Polyarylether resin containing side carboxyl group, synthetic method and application of polyarylether resin in coating aspect

A synthesis method and technology of polyarylether, which is applied in the field of polyarylether resin, can solve the problems of reducing the service life of the coating, the coating is easy to be damaged, and is easy to soften, so as to achieve strong adhesion, improve heat resistance, and hot hardness high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

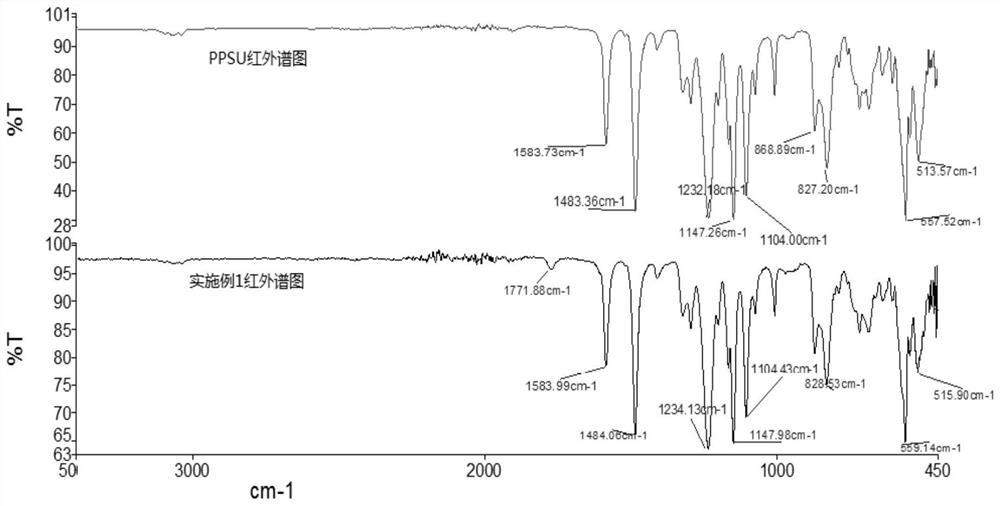

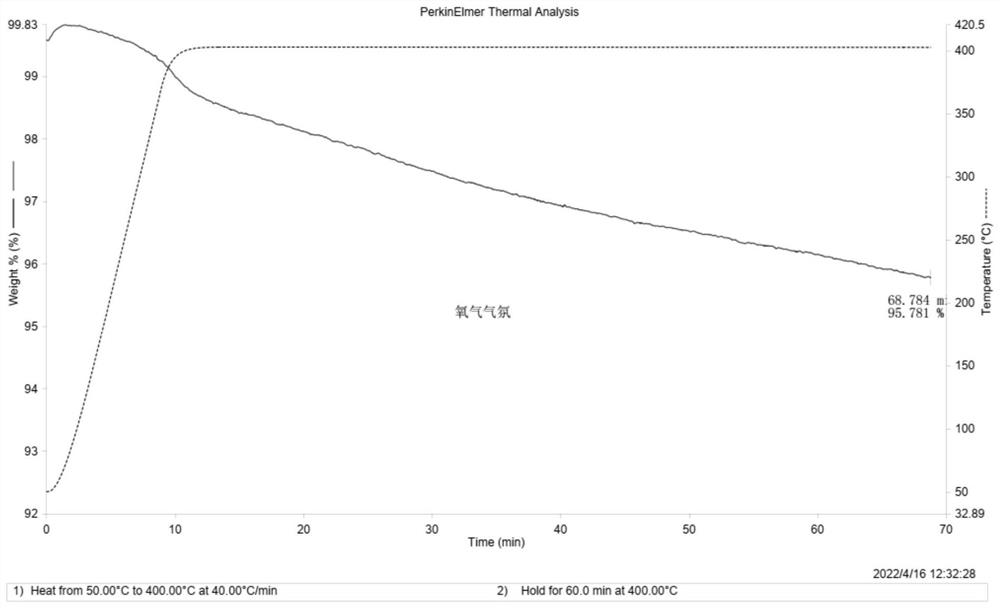

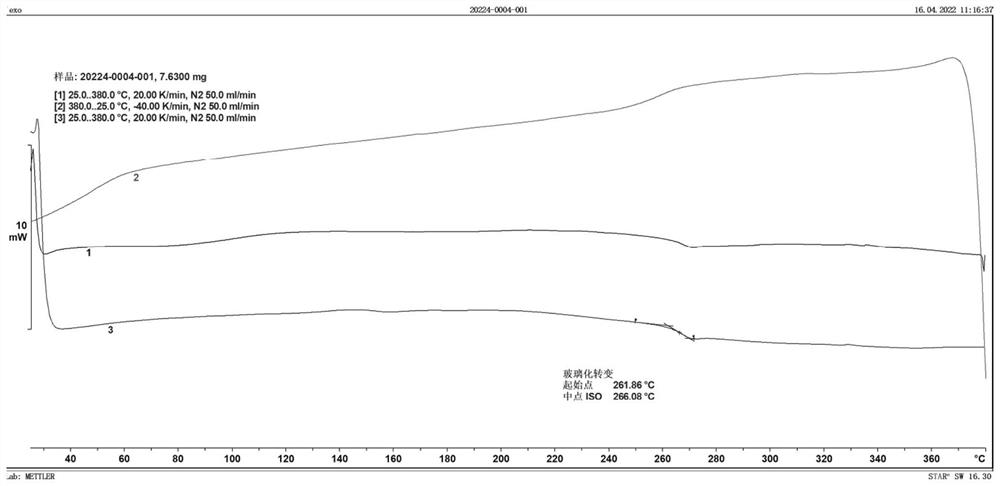

Embodiment 1

[0043] A kind of preparation method of the polyarylene ether resin containing carboxyl side group, the concrete steps are as follows:

[0044] Step 1: In a 500ml four-port reactor equipped with a thermometer, an air inlet pipe, a reflux separator, and a stirrer with torque display, nitrogen was introduced to remove oxygen, and 72 grams of 4,4-dichlorodiphenylsulfone, 44.2 grams of Biphenol, 2.1 g methyl 2,5-dihydroxybenzoate, 28.6 g sodium carbonate, 4.2 g potassium carbonate, 3.8 g sodium dihydrogen phosphate, 1.1 g disodium hydrogen phosphate, 300 g sulfolane and 40 ml xylene , stir, raise the temperature to 110 ℃, when xylene and water azeotrope are evaporated, return xylene to the reactor through the reflux separator, and release the water for weighing. When the temperature reaches 150°C, keep the temperature constant for 30 minutes, the water in the separator will become clear, close the reflux valve to steam out all the xylene, and continue to heat to 215°C for 120 minut...

