Preparation method of carbon nanotube by growing on foamed nickel substrate

A carbon nanotube and nickel foam technology, applied in the direction of carbon nanotube, nanocarbon, nanotechnology, etc., can solve the problems of affecting the power characteristics of electrode materials, large contact resistance, complicated operation, etc., and achieve easy follow-up utilization, low cost, Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

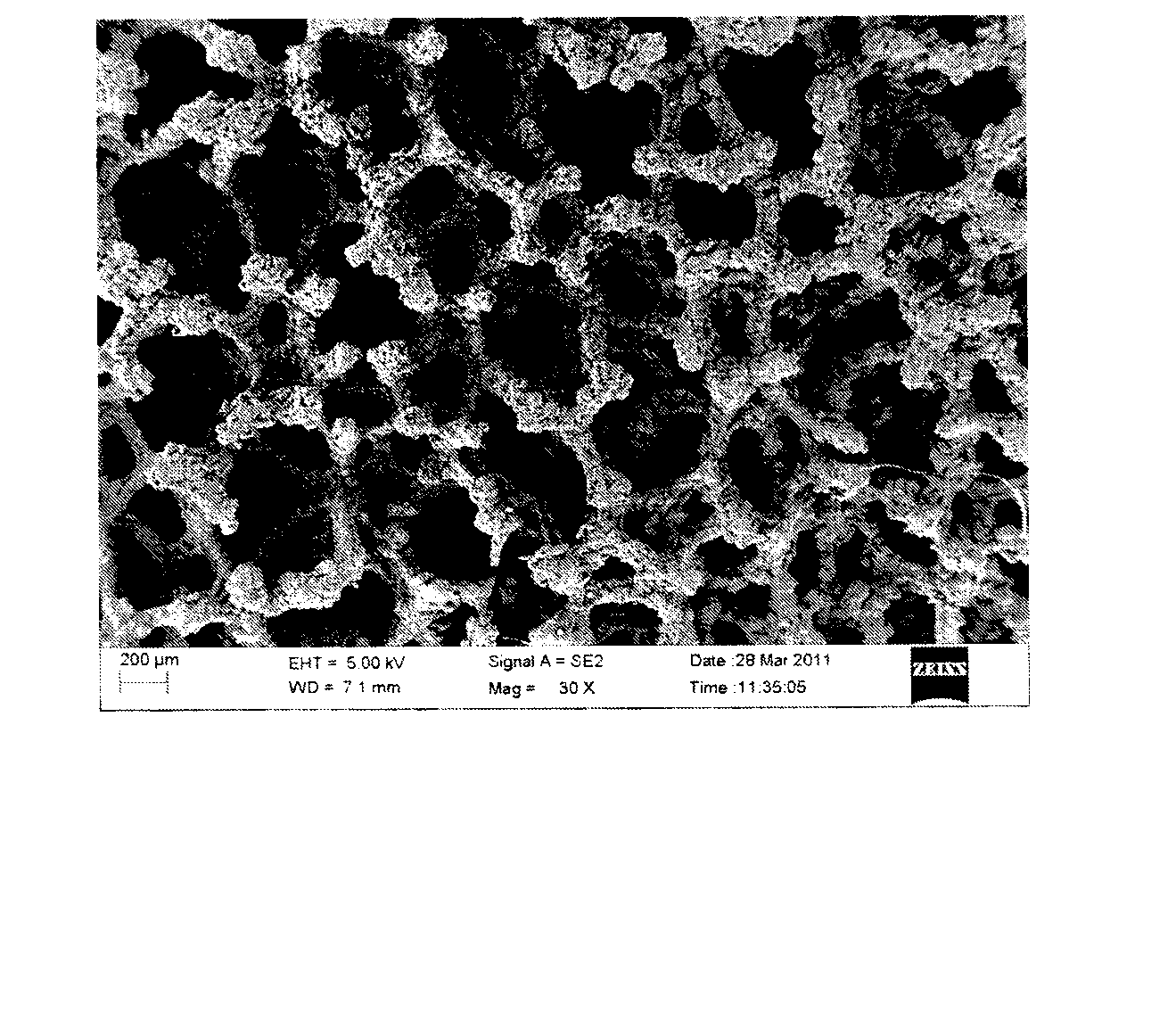

Image

Examples

example 1

[0013] At room temperature, the nickel foam was cleaned with absolute ethanol in an ultrasonic cleaner, and then cleaned several times with deionized water. With 2MNi(NO 3 ) 2 The solution and ethylene glycol methyl ether were used to prepare a sol, and an appropriate amount of ammonia water was added, stirred at a high speed for 10 hours, and then sealed and left to stand for 10 hours to obtain a green transparent sol. The sol is uniformly coated on the surface of the nickel foam by dipping and pulling method, and the pulling speed is 10 cm / min in this example. After the wet film was heat-treated at 100°C, it was dipped and pulled repeatedly, and the number of times of pulling was 5 times. Put the nickel foam coated with Ni-containing sol in the chamber of the chemical vapor deposition system, start to heat up, the target temperature is 500°C, feed the reducing gas hydrogen, and keep it for 10 minutes; the furnace temperature continues to rise to 700°C, and at the same time...

example 2

[0015] At room temperature, the nickel foam was cleaned with absolute ethanol in an ultrasonic cleaner, and then cleaned several times with deionized water. With 0.5MNi(NO 3 ) 2 The solution and ethylene glycol methyl ether were used to prepare a sol, and an appropriate amount of ammonia water was added, stirred at a high speed for 10 hours, and then sealed and left to stand for 10 hours to obtain a green transparent sol. The sol is evenly coated on the surface of the nickel foam by dipping and pulling method, and the pulling speed is 20cm / min in this example. After the wet film was heat-treated at 100°C, it was dipped and pulled repeatedly, and the number of times of pulling was 10 times. Put the nickel foam coated with Ni-containing sol in the chamber of the chemical vapor deposition system, start to heat up, the target temperature is 500°C, feed the reducing gas hydrogen, and keep it for 10 minutes; the furnace temperature continues to rise to 700°C, and at the same time ...

example 3

[0017] At room temperature, the nickel foam was cleaned with absolute ethanol in an ultrasonic cleaner, and then cleaned several times with deionized water. With 0.5MNi(NO 3 ) 2 The solution and ethylene glycol methyl ether were used to prepare a sol, and an appropriate amount of ammonia water was added, stirred at high speed for 24 hours, and then sealed and left to stand for 24 hours to obtain a green transparent sol. The sol is evenly coated on the surface of the nickel foam by dipping and pulling method, and the pulling speed in this example is 5 cm / min. After the wet film was heat-treated at 100°C, it was dipped and pulled repeatedly, and the number of times of pulling was 3 times. Put the nickel foam coated with Ni-containing sol in the chamber of the chemical vapor deposition system, start to heat up, the target temperature is 500°C, feed the reducing gas hydrogen, and keep it for 10 minutes; the furnace temperature continues to rise to 700°C, and at the same time Bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com