Metal hydroxide coated carbon and sulfur lithium-sulfur battery positive electrode material, and preparation method and application thereof

A hydroxide and lithium-sulfur battery technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of cumbersome preparation process, high price, and difficulty in industrialization, and achieve Simple process, low price, and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

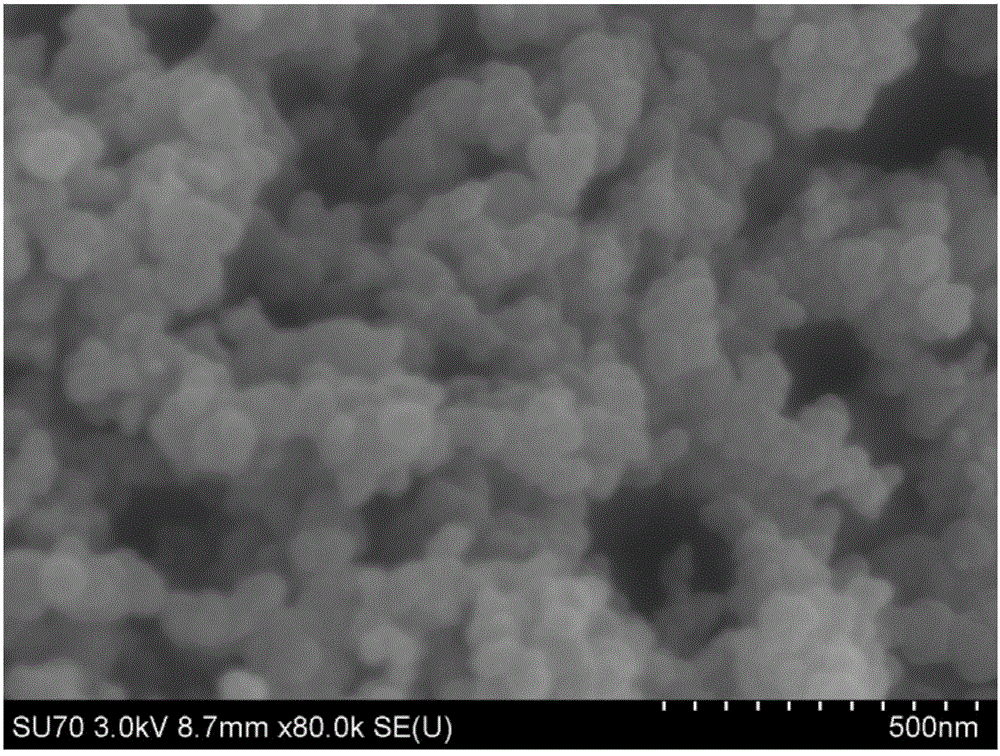

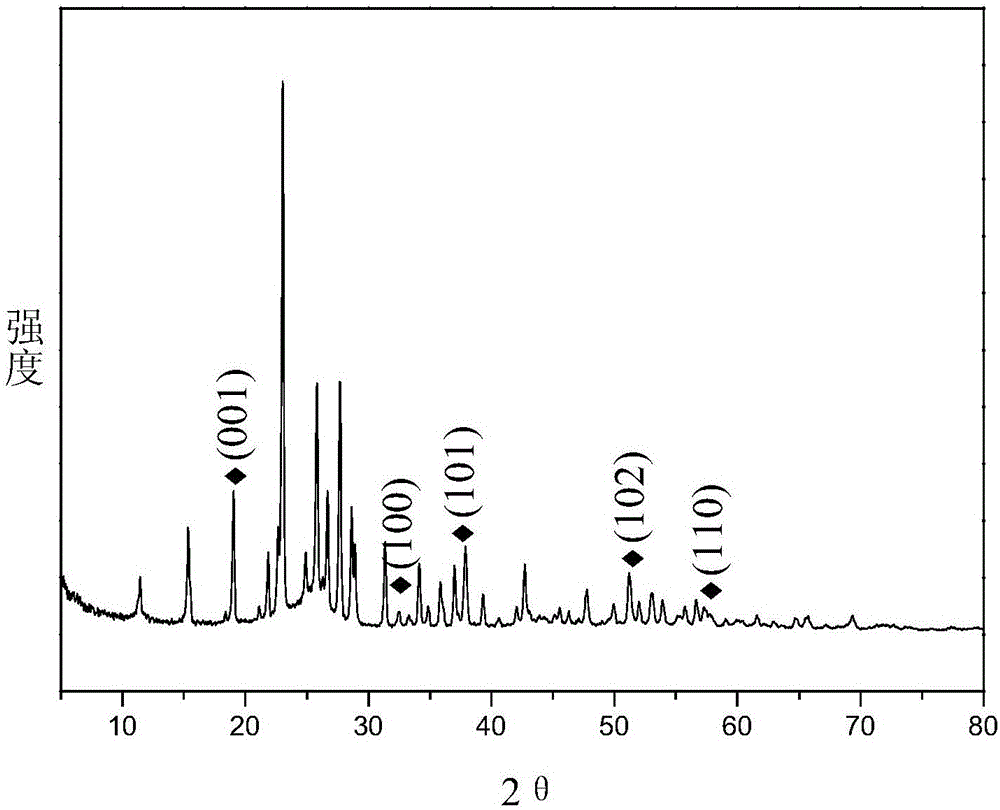

[0037] 1) Uniformly grind sublimated sulfur and conductive carbon black in a mortar with a mass ratio of 3:2, heat-treat and melt mix at 155°C for 12 hours in an argon protective atmosphere, and grind to obtain sulfur-carbon black composite powder after cooling;

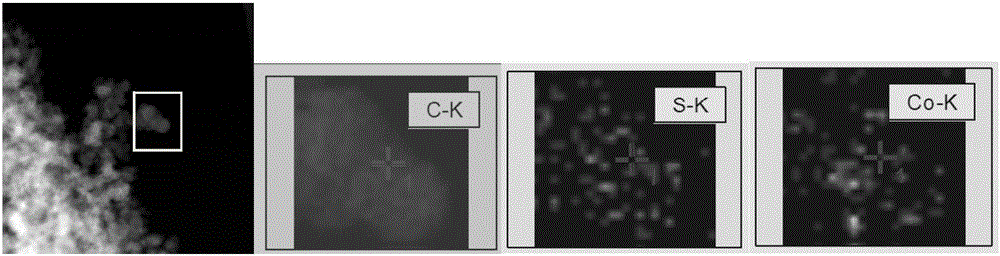

[0038] 2) Co(NO 3 ) 2 ·6H 2 O, hexamethylenetetramine is dissolved in water, then add polyvinylpyrrolidone and the sulfur carbon black composite powder in step 1), vigorously stir and ultrasonically form a black mixed solution, the concentration of cobalt salt in the black mixed solution is 0.05mol / L, the concentration of hexamethylenetetramine is 0.025mol / L, the concentration of polyvinylpyrrolidone is 0.1g / L, the concentration of sulfur carbon black composite powder is 10g / L, this black mixed solution is poured in the reactor, Hydrothermal reaction at 90°C for 2 hours, after cooling, centrifuge with deionized water, and dry in air at 60°C for 24 hours to obtain a lithium-sulfur battery cathode material coated wi...

Embodiment 2

[0044] 1) Uniformly grind sublimated sulfur and conductive carbon black in a mortar with a mass ratio of 3:2, heat-treat and melt mix at 155°C for 12 hours in an argon protective atmosphere, and grind to obtain sulfur-carbon black composite powder after cooling;

