Preparation method of porous graphene

A porous graphene, graphene technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problem of large damage to graphene regularity, low degree of graphene exfoliation, affecting the overall performance of graphene, etc. problems, to achieve the effect of inhibiting the high temperature agglomeration effect, easy to scale production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

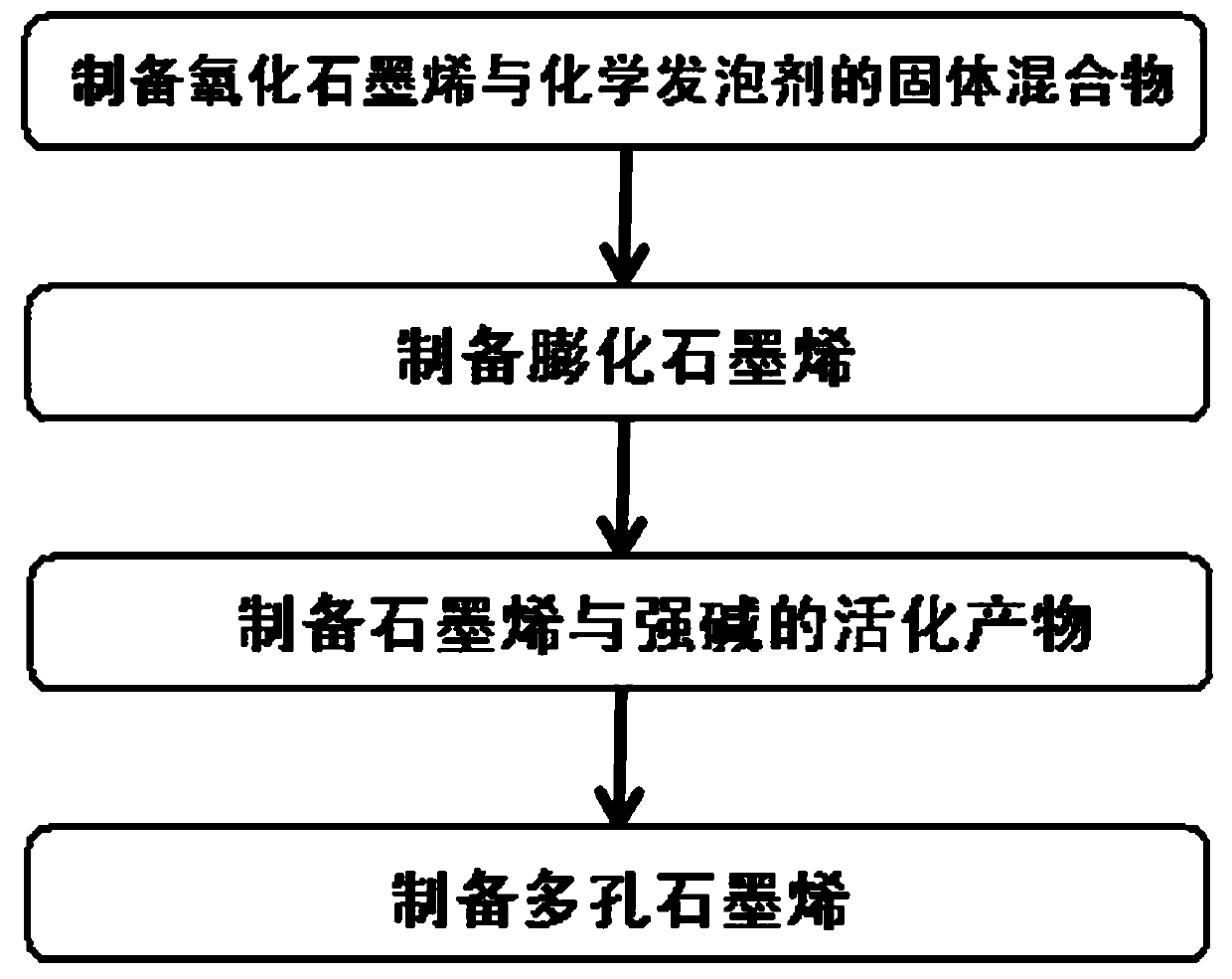

[0056] A preparation method of porous graphene, comprising the following steps:

[0057] (1) Add 0.5g of graphite oxide to 125mL of water / ethanol mixed solution with pH=9~10 (the volume ratio of water to ethanol is 2:1), stir magnetically for 72 hours, and then ultrasonically disperse for 40 minutes to form graphene oxide Colloidal dispersion; then add 0.5g salicylic acid, stir for 6 hours, filter to remove excess salicylic acid, and dry to obtain a solid mixture of graphene oxide and salicylic acid;

[0058] (2) In a reducing atmosphere of hydrogen / argon (volume ratio 1:4), place the solid mixture of graphene oxide and salicylic acid obtained in step (1) in a tube furnace for expansion reduction: from room temperature Gradually rise to 500°C, control the heating rate to 5°C / min, and keep warm at 200°C for 15 minutes, and keep warm at 500°C for 1 hour to obtain expanded graphene;

[0059] (3) Immerse the expanded graphene obtained in step (2) in potassium hydroxide solution, ...

Embodiment 2

[0065] A preparation method of porous graphene, comprising the following steps:

[0066] (1) Add 0.1g graphite oxide to 200mL water / ethanol mixed solution with pH=9~10 (the volume ratio of water and ethanol is 2:1), stir magnetically for 48 hours, and disperse ultrasonically for 1 hour to form graphene oxide Colloidal dispersion; then add 0.3g ammonium bicarbonate, stir for 2 hours, filter to remove excess ammonium bicarbonate, and dry to obtain a solid mixture of graphene oxide and ammonium bicarbonate;

[0067] (2) In a reducing atmosphere of hydrogen / argon (volume ratio 1:8), place the solid mixture of graphene oxide and ammonium bicarbonate obtained in step (1) in a tube furnace for expansion reduction: from room temperature Gradually rise to 500°C, control the heating rate to 10°C / min, and keep warm at 200°C for 20 minutes, and keep warm at 500°C for 2 hours to obtain expanded graphene;

[0068] (3) Immerse the expanded graphene obtained in step (2) in potassium hydroxid...

Embodiment 3

[0073] A preparation method of porous graphene, comprising the following steps:

[0074] (1) Add 0.5g of graphite oxide to 100mL of water / ethanol mixed solution with pH=9~10 (volume ratio of water to ethanol is 2:1), stir magnetically for 60 hours, and then ultrasonically disperse for 2 hours to form graphene oxide Colloidal dispersion; then add 0.15g of azodicarbonamide, stir for 12 hours, filter to remove excess azodicarbonamide, and dry to obtain a solid mixture of graphene oxide and azodicarbonamide;

[0075] (2) In a reducing atmosphere of hydrogen / nitrogen (volume ratio 1:1), place the solid mixture of graphene oxide and azodicarbonamide obtained in step (1) in a tube furnace for expansion reduction: from room temperature Gradually rise to 500°C, control the heating rate to 2°C / min, and keep warm at 200°C for 30 minutes, and keep warm at 500°C for 1 hour to obtain expanded graphene;

[0076] (3) Immerse the expanded graphene obtained in step (2) in potassium hydroxide s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com