Foam nickel-base MnO2/C composite electrode material and preparation method thereof

A composite electrode and nickel foam technology, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of small specific surface area of metal oxides, high specific capacitance, high energy density, and low specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

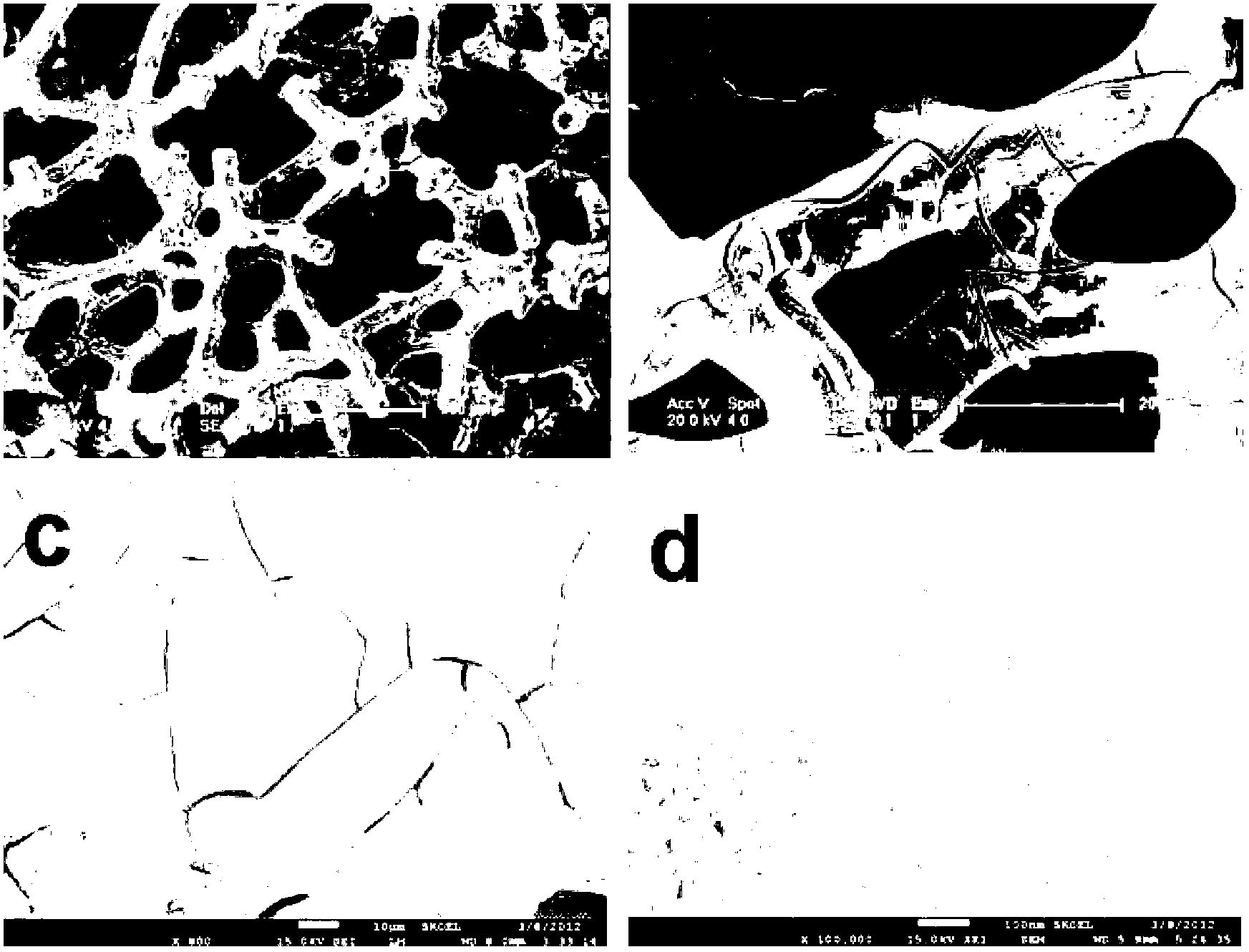

Embodiment 1

[0034] Cleaning of the foamed nickel substrate: Cut the foamed nickel substrate into a 1cm*1cm square, and leave a narrow strip (0.1cm*1cm) on one side for inserting into the base (the base is made of a polytetrafluoroethylene material. A small cube with a volume of about 1cm 3 Left and right, a narrow groove is dug out on it, which is used to fix the foamed nickel substrate. Inserting the foamed nickel substrate into the base can make the foamed nickel substrate immersed in the solution, thereby preventing the foamed nickel substrate from floating on the solution. ; Then the foamed nickel substrate is ultrasonically washed for 10 minutes with deionized water, ethanol, acetone, ethanol and deionized water in turn, then dried, and finally the foamed nickel substrate is fixed on the base that has been cleaned and dried.

