Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

849 results about "Reaction energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The energy that results during a chemical reaction is called chemical energy. It is a type of potential energy. ... During combustion, chemical energy in the form of heat is released when oxygen combines with other substances to form water and carbon dioxide. When two simple substances combine to make a more complex substance during a chemical reaction it is called synthesis.

Molecular sieve based catalysts, preparation method and application thereof in crylic acid preparation by lactic acid dehydration

InactiveCN101602010AExtended service lifeReduce energy consumptionMolecular sieve catalystsOrganic compound preparationPhosphateAcid preparations

The invention discloses a molecular sieve based catalyst, a preparation method and an application thereof in crylic acid preparation by lactic acid dehydration. The method comprises the following steps: processing the ZSM-5 molecular sieve in aqueous alkali, or adopting an impregnation method to support phosphate, drying, roasting and finally obtaining the modified molecular sieve based catalyst. The catalyst realizes the reaction of crylic acid preparation by lactic acid dehydration in low temperature and has the advantages of high lactic acid conversion rate and crylic acid selectivity, and long-life of catalyst, the conversion rate of lactic acid dehydration reaction is 100%, and crylic acid selectivity can reach as high as 83.9%, thus having good industrial application prospect.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

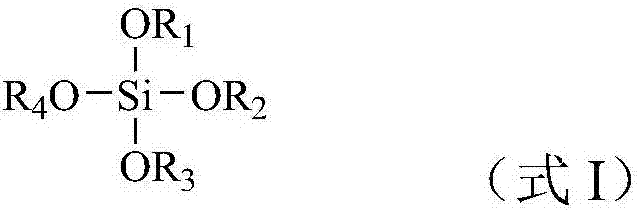

Fluorosilicone rubber nano composite alloy three-proof paint and production method thereof

InactiveCN101230224AImprove anti-corrosion performanceExcellent anti-fouling flashEpoxy resin coatingsCross-linkPolymer science

The invention discloses a fluorosilicone rubber nano-composite alloy triplicate-prevention paint and the production method. The organic silicon provided with hydroxyl is introduced into the carbon resin, and is dispersed into resin polymerize and cross-linked by a variety of polymer resin via nano-particle which is processed by nano-dispersion solution; and then the fluorosilicone rubber nano-composite alloy triplicate-prevention paint which can resist salt spray, acid, alkali and impact; has strong adhesive attraction, strong resistance to elements, and heavy corrosion resistance; can prevent pollution flashover , and can drain for anti-icing is produced by modifying the obtained resin. The invention has high reaction energy and ultra-low surface energy, can resist chemical corrosion and electrochemical corrosion, has ability for resisting strong corrosion medium, has strong adhesive attraction and high reliability between paint film layers, can prevent water, oxygen and other corrosion mediums from destructing, can resist ultraviolet radiation, can resist temperature change, has super resistance to elements, has long coating maintenance usage duration, and is applicable to bad weather conditions and all kinds of strong corrosive environments.

Owner:孟中

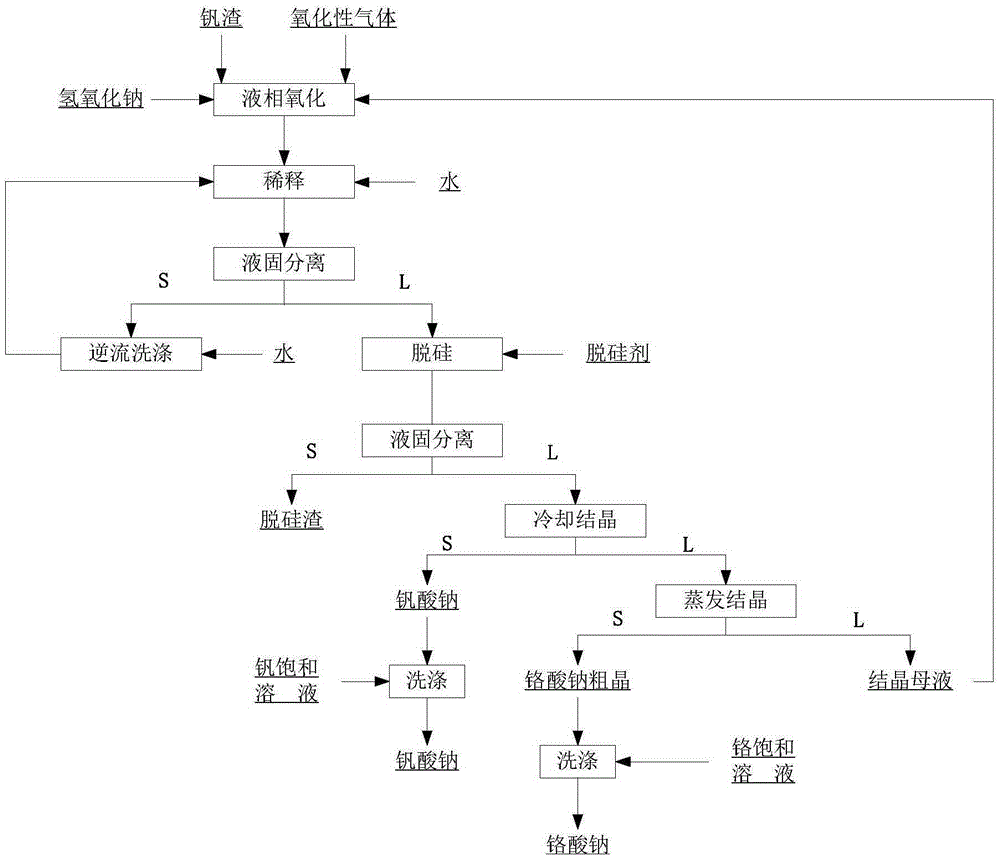

Method for extracting chromium and vanadium from vanadium slag at low temperature and normal pressure

ActiveCN105400967ALow reaction temperatureReduce reaction energy consumptionSlagReaction temperature

The invention relates to the field of vanadium slag hydrometallurgy and vanadium chemical engineering, in particular to a method for extracting chromium and vanadium from vanadium slag at a low temperature and the normal pressure. The method comprises the following steps that firstly, burdening, wherein the vanadium slag and a NaOH solution are mixed to form reaction slurry; secondly, reaction, oxide gas is led into the reaction slurry through a micro-hole arrangement device to carry out normal-pressure oxidative leaching, and after the reaction, solid-liquid mixed slurry of a solution containing NaOH, Na3VO4, Na2CrO4, water soluble impurity components and iron-rich tailings is obtained; thirdly, solid-liquid separation; fourthly, impurity removing; fifthly, sodium vanadate crystallization; and sixthly, sodium chromate crystallization. According to the method, chromium and vanadium efficient common extraction can be achieved, the extraction efficiency of both chromium and vanadium can be higher than 85%, more importantly, after the micro-hole gas distribution manner is adopted, the oxygen solubility can be obviously improved, the reaction temperature and alkali concentration are obviously reduced compared with those of an existing vanadium extraction method, the operation safety is greatly improved, and reaction energy consumption is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Cubic or sheet-shaped nano SAPO-34 molecular sieve and application thereof

ActiveCN102616810AReduce grain sizeHigh yieldMolecular sieve catalystsNanotechnologyMolecular sieveMicrowave

The invention belongs to the technical field of molecular sieves and particularly relates to a cubic or sheet-shaped nano SAPO-34 molecular sieve and application thereof in conversion, separation and absorption of all kinds of hydrocarbons. The dimension range of the molecular sieve is within 20-300nm and is rapidly prepared by using tetraethyl ammonium hydroxide as template agent, mixing the tetraethyl ammonium hydroxide with an aluminum source, a silicon source and a phosphorus source and adding specific solvent to control gel concentration through the traditional hydrothermal or microwave heating method. The nano-scale SAPO-34 molecular sieve synthesized by adopting the method has the characteristics that the cost of raw materials for gel is low, the production speed of the molecular sieve is rapid, the preparation time of crystallized start materials is short, the reaction energy consumption is low, the yield of the molecular sieve is high, the catalytic application life is long and the catalytic effect of the molecular sieve in catalytic reaction can be obviously improved.

