Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

123 results about "Adit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An adit (from Latin aditus, entrance) is an entrance to an underground mine which is horizontal or nearly horizontal, by which the mine can be entered, drained of water, ventilated, and minerals extracted at the lowest convenient level. Adits are also used to explore for mineral veins.

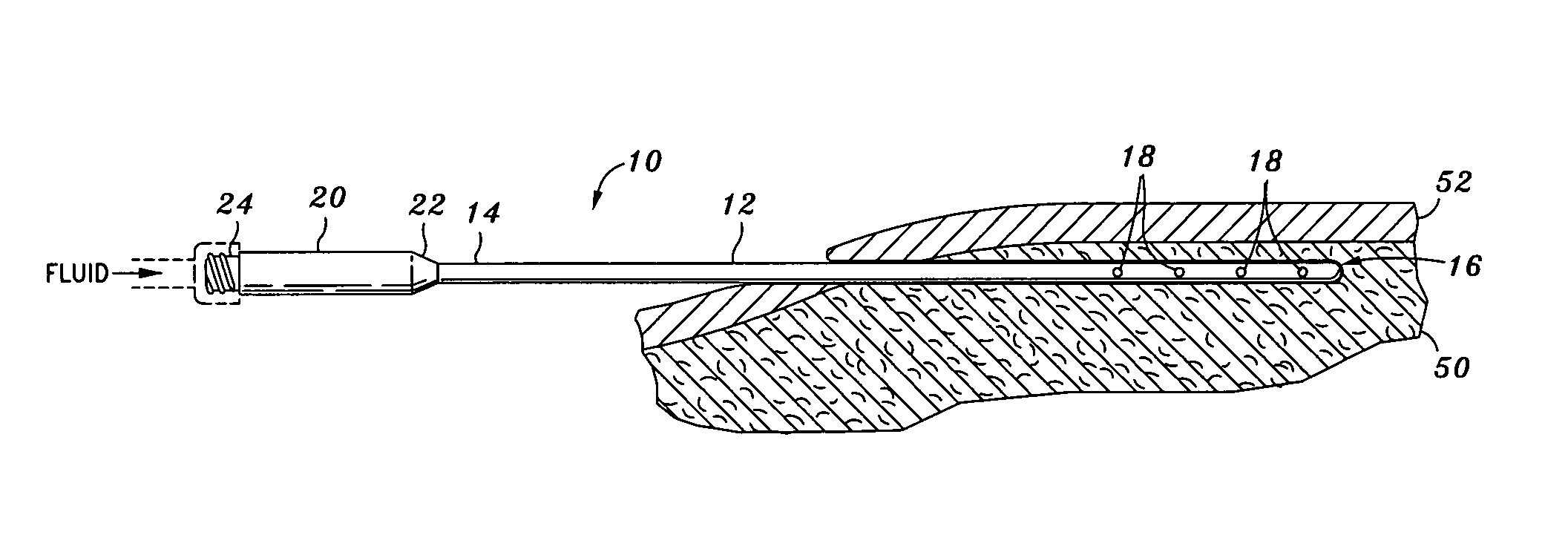

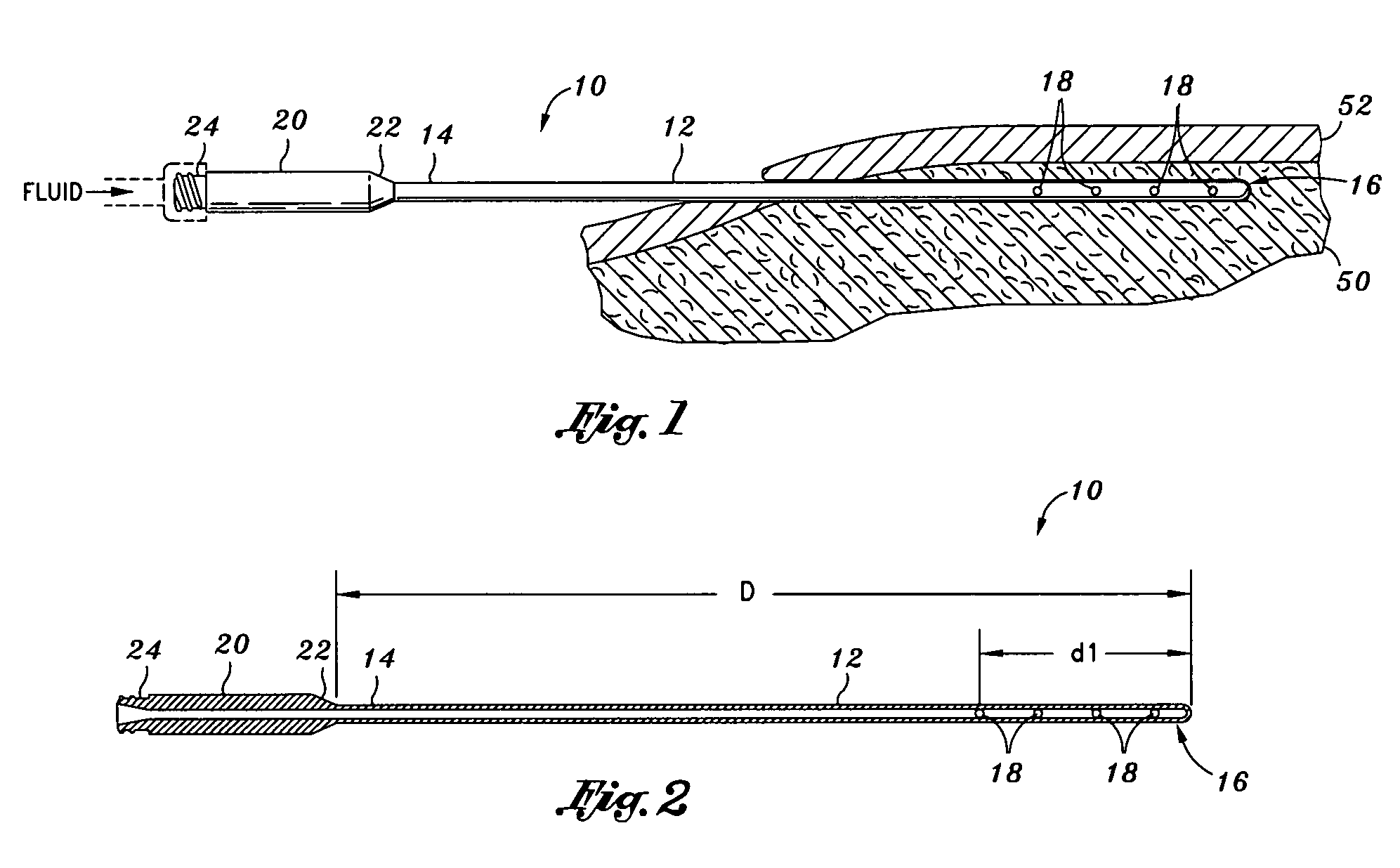

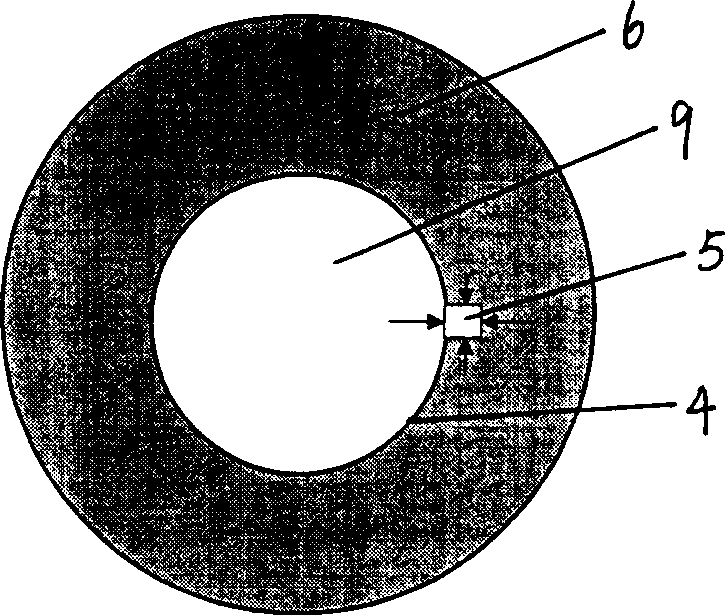

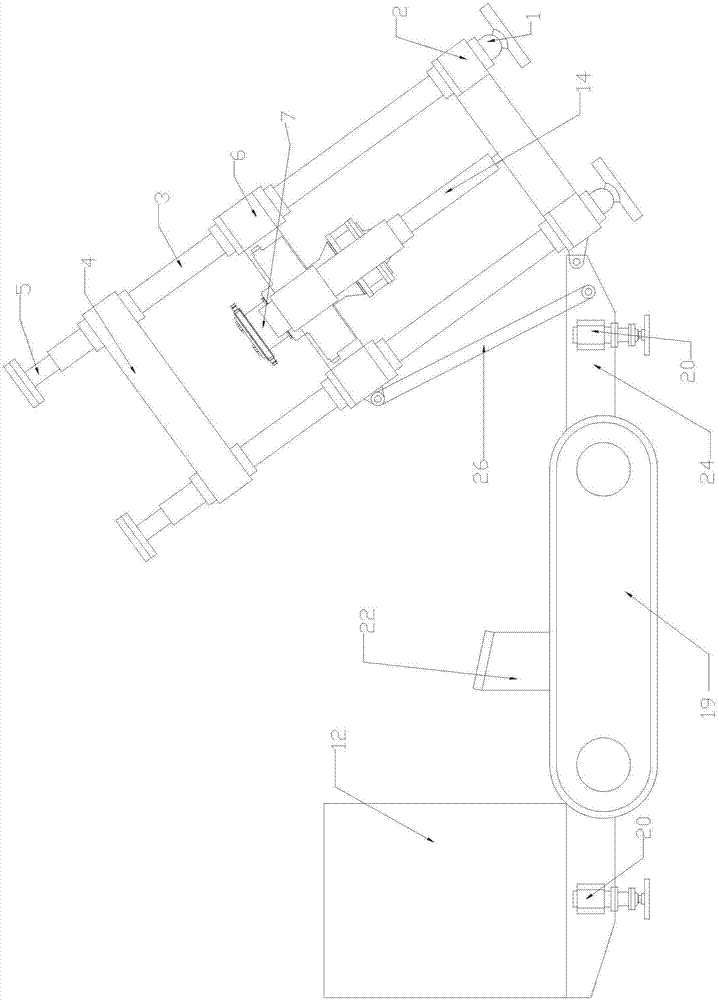

Infiltration cannula

An infiltration cannula and method of using the infiltration cannula during a tumescent infiltration procedure are disclosed herein. The infiltration cannula may have an outwardly flaring hub which may be wedged into an adit of a patient to minimize leakage of fluid being infiltrated into the patient. Also, the infiltration cannula may be utilized to hydrate a dehydrated patient by a medically untrained person. The infiltration cannula may also be used to deliver an antibiotic / vasoconstrictive drug solution to minimize surgical site infections.

Owner:KLEIN JEFFREY A

Infiltration cannula

ActiveUS8105310B2Avoid disruption and disruptionFacilitate rapid delivery of fluidAutomatic syringesMedical devicesAditDrugs solution

An infiltration cannula and method of using the infiltration cannula during a tumescent infiltration procedure are disclosed herein. The infiltration cannula may have an outwardly flaring hub which may be wedged into an adit of a patient to minimize leakage of fluid being infiltrated into the patient. Also, the infiltration cannula may be utilized to hydrate a dehydrated patient by a medically untrained person. The infiltration cannula may also be used to deliver an antibiotic / vasoconstrictive drug solution to minimize surgical site infections.

