A kind of loaded silicone rubber anti-tracking agent and its preparation method and application

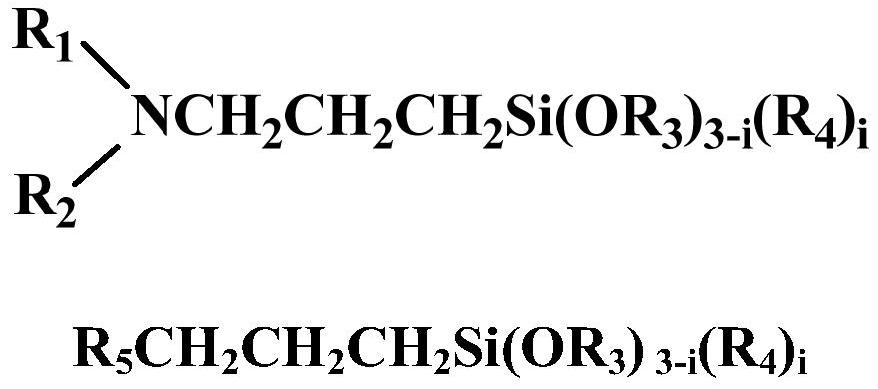

A technology of resistance to tracking and silicone rubber, applied in the field of silicone rubber modification additives and silicone rubber electrical insulation, can solve the problems of damaging the mechanical properties and other properties of silicone rubber, affecting the stability of silicone rubber performance, and easy migration of small molecule additives. , to achieve the effect of enhancing synergistic catalytic activity, improving mechanical properties, and improving the tracking resistance of silicone rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