Owner:JILIN UNIV

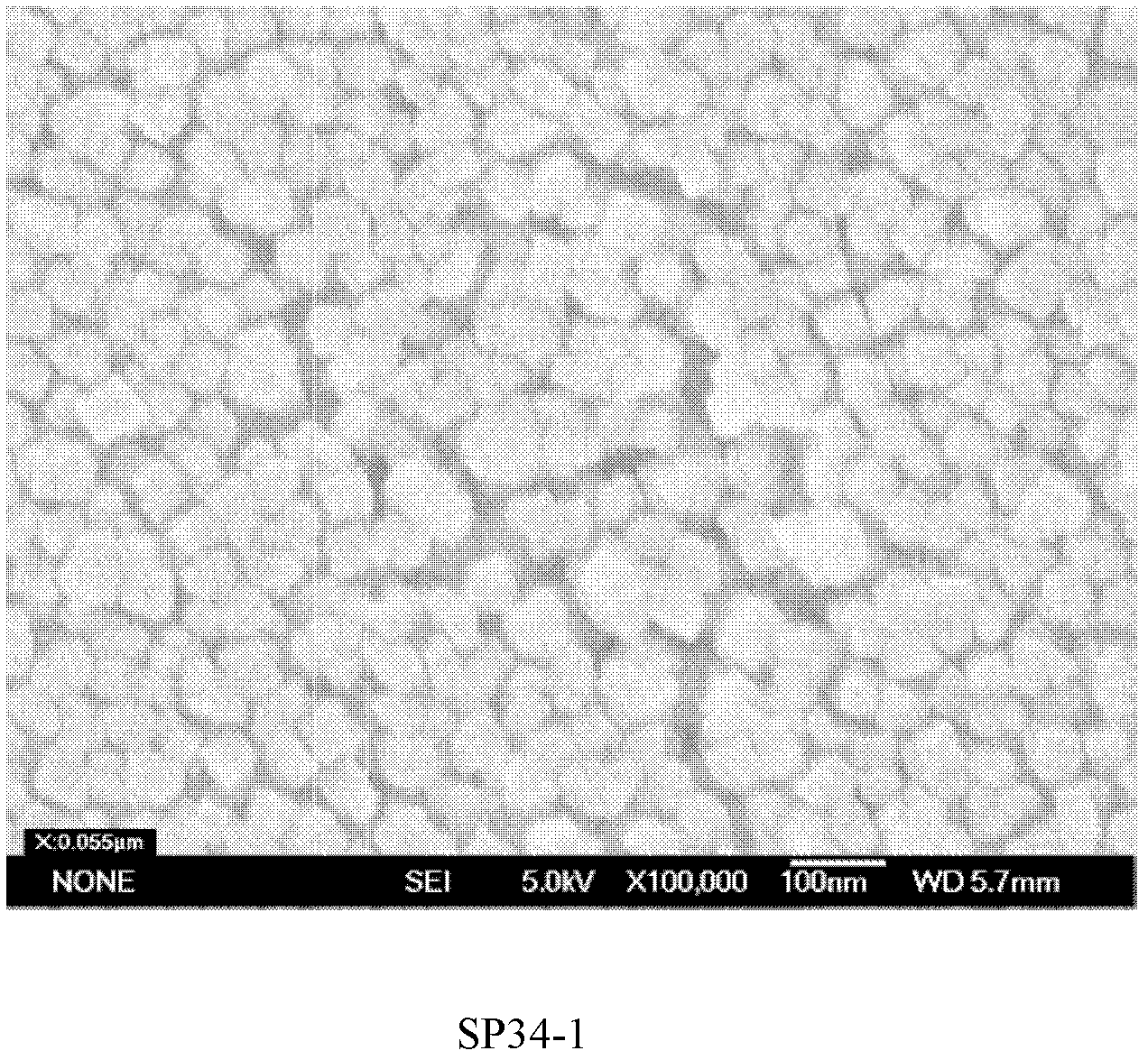

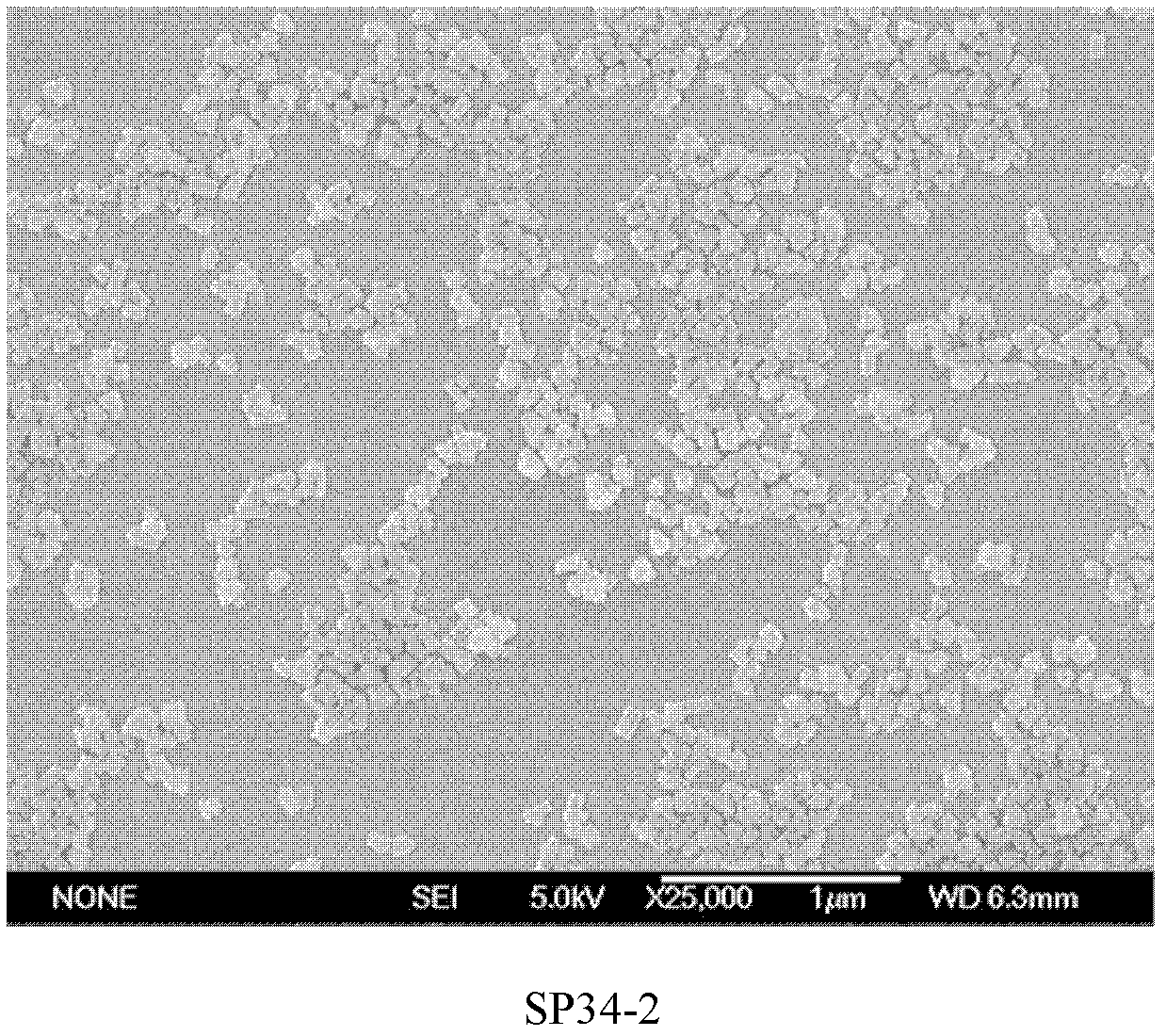

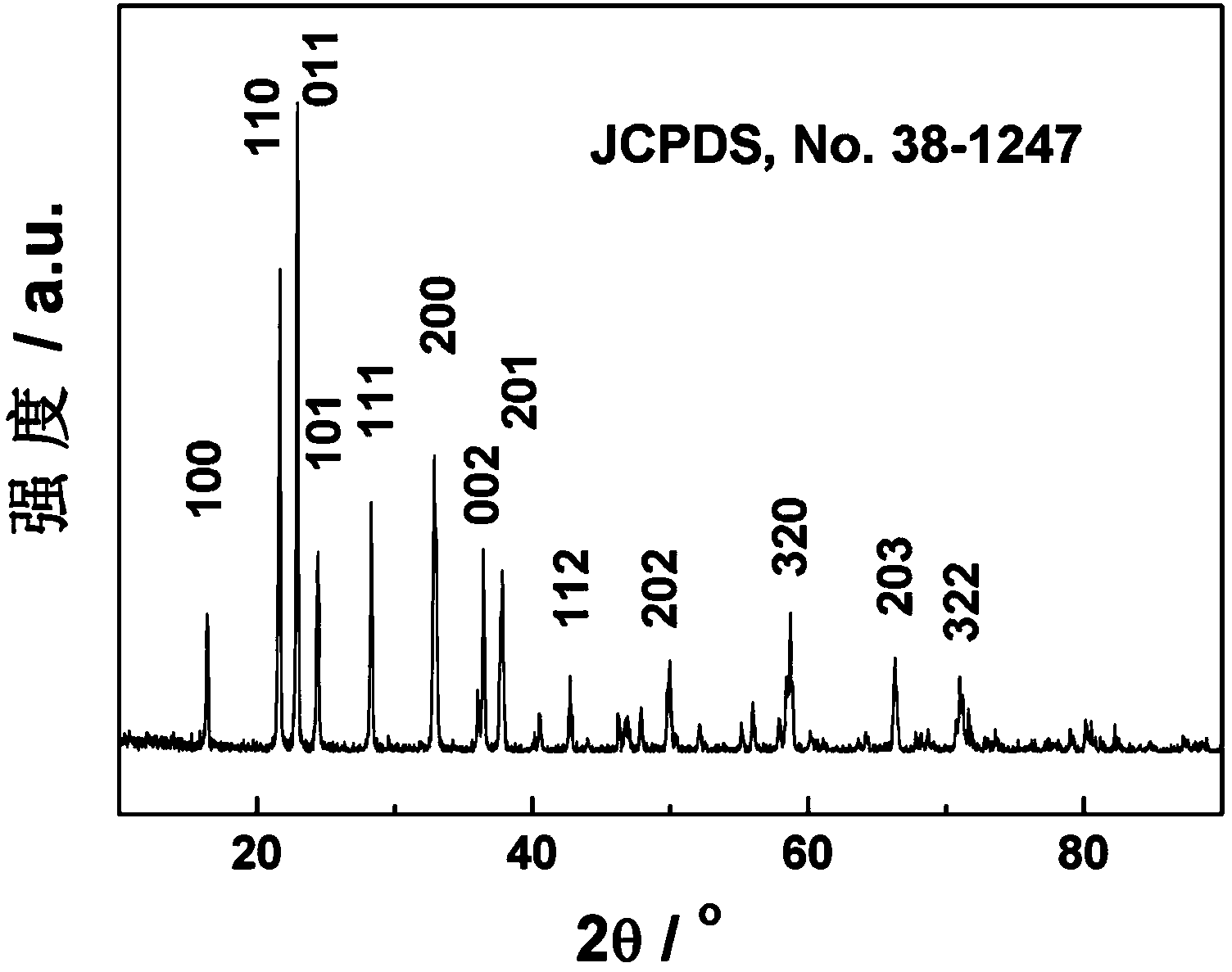

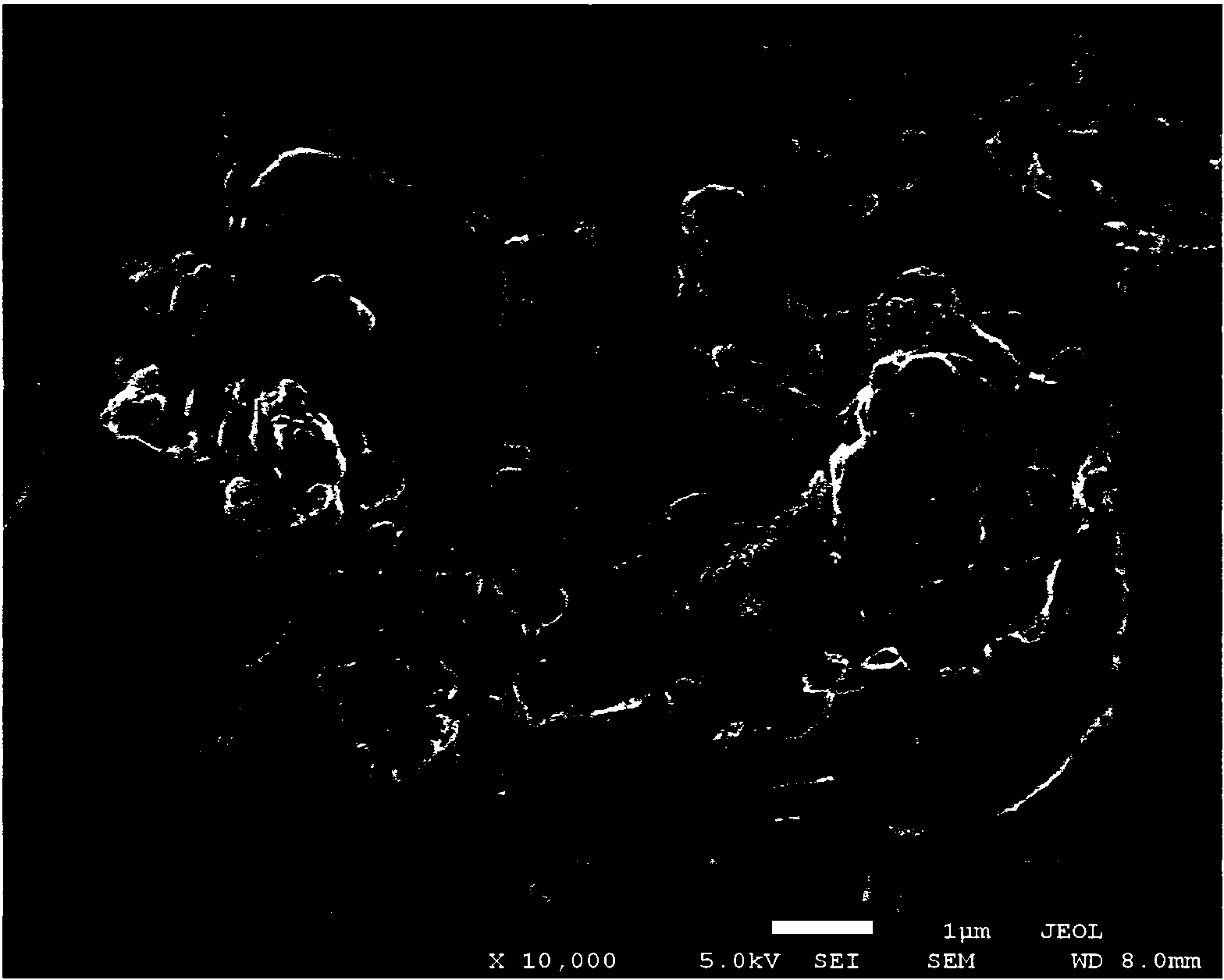

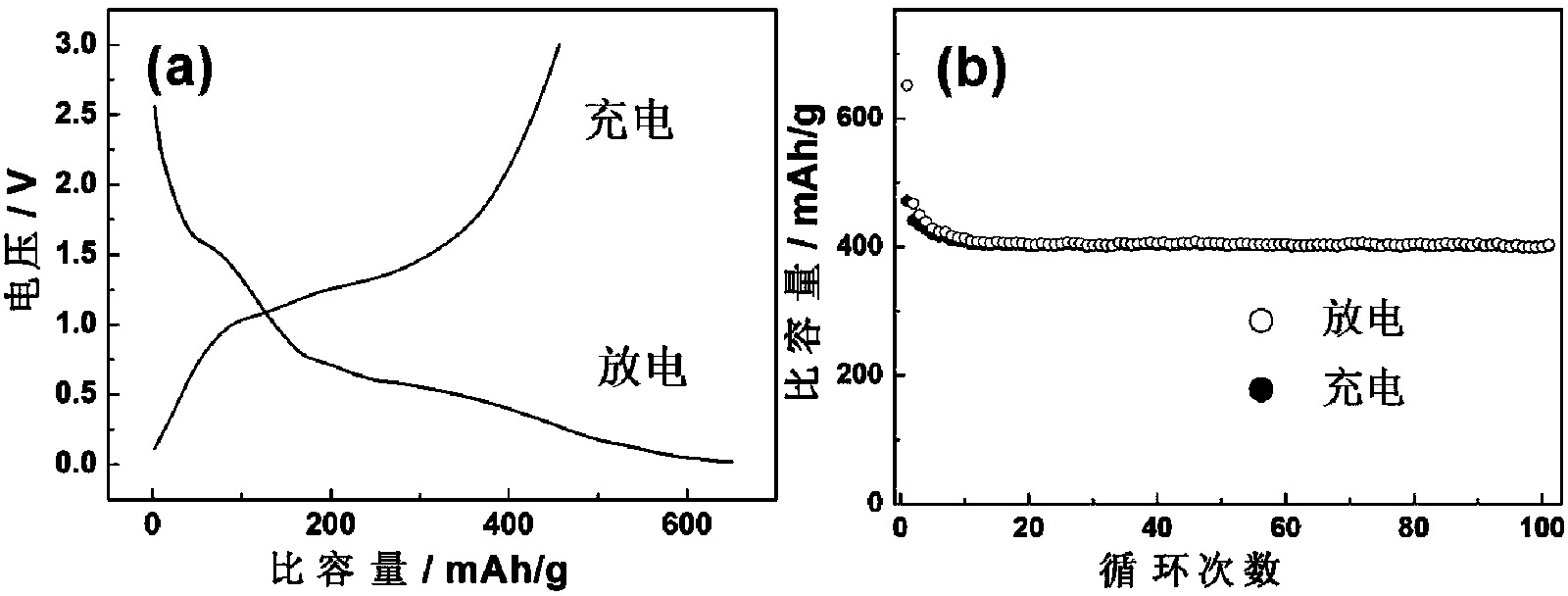

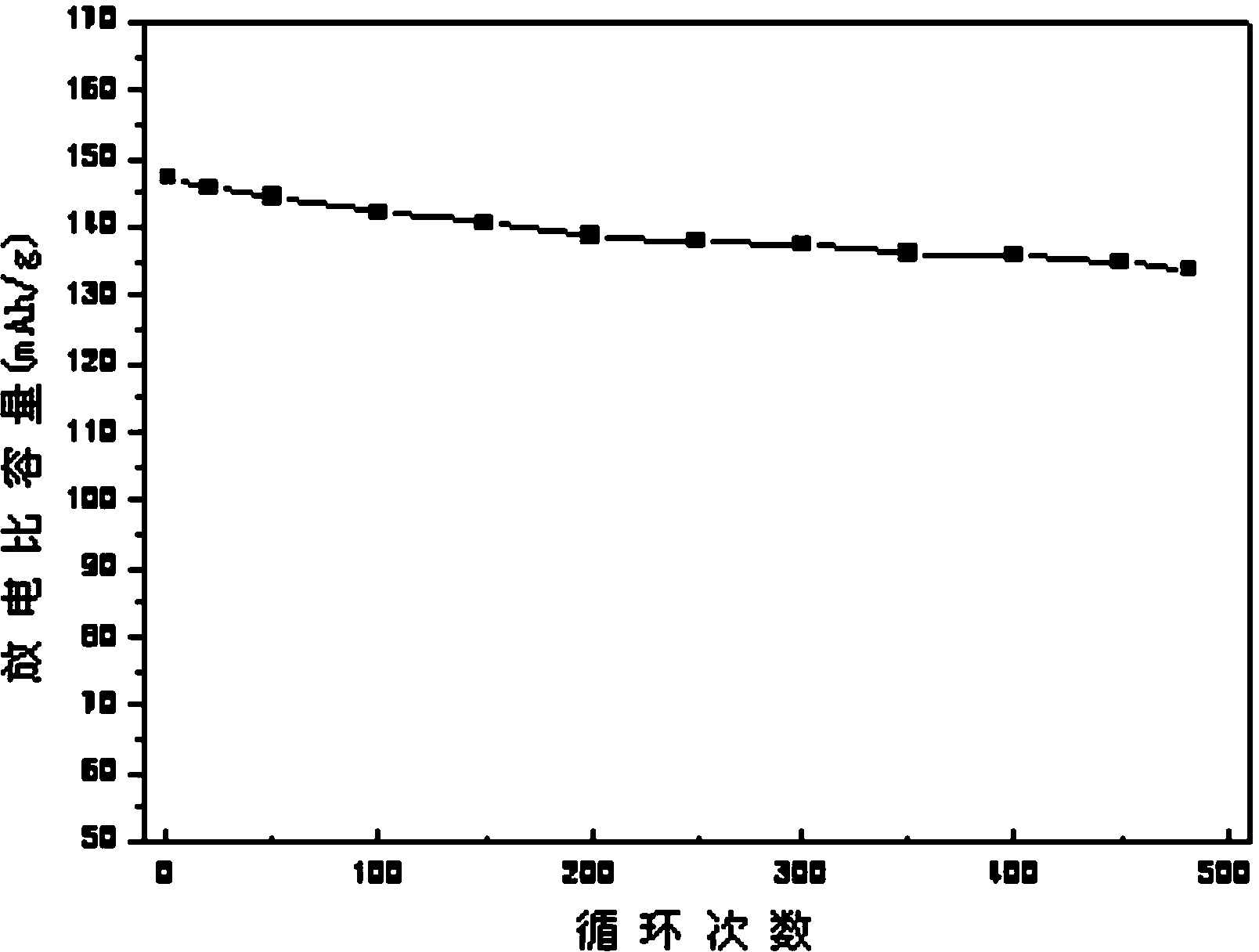

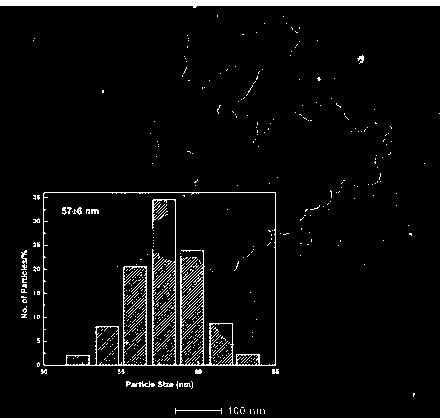

Lithium ion battery anode material Li3VO4 and preparation method thereof

The invention provides a Li3VO4 cathode anode material and a preparation method thereof, particularly a novel lithium ion battery anode material Li3VO4 prapared by carrying out hydrothermal reaction on vanadium pentoxide, lithium carbonate and hexamethylenetetramine used as precursors. The hydrothermal reaction is utilized to prepare an intermediate phase product, and the intermediate phase product is gradually subjected to solid-phase reaction while reaction energy is supplied by high temperature heating, thereby finally obtaining the Li3VO4 with favorable crystallinity. The first charge and discharge capacities of the Li3VO4 are respectively 523 and 423 mAh / g, and the charge and discharge capacities after 100 loops are still 398 mAh / g; and the grain size is uniform, and is less than 200nm.

Owner:CHINA THREE GORGES UNIV

Method for preparing rare earth element-doped nickel cobalt lithium manganate positive electrode material

InactiveCN103730653AUniform particle sizeHigh tap densityCell electrodesSecondary cellsRare-earth elementManganate

The invention discloses a method for preparing a rare earth element-doped nickel cobalt lithium manganate positive electrode material. The method comprises the following steps: dissolving nickel cobalt manganese salts in water to prepare a solution, adding a rare earth soluble salt, preparing ammonia water by taking ammonia water serving as a complexing agent according to a salt ammonia ratio, and preparing into a solution with NaOH as a precipitator; respectively adding the ammonia water and sodium hydroxide in a nitrogen atmosphere under the condition of water bath temperature of 70 DEG C, and stirring during the reaction process so that the reaction can be uniform; stirring and ageing for 10-15 hours, filtering the obtained reaction solution to obtain a precursor of nickel cobalt lithium manganate, performing microwave drying, and drying in a vacuum drying oven for 5 hours; mixing the precursor with a lithium salt, and mechanically performing ball milling and mixing through a wet method; sintering the material at the treatment temperature of 700-850 DEG C, and introducing oxygen in the sintering process; and grinding the material subjected to complete sintering, and allowing the material to pass through a 325-mesh sieve, thus obtaining the final product.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

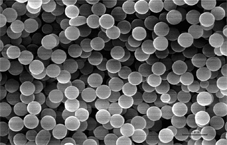

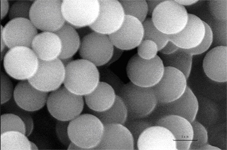

Method for preparing monodisperse polymer microsphere by irradiation polymerization of ultraviolet light

The invention relates to a method for preparing a monodisperse polymer microsphere by irradiation polymerization of ultraviolet light, belonging to the technical field of functional polymer microsphere preparation. In the method, an alkene monomer, a reactive macromolecule dispersion stabilizer and a photoinitiator are taken as raw materials, and polymerization is carried out on the raw materials in a mixed solvent of alcohol and water by the ultraviolet radiation to obtain the monodisperse polymer microsphere; the proportion of the raw materials is as follows: the dosage of the alkene monomer is 5-30g, the dosage of the reactive macromolecule