Owner:KLEIN JEFFREY A

Filling fully-mechanized mining recycling method for compressed coal on end side of opencast coal mine

The invention discloses a filling fully-mechanized mining recycling method for compressed coal on the end side of an opencast coal mine. An adit is driven from the side, close to the end side and close to lower steps of the inner row, at the bottom of the opencast mine to the earth surface boundary line in the direction that a coal bed is perpendicular to the end side, meanwhile, an air shaft is driven; and then a main air return roadway is driven from the bottom of the air shaft and the innermost end of the adit in the direction that the coal bed is parallel to the end side respectively and communicate at the bottom of the air shaft, and thus a complete ventilation system is formed. The driven adit serves as a fully-mechanized working face, and operation is conducted through matching of a filling hydraulic support, a coal mining machine and a scraper conveyer. Mining and filling are conducted simultaneously up to the final boundary in the direction of the working slope of the opencast mine, so that the compressed coal on the end side is mined to the maximum extent, the coal loss is reduced, and the mining rate of the opencast coal mine is increased; and meanwhile, stripped waste of the opencast coal mine can be fully utilized for filling, so that the waste discharge amount is decreased, and environmental-friendly mining of the coal is achieved.

Owner:CHINA UNIV OF MINING & TECH

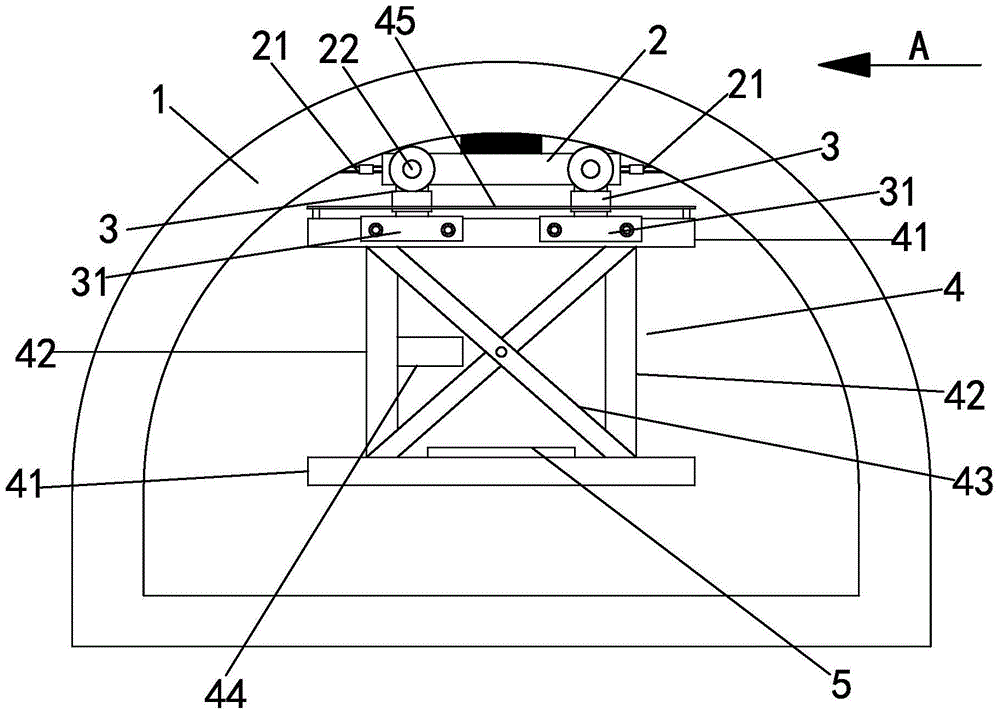

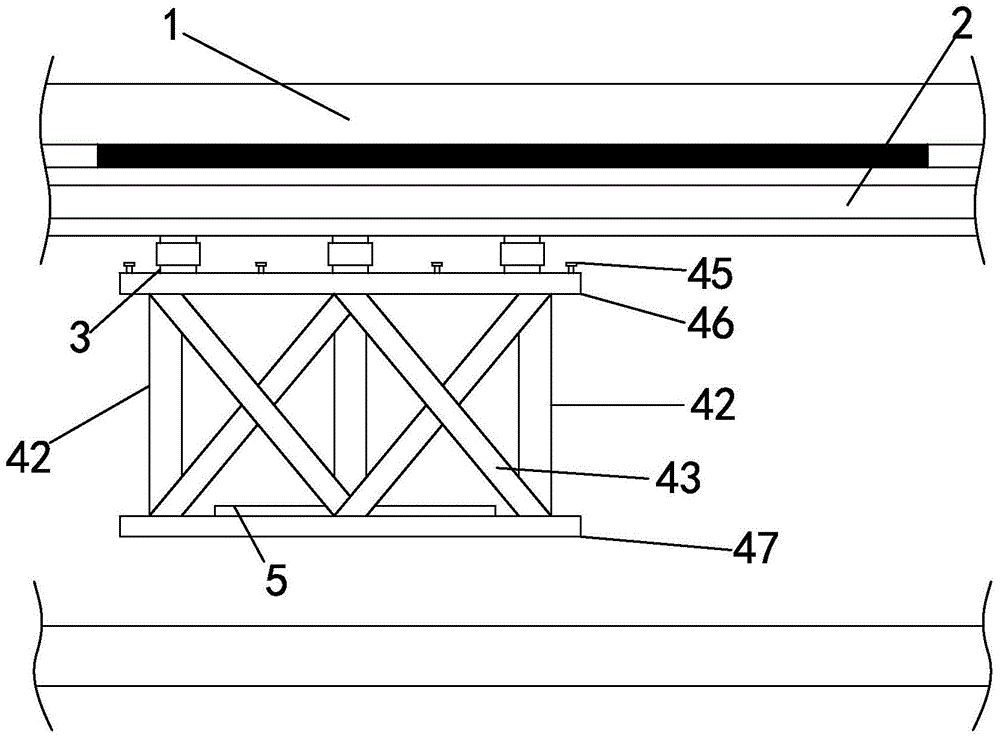

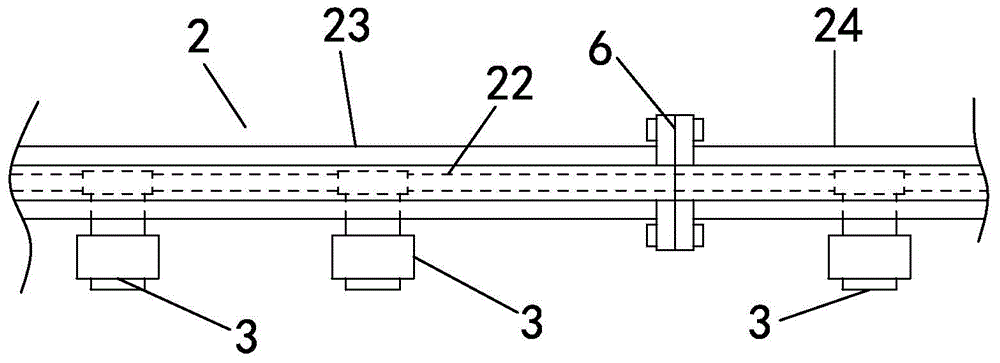

Rack for tunnel excavation and adit construction method applying rack

ActiveCN104533449AEasy to moveImprove work efficiencyUnderground chambersDrainageAditAutomatic control

The invention discloses a rack for tunnel excavation and an adit construction method applying the rack. The rack is automatically controlled through a cable, construction accuracy can be improved, the moving range of the rack can be adjusted, and the rack is very suitable for adit construction. In addition, a device fixing apparatus is added on the rack, movement of a part of machines and tools is facilitated, the machines and tools can be used in the construction process at any time anywhere, and the working efficiency of the adit construction and construction effect can be remarkably improved. The adit construction method applying the rack is characterized by comprising the following steps of (a) construction preparation, (b) opening plane arrangement, (c) spoil area site selection, (d) protection and greening of a spoil area site, (e) opening excavation, (f) main tunnel first-stage construction, (g) rack assembly and (h) main tunnel second-stage construction. The main tunnel construction is performed in a two-stage mode, mutual reference can be achieved in the construction process, and project quality can be improved.

