Method for installing tail shaft on 10,000DWT roll-on-roll-off ship as well as dedicated roller tool

An installation method and technology of roller tools, which are used in manufacturing tools, metal processing, hand-held tools, etc., can solve problems such as difficulty in installation and positioning, adjustment of tail shafts, and inability to lift tail shafts. The effect of shortening the installation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

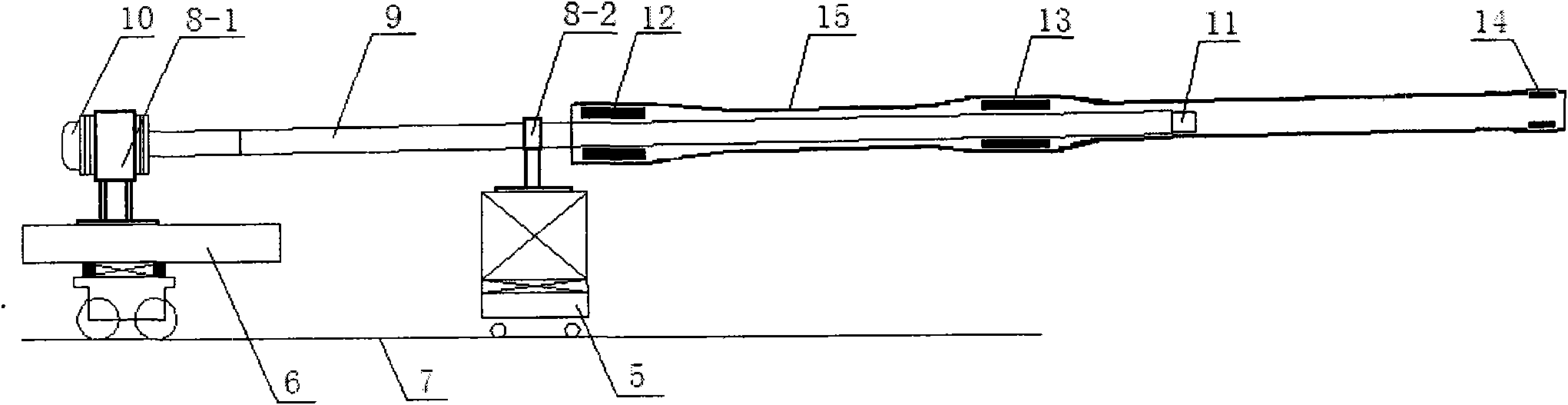

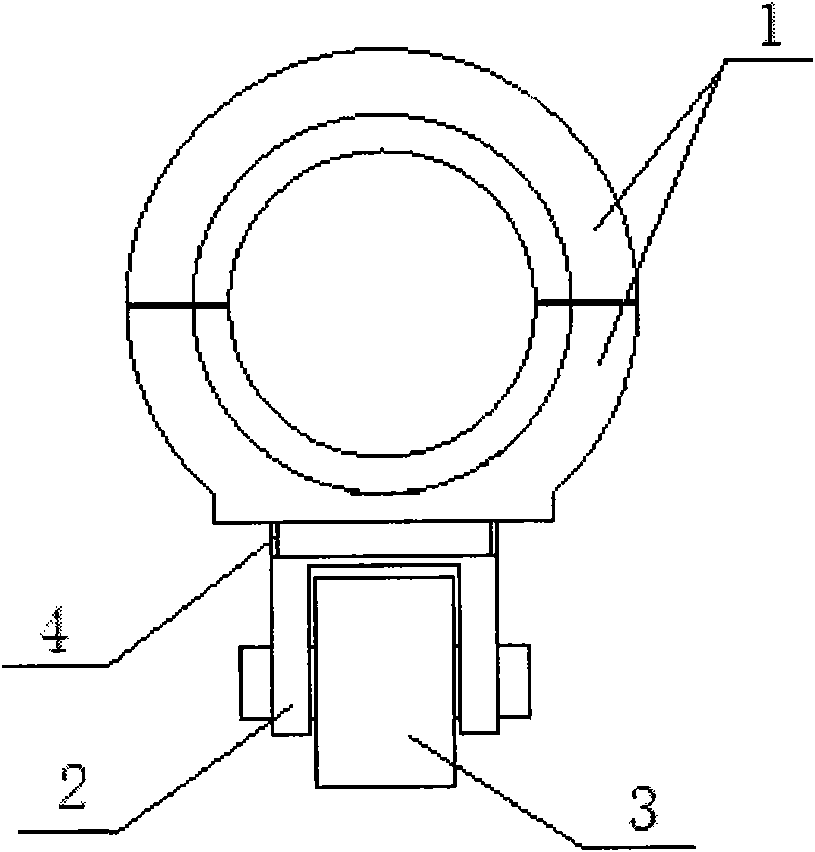

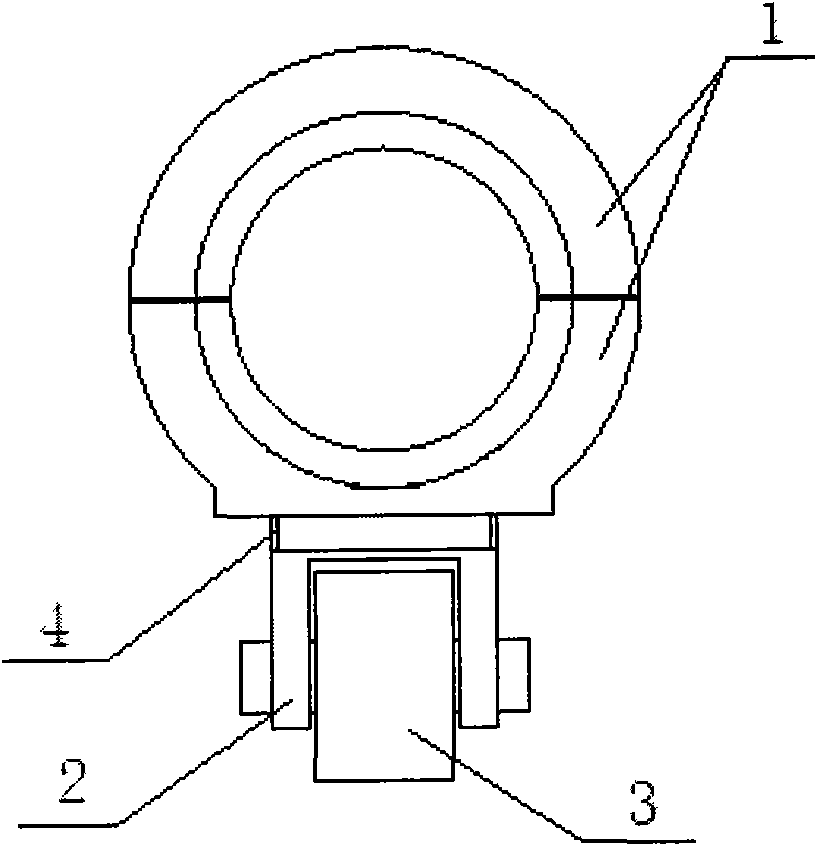

[0019] This example figure 1 , figure 2 As shown, a tail shaft installation method of a 10,000-ton ro-ro ship adopts the following installation steps. Two first trolleys 5 and second trolleys 6 that can move on the guide rails are set. The height of the trolleys can be adjusted by the hydraulic pressure on the trolleys. The top is adjusted, and the trolley is controlled by a motor. An ingot iron 8-1, 8-2 is respectively arranged on the trolley to support and radially locate the tail shaft 9, and the tail shaft 9 is placed on two movable dollies, the ingot iron 8-1, 8-2, the tail shaft propeller hub 10 of the tail shaft 9 is placed on the ingot iron 8-1 of the second trolley 6 at the rear, and the distance between the two cars is 13 meters apart to ensure that the center of gravity of the tail shaft 9 falls on the center of the two cars. In the middle, adjust the distance between the ingot iron 8-2 of the first trolley 5 and the horizontal guide rail 7 to be 4.11 meters, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com