dispersion stabilizer is 0.5-10g, the dosage of the photoinitiator is 0.2-1g and the dosage of the mixed solvent of alcohol and water is 100mL; and the reaction is initiated by the ultraviolet irradiation after the system is evenly mixed to obtain the monodisperse polymer microsphere. By using the method provided by the invention, the monodisperse polymer microsphere is obtained at normal temperature, the reaction energy consumption is low, the reaction speed can be regulated between dozens of minutes and dozens of hours, the diameter of particles of the polymer microsphere is controllable within the range of 100-800nm, and the surface of the microsphere has functional polymer chains.

Owner:广州五行材料科技有限公司

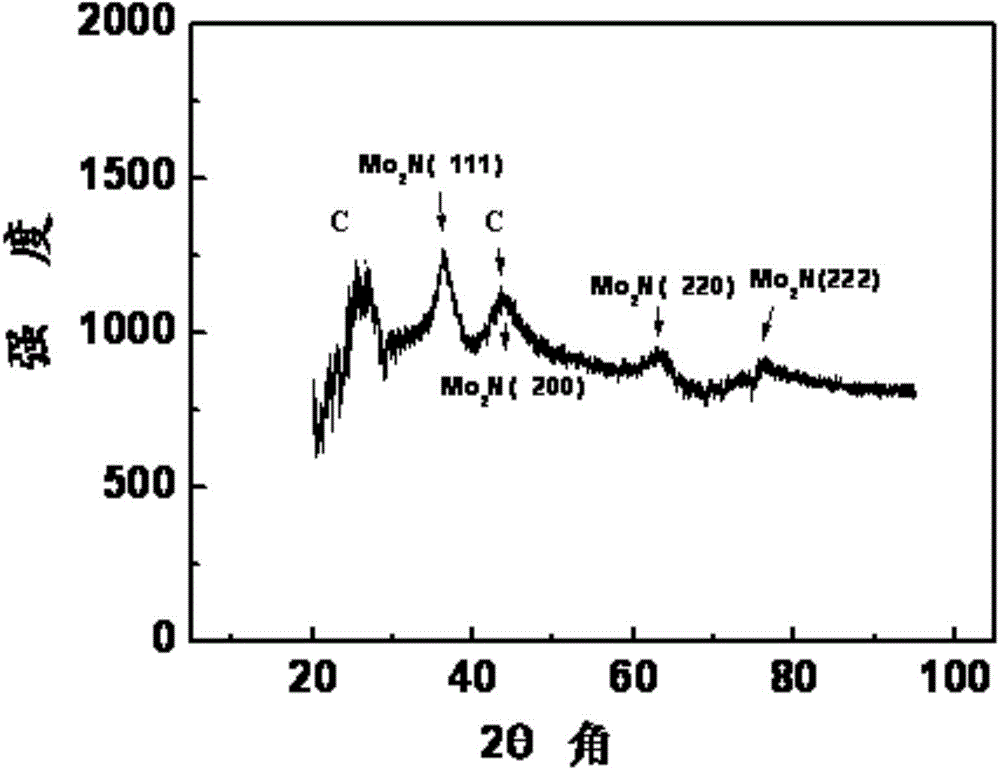

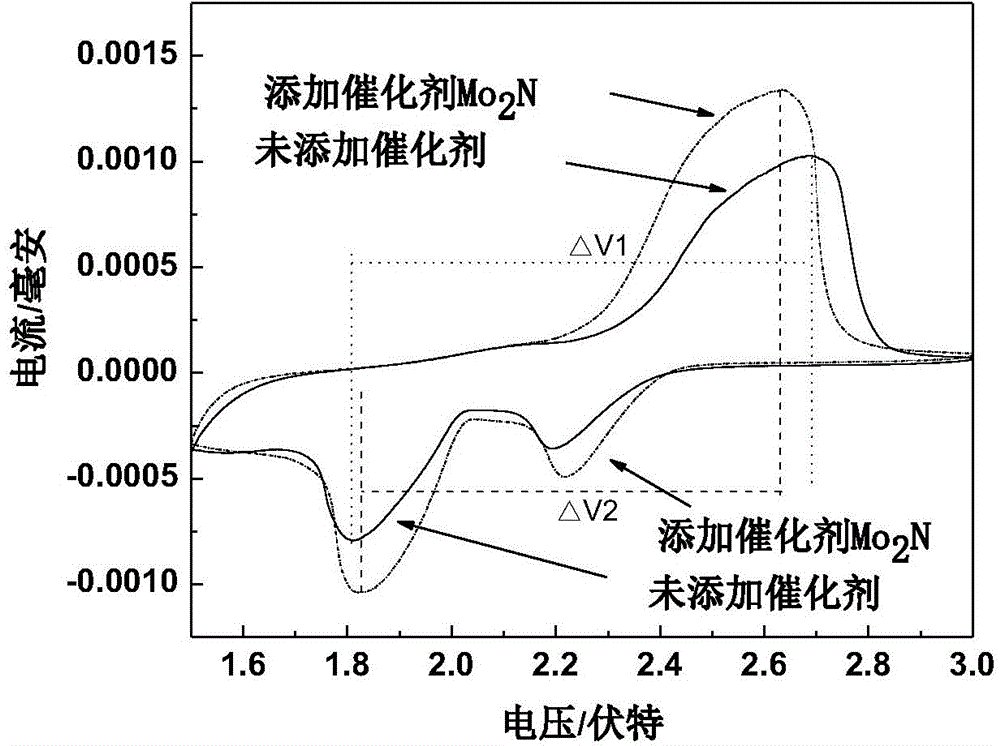

Cathode material used for lithium sulfur battery, preparation and application thereof

The invention relates to a cathode material used for a lithium sulfur battery, preparation and an application thereof. The cathode material employs one or more than two carbides or nitrides of metal elements from transition metal as a catalytic component and employs elementary sulfur as an active component. The catalytic component is supported on a carrier firstly and then the active component is supported on the carrier on which the catalytic component is supported. The content of the catalytic component is 2-30% of the total weight of the cathode material and the content of the sulfur is 30-80% of total weight of the cathode material, and the balanced is the carrier. The cathode material, when being used as a cathode in the lithium sulfur battery, has excellent selectivity on reduction of elementary sulfur and reduces reaction energy barrier required for sulfur reduction, reduces reaction polarization and increases discharge voltage platform. The cathode material is environment-friendly, is low in cost and is abundant in resources.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalyst used in process of preparing furfuryl alcohol by furfural through selective hydrogenation and preparation method of catalyst

InactiveCN103007941AHigh reactivityLow costOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureCopper oxide

The invention discloses and provides a catalyst used in a process of preparing furfuryl alcohol by furfural through selective hydrogenation and a preparation method of the catalyst, wherein the catalyst has the advantages of lower cost, capability of protecting environment, low reaction temperature, long service life and high activity and selectivity. The catalyst is a copper oxide-silicon oxide compound oxide. The preparation method comprises the steps of: 1, adding water in a copper salt, stirring for dissolving, and reacting by using 10-20 weight percent of sodium hydroxide solution to form a colloid A; 2, diluting the silicon oxide colloid by using water accounting for two times of the silicon oxide colloid by weight to form a colloid B; 3, adding the colloid B into the colloid A, mixing, sequentially heating, ageing, filtering, washing, drying and roasting; and 4, carrying out hydrogenation reduction activation for 3-18h to prepare the catalyst. The catalyst does not contain a toxic material Cr, can react at a low temperature, is capable of reducing the production energy consumption, and is high in reaction activity, high in furfural transformation rate, and high in selectivity of furfuryl alcohol.

Owner:ZHUHAI KAIMEI TECH

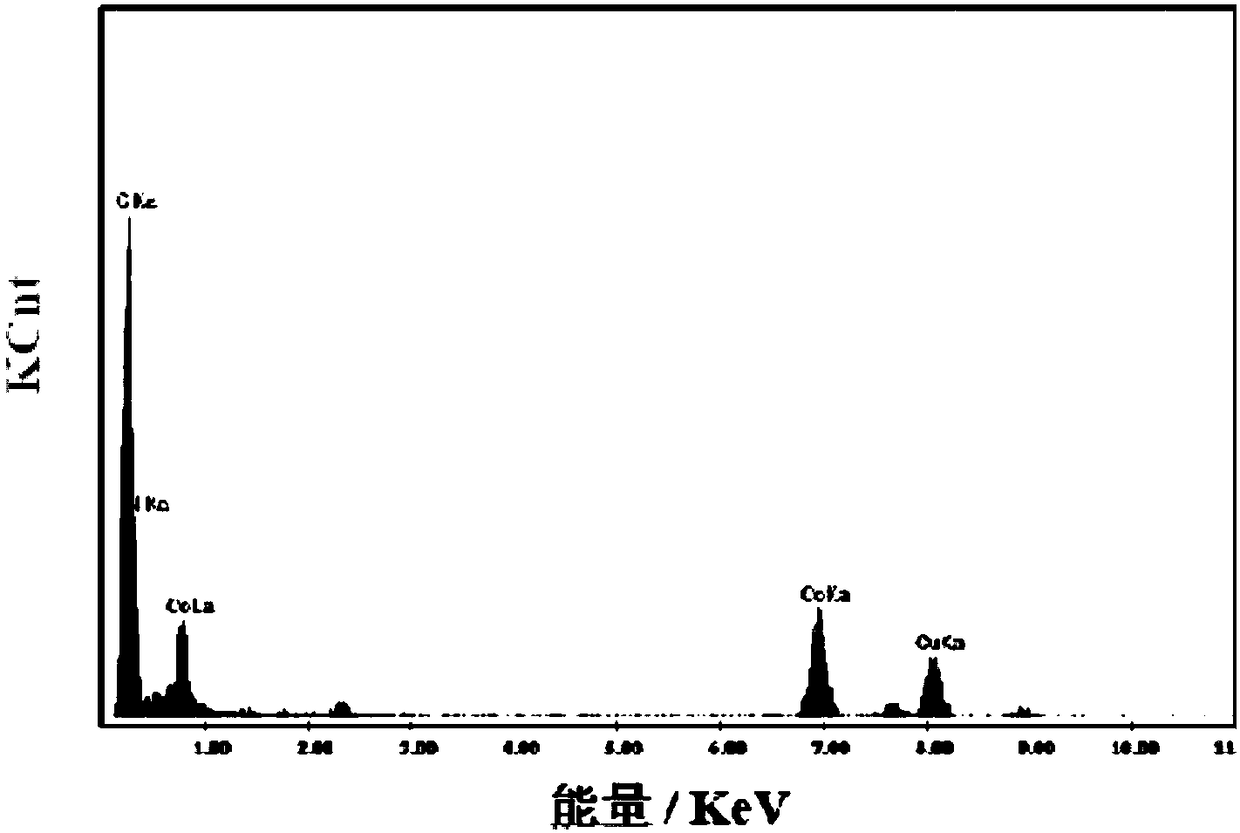

Preparation method and application of carbon-based copper-cobalt oxide nanosheet catalyst

