Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

434 results about "Nickel substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

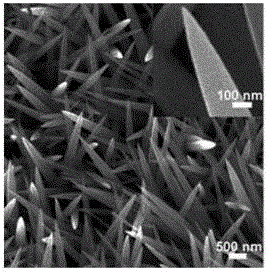

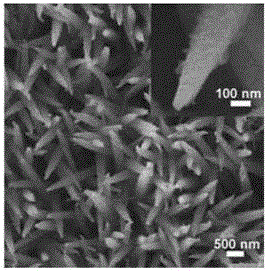

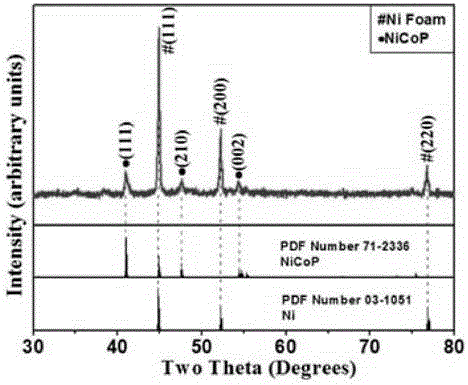

Preparation method for NiCoP nanowire electro-catalytic electrode

InactiveCN105951123AAvoid introducingSimple preparation processMaterial nanotechnologyElectrode shape/formsNanowireReactive material

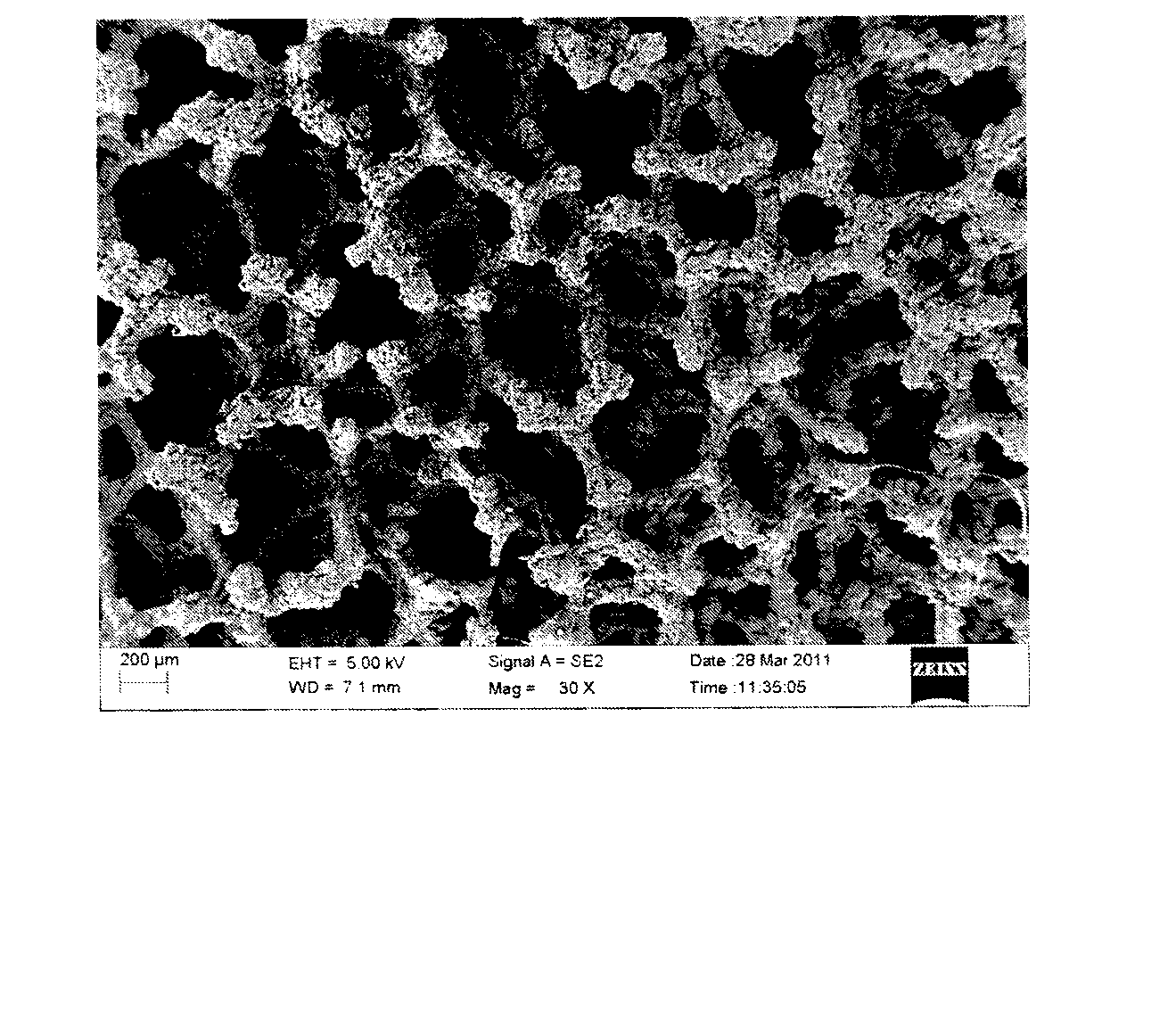

The invention discloses a preparation method for a NiCoP nanowire electro-catalytic electrode. A NiCo salt nanowire is adopted as a phosphorization precursor, hypophosphite is used as a phosphorus source, and the phosphorization process of the NiCo salt nanowire is achieved by controlling the annealing technique in a stored program control tube type annealing furnace. The diameter of the NiCoP nanowire obtained through the method is 140 nanometers, the length of the obtained NiCoP nanowire is about 3.2 micrometers, and the surface of the nanowire is roughly and evenly grown on a 3D netty foamed nickel substrate, so that the specific surface area and the electric conductivity of an electro-catalytic material are effectively improved, and the electro-catalytic hydrogen evolution performance and stability of an electrode material are improved. The electro-catalytic hydrogen production performance of the electrode is tested in 1M of a KOH electrolyte, the overpotential under the electric current density of 10 mA / cm<2> is 109 mV, and the Tafel slope is 88.5 mV / dec, so that the material has the superior electro-catalytic hydrogen production performance compared with common electro-catalytic hydrogen evolution materials. Meanwhile, the preparation technique is simple, the equipment requirement is conventional, reactive materials are abundant, price is low, and the electrode is environmentally friendly.

Owner:HUBEI UNIV

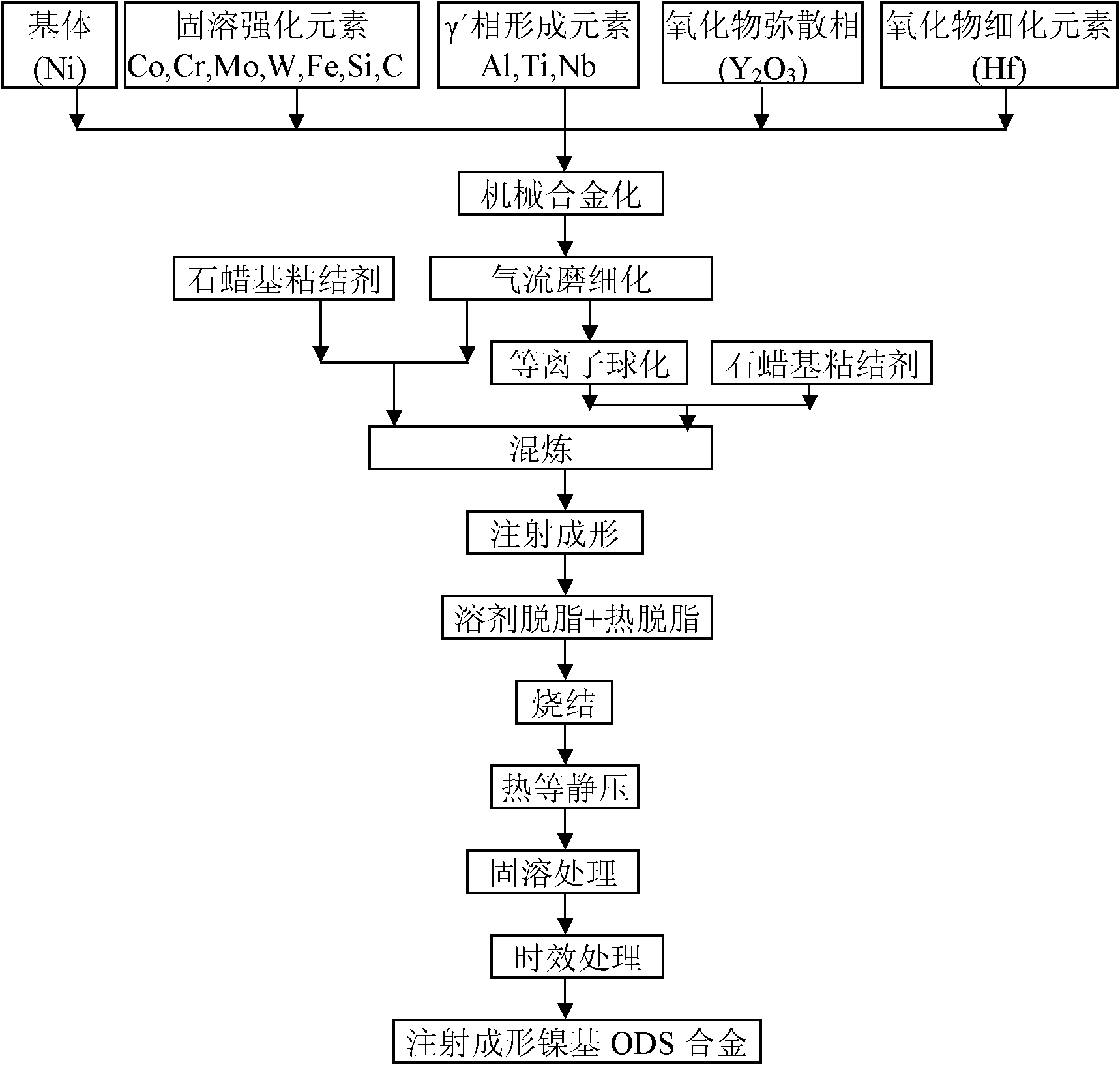

Method for preparing injection-molding nickel-base ODS (oxide dispersion strengthened) alloy

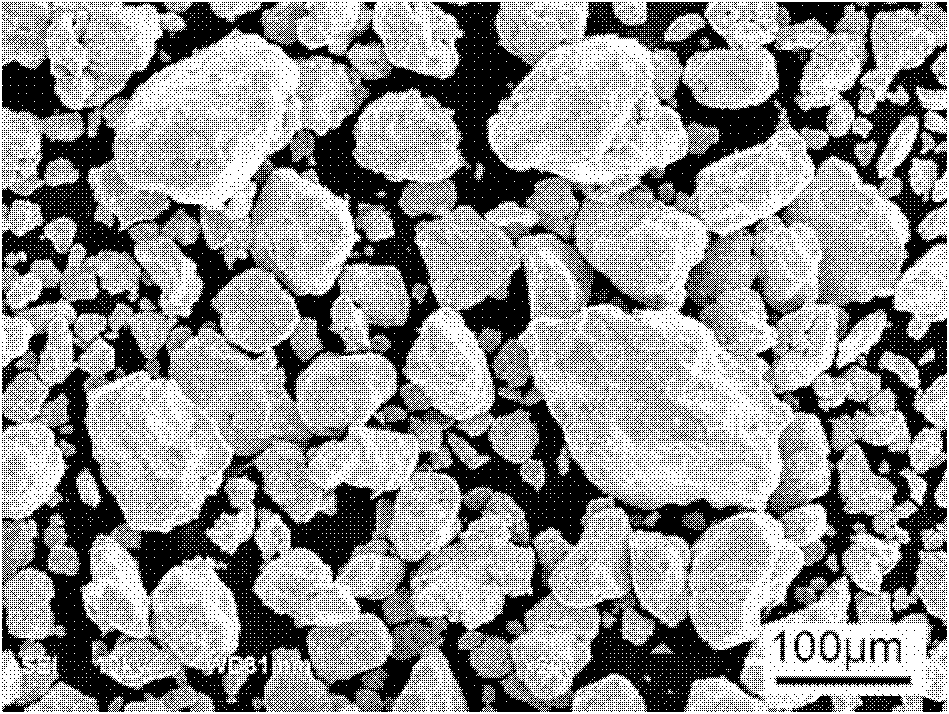

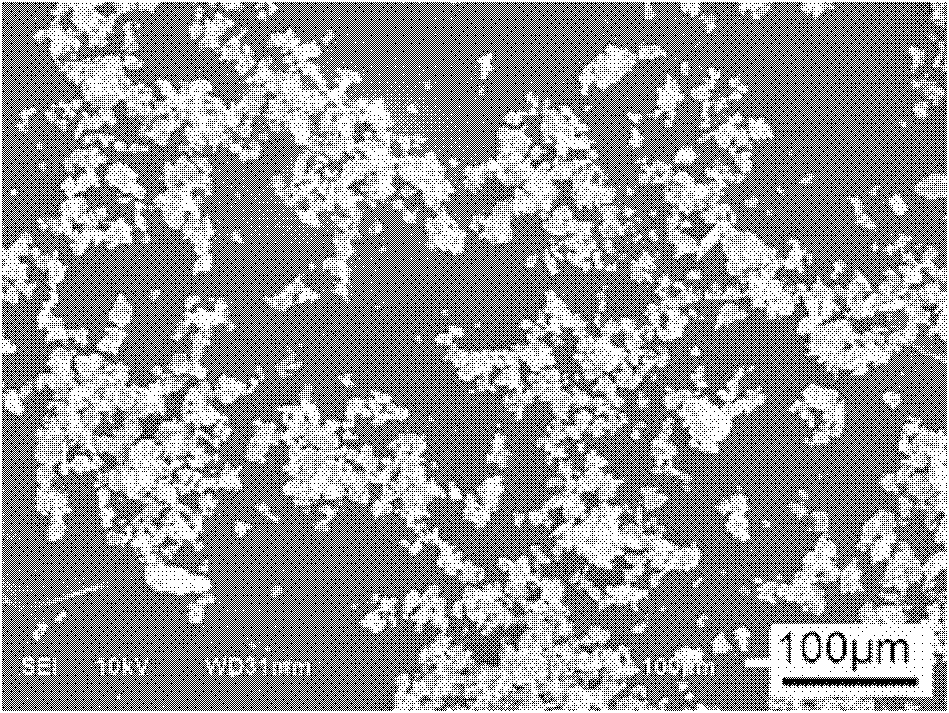

The invention provides a method for preparing a nickel-base ODS (oxide dispersion strengthened) alloy by injection molding, belonging to the technical field of injection molding of powder. The method comprises the following steps: carrying out high-energy ball milling on the raw material powder so that Y2O3 particles are uniformly dispersed in a nickel substrate, refining mechanical alloy powder by jet milling, and carrying out plasma nodularization on the powder which is refined by jet milling; evenly mixing and smelting the powder, which is refined by jet milling and plasma nodularization, and adhesive to obtain a uniform feed material; and carrying out injection molding, two-step degreasing and sintering on the feed material to obtain a sintered blank of which the density is 93-96%, carrying out hot isostatic compaction on the sintered blank so that the sintered blank is completely compact, and finally, carrying solution heat treatment and aging heat treatment to obtain the injection-molding nickel-base ODS alloy. The nickel-base ODS alloy can be prepared into high-precision parts in complex shapes, thereby solving the problem of difficulty in molding of nickel-base ODS alloy. The gamma' phase and the oxide strengthening mechanism are combined to greatly enhance the high-temperature mechanical properties of the nickel-base ODS alloy.

Owner:UNIV OF SCI & TECH BEIJING

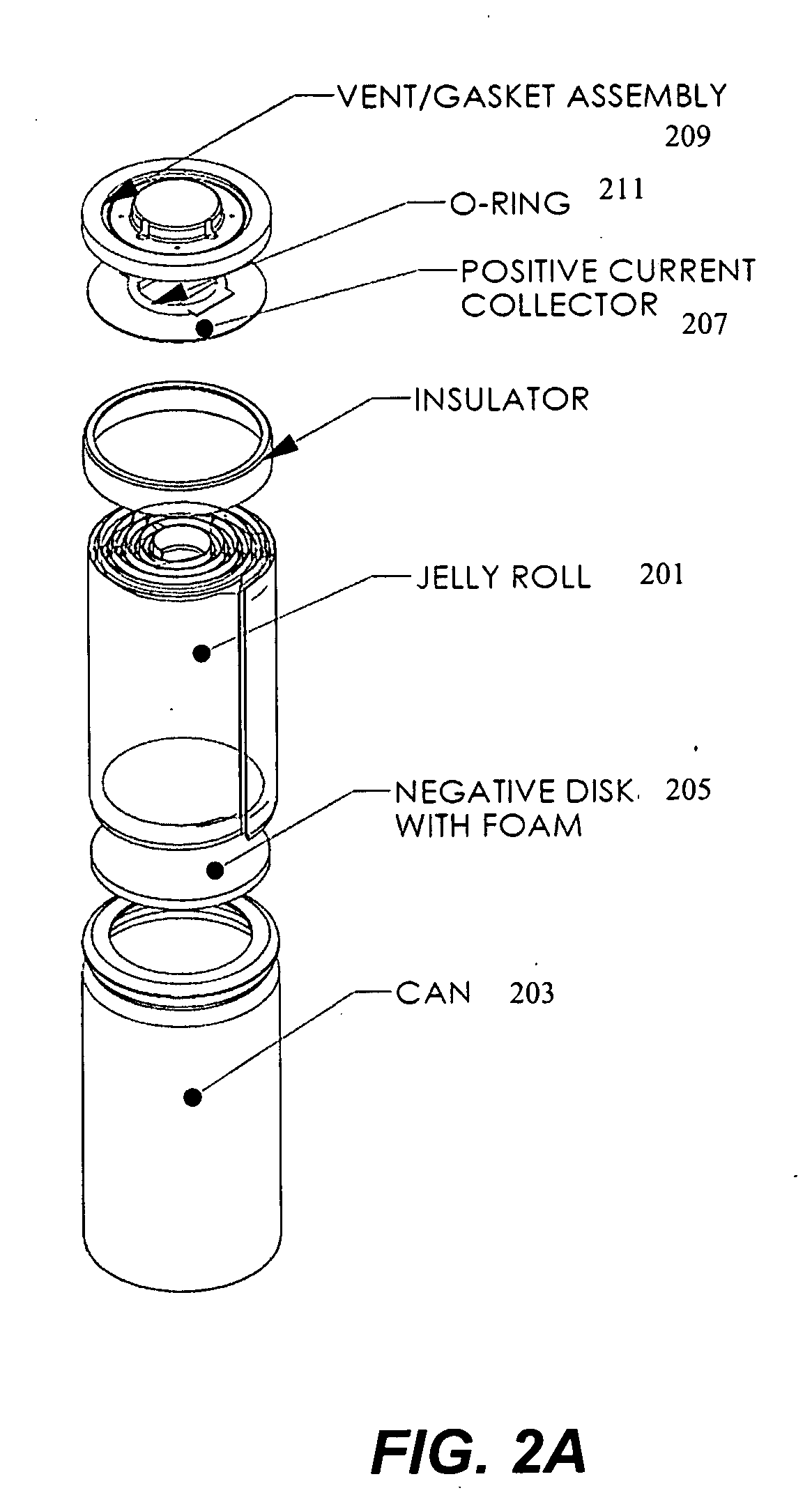

Cylindrical nickel-zinc cell with negative can

A nickel-zinc battery cell is formed with a negative can, a positive cap, and a jelly roll of electrochemically active positive and negative materials within. The inner surface of the can is protected with an anticorrosive material that may be coated or plated onto the can. Good electrical contact between the jelly roll and the cap is achieved through folding the nickel substrate over to contact a positive current collection disk.