Owner:CHENGLONG CONSTR GROUP

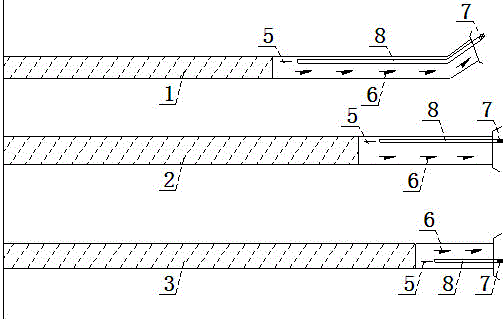

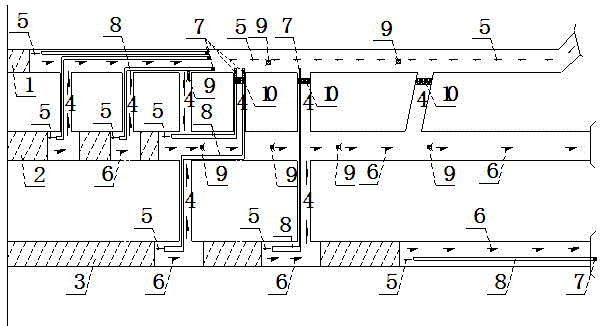

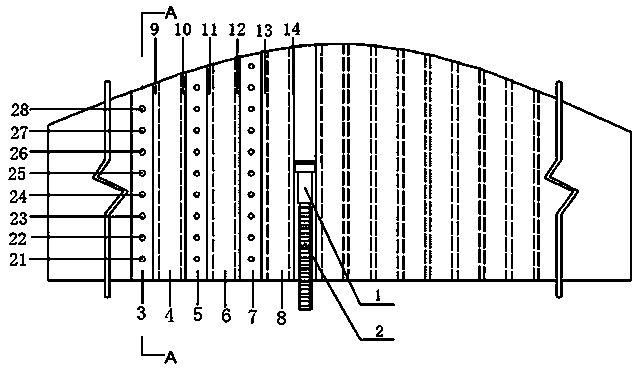

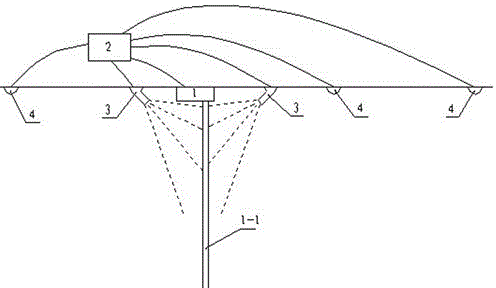

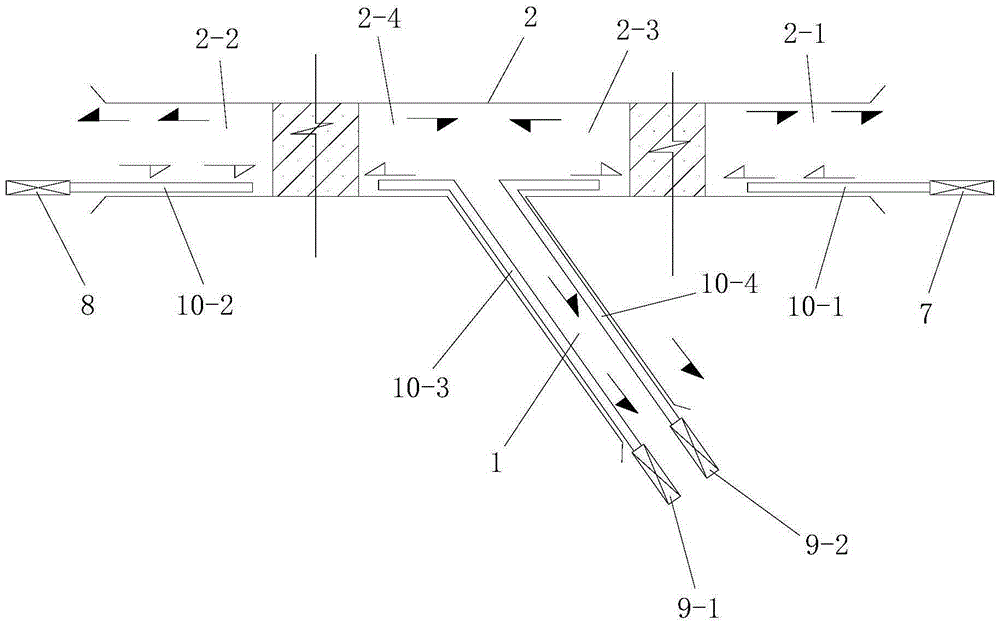

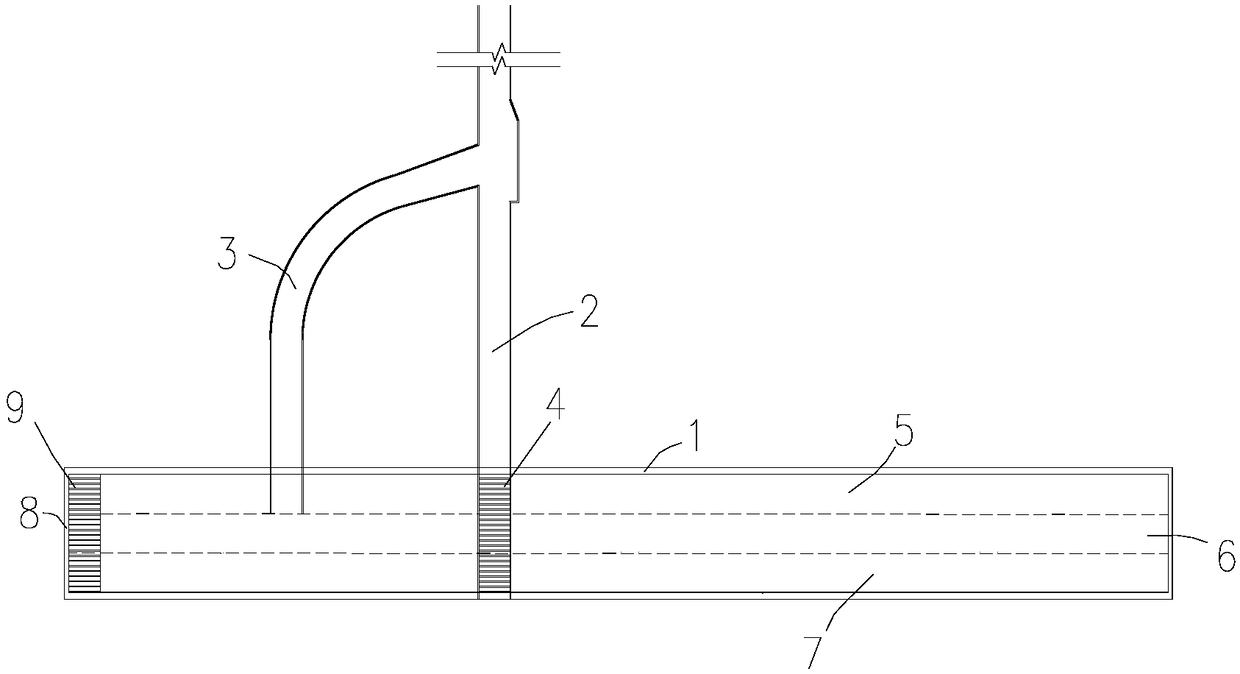

Method for constructing and ventilating three parallel tunnels

ActiveCN104314600ASolve ventilation problemsEnsure Occupational Health RequirementsTunnel/mines ventillationAditFresh air

The invention discloses a method for constructing and ventilating three parallel tunnels. The three parallel tunnels comprise a parallel adit (1), a left-lane forward cave (2) and a right-lane forward cave (3); by a single-entrance parallel construction process, transverse passages (4) for communicating adjacent tunnels are arranged between the adjacent tunnels; by a mixed ventilation way that pressed ventilation and lane ventilation are combined, ventilation equipment adopts an axial flow fan (7); the axial flow fan (7) is connected with air ducts (8); the air ducts (8) are arranged inside the parallel adit (1), the left-lane forward cave (2), the right-lane forward cave (3) and the transverse passage (4); air walls (10) are arranged at the transverse passage (4) entrances of the parallel adit (1) for isolating fresh air (5) from dirt air (6); the parallel adit is constructed in advance, and the parallel adit is taken as a fresh air inlet lane to form the lane ventilation; according to construction progress, the axial flow fan and the air duct which are arranged inside the parallel adit are moved forward timely; the left-lane forward cave and the right-lane forward cave exhaust the dirt air; a jet fan (9) is additionally arranged at a proper position.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

