Auxiliary forming positioning cold heading structure

An auxiliary forming and cold heading technology, which is applied in the direction of manufacturing tools, forging presses, forging/pressing/hammer devices, etc., can solve problems such as uneven material flow, achieve the effects of convenient modification, improve position accuracy, and improve contact quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The proprietary technology will be further described in conjunction with the accompanying drawings and specific embodiments.

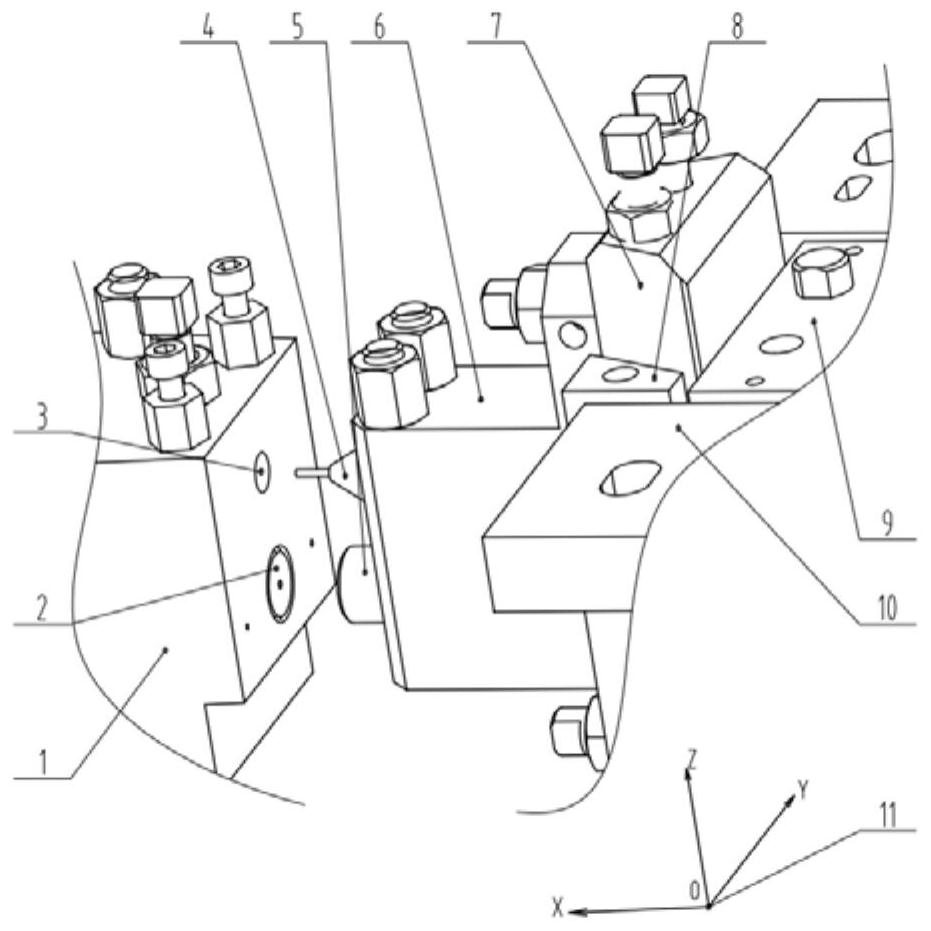

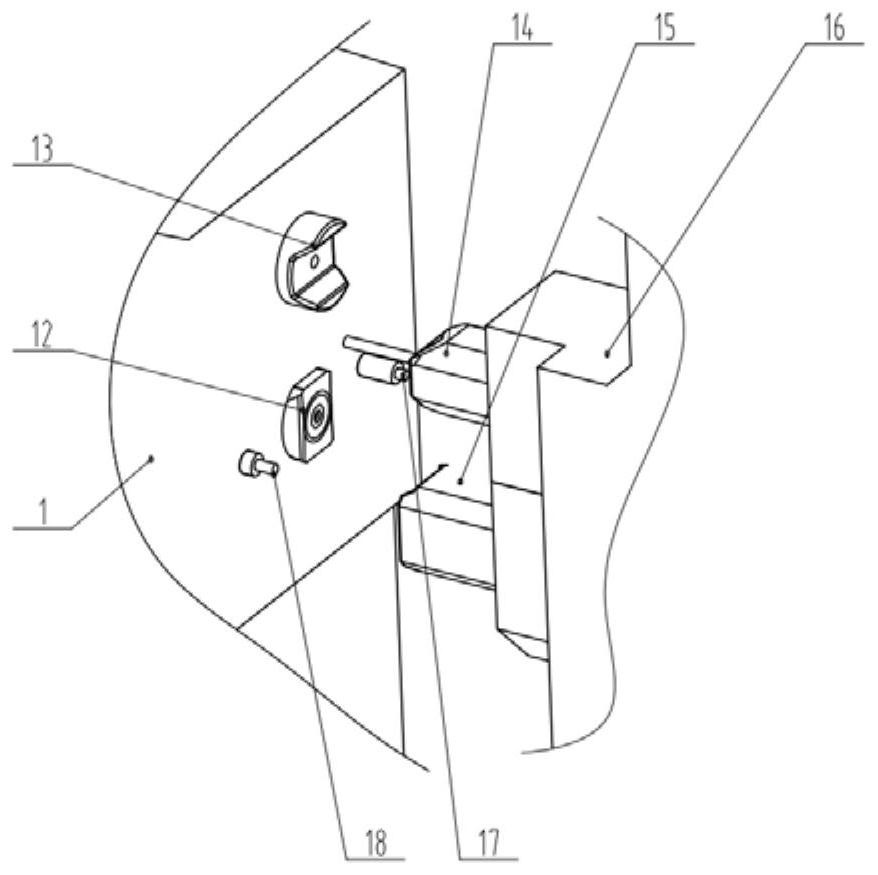

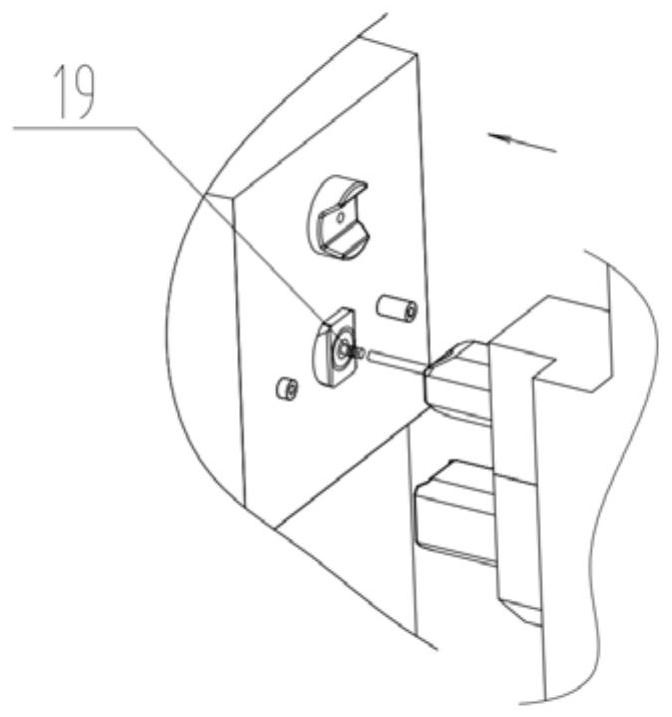

[0025] Such as figure 2 As shown, a cold heading structure for auxiliary forming and positioning mainly includes a fixed base part and a moving slider part.

[0026] The fixed base part is mainly composed of a fixed base 1, a V-shaped fixed platform 12, and a Z-direction correction insert 13 and the like. Compared with the general cold heading structure, the V-shaped fixed table 12 is the figure 1 The shape of the fixed table 2 shown in Fig. 5-1 is redesigned into the shape shown in Fig. 5-1, and the installation and positioning straight surface on the fixed base 1 and the engagement with the V-shaped punch 15 shown in Fig. 5-4 are added. 60° angled convex engagement ramp. Then the original general cold heading structure figure 1 A new Z-direction correction insert 13 is redesigned at the position of the fixed seat avoidance hole 3 on the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening angle | aaaaa | aaaaa |

| Opening angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com