Production method of continuous type rubber flooring mat

A production method and rubber technology are applied in the production field of continuous rubber floor mats, which can solve the problems of dirt accumulation, slow production efficiency, and dense seams between rubber floor mats.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

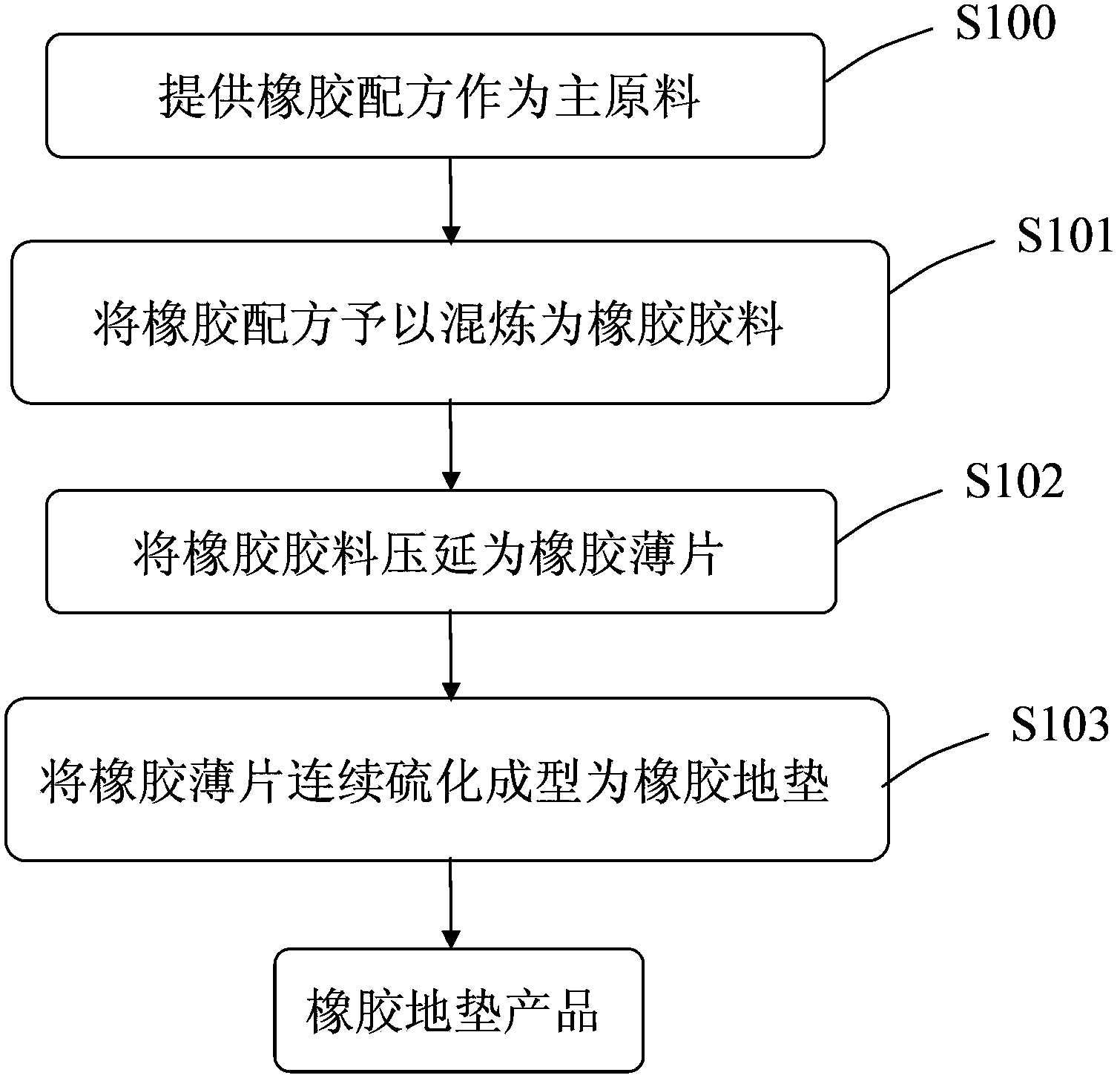

[0014] Such as figure 1 Shown, the production method of the continuous rubber floor mat provided by the present invention comprises the following steps:

[0015] First, as in step S100, a rubber formula is provided as the main raw material; the composition of the rubber formula may include 100 parts by weight of main rubber, 10-20 parts by weight of rubber processing oil, 140-210 parts by weight of filler and functional fine powder 3 ~8 parts by weight. Specifically, the main rubber may be natural rubber, synthetic rubber or regenerated rubber, and may be selected from the group combination of styrene butadiene rubber, nitrile rubber, natural rubber, polybutadiene rubber and ethylene propylene rubber. The filler may contain 100-150 parts by weight of calcium carbonate and 40-60 parts by weight of aluminum silicate. The rubber processing oil may be a naphthenic oil. The functional fine powder contains 1 to 3 parts by weight of antioxidant and 2 to 5 parts by weight of vulcan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com