Etching device and etching method

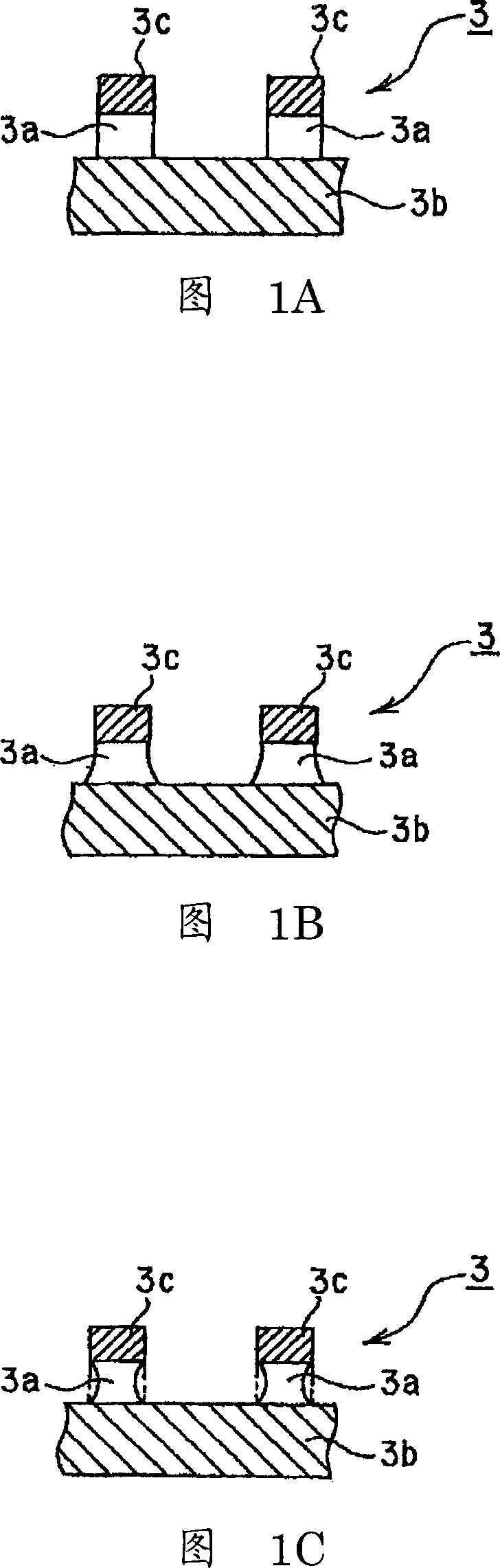

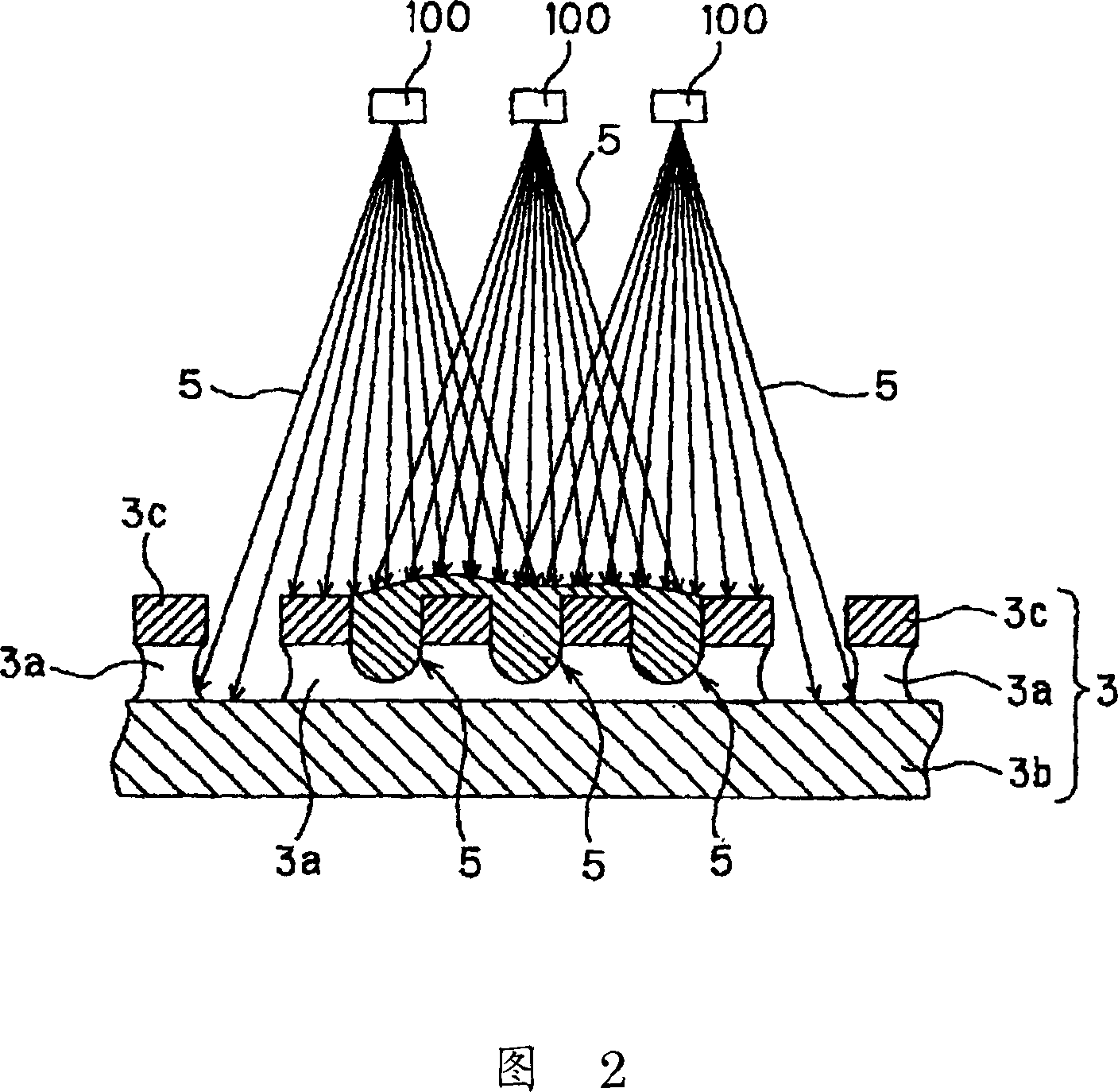

An etching device and an etching technology, which are applied in chemical/electrolytic methods to remove conductive materials, electrical components, printed circuit liquid treatment, etc., can solve the deviation of the width and cross-sectional shape of the conductor pattern 3a, difficulty in etching the conductor pattern 3a, and difficulty in etching Conductor patterns and other issues, to achieve the effect of eliminating deflection, uniform etching speed, and realizing narrow pitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

