Method for preparing crosslinked porous cassavastarch

A technology of porous starch and cross-linked starch, which is applied in the field of modified starch, can solve the problems of poor product quality stability and high process requirements, and achieve the effect of compact structure, simple production process and high cross-linking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

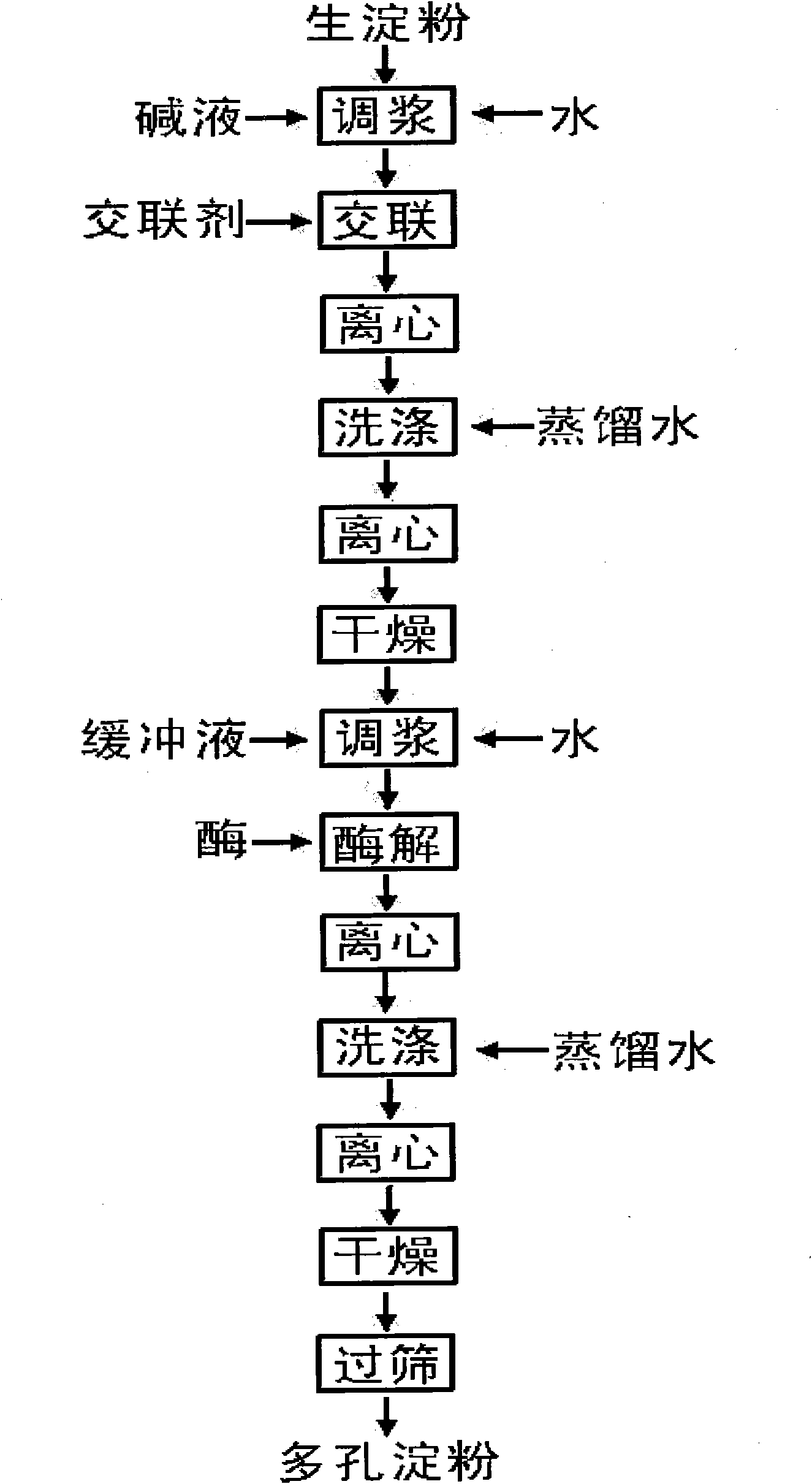

Method used

Image

Examples

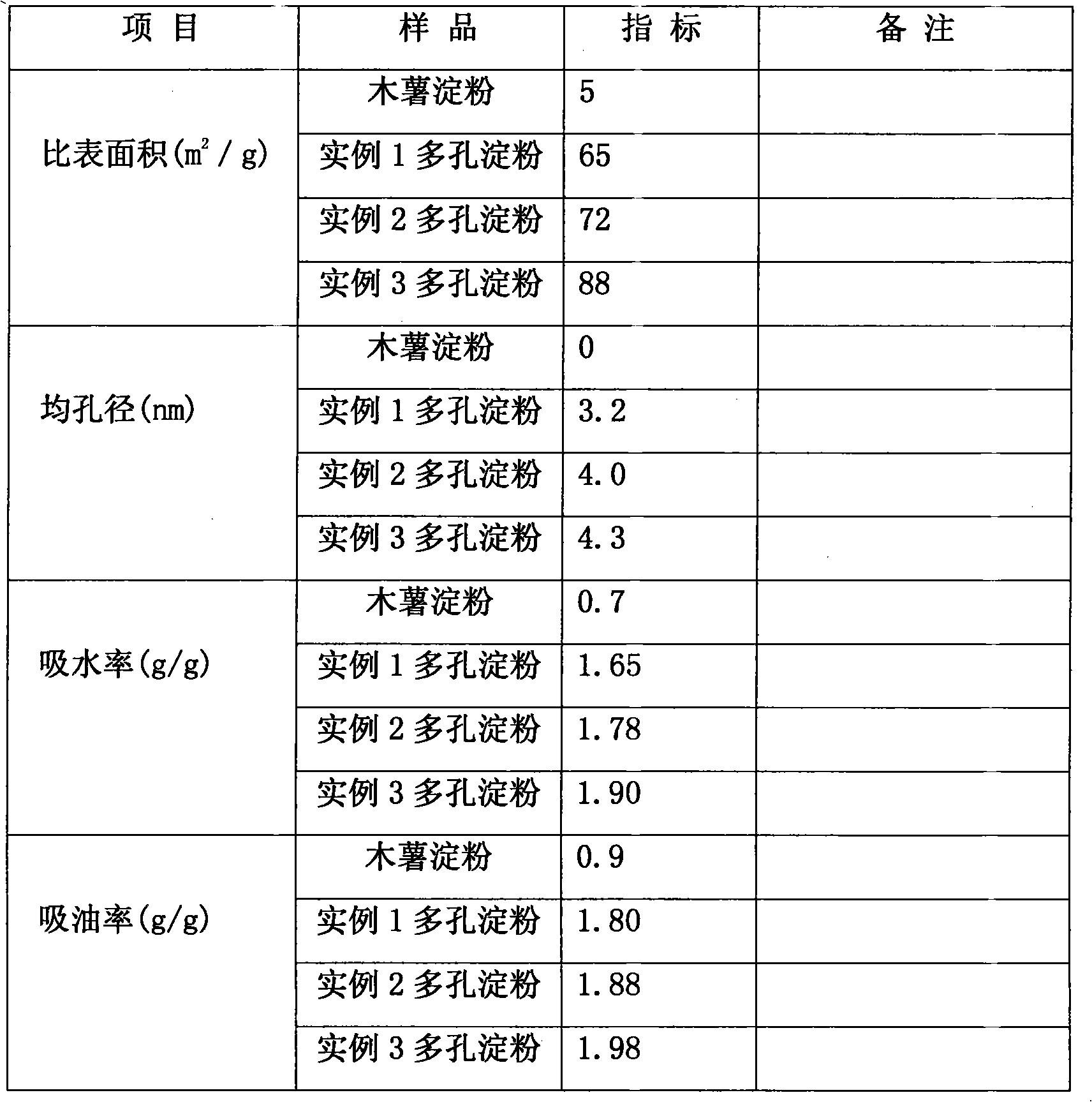

Embodiment 1

[0053] The water of 50 parts by weight is placed in the stainless steel reaction kettle, starts the stirrer, then adds the cassava raw starch raw material of 20 parts by weight, the modulation cassava raw starch suspension is thick to the weight of 28%, then adjusts the pH of the cassava raw starch suspension Value is 9.5, and the control temperature is 48 ℃, in cassava raw starch suspension, according to the cassava raw starch total amount, the cross-linking agent phosphorus oxychloride of the multifunctional group that adds 0.2 weight part, control temperature is 48 ℃, stirring reaction, control The time is 5 hours to prepare the cassava cross-linked starch suspension; adjust the pH value of the cassava cross-linked starch suspension to 7.4, end the cross-linking reaction, use a centrifuge to dehydrate the cassava cross-linked starch suspension at 4000r / min for 5min, and then Wash 3 times with distilled water, then put it into a vacuum drying oven, and control the temperature...

Embodiment 2