Owner:ZINCFIVE POWER INC

Foam nickel-base MnO2/C composite electrode material and preparation method thereof

The invention belongs to the technical field of supercapacitors, and particularly relates to an MnO2 / C composite electrode material prepared on foam nickel by a hydrothermal-electrodeposition combination method, and a preparation method thereof. The electrode material can be widely used in battery electrodes and supercapacitor electrodes. The MnO2 / C composite electrode material is composed of a carbon sphere material hydrothermally deposited on a foam nickel substrate, and a manganese peroxide material deposited on the carbon sphere material by an electrodeposition method. The composite electrode material provided by the invention has the advantages of simple technique and low cost, and can easily implement large-scale production. The maximum discharge specific capacity of the supercapacitor made of the foam nickel-base metal nickel oxide / carbon composite electrode material can reach 1045.5F.g<-1>, and the supercapacitor has favorable power performance and cycle performance.

Owner:JILIN UNIV

Molybdenum doped iron/nickel lamellar array @ nickel foam base composite electrode material and preparing method and application thereof

ActiveCN108754532AImprove stabilityMake up for deficienciesElectrodesNickel substrateComposite electrode

The invention discloses a molybdenum doped iron / nickel lamellar array @ nickel foam base composite electrode material and a preparing method and application thereof. The material uses foamed nickel asa substrate, an iron / nickel lamellar thermometal hydroxide (FeNi-LDHs) array grows on the surface of the foamed nickel, and the metal molybdenum is doped into the array. According to the preparing method of the material, a hydrothermal method is adopted for directly growing FeNi-LDHs nanosheet arrays on the foamed nickel substrate, then the FeNi-LDHs array is used as a substrate to dope metal Moon the surface of the array through the hydrothermal method, and finally high temperature carbonization and revivification are carried out to obtain the electrode material with the electro-catalytic property. The composite material is stable in performance under the alkaline condition, the high reutilization degree is achieved, the large electrochemical active area is achieved, and the material catalytic activity is greatly improved; and the preparing method is simple in preparing process, low in sintering temperature, low in energy consumption in the preparing process and favorable for industrial production.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation method of super capacitor

InactiveCN101661840AEasy to manufactureLower internal resistanceElectrolytic capacitorsHybrid/EDL manufactureGas phaseArgon atmosphere

The invention relates to a preparation method for a super capacitor, comprising the following steps: (1) placing a foam nickel substrate in a chemical gas phase deposition reacting furnace, introducing argon for 10-60 minutes, exhausting air in the furnace, then heating the furnace to 450-750 DEG C, introducing hydrocarbon gases in an argon atmosphere at a flow rate between 25ml / min and 40ml / min,reacting the mixture for 30 seconds to 50 minutes at a temperature of 450-750 DEG C, and obtaining foam nickel on which carbon nano tubes grow after finishing the reaction; (2) removing surface loosing layer products, directly using the foam nickel substrate on which the carbon nano tubes grow as electrodes of the super capacitor; and (3) drying the electrodes with same thickness and size, which are obtained from the step (2), fully soaking the electrode with electrolyte for 1-36 hours, separating a diaphragm soaked with the electrolyte and assembling the components to obtain the super capacitor; and the hydrocarbon gases are acetylene, methane, ethylene or propylene. The carbon nano tubes directly grow on the foam substrate without a binding agent; and the foam nickel is used as the substrate, the volume density of electrode substances is higher and holes are reasonably distributed.

Owner:JIANGSU CHUANGLAN SOLAR AIR CONDITIONER

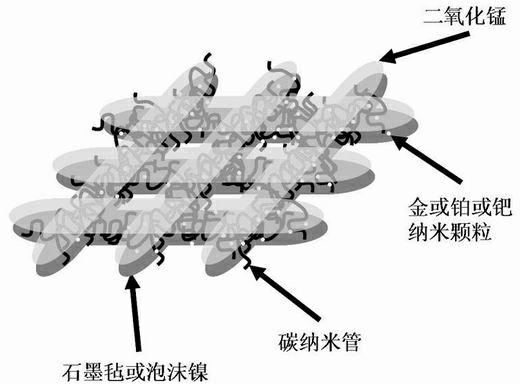

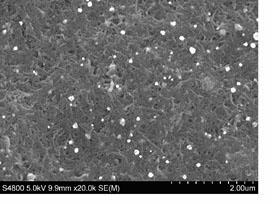

Combined electrode for super capacitor and preparation method thereof

InactiveCN102683044AHigh mechanical strengthLarge specific surface areaElectrolytic capacitorsHybrid capacitor electrodesPlatinumNickel substrate

The invention relates to a nanometer combined electrode material for a super capacitor and a preparation method thereof. The combined electrode material for the super capacitor is as follows: the surface of a graphite felt or a foam nickel substrate material is provided with a carbon nanometer tube layer; the surface of the carbon nanometer tube layer is provided with a layer of trace discontinuous palladium or platinum or gold nanometer particles; and the carbon nanometer tube layer with a layer of trace discontinuous palladium or platinum or gold nanometer particles on the surface is provided with a manganese dioxide layer.

Owner:昆山昆鹏利杰高分子材料技术有限公司

Preparation of metal organic framework membrane and application in gas separation

InactiveCN105126642AImprove mechanical propertiesSemi-permeable membranesHydrogen separation using solid contactNanowireNickel substrate

A preparation of metal organic framework membrane and an application in gas separation. The invention belongs to the technical field of membrane separation. The preparation method includes the steps of (A) adding a treated porous metal nickel substrate into a precursor solution of Co3O4 and heating the solution at a high temperature; (B) rinsing and drying the nickel substrate and heating the nickel substrate under protection of inert gas at a high temperature to obtain the nickel substrate modified with Co3O4 nano wires; and (C) preparing a MOF mother liquid and vertically placing the modified nickel substrate thereinto, so that an organic metal framework compound (MOF), which is generated through coordination effect between an organic ligand and metal ions, is grown on the nickel substrate modified with the Co3O4 nano wires uniformly, thereby preparing a continuous compact MOF membrane. The invention provides a new preparation method of the metal organic framework membrane, wherein the method is simple in process. The MOF membrane is available in gas separation.

Owner:BEIJING UNIV OF TECH

Porous electrode material with three metal Cu-Co-Mo/foamed nickel and preparation method and application of porous electrode material

ActiveCN108796535AImprove bindingImprove corrosion resistanceElectrode shape/formsSolventPorous electrode

The invention discloses a porous electrode material with three metal Cu-Co-Mo / foamed nickel and a preparation method and application of the porous electrode material. The method includes the steps that (1) greasy dirt and an oxide layer on the surface of foamed nickel are removed through an organic solution and acid; (2) a copper-cobalt-molybdenum salt compound precursor and the foamed nickel areput in an autoclave for sealed reaction, then washing and drying are performed, and foamed nickel of which the surface is grown with a hydro-thermal synthetic product; and (3) the foamed nickel obtained in the step (2) is subjected to high-temperature calcination under the H2 atmosphere, then natural cooling is performed, and a porous electrolysed water catalyst with the three metal Cu-Co-Mo / foamed nickel. The binding force between the three metal alloy and the substrate nickel in the composite material is high, the properties are stable under the alkaline conditions, the electrochemical active area is large, and the catalytic activity of the material is greatly improved; and through the preparation method, combination of the three metals with the foamed nickel substrate is achieved through a solvothermal method, the preparation is simple, the sintering temperature is low, the energy consumption during preparation is low, and the industrial production is facilitated.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