InactiveCN107442125ARegular shapeLarge specific surface areaCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsWater basedFiber

The invention discloses a preparation method of a carbon-based copper-cobalt oxide nanosheet catalyst and application to oxygen evolution by electrolyzing water based on the catalyst, and belongs to the technical fields of nano catalysis, nano materials and metal-organic framework (MOF) materials. The preparation method comprises the following main steps of blending an aspartic acid alkaline solution with a copper nitrate-cobalt nitrate solution at a room temperature, generating a sediment at the room temperature, carrying out suction filtration, and drying, so that a Cu-MOF nano fiber loaded Co(II) ion, namely a CuCo-MOF nano fiber, is prepared; heating the CuCo-MOF nano fiber in an air atmosphere, so that the carbon-based copper-cobalt oxide nanosheet catalyst is prepared. The cost of raw materials used for the preparation of the catalyst is low; the preparation process is simple; the reactive energy consumption is low; the carbon-based copper-cobalt oxide nanosheet catalyst has an industrial application prospect. The catalyst is used for efficiently catalyzing and hydrolyzing the water for the oxygen evolution and has favorable oxygen-evolution electrocatalytic activity and electrochemical stability.

Owner:UNIV OF JINAN

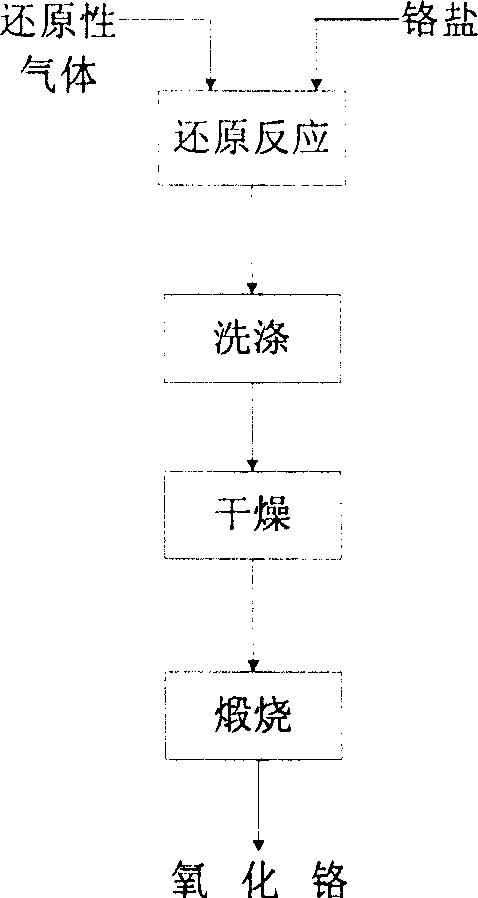

Method of preparing chromium oxide by reducing chromate with gaseous reducing agent at low temperature

InactiveCN1907865ASimple production processEasy to industrializeChromium oxides/hydratesHydrogenReaction temperature

This invention involves a preparation method for chromium oxide with chromium salt as raw materials and reducing gas as a reductant. Said method comprises carrying out reaction of chromium salt with superfluous reducing gas at 300~850DEG C for 0.5-3 h and cooling to obtain a reaction mixture, washing the mixture and drying, and calcining at 400~1100DEG C for 1-3 h to obtain the ultrafine chromium oxide powders, wherein the chromium salt is chromate or dichromate, and the reducing gas is hydrogen, natural gas, gas or their mixtures. Compared with existing technologies, this invention has the advantages of simple production process and being easy for industrialization. The obtained chromium oxide has high purity, uniform particle size distribution and small particle size. The whole process does not produce containing chromium-containing waste, and is environmental friendly. The reaction by-product can be reused, which greatly reduces the cost of production. Low reaction temperature greatly reduces the reaction energy.

Owner:中蓝义马铬化学有限公司

Preparation method of transition group metal/carbon pipe/graphene electrocatalyst for hydrogen evolution reaction

ActiveCN108385124AUnique structureImprove conductivityGrapheneCarbon nanotubesPorosityCarbon nanotube

The invention discloses a preparation method of a transition group metal / carbon pipe / graphene electrocatalyst for a hydrogen evolution reaction. A core-shell bimetallic zeolite imidazolyl framework coated with oxidized graphene acts as a precursor, GO is subjected to thermal reduction by a one-step heating process so that rGO is obtained, ZIF-67@ZIF-8 nano particles are subjected to in-situ carbonization so that an N-doped carbon nano tube coated with superfine Co nano particles, and thus a Co@N-CNTs@rGO composite is prepared. The composite has the advantages of a unique three-dimensional hierarchic structure, high porosity, rich N-doped property, high conductivity of rGO, homogeneous dispersion of Co nano particles, and the like, so that when the composite acts as a catalyst for HER, thecomposite shows excellent electro-catalytic characteristics. The obtained composite is high in conductivity, multiple in active sites and good in electro-catalytic property, the cost of raw materialsfor preparation is low, a technology is simple, reaction energy consumption is low, large-scale preparation can be realized, and the preparation method is an efficient and economical novel HER electrocatalyst preparation method.

Owner:FUDAN UNIV

Titanium-silicon-aluminum molecular sieve, preparation method and applications thereof, and a cyclic ketone oxidation method

ActiveCN106032277AFacilitated DiffusionHigh benzene adsorption capacityMolecular sieve catalystsSolid waste disposalMolecular sieveBenzene

The present invention relates to the field of molecular sieves, and mainly provides a titano-silicon-alumina molecular sieve and its preparation method and application. The titano-silicon-alumina molecular sieve contains aluminum, titanium, silicon and oxygen, and its pore volume is 0.3 cm 3 / g or more, the total specific surface area is 200m 2 / g or more, the outer area is 30m 2 / g or more, and the ratio of the outer surface area to the total specific surface area is 10-55%; 0 = 0.10 and the adsorption time is 1h, the measured benzene adsorption is at least 65mg / g molecular sieve, N 2 Under the static adsorption test, it has a micropore size distribution in the range of 0.9-2.0nm. The invention also provides a method for oxidizing cyclic ketones. The titano-silicon-alumina molecular sieve with special physical and chemical characteristic structure of the present invention has the advantages of high benzene adsorption capacity and micropore pore size distribution in the range of 0.9-2.0nm, for example, it is used for cyclic molecules, especially cyclic ketone molecules to participate or The generated reaction can achieve better catalytic effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

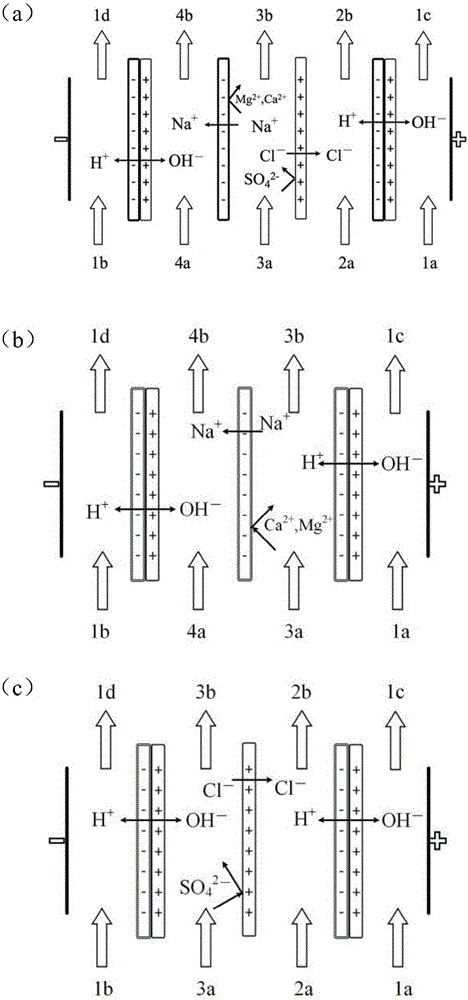

Selective bipolar membrane electrodialysis system and application thereof

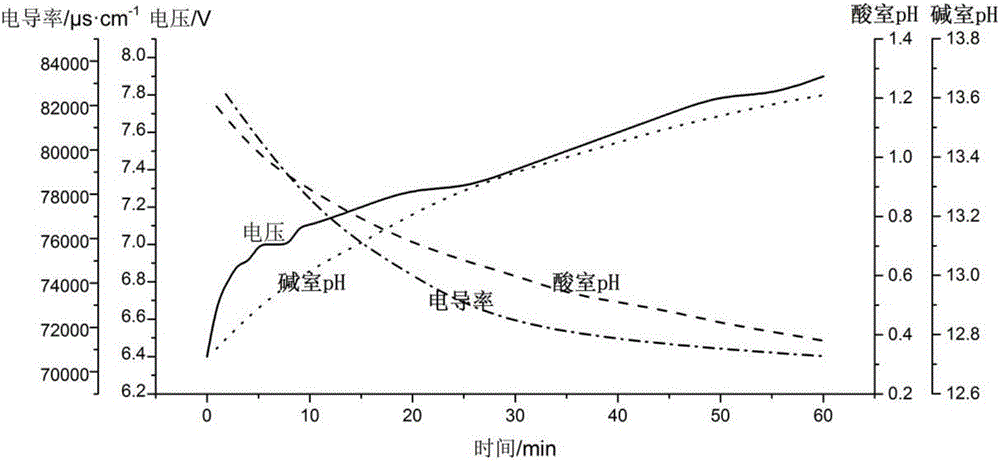

InactiveCN106630040AReduce reaction energy consumptionSimple processGeneral water supply conservationDispersed particle separationIon exchangeElectrodialysis

The invention discloses a selective bipolar membrane electrodialysis system and application thereof. The selective bipolar membrane electrodialysis system comprises an electrodialysis membrane pile, a positive electrode plate and a negative electrode plate, wherein the positive electrode plate and the negative electrode plate are fixed at the two sides of the electrodialysis membrane pile through clamping plates; the electrodialysis membrane pile is formed by sequentially and alternately laminating several kinds of functional membranes and adding a flow passage separation net and a sealing gasket; the functional membranes comprise a bipolar membrane and a multiple valence ion selective passing membrane; an anion exchange layer of the bipolar membrane faces the positive electrode plate; the cation exchange layer faces the negative electrode plate. The selective bipolar membrane electrodialysis system provided by the invention has the advantages that the bipolar membrane electrodialysis and the selective electrodialysis are combined in the same device; when the system is used for salt-containing material desalting and acid-base production, the bipolar membrane electrodialysis and the selective electrodialysis are merged into one operation; the flow process is simplified; the operation quantity is reduced; the electrode reaction energy consumption is reduced; the production efficiency is improved.

Owner:UNIV OF SCI & TECH OF CHINA

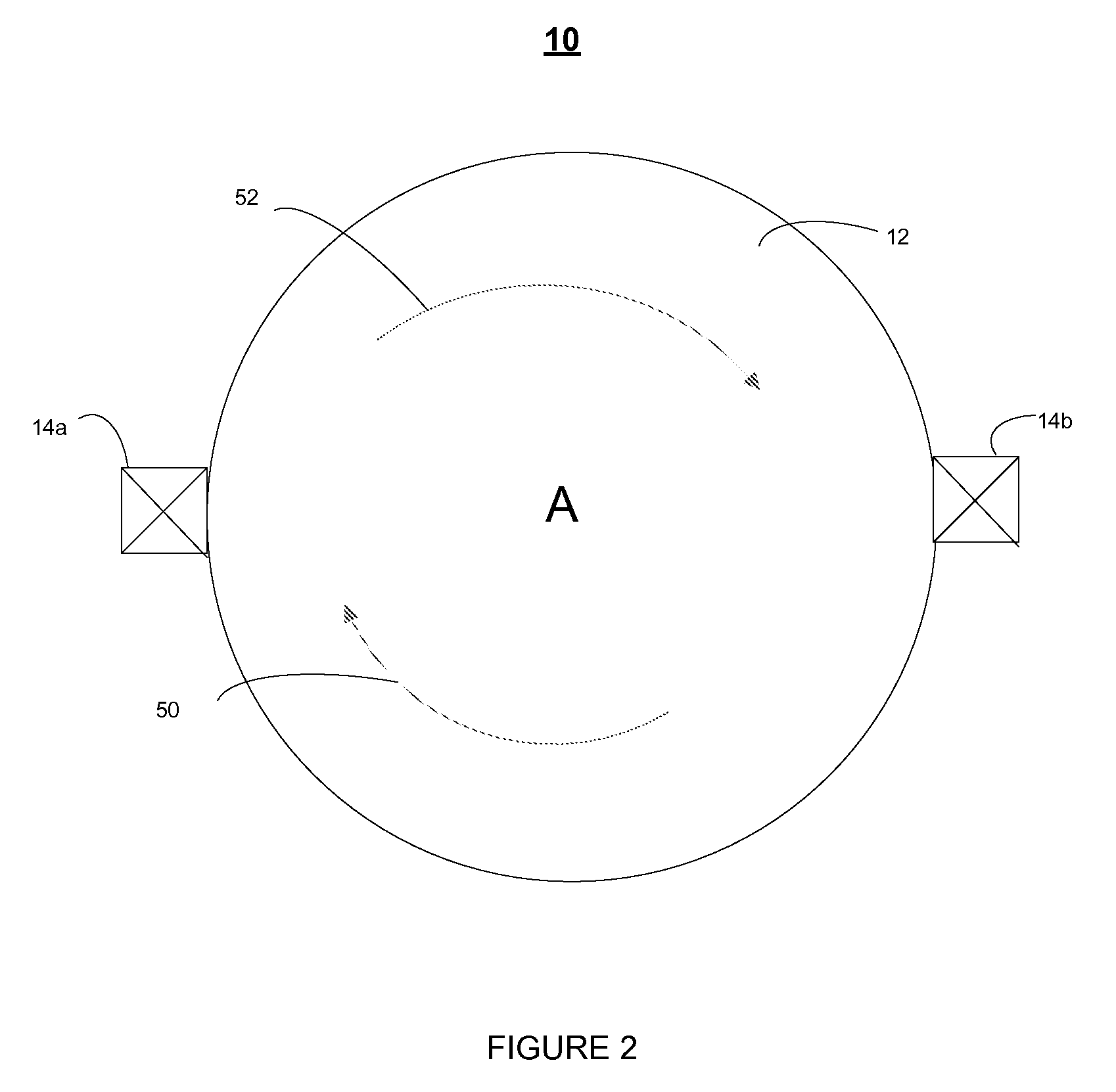

Cyclonic reactor with non-equilibrium gliding discharge and plasma process for reforming of solid hydrocarbons

A reactor for reforming a hydrocarbon, and associated processes and systems, are described herein. In one example, a reactor is provided that is configured to use non-equilibrium gliding arc discharge plasma. In another example, the reactor uses a vortex flow pattern. Two stages of reforming are described. In a first stage, the hydrocarbon absorbs heat from the wall of the reactor and combusts to form carbon dioxide, carbon monoxide, and water. In a second stage, a gliding arc discharge is use to form syngas, which is a mixture of hydrogen gas and carbon monoxide. The heat generated by the combustion of the first stage transfers to the wall of the reactor and heated products of the second stage mix with incoming hydrocarbon to provide for partial recuperation of the reaction energy.