[0056] The water of 40 parts by weight is placed in the stainless steel reactor, starts agitator, then adds the tapioca raw starch raw material of 20 parts by weight, the modulation cassava raw starch suspension is thick to be 33% weight, then regulates the pH of tapioca raw starch suspension Value is 10, and the control temperature is 47 ℃, in cassava raw starch suspension, according to the cassava raw starch total amount, add the phosphorus oxychloride of 0.5 weight part 1: 1 and sodium trimetaphosphate polyfunctional group cross-linking agent, control temperature is 46 ℃, stirring reaction, control time is 6 hours, prepare cassava cross-linked starch suspension; adjust the pH value of cassava cross-linked starch suspension to 7.2, end the cross-linking reaction, use a centrifuge to centrifuge the cassava cross-linked starch suspension at 4000r / Centrifuge for 5 minutes to dehydrate, then wash with distilled water for 3 times, then put it into a vacuum drying oven, and dry it...

Embodiment 3

[0059] The water of 50 parts by weight is placed in the enamel reaction kettle, starts the stirrer, then adds the tapioca raw starch raw material of 16 parts by weight, the modulation cassava raw starch suspension is thick to be 24% weight, then adjusts the pH of the tapioca raw starch suspension Value is 10, and the control temperature is 48 ℃, in cassava raw starch suspension, according to the cassava raw starch total amount, the cross-linking agent phosphorus oxychloride of the multifunctional group of adding 0.8 weight part, control temperature is 46 ℃, stirring reaction, control The time is 6 hours to prepare the cassava cross-linked starch suspension; adjust the pH value of the cassava cross-linked starch suspension to be 7, end the cross-linking reaction, use a centrifuge to dehydrate the cassava cross-linked starch suspension at 4000r / min for 5min, and then Wash 3 times with distilled water, then put it into a vacuum drying oven, and control the temperature to dry at 48...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com