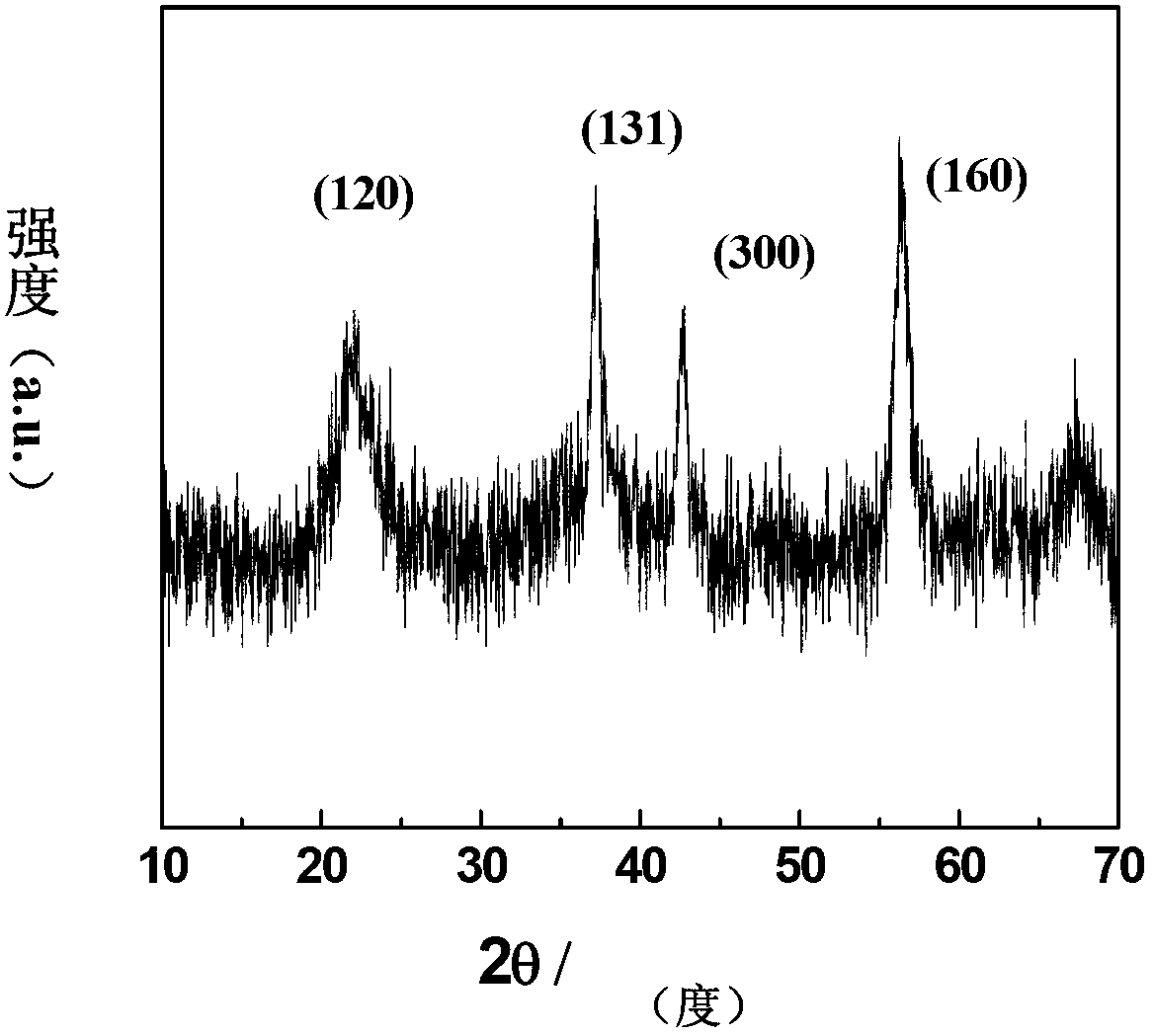

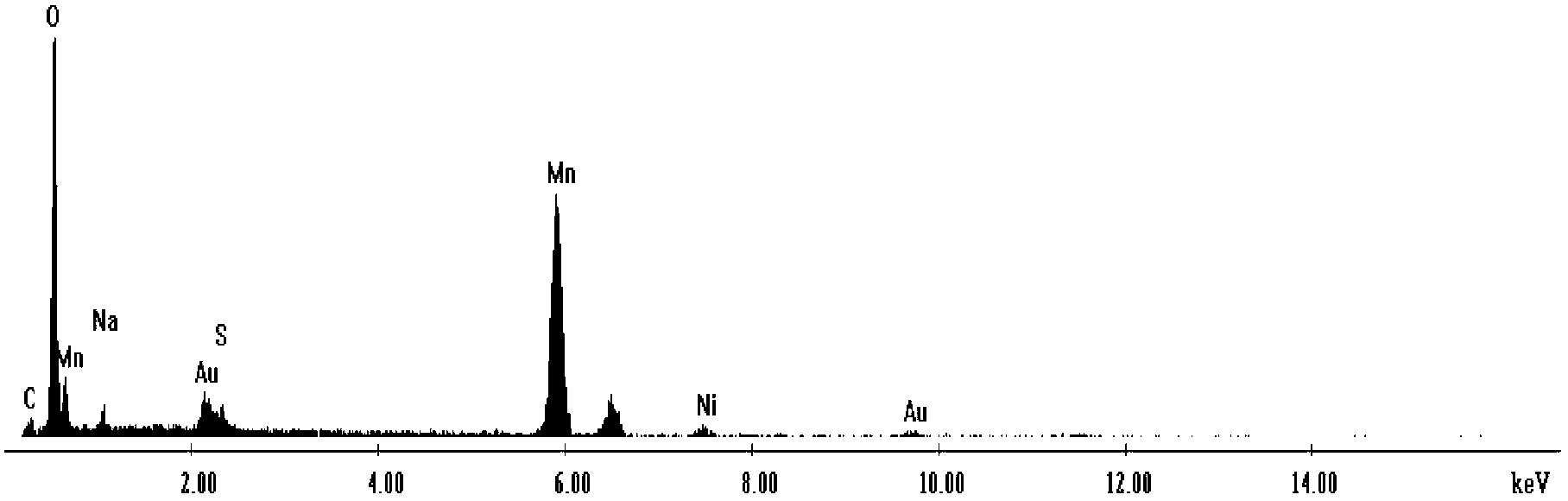

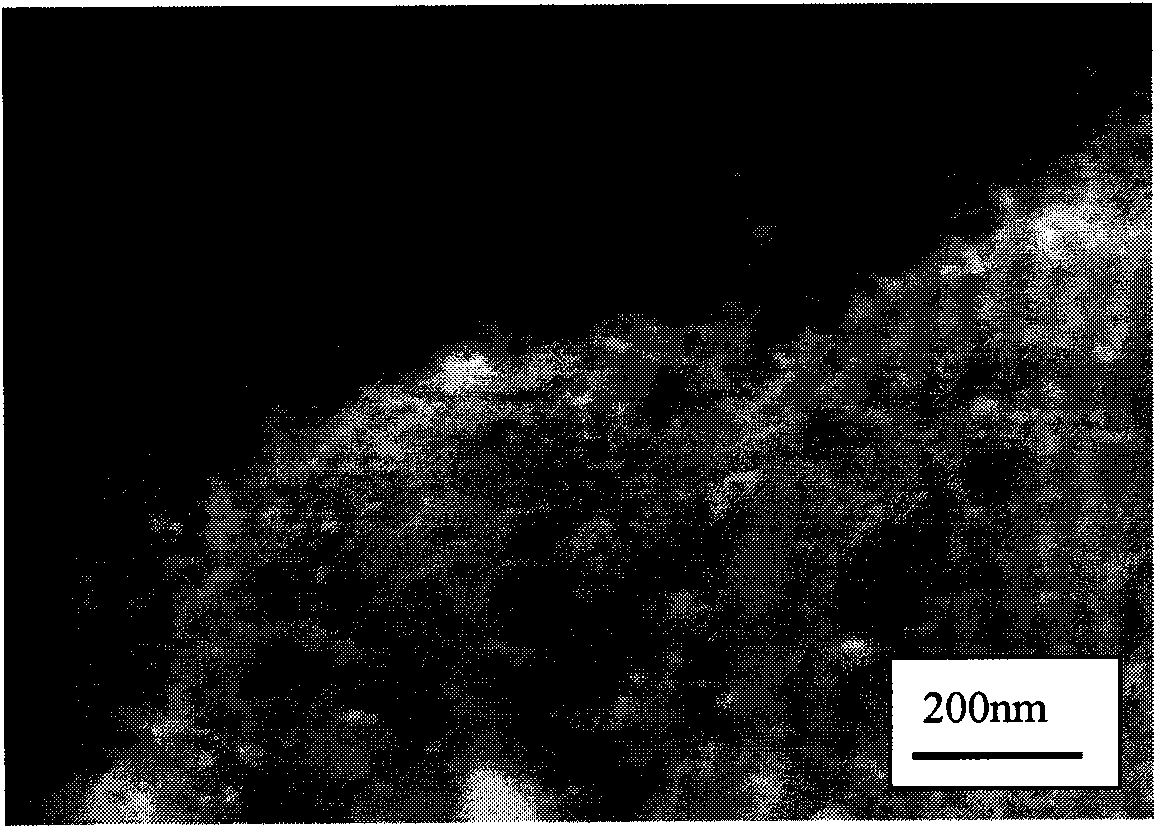

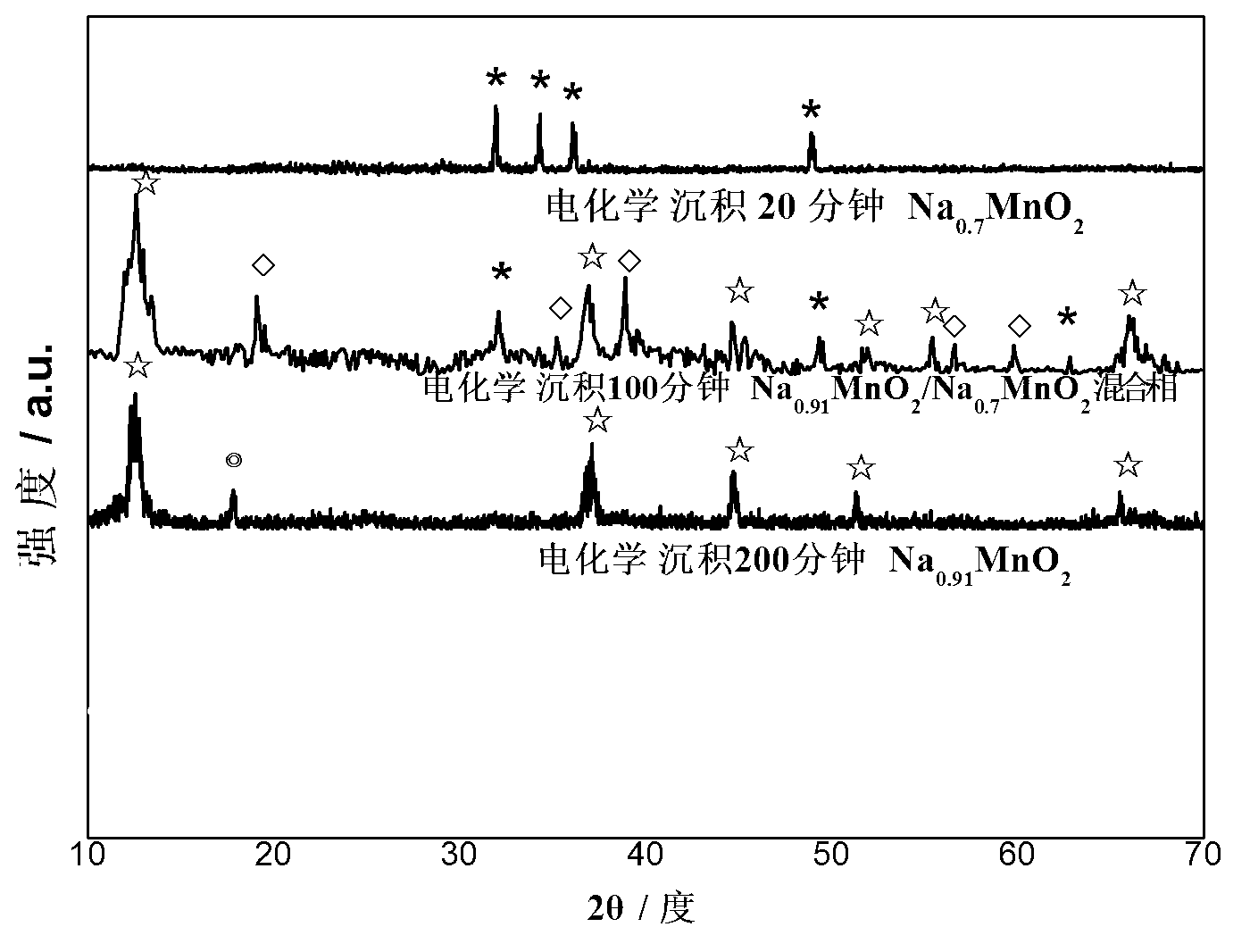

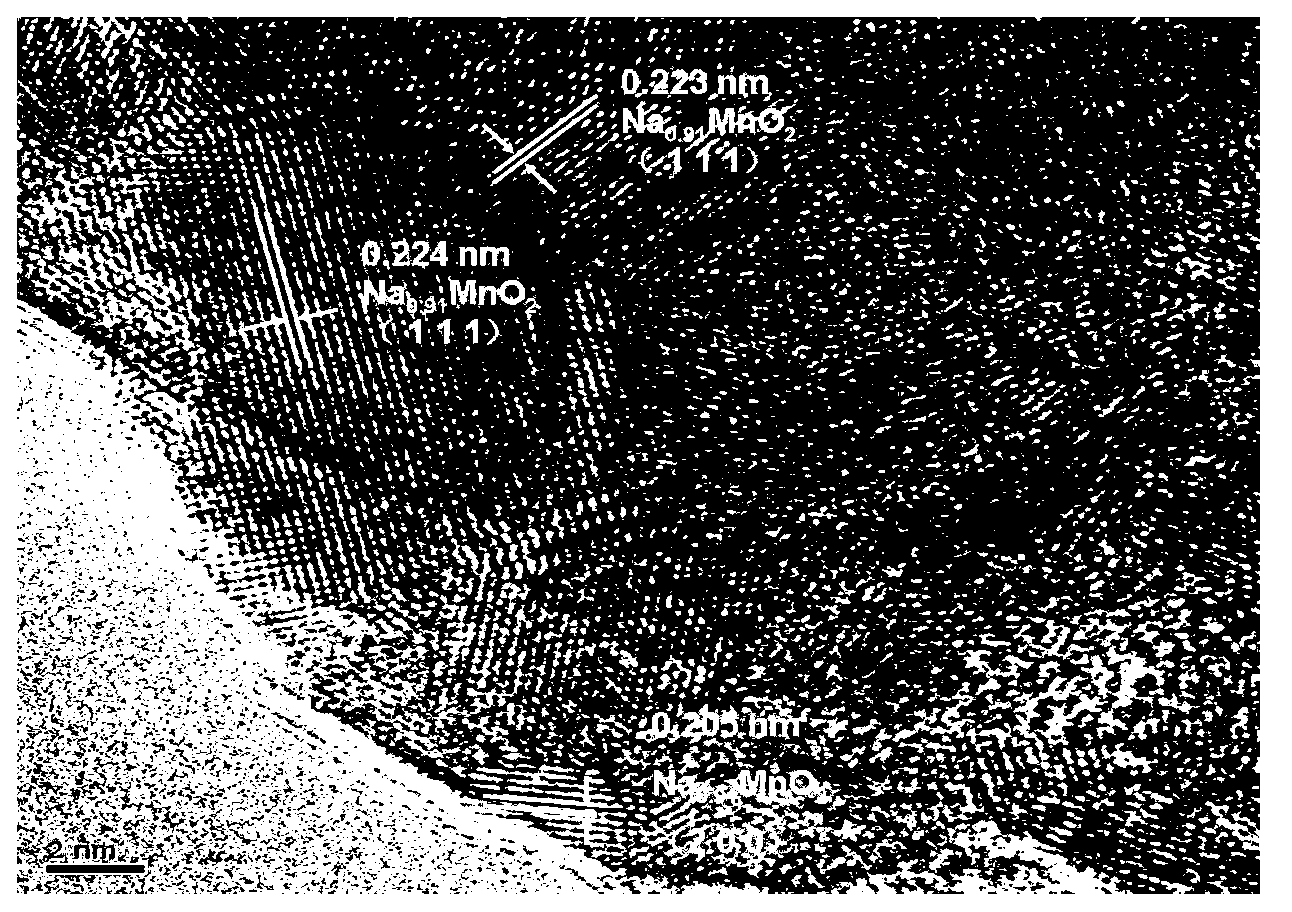

Sodion-embedded manganese dioxide nanometer sheet electrode as well as preparation method and application of electrode

ActiveCN103065806AImprove conductivityEnsure structural stabilityHybrid capacitor electrodesHybrid/EDL manufactureMANGANESE ACETATEStopped work

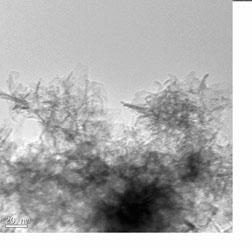

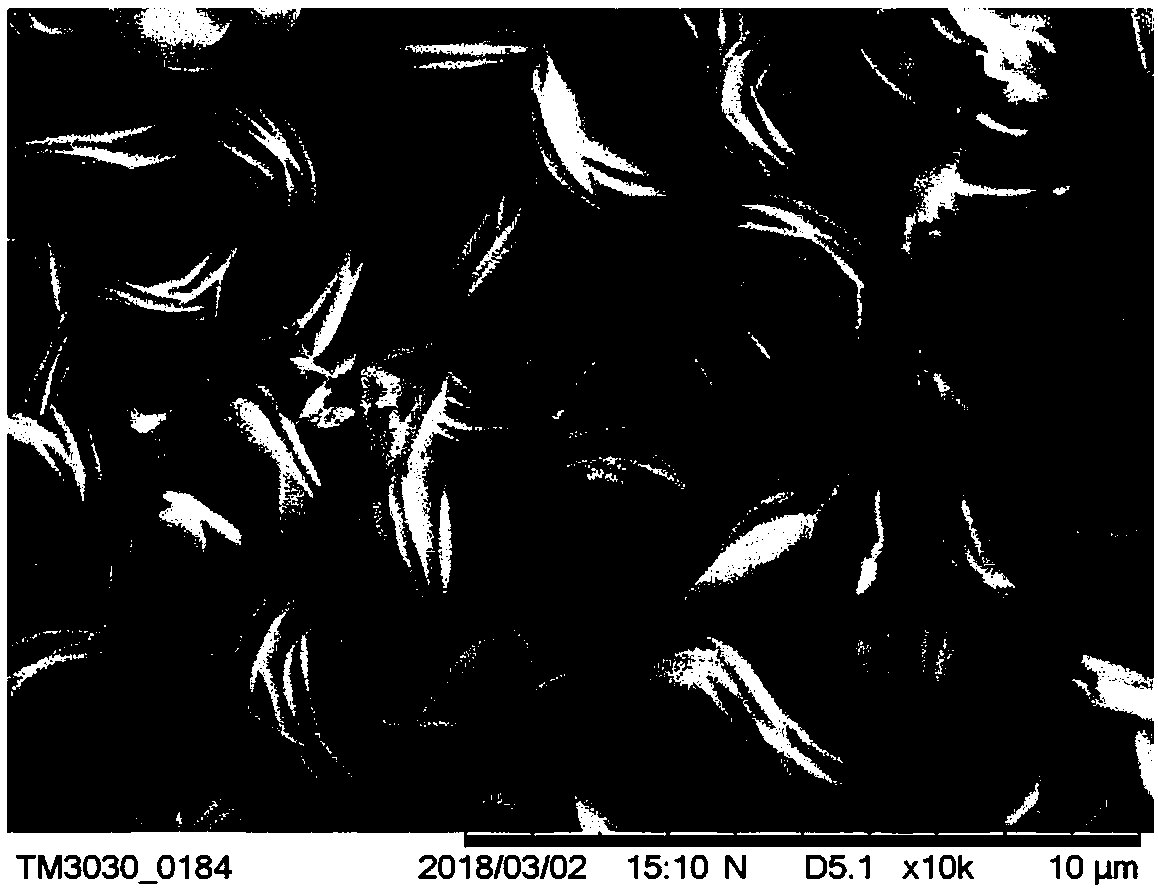

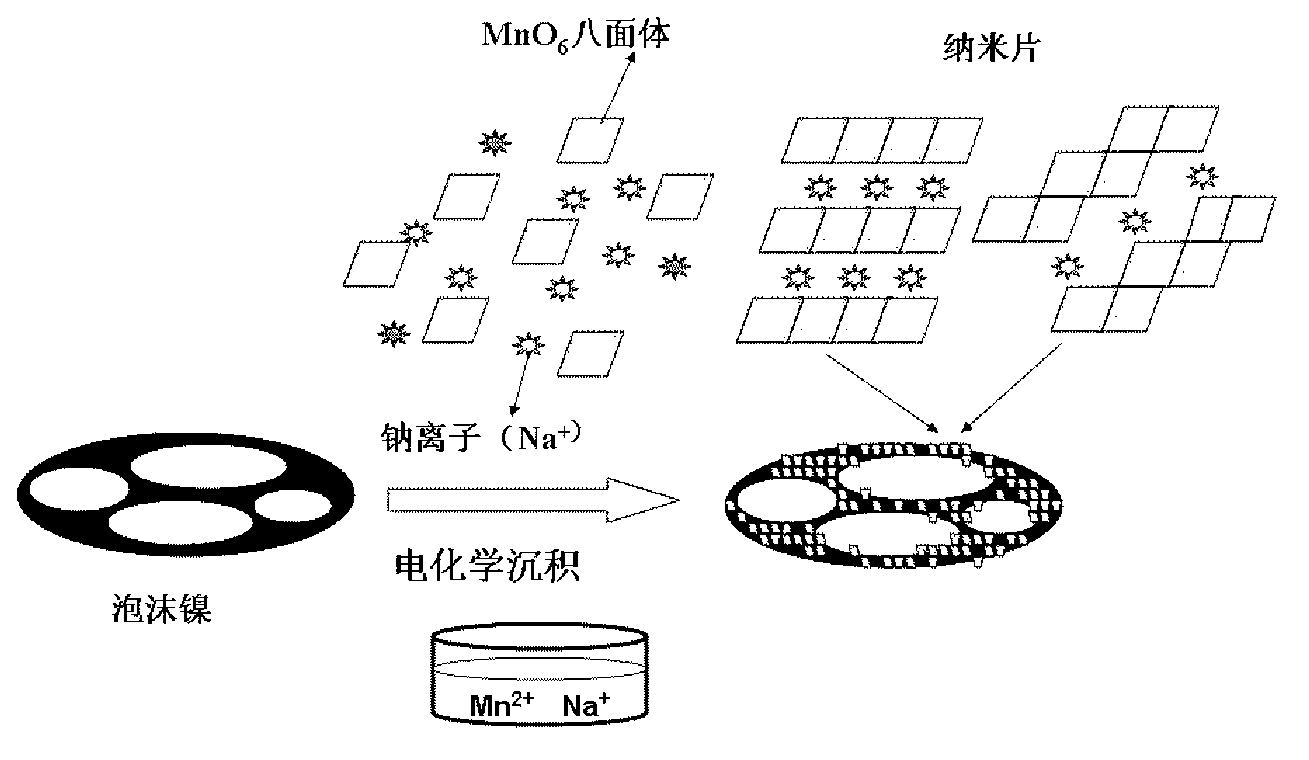

The invention relates to a sodion-embedded manganese dioxide nanometer sheet electrode as well as a preparation method and an application of the electrode. The electrode can be used as the active material of a supercapacitor and comprises sodion-embedded manganese dioxide nanometer sheets evenly distributed on the surface of a foamed nickel substrate. The preparation method comprises the following steps of: (1) mixing sodium sulfate and manganese acetate to prepare an electrochemical deposition precursor solution; (2) setting up an electrochemical deposition platform through a three-electrode method and taking the foamed nickel substrate after pretreatment as a working electrode, a platinum electrode as a counter electrode and a saturated calomel electrode as a reference electrode; (3) soaking the electrodes in the electrochemical deposition precursor solution at same depth; (4) opening an electrochemical workstation, setting the working electrode to the anode, setting the working mode to a timing potential mode, and starting up the electrochemical workstation; (5) taking out and washing the working electrode after the electrochemical workstation stops working; and (6) drying to obtain the sodion-embedded manganese dioxide nanometer sheet electrode. The sodion-embedded manganese dioxide nanometer film electrode as well as the preparation method and the application of the electrode disclosed by the invention have the characteristics of simple technique, mild reaction condition and excellent electrochemical performance of materials.

Owner:WUHAN UNIV OF TECH

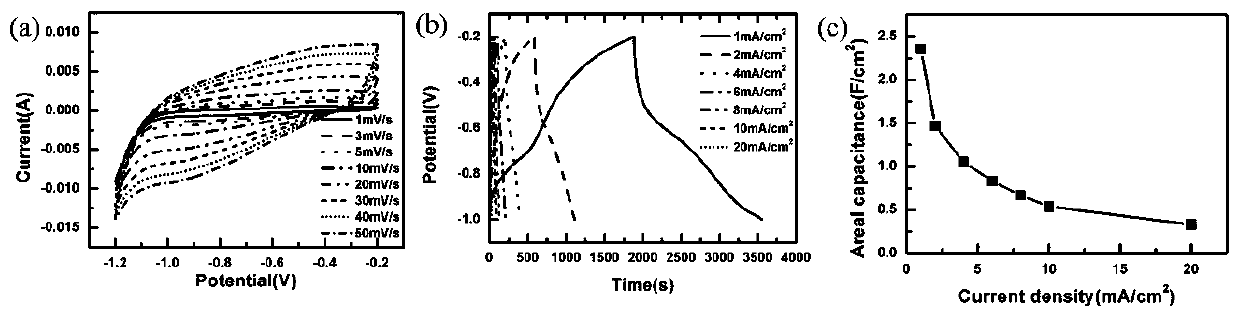

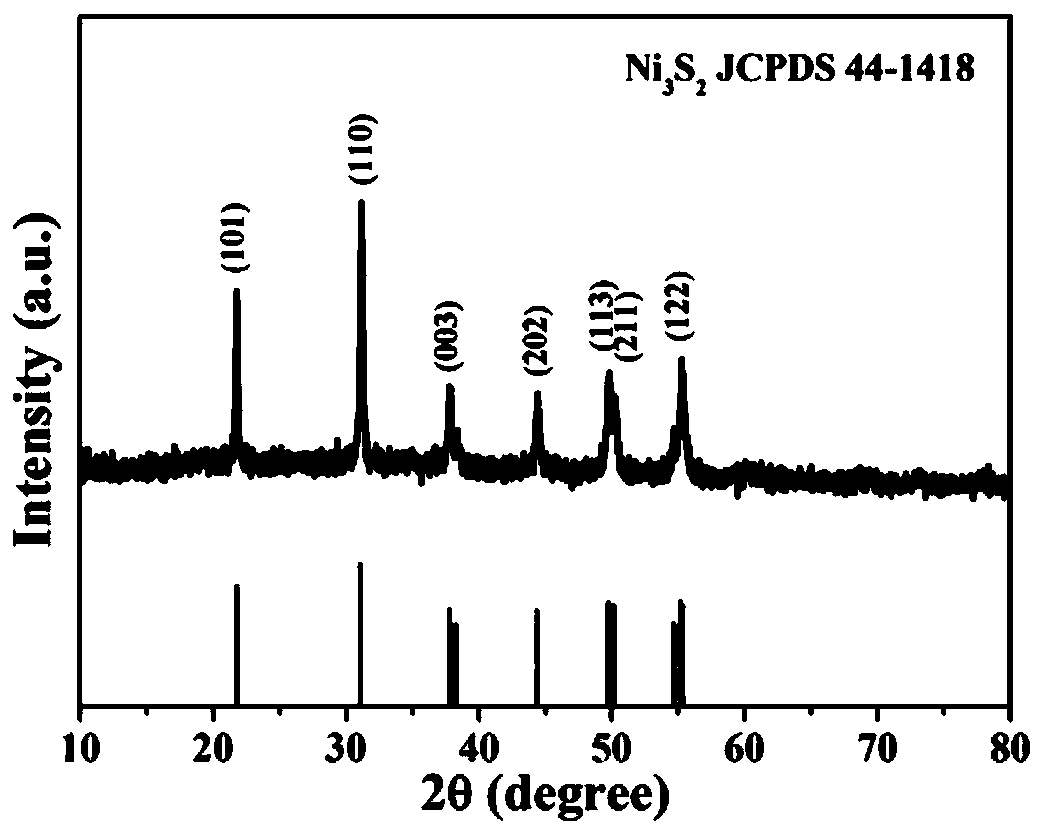

Preparation method of porous nanometer trinickel disulfide film electrode

ActiveCN106683905AIncrease capacityExcellent rate performanceHybrid capacitor electrodesHybrid/EDL manufactureHigh rateThiourea

The present invention discloses a trinickel disulfide film electrode directly grown on a foam nickel substrate and a preparation method thereof. The foam nickel is used as the substrate and a nickel source, thiourea is used as a vulcanizing agent, and glycol is used as a solvent. The trinickel disulfide film electrode directly grown on a surface of the foam nickel is obtained through a simple solvent thermal method. The preparation method has the advantages of simple process and low costs, and is applicable to large-scale industrial production. The present invention further discloses application of the trinickel disulfide electrode. The trinickel disulfide film electrode has a porous nanometer structure, so that a material and an electrolyte can contact fully. The trinickel disulfide grows on the nickel source, that is, the foam nickel, and is firmly combined with the substrate, so that the electric charge can be transferred rapidly. The prepared trinickel disulfide has high rate performance and excellent circulation stability, and is an ideal super capacitor electrode material.

