Stephanoporate carbon electrode material and preparation method thereof

A porous carbon electrode and mesoporous technology, which is applied in the manufacture of capacitors, hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problem of low micropore occupancy, achieve good stability, easy control, and specific electric capacity The effect of capacity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Using the mesoporous silica molecular sieve MCM-48 with a cubic channel structure as a template, organic sucrose was used as a carbon precursor, and the ordered mesoporous carbon was prepared by template carbonization, and then at 850 °C, CO 2 The modified porous carbon material was obtained by treating under the atmosphere for 2 hours, and then prepared into an electrode for a supercapacitor. The specific surface area of the MCM-48 used is 1736m 2 / g, the pore volume is 0.97cm 3 / g, BJH mesopore diameter is 2.4nm. First weigh 1g of MCM-48 and immerse it into a solution consisting of 1.10g of sucrose, 5g of deionized water and 0.14g of concentrated sulfuric acid, stir and mix thoroughly, and then heat at 100°C and 160°C for 6h respectively, and the obtained black The brown solid powder was again immersed in a solution consisting of 0.65g sucrose, 5g deionized water and 0.09g concentrated sulfuric acid, stirred thoroughly, and repeatedly heated at 100°C and 160°C for...

Embodiment 2

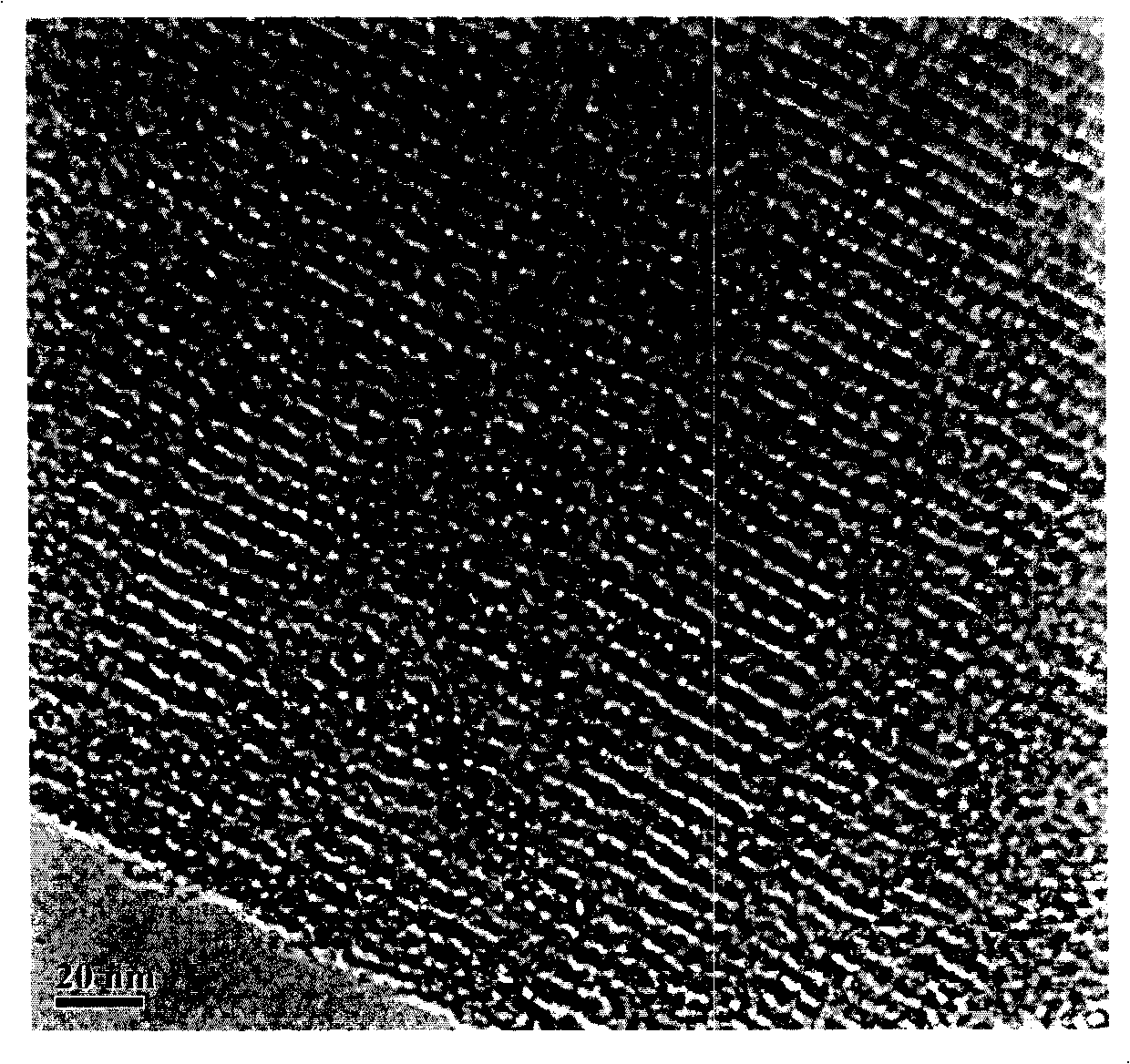

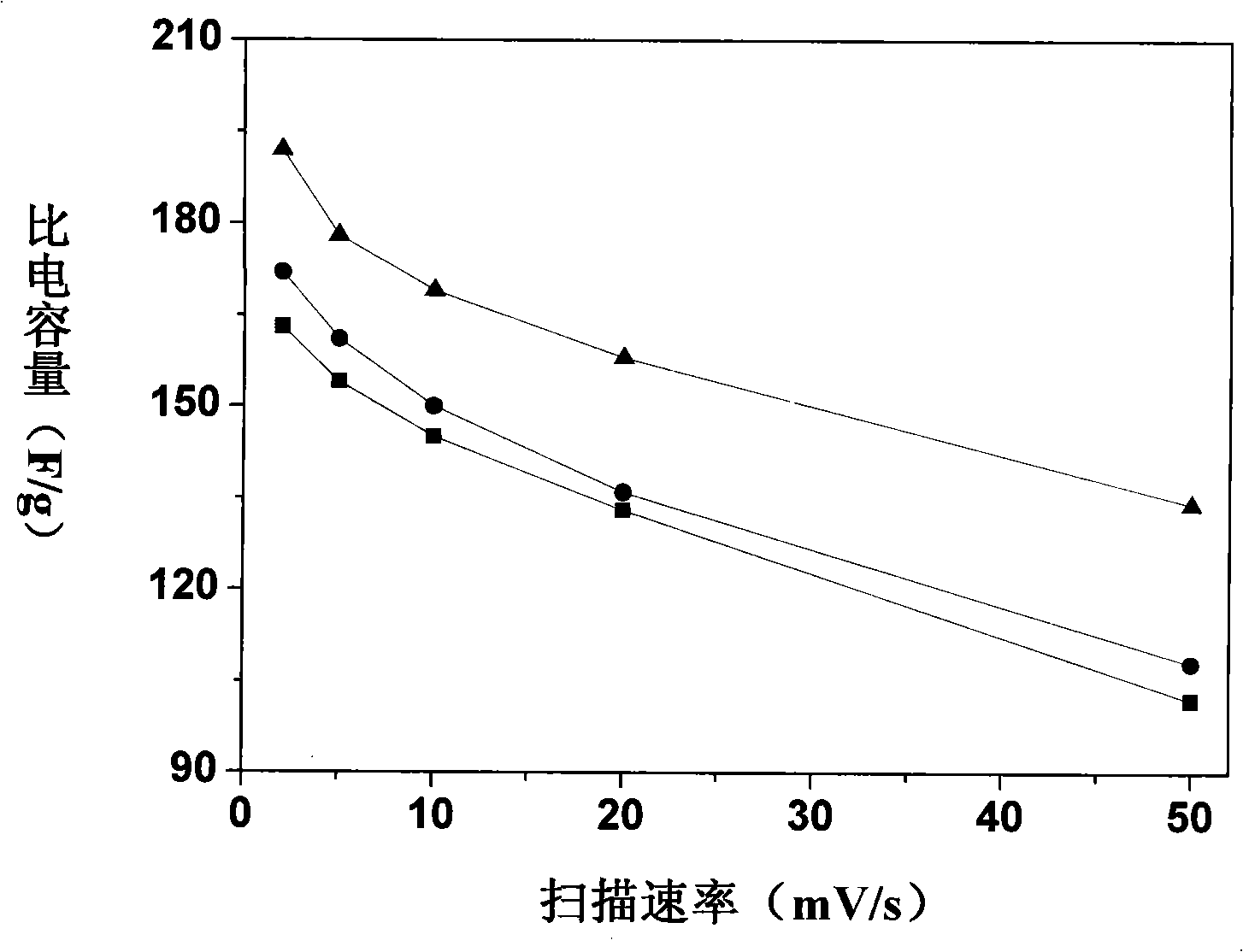

