A soft and smooth woven non-ironing fabric and its processing method

A processing method and fabric technology, applied in the textile field, can solve the problems of poor durability, hardened fabric feel, reduced wearing comfort, hardened feel, etc., to achieve excellent non-iron performance and improve the effect of non-iron appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

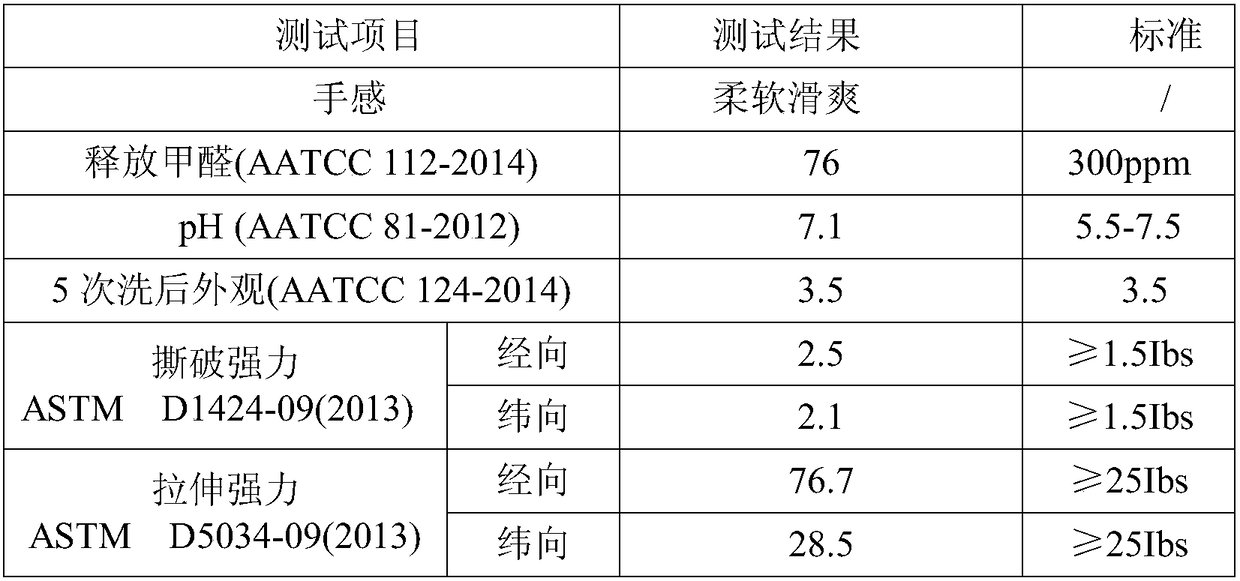

Embodiment 1

[0039] This embodiment provides a method for processing soft and smooth hand-woven non-ironing fabrics

[0040] In this embodiment, pure cotton woven fabric with a texture of 1 / 1 plain weave is used as the gray cloth, and its specification is pure cotton 40s×pure cotton 80s / 2, and the warp density×weft density is 130×80 threads / inch, and then the post-finishing is carried out processing. The finishing process is as follows: gray cloth→singeing→desizing→liquid ammonia finishing→enzyme treatment→acid washing wet stacking→pre-softening→non-ironing setting→baking→alkali washing→setting→preshrinking.

[0041] Among them, singeing, desizing, and liquid ammonia finishing can be processed by conventional methods in the art.

[0042] Arrange the singeing, desizing and liquid ammonia finishing blanks in the enzyme washing liquid and use a beating machine for enzyme treatment to obtain enzyme-treated fabrics; in this enzyme treatment process, the processing speed of the beating machine ...

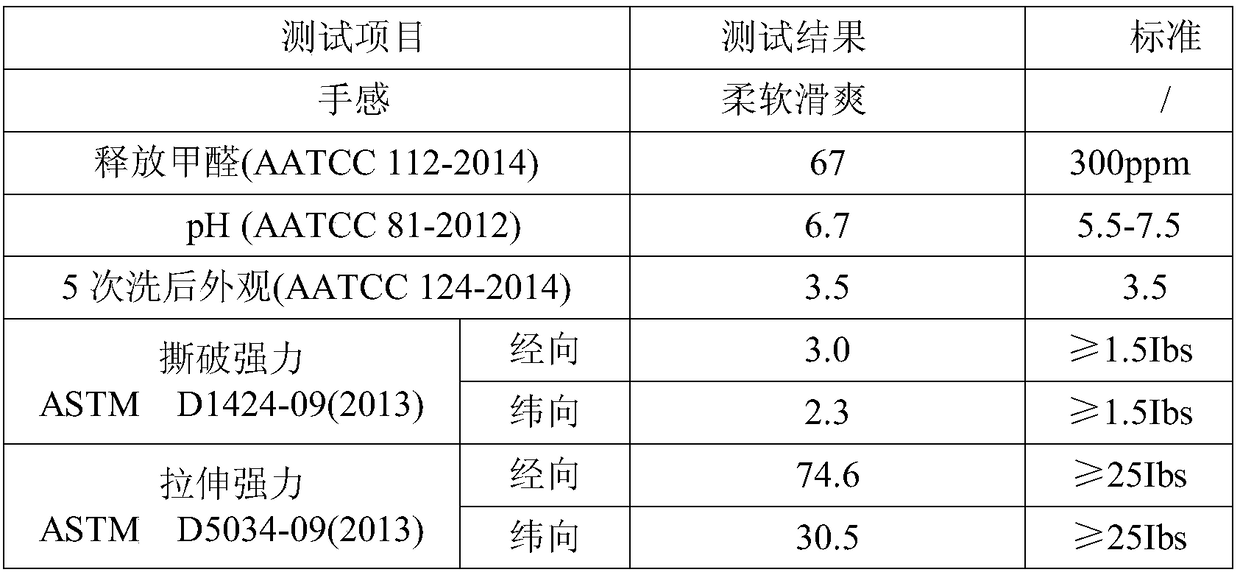

Embodiment 2

[0053] This embodiment provides a method for processing soft and smooth hand-woven non-ironing fabrics

[0054] This embodiment adopts the cotton-tencel blended fabric woven with 1 / 1 plain weave as the gray cloth, and its specification is pure cotton 50s×cotton / tencel 80 / 2, wherein the blending ratio of cotton / tencel is 75% cotton, 25% tencel, the warp density x weft density is 130 x 76 pieces / inch, and then the post-finishing process is carried out. The finishing process is as follows: gray cloth→singeing→desizing→liquid ammonia finishing→enzyme treatment→acid washing wet stacking→pre-softening→non-ironing setting→baking→alkali washing→setting→preshrinking.

[0055] Among them, singeing, desizing, and liquid ammonia finishing can be processed by conventional methods in the art.

[0056] Arrange the singeing, desizing and liquid ammonia finishing blanks in the enzyme washing liquid and use a beating machine for enzyme treatment to obtain enzyme-treated fabrics; in this enzyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com