Owner:CHINA THREE GORGES UNIV

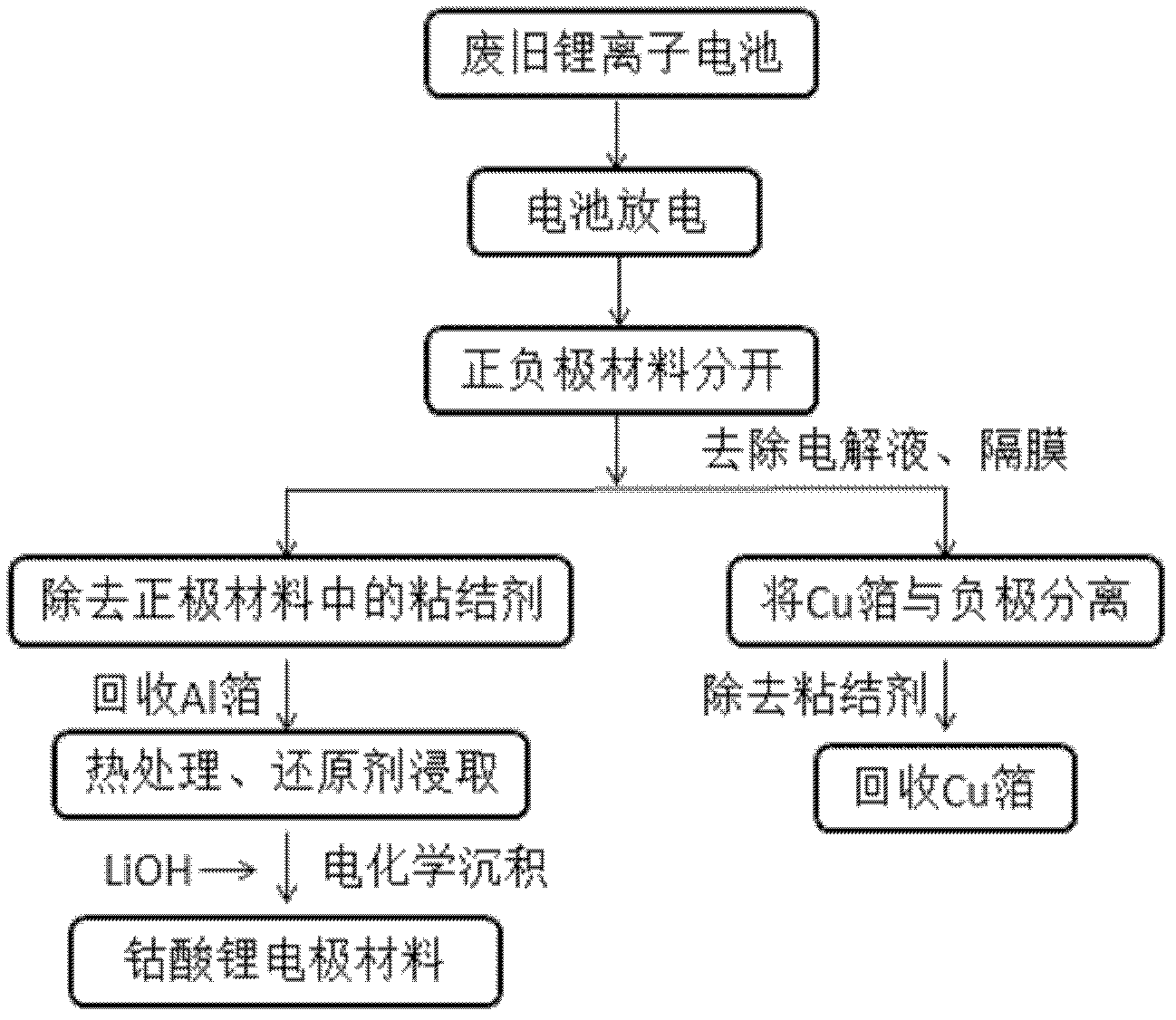

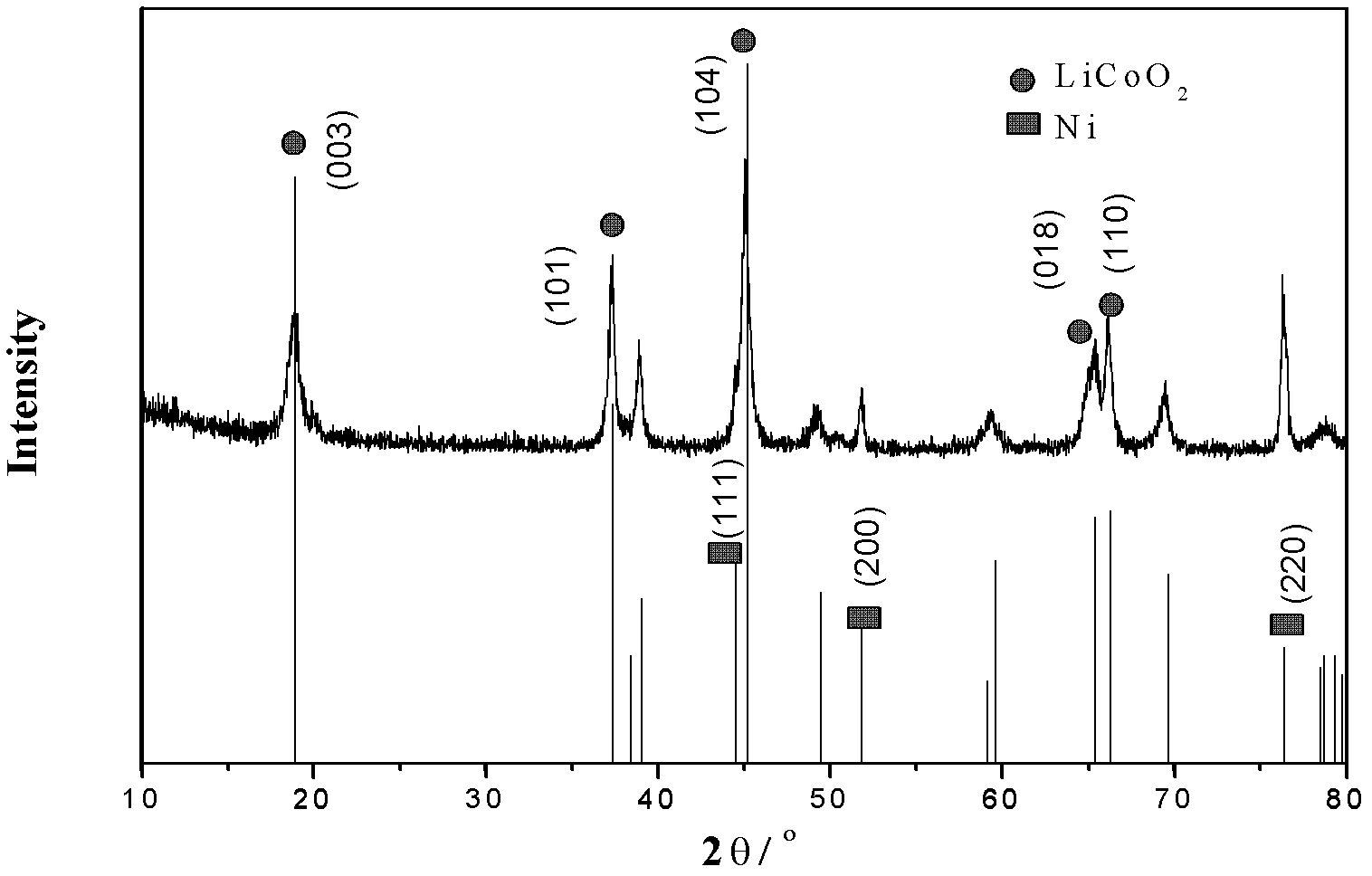

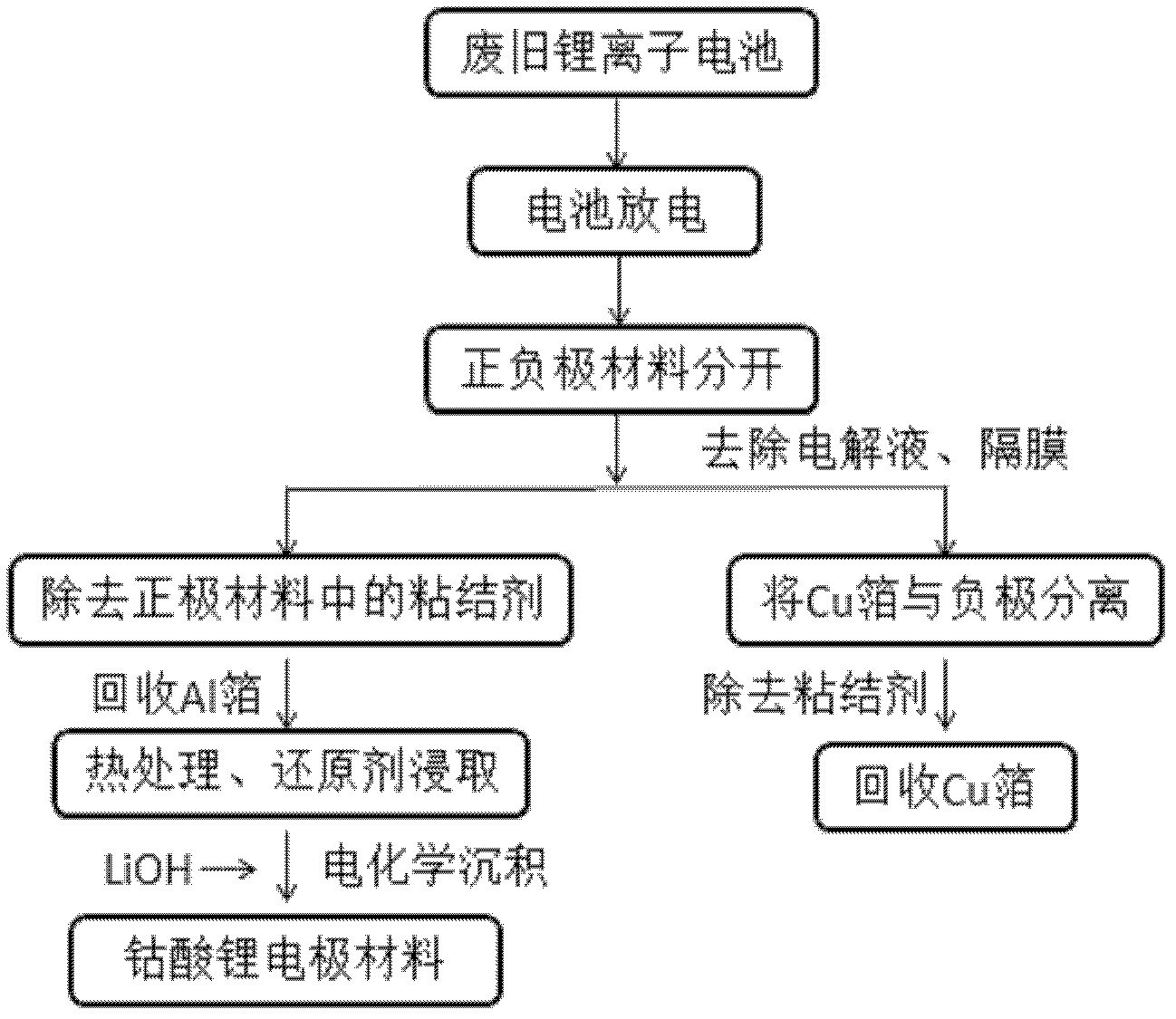

Method for recovering and regenerating positive electrode material of lithium ion battery

ActiveCN102382987ACause secondary pollutionReduce energy consumptionElectrolysis componentsWaste accumulators reclaimingFiltrationDecomposition

The invention relates to a method for recovering and regenerating a positive electrode material of a lithium ion battery and belongs to the technical field of recovery and circulating reuse of an electrode material. The method comprises the following steps: successively carrying out discharge, decomposition, an NMP (N-methyl-2-pyrrolidone) ultrasonic treatment and dissolution, filtration and firing on a waste lithium ion battery to obtain black solid powder; carrying out acid leaching on the black solid powder, and filtering to obtain a leachate solution containing Co<2+> and Li<1+>; and mixing the leachate solution with a LiOH solution to obtain electrolyte, stirring and reacting for 3-18 hours by using an electrochemical deposition technology at the constant current density of 5.0-9.0mA / cm<2> and the temperature of 30-90 DEG C, and directly synthesizing on a nickel substrate to obtain the regenerated lithium cobalt oxide positive electrode material, namely a regenerated positive electrode material of the lithium ion battery. By using the method, the recovery and regeneration of the lithium cobalt oxide positive electrode material of the waste lithium ion battery are realized; and the method has the advantages of low energy consumption, simple preparation process, short treatment period, obvious effect and no secondary environment pollution.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

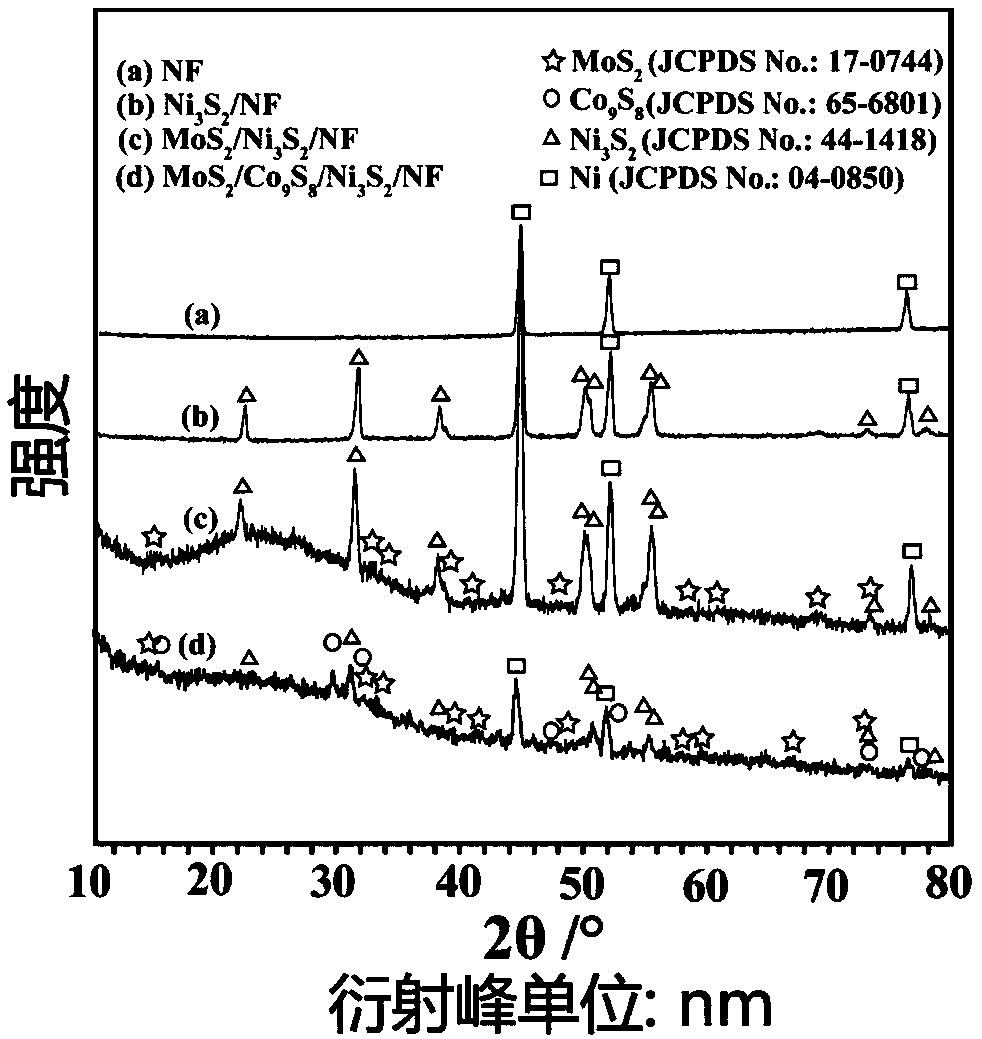

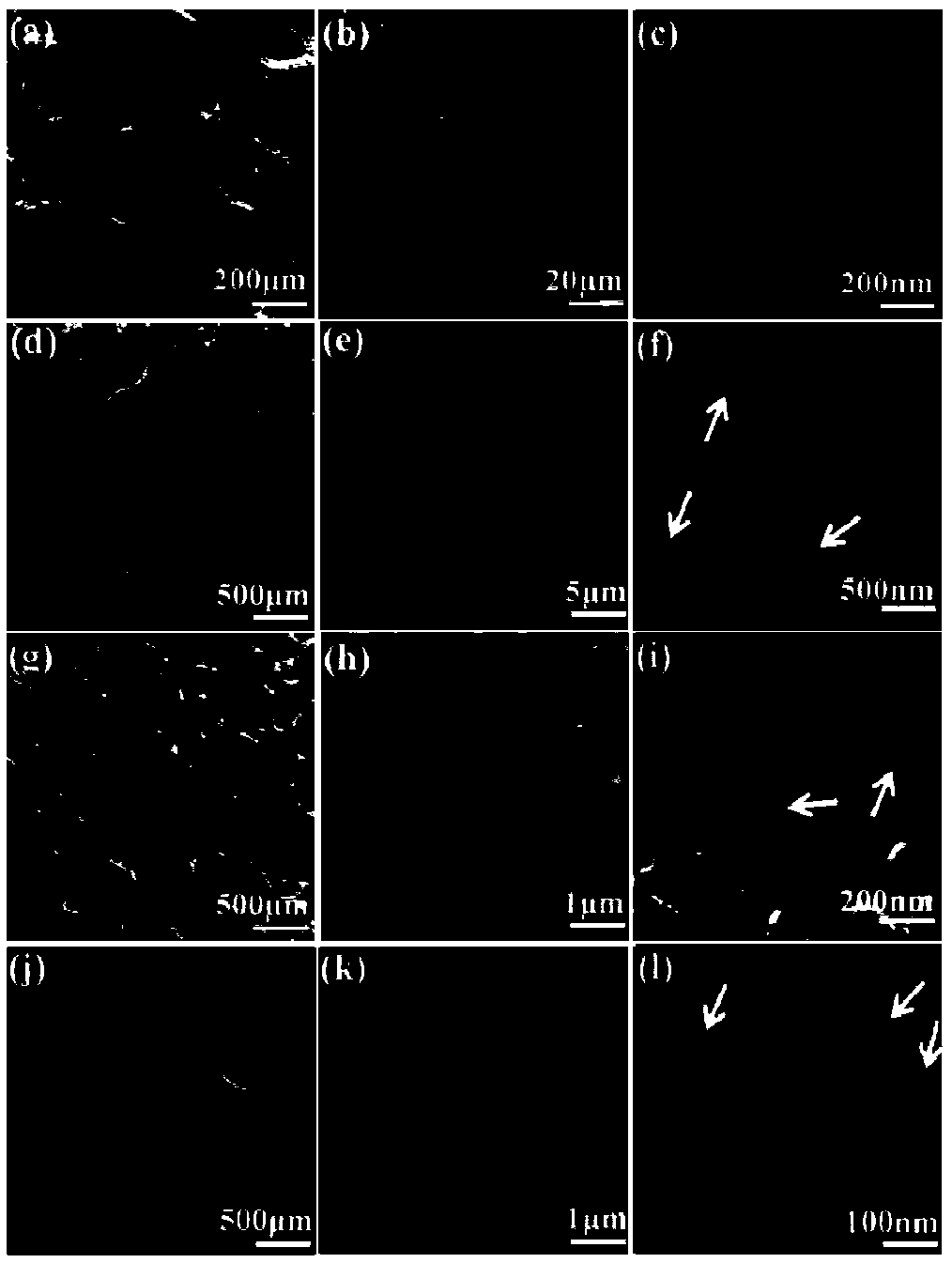

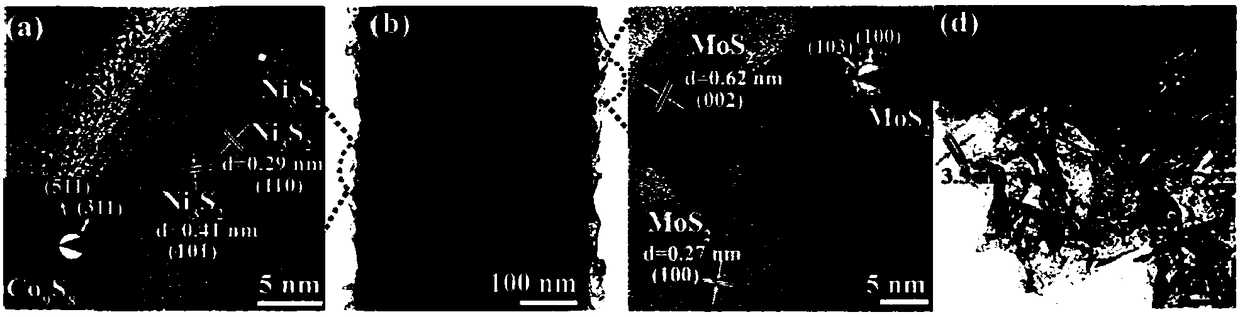

Nano-rod array composite material as well as preparation method and application thereof

ActiveCN108816250AMore exposureLarge specific surface areaPhysical/chemical process catalystsElectrodesNickel substrateActive site

The embodiment of the invention provides a Co9S8 / MoS2 / Ni3S2 / NF nano-rod array composite material which is characterized in that foamed nickel is taken as a substrate and is partially vulcanized to form a Ni3S2 nano-rod, and the Ni3S2 nano-rod is arranged to grow on the foamed nickel substrate; Co9S8 and MoS2 respectively grow on the Ni3S2 nano-rod in the form of ultra-thin nano-sheets. The Co9S8 / MoS2 / Ni3S2 / NF nano-rod array composite material provided by the invention can simultaneously catalyze the OER and HER reaction and is a bifunctional catalyst; as the material is assembled by the ultra-thin nano-sheets, the material has large specific surface area and multiple exposed active sites; meanwhile, the foamed nickel with good electrical conductivity is introduced as the substrate, so thathe electrical conductivity is good, and the catalytic activity is high; the composite material is synthesized by a one-step hydrothermal process and is simple and convenient to operate.

