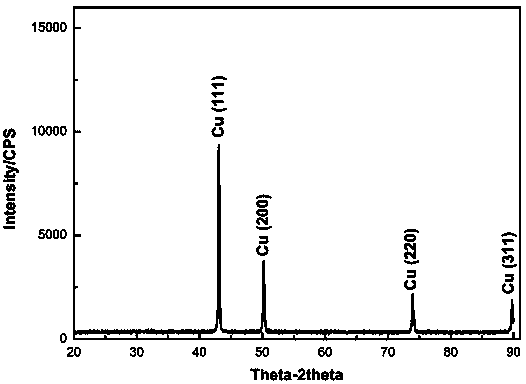

Method for utilizing low co-fusion type ionic liquid electro-deposition to manufacture nanometer copper powder

A technology of ionic liquid and nano-copper powder, which is applied in the field of low-eutectic ionic liquid electrodeposition to prepare nano-copper powder, can solve the problems of water introduction, hydrogen evolution interference, etc., and achieve high added value, short production process and stable product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

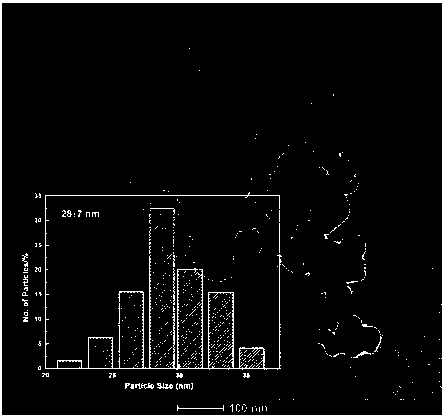

Embodiment 1

[0017] The method for preparing nano-copper powder by electrodeposition of low-eutectic ionic liquids, the specific steps are as follows: firstly, choline chloride and urea are dried under vacuum at 80°C, then mixed according to the molar ratio of 1:2 and heated at a constant temperature of 80°C The low-eutectic ionic liquid can be prepared by reacting for 2 hours under the same conditions; the copper precursor is added to the prepared 50mL low-eutectic ionic liquid and mixed evenly, and the ionic liquid-copper salt composite electrolyte is prepared, wherein the copper precursor is Cuprous oxide, the mass ratio of the volume of eutectic ionic liquid to cuprous oxide is 100:300ml / mg; under an inert atmosphere, use stainless steel (1.0cm×1.0cm×0.2cm) as the cathode and graphite as the anode, The electrode spacing is 1cm, and the temperature is 30°C, the stirring rate is 100r / min, the control cell voltage is 2.5V, and the electrodeposition is in the ionic liquid-copper salt compos...

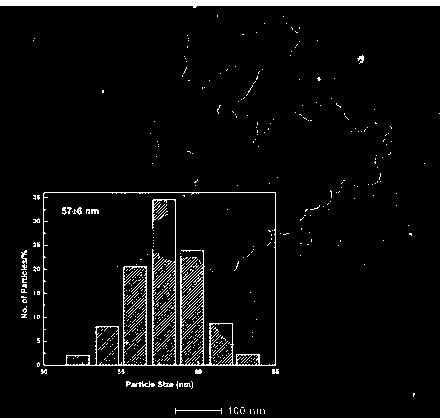

Embodiment 2

[0020] The method for preparing nano-copper powder by electrodeposition of low-eutectic ionic liquids, the specific steps are as follows: firstly, choline chloride and urea are dried under vacuum at 80°C, then mixed according to the molar ratio of 1:4 and heated at a constant temperature of 80°C Under the conditions, the low eutectic ionic liquid can be prepared by reacting for 2 hours; the copper precursor is added to the prepared 50ml low eutectic ionic liquid and mixed evenly, and the ionic liquid-copper salt composite electrolyte is prepared, wherein the copper precursor is Cuprous oxide, the mass ratio of the volume of low-eutectic ionic liquid to cuprous oxide is 100:600ml / mg; under an inert atmosphere, use a nickel sheet (1.0cm×1.0cm×0.2cm) as the cathode and graphite as the anode , with a pole spacing of 1 cm, electrodeposited in the prepared ionic liquid-copper salt composite electrolyte for 2 hours at a temperature of 30 °C, a stirring rate of 300 r / min, and a control...

Embodiment 3

[0023] The method for preparing nano-copper powder by electrodeposition of low-eutectic ionic liquids, the specific steps are as follows: first, dry choline chloride and urea under vacuum at 80°C, mix them in a molar ratio of 1:3, and heat at a constant temperature of 80°C Under the conditions, the low eutectic ionic liquid can be prepared by reacting for 2 hours; the copper precursor is added to the prepared 50ml low eutectic ionic liquid and mixed evenly, and the ionic liquid-copper salt composite electrolyte is prepared, wherein the copper precursor is Cuprous oxide, the mass ratio of the volume of low eutectic ionic liquid to cuprous oxide is 100:500ml / mg; then under an inert atmosphere, graphite is used as the anode, nickel sheet (1.0cm×1.0cm×0.2cm) is used as The cathode, the distance between electrodes is 1cm, the above-mentioned low eutectic ionic liquid is electrolyte solution, at a temperature of 50°C, a stirring rate of 300r / min, and a controlled current density of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com