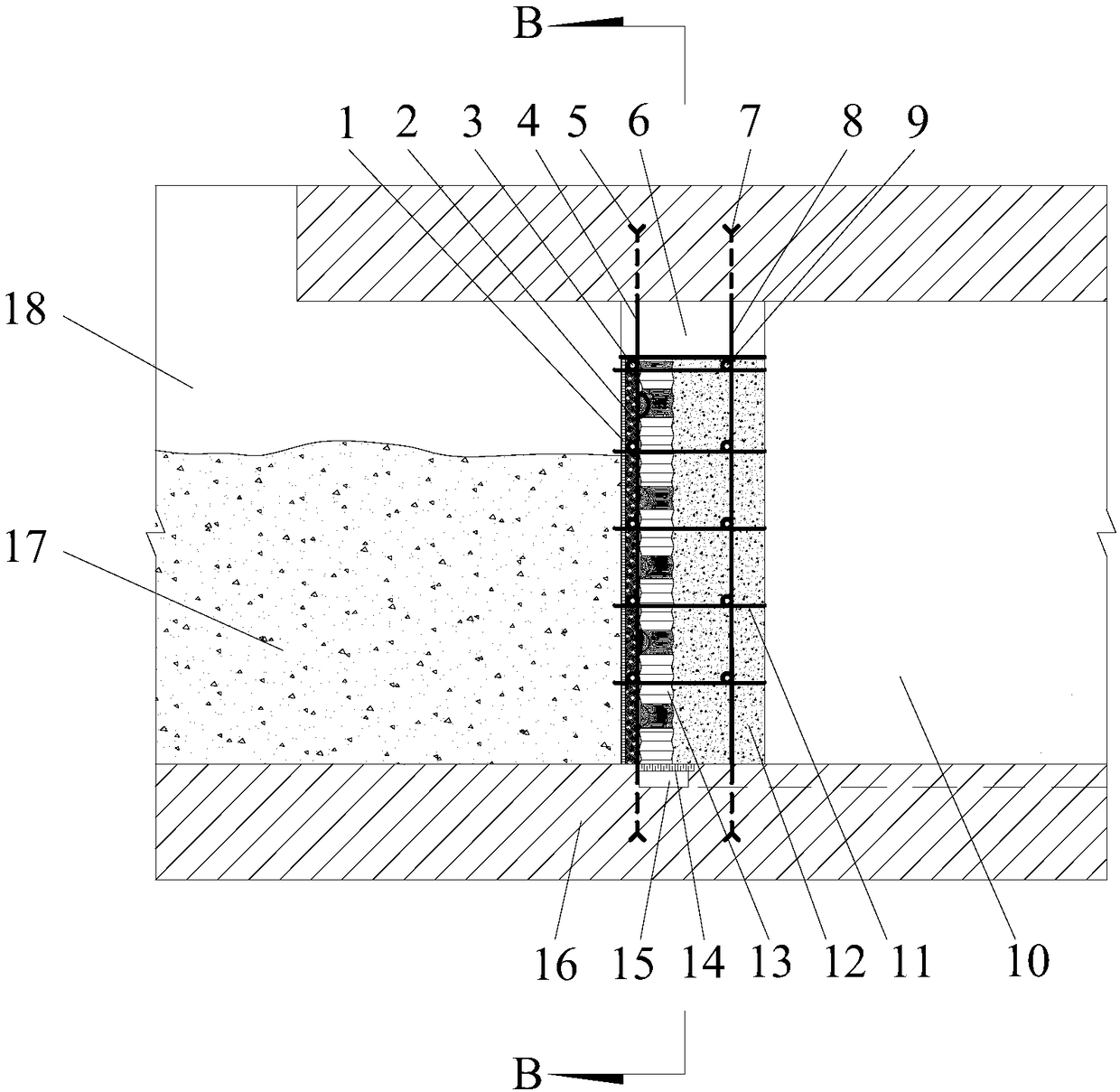

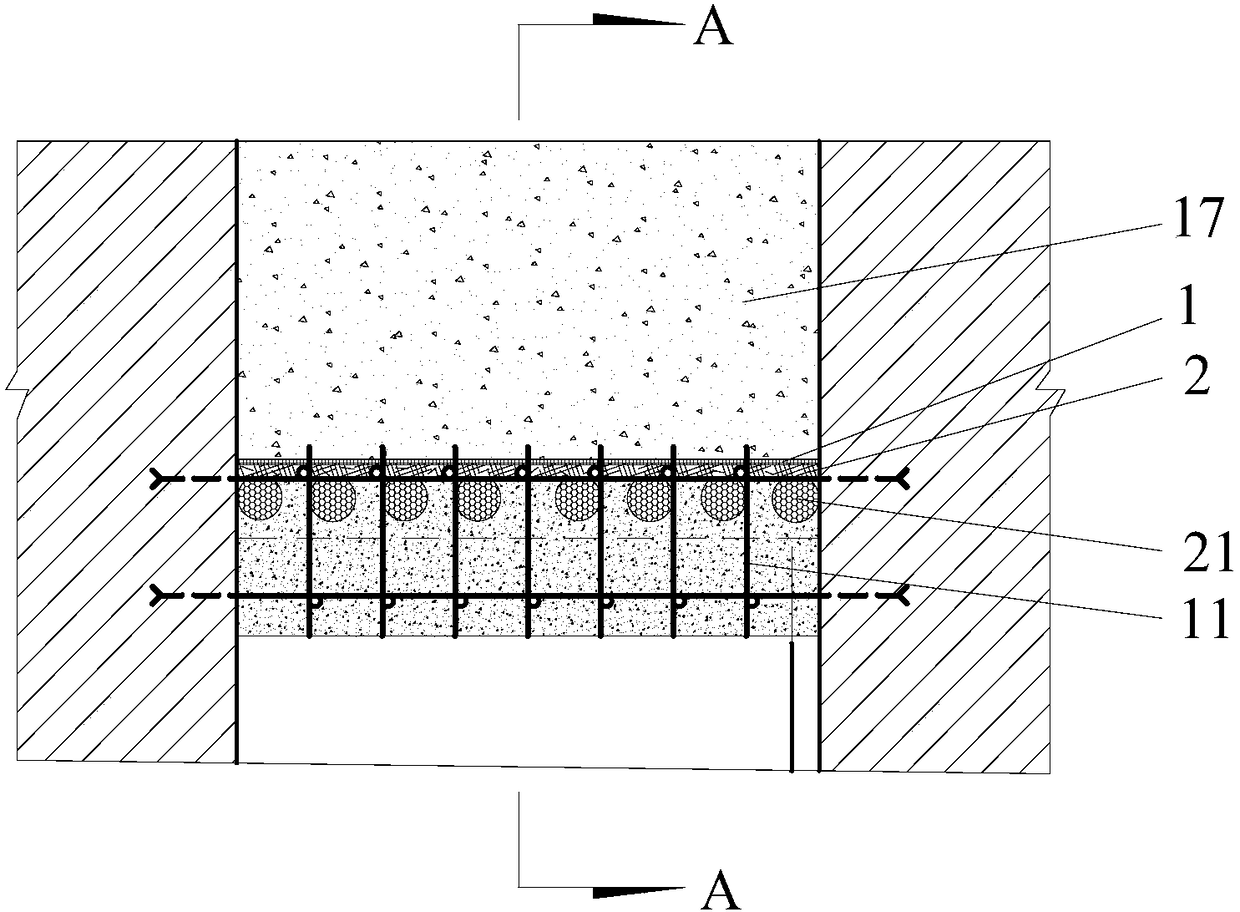

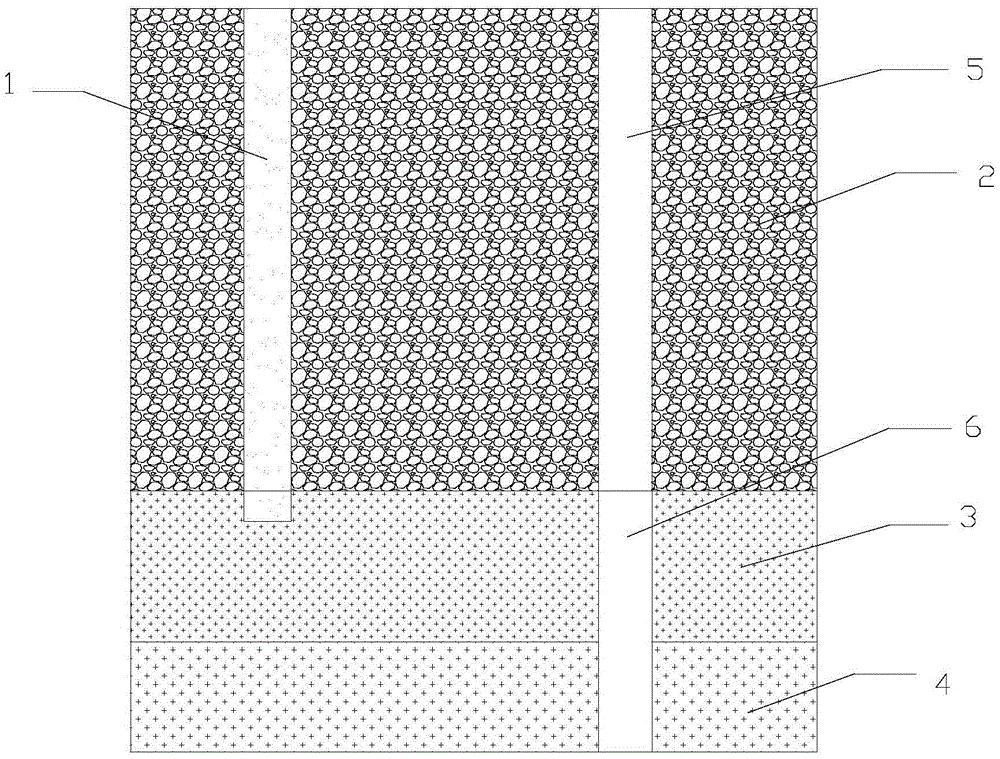

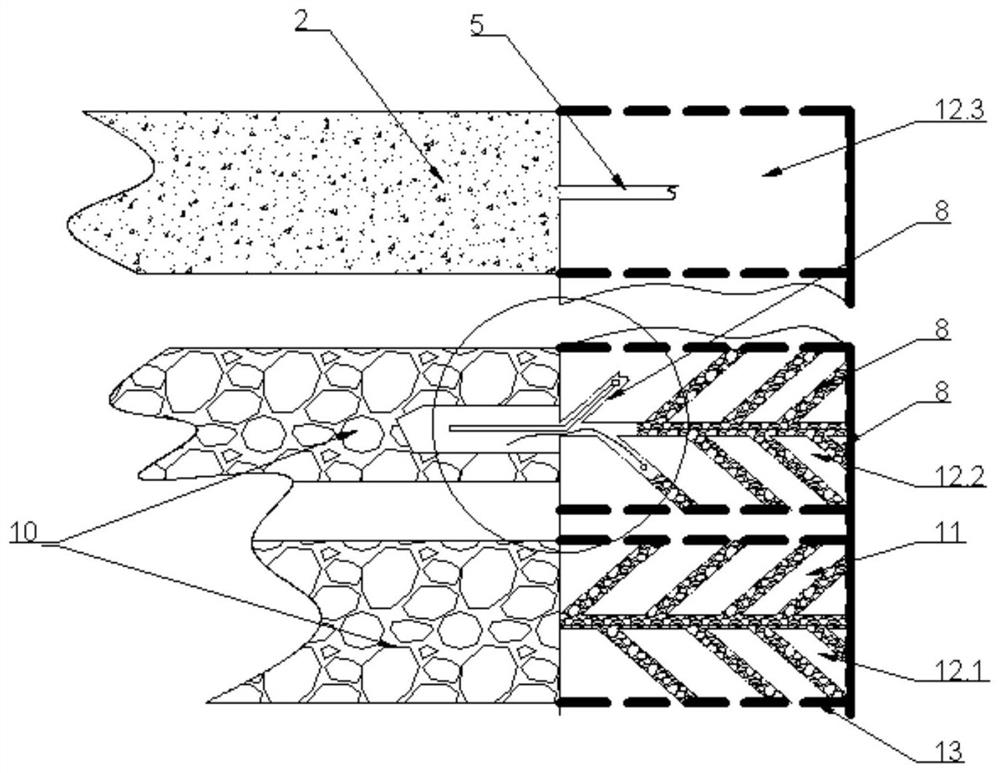

Mine underground tailing water in-situ processing method and retaining wall capable of being filled by osmotic response

PendingCN108590751AEasy constructionImprove mechanical performanceMaterial fill-upStationary filtering element filtersAditShotcrete

The invention discloses a mine underground tailing water in-situ processing method and a retaining wall capable of being filled by osmotic response. When stoping is finished in a stope, before filling, a flexibly closed water filtering retaining wall is built at an access adit which needs to be sealed at the bottom of the stope; a retaining wall framework is formed by rock bolts and two layers ofreinforced steel nets in a welded mode; an inner layer reinforced steel net is bonded with a metal net; a water filtering material is arranged between the metal net and the reinforced steel net and covers the whole cross section of the access adit; bellow PRB reaction units with through holes are arranged between the two layers of the reinforced steel nets in vertical-parallel-arrangement mode; afunctional active filler is arranged in the bellow PRB reaction units in a filling mode; and the bellow PRB reaction units are fixed to the inner layer reinforced steel net. Jet concrete is arranged for filling the reinforced steel nets and forming a retaining wall with a certain thickness. The construction of the retaining wall body is convenient, under-stress performance is good, the water blocking and filtering effect is good, and operation and maintenance cost is low; an active reaction area is formed in the retaining wall, and pollutants in the tailing water can be caught and removed effectively; and underground water pollution is prevented.

Owner:CENT SOUTH UNIV

Parallel digging, mining and filling operation coal mining method for controlling overlaying strata fracture and surface subsidence

InactiveUS20180195386A1Guaranteed safe recoveryQuantity minimizationUnderground miningSurface miningCoal miningMineralogy

Disclosed is a parallel digging, mining and filling operation coal mining method, in which a stope haulage roadway, stope branch roadways, and two-winged adits are arranged in a stope. The stope haulage roadway and the stope branch roadways serve as haulage passages, and coal mining work is carried out in the two-winged adits. All two-winged adits are mined sequentially and filled timely, and coal mass that has not been mined or two-winged adits that have been filled always exist at the two sides of the two-winged adit that are being mined, to support and control the roof. The two-winged adits can be mined without support or with less supports by controlling the length of the two-winged adits and the number of two-winged adits filled in one time, whereupon pillar-free mining can be realized.

Owner:CHINA UNIV OF MINING & TECH

Isolation processing method of polluted groundwater

ActiveCN105544574AImprove leak control efficiencyMeet zero emission requirementsFoundation engineeringAditGroundwater recharge

The invention provides an isolation processing method of polluted groundwater. The isolation processing method comprises the following steps: an anti-seepage curtain separated moderately-strong permeable layer is established through a vertical anti-seepage system and a horizontal drill hole or an adit, and a vertical and horizontal draining device and a monitoring system are arranged in a weak permeable layer to change and control the groundwater seepage path to control the groundwater leakage amount of the weak permeable layer, so that the requirement that the permeability coefficient reaches 10<-7> cm / s is met, and the influence of groundwater seepage pollution on the surrounding environment can be completely controlled. The isolation processing method combines a vertical anti-seepage technology, a horizontal and vertical groundwater draining and dynamic monitoring technology and a dynamic groundwater control technology, and thus has a high application value, and is especially suitable for seepage control of polluted groundwater in a tailings impoundment and other polluted groundwater.

Owner:中冶华成(武汉)工程技术有限公司

Open-cast side shrouded beneficial mineral open well combined mining method

InactiveCN101338675ASave the amount of excavationSave the amount of support engineeringUnderground miningSurface miningAditEarth surface

The present invention provides a combined exploitation method for a beneficial mineral open well is covered under a strip mine boundary slope. The problems to be solved by the combined exploitation method are as follows: firstly, a spiral drill is used for recovering, a stable is required to be reserved between two drills due to the restriction of the length of a drill rod, so the percentage extraction is very low; secondly, a slope mine is excavated from the proper position on the surface of ground, a roadway is extended to a ledge for arranging a mining area, and underground mining is realized. The slope mine construction and support project quantity is large, which is expense-wasting and time-consuming. In the key points of the combined exploitation method, the ledge section at the boundary slope of the goaf of the strip mine is used, a main adit and a secondary adit are excavated in the ledge directly and are extended into the boundary slope for arranging the mining area to realize the underground exploitation and recovery of the beneficial mineral in the strip mine boundary slope. Then the mineral is transported to the ground by a transportation channel or a haulage plant which is formed in a strip mine stope. The combined exploitation method has the advantages of saving a great deal of slope mine construction project quantity and support project quantity, avoiding the unsafe factor of the slope mine during the processes of construction and operation and improving the production system safety of the mine.