Embodiment 2

[0048]According to the same method as in Example 1, except that the weight of the input materials in the reactor was adjusted to add 72 grams of 4,4-dichlorodiphenyl sulfone, 59.4 grams of bisphenol S (instead of biphenol), 2.1 grams of 2,5-diphenylsulfone Methyl dihydroxybenzoate, 26.5 g of sodium carbonate, 6.9 g of potassium carbonate, 4.6 g of sodium dihydrogen phosphate, 1.4 g of sodium phosphate, 360 g of sulfolane and 40 ml of xylene; when the temperature reaches 220 ° C, the temperature is kept constant for 150 minutes. Finally, the polyarylene ether polymer EX-2 containing pendant carboxyl groups was obtained.

Embodiment 3

[0050] According to the same method as in Example 1, except that the weight of the input materials in the reactor was adjusted to add 72 grams of 4,4-dichlorodiphenylsulfone, 50 grams of bisphenol S, 8.4 grams of methyl 2,5-dihydroxybenzoate, 28.1 g of sodium carbonate, 4.8 g of potassium carbonate, 8 g of sodium dihydrogen phosphate, 3 g of disodium hydrogen phosphate, 1.4 g of sodium phosphate, 350 g of dimethyl sulfoxide and 40 ml of xylene; when the temperature reaches 183 ° C, the constant temperature is 120 minute. Finally, the polyarylene ether polymer EX-3 containing pendant carboxyl groups was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com