Easily stripped pressure-sensitive adhesive and preparation method thereof

A pressure-sensitive adhesive and easy-peeling technology, which is applied in the direction of pressure-sensitive film/sheet, adhesive, film/sheet-shaped adhesive, etc., can solve the problem of pressure-sensitive adhesive high-temperature or low-temperature peel strength reduction, etc., to achieve strong cohesion, Improve the degree of cross-linking, the effect of high cross-linking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An easy-peeling pressure-sensitive adhesive, the following raw materials are weighed:

[0024] Acrylic acid monomer 0.8kg; 2-ethylacrylic acid 0.2kg, 2-acetamidoacrylic acid 0.6kg;

[0025] Acrylate monomer 4kg, of which; 2,3-dihydroxypropyl acrylate 2kg; octadecyl acrylate 0.4kg; 2-cyanoethyl acrylate 1.2kg, methyl methacrylate 0.4kg.

[0026] Benzyl dithiobenzoate 1.4kg;

[0027] Polyoxypropylene mannitol dioleate 0.8kg;

[0028] Dithioester 0.3kg;

[0029] Azobisisobutyronitrile 0.3kg;

[0030] Polystyrene copolymer 0.8kg;

[0031] Solvent ethyl acetate 0kg.

[0032] 1) first mix acrylic acid monomer, acrylate monomer, benzyl dithiobenzoate and polyoxypropylene mannitol dioleate, stir evenly to obtain a monomer mixed solution, 2) take 40% of the monomer mixed solution Add -50% into the reactor, control the reactor to heat, add the chain transfer agent and initiator at a temperature of 70°C, and stir and mix. The dropwise addition condition is 70°C, 60min, and k...

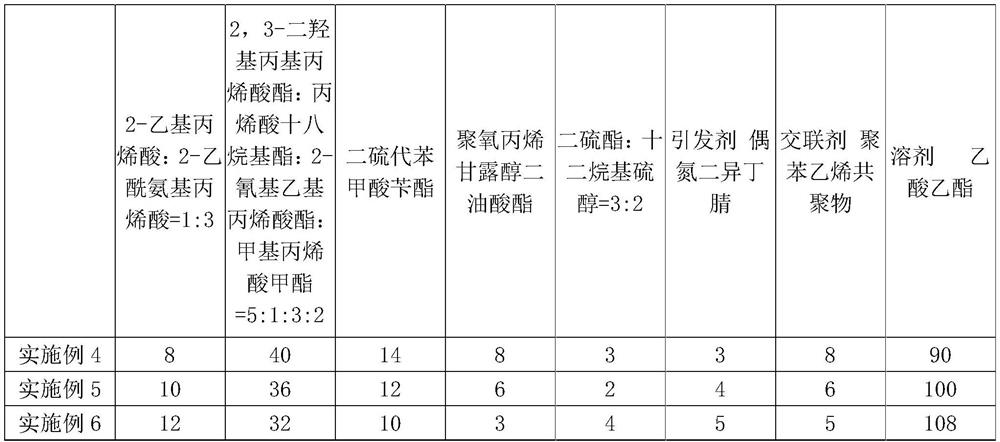

Embodiment 4

[0042] An easy-peeling pressure-sensitive adhesive, the following raw materials are weighed:

[0043] Acrylic acid monomer 0.8kg; 2-ethylacrylic acid 0.2kg, 2-acetamidoacrylic acid 0.6kg;

[0044] Acrylate monomer 4kg, of which; 2,3-dihydroxypropyl acrylate 2kg; octadecyl acrylate 0.4kg; 2-cyanoethyl acrylate 1.2kg, methyl methacrylate 0.4kg.

[0045] Benzyl dithiobenzoate 1.4kg;

[0046] Polyoxypropylene mannitol dioleate 0.8kg;

[0047] Dithioester 0.18kg;

[0048] Dodecyl mercaptan 0.12kg;

[0049] Azobisisobutyronitrile 0.3kg;

[0050] Polystyrene copolymer 0.8kg;

[0051] Solvent ethyl acetate 0kg.

[0052] 1) first mix acrylic acid monomer, acrylate monomer, benzyl dithiobenzoate and polyoxypropylene mannitol dioleate, stir evenly to obtain a monomer mixed solution, 2) take 40% of the monomer mixed solution Add -50% into the reactor, control the reactor to heat, add the chain transfer agent and initiator at a temperature of 70°C, and stir and mix. The dropwise add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com