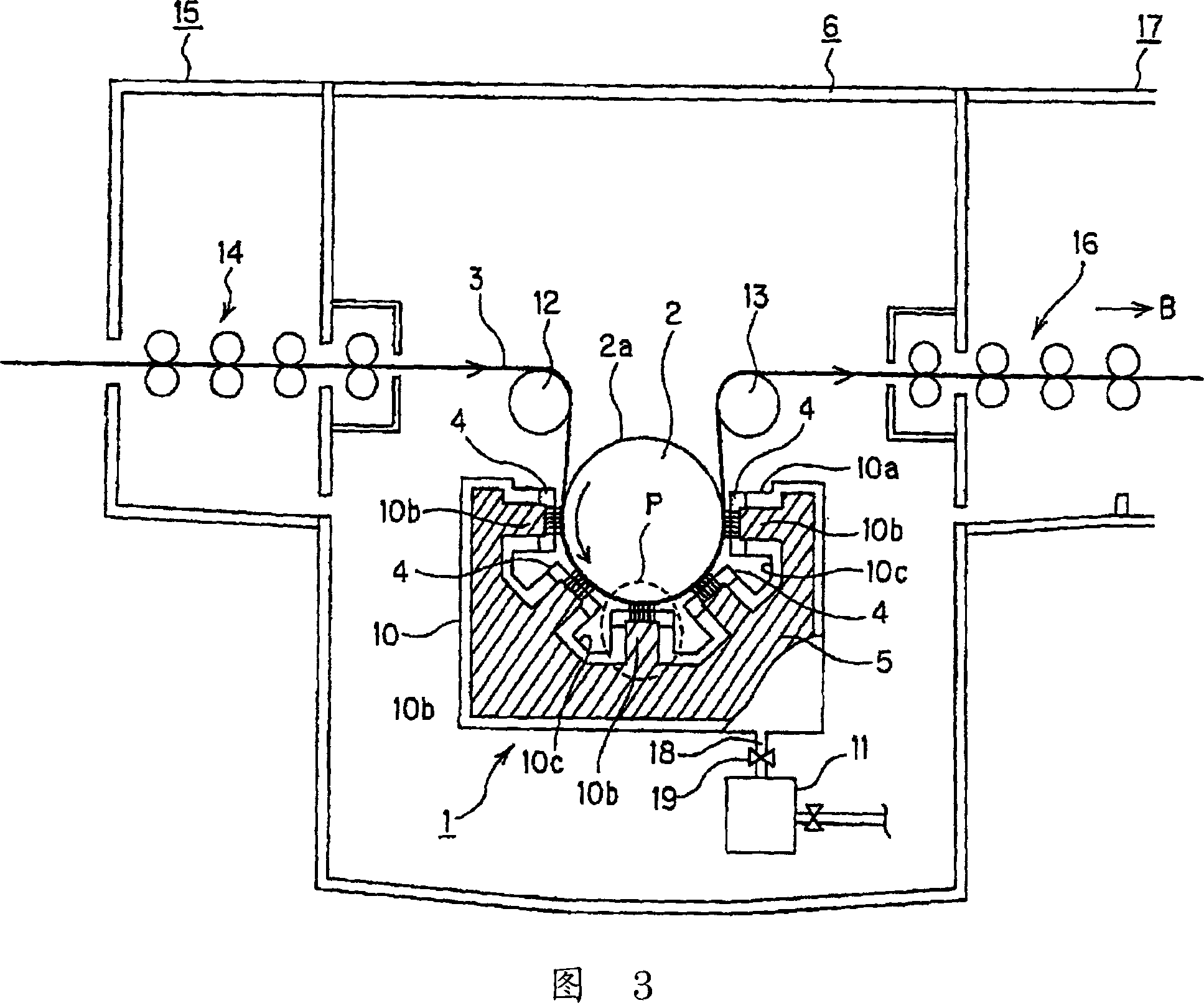

[0030] The preferred embodiments of the etching apparatus and etching method of the present invention will be described below with reference to the accompanying drawings.

[0031] As shown in FIGS. 3 and 4 , the etching device 1 of the present invention is a device in which a shower head 4 is arranged close to a substrate 3 for flexible wiring wound on the outer peripheral surface of a drum 2 , and the flexible wiring from the shower head 4 The etchant 5 is sprayed in a straight line to the substrate 3 for wiring.

[0032] This etching device 1 is used for the etching process in each process of the metal surface etching method for forming a conductive pattern on the flexible wiring substrate 3, and is installed in an etching system configured by connecting processing chambers for performing each process. Room 6.

[0033] As shown in FIGS. 3 and 4 , the etching apparatus 1 includes a drum 2 , a container 10 , a shower head 4 , a pump 11 , and the like.

[0034] The drum 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com