Automatic moving type spiral hole milling manufacturing system

A technology of autonomous movement and helical milling, applied in milling machine equipment, manufacturing tools, details of milling machine equipment, etc., can solve the problems of low processing efficiency, poor steering ability, weak normal vector adaptability, etc., and achieve the effect of improving position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

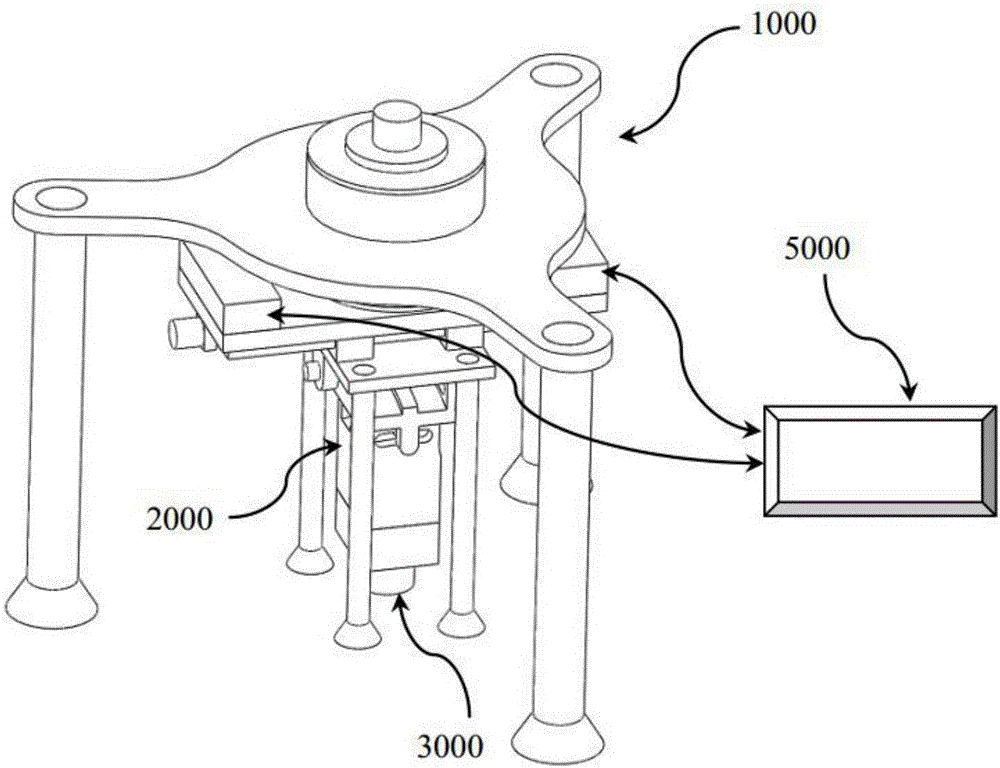

[0023] Such as figure 1 and 2 As shown, the autonomous mobile helical milling hole system provided by the present invention includes an autonomous mobile mechanism 1000 composed of a crawler mechanism 1100 and a double pendulum platform 1200 .

[0024] Such as image 3 and 4 As shown, the crawling mechanism 1100 includes an upper support plate 1101, a lower support plate 1102, a bearing 1103, a rotating shaft 1104, a rectangular rotating plate 1105, a first slide rail 1106, a first slider 1107, a first driving device 1115 and three peripheral electric motors. Telescopic rod 1108; bearing 1103 is installed on the upper support plate 1101, and the rotating shaft 1104 is vertically penetrated and fixed on the bearing 1103; the first driving device 1115 is installed on the upper supporting plate 1101 through the fixed bracket 1114, the upper end of the rotating shaft 1104 is The output shaft of the first driving device 1115 is connected, and the lower end is vertically installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com