Owner:BEIJING NORMAL UNIVERSITY +1

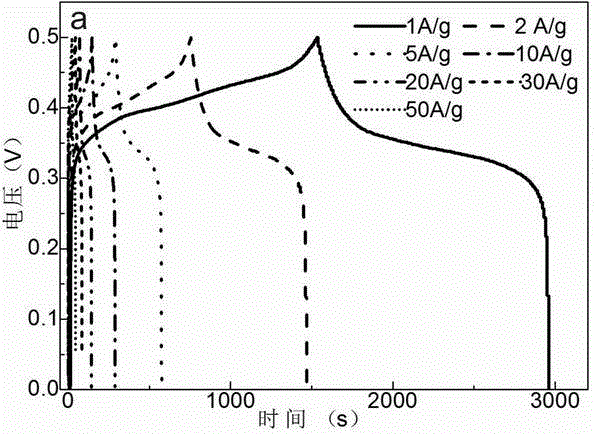

Preparation method of cobalt-based bimetallic sulfide negative electrode material and application thereof

ActiveCN109686594AAvoid impuritiesFast transferHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNickel substrate

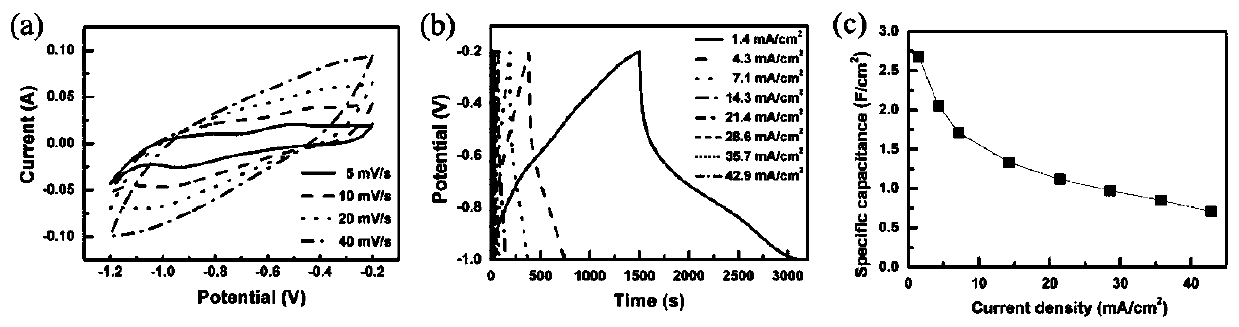

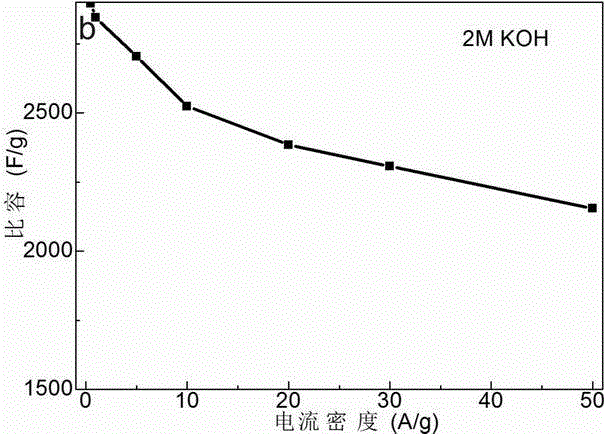

The invention discloses a preparation method of a cobalt-based bimetallic sulfide negative electrode material (M-Co-S, M = Ni, Fe, Mo, Bi, Zn) and application of the cobalt-based bimetallic sulfide negative electrode material in a water system supercapacitor. Foamed nickel with graphene on the surface is used as a substrate, cobalt salt is used as a cobalt source, M salt is used as an M source, ammonium fluoride and hexamethyltetramine are used as precipitators, sodium sulfide is used as a vulcanizing agent, an M-Co-S film is obtained through a two-step hydrothermal method, and the M-Co-S is uniformly coated on the surface of the foamed nickel substrate with the graphene. The prepared M-Co-S material is assembled into a three-electrode system, electrochemical performance evaluation is conducted in a 1M KOH electrolyte, the maximum specific capacitance of the M-Co-S material is up to 2.6 F / cm<2> (1625 F / g) and higher than that of common negative electrode materials, and the M-Co-S is asupercapacitor negative electrode material with great application prospects.

Owner:CHINA THREE GORGES UNIV

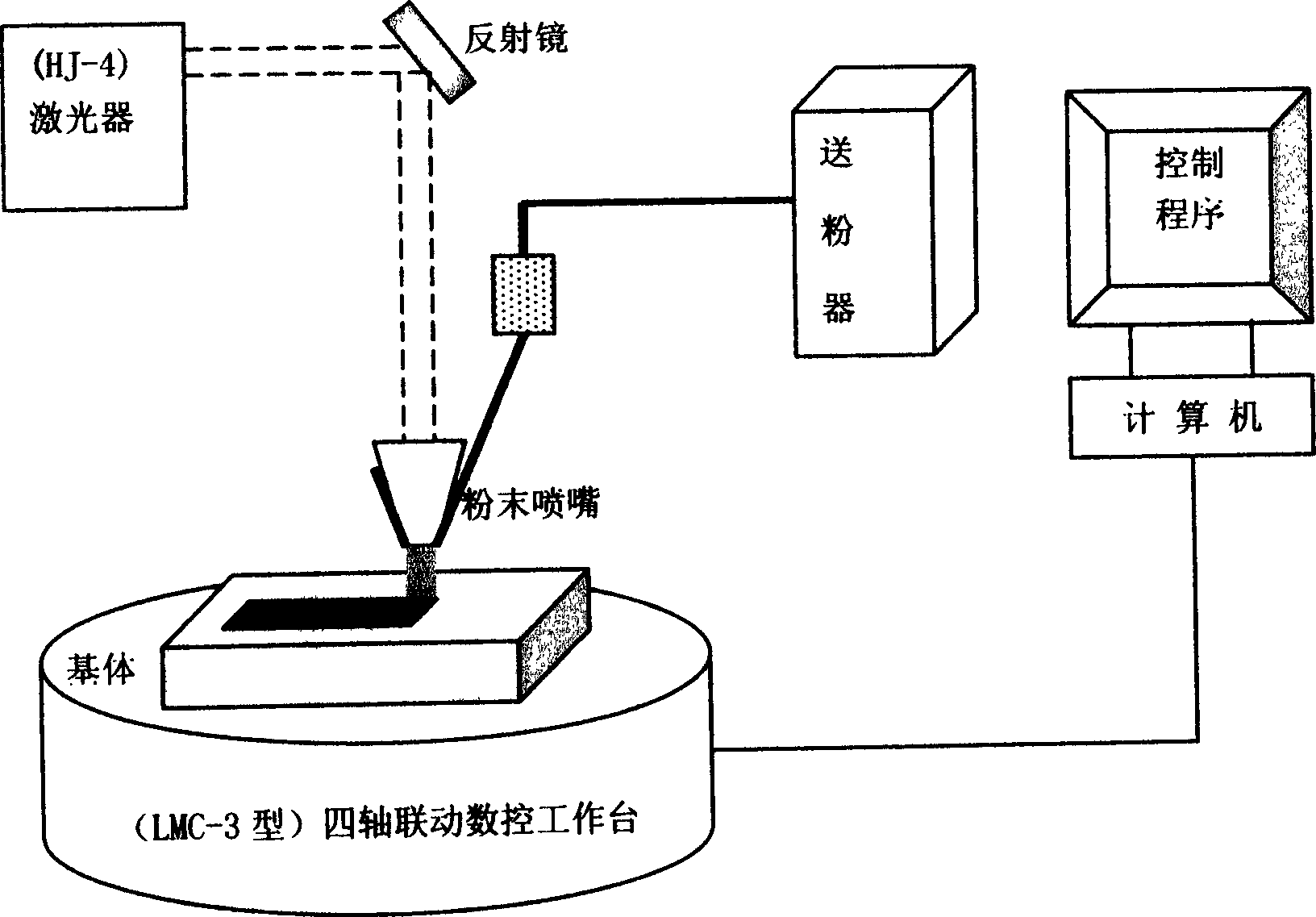

Ni-base alloy powder laser melt-cladding sinter forming method

Owner:BEIJING AVIATION MFG ENG INST CHINA AVIATION NO 1 GRP +1

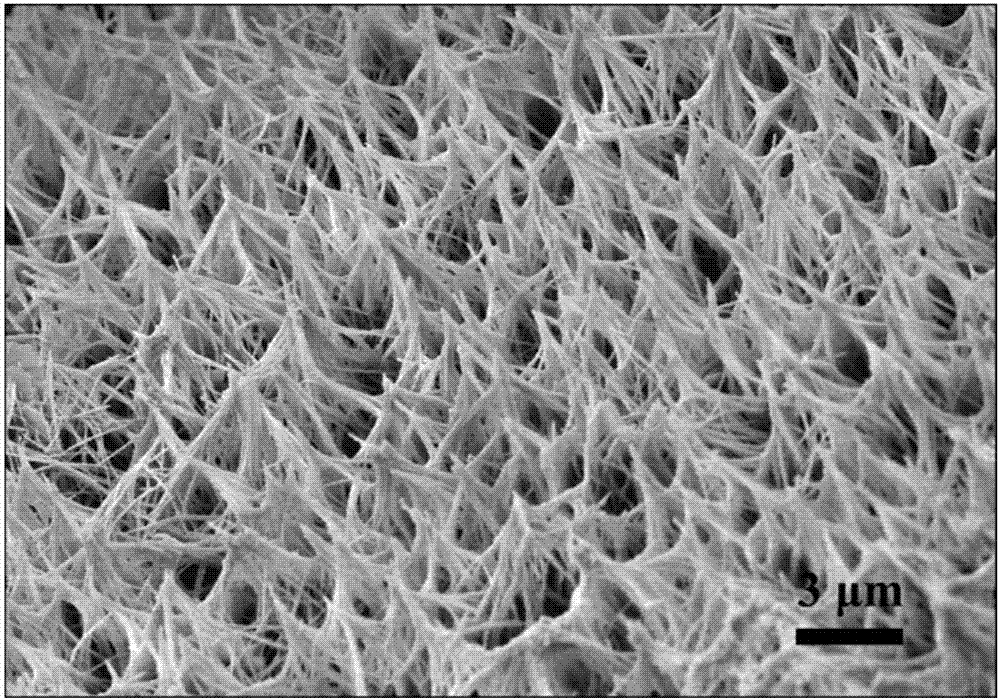

Sulphur vacancy richened Ni3S2 nanorod oxygen evolution electro-catalysis material and preparing method and application thereof

InactiveCN108677207AImprove conductivityHigh catalytic activityMaterial nanotechnologyAnodisationElectrolysisNickel substrate

The invention discloses a sulphur vacancy richened Ni3S2 nanorod oxygen evolution electro-catalysis material and a preparing method and application thereof, and belongs to the field of electrolytic water catalysis. The preparing method comprises three steps that firstly, a precursor film layer is prepared through anodic oxidation treatment of a nickel sheet; secondly, the precursor film layer is subjected to annealing treatment to obtain oxygen vacancy richened NiO film layer; and finally, the film layer obtained after annealing is subjected to hydrothermal sulfidizing to obtain the sulphur vacancy richened Ni3S2 nanorod oxygen evolution electro-catalysis material. As the existence of the sulphur vacancy, energy barriers needing to be overcome by a midbody on adsorption or desorption on the catalyst surface are reduced, and the oxygen evolution catalytic performance is greatly improved. Sulphur vacancy richened Ni3S2 nanorods grow on a nickel substrate in situ, the resistance between acatalyst and the substrate is reduced, and meanwhile, the oxygen evolution catalyzing stability is improved. The method is simple in operation, the requirement for preparing equipment is low, the material is environment-friendly, the preparing method has generalizability, and the development and application of the transition metal sulfide catalyst are further promoted.

Owner:SOUTH CHINA UNIV OF TECH

Nickel phosphide / graphene composite film preparing method

InactiveCN104810165AThe experimental method is simple and easy to controlEase of mass productionHybrid capacitor electrodesHybrid/EDL manufactureComposite filmNickel substrate

The invention discloses a nickel phosphide / graphene composite film preparing method. The method includes under the ultrasonic effect, dispersing graphene oxide and red phosphorus in deionized water to obtain dispersion, transferring dispersion to a hydrothermal reactor, soaking a metal nickel substrate (nickel foam, nickel plate or nickel mesh) into the dispersion, and carrying out hydrothermal reaction to obtain nickel phosphide / graphene composite film material. The preparing method is simple and easy to implement, the reaction conditions are mild, material cost is low, and large-scale production and utilization are facilitated.