[0029] The method of the present embodiment is basically the same as that of Example 1, the difference is only: in the preparation process, CO 2 The post-treatment temperature is 950°C, and the treatment time is 4h. Then characterize its morphology, texture characteristics and electrochemical capacitive performance (electrolyte is 6M KOH). from figure 1 It can be seen from the above that the material is an ordered mesoporous arrangement structure, which is disordered in local areas, and its mesopore size ranges from 2 to 5 nm. In addition, there are a large number of micropores of 0.1 to 2 nm in the mesoporous wall. Secondary channels of porous carbon materials. The change of the specific capacitance of the electrode material at different scan rates is reflected in image 3 middle. Table 1 lists the specific test results of the electrode material.

Embodiment 3

[0031]Using the mesoporous silica molecular sieve SBA-15 with a hexagonal channel structure as a template and organic sucrose as a carbon precursor, the ordered mesoporous carbon was prepared by the template carbonization method, and then at 950 °C, CO 2 The modified porous carbon material was obtained by treating under the atmosphere for 4 hours, and then prepared as an electrode material for a supercapacitor. The specific surface area of SBA-15 used is 675m 2 / g, the pore volume is 1.10cm 3 / g, BJH mesopore diameter is 9.3nm. First weigh 1g of SBA-15 and immerse it into a solution consisting of 1.25g of sucrose, 5g of deionized water and 0.14g of concentrated sulfuric acid, stir and mix well, then heat at 100°C and 160°C for 6h respectively, and the black The brown solid powder was again immersed in a solution consisting of 0.8g sucrose, 5g deionized water and 0.09g concentrated sulfuric acid, stirred thoroughly, and repeated heating at 100°C and 160°C for 6h respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com