Pumped storage power plant tail water retained rock step blasting safety protection method

A pumped-storage power station and safety protection technology, which is applied in the field of underwater rock sill blasting safety protection, can solve problems such as threatening the construction safety of workshops, and achieve the effects of convenient slag cleaning and scientific and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

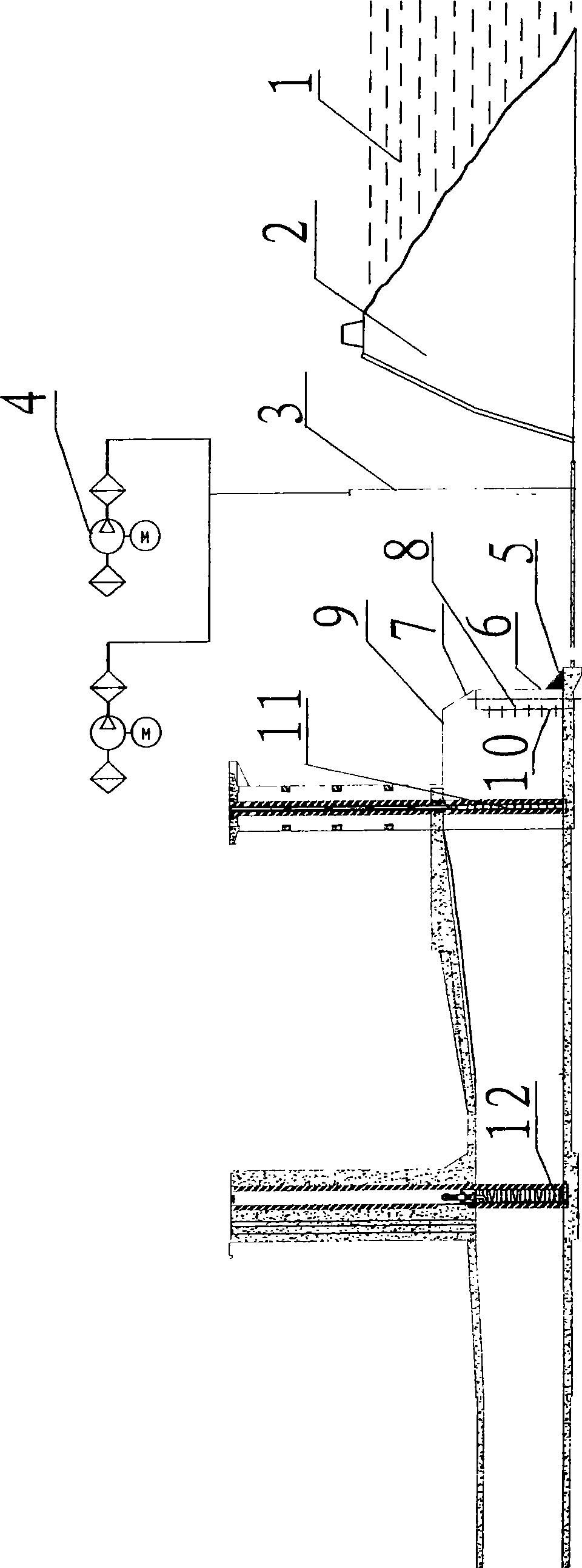

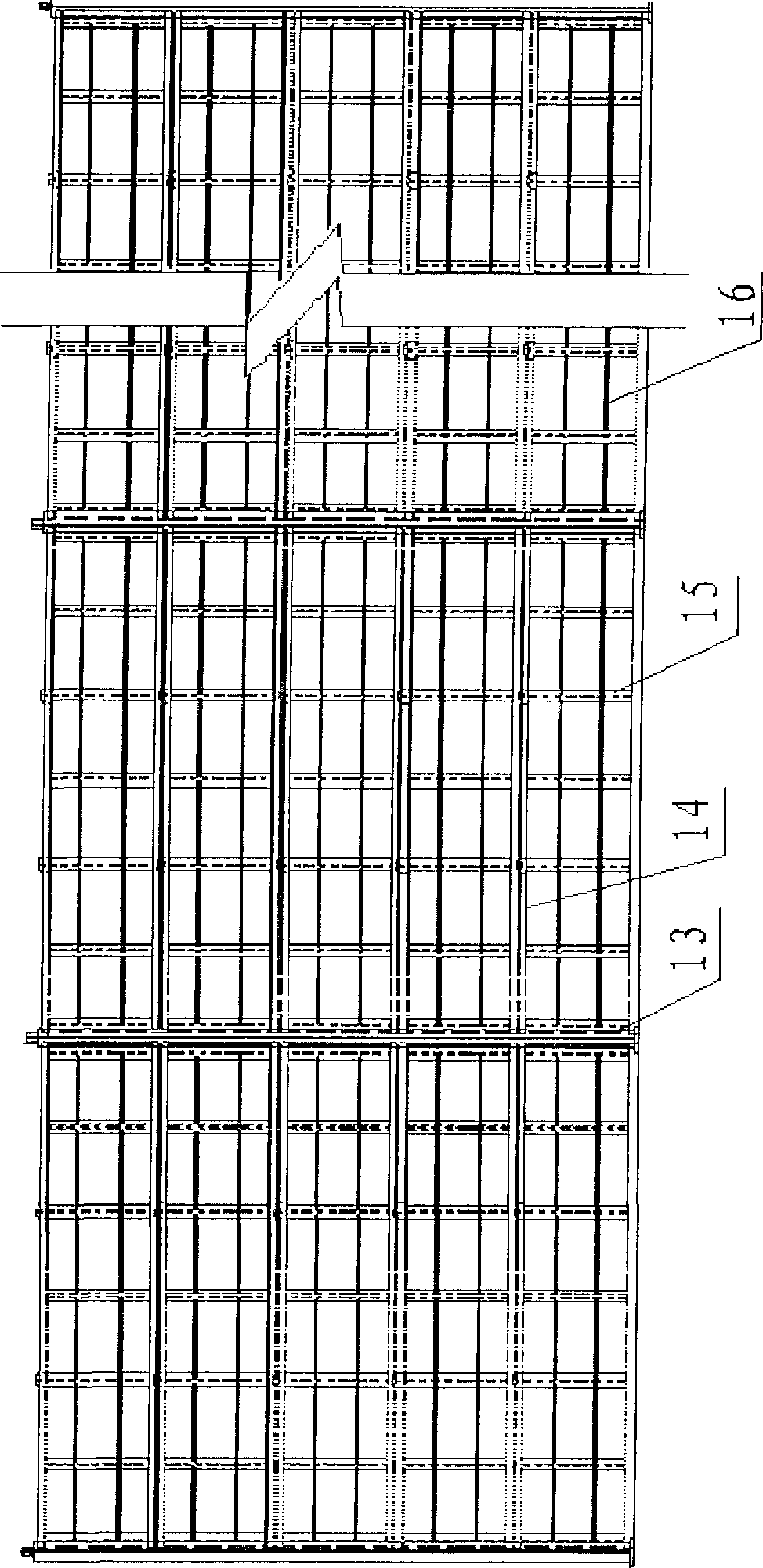

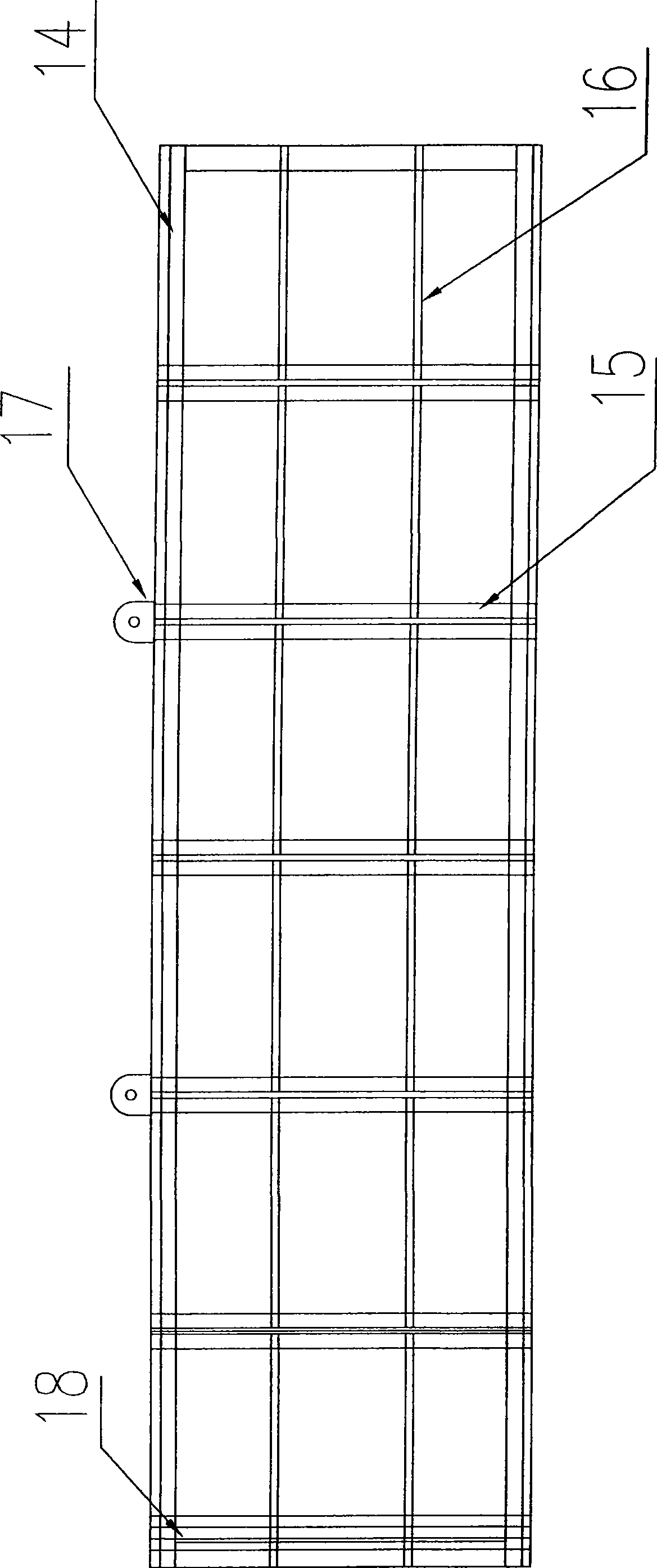

[0019] refer to figure 1 , build a water bubble curtain at a distance of 5±1m from the blasting rock sill, and build a porous stacked beam door at a distance of 20±5m from the water bubble curtain. The blasting rock ridge 2 is built at the blasting position of the lower reservoir 1 . The lower reservoir is provided with a water retaining gate 12 for the inlet and outlet of the lower reservoir.

[0020] The water bubble curtain is composed of 20±3 steel pipes 3, the pipe length is 20m, and the pipe distance is 3m. Two rows of φ1.5mm holes are drilled on each pipe, and the distance between the holes is 50-70mm. The distance between each steel pipe and the air compressor Air pipe is connected. 5 minutes before ignition, use two 9m3 / min, 2-4×105Pa air compressors to supply air to each steel pipe, so that the air volume per meter of steel pipe is greater than 0.008m3 / s. In the two-phase curtain layer, due to the compressibility of the bubbles, part of the energy of the water sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com