Owner:EAST CHINA UNIV OF SCI & TECH

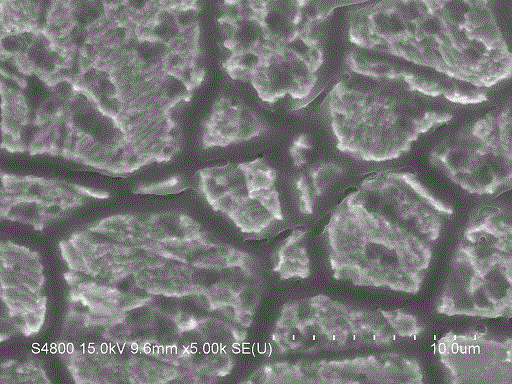

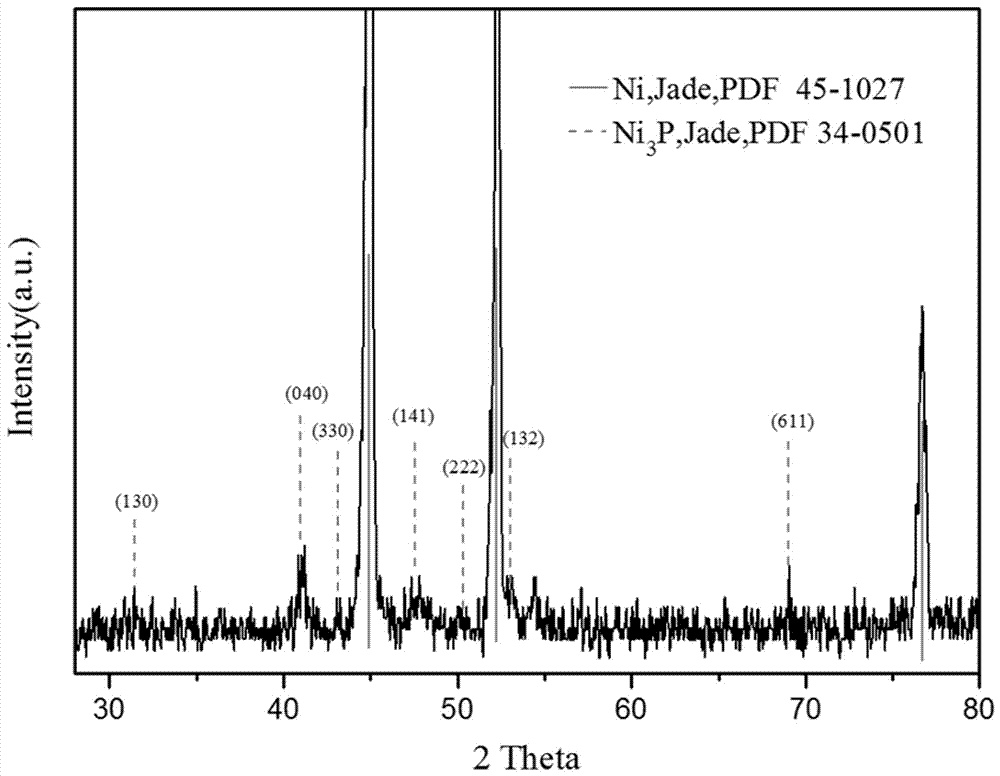

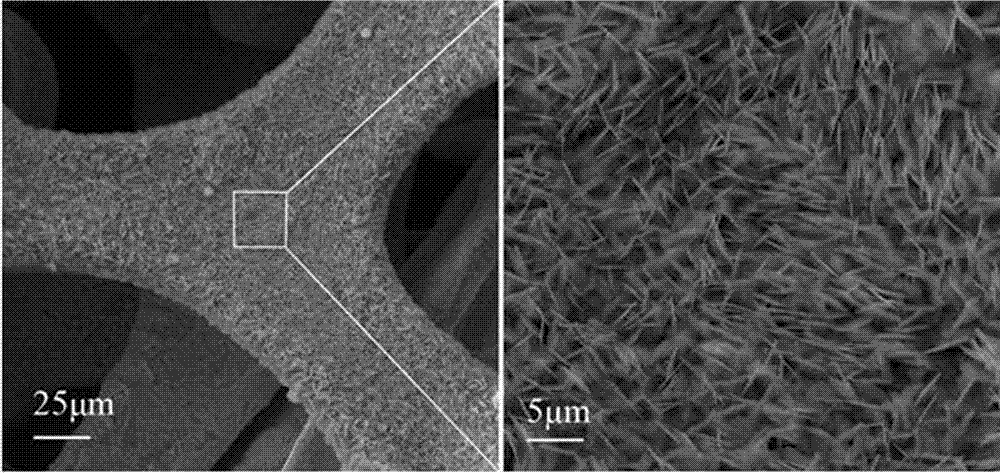

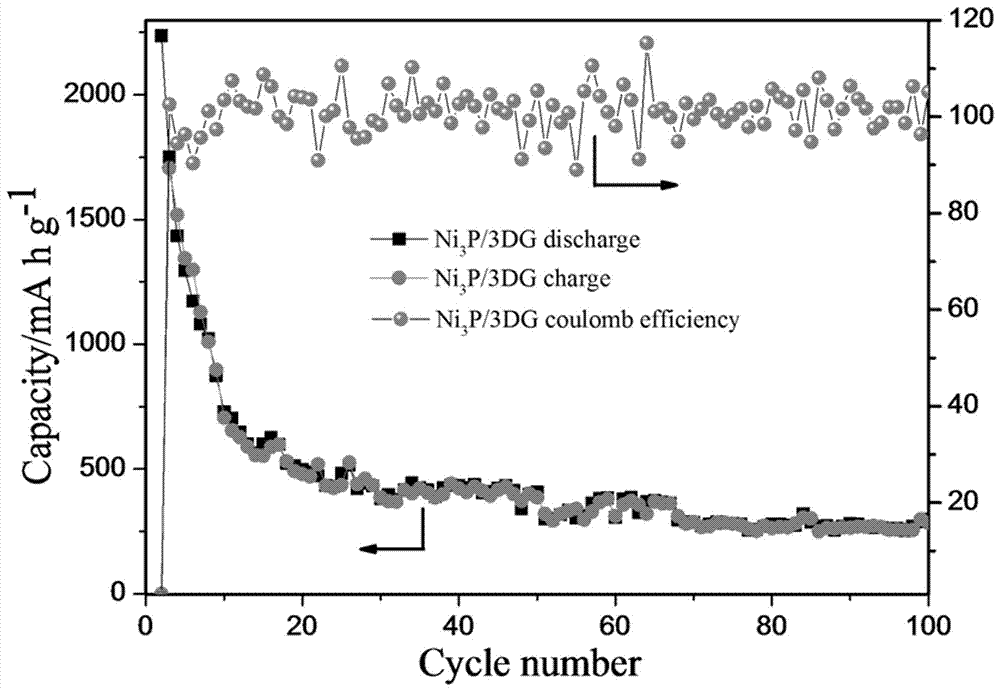

Sodium ion battery nanosheet array nickel phosphide/three-dimensional (3D) graphene composite material and preparation method thereof

ActiveCN107331851AImprove cycle stabilityImproved magnification performanceMaterial nanotechnologyCell electrodesSodium-ion batteryInorganic phosphorus

The invention discloses a sodium ion battery nanosheet array nickel phosphide / three-dimensional (3D) graphene composite material and a preparation method thereof. The preparation method comprises the steps of preparing 3D graphene by using foam nickel and a chemical vapor deposition (CVD) method, enabling the 3D graphene and deionized water having a pH value of 3 to be subjected to a hydrothermal reaction, and generating an Ni(OH)2 nanosheet array structure on a foam nickel substrate loaded with the 3D graphene; respectively placing nanosheet array Ni(OH)2 / 3D graphene composite material and a phosphorus source at the two ends of a tube furnace, heating the tube furnace, replenishing one end of the tube furnace, where the inorganic phosphorus source is placed, with flowing inert gas, and carrying out heat treatment; cooling the product of the reaction to room temperature to obtain the nanosheet array nickel phosphide / 3D graphene composite material. The whole preparation method provided by the invention is simple and environmentally-friendly; nickel phosphide is compounded with the 3D graphene, so that the material performance is improved; when the composite material is used as a self-supported sodium ion battery anode material, a conductive additive is not needed; the sodium ion battery nanosheet array nickel phosphide / 3D graphene composite material has high specific capacity and good rate performance, thus having a wide industrial application prospect.

Owner:TAIYUAN UNIV OF TECH

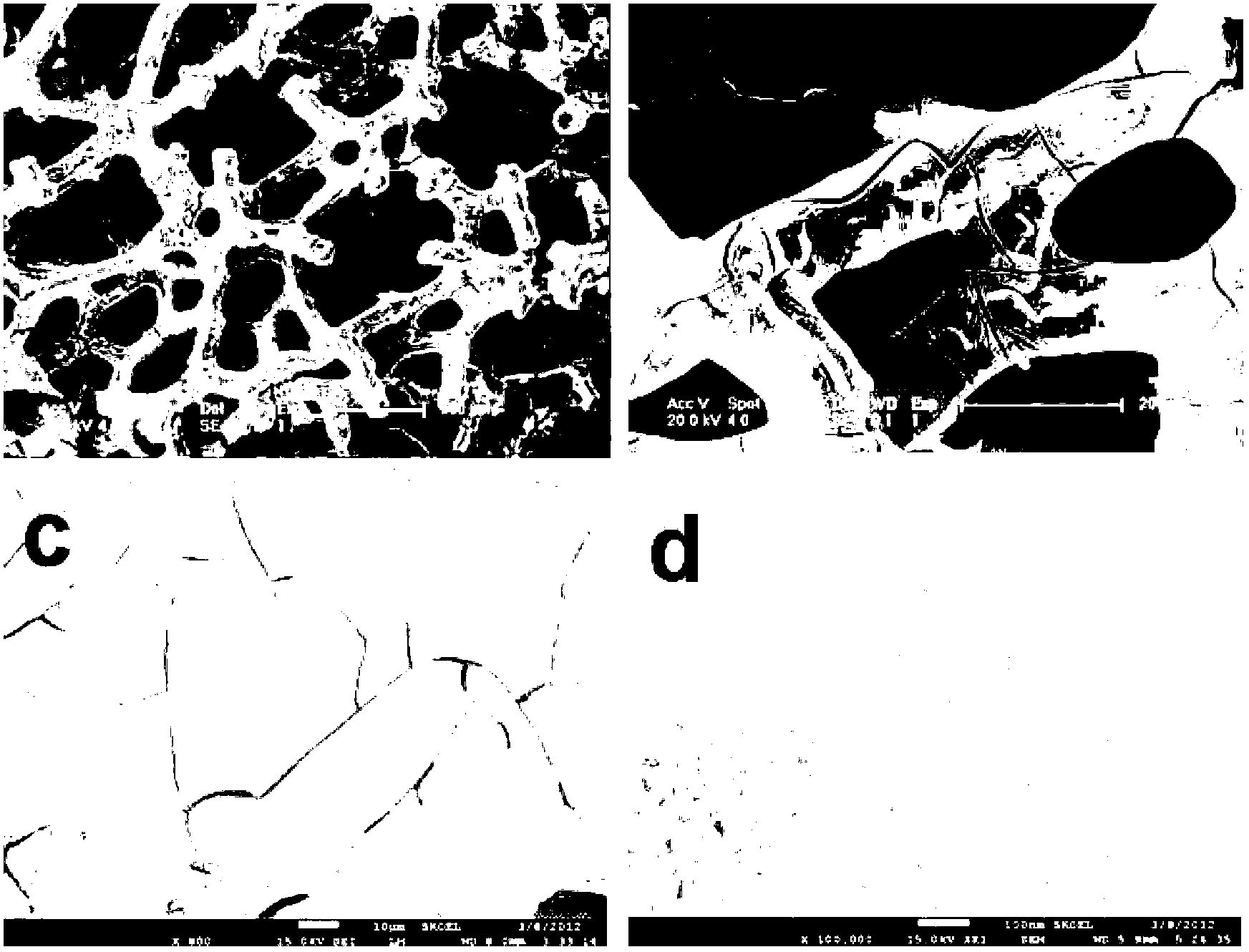

Preparation method of carbon nanotube by growing on foamed nickel substrate

InactiveCN103253648ASimple processSimple ingredientsMaterial nanotechnologyCarbon nanotubesCarbon nanotubeNitrogen gas

The invention discloses a preparation method of carbon nanotube by growing on a foamed nickel substrate. The method is a plasma chemical vapor deposition method. Nickelate containing Ni element is dissolved in 2-methoxyethanol firstly, a proper amount of ammoniacal liquor is added, after several hours of high speed stirring, a green transparent sol is obtained after sealing and standing. The sol is coated on the foam nickel substrate material. The foamed nickel substrate formed with sol is placed in the vacuum furnace chamber, when the temperature reaches to 500-600 DEG C., hydrogen and nitrogen according to a certain volume ratio which are used as catalyst for carbon nanotube growth are let in to reduce nickel element for keeping 10 minutes. When the temperature reaches to 700-800 DEG C., a carbon source gas is let in, and hydrogen and nitrogen are kept at a certain volume ratio, after 30 minutes reaction, the growth is finished. The carbon nanotube is grown on the foamed nickel. The method has a simple preparation technology process, and the product can be used as electrode material of green energy storage device.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Photocatalysis air purifying device

InactiveCN102078634AHigh load rateEfficient removalLighting and heating apparatusAir conditioning systemsAntibiosisNickel substrate

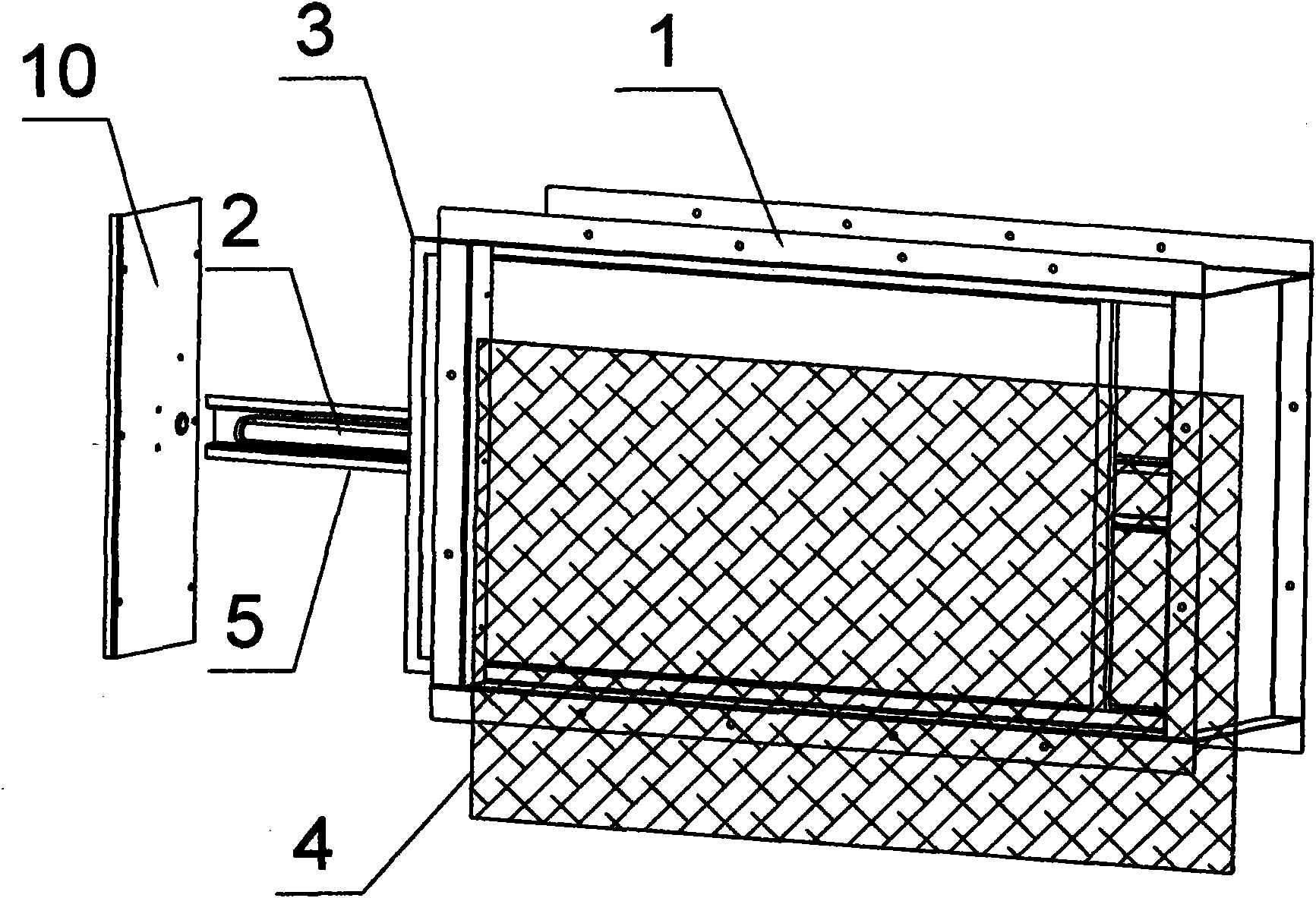

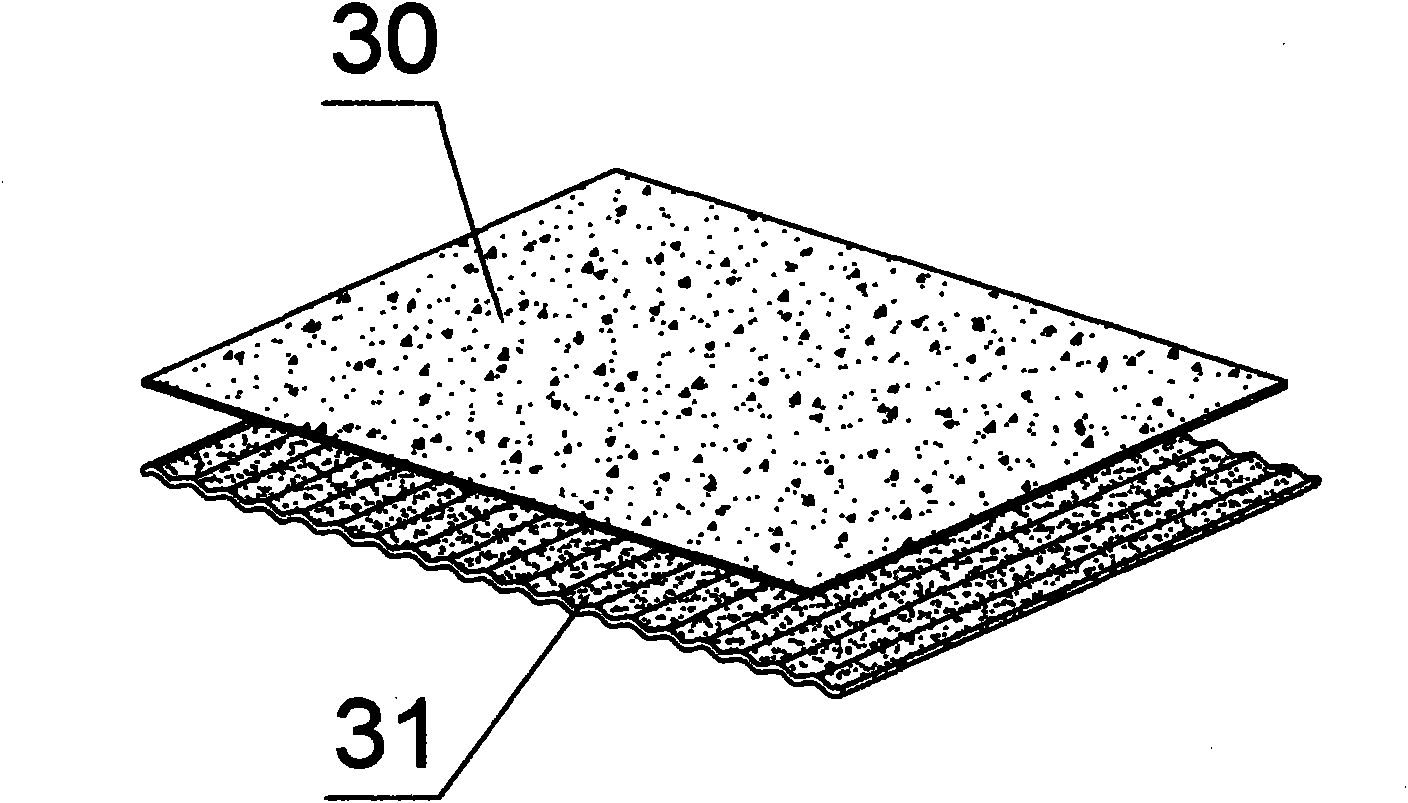

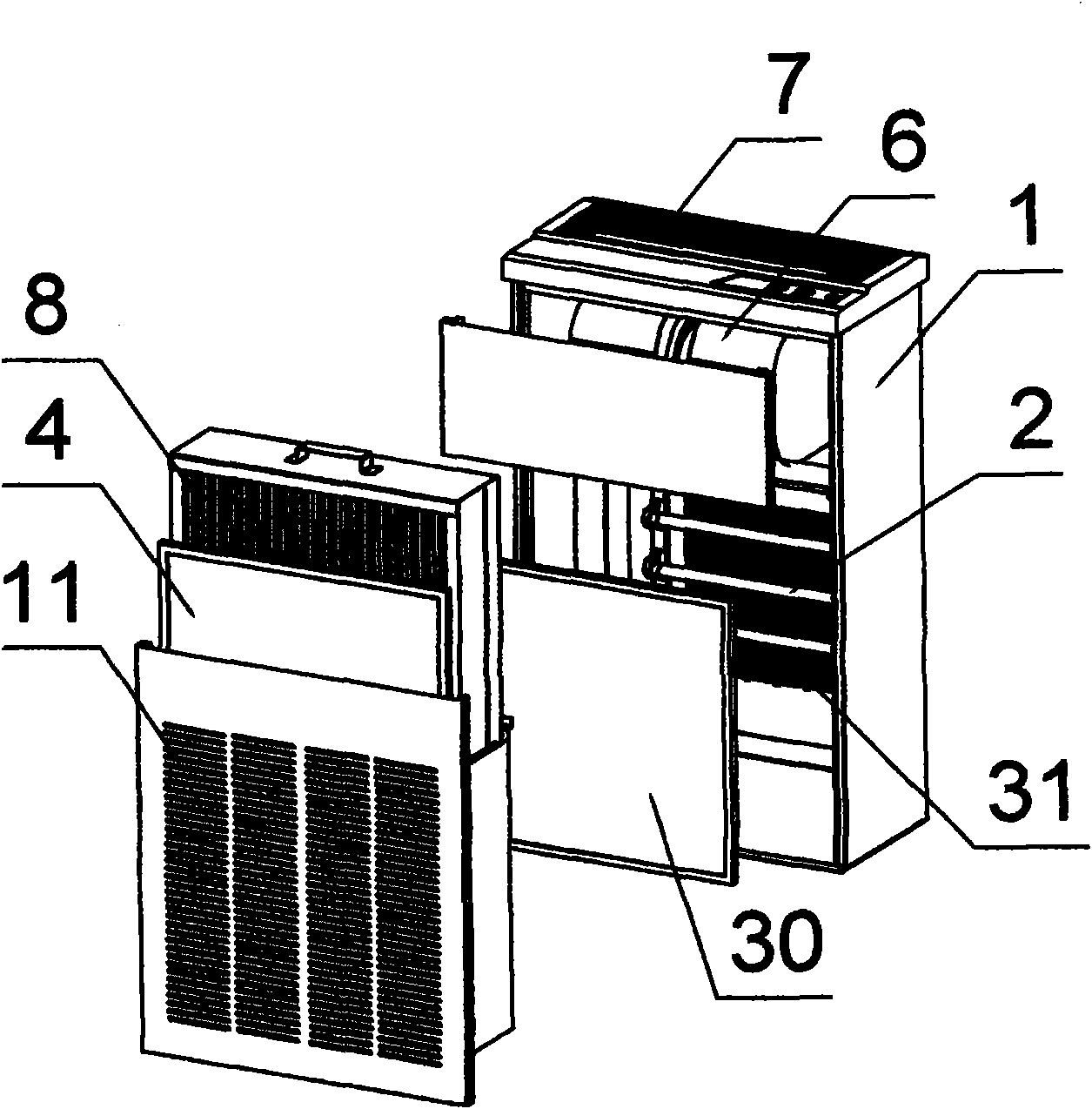

The invention relates to a photocatalysis air purifying device. The device comprises a frame (1) and an ultraviolet lamp tube (2) installed in the frame (1), wherein the frame (1) is provided with an airflow passageway with a cross-ventilation function. The device is characterized in that the frame (1) is internally provided with a titanium-nickel compounded photocatalysis net (3); the titanium-nickel compounded photocatalysis net (3) comprises a photocatalysis titanium net (30) and a photocatalysis nickel net (31); the titanium-nickel compounded photocatalysis net (3) is a compounded photocatalysis antibiosis foam metal net of a three-dimensional space structure and comprises a foam nickel substrate and TiO2 loaded on the surface of the foam nickel substrate; the air inlet of the airflow passageway of the frame (1) is provided with a dust filtering net (4); the outlet of the airflow passageway of the frame (1) is provided with strip bars (7) or a porous baffle; and a fan (6) is arranged in the frame (1) or at the rear part of the frame (1). By using the photocatalysis air purifying device of such structure, the effects of volatile organic compound (VOC) degradation, disinfection and sterilization are obvious.