[0035]Dissolve 2.4g of glucose in 40mL of deionized water to form a clear solution, prepare an aqueous glucose solution, and place the aqueous glucose solution...

Embodiment 2

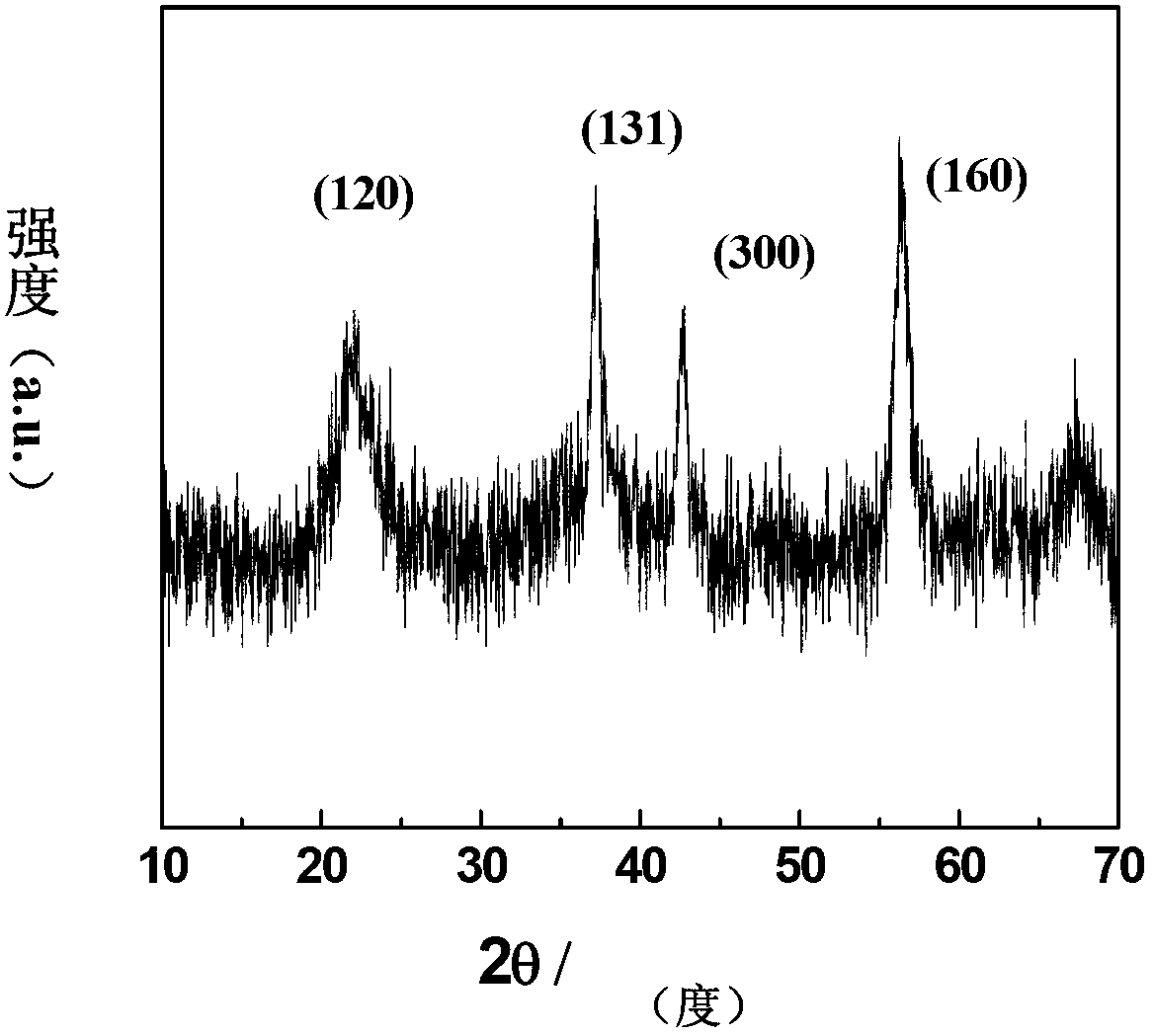

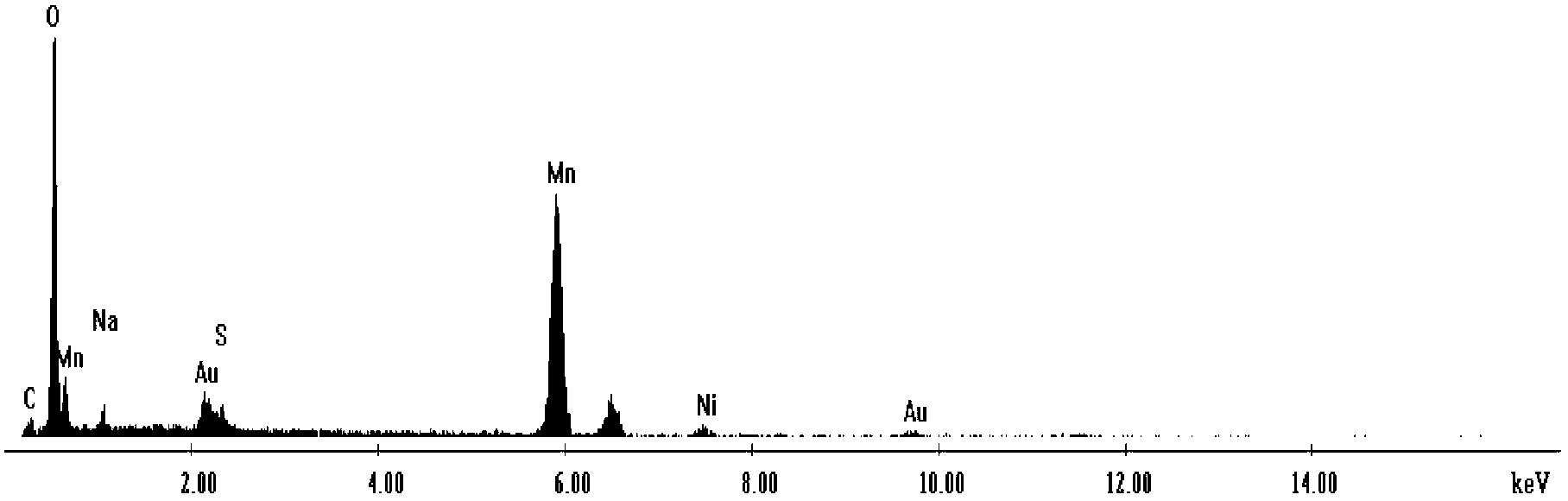

[0041] The method and dosage of hydrothermally depositing carbon material on the pretreated nickel foam are the same as in Example 1, except that the concentration of the glucose deionized aqueous solution is 0.5 mol / L. Electrochemical deposition method was used, in the presence of 0.2 mol·L -1 Na 2 S0 4 and 0.04mol·L -1 MnS0 4 In the aqueous solution of , the voltage of the potentiostatic I-t curve is set to 1.1V, the deposition time is 2h, and Mn0 is deposited on the surface of the carbon electrode. 2 Thin layer, the auxiliary electrode used in this experiment is a metal platinum sheet electrode, so as to obtain a foamed nickel-based Mn0 2 / C composite electrode.

[0042] Weighing Foam Nickel Base Mn0 2 / C mass of composite electrode, the mass minus the mass of blank nickel foam after pretreatment is the Mn0 on growth 2 / C quality of composites, Mn0 prepared in this example 2 The mass of the / C composite is 0.0126 g. The prepared foamed nickel-based Mn0 2 The / C ...

Embodiment 3

[0045] The method and dosage of hydrothermally depositing carbon material on the pretreated nickel foam are the same as in Example 1, except that the concentration of the glucose deionized aqueous solution is 0.3 mol / L.

[0046] Electrochemical deposition method was used, in the presence of 0.3 mol·L -1 Na 2 S0 4 and 0.06mol·L -1 MnS0 4 In the solution, the voltage of the potentiostatic I-t curve was set to 1.1V, and the deposition time was 2h. The auxiliary electrode used in this experiment was a metal platinum sheet electrode, and Mn0 was deposited on the surface of the carbon electrode. 2 thin layer to obtain foamed nickel-based Mn0 2 / C composite electrode.

[0047] Weighing Foam Nickel Base Mn0 2 / C the mass of the composite electrode, the mass minus the mass of the blank nickel foam after pretreatment is the Mn0 on the growth 2 / C quality of composites, Mn0 prepared in this example 2 The mass of the / C composite is 0.0126 g. The prepared foamed nickel-based and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| cycle efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com