Owner:中煤科工集团沈阳设计研究院有限公司

Continuous miner drilling-type paste filling mining method for end slope coal

ActiveCN111364992APromote recoveryProtect environmentUnderground miningSurface miningAditResource recovery

The invention discloses a continuous miner drilling-type paste filling mining method for end slope coal, and belongs to the field of coal mining methods. The problems of the poor filling rate and topfilling effect, the low resource recovery rate, destruction of the ecological environment of a mining area, poor slope stability and the like when people enter an adit to pave filling pipelines duringexisting mining of end slope coal are solved. The end slope coal of an open-pit coal mine is divided into several sections, a plurality of mining adits are planned in the sections, and inter-mining-adit coal pillars are reserved among the mining adits; and initial skip-mining is carried out in the sections, at the same time, a plurality of filling holes are formed in the upper earth surfaces of the middles of the mining adits, a steel sleeve sleeving wall is adopted, after a high-concentration filling body is injected into the mining adits for mining, a goaf is formed, the filling operation is completed in two times, and the secondary mining is carried out after the initial mining is completed in the sections until the mining and filling of the mining adits in all sections are completed.The safety during mining and filling can be improved, and personnel are not needed to enter a roadway; and the filling process is simplified, and the filling cost is reduced.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

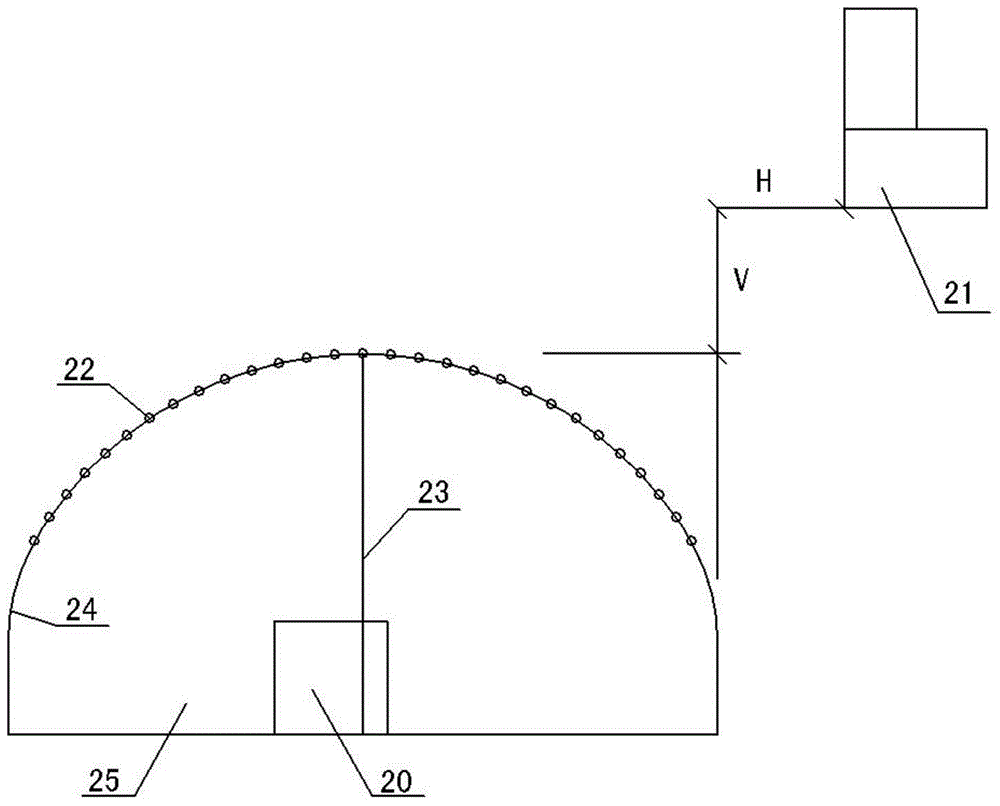

Advanced adit hole-by-hole delayed blasting network in tunnel blasting

ActiveCN103557756AReduce the total charge of blastingReduce the impact of vibrationBlastingAditDetonation

The invention discloses an advanced adit hole-by-hole delayed blasting network in tunnel blasting. The network is characterized in that blasting excavation is performed by using a three-step method for an underground excavated metro interval tunnel; longitudinal excavation is performed along the tunnel to form an upper step, a middle step and a lower step in sequence; the excavation of the upper step is performed by prearranging each external contour overhead hole at equal intervals along the upper arch of an excavation contour line of the upper step; an advanced adit is arranged at the bottom; a central blast hole is positioned in the geometric center of the advanced adit; four central overhead holes are prearranged at the positions of four vertexes of a square ring with the central blast hole as the center; the advanced adit and an upper step expanded excavation region are blasted at two steps; the advanced adit hole-by-hole delayed blasting network is arranged in the way that each layer of expanded slot blast holes is arranged at the periphery of the central blast hole at intervals from near to far away from the central blast hole; the first layer of expanded slot blast holes are crosswise distributed at the periphery of the central blast hole and form the square ring together with four central overhead holes. The detonation explosive load of the same section is greatly reduced by using hole-by-hole delayed blasting.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

Method to detect dendroctonus valens and detection kit

InactiveCN103146811AAccurate detectionHigh sensitivityMicrobiological testing/measurementDNA/RNA fragmentationScolytus schevyrewiAdit

The invention provides a method to detect dendroctonus valens and a detection kit. The detection method is a nested polymerase chain reaction (PCR). Nucleotide sequences of a first pair of used primers are shown in SEQ ID NO.1-2, and nucleotide sequences of a second pair of primers are shown in SEQ ID NO.3-4. The invention further provides a kit for detecting the dendroctonus valens. The method to detect the dendroctonus valens and the detection kit have the advantages of being precise in detection, strong in specificity, simple, convenient and quick, can discriminate the dendroctonus valens from four kinds of similar bark beetles including scolytus schevyrewi semenov, round cavity timber beetles, xyleborus interjectus blandfor and adit cutting beetles, and is good in dendroctonus valens detection capacity. The detection sensitivity is 40pg.

Owner:BEIJING FORESTRY UNIVERSITY +1

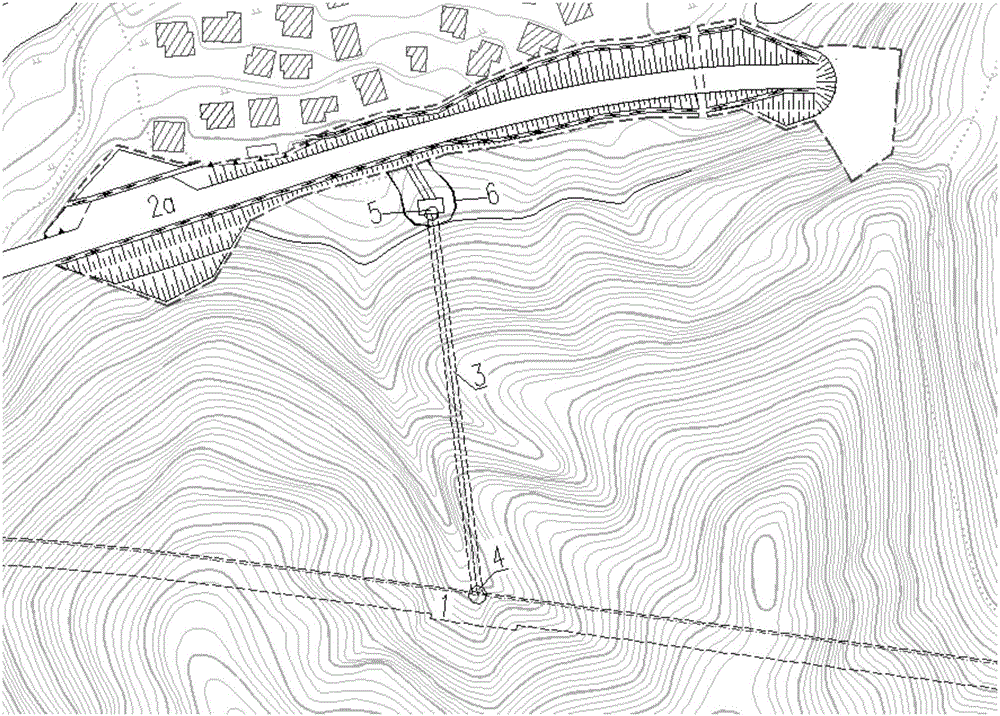

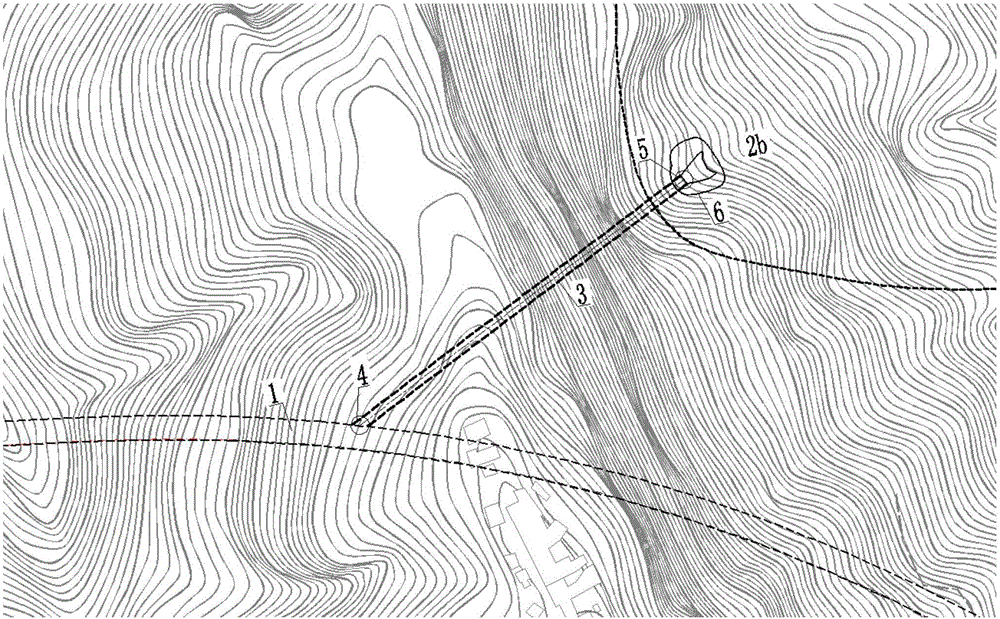

Method and system for electronically acquiring geological survey adit joint data

InactiveCN106772665AImprove efficiencyRealize electronicGeological measurementsAditGeological survey

The invention relates to a method and a system for electronically acquiring geological survey adit joint data. The method includes steps of S1, acquiring geometric information of survey adits and drawing planar electronic grid adit three-wall display graphs; S2, selecting a plurality of geological points from adit joints, measuring location information and joint attitude information of the various geological points, generating geological points with attributes on electronic grids and sequentially connecting the geological points with one another to form joints; S3, determining joint groundwater states and joint state information according to site conditions and attaching the joint groundwater states and the joint state information to the corresponding joints; S4, repeatedly carrying out the steps S2 and S3, forming catalog results of the integral adits, updating work results and uploading the work results to general databases to summarize the work results. The method and the system have the advantages that the method and the system are beneficial to improving the efficiency of geological catalog work, and adit data acquisition processes can be electronized and standardized.

Owner:加华地学(武汉)数字技术有限公司

System and method of chamber destruction of bomb

The invention discloses a system and method to destroy bomb in underground chamber that is made up of destroying underground chamber located in wall rock and the bottom has impacting resistance material layer, adit and communicating laneway that has laneway structure. The destroying underground chamber connects to adit through laneway. After setting the system, laying the bomb and blasting charge into the underground chamber to take remote detonation and take forced draught after detonating to release the waste gas into atmosphere and the harmful gas thickness would be lowered to safe range. The system would destroy 200kg detonator equivalent weight bomb, and the bow wave would not harm human over 200m distance. Even in the area of popuousness.