Owner:潘华耿

Method for producing microelectromoulding metal mould

InactiveCN1715455AReduce internal stressGood side wall verticalityElectroforming processesMicro structureHigh surface

The microelectromolding metal mold making process belongs to the field of micro machine building technology. The microelectromolding metal mold making process includes the steps of: pre-treatment of mold base, making microelectromolding mother mold, microelectromolding, post-treatment and detection. The present invention adopts so-called 'no-back board growth process', in which micro structure pattern is electromolded directly on nickel substrate via ultraviolet irradiation on photoetching mask. During making microelectromolding mother mold, one seed layer is added between the SU-8 photoresist and the substrate; and in the post-treatment, vacuum annealing is adopted. The microelectromolding metal mold made in the method of the present invention has the merits of high side wall verticality and high surface smoothness. The present invention is suitable for fine machining of organic polymer, including plastic.

Owner:DALIAN UNIV OF TECH

Au/Co(OH)2 nano-array structured catalyst

ActiveCN104226330AGood electron transport propertiesImprove conversion rateOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsMacroscopic scaleGold particles

Belonging to the technical field of catalysis, the invention relates to an Au / Co(OH)2 nano-array structured catalyst. A rectangular flaky nano-array directly grows on a foamed nickel substrate, and the formed nano-material has a determined and ordered structure, and can realize a high specific surface area. The micron pieces on the foamed nickel substrate are connected with the macroscopic scale substrate and of nanoscale noble metal particles, thus ensuring enough adhesion and avoiding leaching in catalytic reaction. The average size of a single square nano-sheet is 1.5-micrometer wide, and the size of gold particles is 3-5nm. The catalyst can be effectively used for hydrogenation reduction reaction of p-nitrophenol, and the reaction rate is 30.8s<-1>g<-1>. The Au / Co(OH)2 nano-array structured catalyst also has excellent cycling stability, basically has no appearance change after 6 cycles of use, and more importantly, generally maintains unchanged catalytic performance. The problems of nonuniform active component distribution, weak cohesiveness with the carrier and gradual decrease of activity during reaction in traditional monolithic catalysts are solved.

Owner:BEIJING UNIV OF CHEM TECH

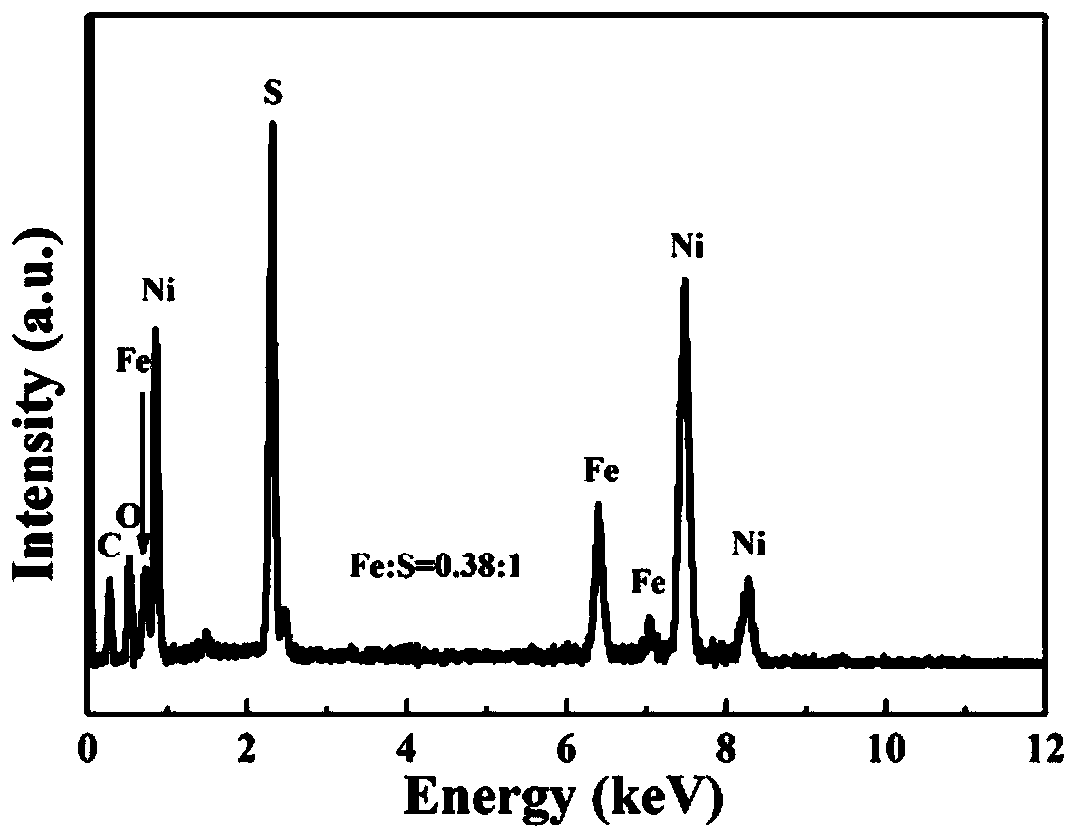

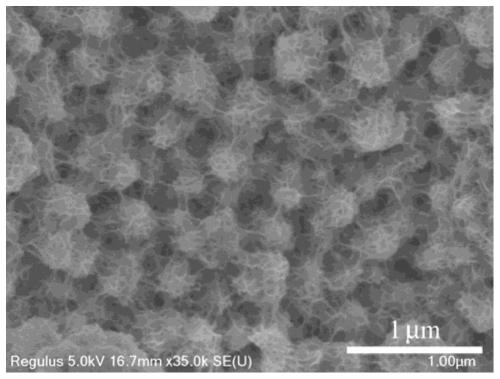

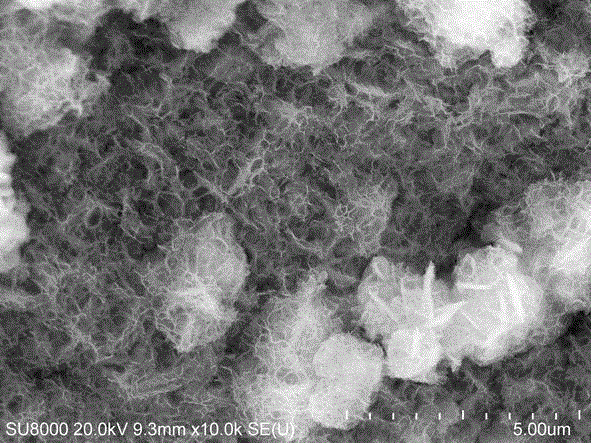

Microspherical Fe-doped trinickel disulfide nanostructured material composed of nanosheets, and preparation method and application thereof

ActiveCN110227496ASimple preparation process environmentHigh catalytic activityPhysical/chemical process catalystsElectrodesNickel saltThiourea

The invention discloses a microspherical Fe-doped trinickel disulfide nanostructure material composed of nanosheets, and a preparation method and application thereof. The preparation method comprisesthe following steps: dissolving a nickel salt, an iron salt and thiourea in ethylene glycol, transferring the formed solution into a reaction vessel, obliquely placing foamed nickel into the solution,performing a solvothermal reaction, carrying out cooling to room temperature after completion of the reaction, and washing and drying a product so as to obtain the microspherical Fe-doped trinickel disulfide nanostructured material composed of nanosheets. Compared with the prior art, the invention is different in that the microspherical Fe-doped Ni3S2 nanostructure composed of the nanosheets is designed and synthesized on a conductive foamed nickel substrate. Fe doping is used for improving the electrochemically active area and conductivity of the material. The microspherical Fe-doped Ni3S2 nanostructured material composed of the nanosheets in the invention is applied as an electrocatalyst for oxygen evolution reactions, hydrogen evolution reactions and full water decomposition reactionsand has the advantages of high catalytic activity, excellent stability, simple preparation process and low cost.

Owner:ANHUI NORMAL UNIV

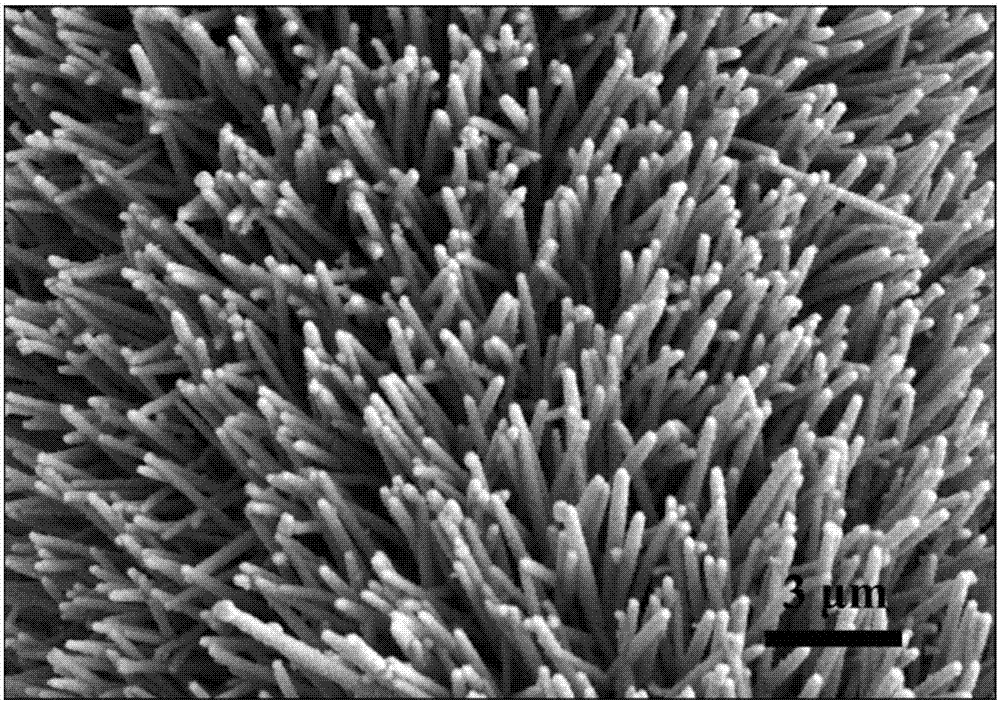

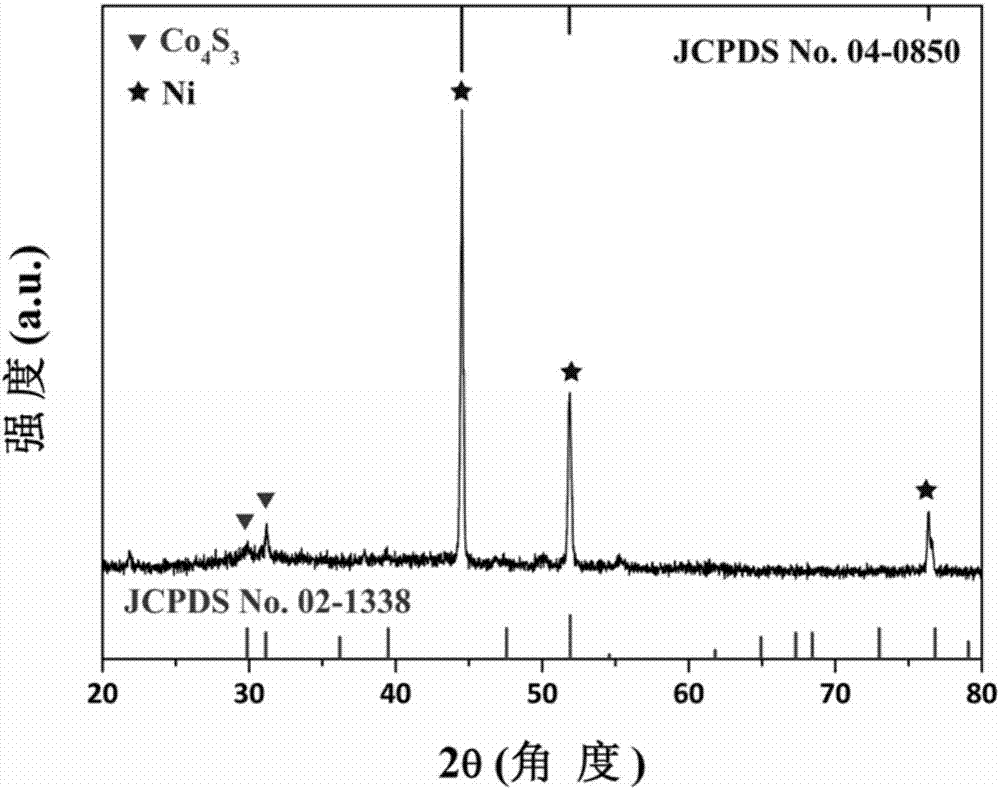

Tetracobalt trisulfide nanometer hollow tube@foam nickel composite array material and preparation method and application thereof

ActiveCN107213908ALarge specific surface areaIncrease contact areaPhysical/chemical process catalystsElectrodesNanotubeMaterials science

The invention provides a tetracobalt trisulfide nanometer hollow tube@foam nickel composite array material and a preparation method and application thereof. Compared with the prior art, a hydrothermal method for preparing the tetracobalt trisulfide nanometer hollow tube@foam nickel composite array material has the advantages of mature and stable synthesizing process, easiness in operation, low influence by the environment, easiness in controlling and high yield. The synthesized tetracobalt trisulfide nanometer hollow tube@foam nickel composite array material is of a one-dimensional hollow tubular structure and has a large surface-specific area, and a Co4S3 nanotube directly grows on a foam nickel substrate with high conductivity, so that a product has high electrocatalytic activity in a hydrogen evolution reaction. Compared with other electro-catalysts loaded with noble metal elements, the tetracobalt trisulfide nanometer hollow pipe@foam nickel composite array material has the advantages that a transition metal is effectively combined with foam nickel to serve as an electro-catalyst of the hydrogen evolution reaction, and raw materials are rich in sources and cheap, so that the cost of the electro-catalyst of the hydrogen evolution reaction is lowered greatly.

