Refractory high-entropy alloy/titanium carbide composite and preparation method thereof

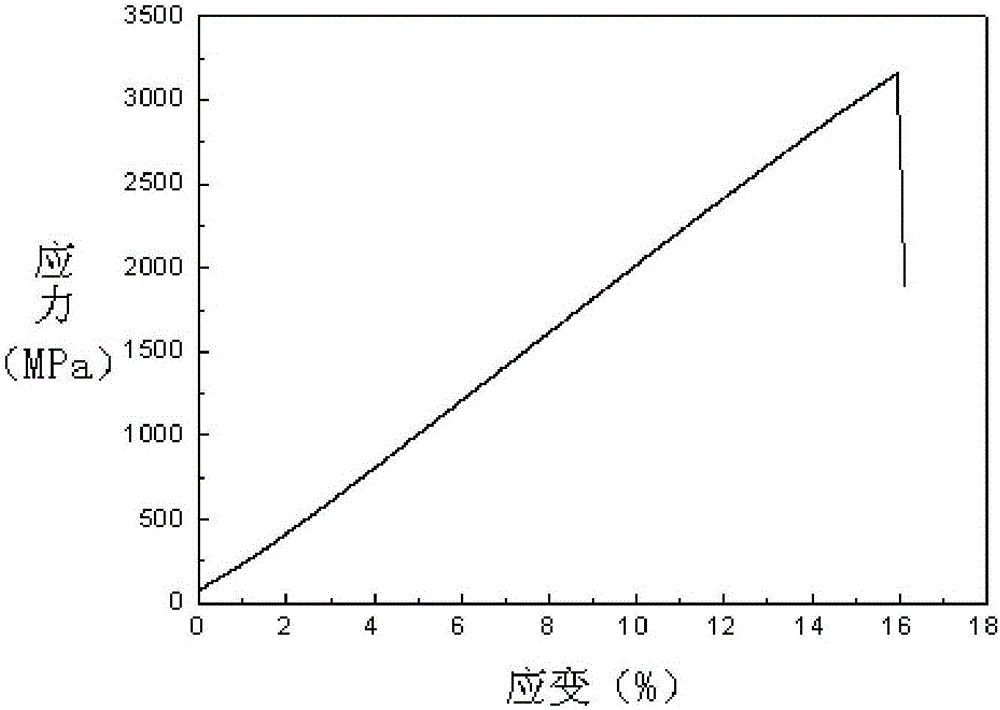

A high-entropy alloy and composite material technology, applied in the field of refractory high-entropy alloy/titanium carbide composite materials and its preparation, can solve problems such as failure to meet service requirements and poor mechanical properties, and achieve high hardness, good mechanical properties, The effect of high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