[0045] 2) Ni(NO 3 ) 2 ·6H 2 O, hexamethylenetetramine is dissolved in water, then add polyvinylpyrrolidone and the sulfur carbon black composite powder in step 1), vigorously stir and ultrasonic, form black mixed solution, the concentration of nickel salt in the black mixed solution is 0.05mol / L, the concentration of hexamethylenetetramine is 0.025mol / L, the concentration of polyvinylpyrrolidone is 0.1g / L, the concentration of sulfur carbon black composite powder is 10g / L, this black mixed solution is poured in the reactor, Hydrothermal reaction at 100°C for 2 hours, after cooling, centrifuge with deionized water, and dry in air at 60°C for 24 hours to obtain a lithium-sulfur battery positive electrode material co...

Embodiment 3

[0051] 1) Uniformly grind sublimated sulfur and conductive carbon black in a mortar with a mass ratio of 7:3, heat-treat and melt mix at 155°C for 12 hours in an argon protective atmosphere, and grind to obtain sulfur-carbon black composite powder after cooling;

[0052] 2) Co(NO 3 ) 2 ·6H 2 O, hexamethylenetetramine is dissolved in water, then add polyvinylpyrrolidone and the sulfur carbon black composite powder in step 1), vigorously stir and ultrasonically form a black mixed solution, the concentration of cobalt salt in the black mixed solution is 0.05mol / L, the concentration of hexamethylenetetramine is 0.025mol / L, the concentration of polyvinylpyrrolidone is 0.1g / L, the concentration of sulfur carbon black composite powder is 10g / L, this black mixed solution is poured in the reactor, Hydrothermal reaction at 90°C for 2 hours, after cooling, centrifuge with deionized water, and dry in air at 60°C for 24 hours to obtain a lithium-sulfur battery cathode material coated wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com