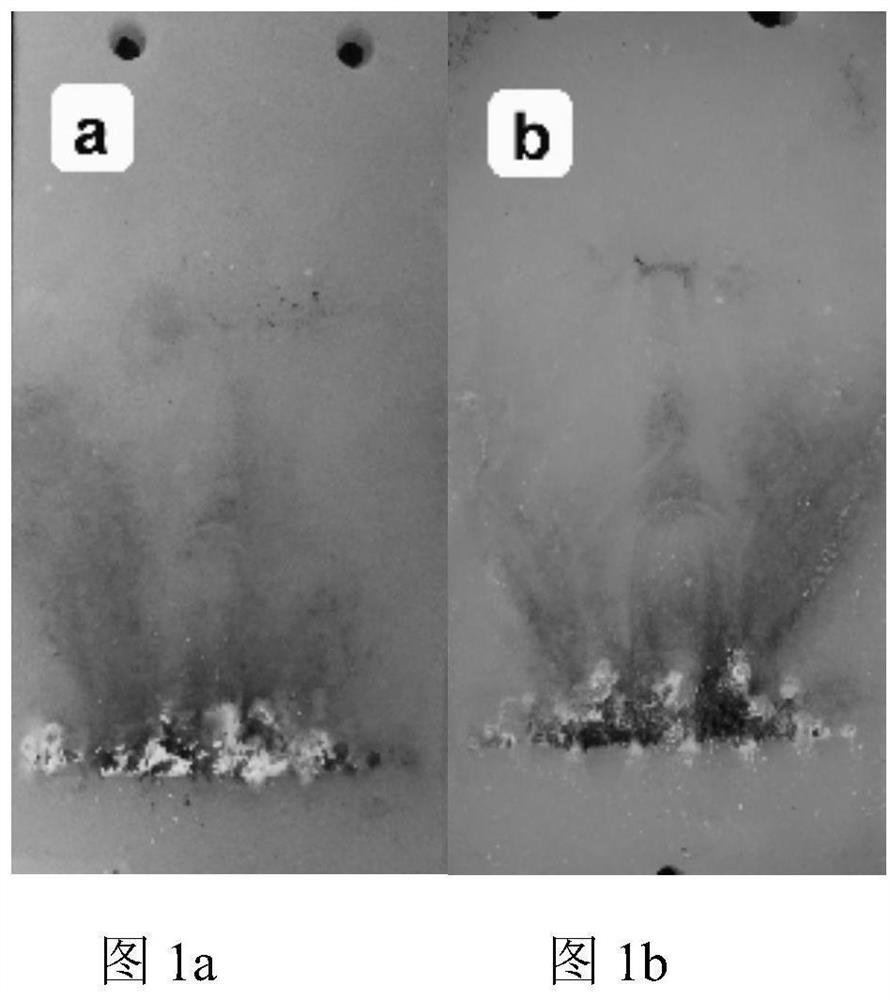

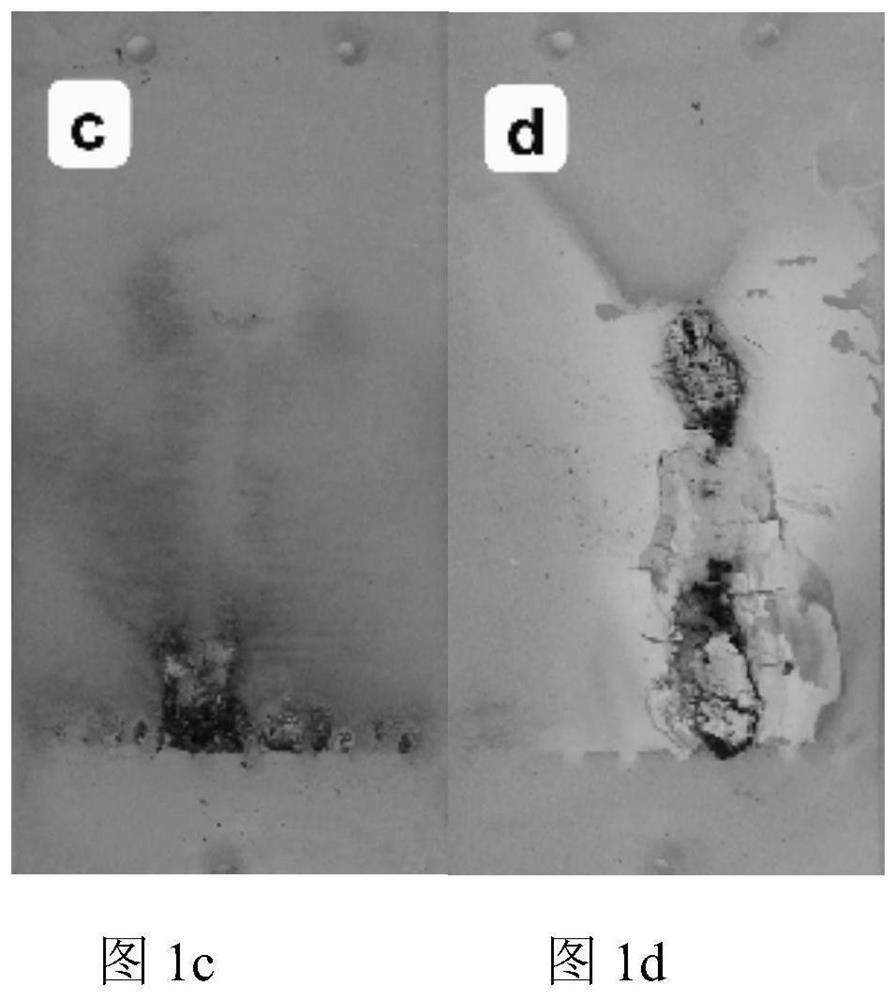

Image

Examples

Embodiment 1

[0034] With 20g fumed silica (specific surface area 300m 3 / g) was dispersed in 300 g of distilled water, 4 g of γ-aminoethylaminopropyl triethoxysilane was added, and stirred at 70° C. for 8 hours. Then cooling, suction filtration, ethanol washing and vacuum drying for 8 hours to obtain modified gas phase white carbon black. Disperse modified fumed silica and 0.5 g of isopropanol solution of chloroplatinic acid (platinum content 3000 ppm) into 100 g of absolute ethanol, and react under nitrogen protection at 70° C. for 6 hours with stirring. Cooling, suction filtration, washing, and vacuum drying for 8 hours to obtain a loaded silicone rubber anti-tracking agent.

[0035] 90 parts by mass of methyl vinyl silicone rubber (molecular weight: 560,000) with a vinyl content of 0.06 mol%, 10 parts by mass of methyl vinyl silicone rubber with a vinyl content of 1 mol% (molecular weight: 600,000), 40 parts by mass of fumed silica (Specific surface area 300m3 / g), 8 parts by mass of h...

Embodiment 2

[0038] Disperse 4g of aminopropyltrimethoxysilane in 50g of toluene, add 0.5g of divinyltetramethyldisiloxane complex of chloroplatinic acid (platinum content 3000ppm), and stir the reaction under nitrogen protection and 70°C After 6 hours, a complex compound of nitrogen-containing silane and platinum was obtained. Then 20g fumed silica (specific surface area 200m 3 / g) Disperse in 200g of toluene, transfer the complex of nitrogen-containing silane and platinum to the toluene solution of the above-mentioned fumed silica, and stir and react under nitrogen protection at 70°C for 8 hours. Then cooling, suction filtration, washing, and vacuum drying for 8 hours, the finished product 2 of Example was obtained.

Embodiment 3

[0040] With 20g fumed silica (specific surface area 150m 3 / g) was dispersed in 300 g of distilled water, 4 g of aminopropyltriethoxysilane was added, and stirred at 70° C. for 8 hours. Then cooling, suction filtration, ethanol washing and vacuum drying for 8 hours to obtain modified gas phase white carbon black. Disperse the modified fumed silica and 0.5g of divinyltetramethyldisiloxane complex of chloroplatinic acid (platinum content 3000ppm) into 100g of toluene, and react with stirring under nitrogen protection and 70°C for 6 hours . Then cooling, suction filtration, washing, and vacuum drying for 8 hours, the finished product 3 of Example was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com