Owner:GUANGDONG HONGDA BLASTING

High-definition drilling color television-based rock mass structure surface search method

The invention discloses a high-definition drilling color television-based rock mass structure surface search method. The method comprises the implementation steps of extracting information such as spatial coordinates, occurrence, characters and the like of a structure surface according to geological surveying and mapping, exploratory adit geological recording and high-definition drilling color television interpretation; establishing a spatial planar geometric equation of the structure surface; comparing spatial positions and characters of two structure surfaces; and judging whether a spatial relationship between the two structure surfaces belongs to the same structure surface or not. The method is used for finding out characteristics of spatial distribution, characters and the like of thestructure surface in rock mass; structure surface information disclosed by drilling is fully utilized; the limitation of a conventional method is overcome; the search range is expanded; the search reliability is improved; and the method has the characteristics of simple operation and high reliability.

Owner:长江三峡勘测研究院有限公司(武汉)

Method for forming escaping-rescuing transverse channel in road tunnel

ActiveCN106014442AFlexible settingsConvenient and quick escapeTunnelsSafety equipmentsAditRoad engineering

The invention relates to a method for forming an escaping-rescuing transverse channel in a road tunnel, and belongs to the technical field of road engineering. Specific to medium, long and extra-long tunnels with overlarge single-hole or double-hole distances or overlarge altitude differences on roads, an escaping-rescuing transverse channel straight to the ground is formed according to the relationships between the tunnel position and peripheral mountains under the situation that a double-hole transverse channel cannot be formed. The transverse channel comprises a main hole intersection, a channel hole body segment and a ground outlet, wherein the channel hole segment can be set in a climbing type, a flat slope type and a downhill type; the ground outlet is connected with a traffic instrument or flat ground according to the ground outlet appearance and a building situation; an isolation fence needs to be arranged at the outlet. Compared with the conventional disaster prevention and rescue scheme of forming a transverse channel between two holes of a separate tunnel and forming an emergency parking lot or a parallel adit, a bomb shelter and the like in a single-hole tunnel, the escaping-rescuing transverse channel setting method has the advantages of adaptation to local conditions, flexible arrangement, realization of rapid escape or rescue of personnel trapped in the tunnel to a safety belt outside the holes through the transverse channel.

Owner:BROADVISION ENG CONSULTANTS

Large-section steep hill long inclined shaft high-precision pilot shaft excavating construction method and system and application

InactiveCN111441718AAdvanced excavation construction technologyConstruction stabilityWater-power plantsDirectional drillingAditPilot hole

The invention belongs to the technical filed of water conservancy and hydropower underground projects, and discloses a large-section steep hill long inclined shaft high-precision pilot shaft excavating construction method and system and application. A full-section drilling and blasting method is adopted for excavating to form an upper adit and a lower adit, and the upper adit and the lower adit serve as a construction channel; after the upper adit is formed, the upper adit is used as the construction channel, and a directional drilling machine is mounted and debugged, and carries out forward drilling to excavate a high-precision pilot hole with the diameter of 216 mm; after the high-precision pilot hole with the diameter of 216 mm is formed in the second step, a hole is drilled in a directional manner and connects with the lower adit, a drill pipe is pulled out, a drill bit is replaced to process the pilot hole into a hole of the diameter of 250 mm in a brushing manner, and the directional drilling machine is dismounted; the above work is finished, a raise boring machine is mounted and debugged, and forward drilling is carried out to excavate a drill hole of the diameter of 270 mm;and after work in the fourth step is finished, the lower portion of the raise boring machine is provided with an expanding excavation drill bit, and the pilot hole is subjected to expanding excavation from bottom to top to form a pilot shaft with the diameter of 2.2 m. The mechanization level is high, and the construction efficiency is high.

Owner:SINOHYDRO BUREAU 1 CO LTD

Mine adit fire separation device

A mine adit fire separation device provided with an automatic roller shutter door, a controller, sprinkler heads, sensors, a water tank, an injection pump, a recycling pump and a water trough. The sensors are in communication connection with the controller. The automatic roller shutter door, the injection pump and the recycling pump are controlled through the controller. The injection pump and the recycling pump are respectively connected with a water tank pipe, the water tank is connected with a fire-fight pipeline, a cooling device and an electronic liquid level meter are arranged in the water tank, the injection pump is connected with a sprinkler head pipe, and the recycling pump is further connected with a water outlet below the end of the water trough through a hose. Canvas strips are sequentially arranged to form a door curtain, the canvas strips at the edges on two sides of the door curtain are fixed in the middle of the water trough through rivets, the width of the water trough is 1-1.4m, and the height of the water trough is 30-50cm. The electronic liquid level meter, the controller, the sensors, the injection pump and the recycling pump are electrically connected with a control panel of a remote control chamber, the running conditions of the mine adit fire separation device can be monitored, and water can be supplemented to the water tank at any time.

Owner:宋英明

Method for exploiting two layers of coal seam gas

The invention provides a method for exploiting two layers of coal seam gas. The method comprises the following steps that a near vertical well and a far vertical well are drilled in the distance at a preset distance with a main roadway; a ground horizontal well is drilled, directional angle building is conducted on the ground horizontal well to a lower coal seam, a horizontal section of the ground horizontal well penetrates through the far vertical well firstly and then penetrates through the near vertical well in the lower coal seam; directional angle building is conducted on the ground horizontal well to an upper coal seam, the horizontal section of the ground horizontal well penetrates through the far vertical well firstly and then penetrates through the near vertical well in the upper coal seam; an adit horizontal well is drilled along the upper coal seam in the main roadway; two layers of coal mine seam sections of the near vertical well and the far vertical well are subjected to broaching, and the ground horizontal well is made to communicate with the adit horizontal well and the vertical wells; and coal gas exploiting is conducted through the near vertical well and / or the far vertical well and / or the ground horizontal well and / or the adit horizontal well. According to the technical scheme, the problem that in the prior art, simultaneous exploiting of the upper and lower coal seam gas cannot be conducted on the coal seam gas in the two coal mine seams which do not communicate mutually is solved.

Owner:CHINA SHENHUA ENERGY CO LTD +1

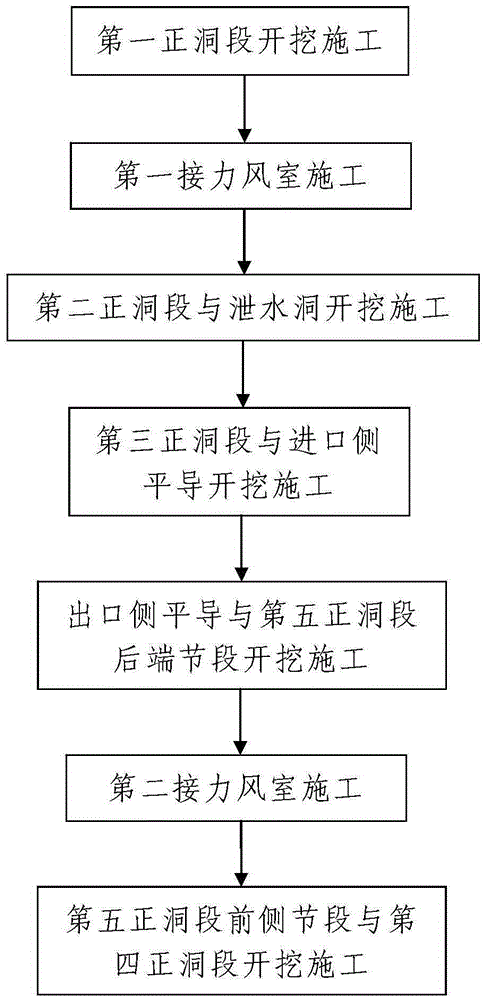

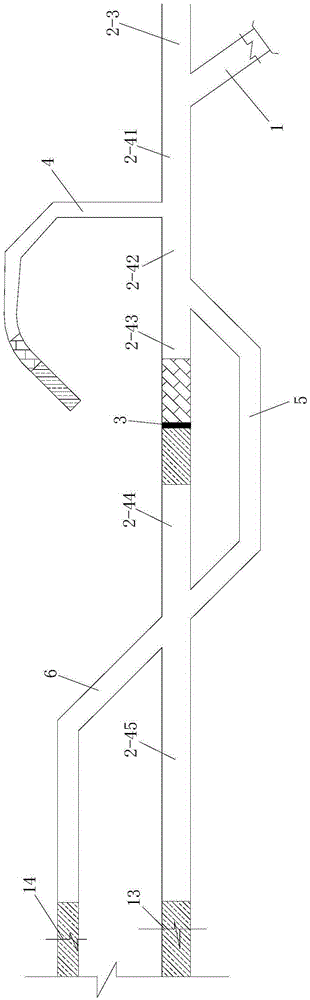

Plateau long tunnel multi-dead end ventilation construction method

The present invention discloses a plateau long tunnel multi-dead end ventilation construction method. A tunnel inclined shaft is disposed at one side of a main cave of a plateau long tunnel, a middle connection section of the main cave is an inclined shaft auxiliary construction section which is divided into an inclined shaft auxiliary construction entrance section and an inclined shaft auxiliary construction exit section, and the inclined shaft auxiliary construction exit section has a sudden surging point and intersects with derious parallel adits. The construction method comprises a first step of ventilator installation; and a second step of tunnel excavation construction, carrying out excavation construction on the inclined shaft auxiliary construction entrance section and the inclined shaft auxiliary construction exit section through the tunnel inclined shaft while carrying out excavation construction on a tunnel entrance section and a tunnel exit section, and assisting the excavation construction through the derious parallel adits while carrying out excavation construction on the inclined shaft auxiliary construction exit section. The method provided by the present invention is simple in procedure, reasonable in design, convenient to construct, excellent in ventilation effect, and capable of solving problems of a large amount of roadways requiring ventilation during a tunnel construction process, long ventilation distance and large difficulties in ventilation construction.

