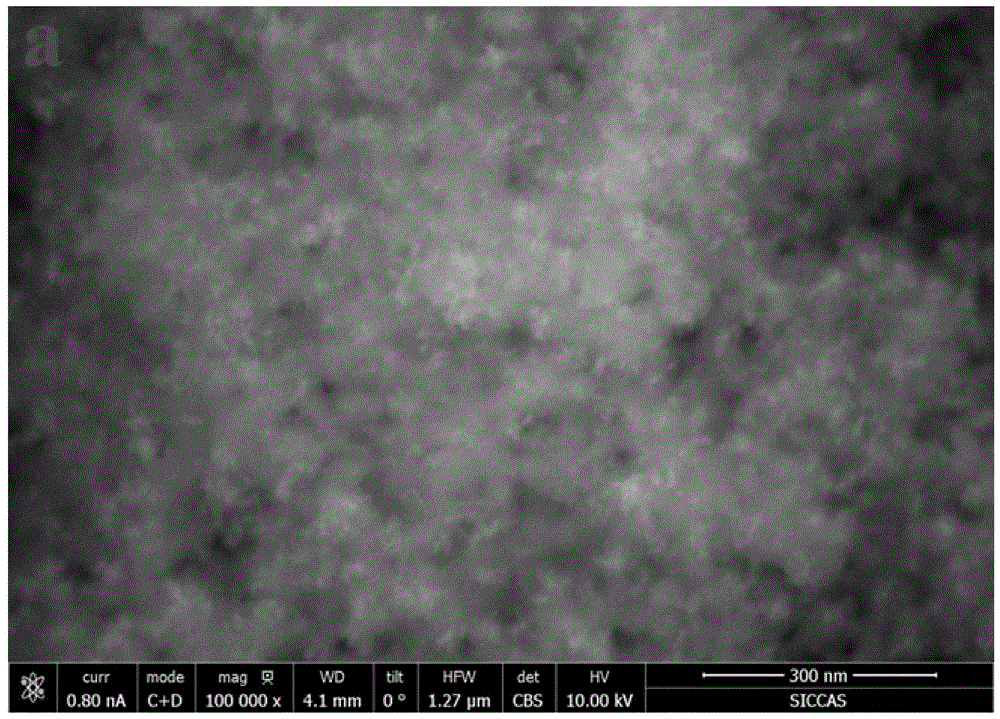

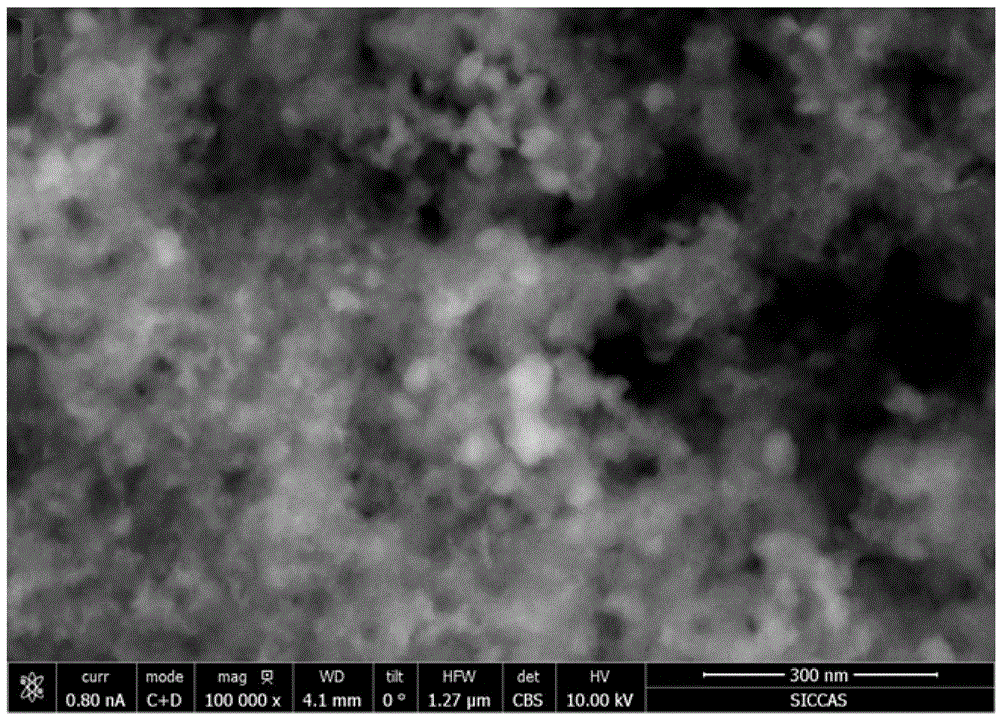

[0043] figure 1 a is the XRD pattern of the sample after hydrothermal treatment and drying, figure 1 b is the XRD pattern after calcination under protective atmosphere. From figure 1 As can be seen in a, the sample after hydrothermal treatment is MoO 2 / C composites, indicating that after hydrothermal treatment, the molybdenum source was converted to MoO by redox reaction 2 The form is fixed and dispersed on the carbon material. From figure 1 It can be seen from b that after calcination in a protective atmosphere, both β-Mo 2 The phase of C and the phase of η-MoC are mixed phases of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com