Nano-rod array composite material as well as preparation method and application thereof

A nanorod array and composite material technology, applied in the field of nanorod array composite materials, can solve the problems of easy deactivation, low reserves, high price, etc., and achieve the effects of simple operation, large specific surface area, and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

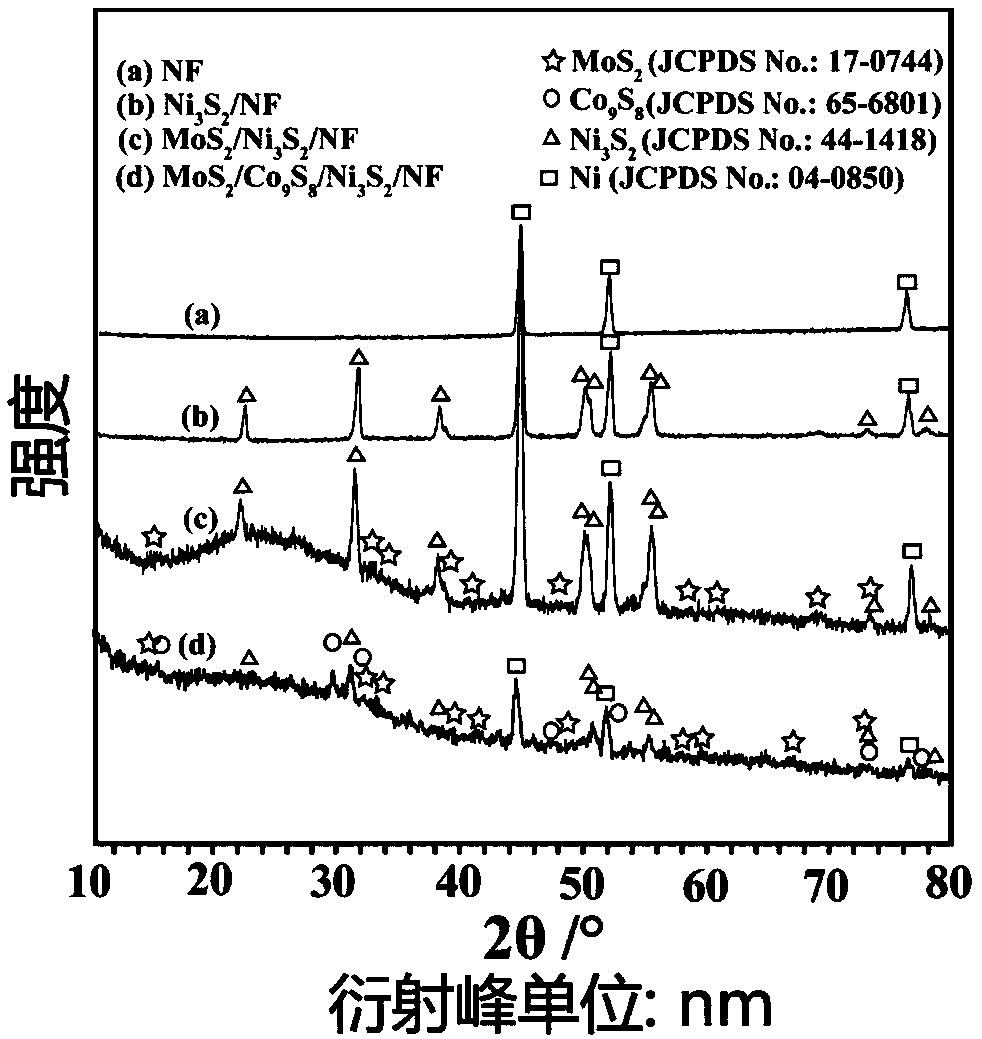

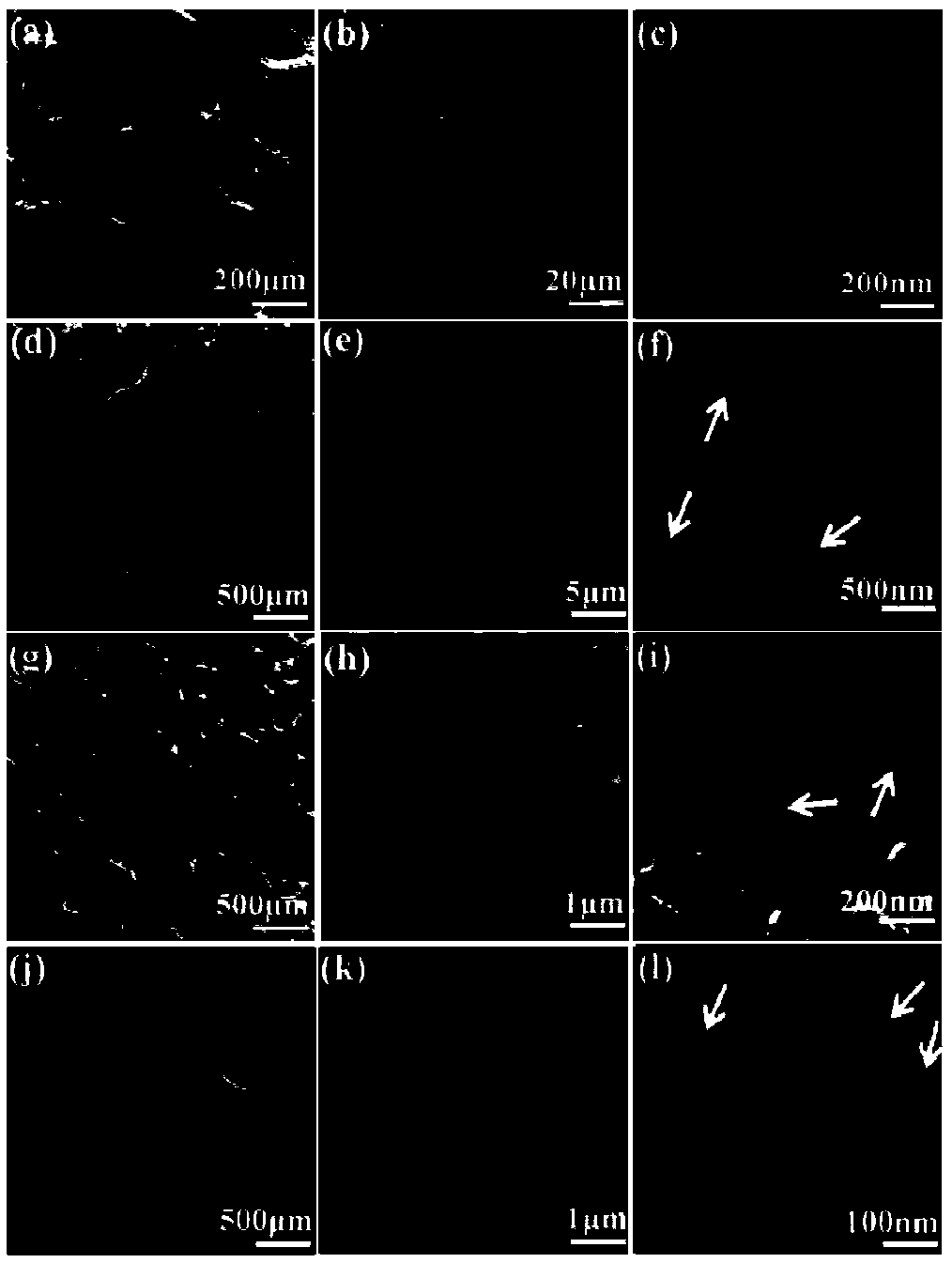

[0032] Foam nickel pretreatment: Soak a piece of 6cm×10cm foam nickel (NF, pore size 200-500μm, Shenzhen Tianchenghe Co., Ltd.) in 1M HCl for 20 minutes to remove surface oxides, then wash with water and ethanol, dry, weigh Heavy.

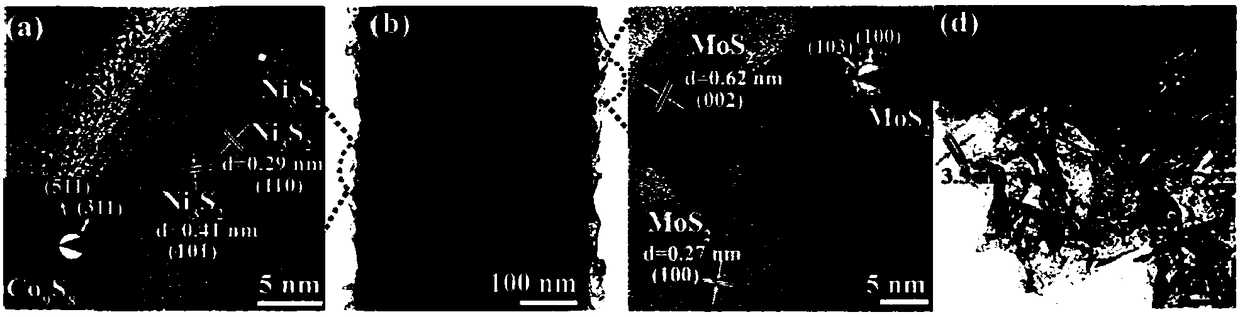

[0033] Weigh 0.843g CoSO 4 ·7H 2 O, 0.723g Na 2 MoO 4 2H 2 O and 0.685g CH 4 N 2 S (cobalt, molybdenum, sulfur molar ratio 1:1:3) was added to 80mL reactor, then 33mL water and 12.36g hydrazine hydrate aqueous solution (mass fraction 80%, volume 15mL) were added, after stirring for 30 minutes, NF was added to seal the reaction Reactor in an oven at 200°C for 24h. Cool naturally to room temperature, wash with water and ethanol alternately, and dry the product in a vacuum oven at 40°C for 24 hours to obtain a composite material, denoted as Co 9 S 8 / MoS 2 / Ni 3 S 2 / NF. Co in the composite 9 S 8 、MoS 2 and Ni 3 S 2 The total loading capacity is 1.85mg·cm -2 ).

Embodiment 2

[0035] Prepare Co according to the method of embodiment 1 9 S 8 / MoS 2 / Ni 3 S 2 / NF nanorod array composite material, the difference from Example 1 is: the nickel foam pretreatment process is: nickel foam (NF) is soaked in 0.8M HCl for 30 minutes.

Embodiment 3

[0037] Prepare Co according to the method of embodiment 1 9 S 8 / MoS 2 / Ni 3 S 2 / NF nanorod array composite material, the difference from Example 1 is: the nickel foam pretreatment process is: nickel foam (NF) is soaked in 1.2M HCl for 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com