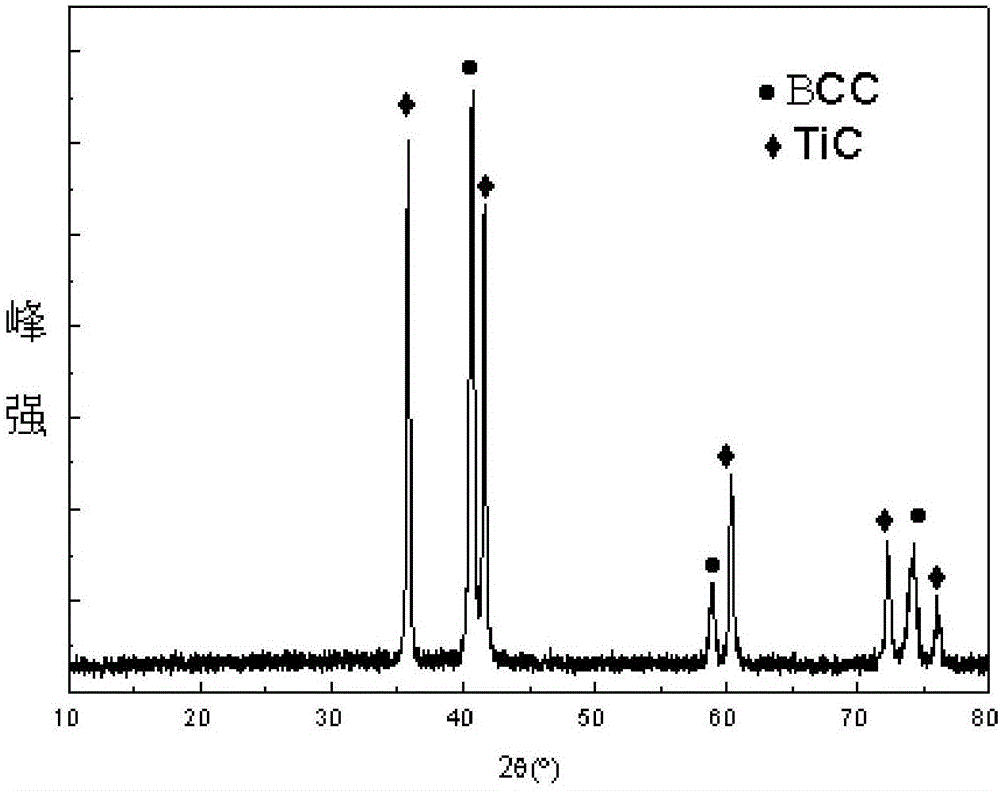

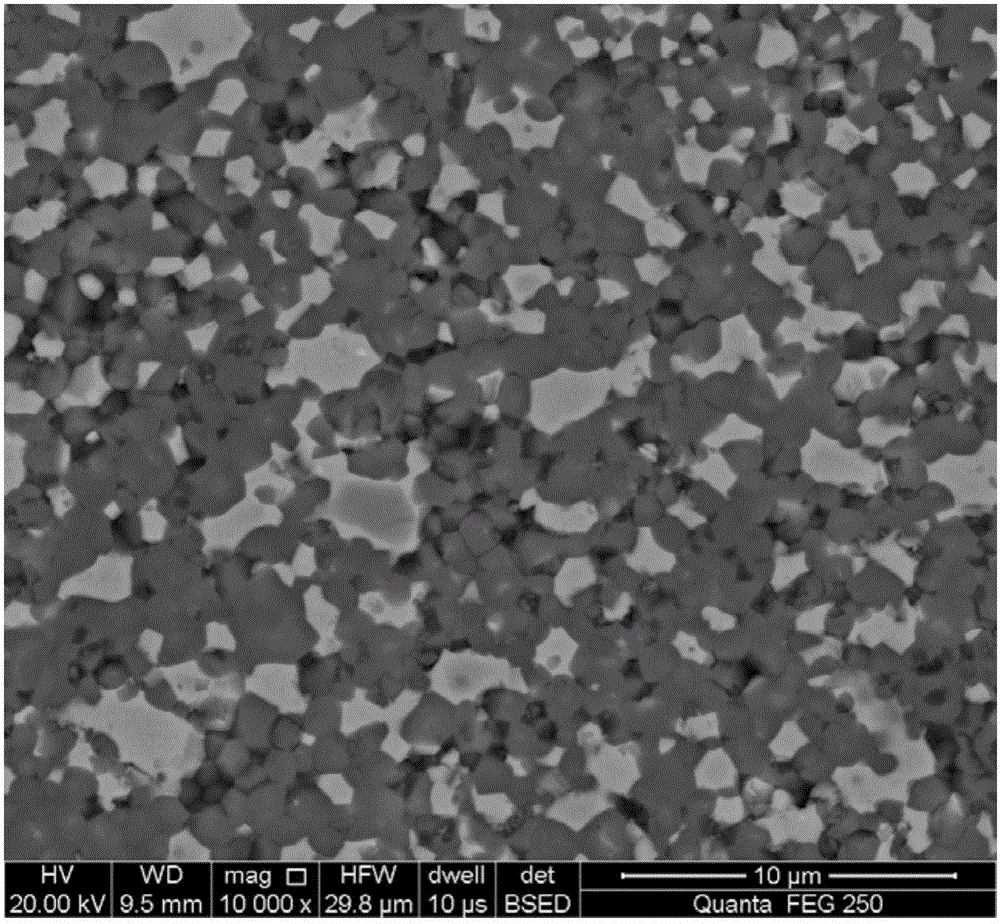

[0034] A refractory high-entropy alloy / titanium carbide composite material of the present invention, with the refractory high-entropy alloy as the matrix phase and titanium carbide as the reinforcing phase; the matrix phase refractory high-entropy alloy mainly contains W, Mo, Ta, Nb , V, Ti six elements, and the molar amounts of these six elements are equal, the volume ratio of the matrix phase and the reinforcement phase is about 1:2.

[0035] The preparation method of the refractory high-entropy alloy / titanium carbide composite material of the present embodiment comprises the following steps:

[0036] (1) Select commercially available WC and Mo with a purity higher than 99.5% (mass percentage) and an average particle size between 1 and 2 μm 2 C, TaC, NbC, VC, TiC, the molar ratio is WC:Mo 2 C:TaC:NbC:VC:TiC=1:0.5:1:1:1:1 ratio mixed into high entropy matrix powder;

[0037] (2) According to the molar ratio WC:Ti=1:5.5, the titanium powder and the high-entropy matrix powder...

Embodiment 2

[0043] A kind of refractory high-entropy alloy / titanium carbide composite material of the present invention, with refractory high-entropy alloy as the matrix phase and titanium carbide as the reinforcing phase; the matrix phase refractory high-entropy alloy mainly contains W, Ta, Nb, V , Ti, Cr six elements, and the molar amounts of these six elements are equal, the volume ratio of the matrix phase and the reinforcement phase is about 1:3.

[0044] The preparation method of the refractory high-entropy alloy / titanium carbide composite material of the present embodiment comprises the following steps:

[0045] (1) Select commercially available WC, TaC, NbC, VC, TiC, Cr with a purity higher than 99.5% (mass percentage) and an average particle size between 1 and 2 μm 3 C 2 WC:TaC:NbC:VC:TiC:Cr in molar ratio 3 C 2 = 1:1:1:1:1:0.33 ratio mixed into high entropy matrix powder;

[0046] (2) According to the molar ratio of WC:Ti=1:5, the titanium powder and the high-entropy matrix ...

Embodiment 3

[0052] A refractory high-entropy alloy / titanium carbide composite material of the present invention, with the refractory high-entropy alloy as the matrix phase and titanium carbide as the reinforcing phase; the matrix phase refractory high-entropy alloy mainly contains W, Mo, Ta, Nb , V, Ti six elements, and the molar amounts of these six elements are equal, the volume ratio of the matrix phase and the reinforcement phase is about 1:1.

[0053] The preparation method of the refractory high-entropy alloy / titanium carbide composite material of the present embodiment comprises the following steps:

[0054] (1) Select commercially available WC and Mo with a purity higher than 99.5% (mass percentage) and an average particle size between 1 and 2 μm 2 C, TaC, NbC, VC, TiC, the molar ratio is WC:Mo 2 C:TaC:NbC:VC:TiC=1:0.5:1:1:1:1 ratio mixed into high entropy matrix powder;

[0055] (2) According to the molar ratio WC:Ti=1:5.5, the titanium powder and the high-entropy matrix powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average microhardness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com