A kind of modified hydroxyacrylic acid emulsion for water-based iron printing paint and preparation method thereof

A technology of hydroxyacrylic and iron-printing coatings, which is applied in the direction of anti-corrosion coatings and coatings, and can solve problems such as unsatisfactory comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

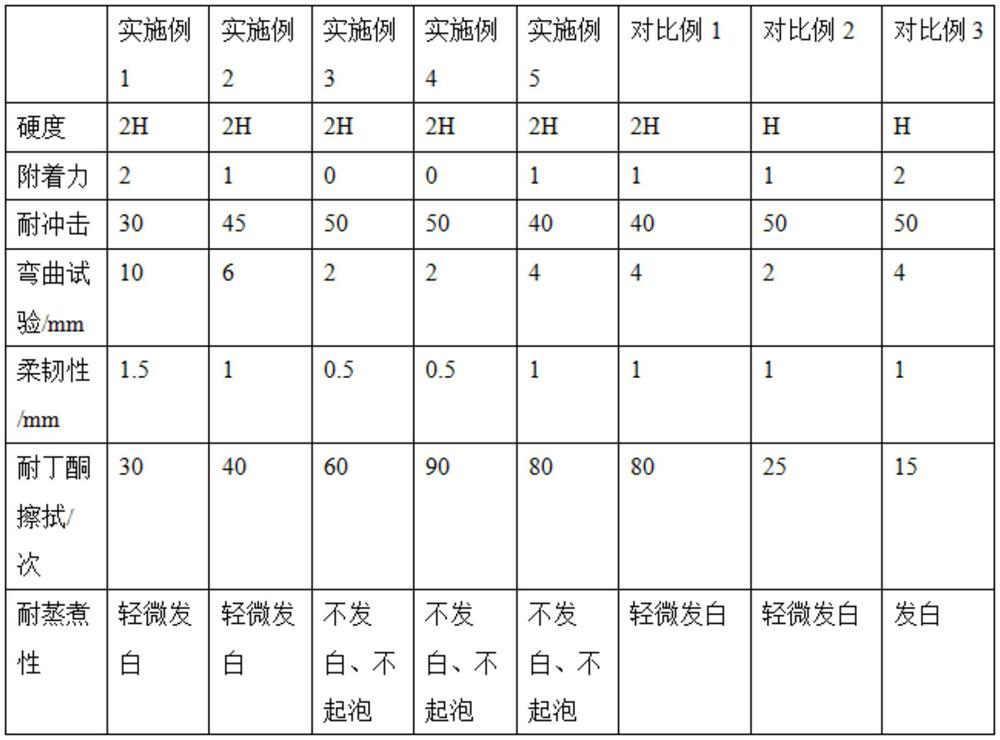

Examples

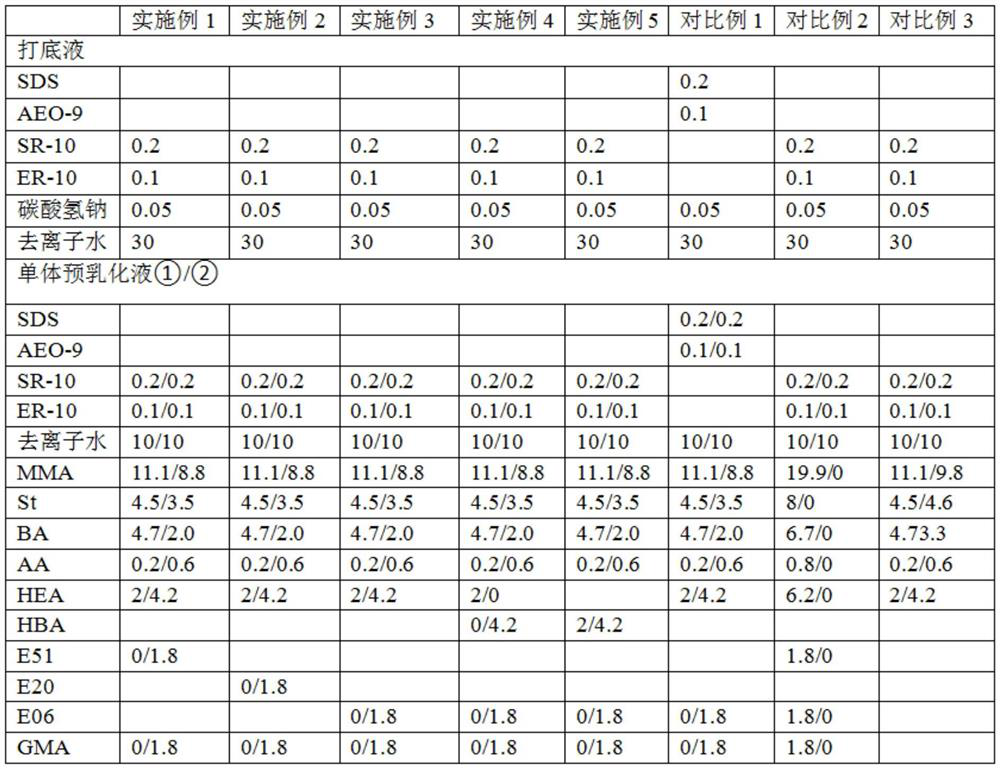

Embodiment 1

[0033] (1) Add 10 parts of deionized water and 0.3 parts of compound emulsifier in turn to the emulsification tank, stir until fully dissolved, then add 11.1 parts of methyl methacrylate, 4.5 parts of styrene, 4.7 parts of butyl acrylate, and 0.2 parts of acrylic acid , 2.0 parts of monomer mixture composed of hydroxyethyl acrylate, stirred at high speed for 30 minutes to obtain white monomer pre-emulsion ①. Similarly, add 10 parts of deionized water and 0.3 parts of compound emulsifier to the emulsification tank in turn, stir until fully dissolved, then add 8.8 parts of methyl methacrylate, 3.5 parts of styrene, 2.0 parts of butyl acrylate, and 0.6 parts of acrylic acid , 4.2 parts of hydroxyethyl acrylate, 1.8 parts of epoxy E51, 1.8 parts of glycidyl methacrylate monomer mixture, stirred at high speed for 30 minutes to obtain white monomer pre-emulsion ① to prepare monomer pre-emulsion ②.

[0034] (2) Add 30 parts of deionized water, 0.3 parts of compound emulsifier, and 0....

Embodiment 2-5

[0038]Prepare Example 2-5 according to the method of Example 1, and its formula composition is shown in the following table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com