Owner:CHINA RAILWAY 20 BUREAU GRP

Accurate excavation method for gentle slope inclined shaft

ActiveCN112012751AReduce construction safety risksReduce construction costsClimate change adaptationDirectional drillingAditSlag

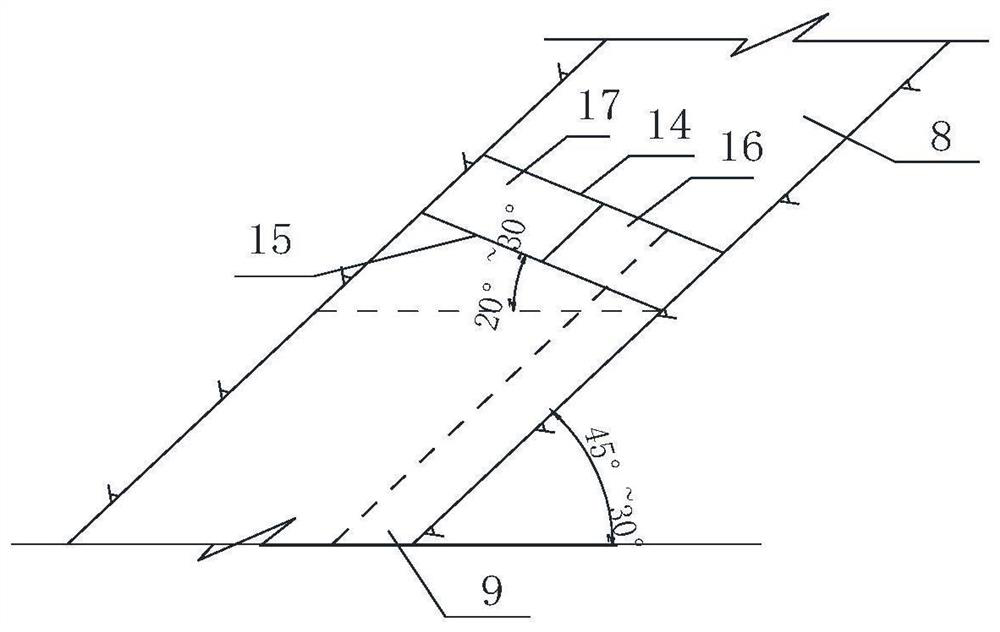

The invention discloses an accurate excavation method for a gentle slope inclined shaft. The accurate excavation method comprises the steps that expanding excavation is carried out on a lower adit andan upper adit; a hole guiding and drilling are carried out by a directional drilling machine; a MWD inclinometer and an RMRS rotating magnetic field distance measuring system are adopted for drill bit positioning; hole guiding forward reaming is carried out by a raise boring machine; and then the raise boring machine is used for reverse expanding excavation of a pilot shaft, the pilot shaft is used for slag sliding and is parallel to the bottom of a designed contour line of an inclined shaft bottom plate, forward control of blasting excavation is carried out after the pilot shaft is communicated, and finally, slag sliding is completed. According to the accurate excavation method for the gentle slope inclined shaft, the method of directional drilling, inverse shaft expanding and forward blasting excavation is adopted for the 30-45-degree gentle slope inclined shaft, the pilot shaft is arranged on the inclined shaft bottom plate, the slagging-off efficiency is effectively improved, an included angle between an excavation tunnel face and the horizontal plane is 20-30 degrees, and blasting rock ballast is conveniently accumulated to the bottom and slides to the lower adit along the pilot shaft; the maximum blasting work amount is reduced through segmented blasting, and the rock ballast shaft blocking risk is reduced; forward one-time blasting excavation is carried out, and the blasting procedure construction time is shortened; and the construction efficiency is effectively improved, and the construction safety risk is reduced.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

Construction method and structure of dam toe hydropower station workshop retaining wall

ActiveCN104074176AEnsure construction safetyPrevent roll inWater-power plantsExcavationsAditPenstock

The invention discloses a construction method and structure of a dam toe hydropower station workshop retaining wall. The method is characterized in that after a foundation pit of a workshop is excavated, firstly, the workshop retaining wall is constructed at the side, close to an earth and rockfill dam, of the foundation pit, an obstruction barrier is formed between the workshop and the earth and rockfill dam, and therefore the phenomenon that large construction rocks of the earth and rockfill dam roll into the foundation pit of the workshop, so that safety of the workshop structure and construction personnel is endangered is prevented. The workshop retaining wall is constructed according to the following steps: A, concrete construction of a balance weight platform is performed; B, sloping core concrete construction is performed on the balance weight platform; and C, rock ballast backfilling is performed on the upper portion of the balance weight platform and the outer side of the sloping core. The construction method and structure are set in combination with the retaining wall of the end of the workshop, the construction structure can be used as a permanent retention wall structure of the workshop, and engineering investment is saved; a transportation channel is arranged in the wall and is connected with a construction adit of a pressure steel pipe, and construction of the pressure steel pipe is facilitated; and rock ballast backfilling is performed on the outer side of the wall, and therefore the wall can be connected with a workshop entering roadway, and the transportation problem for entering the workshop is solved. The construction method and structure have the prominent advantage that multiple purposes of one wall are achieved, water diversion lines are shortened, and project investment is saved.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Overhead maintenance passage for diversion tunnels

ActiveCN102505671AReduce in quantityPrevent poppingWater-power plantsConventional hydroenergy generationAditEngineering

The invention discloses an overhead maintenance passage for a plurality of diversion tunnels, which can reduce the construction cost. The maintenance passage comprises an un-blocked construction tunnel forming an external maintenance adit, and further comprises an upper maintenance branch adit, wherein the upper maintenance branch is higher than the external maintenance adit, communicated with the external maintenance adit through an external maintenance well, and communicated with the diversion tunnels through internal maintenance wells. The maintenance passage can drain ponded water without the need of a dedicated drain hole, which greatly reduces the construction cost; as the number of maintenance blocking doors is greatly reduced, the construction cost is greatly reduced, the construction difficulty is reduced, and the maintenance operation is more convenient; moreover, when one of the diversion tunnels is maintained, the normal operation of the other diversion tunnels cannot be impacted. Therefore, the overhead maintenance passage is suitable to be popularized and applied in the field of diversion power generation systems.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

Coal mining adit ending roadway or dead region supporting support and hydraulic support withdrawing method

The invention relates to a coal mining adit ending roadway or dead region supporting support and a hydraulic support withdrawing method and discloses a coal mining adit ending roadway supporting support. The support comprises a plurality of hydraulic supports which are arranged in an ending roadway or a dead region for supporting the ending roadway or dead region roofs. The hydraulic supports are close to one side of an ending roadway caving region and are vertically and parallelly arranged on the back goaf coal wall side arranged in the ending roadway or the dead region. A plurality of rows of hydraulic single props are further arranged in the ending roadway and are arranged along the ending roadway vertically and form a withdraw channel with one side coal wall of the ending roadway, which is away from the hydraulic supports, and the tops of the hydraulic single props support the roadway air channel. The invention further discloses a coal mining adit supporting support hydraulic support withdrawing method. By means of the supporting support and the method, recyclable support material hydraulic supports and hydraulic single props are withdrawn, and accordingly, the hydraulic support safety withdrawing is guaranteed, and potential safety hazards of withdrawing of the hydraulic supports are prevented.

Owner:CHINA COAL XINJI ENERGY CO LTD

Strip mine end slope thin coal seam dendritic reverse type underground mining method

ActiveCN112922596AImprove stabilityDoes not affect normal productionUnderground miningSurface miningAditCoal pillar

The invention discloses a strip mine end slope thin coal seam dendritic reverse type underground mining method. The method includes the specific steps that S1, a continuous coal mining machine is adopted to excavate a main adit in the boundary direction of a strip mine along a coal seam bottom plate; S2, secondary adits start to be tunneled from the two sides of the main adit in the inclined front direction of the main adit, and the secondary adits are in lap joint with a plurality of sets of self-moving belt conveyors in the main adit; S3, the continuous coal mining machine is remotely controlled to be responsible for coal mining, and the self-moving belt conveyors transport excavated coal out of the main adit; S4, after excavation of one secondary adit is stopped, the continuous coal mining machine and the self-moving belt conveyors in the secondary adit are withdrawn, and subsequent secondary adits are arranged in sequence in the same way; S5, the secondary adit is filled, and a goaf of the main adit is filled; and S6, a project is circulated. According to the strip mine end slope thin coal seam dendritic reverse type underground mining method, end slope coal mining is achieved in a dendritic adit arrangement mode, so that the coal output is improved, meanwhile, coal retaining pillars and filling bodies are fully utilized to keep a roof stable, and the difficulty and the cost of construction and equipment moving are reduced.

Owner:CHINA UNIV OF MINING & TECH

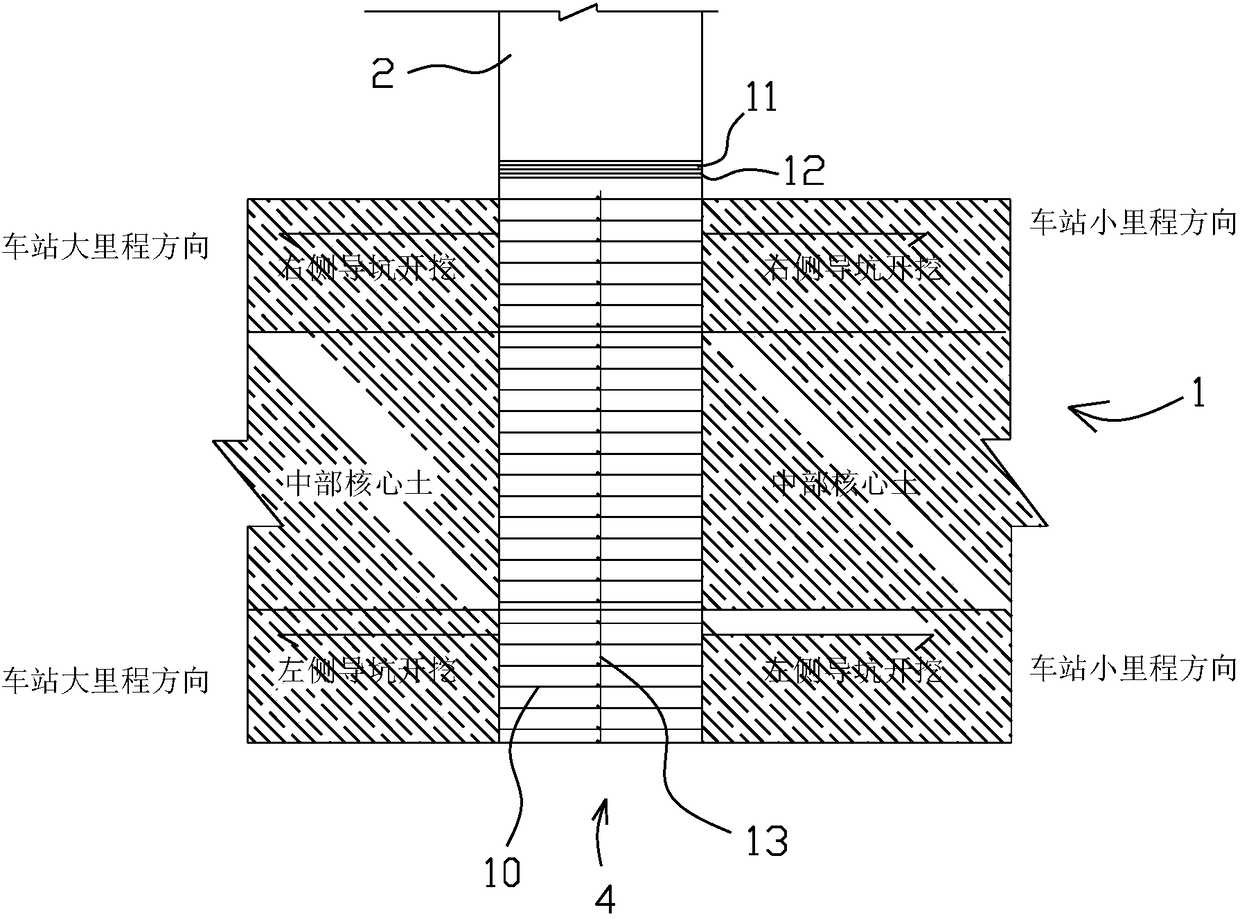

Construction method of excavating outsized-section subway underground excavation station by utilizing main layered adit and auxiliary layered adit

ActiveCN108222945AEasy to operateIncrease the number of excavation facesUnderground chambersTunnel liningAditAssembly line

The invention relates to the technical field of tunnel construction, and provides a construction method of constructing an outsized-section subway underground excavation station by utilizing layered auxiliary adits. The construction method comprises the steps that a main adit enters a station hall layer, an auxiliary adit is branched to enter a platform layer, and the two adits are arranged for asuper-large section tunnel and enter the upper portion and the lower portion of the tunnel correspondingly; and the main adit provides a channel for excavation construction of the upper portion of thetunnel, and the auxiliary adit provides a channel for excavation construction of the lower portion of the tunnel. By utilizing the contact channel formed by a door-type arch frame, the number of excavation faces is greatly increased, muck removing and material conveying are not mutually interfered, operation of all machines is facilitated, and quick and safe assembly-line operation is formed; during later construction of an inverted arch, an arch wall lining and a platrform layer structure, goods and materials can directly be transported and enter through the auxiliary adit; and during construction of the station hall layer structure and a wind pavilion group and an exit and entrance structure, goods and materials can directly be transported and enter through the main adit, the working efficiency is improved, and the construction progress is greatly accelerated.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