Owner:DREXEL UNIV

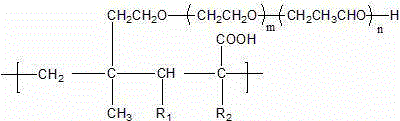

Concrete polycarboxylate water reducing agent and preparing method thereof

The invention provides a concrete polycarboxylate water reducing agent and a preparing method thereof. The concrete polycarboxylate water reducing agent is a polymer copolymerized by a monomer A and a monomer B, wherein the weight-average molecular weight of the polymer ranges from 5,000 to 30,000. The chemical structural formula is shown in the specification, wherein m is an integer ranging from 14 to 66, n is an integer ranging from 0 to 40, R1 is H or COOH, and R2 is H or CH3. The performance is stable, the water-reducing rate is high, and cement adaptation is high; the concrete polycarboxylate water reducing agent has the excellent water reducing performance and the excellent slump retaining performance, and has the advantages that the preparing process is simple in technology, time is short, reaction energy consumption is low, operability is high, and pollution to the environment is avoided.

Owner:国能辽宁环保产业集团有限公司材料分公司

Pocket-size ozone generator

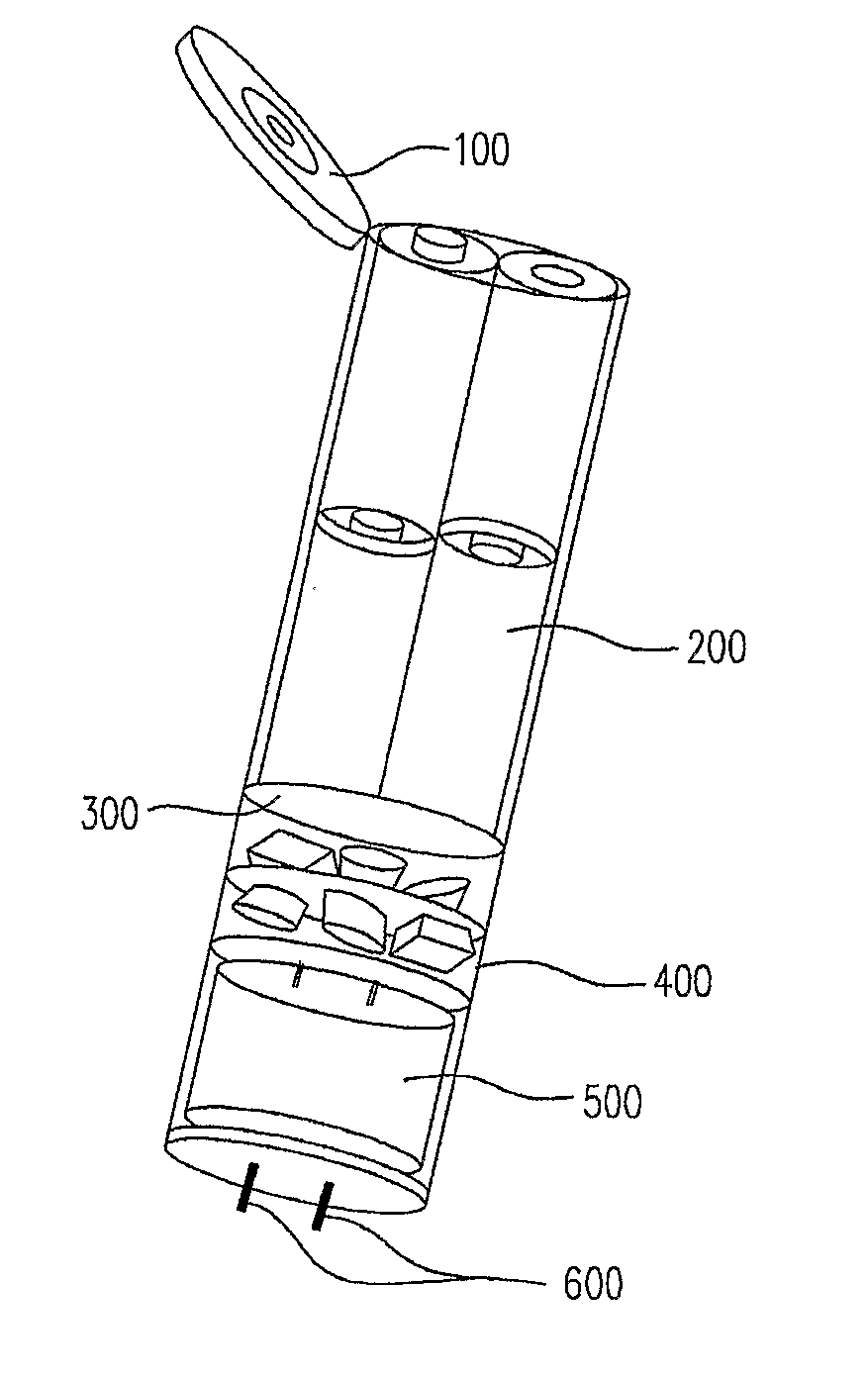

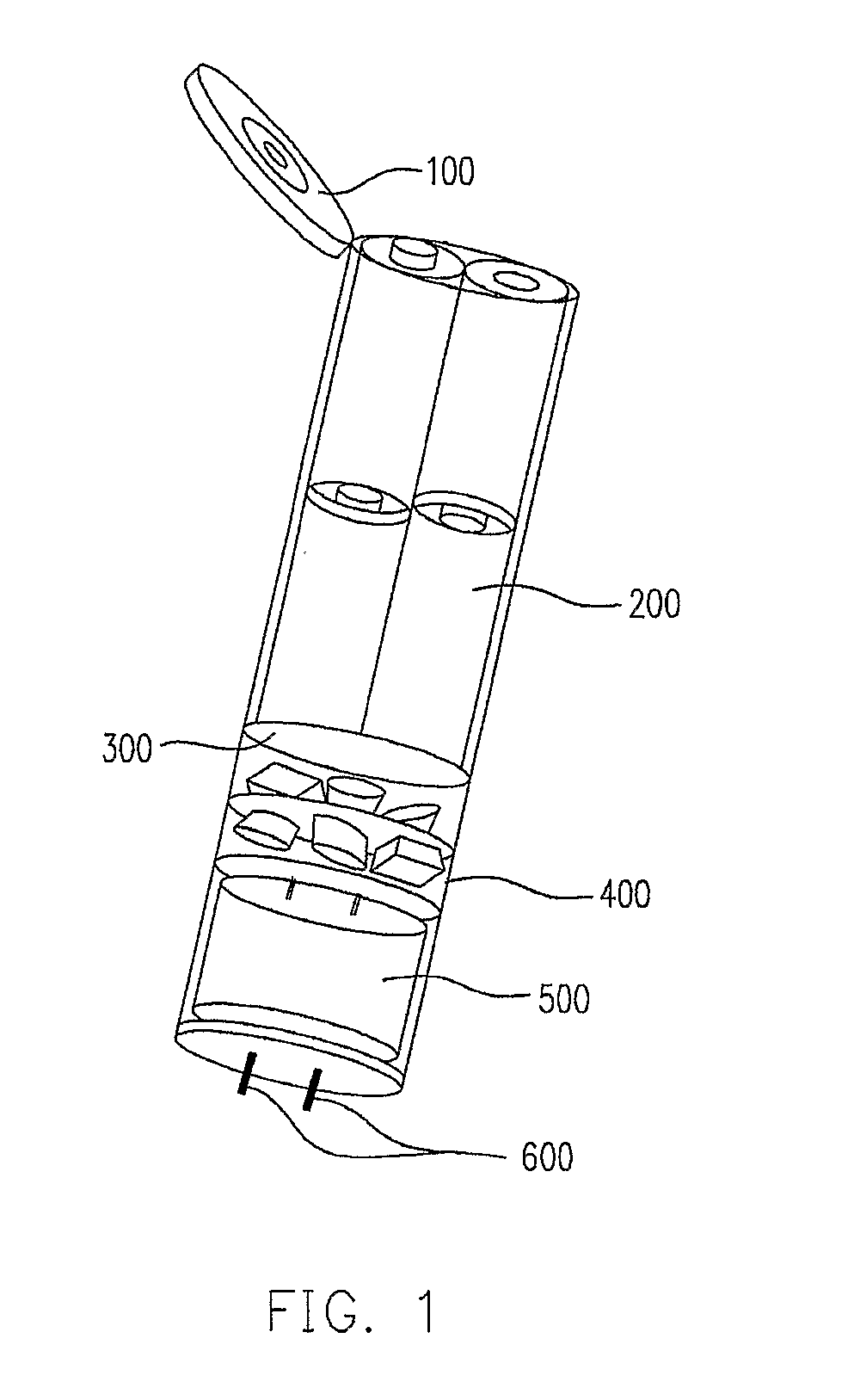

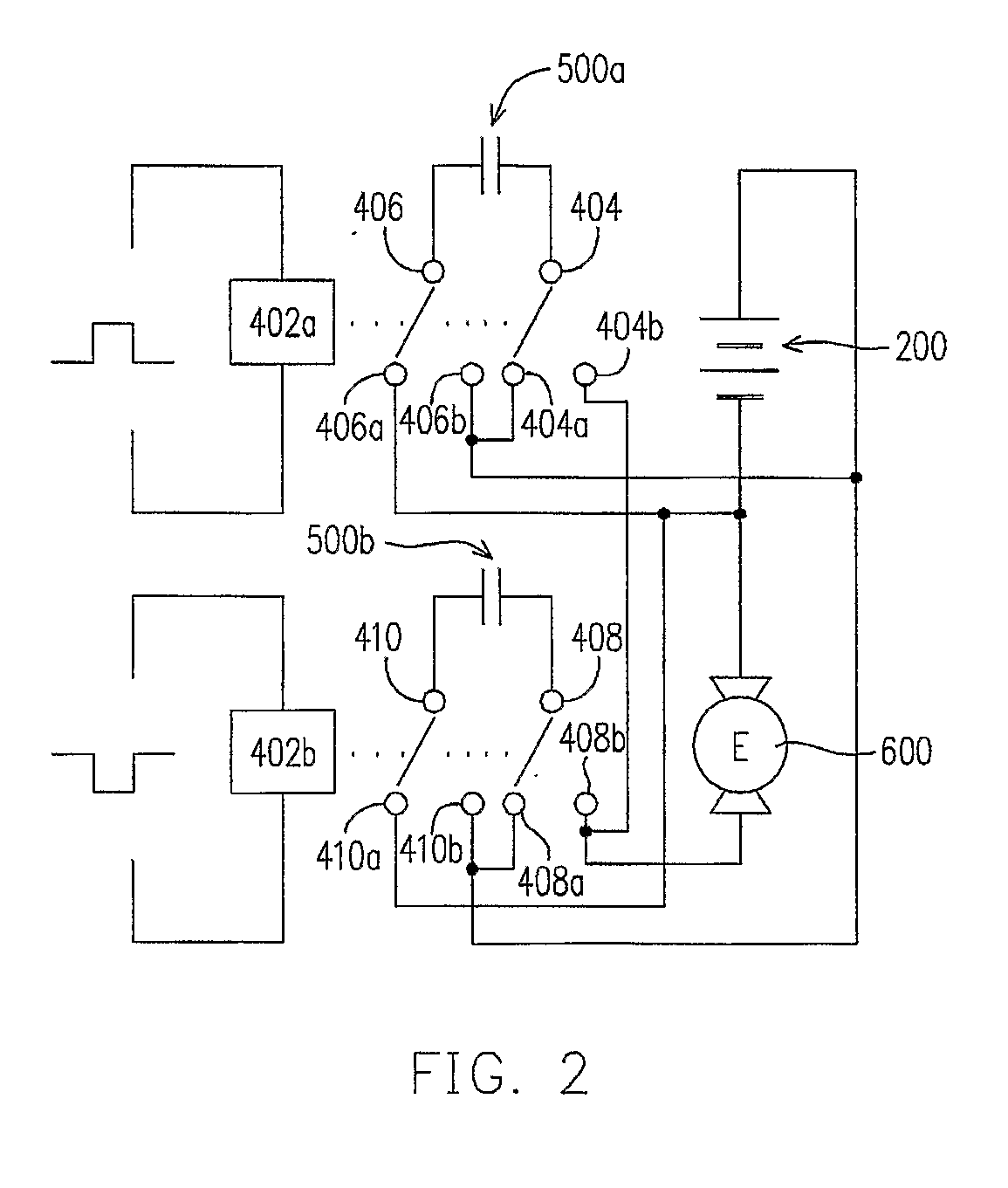

InactiveUS20080181832A1Minimized in sizeExtended use timeBatteries circuit arrangementsElectrical discharge ozone preparationOzone generatorSupercapacitor

A pocket-size ozone generator for in-situ sterilization of water is disclosed. The pocket-size ozone generator comprises a power source, at least a supercapacitor, a switching circuit and at least a pair of electrodes. The power source is adapted for providing a reaction energy to generate ozone gas within the water to be treated. The supercapacitor is adapted for amplifying the reaction energy provided by the power source. The circuitry is adapted for controlling the supercapacitor to deliver consistent power supply to generate ozone. The electrodes are adapted for receiving the amplified reaction energy from the supercapacitor to generate ozone within the water to be treated.