Owner:ANHUI NORMAL UNIV

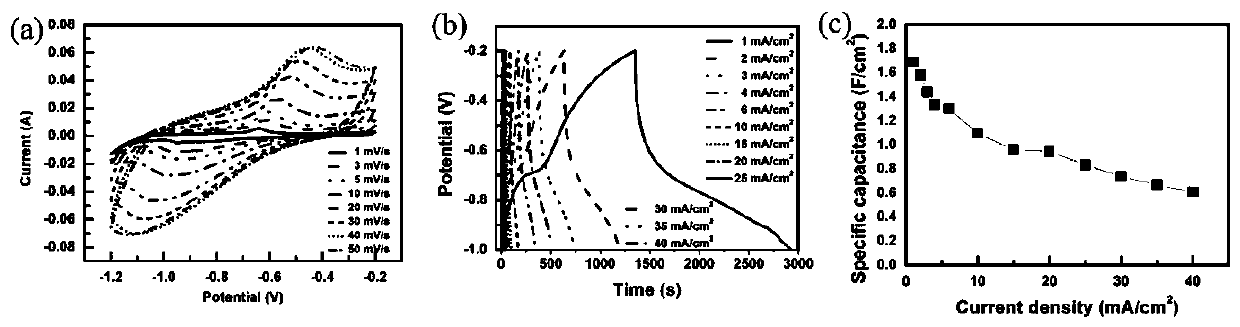

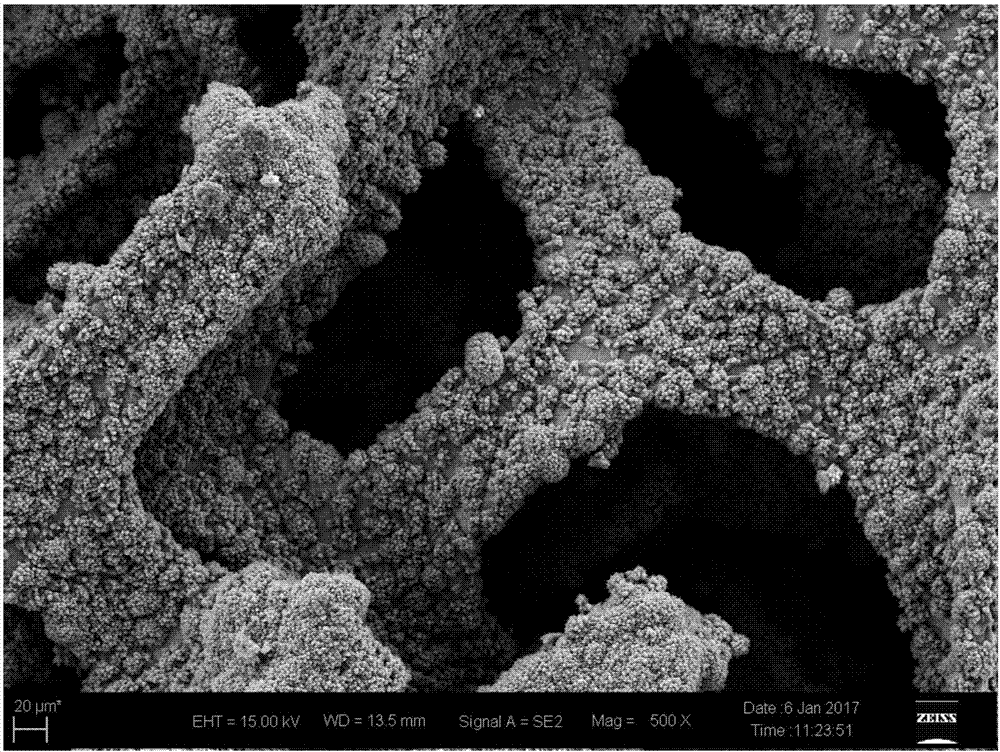

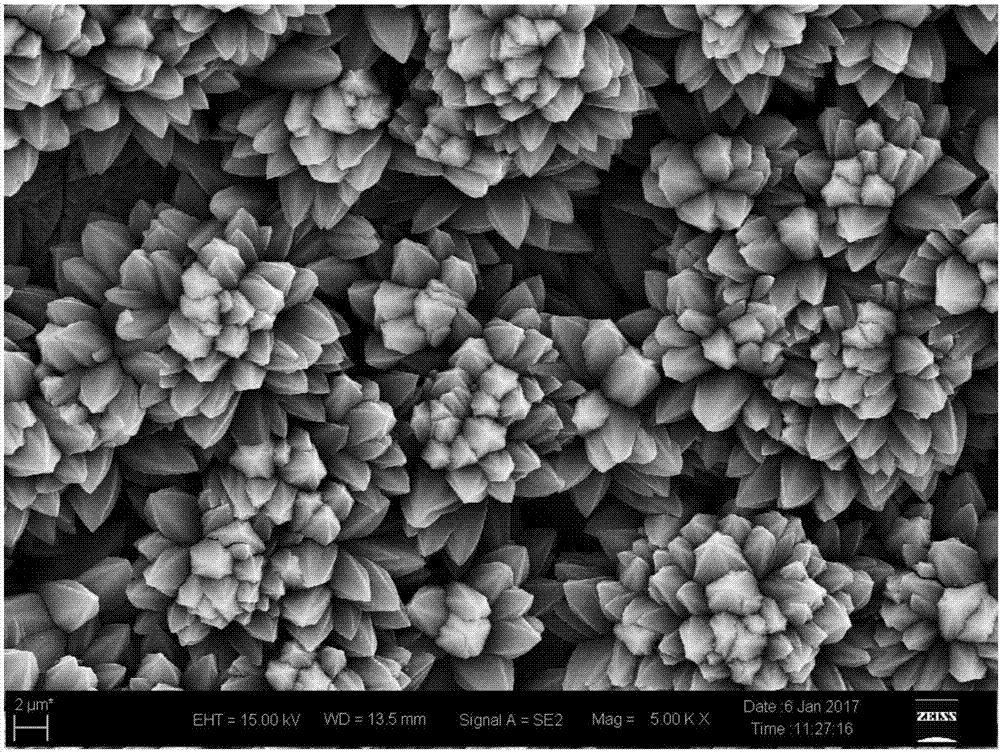

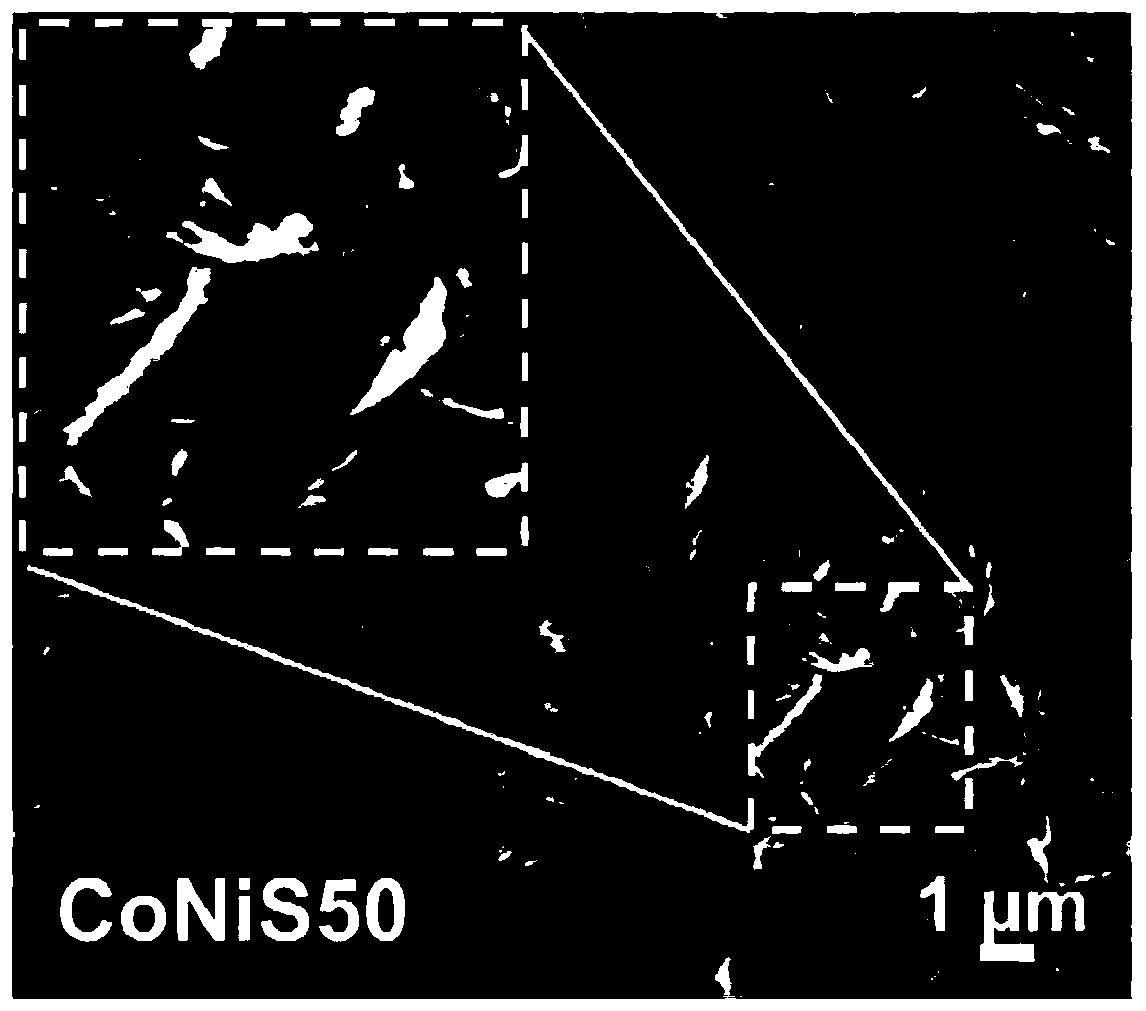

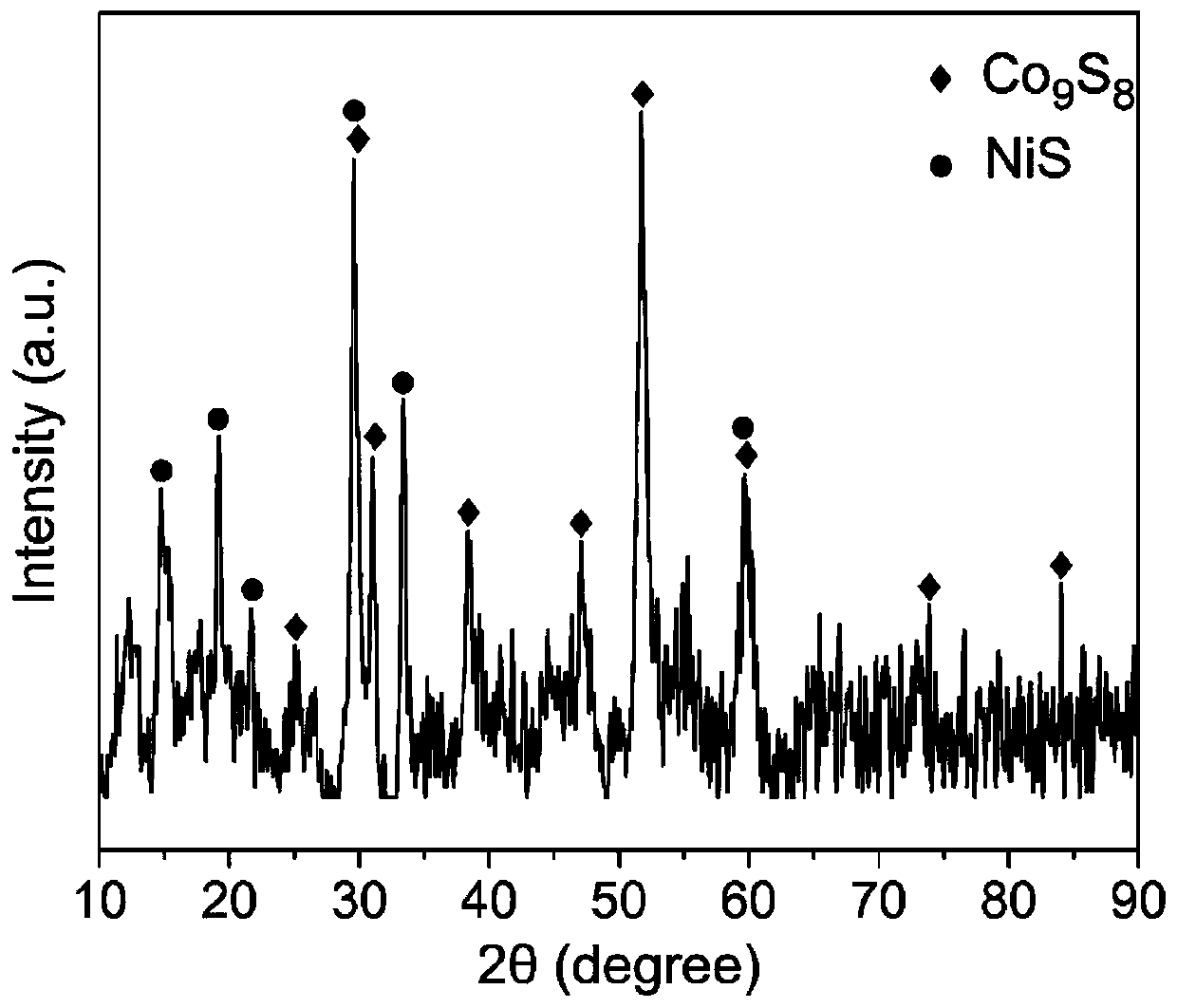

Preparation method of cobalt nickel sulfide/foam nickel super capacitor electrode

InactiveCN106158419AIncrease specific volumeExcellent rate performanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceThiourea

Owner:HENAN NORMAL UNIV

Particle-reinforced nickel-base metal powder for ultra high-speed laser cladding

InactiveCN108130529AHigh strengthExcellent resistance to inorganic acid corrosionTransportation and packagingMetal-working apparatusUltra high speedChemical composition

The invention relates to particle-reinforced nickel-base metal powder for ultra high-speed laser cladding, and belongs to the field of metal material manufacturing. The particle-reinforced nickel-basemetal powder is composed of nickel substrate metal powder and oxide or carbide particles, and mainly comprises 50-98% of the nickel substrate metal powder, 2-50% of one of Al2O3, ZrO2, WC and TiC ormixed powder formed by combing two or more of the Al2O3, the ZrO2, the WC and the TiC. The nickel substrate comprises the chemical components of, by mass, 0-0.1% of C, 2.0-30.0% of Cr, 2.0-30.0% of Mo, 0.1-5.0% of Nb, 0-6.0% of Fe, 0-0.6% of Al, 0-0.6% of Ti, 0-0.8% of Mn, 0-0.8% of Si, 0-2.0% of Co, 0-0.030% of P, 0-0.030% of S, and the balance Ni and inevitable impurities, and the optimal totalcontent of the Cr and the Mo is 5.0-40.0%. The particle-reinforced metal powder is applied, the laser cladding technology is adopted, different processes are matched, and the surface of the substrateis subjected to strengthening and repairing.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Preparation method for supercapacitor electrode material containing MnCo2O4.5

ActiveCN103474254AStrong mechanical propertiesEasy to passHybrid capacitor electrodesHigh rateNickel substrate

Owner:HARBIN ENG UNIV

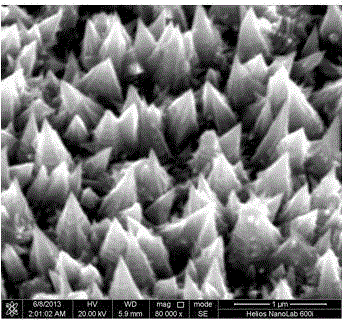

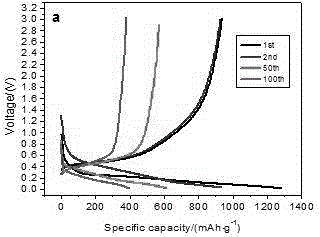

Method for preparing germanium cathode material on nickel nanoneedle conical array

ActiveCN103985836AReduce chalkingIncrease the base areaMaterial nanotechnologyPolycrystalline material growthNickel substrateElectrical battery

The invention discloses a method for preparing a germanium cathode material on a nickel nanoneedle conical array. The preparation method comprises the following steps: firstly preparing the nickel nanoneedle conical array with a certain height by utilizing a water solution electrodeposition method on a nickel basal body, then preparing a germanium cathode material by utilizing an ionic liquid electrodeposition method in an anaerobic and hydrophobic environment, assembling a battery after carbon spraying treatment, and testing the electrochemical performance of the battery. The ionic liquid electrodeposition method is utilized on the nickel nanoneedle conical array for preparing the germanium cathode material with high specific capacity, long cycle life and high coulombic efficiency; during the ionic liquid electrodeposition process, the current density is low, and prepared germanium films are uniform; moreover, the prepared material comprises nano-sized particles, so that pulverization during the material cyclic process is reduced, the foundation area of the prepared cathode material and the prepared basal body (nickel nanoneedle conical array) is large, the binding force is good, and the preparation method is simple in process and convenient to operate.

Owner:HARBIN INST OF TECH

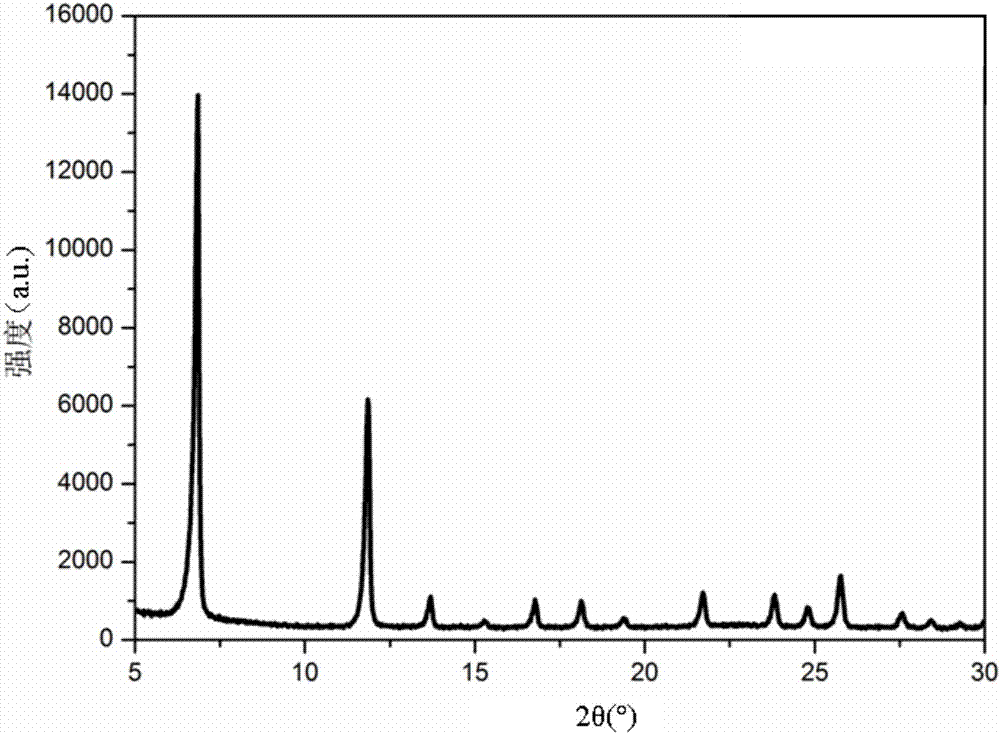

Method for realizing Ni-MOF-74 in-situ growth on foam nickel

ActiveCN107887180AThe preparation method is simple and controllableLow costHybrid capacitor electrodesHybrid/EDL manufactureNickel substrateSupercapacitor

The invention relates to a method for realizing Ni-MOF-74 in-situ growth on foam nickel, particularly relates to a preparation method for Ni-MOF-74 in-situ growth on a foam nickel substrate having nonickel source ions and solves technical problems of complex process, high cost and not-suitable-for-industrial production existing in an MOFs method in the prior art. The method comprises steps that 1, a foam nickel current collector is prepared; and 2, the hydrothermal in-situ growth method is utilized to prepare Ni-MOF-74. The method is advantaged in that the method is simple and controllable, cost is low, the raw material is simple and available, large-scale preparation can be realized, additionally adding the nickel ions for the prepared Ni-MOF-74 is not needed, uniform in-situ growth of an organic-ligand 2,5-dihydroxy-terephthalic acid on the foam nickel is realized, and the prepared Ni-MOF-74 can be widely applied to the super capacitor and gas separating field.

Owner:黑龙江省工研院资产经营管理有限公司

Bimetallic sulfide composite electrocatalyst and preparation method and application thereof

ActiveCN110694646ASimple interfaceShorten transfer pathPhysical/chemical process catalystsElectrodesPtru catalystThiourea

The invention relates to a bimetallic sulfide composite electrocatalyst and a preparation method and application thereof. The electrocatalyst comprises a foamed nickel substrate and bimetallic sulfides growing on the foamed nickel substrate to form a 2D nano structure, and the bimetallic sulfides are NiS / Co9S8; the preparation method comprises the following steps: 1) foamed nickel is pretreated; 2) thiourea and Co(NO3).6H2O are dissolved in water, then the pretreated foam nickel is added, hydrothermal reaction is carried out, and then cooling, washing and drying are carried out to obtain the bimetallic sulfide composite electrocatalyst; and the electrocatalyst is used in electrocatalytic oxygen evolution or electrocatalytic hydrogen evolution. Compared with the prior art, the preparation process of the electrocatalyst is simple, safe and cheap; the electrocatalyst is high in catalytic activity and low in reaction energy barrier, has more activand e sites, and shortens the path of electron transfer; and the specific surface area is large, the electron transfer efficiency is improved, and the long-time stability is realized.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com