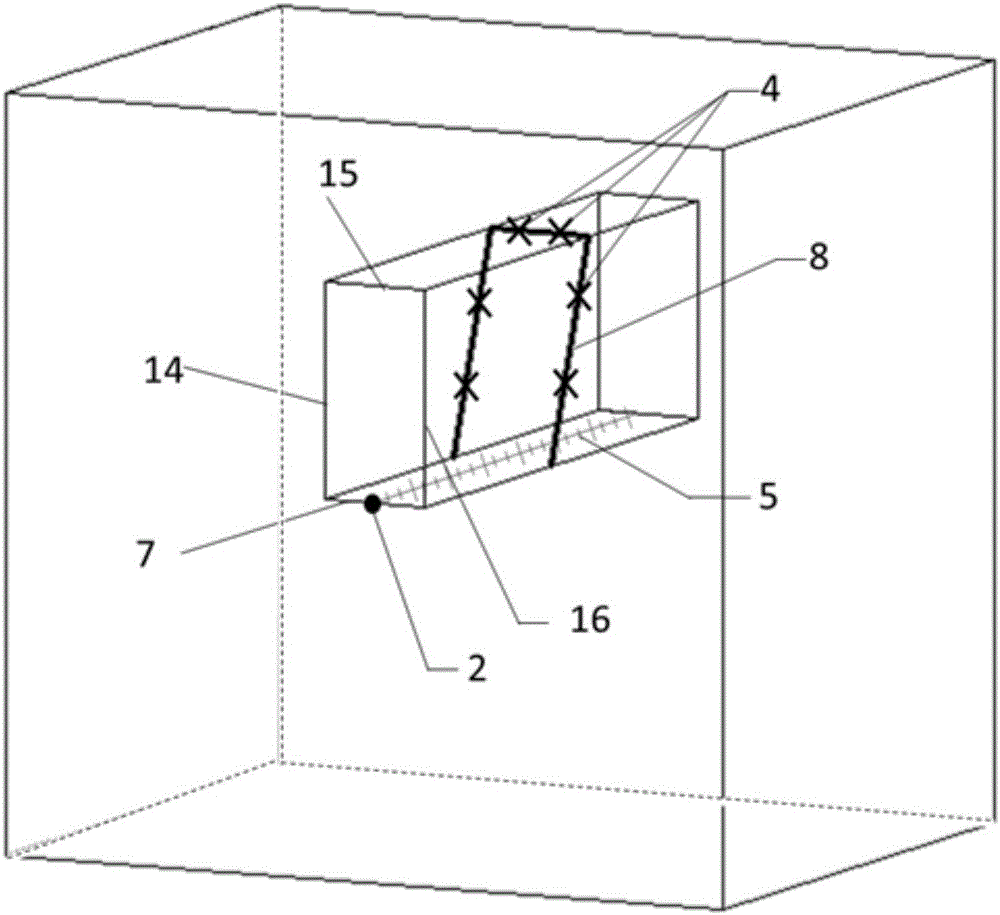

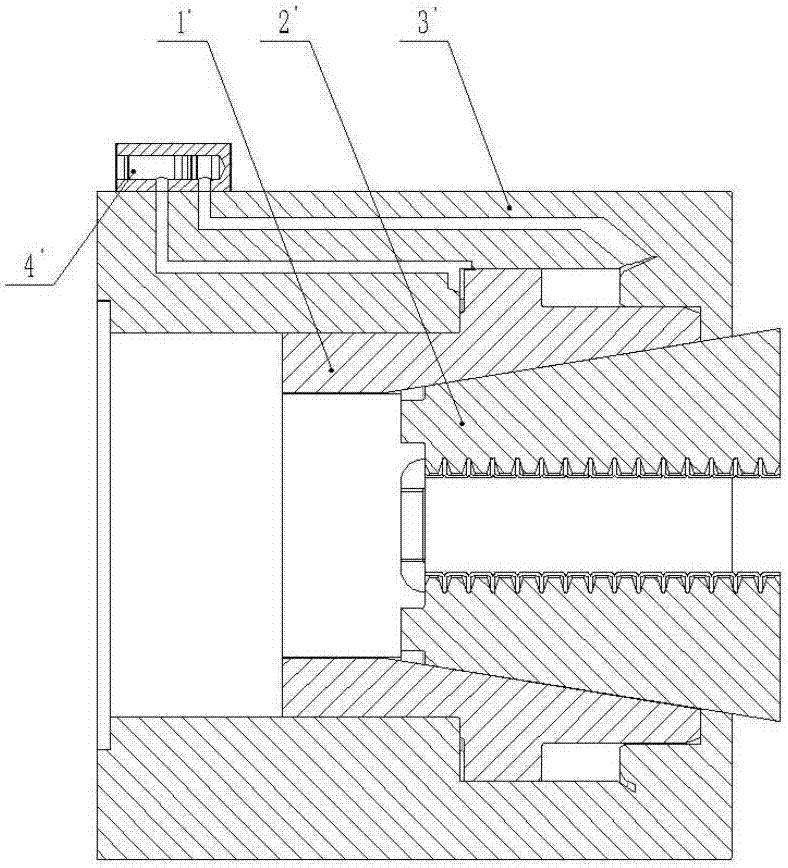

Live-action shooting device for exploratory adit and high-resolution three-dimensional image reconstruction method

InactiveCN106443813AQuick verificationImprove use valueOptical prospectingPhotogrammetry/videogrammetryAditModeling software

The invention discloses a live-action shooting device for an exploratory adit and a high-resolution three-dimensional image reconstruction method. According to the scheme, pile numbers are made at intervals in the adit, control points are uniformly arranged at different positions in the adit through a total station, and control point coordinates are measured; a track (1) is laid on the axis in the adit, and an automatic shooting device system is installed on the track (1); the power of the automatic shooting device system is turned on, working parameters of the system are set, and image shooting and storing work of the whole adit can be completed according to a set method; series processing is conducted on shot pictures through three-dimensional live-action modeling software, and a high-resolution three-dimensional live-action reconstruction result picture of the adit is led out; at last, a series of subsequent operations comprising a series of management work such as browsing, measuring, cataloging, counting and roaming are conducted on the high-resolution three-dimensional live-action reconstruction result picture.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Movable type upward inverse well drilling machine

The invention discloses a movable type upward inverse well drilling machine. The upward inverse well drilling machine is movable. The movable type upward inverse well drilling machine comprises a well drilling device and a movable device. The well drilling device comprises a drilling machine supporting mechanism, main pushing oil cylinders, a power head and a drilling tool. The movable device comprises a bearing table, and a crawler travelling mechanism is installed on two opposite side faces of the bearing table. The movable type upward inverse well drilling machine is applied to an inverse well drilling technique, so that consumption of well drilling liquid can be reduced, and the well drilling time is shortened; and meanwhile, the requirement for well drilling on the stratum above an adit in the single adit is met, construction difficulty is lowered, manpower and material sources are saved easily, and production efficiency is improved.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

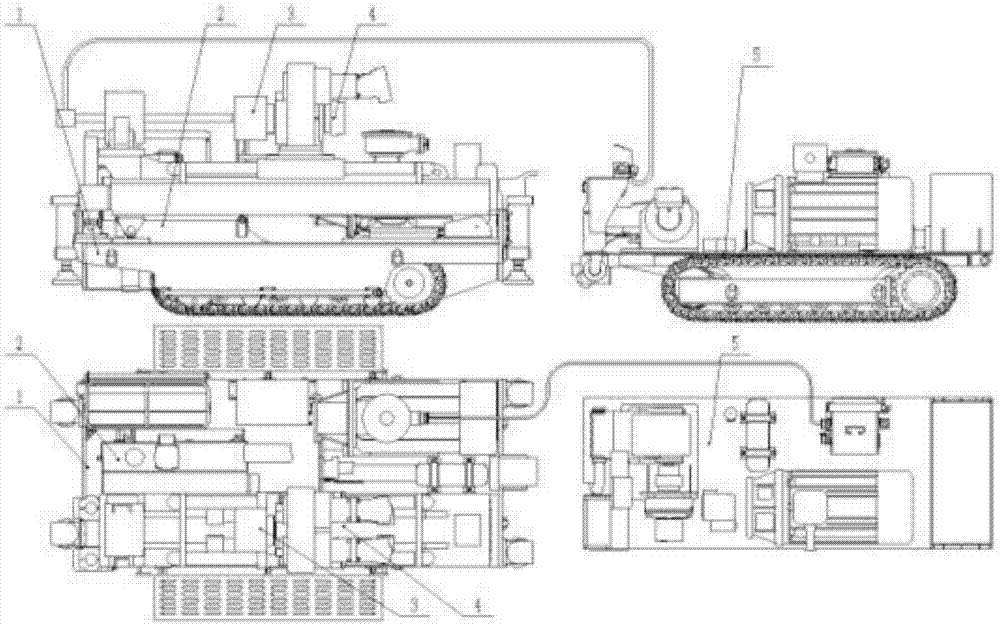

Coal-mine underground-adit directional drilling machine

ActiveCN107420036AHigh working reliabilityExtended service lifeDrilling rodsDrilling casingsAditOil distribution

The invention provides a coal-mine underground-adit directional drilling machine. The coal-mine underground-adit directional drilling machine comprises a drill carriage and a pump truck. The drill carriage mainly comprises a carriage body, a clamping mechanism, an oil tank and an oil distribution sleeve. The clamping mechanism comprises a front clamping part and a rear clamping part, the front clamping part and the rear clamping part are sequentially arranged on a feed frame of the drill carriage, the oil distribution sleeve comprises a cylinder barrel and a piston, and the position between the piston and the cylinder barrel is of a double-oil-line rotary sealed type structure. The coal-mine underground-adit directional drilling machine has the characteristics of being simple and convenient in structure, compact in space, safe and reliable and the like.

Owner:SHAANXI TAIHE TECH CO LTD +1

High-pressure group hole replacement grouting method and structure in karst region

ActiveCN104594369AReduce wasteRapid grouting treatment technologyFoundation engineeringGeomorphologyStructure of the Earth

The invention discloses a high-pressure group hole replacement grouting method and structure in a karst region. A grouting gallery or an adit (2) is arranged above a karst cave area (1), a drilling hole (3) is distributed in the grouting gallery or the adit (2) towards the karst cave area (1), the lower end of the drilling hole (3) is located in the karst cave area (1), and the range where the drilling hole (3) is located is divided into a replacement inlet area (4) and a replacement outlet area (5); sand-mixed cement mortar with the mass ratio of 0.5:1 is injected into the drilling hole (3) in the replacement inlet area (4) through high pressure, filler of the karst cave is extruded out of the drilling hole (3) of the replacement outlet area (5) fully or partially, and then a common cement grouting method is adopted for grouting 24-36 hours later after condensation. The high-pressure group hole replacement grouting method and structure in the karst region realize grouting of medium and small filling-type karst cave and other geological flaw sections in the karst region, and have the advantages of being simple, capable of largely shortening the construction period, low in expense, obvious in effect, capable of guaranteeing grouting quality, and the like.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com