Owner:SHIUE LIH REN

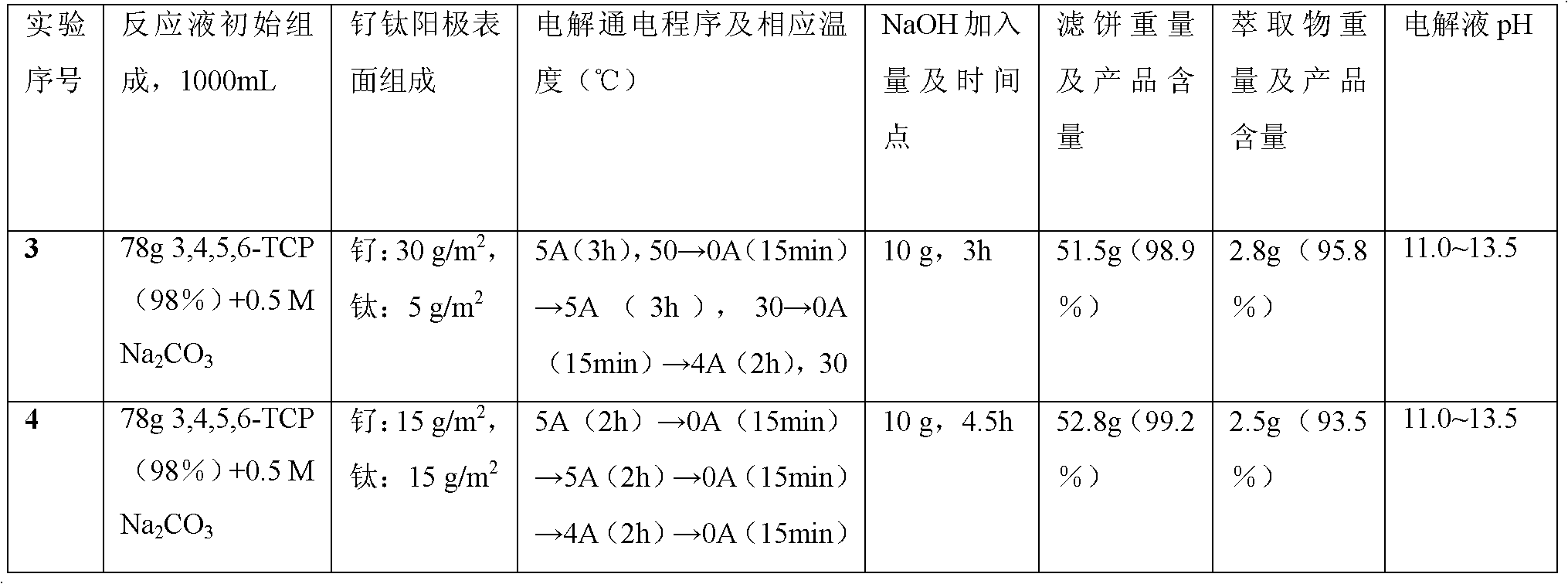

Selective electrolysis hydrogenation and dechlorination method for chlorinated organic matter

ActiveCN102181880ALong-term activityReduce reaction energy consumptionOrganic chemistryElectrolytic organic productionElectrolysisSilver electrode

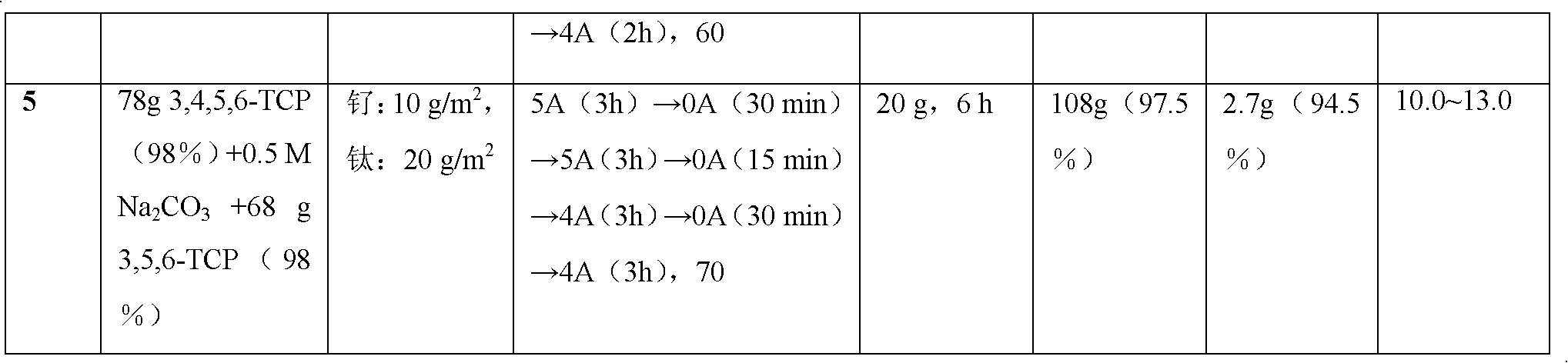

The invention discloses a selective electrolysis hydrogenation and dechlorination method for a chlorinated organic matter. The method comprises the following steps of: dissolving the chlorinated organic matter in alkaline solution serving as a reaction medium, and performing an electrolytic reaction; and acidizing after the electrolytic reaction is finished to obtain a target product, wherein a ruthenium titanium positive electrode is used as the positive electrode of the electrolytic reaction, a silver electrode is used as the negative electrode of the electrolytic reaction, and energizationis stopped for 5 to 60 minutes when electrolysis is performed for 1 to 5 hours every time in the electrolysis reaction process. The method is easy to operate; and by the method, the step of repeatedly performing electrochemical oxidation on the activated silver electrode in the reaction process can be prevented, and the energy consumption of the reaction can be effectively reduced.

Owner:ZHEJIANG UNIV OF TECH

Ozone generators

InactiveUS20100135869A1Effective sterilizationEasy to carryElectrical discharge ozone preparationEnergy based wastewater treatmentSupercapacitorEngineering

An ozone generator for in-situ sterilization of water, which may be pocket-sized, is disclosed. The ozone generator includes a power source, at least a supercapacitor, a switching circuitry and at least a pair of electrodes. The power source is adapted for providing a reaction energy to generate ozone gas within the water to be treated. The supercapacitor is adapted for amplifying the reaction energy provided by the power source. The circuitry is adapted for controlling the supercapacitor to deliver consistent power supply to generate ozone. The electrodes are adapted for receiving the amplified reaction energy from the supercapacitor to generate ozone within the water to be treated.

Owner:LINXROSS

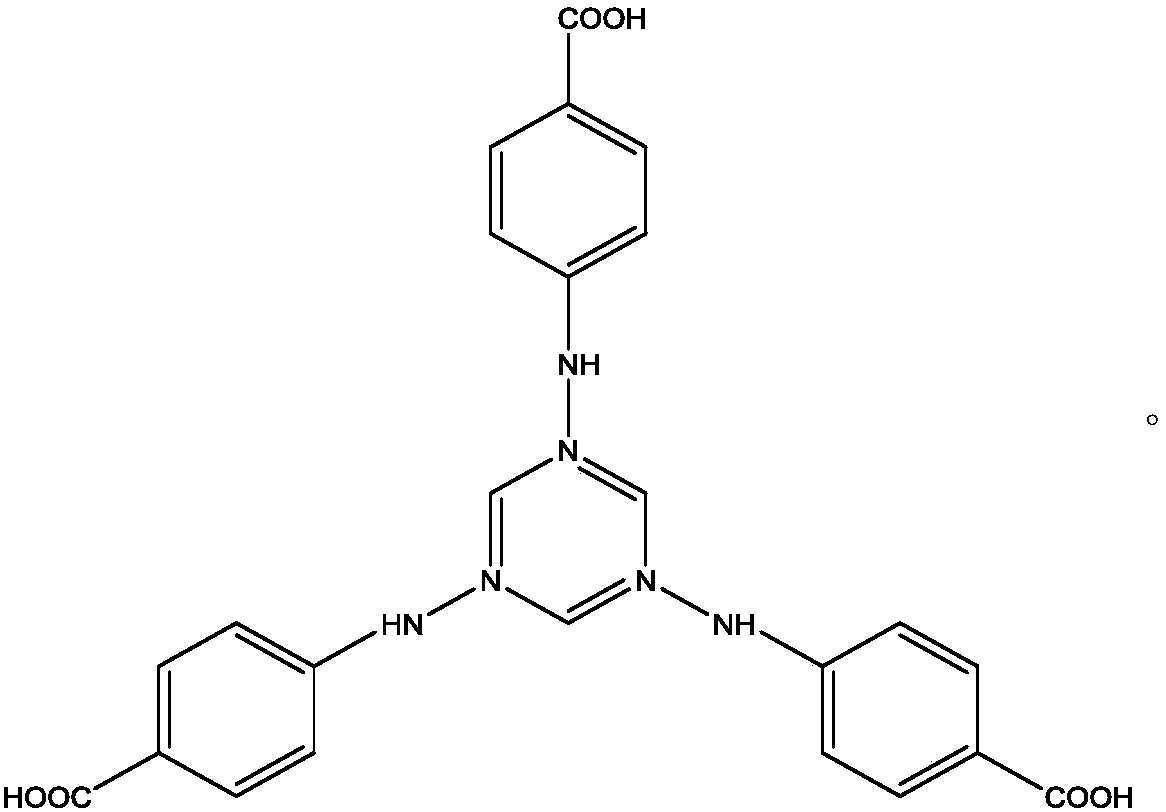

Preparation method and application of catalyst based on nickel-based three-dimensional metal organic frame substance

InactiveCN108080034AImprove production efficiencySimple preparation processOrganic-compounds/hydrides/coordination-complexes catalystsElectrodesAir atmosphereElectrolysis

The invention discloses a preparation method of a catalyst based on a nickel-based three-dimensional metal organic frame substance and an application of oxygen evolution by water electrolysis based onthe catalyst, and belongs to the technical field of nanomaterials, nano catalysis and metal organic frame substance materials. The method mainly comprises the steps of performing electro-deposition on polyaniline with foamed nickel to form a Ni@PANI composite, applying gel prepared from a ligand H3TATAB and cobalt nitrate on the Ni@PANI composite, and heating in an air atmosphere to form a Ni@Co2O3 / CN composite catalyst, namely the catalyst based on the nickel-based three-dimensional metal organic frame substance. Raw materials used for preparation of the catalyst are low in cost; a preparation technology is simple; the reaction energy consumption is low; and the catalyst has industrial application prospects. The catalyst is used for efficient catalysis of water electrolysis for oxygen evolution and has good oxygen evolution electrocatalytic activity and electrochemical stability.

Owner:UNIV OF JINAN

Method for treating carbon-containing organic matter by supercritical water oxidation

ActiveCN103073103AAchieve self-sufficiencyStart raw material without heatingWater/sewage treatment by oxidationDecompositionSupercritical water oxidation

The invention relates to a method for treating carbon-containing organic matter by supercritical water oxidation. The method comprises the step of obtaining oxidative decomposition product by oxidizing the carbon-containing organic matter in the supercritical state of water and under the effect of oxidant; heat released by the supercritical water oxidation treatment of the carbon-containing organic matter at least can satisfy the heat required by warming the carbon-containing organic matter to the supercritical state of the water, thereby energy is not required to be provided by the outside in the stable operation process, and the self-supply of reaction energy is completely achieved; and the cold start of the reaction is achieved by the cold start mode of low-temperature combustion catalysis.

Owner:ENN SCI & TECH DEV

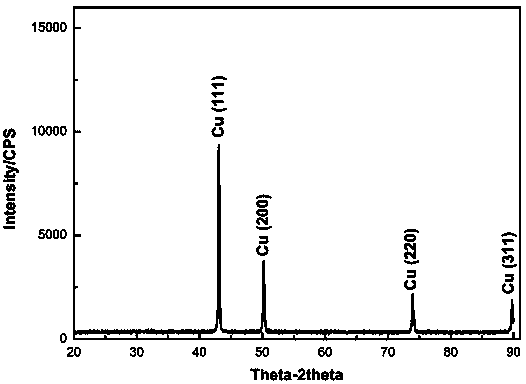

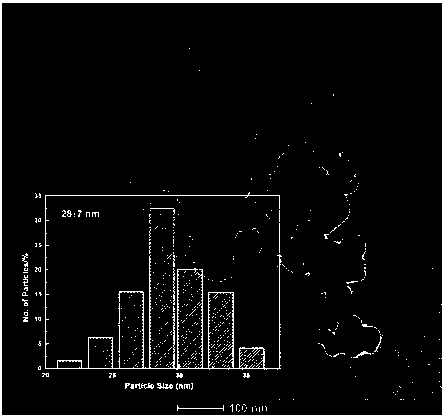

Method for utilizing low co-fusion type ionic liquid electro-deposition to manufacture nanometer copper powder

The invention relates to a method for utilizing low co-fusion type ionic liquid electro-deposition to manufacture nanometer copper powder and is mainly applied to the field of material preparation. The method comprises the steps of mixing choline chloride and urea after performing vacuum drying on choline chloride and urea, performing reaction to obtain low co-fusion type ionic liquid, adding a copper precursor to perform uniform mixing, and obtaining an ionic liquid-copper salt compound electrolyte; finally under the inert atmosphere, enabling stainless steel, a nickel sheet or a titanium sheet to serve as a negative pole, enabling graphite or an inertial positive pole to serve as a positive pole, performing electro-deposition in the ionic liquid-copper salt compound electrolyte, and obtaining the nanometer copper powder with the grain size of 30-50nm on the surface of the negative pole. The method has the advantages that the method is low in cost and reaction energy consumption, short in production flow, free of pollution and simple in process, product quality is stable, and added values are high.

Owner:KUNMING UNIV OF SCI & TECH

Metal antirust agent and production process thereof

InactiveCN101565582AImprove surface activityGood corrosion inhibitionAnti-corrosive paintsBenzoic acidChemical reaction

The invention discloses a metal antirust agent and a production process thereof. The metal antirust agent includes 30-50g of sorbol, 20-29g of triethanolamine, 13-17g of benzoic acid, 18-22g of boric acid, 20-50g of potassium sorbate, 5-10g of glycerin, 5-10g of Marpropy copolymer, 15-25g of sodium hydroxide, 4-6g of sodium carbonate in every litter of the solution thereof. Comparing with technologies in prior art, the adopted raw material is in food stage and low in cost; the antirust agent is not harmful to human body in industrial use, contains no heavy metal or carcinogenic substance of sodium nitrite, and meets the environment protection requirement; the antirust agent adheres to the metal surface, without chemical reactions with the metal surface, and is capable of keeping the metal surface smooth, wet, glossy, maintaining pH value thereof in the range between 8 to 9, and reducing oxygen content of the metal surface. Thus, the metal antirust agent has great antirust performance which makes it especially suitable for rust protection between processing steps, and capable of rust protection for over a year.

Owner:CHERY AUTOMOBILE CO LTD

Method for preparing biological oil by liquefying biomass under atmospheric pressure by using solid acid catalyst

ActiveCN103013552AAvoid wastingRelieve pressureLiquid hydrocarbon mixture productionLiquid productFiltration

The invention discloses a method for preparing biological oil by liquefying biomass under atmospheric pressure by using a solid acid catalyst, belonging to the field of preparation of chemical engineering high polymer material products and biological fuels. The method comprises the following steps: putting mixed liquefier and liquefying catalyst in a container, heating to 120-180 DEG C, adding biomass or biomass waste, liquefying for 30-120 minutes, cooling to room temperature, dissolving the liquefied mixture in a solvent until the liquid product is sufficiently dissolved, carrying out vacuum filtration to implement solid-liquid separation, and carrying out rotary evaporation to concentrate the liquid product. The method can be operated under atmospheric pressure, has the advantages of simple technique, high heat efficiency, high liquid product yield and high liquefying rate (up to higher than 70%); the hydroxyl value of the liquefied product of various types of agricultural and forestal biomass waste is up to 260-340mg KOH / g; and the heat value is up to 29-33 KJ / g. The invention can lower the reaction energy consumption and the cost.

Owner:如东文园投资开发有限公司

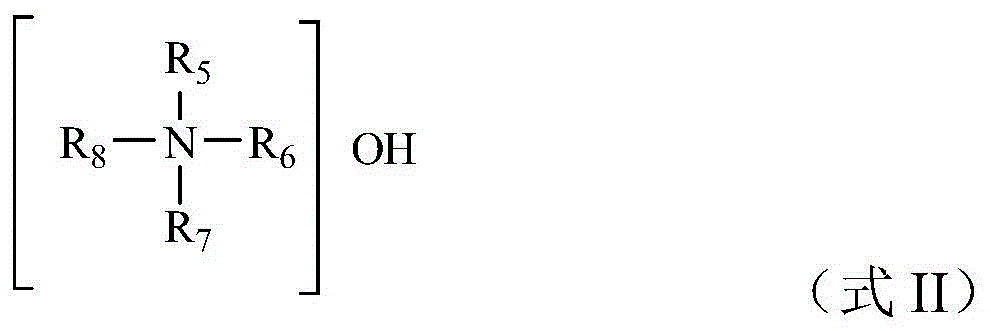

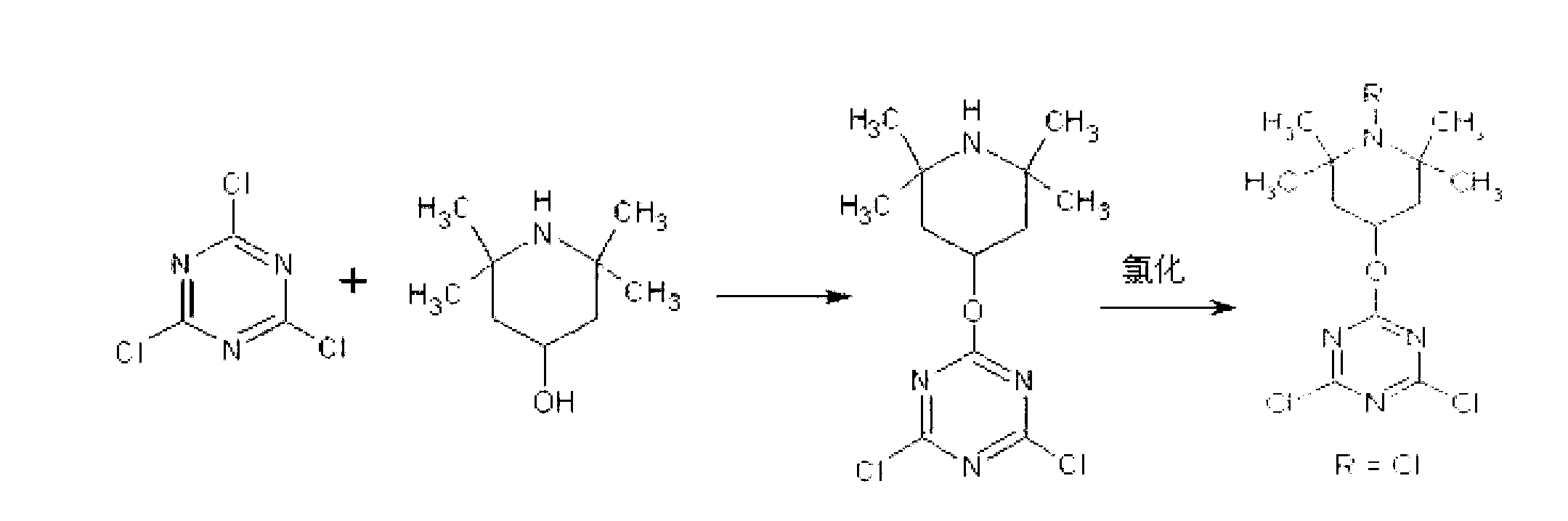

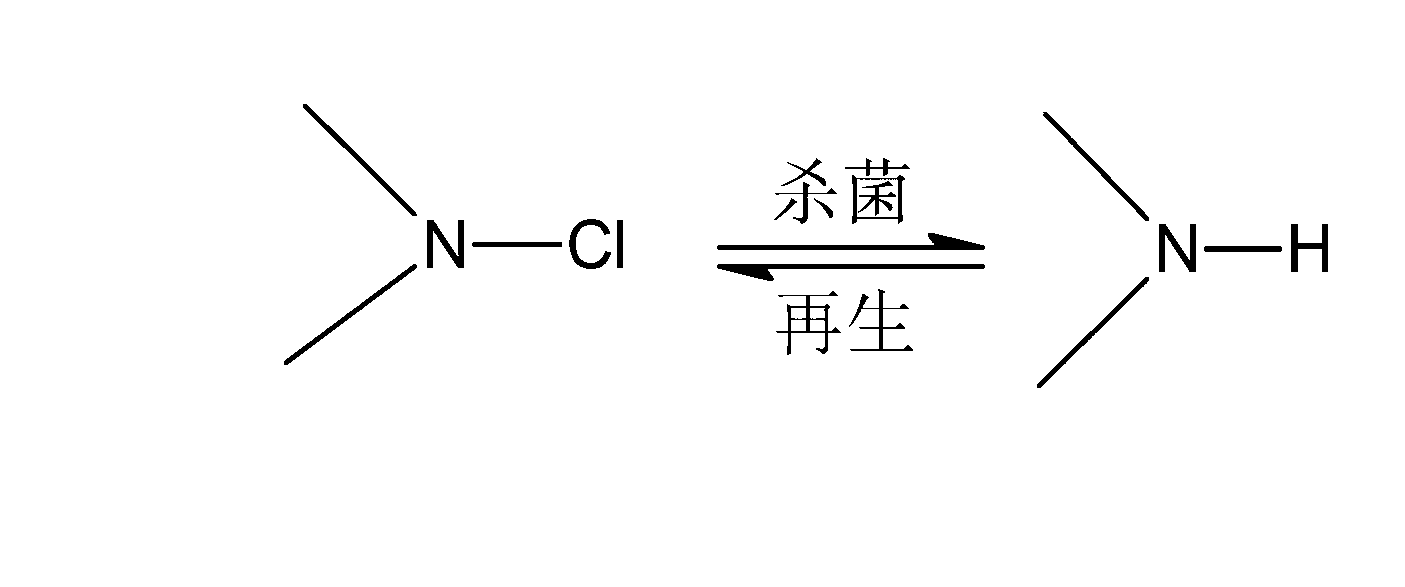

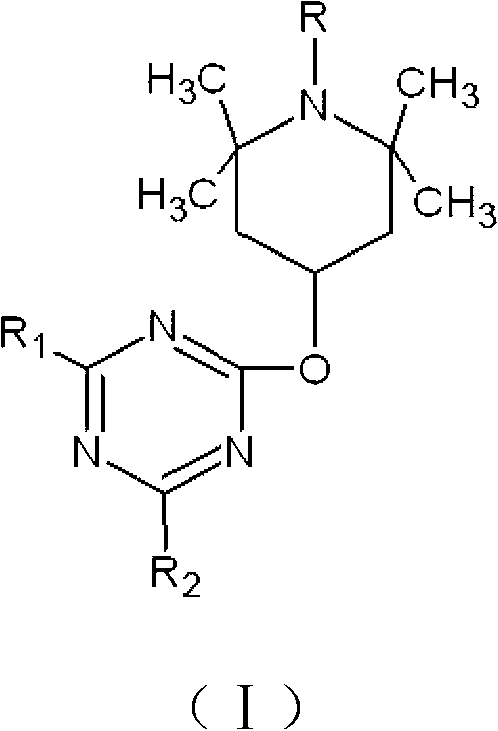

Halamine antibacterial agent, its preparation method and application

ActiveCN102797150ALow priceShort reaction timeOrganic chemistryFibre treatmentReaction temperatureAntibacterial agent

The invention provides a halamine antibacterial agent, its preparation method and application. The halamine antibacterial agent is a compound with a structure shown in formula (I). The preparation method consists of: in the presence of an acid-binding agent, taking cyanuric chloride or cyanuric fluoride or their derivative, and 2, 2, 6, 6-tetramethyl-4-piperidinol as synthesis raw materials to prepare a halamine antibacterial agent precursor with a structure shown in formula (II), and then reacting the precursor with a sodium hypochlorite solution to prepare a halamine antibacterial agent finished product. The halamine antibacterial agent can be applied in textile antibacterial finishing. Specifically, a textile to be treated is dipped in a finishing solution containing the halamine antibacterial agent precursor and a metal salt catalyst for finishing, and finally a halogenation reaction is carried out so as to obtain an antibacterial textile. The method provided in the invention for preparation of the halamine antibacterial agent has the advantages of low cost, simple process, low reaction temperature, no toxicity or pollution, and is in line with the requirements of ecological textile antibacterial finishing. According to the invention, the application process has the characteristics of simple operation and low reaction energy consumption, and antibacterial textiles with good antibacterial properties can be prepared.

Owner:JIANGNAN UNIV

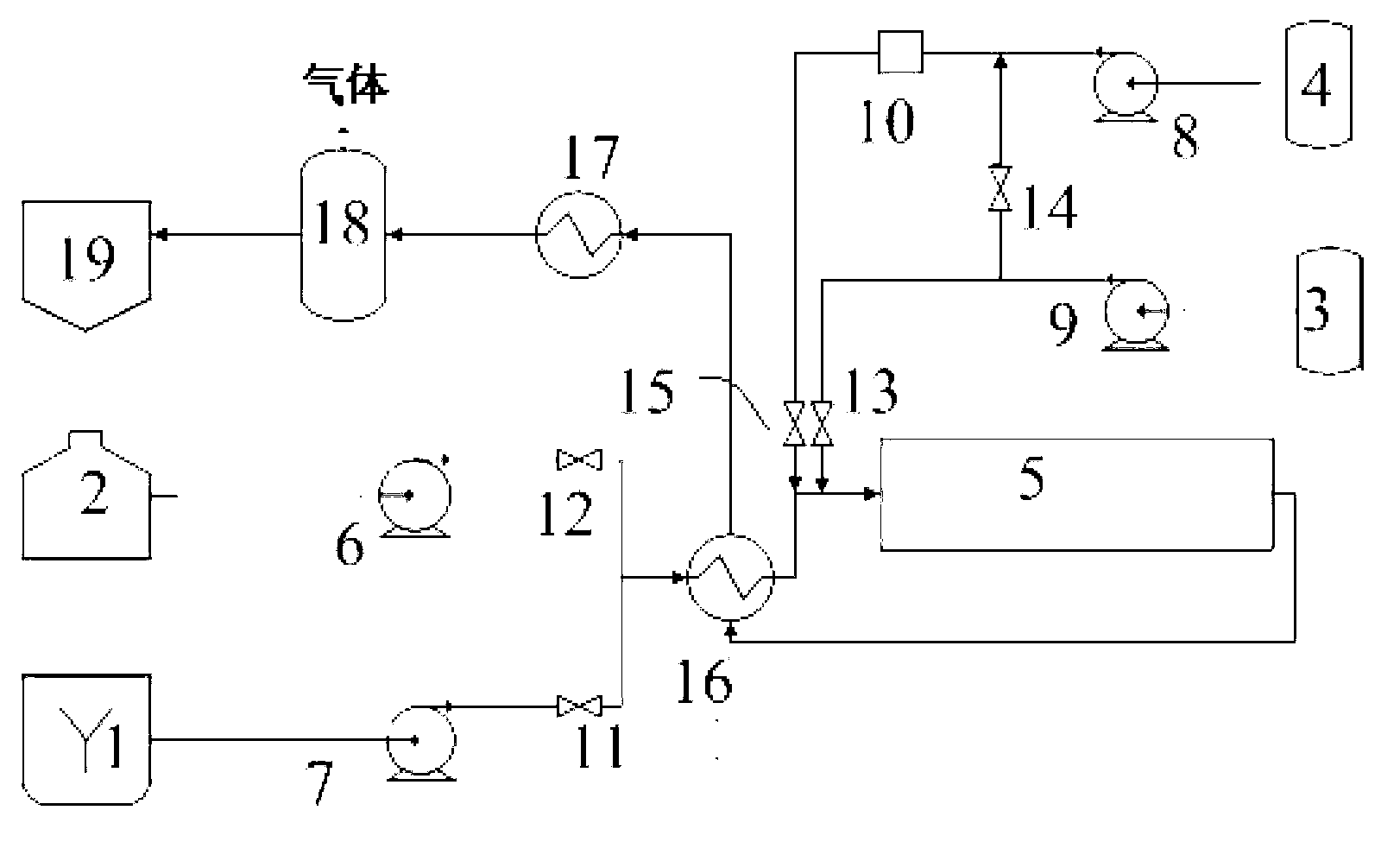

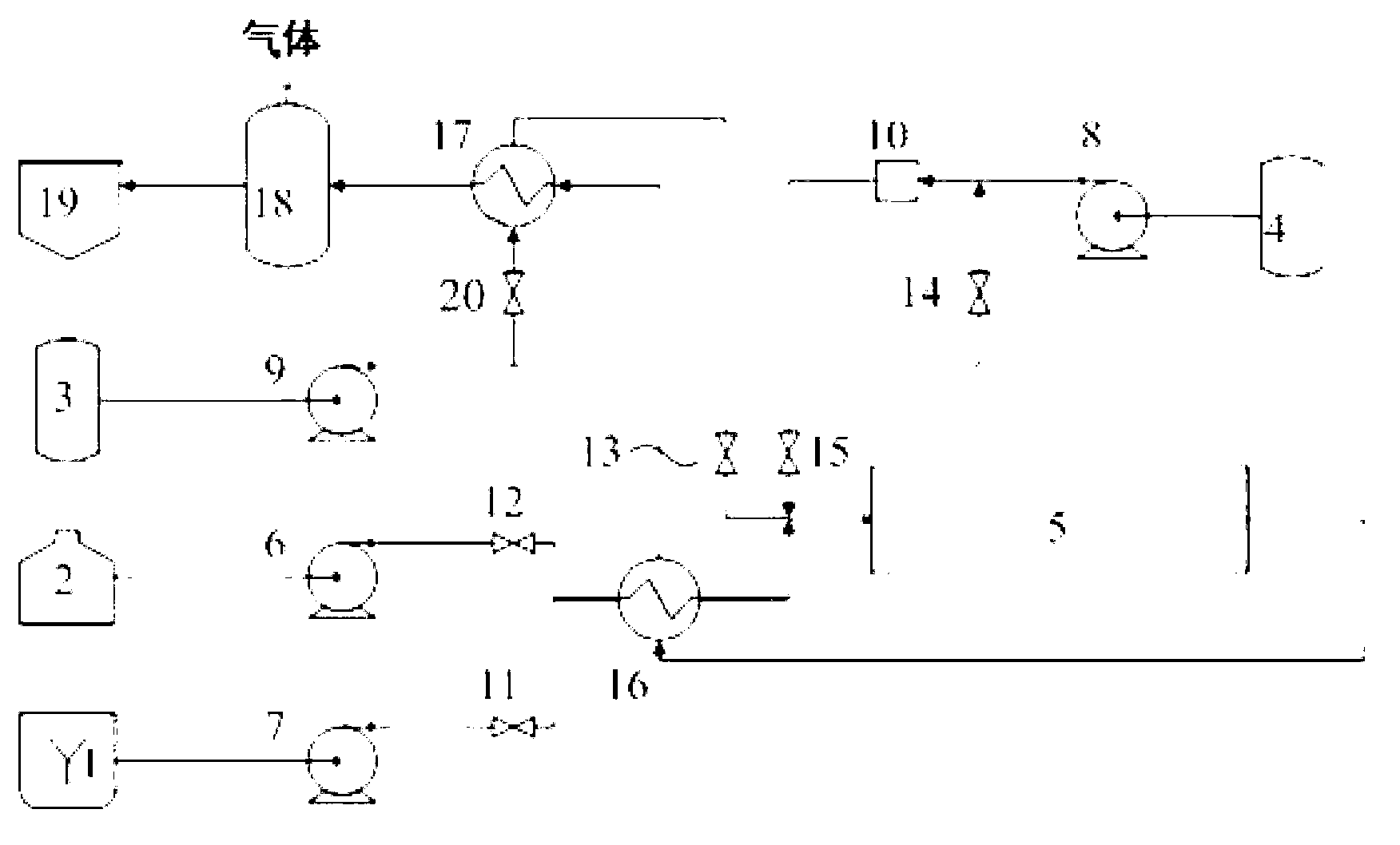

Method and device for synchronously dehydrating and recycling oil from oil-containing sludge

ActiveCN108892348AEfficient recyclingHigh recovery rateWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningChemical oxygen demandEvaporation

The invention provides a method and a device for synchronously dehydrating and recycling oil from oil-containing sludge. The method comprises the following steps: mixing oil-containing sludge with a conditioning chemical, and preheating; further heating the oil-containing sludge and the conditioning chemical to carry out a hydrothermal reaction so as to obtain hydrothermal oil sludge; carrying outflash evaporation rapidly to achieve separation of steam, oil gases and solid-phase residues, wherein generated flash vapor is adopted for preheating to achieve heat recycling; carrying out filter pressing dehydration on separated flash evaporation oil sludge, thereby obtaining a solid-phase residue and liquid-phase oil-water mixture; and standing and layering the oil-water mixture, recycling oilfrom an upper layer, and recycling organic wastewater from a lower layer, wherein the conditioning chemical is composed of a heat-sensitive metal oxide, a catalyst and a demulsifier. By adopting theprocess, good reduction and oil recycling effects can be achieved at a low hydrothermal temperature, the reaction energy consumption can be greatly reduced, the COD (Chemical Oxygen Demand) of a generated waste liquid can be greatly reduced, in addition, the toxicity is degraded, and biochemical treatment can be facilitated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Titanium silicalite molecular sieve, synthetic method and application of titanium silicalite molecular sieve, and cyclic ketone oxidation method

ActiveCN107879354AFacilitated DiffusionImprove filtering effectMolecular sieve catalystsOrganic compound preparationMolecular sieveFiltration

The invention relates to the field of catalytic materials and in particular provides a titanium silicalite molecular sieve, a synthetic method and application of the titanium silicalite molecular sieve. The titanium silicalite molecular sieve is composed of the following elements in percentage by mass: 0.01-5% of precious metals, silicon, 0.02-8% of titanium and oxygen, wherein the I960 / I550 valueis 0.6-0.9; the U480 / U330 value is 0.5-5; and the N-116 / N-112 value is 0.01-0.2. The invention further provides a cyclic ketone oxidation method. The cyclic ketone oxidation method comprises the following step: contacting cyclic ketone, an oxidizing agent and a catalyst, wherein the catalyst contains the titanium silicalite molecular sieve disclosed by the invention. Compared with the prior art,the titanium silicalite molecular sieve disclosed by the invention has the advantages that diffusion of the reactants and product is facilitated in an oxidation reaction, so that oxidative activity isfully achieved, and the selectivity is improved. For example, when applied to a reaction in which ring molecules, particularly cyclic ketone molecules, participate or are produced, the titanium silicalite molecular sieve can achieve excellent catalytic effects. Moreover, filtration and separation of the catalyst after the reaction can be further facilitated, and industrialized application is easily realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

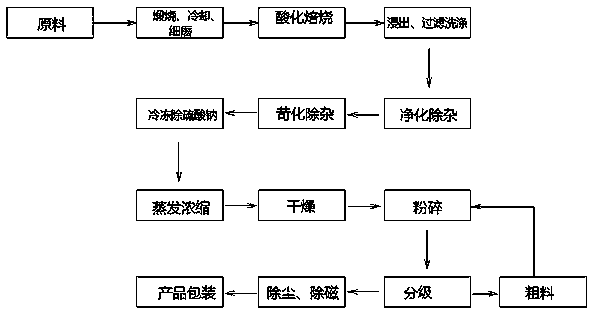

Production process of micro-powder-grade lithium hydroxide monohydrate

PendingCN111439760AMeet production needsAdequate responseSulfate/bisulfate preparationLithium oxides/hydroxidesPhysical chemistryProcess engineering

The invention discloses a production process of micro-powder-grade lithium hydroxide monohydrate. The production process comprises the following steps: (1) sequentially calcining spodumene, cooling the calcining product, finely grinding the calcining product, adding acid for reaction, and then mixing the obtained powder and the acid into slurry; (2) adding calcium salt into the slurry, and carrying out stirring and leaching; (3) filtering the filtered clear liquid again, and purifying the filtered clear liquid by using an alkaline solution; (4) filtering the causticized solution; (5) freezingthe filtered causticized liquid in a freezing workshop to separate out sodium sulfate decahydrate and a lithium hydroxide solution; (6) evaporating, concentrating and purifying the sodium sulfate decahydrate; (7) screening and weighing the sodium sulfate decahydrate; (8) carrying out shunting; (9) carrying out crushing; (10) carrying out grading; and (11) carrying out packaging.

Owner:广西雅保锂业有限公司

Solar energy and alternative fuel complementary distributed internal combustion engine cooling heating and power system and method

ActiveCN103807009ASmall volumeHigh energy storage densitySolar heating energyInternal combustion piston enginesAlternative fuelsHigh energy

The invention discloses a solar energy and alternative fuel complementary distributed internal combustion engine cooling heating and power system and method. The system comprises a solar energy and alternative fuel complementary reaction energy-accumulating system, a solar fuel internal combustion engine power generation system, a solar fuel flue gas residual heat absorptive lithium bromide refrigerating system, a flue gas residual heat recovery reaction device, a tail gas residual heat recovery heat exchanger and a cylinder jacket water plate heat exchanger. By adopting solar energy and alternative fuel in a complementary manner, conversion from solar energy to chemical energy of fuel is realized; light-converted synthetic gas fuel is stored and coupled with an internal combustion engine combined cooling heating and power system, so that high energy density is achieved, and the volume of an energy-storing device is reduced. Meanwhile, the aim of realizing multiple functions of combined solar cooling, heating and power at low cost and high efficiency is fulfilled, and separate solar cooling, heating and power at a high cost are avoided, so that the problems of difficulty in accumulating energy, high cost and low efficiency in the conventional solar heat utilization are solved effectively.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

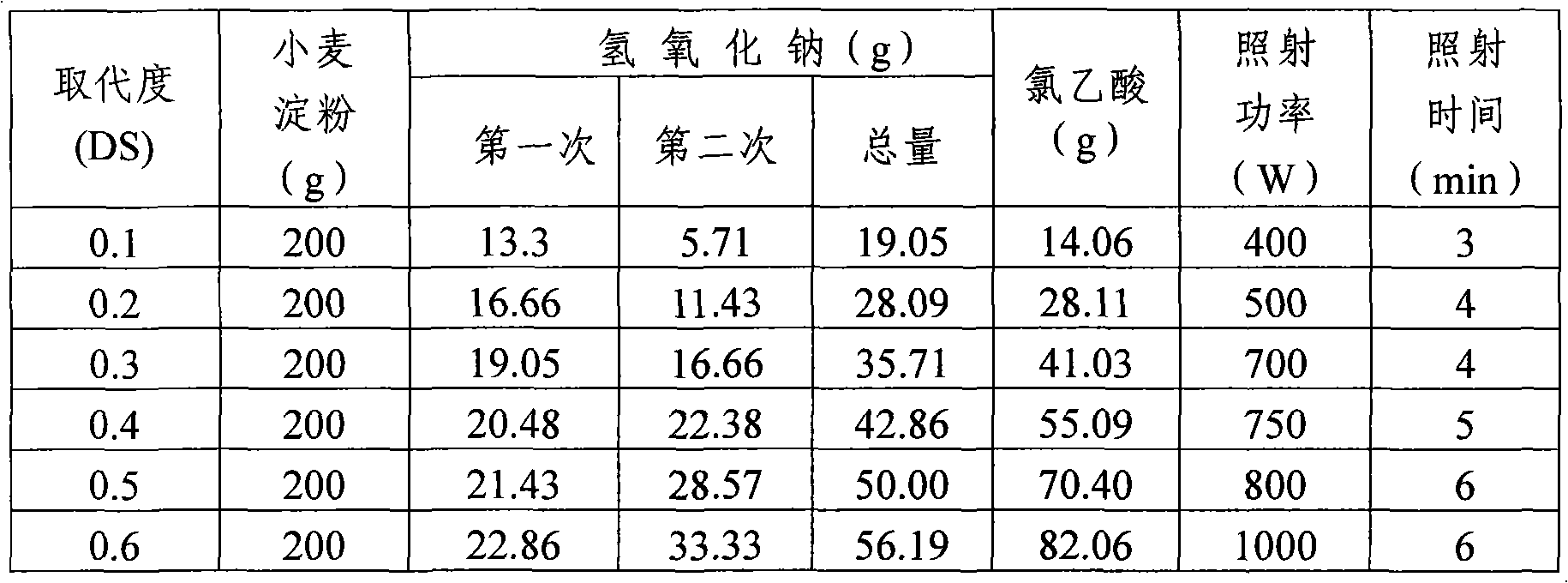

Method for preparing carboxymethyl modified starch

ActiveCN101624424AElimination of crystalline structuresImprove permeabilitySodium chloroacetateMicrowave method

The invention discloses a method for preparing carboxymethyl modified starch, which uses non-crystallization granule state starch as a basis and a microwave method as a core, and combines a part of processes of a drying method and a solvent method. The method comprises the following steps : (1) mixing certain amount of pure water with 95 percent of ethanol; adding the starch at a stirring state, keeping stirring and keeping a reaction container to be obturated, maintaining the temperature of a reaction system, and stirring to react for several minutes; (2) crushing a filter cake at the stirring state, spraying the prepared sodium hydroxide solution to stir at 25 DEG C and react for several minutes, again spraying a sodium chloroacetate ethanol liquid after the reaction is finished, stirring and evenly mixing; (3) evenly spreading a reaction mixture and placing the reaction mixture in a microwave oven to irradiate for several minutes; (4) washing the reaction product after being irradiated by microwave with the ethanol and centrifuging; and (5) drying, pulverizing and screening to prepare the carboxymethyl modified starch. The carboxymethyl starch with high substitution degree prepared through the method has the advantages of high reaction efficiency, short reaction period and low reaction energy consumption.

Owner:甘肃圣大方舟马铃薯变性淀粉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com